Method and device for treating waste incineration fly ash through cooperation of metallurgy waste residues

A waste incineration fly ash and co-processing technology, applied to the removal of solid waste, etc., can solve the problems of high capacity increase ratio, large land occupation, etc., and achieve the effect of reducing landfill volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

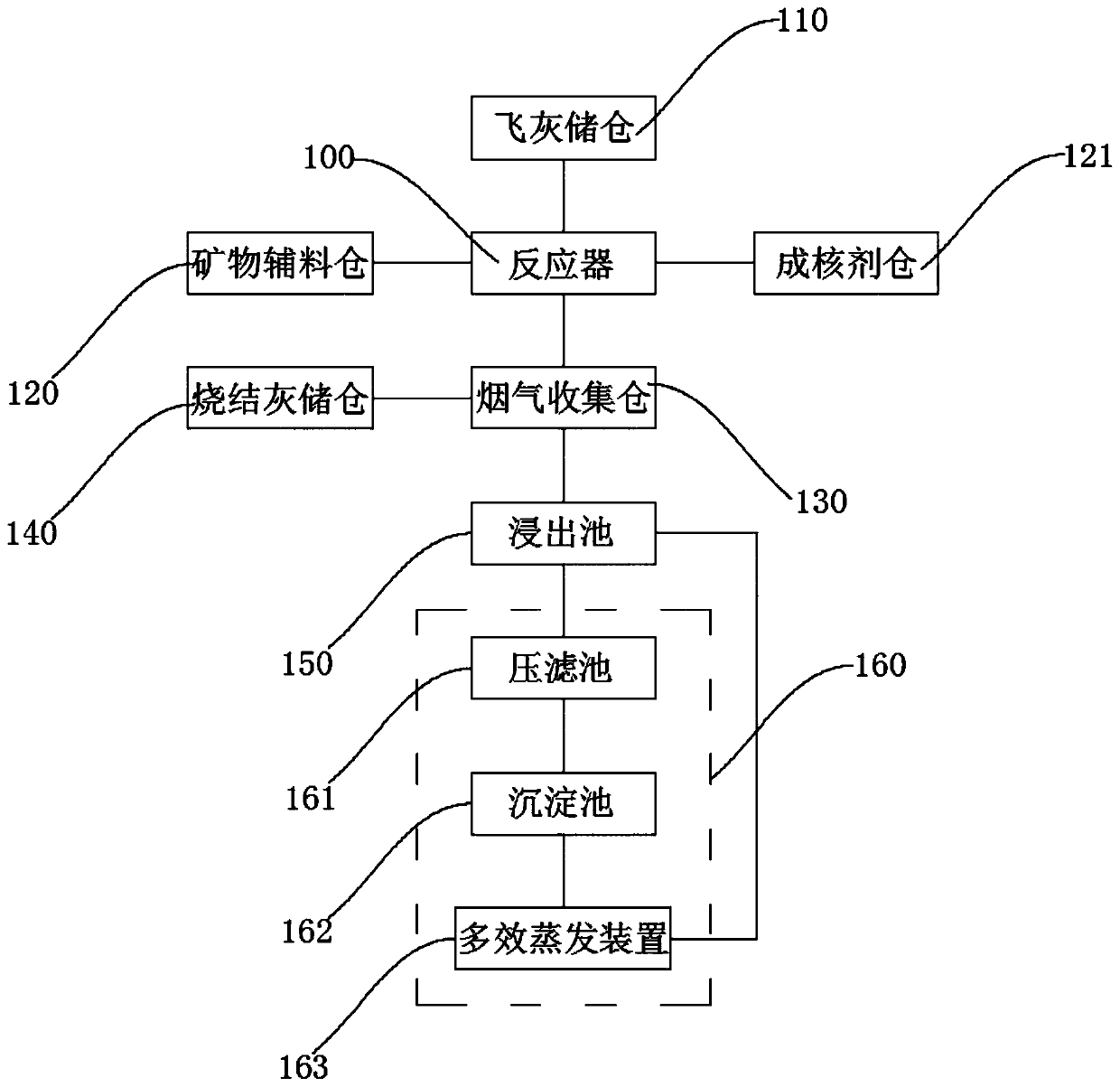

[0032] like figure 1 As shown, this embodiment provides a device for co-processing waste incineration fly ash with metallurgical waste residue, which includes: a reactor 100 for melting, a fly ash storage bin 110 connected to the reactor 100, and a mineral auxiliary material bin 120 1. A nucleating agent bin 121, the reactor 100 is also connected with a flue gas collection bin 130, the flue gas collection bin 130 is respectively connected with a sintered ash storage bin 140 and a leaching tank 150, and the leaching tank 150 is connected with a separation tank 160. In this embodiment, the fly ash storage bin 110, the auxiliary mineral material bin 120, and the nucleating agent bin 121 are respectively connected to the reactor 100 through pipes, the reactor 100 is connected to the flue gas collection bin 130 through pipes, and the flue gas collection bin 130 is respectively passed through The pipeline is connected with the sintered ash storage bin 140 and the leaching tank 150, ...

Embodiment 2

[0037] The embodiment of the present application provides a method for co-processing waste incineration fly ash with metallurgical waste slag, which is carried out by using the device for co-processing waste incineration fly ash with metallurgical waste slag in Example 1, which includes the following steps:

[0038] Take 30kg of dust collected from the heat recovery system and flue gas purification system during operation of a waste incineration power plant in Wuhan, which is waste incineration fly ash. The composition of the waste incineration fly ash has been tested and mainly contains the following elements by mass percentage: 22.47% of Ca, 11.62% of Si, 15.7% of Cl, 4.81% of S, 3.45% of K, 2.64% of Na, 1.43% of Mg.

[0039] Add 30kg of waste incineration fly ash, 5kg of talc, 3kg of carbon black, 3kg of calcium carbonate, and 2kg of calcium oxide to 50kg of blast furnace slag (the composition of blast furnace slag mainly includes the following mass percentages after testin...

Embodiment 3

[0043] The embodiment of the present application provides a method for co-processing waste incineration fly ash with metallurgical waste slag, which is carried out by using the device for co-processing waste incineration fly ash with metallurgical waste slag in Example 1, which includes the following steps:

[0044] Take 40kg of dust collected from the heat recovery system and flue gas purification system during operation of a waste incineration power plant in Wuhan, which is waste incineration fly ash. The composition of the waste incineration fly ash has been tested and mainly contains the following elements by mass percentage: 22.47% of Ca, 11.62% of Si, 15.7% of Cl, 4.81% of S, 3.45% of K, 2.64% of Na, 1.43% of Mg.

[0045] Add 30kg of waste incineration fly ash, 5kg of talc, 3kg of carbon black, 3kg of calcium carbonate, and 2kg of calcium oxide to 65kg of blast furnace slag (the composition of blast furnace slag mainly includes the following mass percentages after testin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com