Curing method for heavy metal in waste catalyst

A technology of waste catalyst and solidification method, which is applied in the direction of solid waste management, sustainable waste treatment, climate sustainability, etc., can solve problems such as pollution, achieve the effects of preventing environmental pollution, saving land resources, and achieving sustainable development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

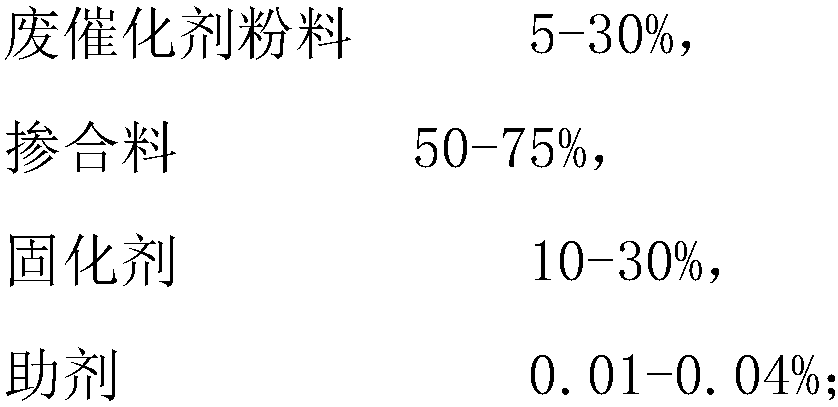

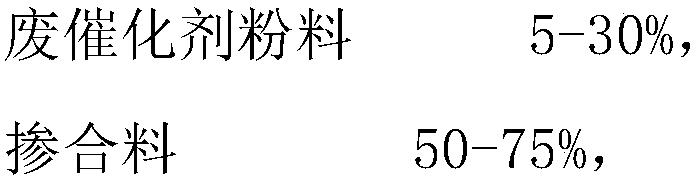

Method used

Image

Examples

specific example

[0065] Adopt the solidification method of heavy metal in the above-mentioned spent catalyst to carry out concrete example as follows:

[0066] In the following examples 1-3, the spent catalyst used is FCC spent catalyst, the main chemical composition content of the FCC spent catalyst is shown in Table 1, and the heavy metal content of the FCC spent catalyst is shown in Table 2.

[0067] Table 1 Contents of main chemical components of spent FCC catalysts

[0068] chemical composition

SiO 2

Al 2 o 3

Fe 2 o 3

K 2 o

Na 2 o

Content (wt%)

39.6

50.7

1.73

0.17

0.16

[0069] Table 2 Heavy metal content of FCC spent catalysts

[0070] heavy metal

Embodiment 1

[0072] 1) Grinding the spent FCC catalyst so that the 7d activity index is 21, and the 28d activity index is 29;

[0073] 2) 15wt% 42.5 grade ordinary silicate is mixed with 10wt% FCC waste catalyst powder and 75wt% red brick fine powder (0.1-5cm particle size) to obtain the first mixture; the lignin water reducer ( Weight accounted for 0.02wt% of the total weight of the first mixture) was dissolved in water (weight accounted for 15wt% of the total weight of the first mixture), to obtain the second mixture;

[0074] Stirring the first mixture in a mixer for 20 minutes, adding the second mixture dropwise to the first mixture during the stirring process, mixing the first mixture and the second mixture uniformly to obtain a mixture;

[0075] 3) Seal the above mixture and age it for 6 hours;

[0076] 4) Fill the mold with the aged mixture, press and form it on a press to obtain an adobe, the pressing pressure is 20MPa, and the size of the adobe is: length×width×height=195mm×95mm×...

Embodiment 2

[0084] 1) Grinding the spent FCC catalyst so that the 7d activity index is 29, and the 28d activity index is 42;

[0085] 2) Mix 20wt% 42.5-grade ordinary silicate with 20wt% FCC waste catalyst powder, 30wt% fine sand (0.2-1cm in size), and 30wt% stones (1-5cm) to obtain the first mixture ; The lignin water reducer (weight accounts for 0.04wt% of the total weight of the first mixture) is dissolved in water (the weight accounts for 10wt% of the total weight of the first mixture) to obtain a second mixture;

[0086] Stirring the first mixture in a mixer for 16 minutes, adding the second mixture dropwise to the first mixture during the stirring process, mixing the first mixture and the second mixture evenly to obtain a mixture;

[0087] 3) Seal the above mixture and age it for 10 hours;

[0088] 4) Fill the mold with the aged mixture, press and form it on a press to obtain an adobe, the pressing pressure is 30MPa, and the size of the adobe is: length×width×height=240mm×115mm×53m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com