Air-cooled ash cooling device

An ash and slag cooling and air-cooled technology, applied in the field of air-cooled ash and slag cooling devices, can solve the problems of high water content of ash, large landfill volume, large water consumption, etc. simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the examples, the purpose is only to better understand the contents of the present invention, therefore, the examples given do not limit the protection scope of the present invention.

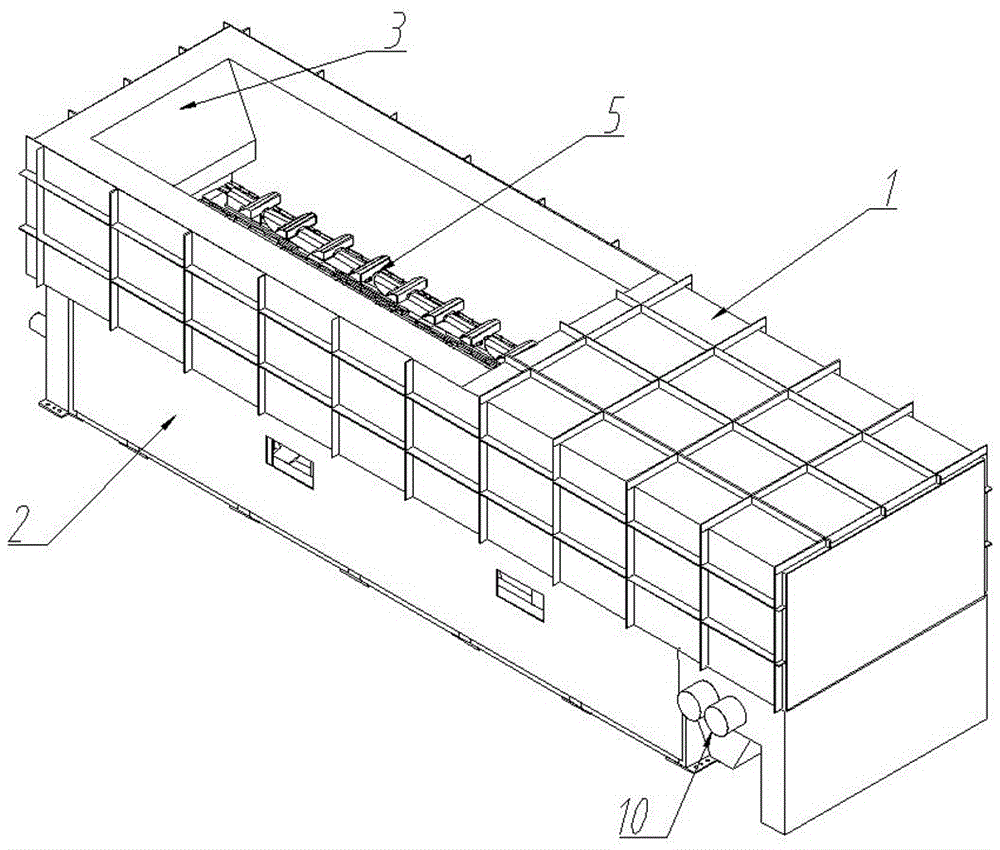

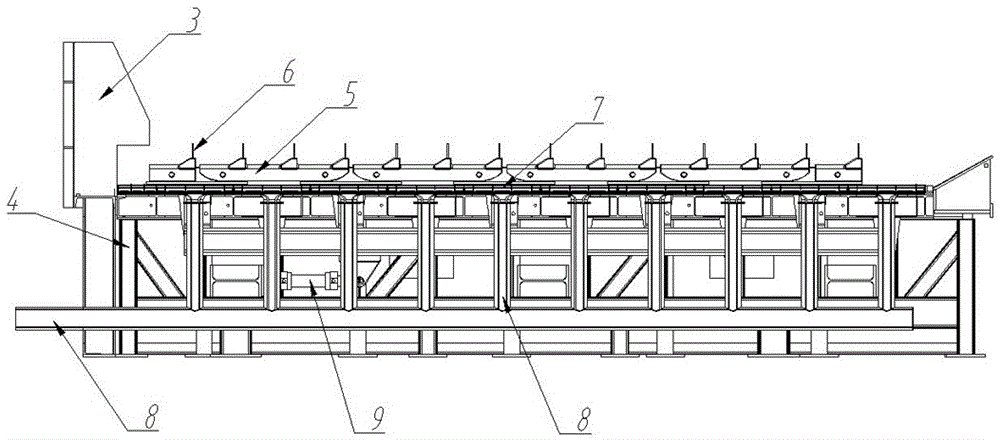

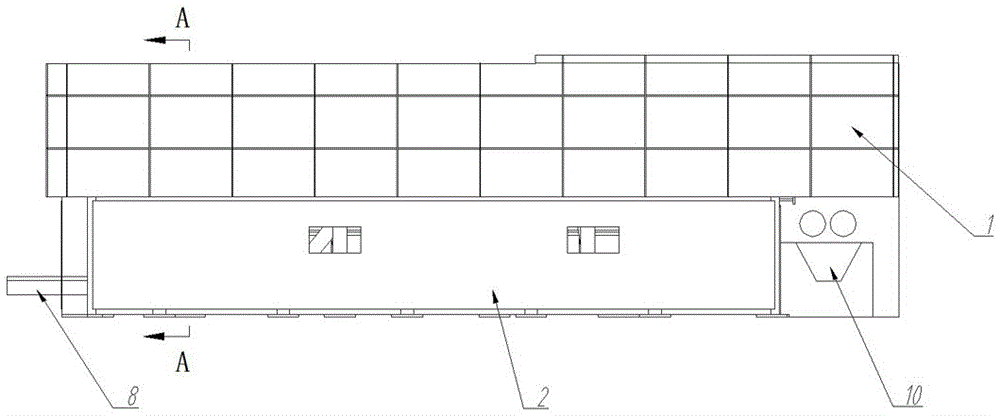

[0019] see figure 1 , figure 2 , image 3 , Figure 4 , including upper casing 1, lower casing 2, material guide plate 3, bracket 4, conveying device 5, stirring rod 6, cooling plate 7, cooling air inlet pipe 8, hydraulic cylinder 9, crushing device 10, connecting rod 11 .

[0020] A material guide plate 3 is installed at the feeding place of the upper shell 1 to guide the material entering the cooling device. The heat insulation material is laid on the cooling plate to reduce the corrosion of the cooling plate by high-temperature ash and slag, and at the same time prevent the high-temperature material from sticking to the cooling plate. A crushing device is installed at the outlet of the lower shell. Since t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com