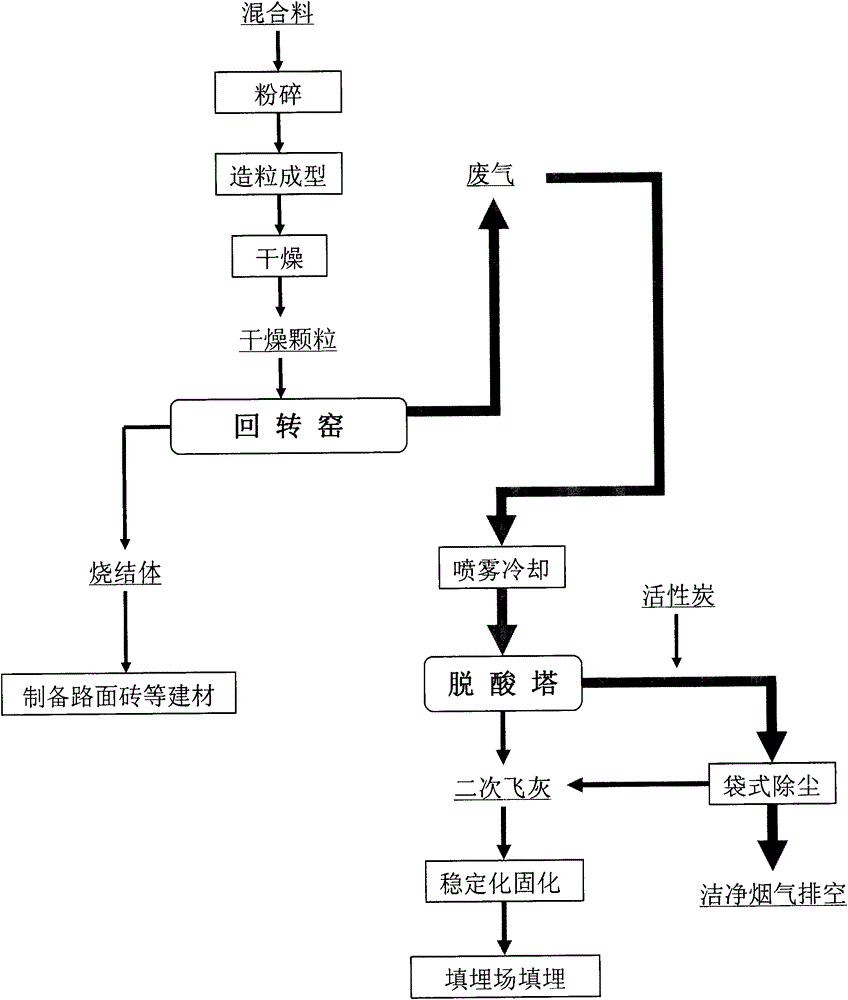

Garbage burning fly ash sintering harm-eliminating resource-utilization treatment system

A waste incineration fly ash and treatment system technology, which is applied in the field of waste incineration fly ash treatment by sintering technology, can solve the problems of increased release of heavy metals, secondary hazards to the environment and human health, etc., to alleviate the pressure of serious shortages and shorten the sintering process. time and reduce the effect of external coal consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

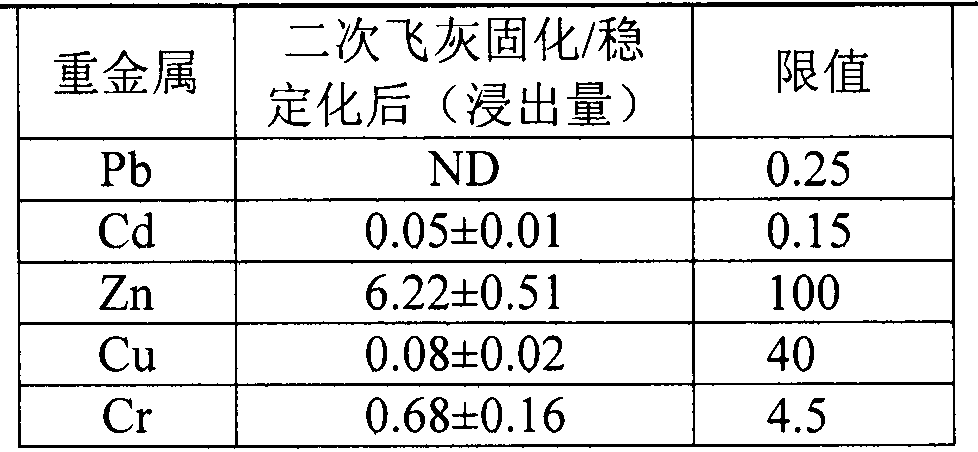

Embodiment 1

[0025] The mass ratio of the mixture is: 90% waste incineration fly ash, 0.5% premixed coal, 5% polluted soil, 4.5% sludge, after uniform mixing, crushing, granulation and molding, the formed particles are naturally dried to a moisture content of 15% , and then sent to the rotary kiln for sintering, the sintering temperature is 1350°C, sintering for 35min, and the fly ash sintered body is obtained after cooling; the flue gas produced by the rotary kiln is sprayed with water for rapid cooling and cooling, and then enters the deacidification reaction tower and deacidification agent (lime slurry ) reaction, followed by bag dust removal. After the treatment reaches the standard, the clean flue gas is discharged into the atmosphere; the secondary fly ash produced by the deacidification reaction tower and bag filter is collected and added with 8% cement and 1% sodium sulfide. After solidification / stabilization The fly ash will enter the landfill site for safe landfill after reaching ...

Embodiment 2

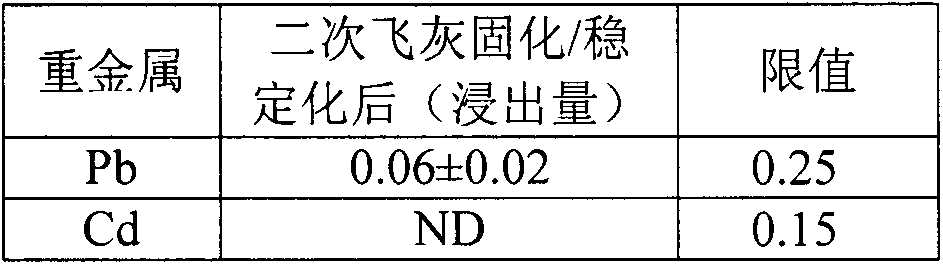

[0035] The mass ratio of the mixture is: 80% waste incineration fly ash, 2% premixed coal, 10% industrial waste residue, and 8% sludge. After uniform mixing, pulverization, granulation and molding, the formed granules are naturally dried to a moisture content of 12%, and then sent to a rotary kiln for sintering at a sintering temperature of 1150°C for 25 minutes, and the fly ash sintered body is obtained after cooling; the flue gas produced by the rotary kiln After spraying water for rapid cooling and cooling, it enters the deacidification reaction tower to react with the deacidification agent (calcium carbide slag), and then carries out bag dust removal. After the treatment reaches the standard, the clean flue gas is discharged into the atmosphere; Secondary fly ash is added with 12% lime and 1% soluble phosphate, and the solidified / stabilized fly ash will enter the landfill site for safe landfill after reaching the standard.

[0036] The cylinder compressive strength of the ...

Embodiment 3

[0046] The mass ratio of the mixture is: 70% of waste incineration fly ash, 5% of premixed coal, and 25% of sludge. After uniform mixing, pulverization, granulation and molding, the formed granules are naturally dried to a moisture content of 10%, and then sent to a rotary kiln for sintering at a sintering temperature of 1050°C for 10 minutes, and the fly ash sintered body is obtained after cooling; the flue gas produced by the rotary kiln After spraying water for rapid cooling, it enters the deacidification reaction tower and deacidification agent (Mg(OH) 2Solution) reaction, followed by bag dust removal. After the treatment reaches the standard, the clean flue gas is discharged into the atmosphere; the secondary fly ash produced by the deacidification reaction tower and the bag filter is collected and added with 15% cement and 2% mercapto collector. After curing / The stabilized fly ash will enter the landfill site for safe landfill after reaching the standard.

[0047] The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cylinder compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| cylinder compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com