Comprehensive utilization process of city sludge in sintering brick making

A sludge and urban technology, applied in the petroleum industry, solid fuels, biofuels, etc., can solve the problems of difficult treatment, high investment and operating costs, and inability to transform growth links, reducing the demand for land resources and realizing resource utilization. The effect of low utilization and operation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

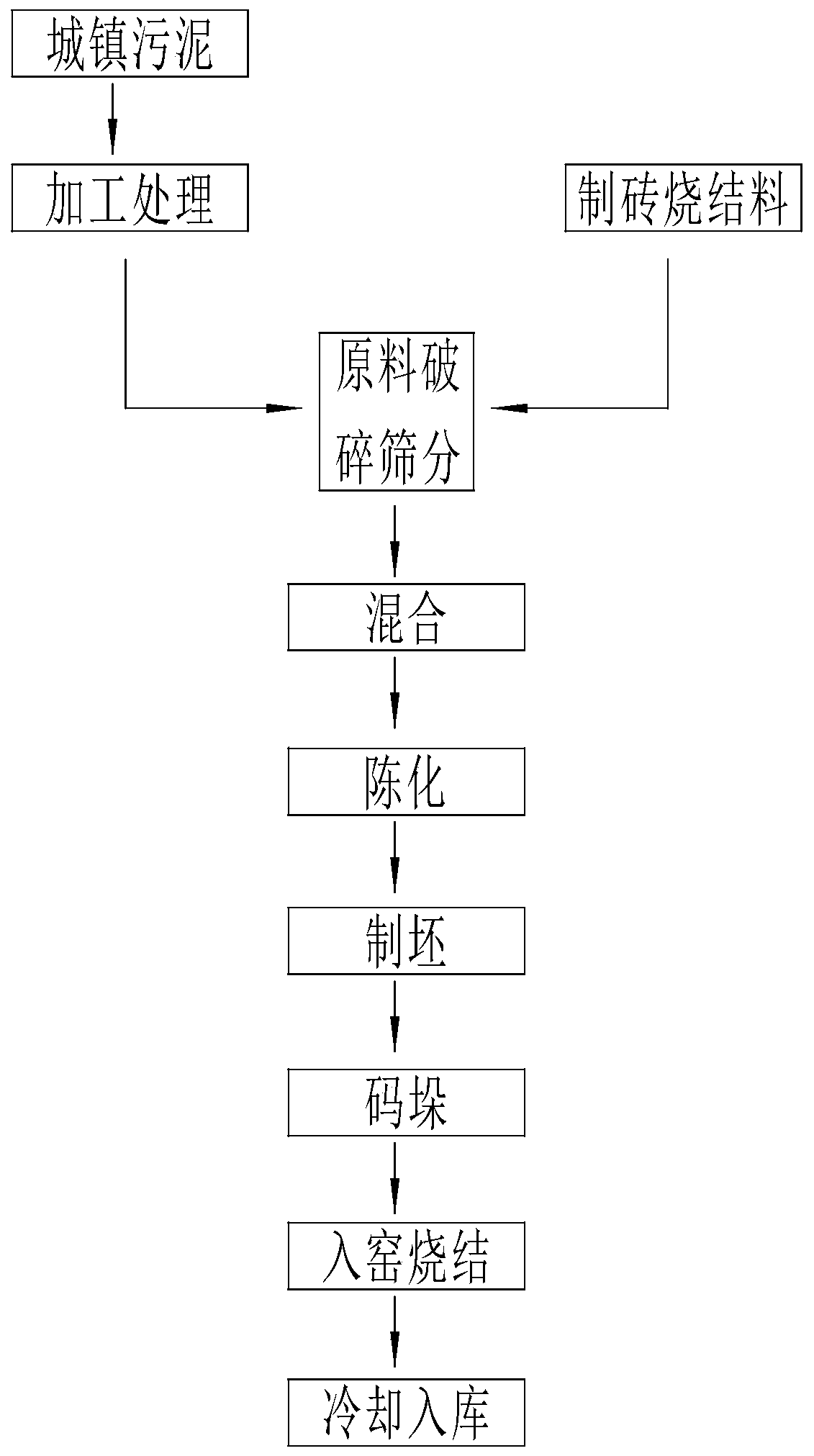

[0019] The process steps are as follows: After the urban sludge is processed, it is crushed and screened with the brick-making sintering material → mixed → aged → billet making → stacking → put into the kiln for sintering → cooled and put into storage; the specific implementation steps are as follows:

[0020] Crushing and screening of raw materials: crushing and screening the sludge regeneration fuel and brick-making sintering material formed after the urban sludge is processed;

[0021] Mixing: Mix the crushed and screened brick-making sintered material and sludge recycled fuel, and transport the mixed mixture to the aging warehouse;

[0022] Aging: The mixture is aged in the aging warehouse, so that various raw materials can be fully infiltrated and contacted, and the aging time is 36-40h.

[0023] Billet making: the aged mixture is extruded into specific adobe strips under the action of an extruder, and the strips are cut into specific adobes by a cutting machine;

[0024...

Embodiment 2

[0028] The brick making sintering material is: 70%-80%, the sludge regenerated fuel is: 21%-30%, and the sum of the composition weights of the above components is 100%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com