Patents

Literature

299 results about "Rise over thermal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

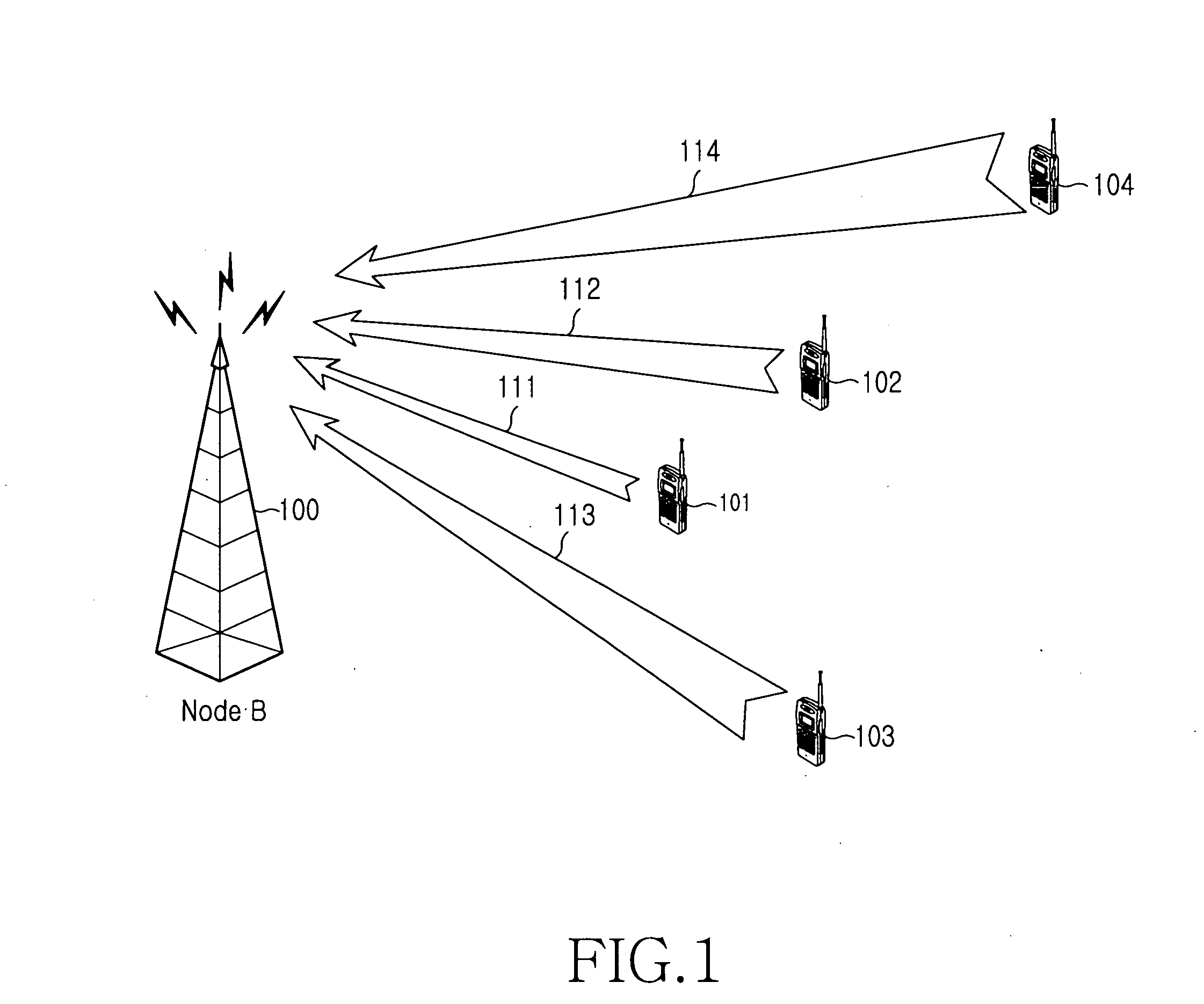

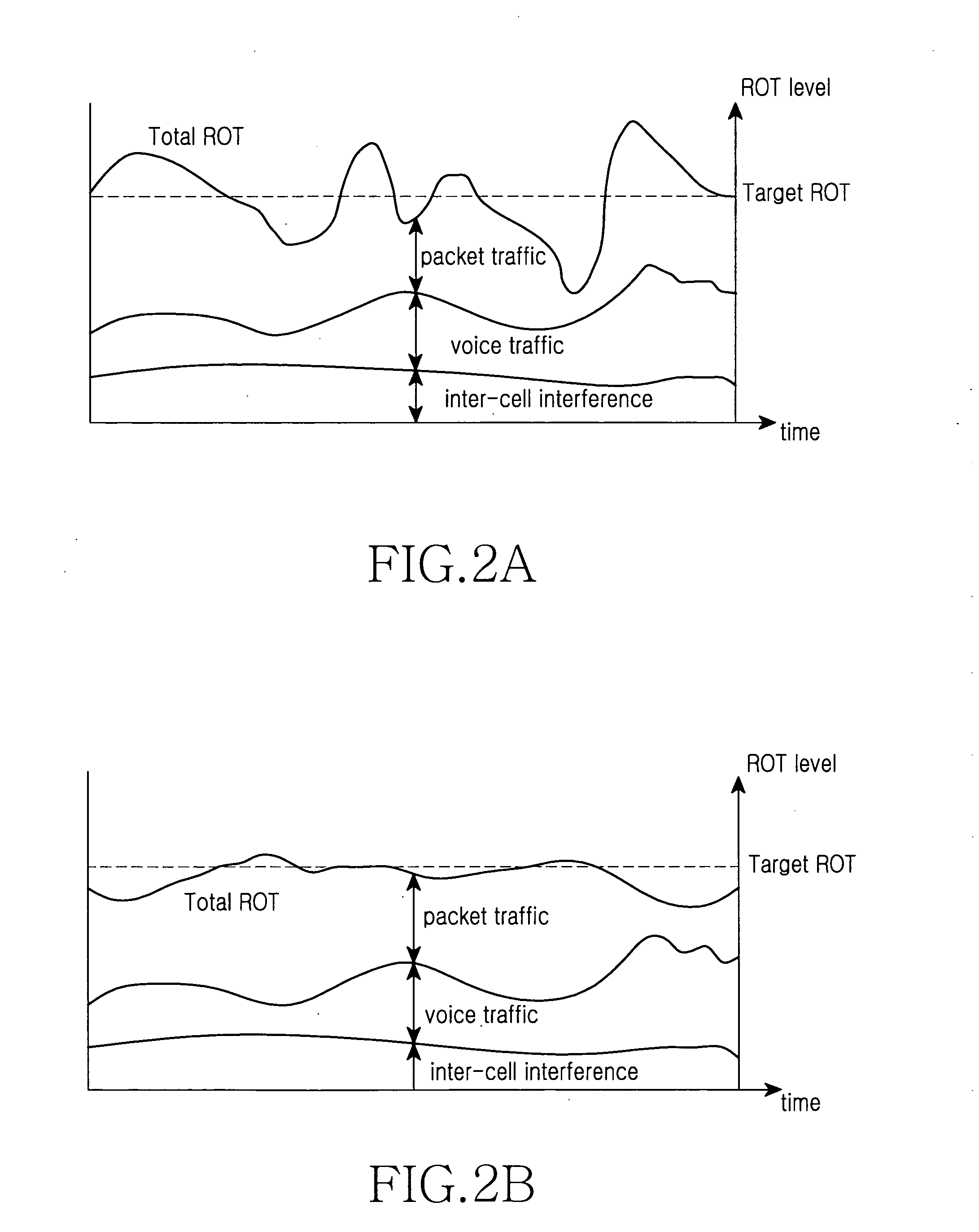

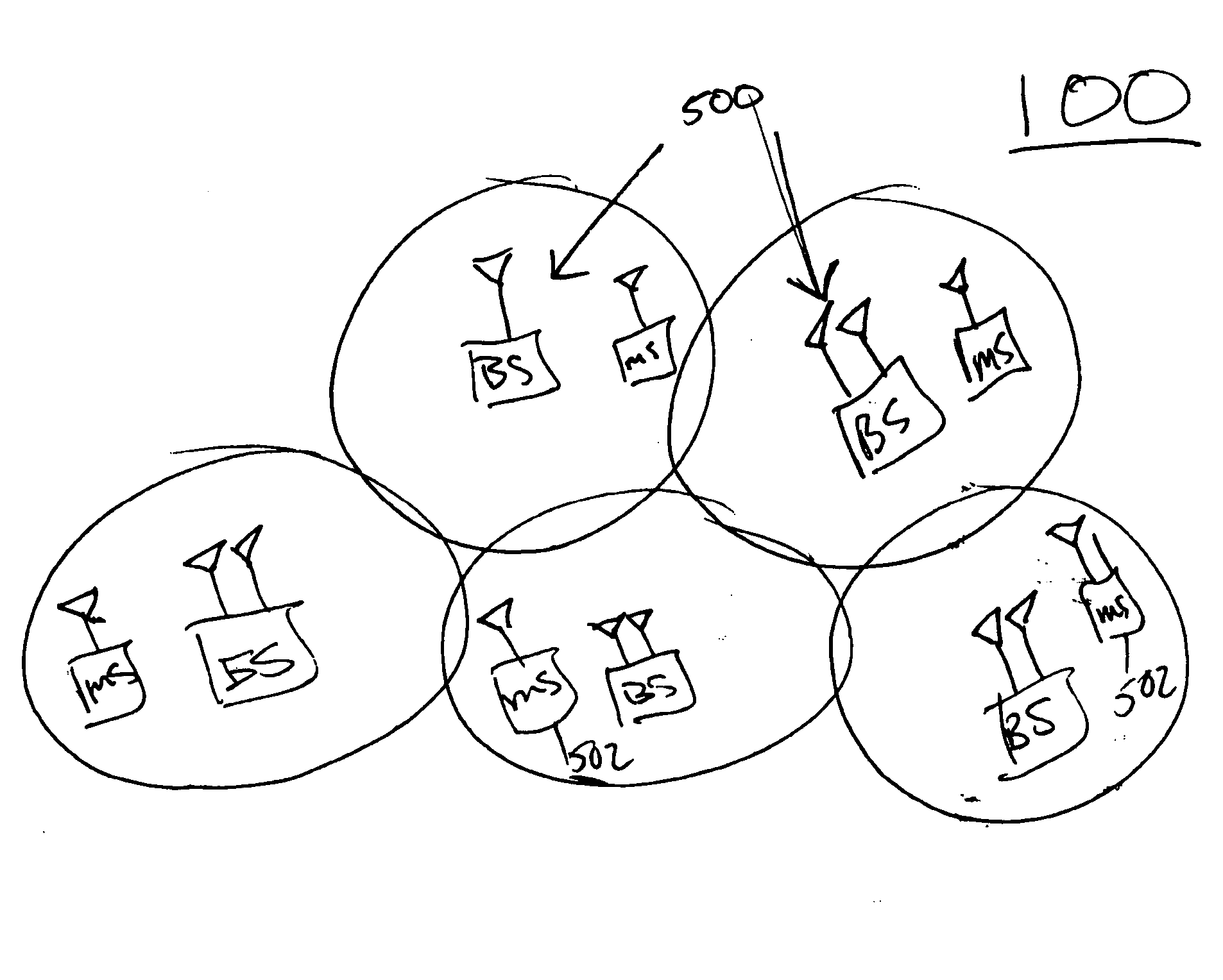

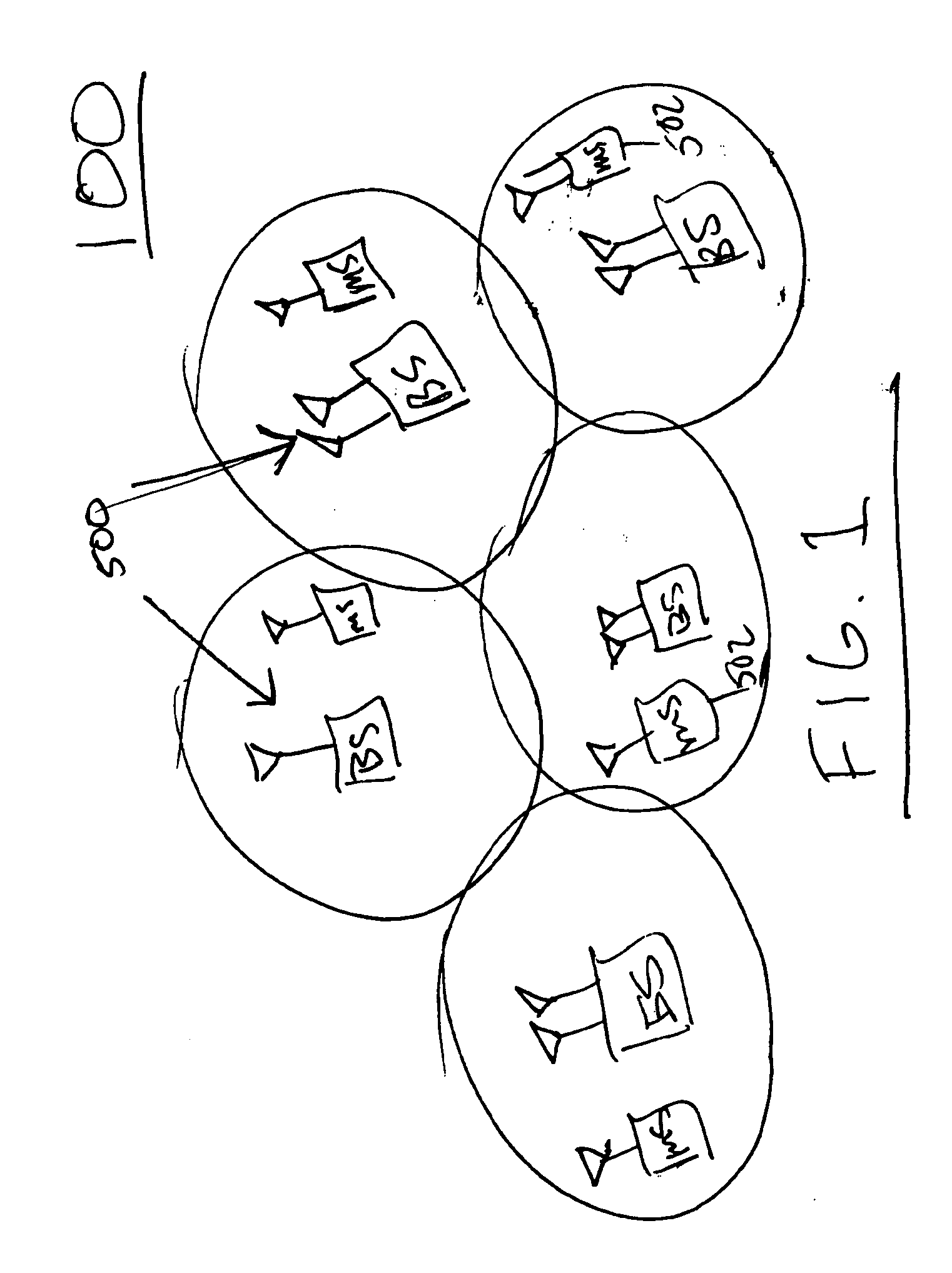

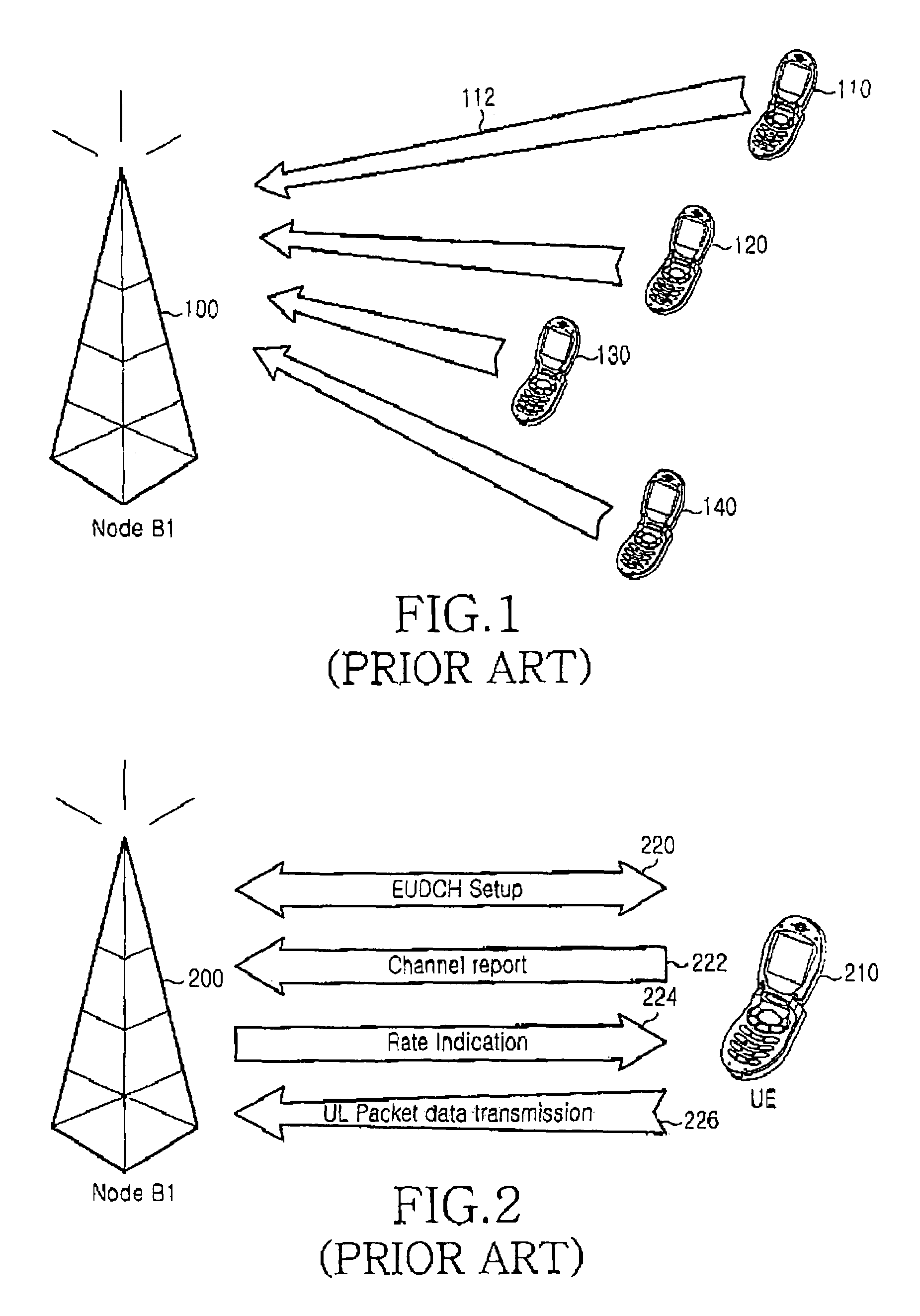

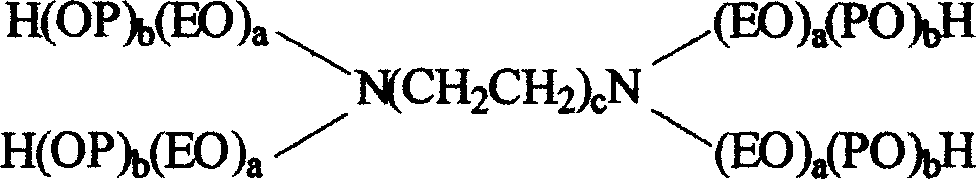

In wireless communication systems, the rise over thermal (ROT) indicates the ratio between the total interference received on a base station and the thermal noise. The ROT is a measurement of congestion of a cellular telephone network. The acceptable level of ROT is often used to define the capacity of systems using CDMA (code division multiple access).

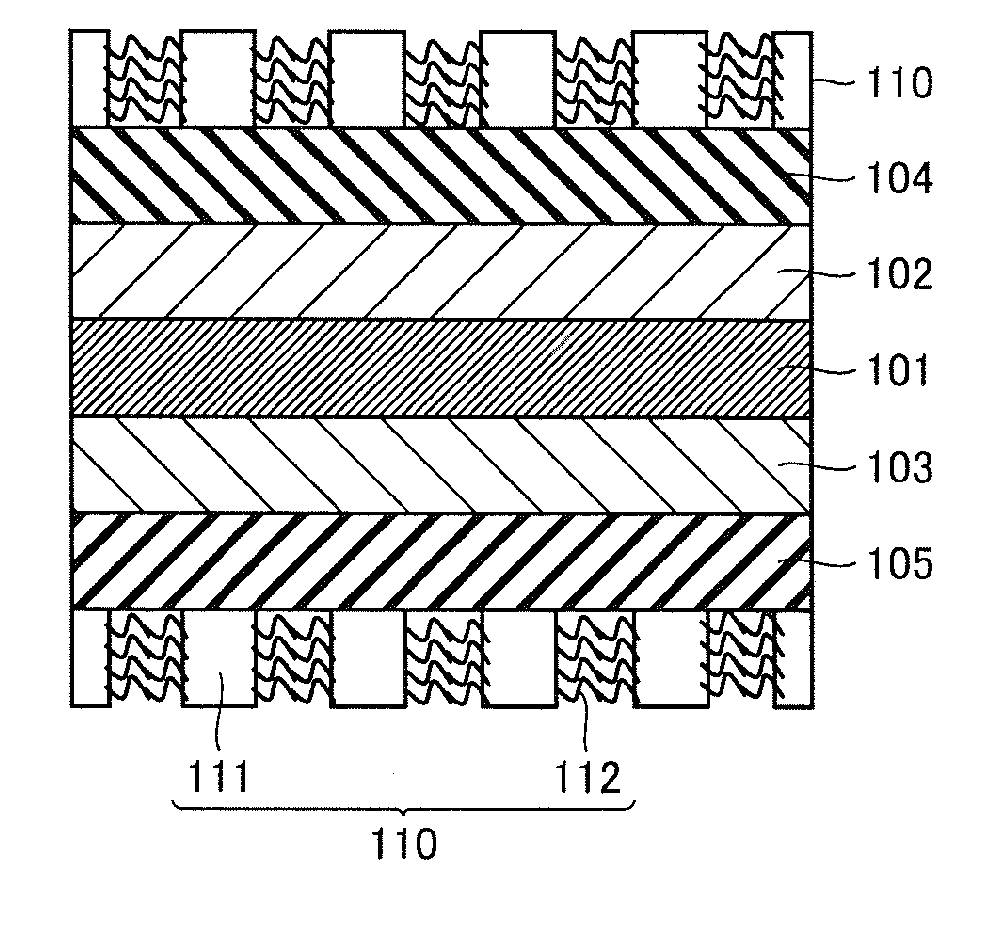

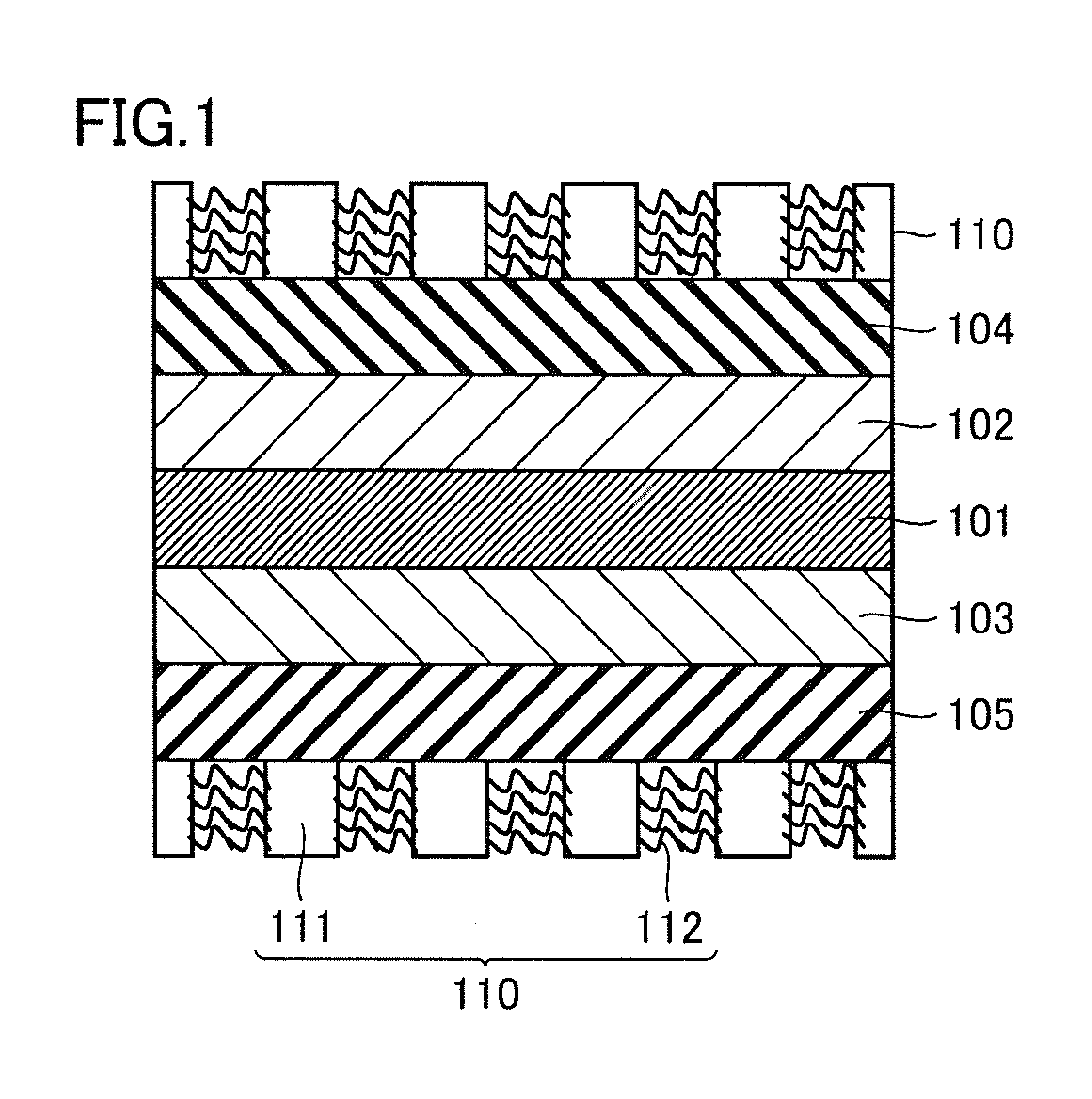

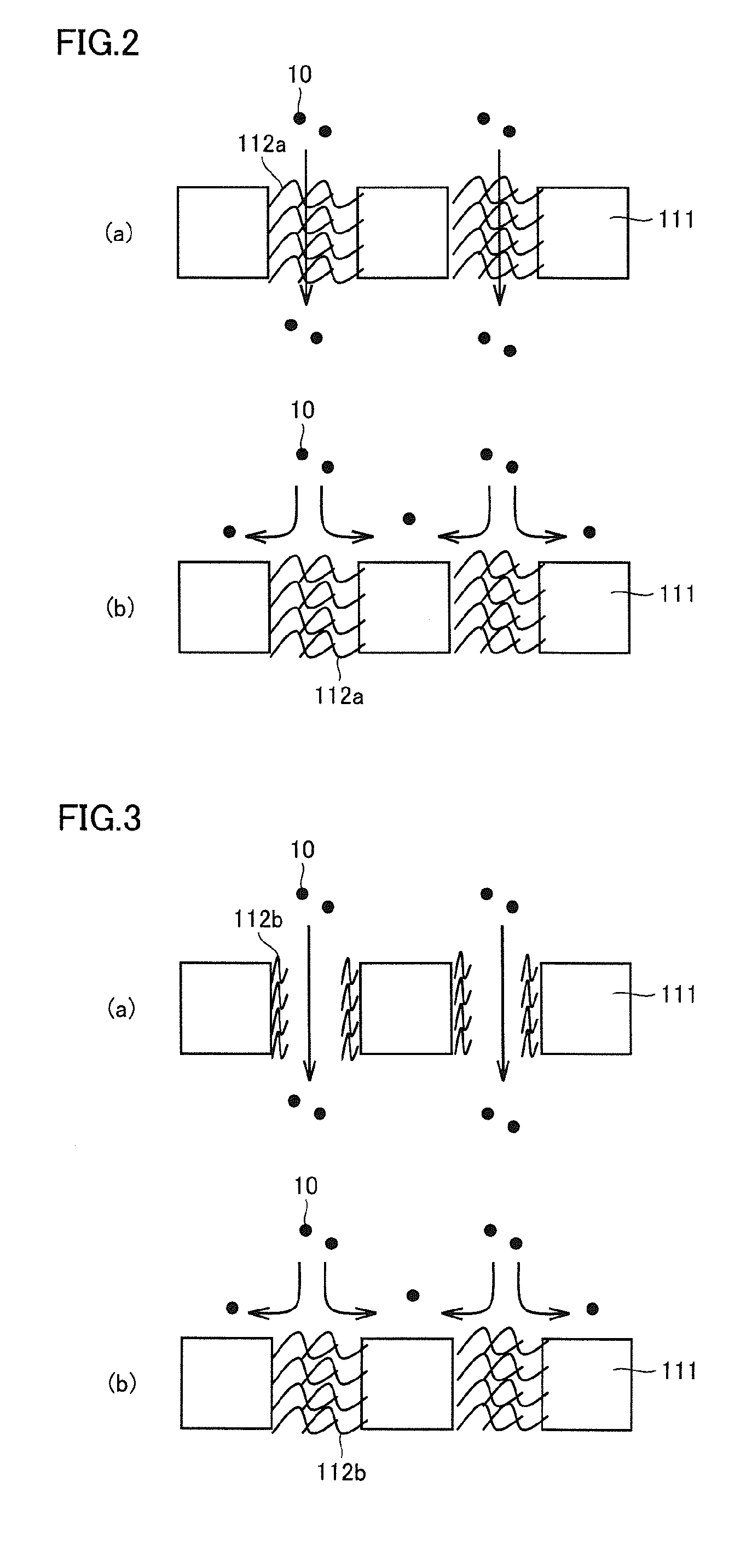

Separator for electrochemical device, electrode for electrochemical device, and electrochemical device

ActiveUS20100015530A1Improve reliabilityImprove load characteristicsHybrid capacitor separatorsHybrid capacitor electrodesPhysical chemistryPolyresin

A separator for an electrochemical device of the present invention includes a porous film including: a filler; an organic binder; and at least one resin selected from resin A that has a melting point of 80 to 140° C. and resin B that absorbs a non-aqueous electrolyte and swells upon heating and whose swelling degree increases with increasing temperature, and the filler contains boehmite having a secondary particle structure in which primary particles are connected.

Owner:MAXELL HLDG LTD

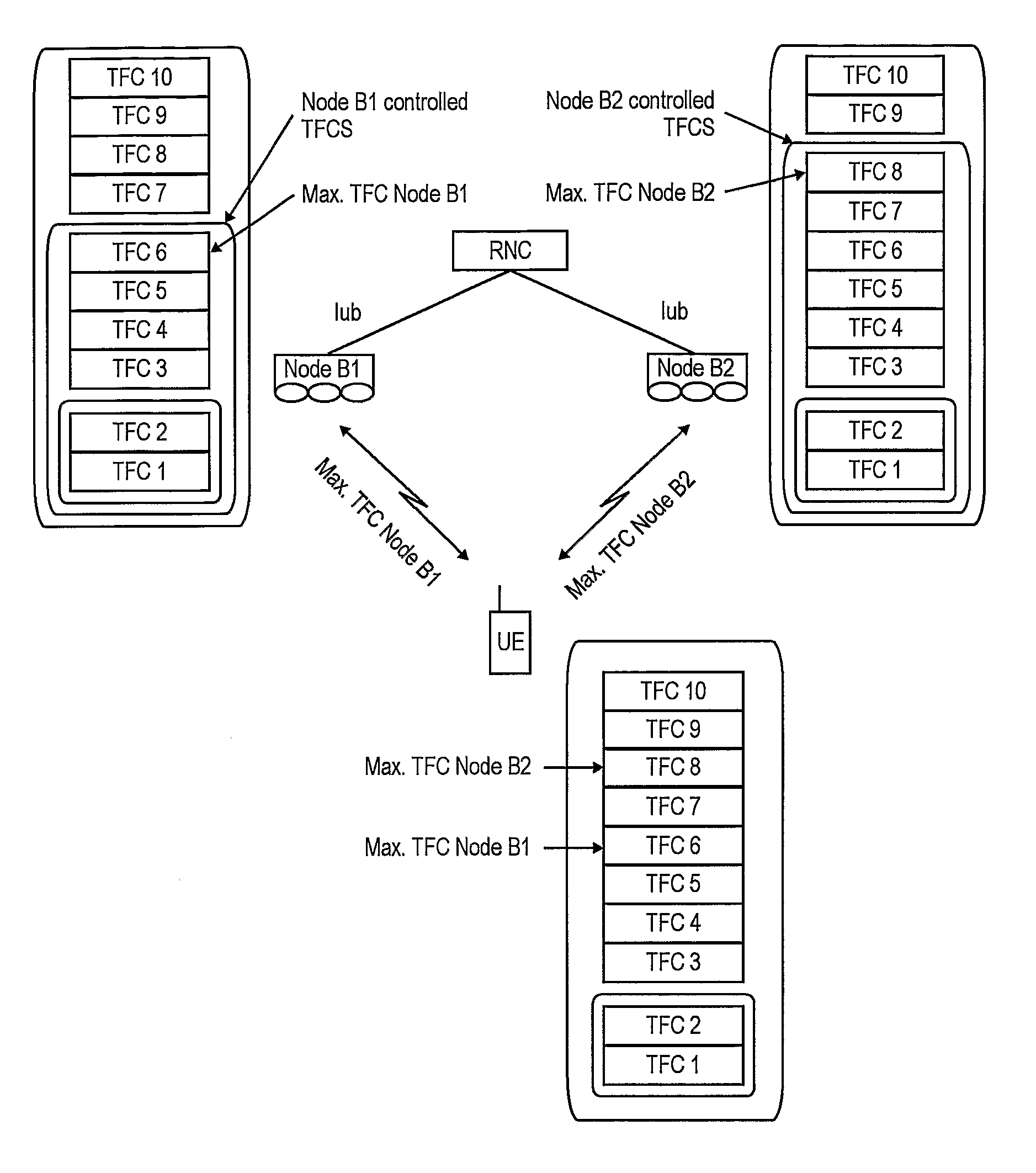

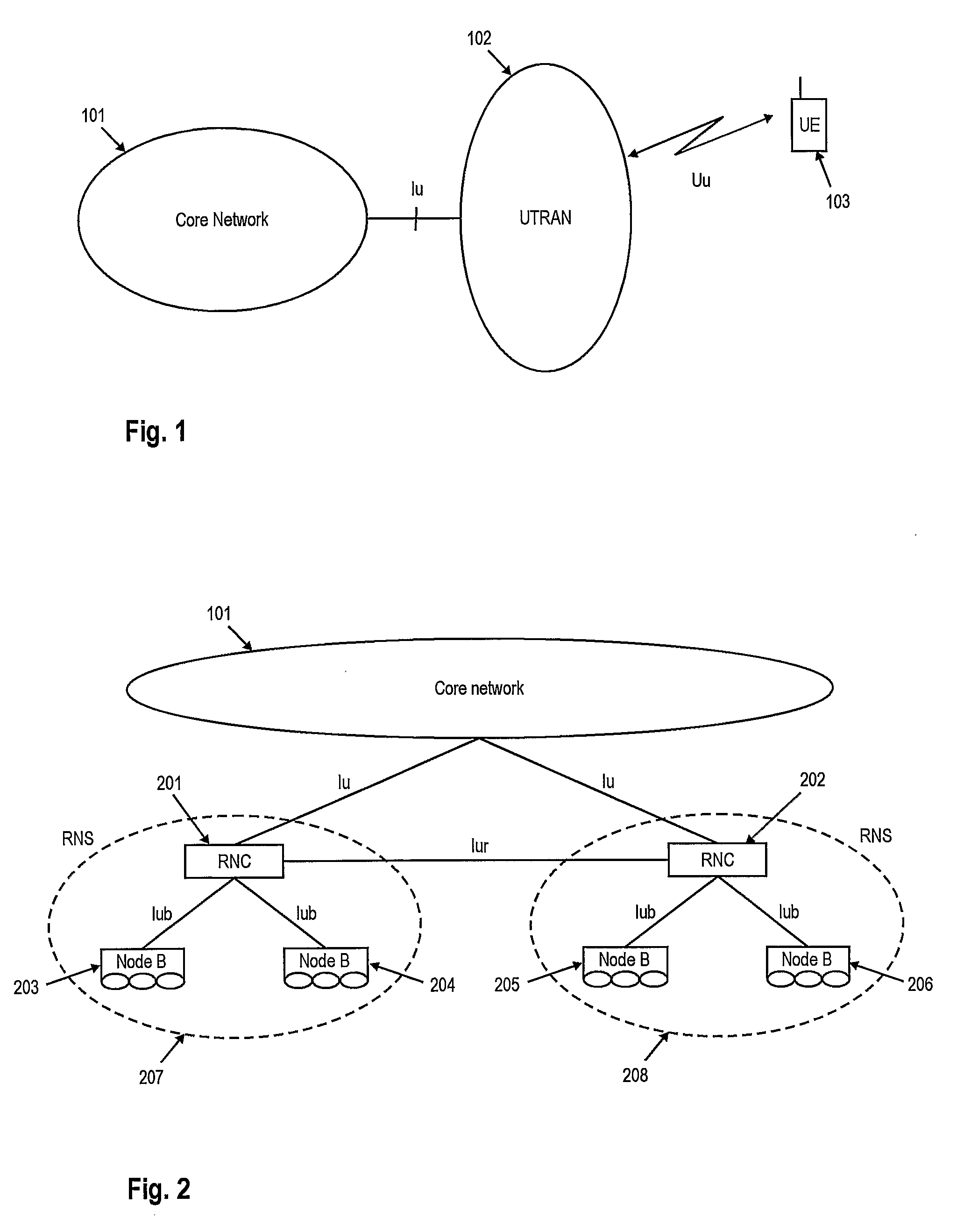

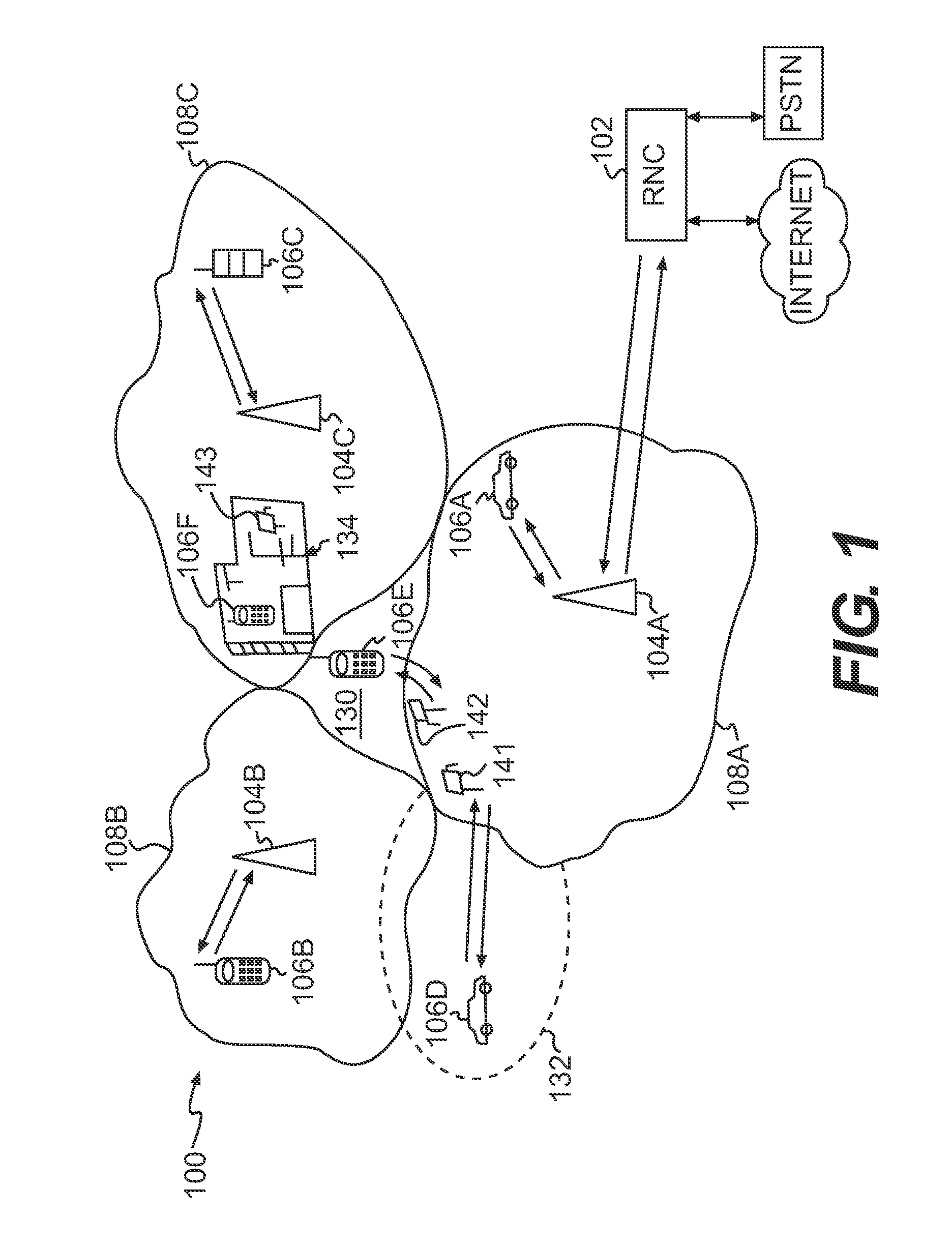

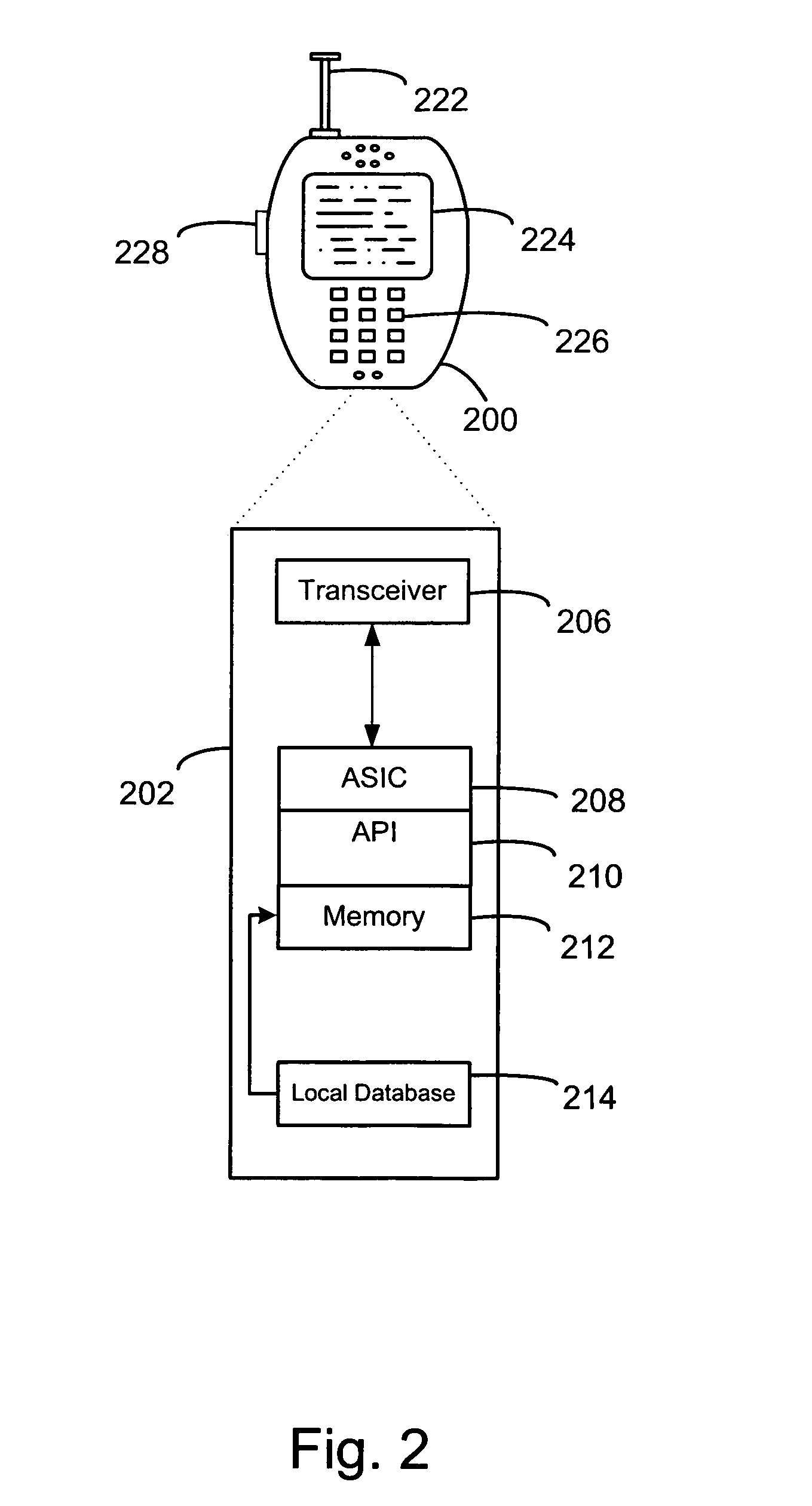

Efficient Rise Over Thermal (Rot) Control During Soft Handover

InactiveUS20070281695A1Control impactEffective controlRadio/inductive link selection arrangementsWireless commuication servicesCommunications systemUplink transmission

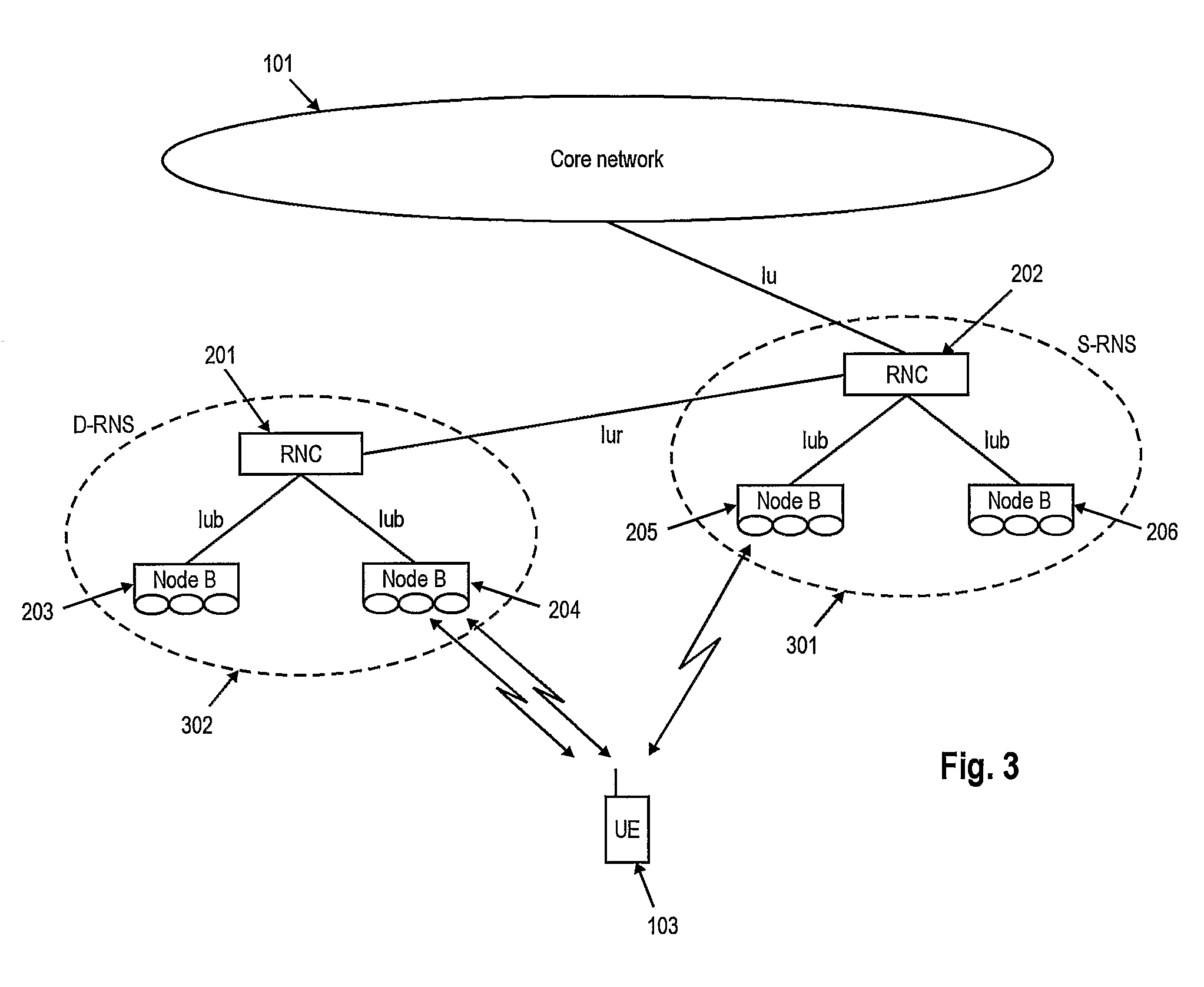

The invention relates to a method for communicating information relating to the scheduling of uplink data transmissions for a mobile terminal transmitting data on the uplink to a plurality of base stations during soft handover of the mobile terminal in a mobile communication system. Further at least one base station of said plurality of base stations schedules uplink data transmissions of the mobile terminal in soft handover. The different embodiments of the invention provide a communication system, a radio resource controller, a base station and mobile terminal which may perform different tasks of the method disclosed. To provide a method reducing the impact of uplink transmissions during soft handover on the rise over thermal it is suggested to provide all base stations communicating with the mobile terminal during soft handover with information on the maximum amount of resources allocated to the mobile terminal for uplink transmissions thereby allowing the base stations to schedule other terminal taking into account this information.

Owner:INVT SPE LLC

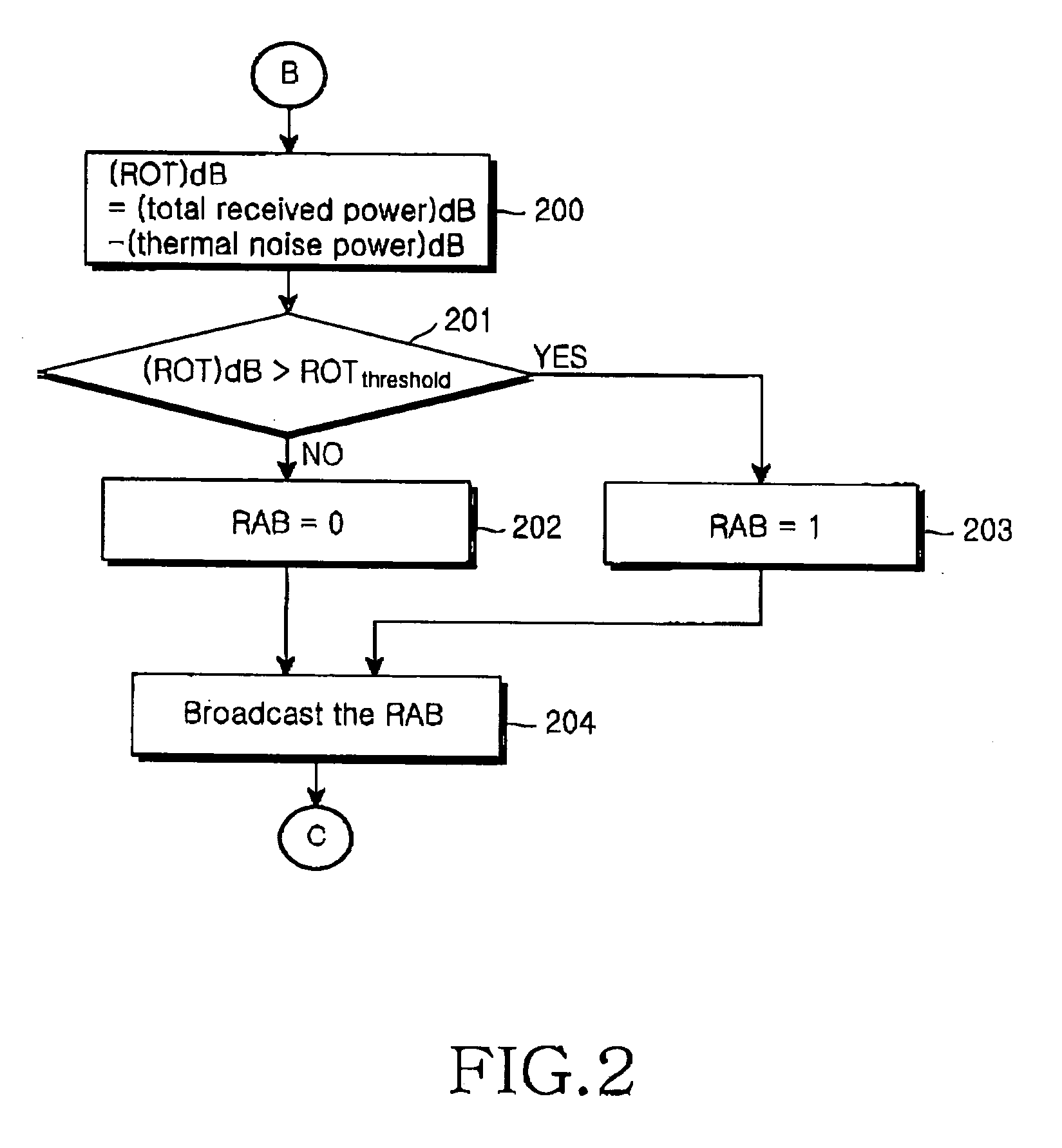

Apparatus and method for measuring and reporting uplink load in a cellular mobile communication system

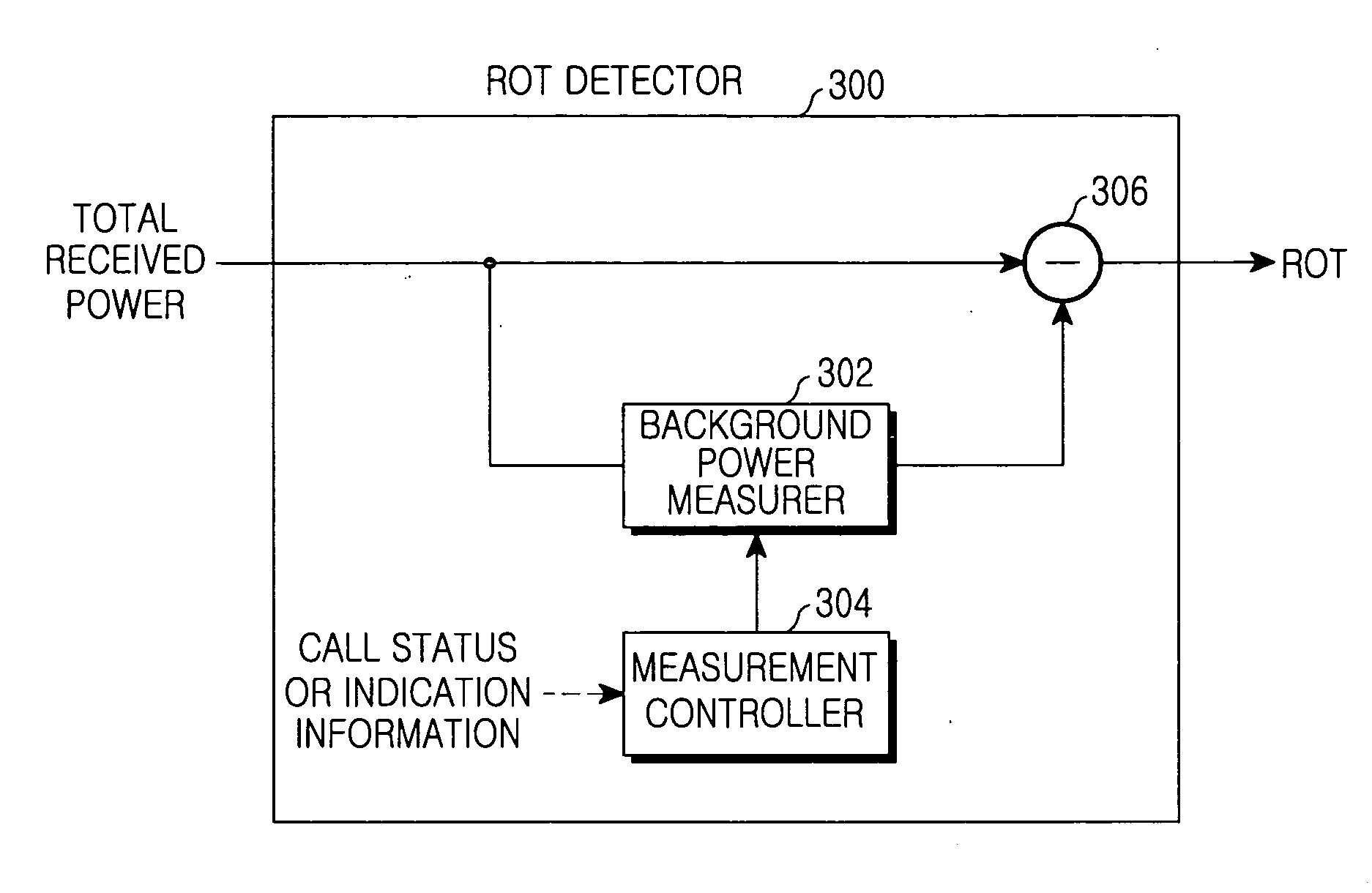

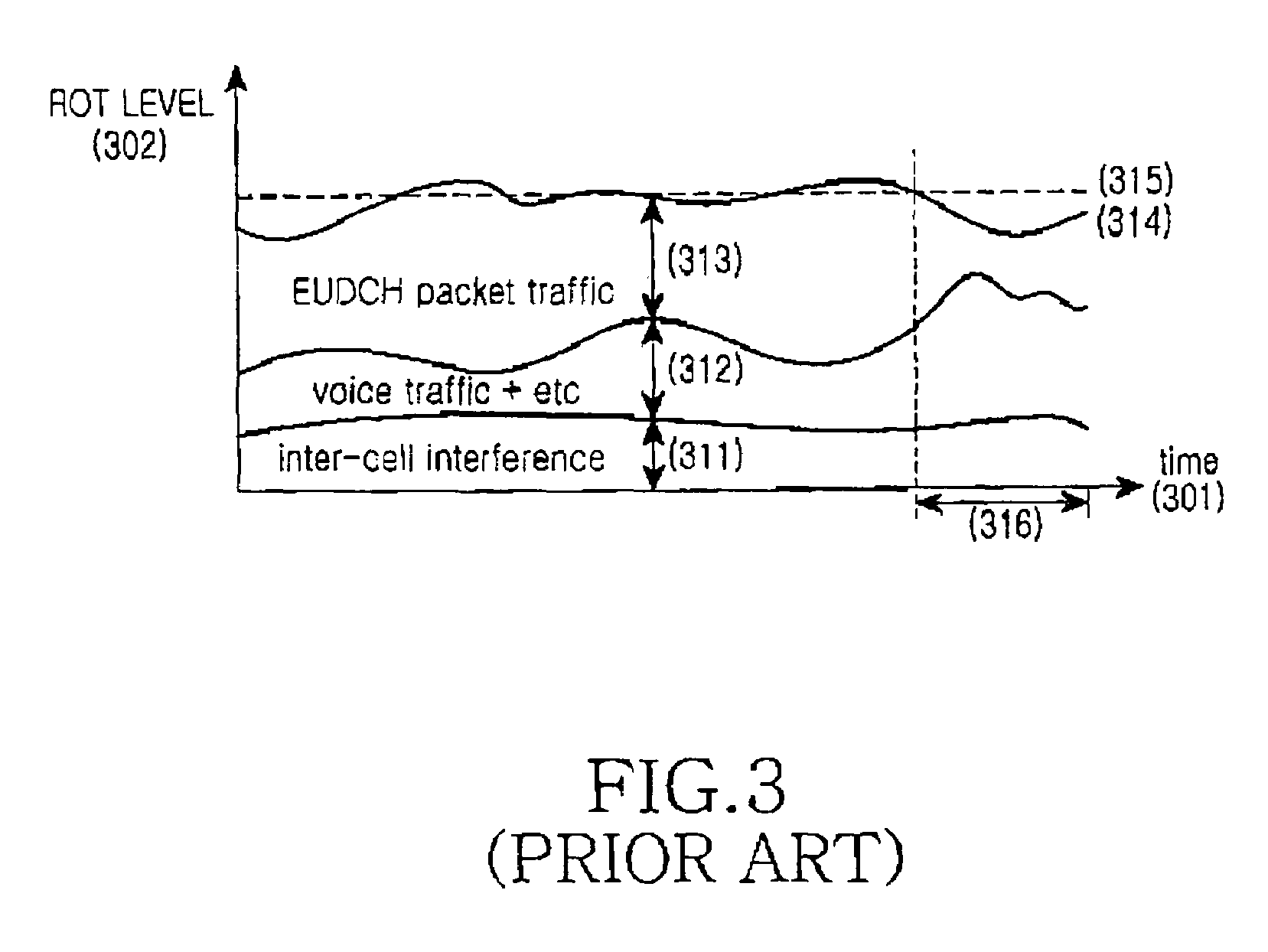

InactiveUS20060079267A1Improve accuracyImprove robustnessRadio transmissionTransmission monitoringTime segmentEngineering

An apparatus and method for measuring and reporting uplink load in a base station (BS) in a cellular mobile communication system are provided. The BS includes a rise over thermal (ROT) detector for measuring a ROT representing uplink load, and reporting information from which the ROT can be derived to a base station controller (BSC) via a standard interface. The ROT detector measures as background power the received power of the BS for a call-free period, the minimum of received power of the BS, or the minimum of received power of the BS measured for a predetermined time period. Then the ROT can be obtained by subtracting the background power from the received power of the BS.

Owner:SAMSUNG ELECTRONICS CO LTD

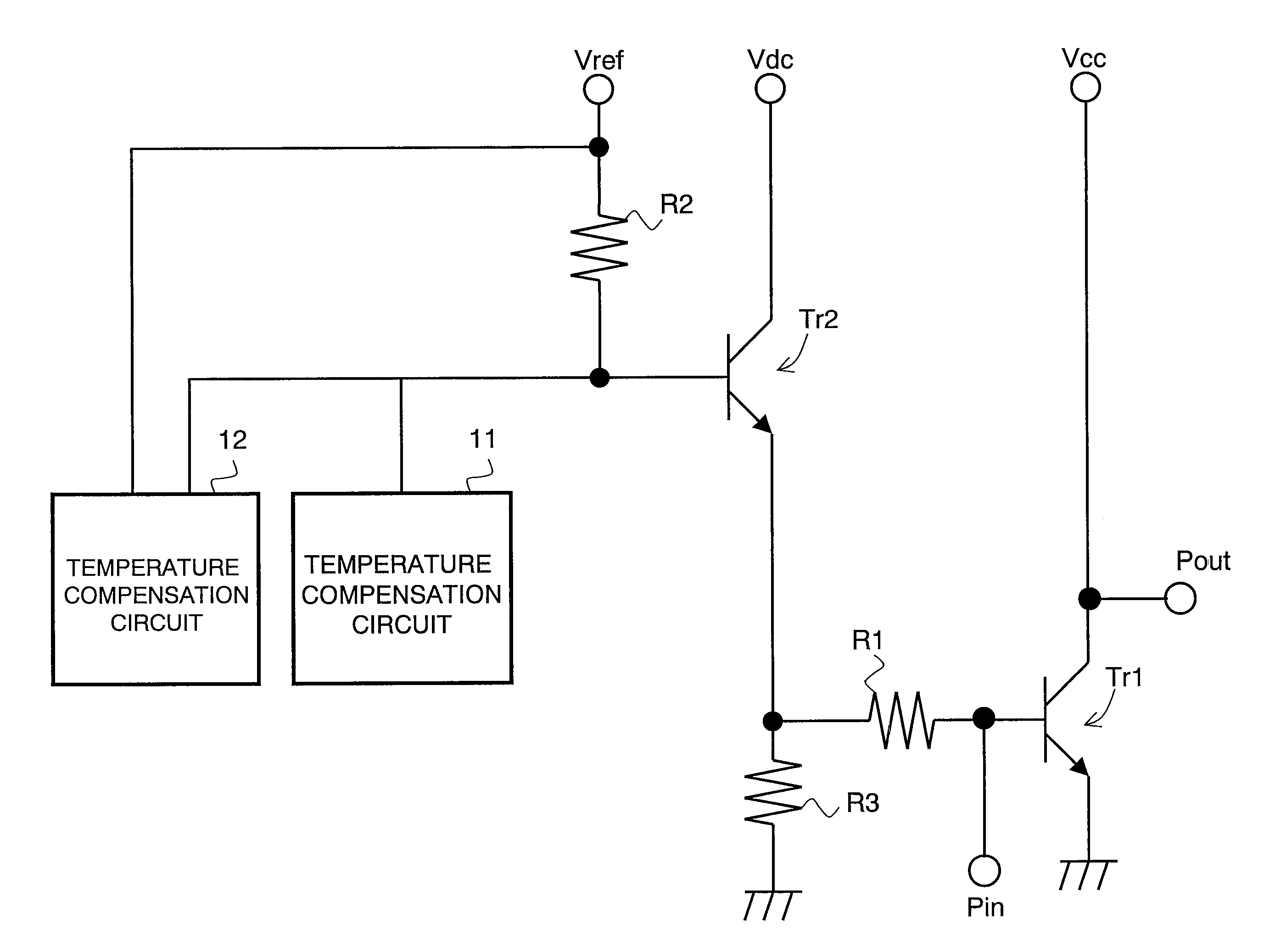

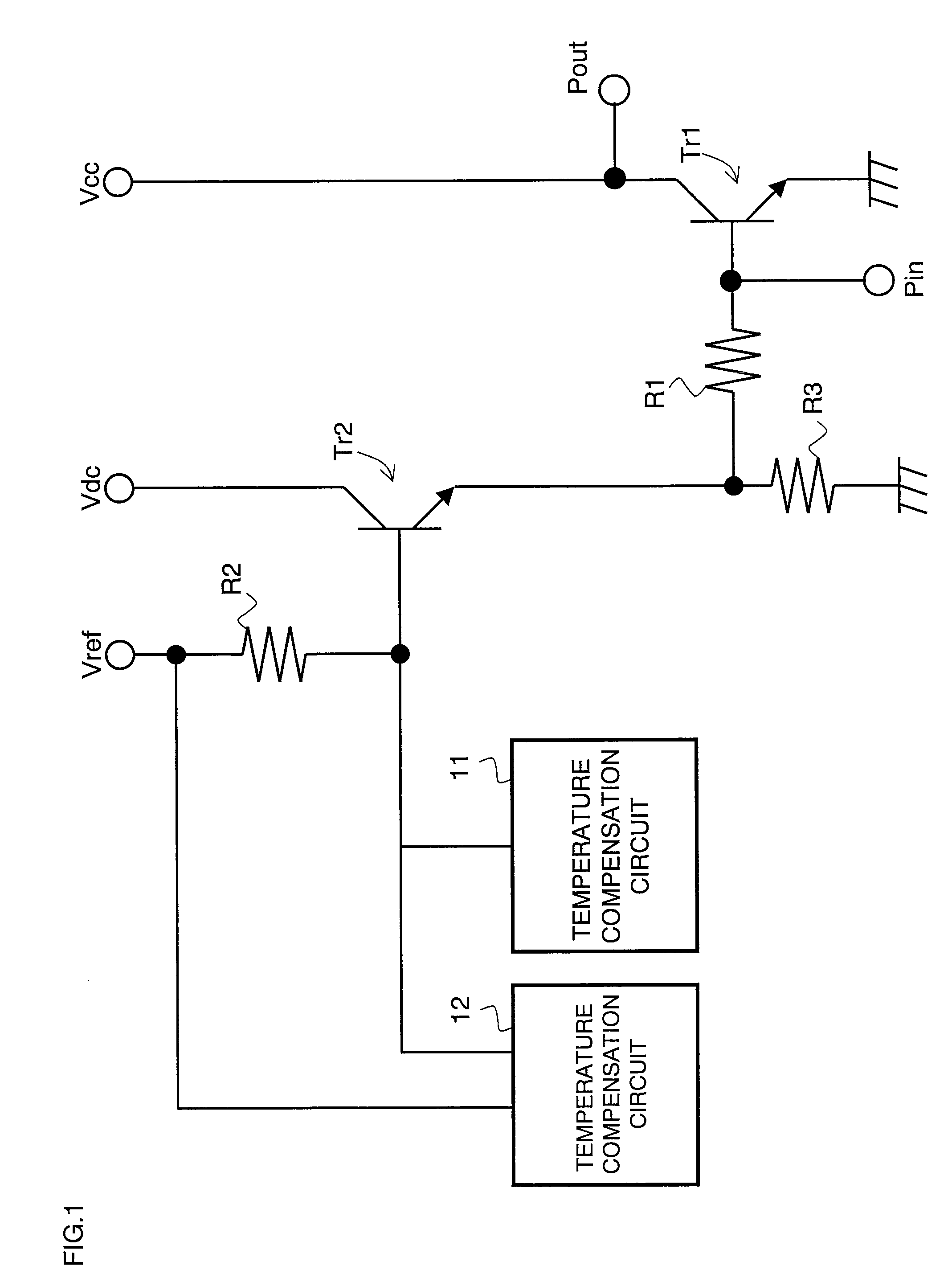

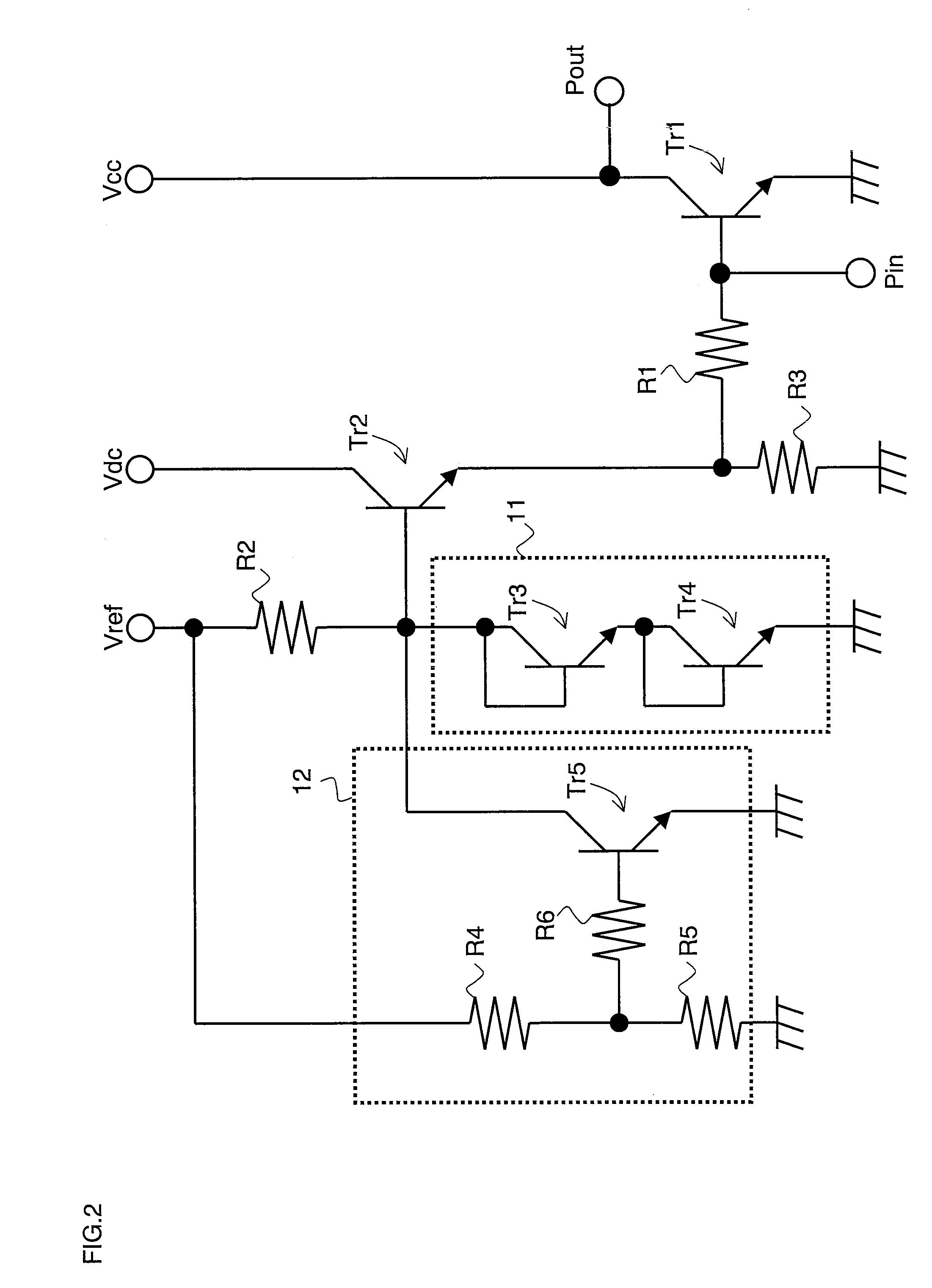

Radio-frequency power amplifier

ActiveUS7768354B2Lower average currentSolve the high dependenceHigh frequency amplifiersAmplifier combinationsEngineeringRadio frequency

A bias circuit operable to supply a bias current to a first transistor includes: a second transistor having a collector terminal connected to a first power supply; a first resistance element having one end connected to an emitter terminal of the second transistor and having the other end connected to a base terminal of the first transistor; a second resistance element having one end connected to the emitter terminal of the second transistor and having the other end connected to ground potential; at least one third resistance element provided between a base terminal of the second transistor and a second power supply; and a plurality of temperature compensation circuits connected to the base terminal of the second transistor which are operable to control a base potential of the second transistor so that the potential falls as a temperature rises.

Owner:GK BRIDGE 1

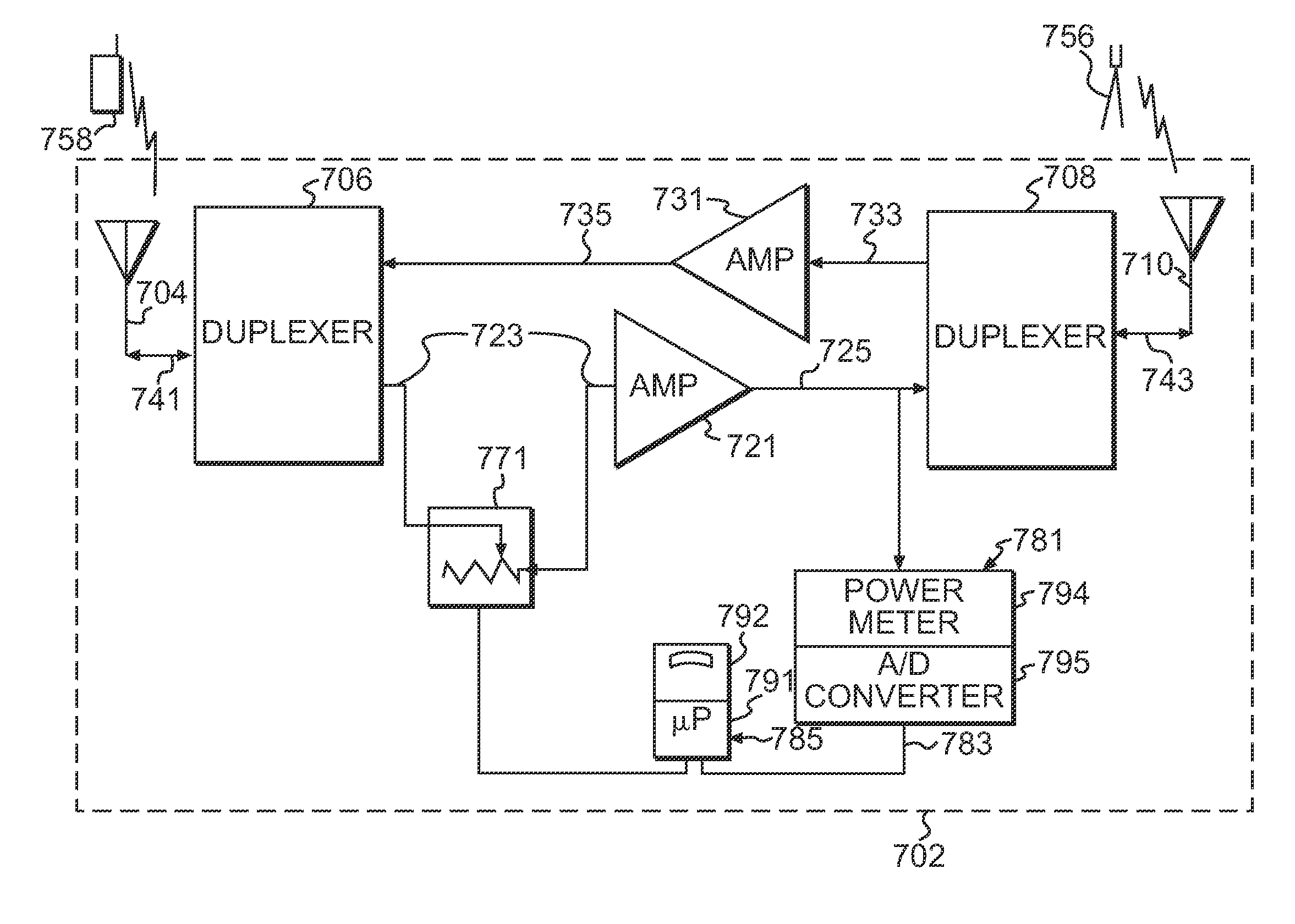

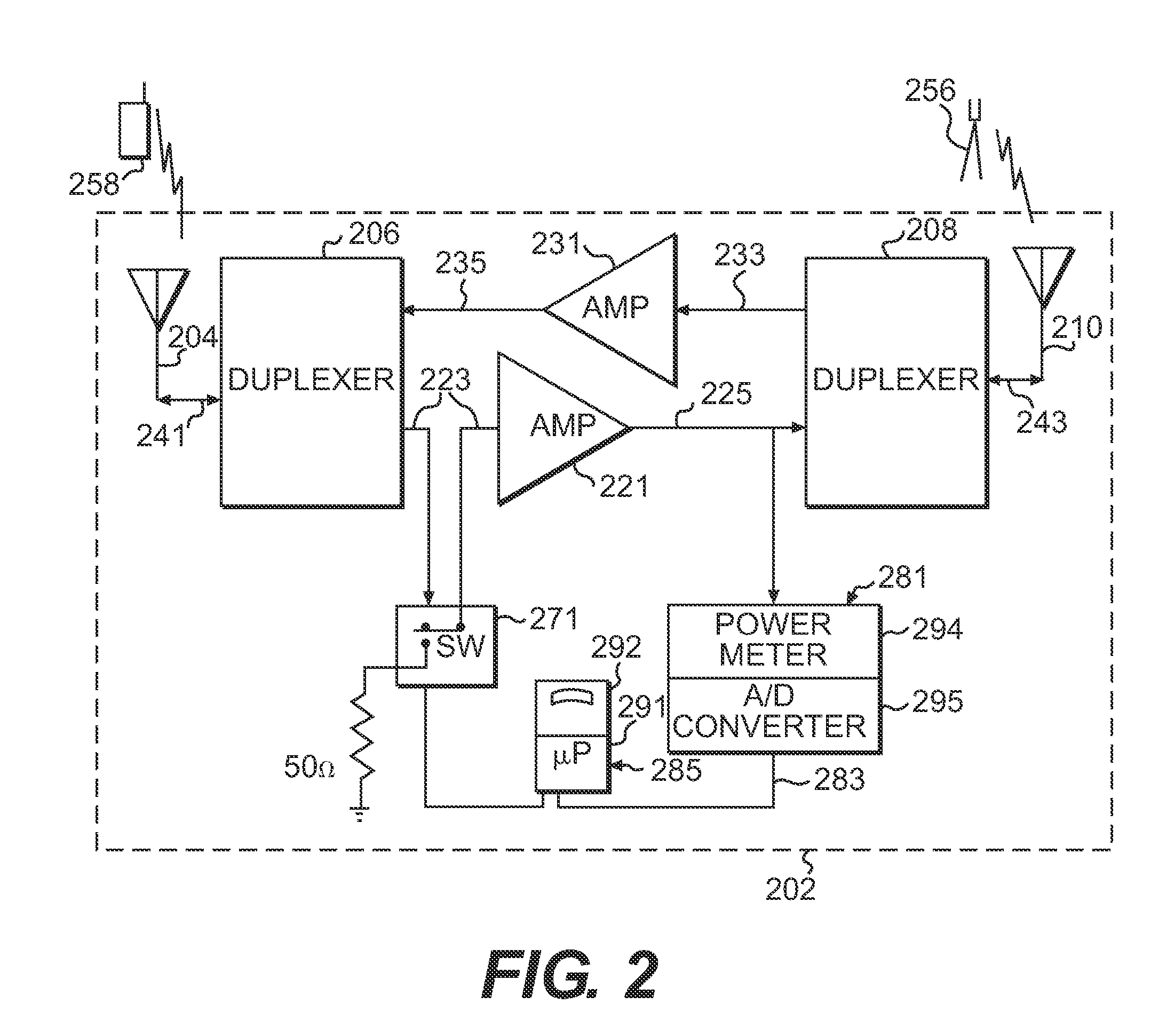

Repeater rise-over-thermal (ROT) value calibration

InactiveUS20070202826A1Receivers monitoringActive radio relay systemsAudio power amplifierEngineering

An RF switch is used in the signal path to an amplifier, for example between a receiving antenna and an amplifier. The switch is used to alternately connect the amplifier between a normal signal source for the amplifier and a fixed load for calibration. The power difference between the two switch states at the output of the amplifier would then yield a calibrated measurement of a signal value, such as rise over thermal (RoT). The amount of time spent in the calibration position is maintained at a minimized level so as to reduce impact on the normal operation of the amplifier. The invention provides an ability to estimate traffic load in a repeater system based on RoT measurements of repeater reverse-link output power by determining a reverse link gain.

Owner:QUALCOMM INC

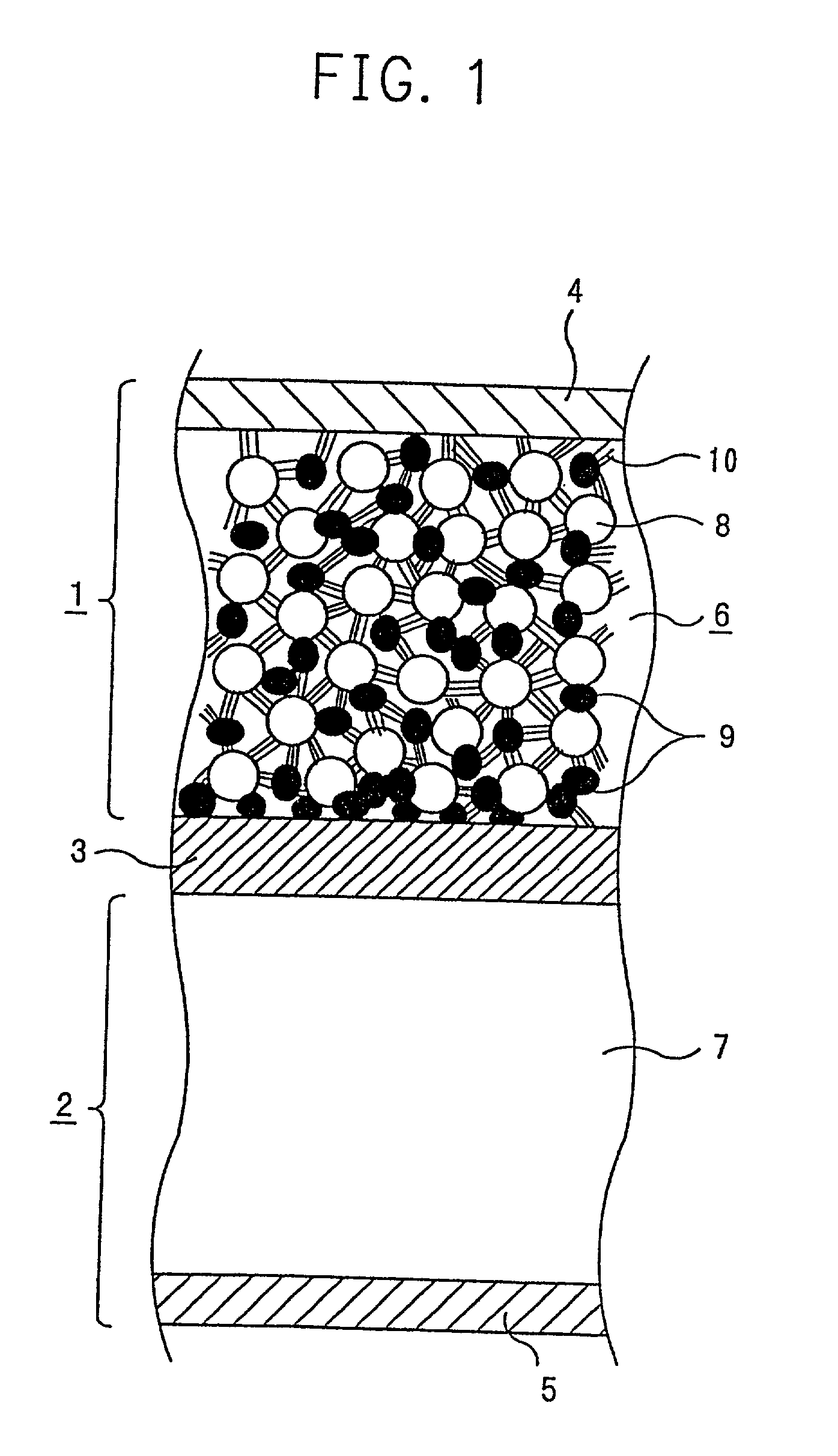

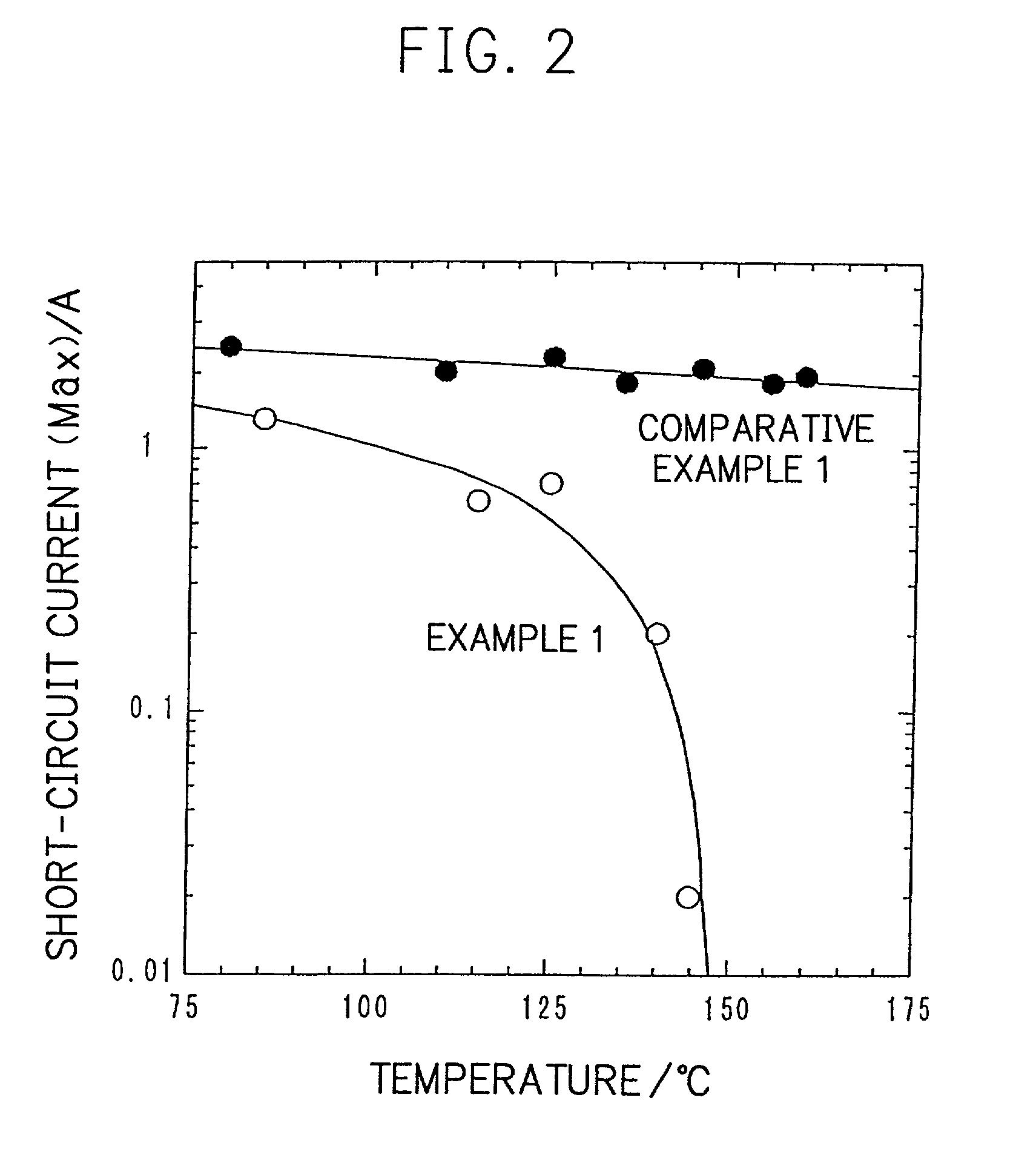

Battery and process for preparing the same

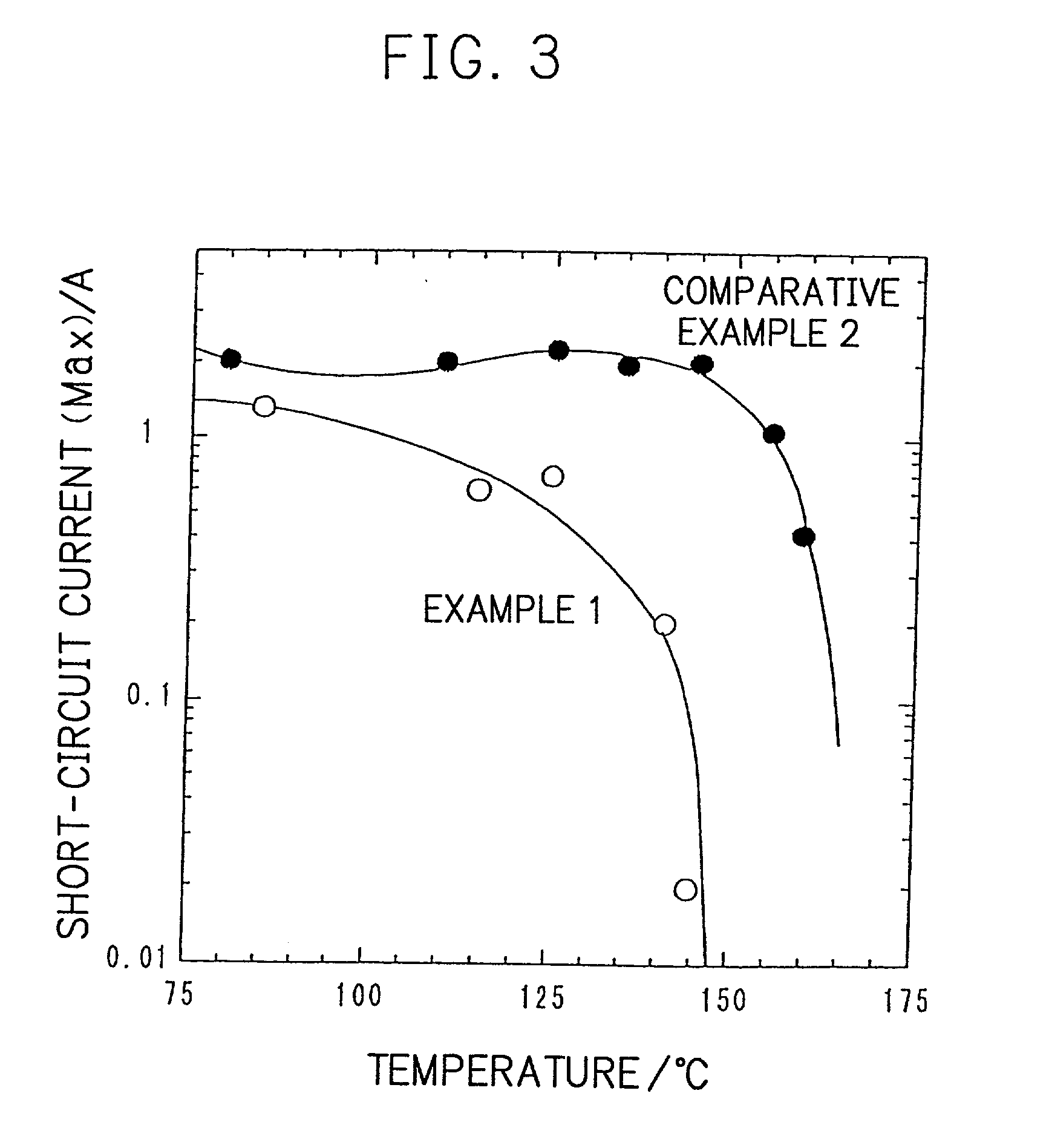

InactiveUS20010005562A1Supplement low electronic conductivityLow electronic conductivityPrimary cell maintainance/servicingElectrode carriers/collectorsElectrical resistance and conductanceConductive materials

A conventional battery has a problem that a large short-circuit current is generated with temperature rise due to internal short-circuit, and therefore, the temperature of the battery further increases due to heat and the short-circuit current is increased. Also, there is a problem in safety that the sealed part can be easily opened with temperature rise in case of using the aluminum laminated bag as the outer body for sealing the battery body. The present invention has been carried out in order to solve the above problems. The battery of the present invention is a battery wherein at least one of the positive electrode 1 and the negative electrode 2 comprises the active material layer 6 containing the active material 8 and the electronically conductive material 9 contacted to the active material 8; wherein the battery body 11 is constructed by containing the electrolytic layer 3 between the above positive electrode 1 and negative electrode 2, and the above battery body is sealed with the outer body 14 comprising the aluminum 13 and the thermal fusion resin 12; and wherein the electronically conductive material 9 comprises the electrically conductive filler and the resin so that the resistance increases in accordance with temperature rise.

Owner:MITSUBISHI ELECTRIC CORP

Laser driver and temperature compensation circuit thereof

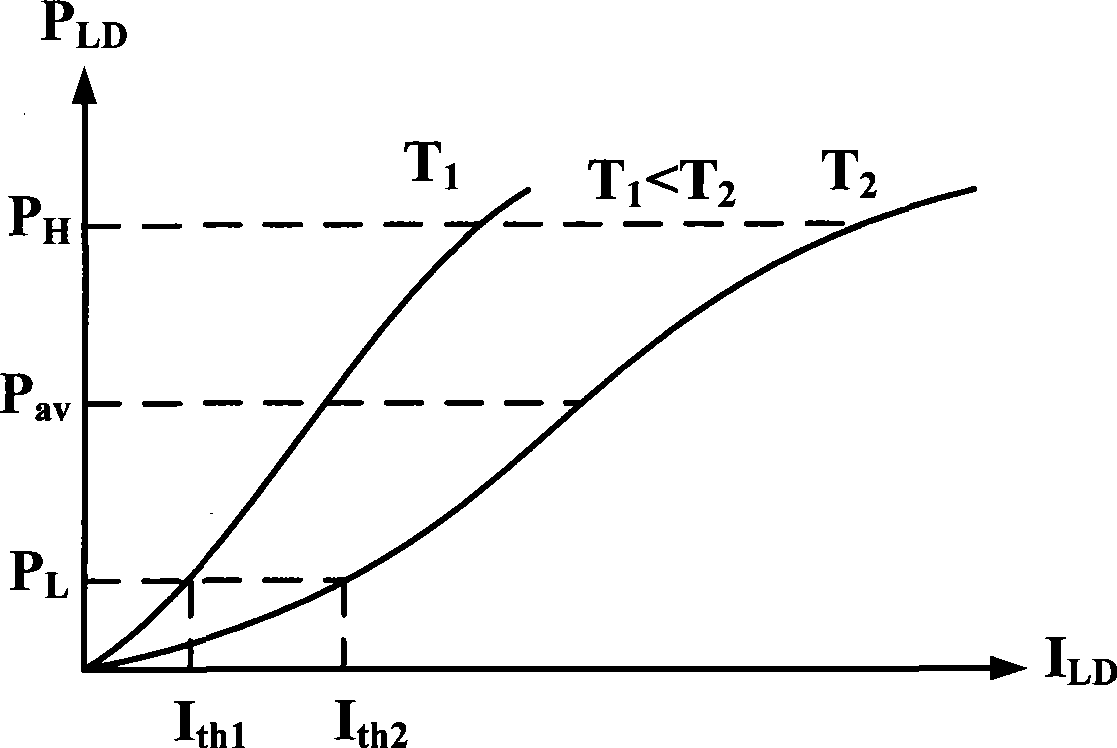

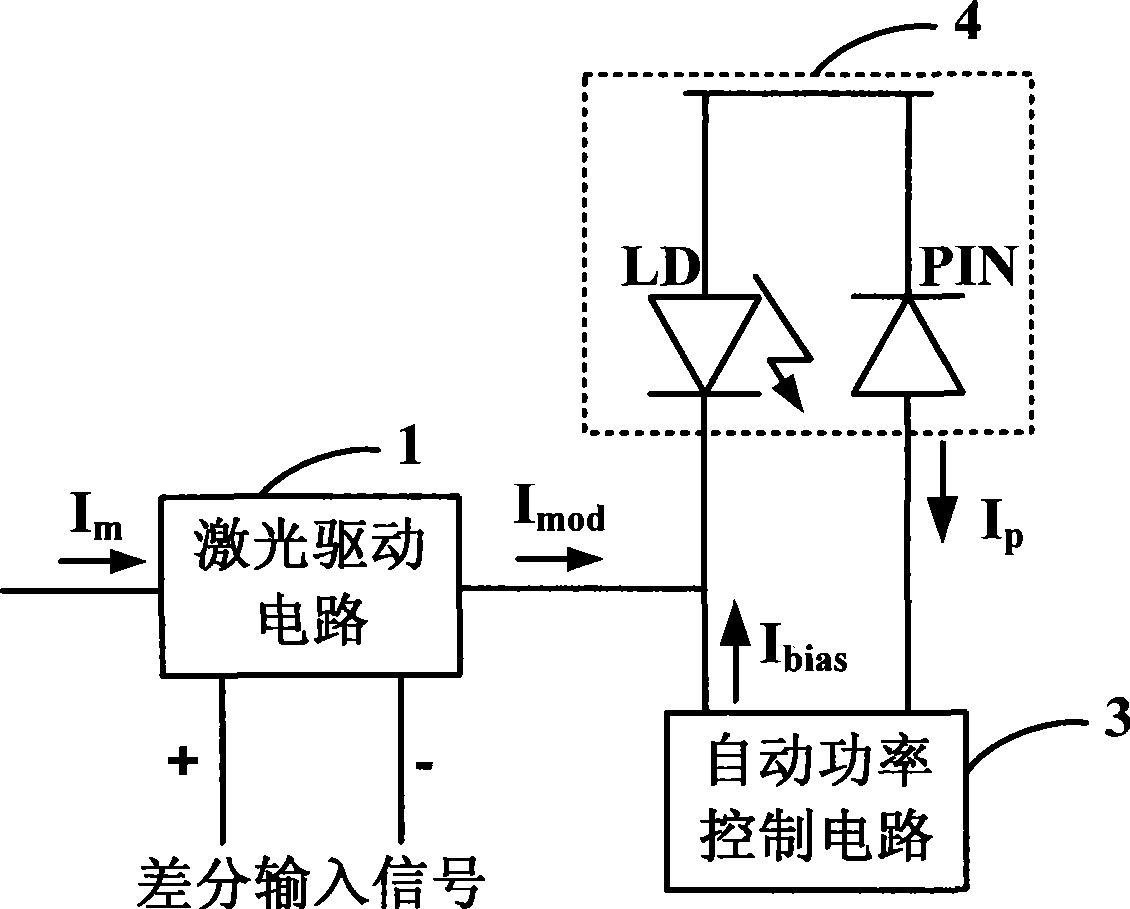

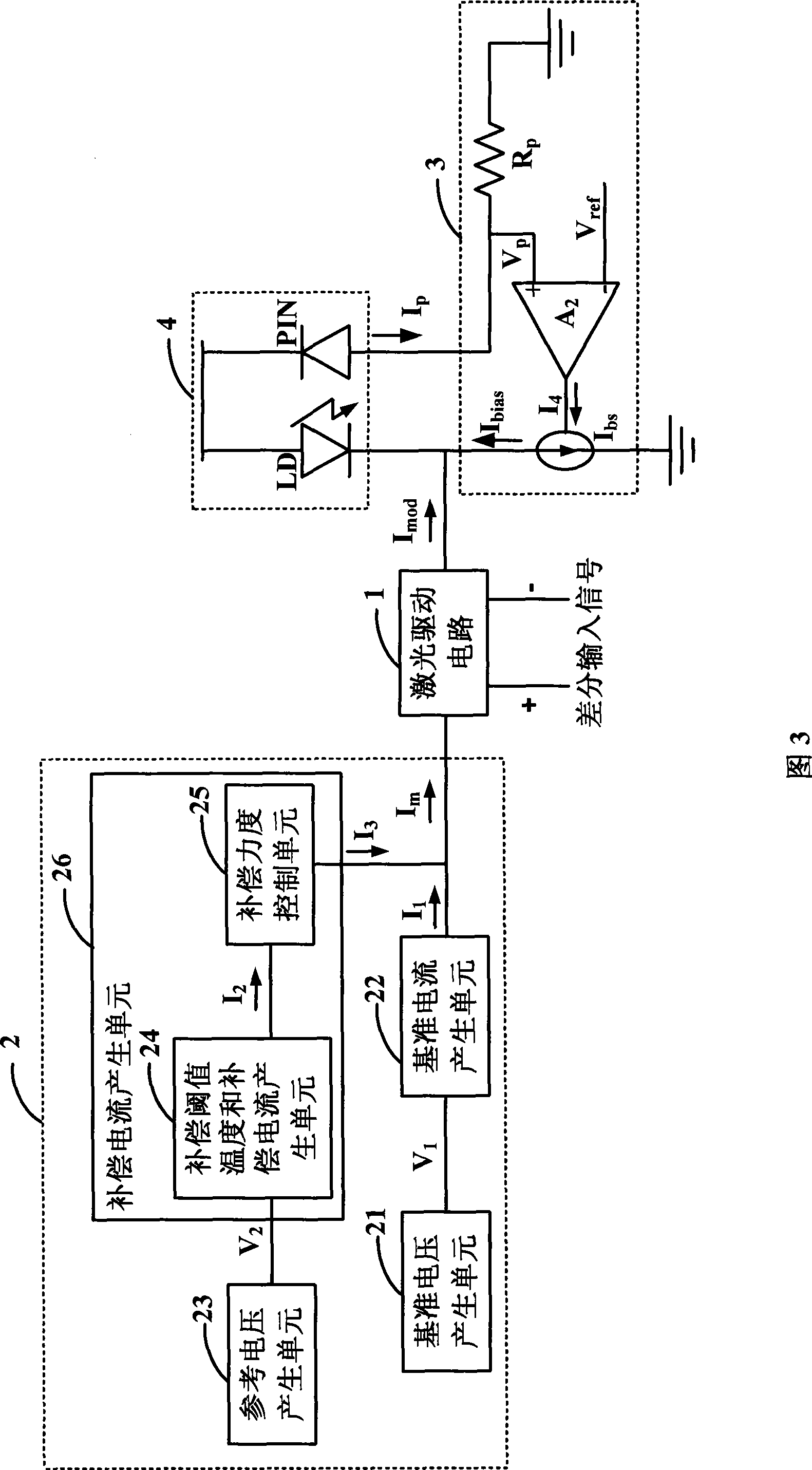

InactiveCN101453270AHas a constant extinction ratioStable output optical powerElectronic switchingElectromagnetic transmissionOptical powerVoltage reference

The invention discloses a laser driver and a temperature compensation circuit thereof. The temperature compensation circuit comprises a benchmark voltage generation unit, a benchmark current generation unit, a reference voltage generation unit, and a compensation current generation unit, wherein the benchmark voltage generation unit generates a benchmark voltage which increases with the increase of the temperature; the benchmark current generation unit is connected with the benchmark voltage generation unit and outputs benchmark current which increases with the increase of the benchmark voltage; the reference voltage generation unit generates a reference voltage which increases with the increase of the temperature; the compensation current generation unit is connected with the reference voltage generation unit, obtains the compensation threshold temperature according to the reference voltage, and outputs compensation current when the temperature is higher than or equal to the compensation threshold temperature; and the benchmark current and the compensation current are overlapped to form benchmark modulation current. The laser driver comprises the temperature compensation circuit and a bias current regulation circuit. An optical signal output by the laser can have constant extinction ratio by compensating modulation current of a laser through the temperature compensation circuit, and the laser can obtain steady output optical power by compensating bias current of the laser through the bias current regulation circuit.

Owner:JIANGNAN INST OF COMPUTING TECH

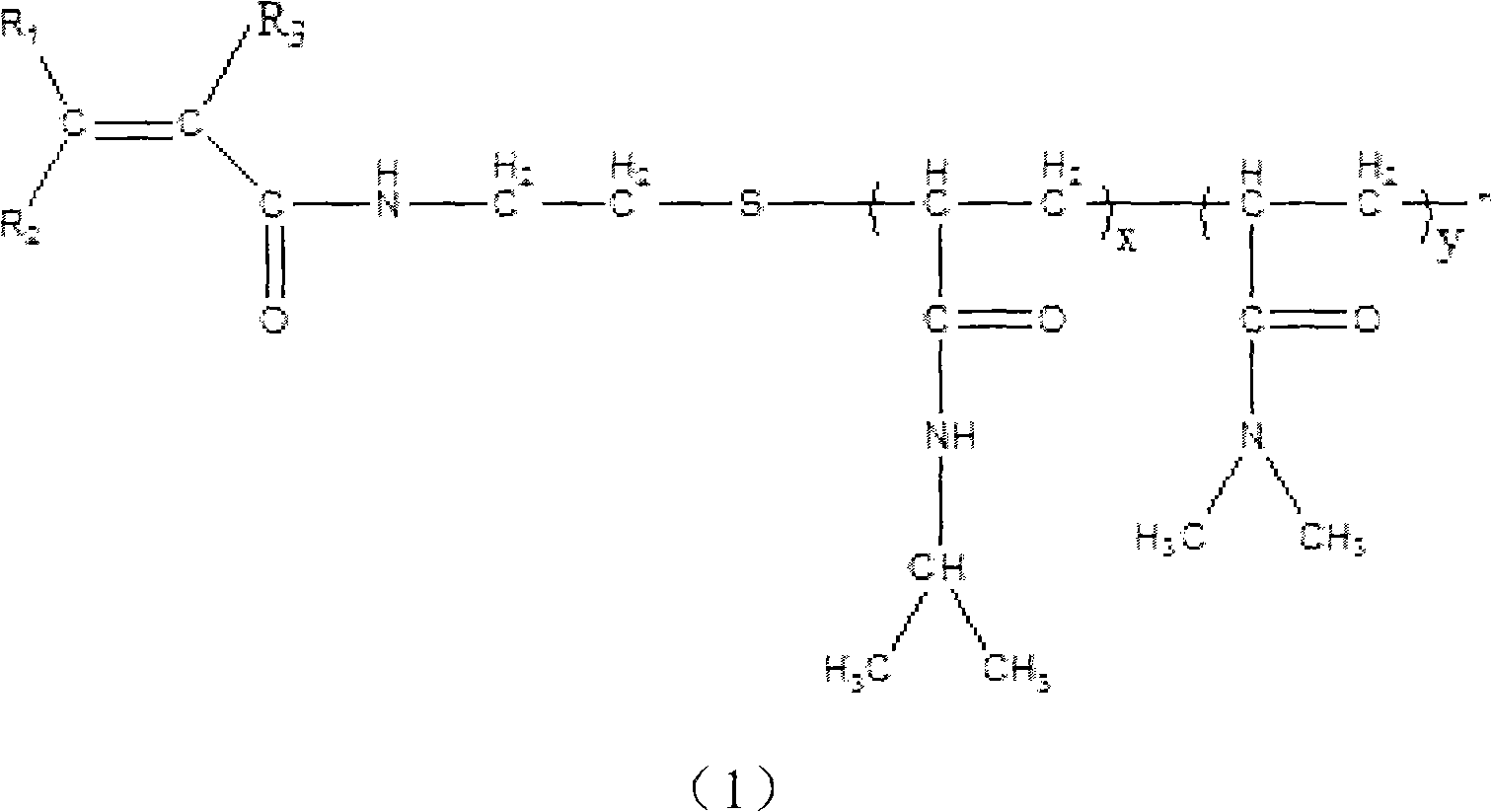

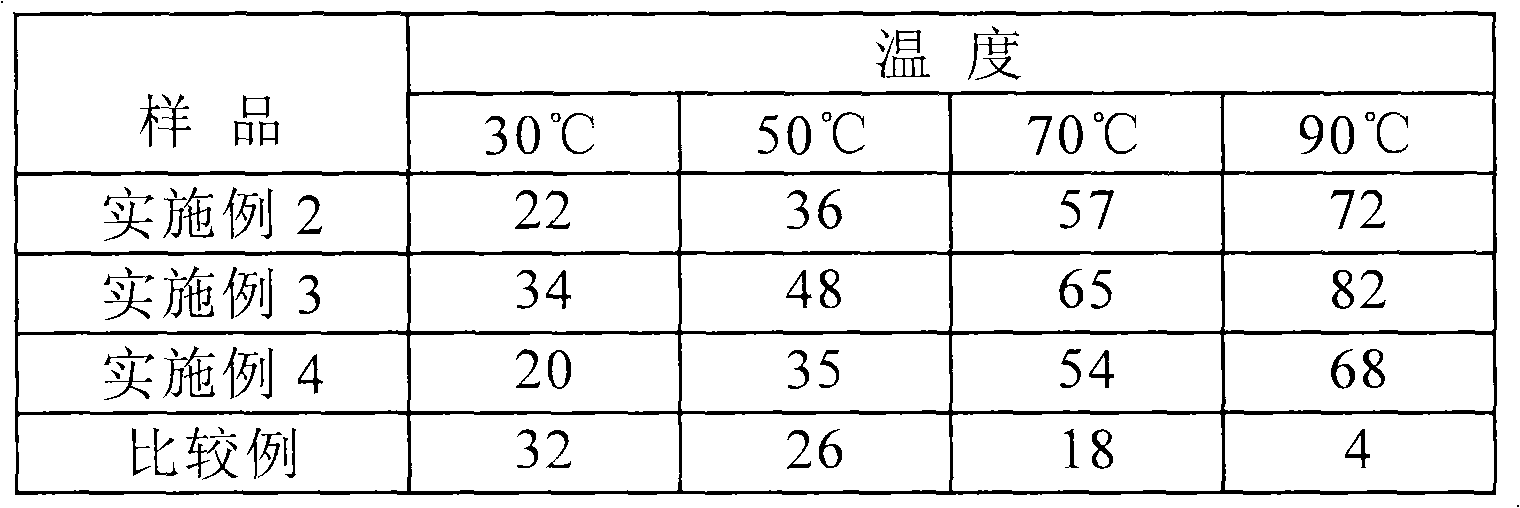

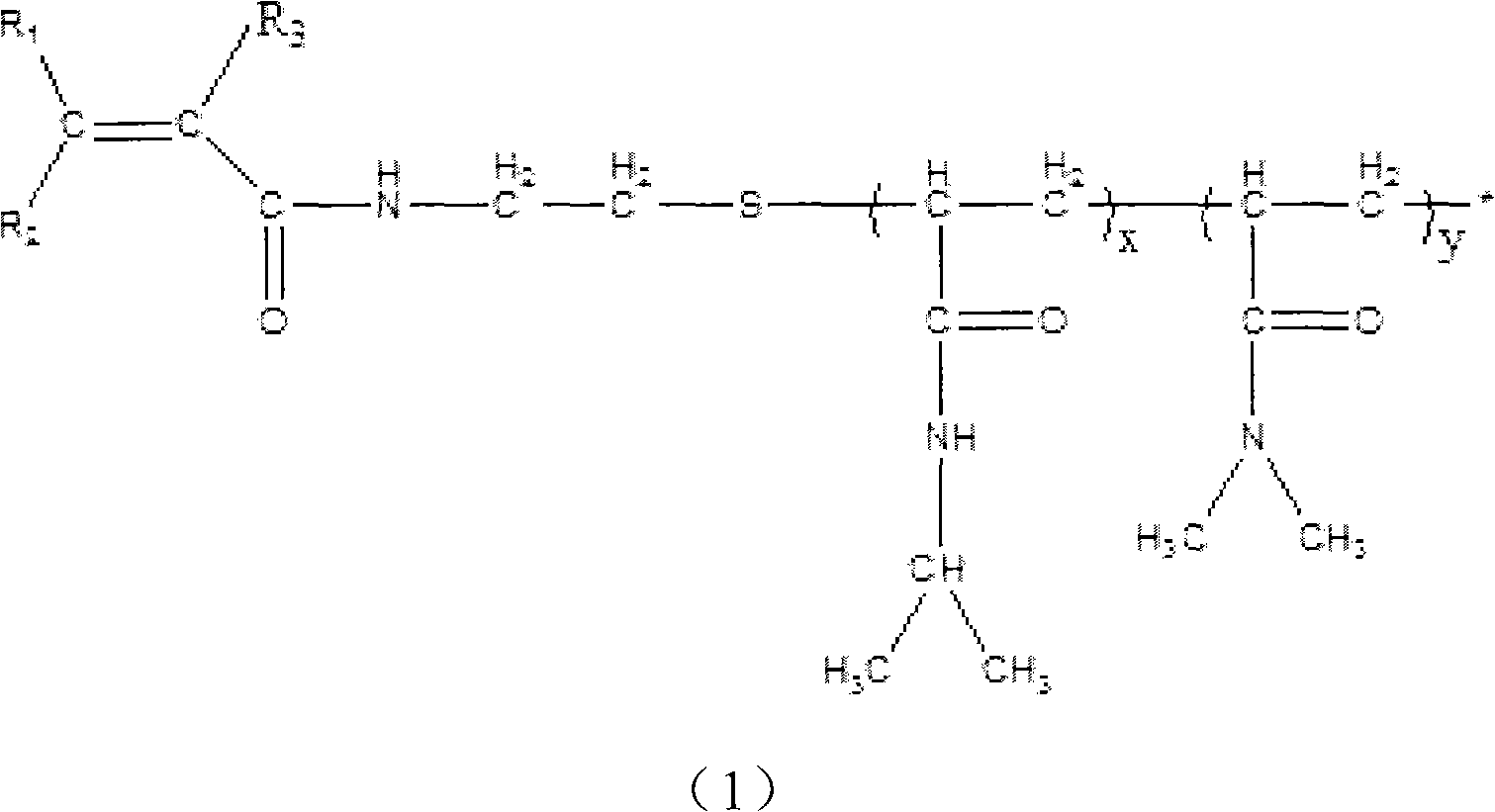

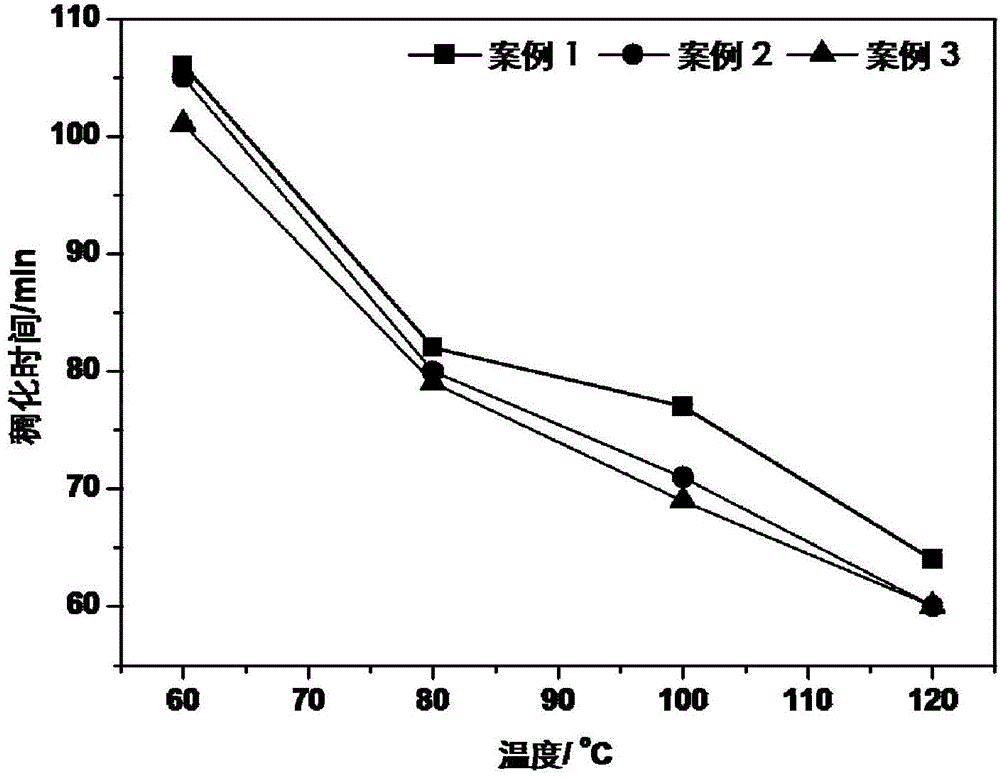

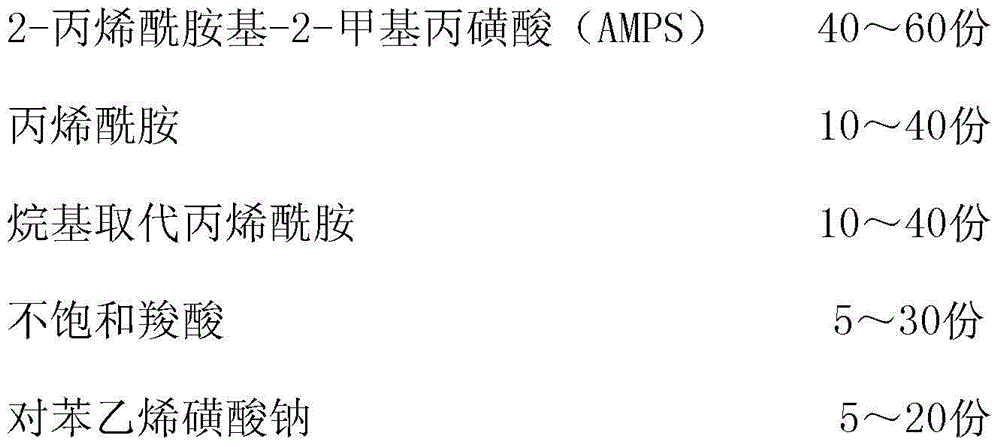

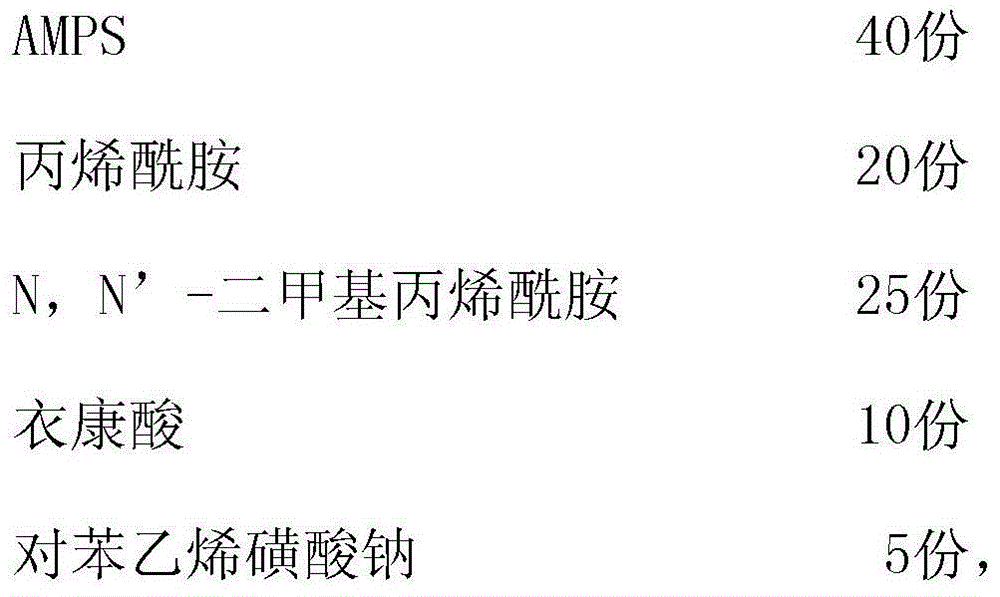

Thermothickening terpolymer, its preparation method and application

ActiveCN102464781AHas thermal thickening propertiesGood water solubilityDrilling compositionApparent viscositySalinity

The invention provides a thermothickening terpolymer and its preparation method. The water solution viscosity of the copolymer provided in the invention increases with the rise of temperature within a certain temperature range. The water solution of the copolymer has a thermothickening property, and has high apparent viscosity under high temperature and high salinity conditions. Thus, the terpolymer of the invention boasts good application prospects in tertiary oil recovery of high temperature and high salinity oil reservoirs.

Owner:CHINA PETROLEUM & CHEM CORP +1

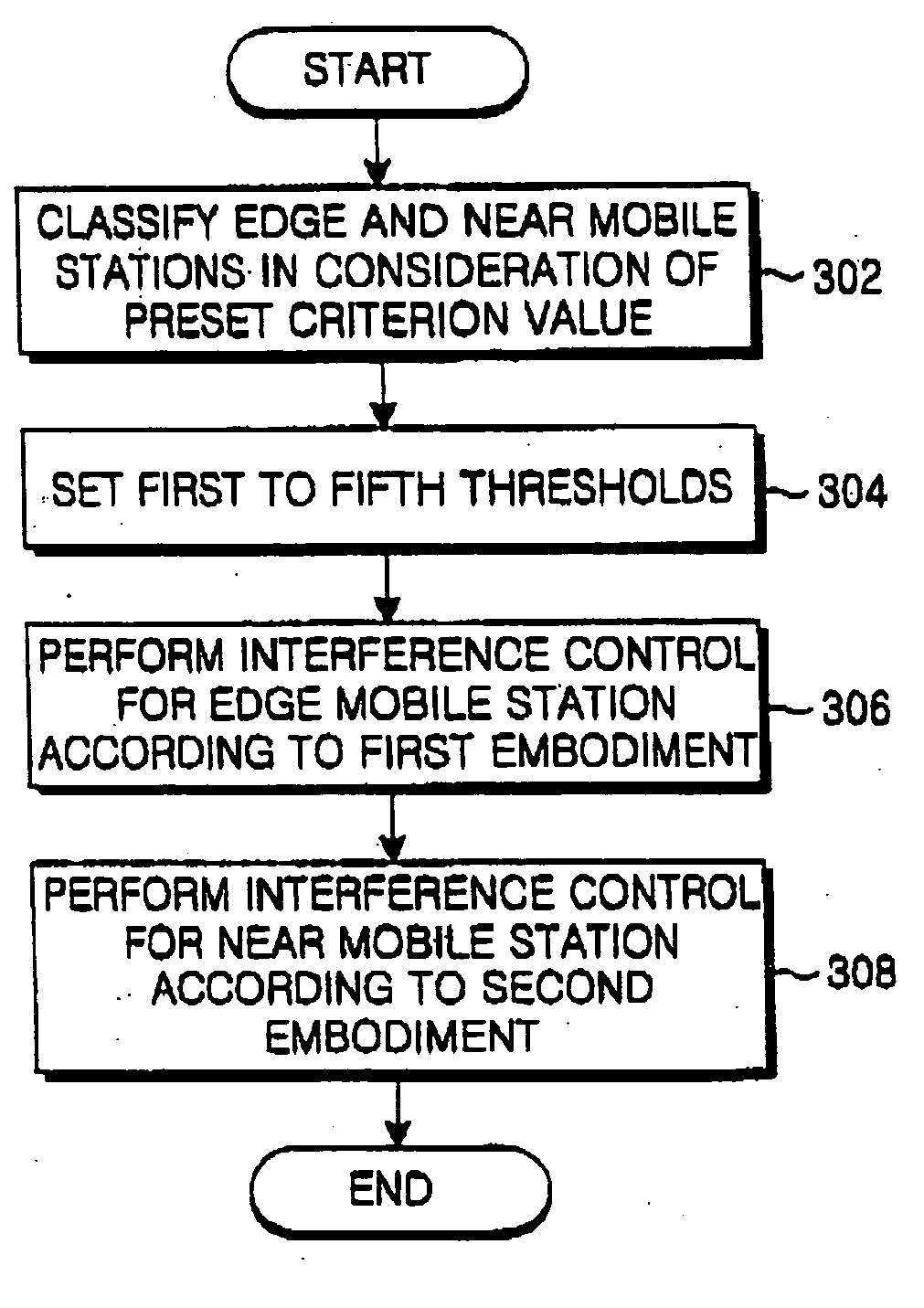

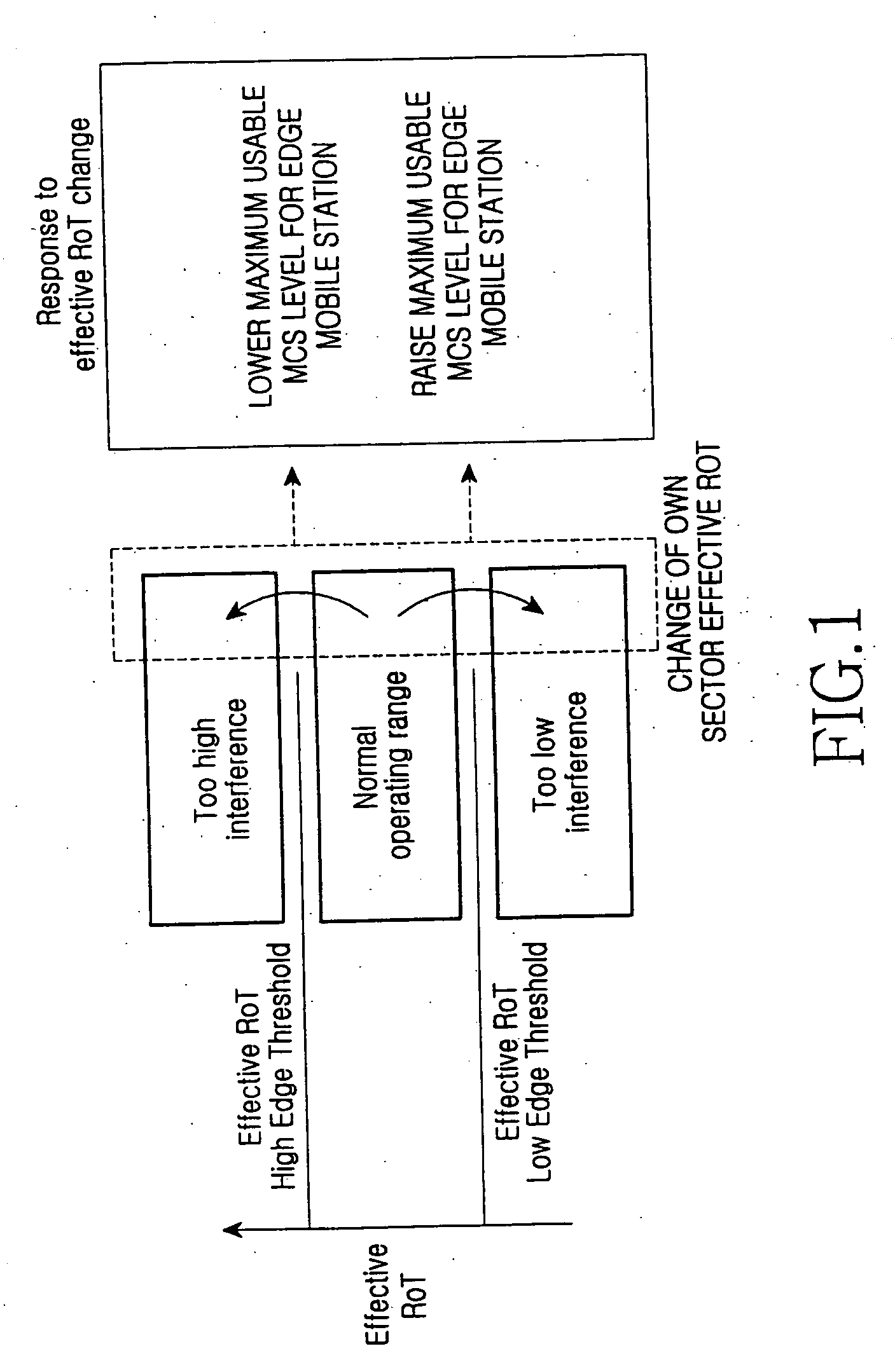

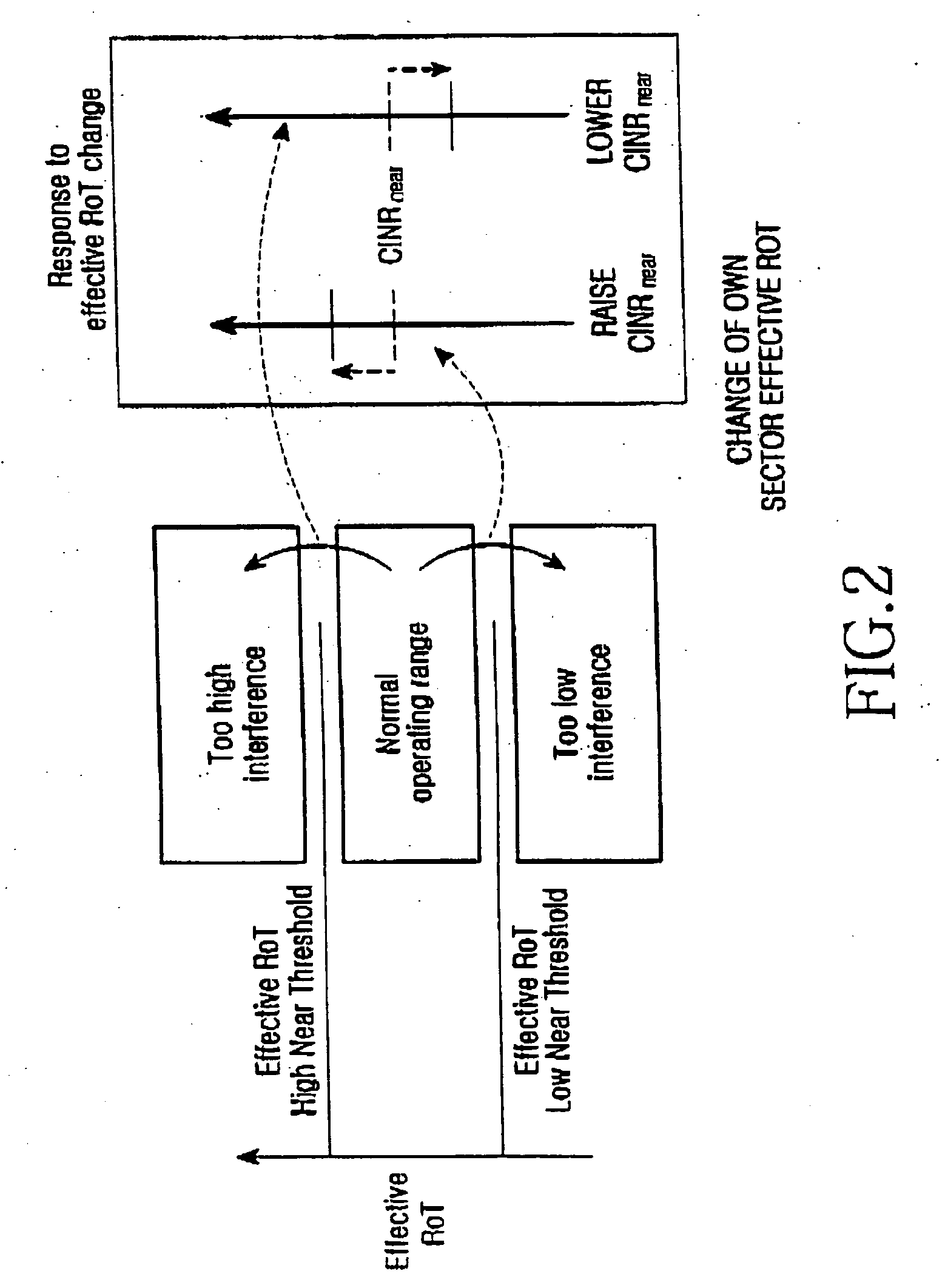

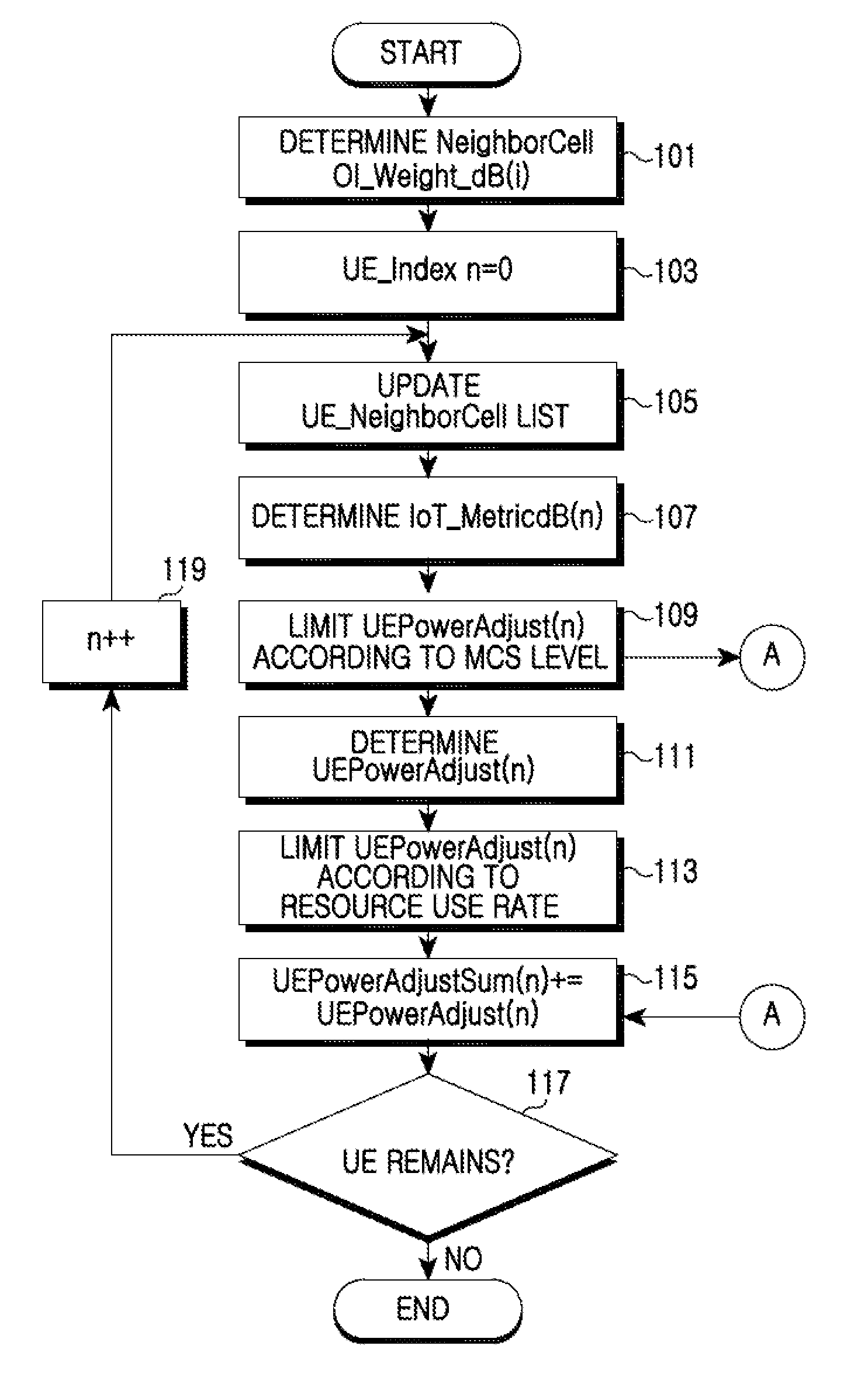

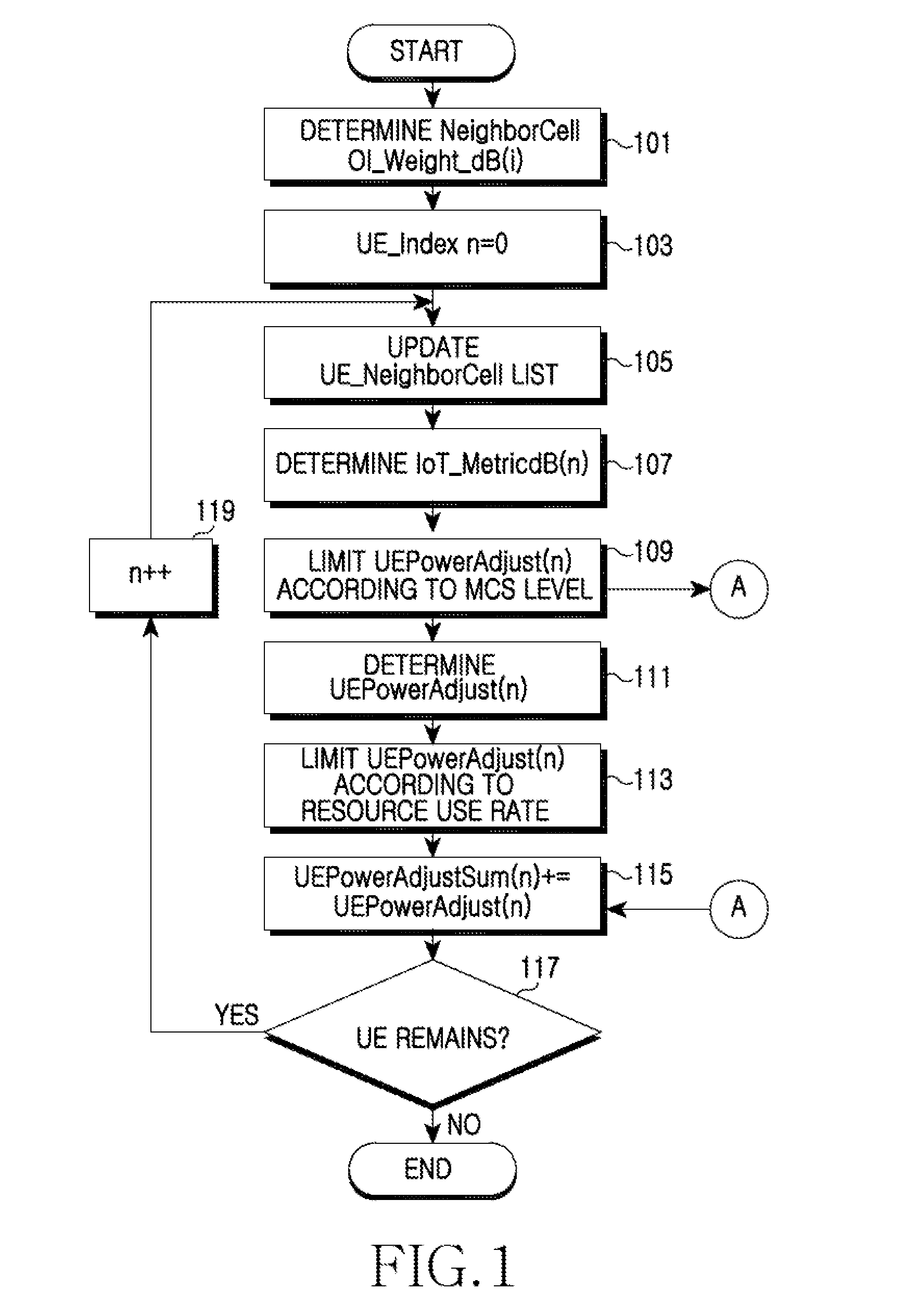

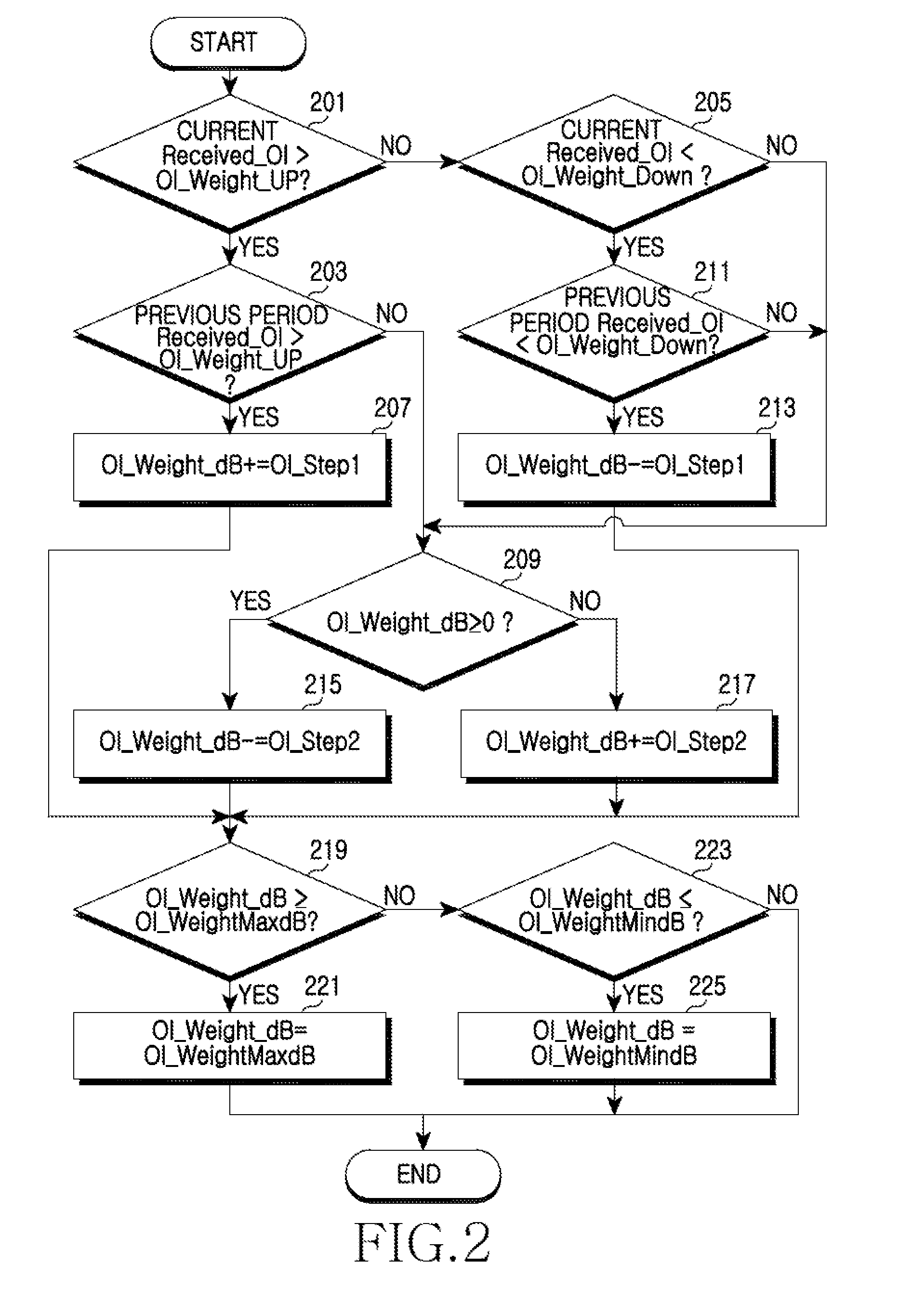

Method for controlling interference in a wireless mobile communication system

InactiveUS20070141995A1Effective controlPower managementRadio transmissionMobile stationMobile communication systems

Disclosed is a method for controlling interference signals by a base station in a wireless mobile communication system, the method including classifying a plurality of mobile stations into first and second mobile station groups including the mobile stations having good channel conditions and the mobile stations having poor channel conditions, respectively; and setting first and second thresholds for controlling interferences of the mobile stations belonging to the first mobile station group, adjusting downward an Modulation and Coding Scheme (MCS) level for the mobile stations having Rise over Thermal (RoT) values higher than the first thresholds, and adjusting downward the maximum allowable MCS level for the mobile stations having RoT values lower than the second threshold.

Owner:SAMSUNG ELECTRONICS CO LTD

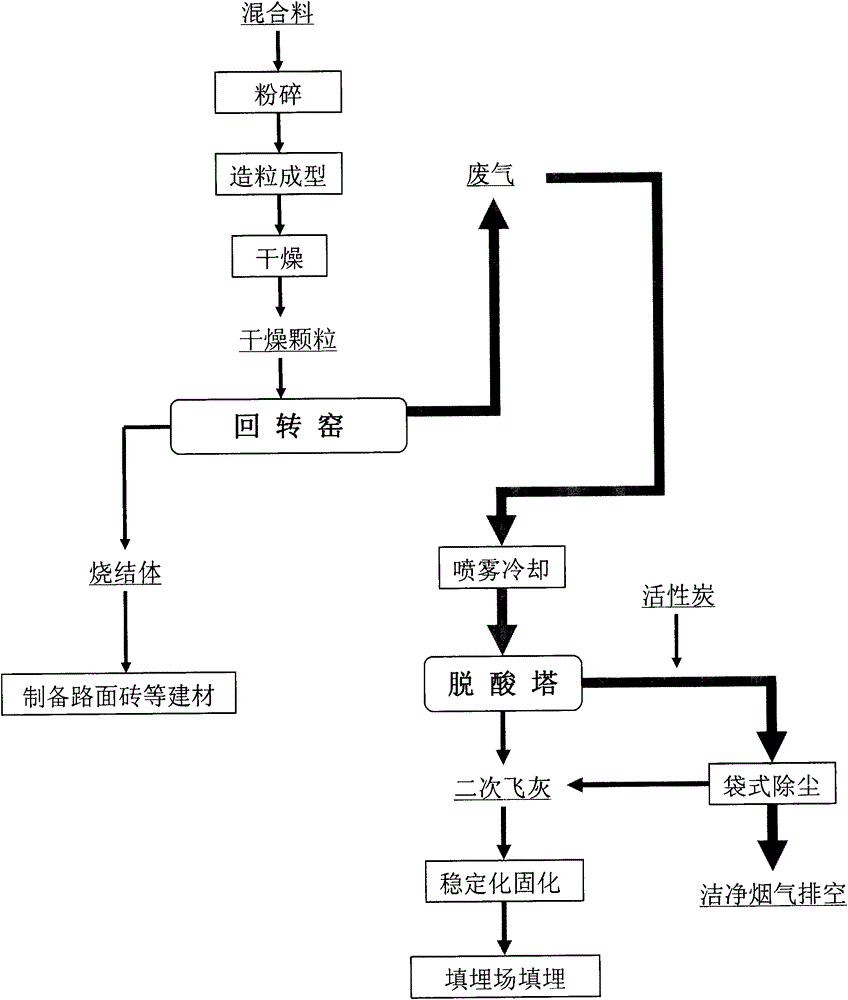

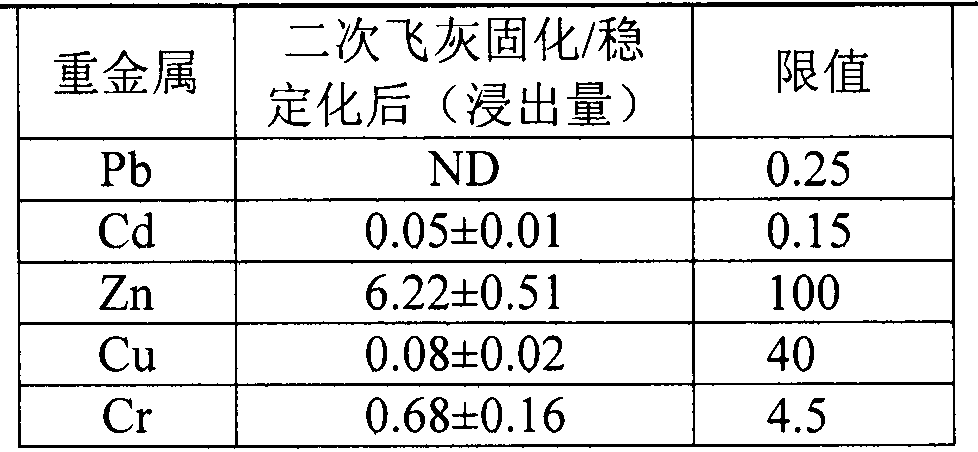

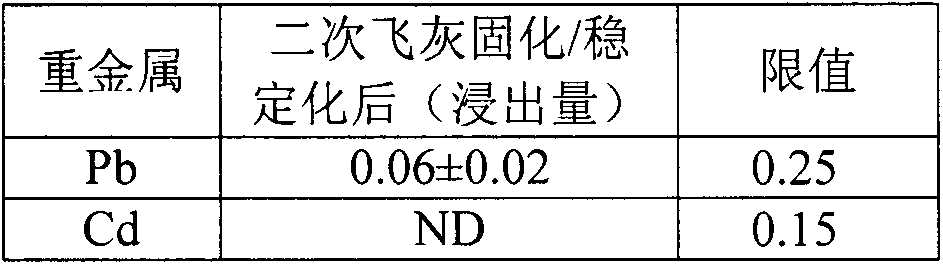

Garbage burning fly ash sintering harm-eliminating resource-utilization treatment system

The invention relates to a garbage burning fly ash sintering harm-eliminating resource-utilization treatment technology. According to the invention, garbage burning fly ash is mixed with premixed coal and auxiliary materials; the mixture is granulated and shaped; and the material is dried and is sintered in a rotary kiln. During the sintering process, when the temperature is increased and a coal ignition point is reached, the premixed coal is spontaneously combusted. Therefore, external coal dose can be reduced. Initial combustion of the premixed coal can provide a reductive atmosphere, such that dechlorination and detoxification of dioxin in fly ash can be benefited. Large amount of gas is produced by subsequent combustion, such that dust pores and holes are produced on inner and outer parts of the sintered body, and heavy metal volatilization can be promoted, and fly ash sintered body with low heavy metal content and leaching amount can be obtained. The sintered body has no potential harm to the environment, such that fly ash harm-eliminating and resource-utilization are sufficiently realized. During the processing process, smoke and secondary fly ash production amounts are low, and heavy metal and acidic component contents are high. In deacidification and heavy metal stabilization processes, agent utilization rate is improved. Compared with a traditional original fly ash curing / stabilizing process, a landfill amount can be reduced by 80-90%, such that pressure caused by serious landfill space shortage can be effectively relieved.

Owner:TIANJIN YIMING ENVIRONMENTAL TECH CO LTD

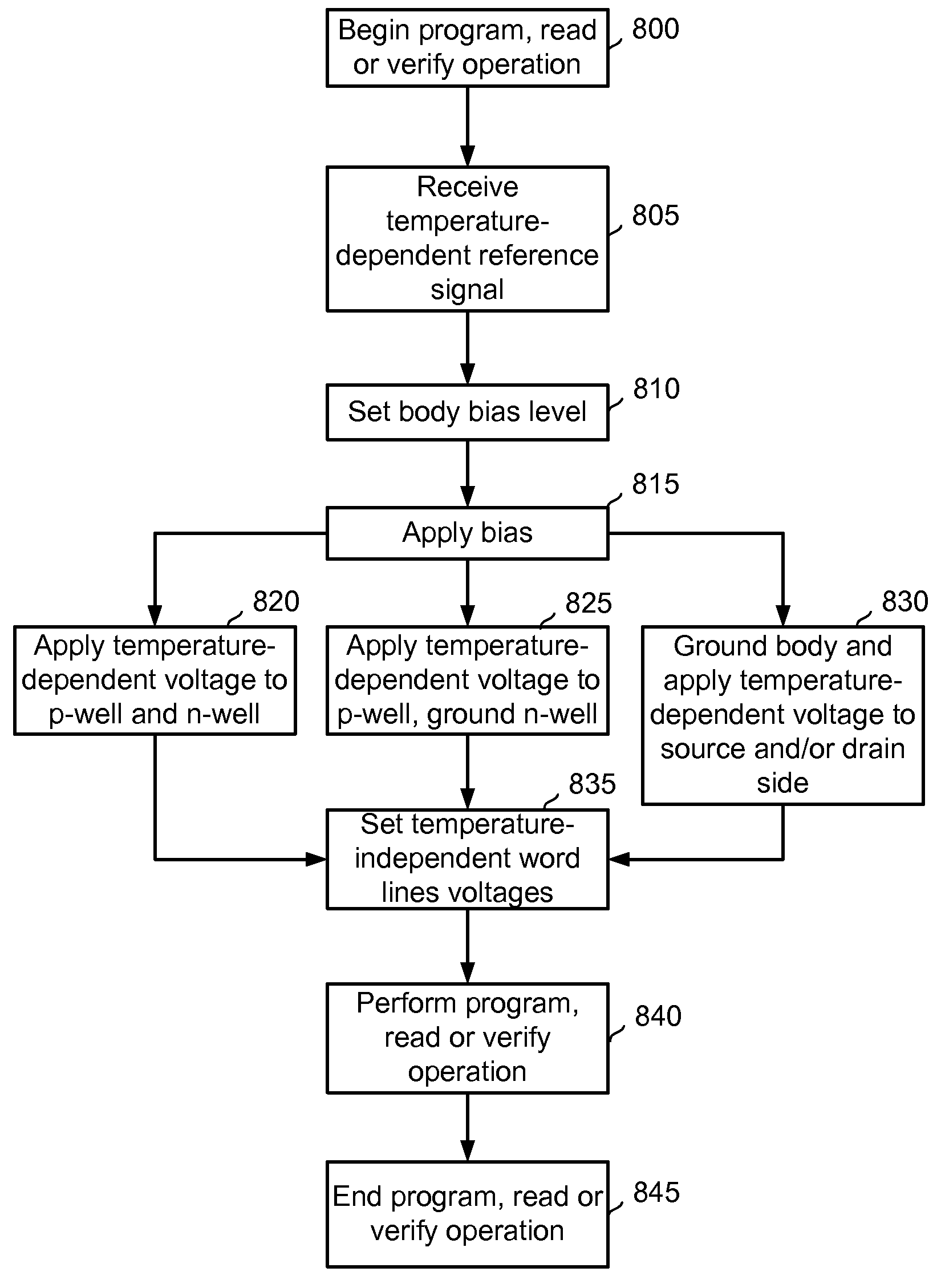

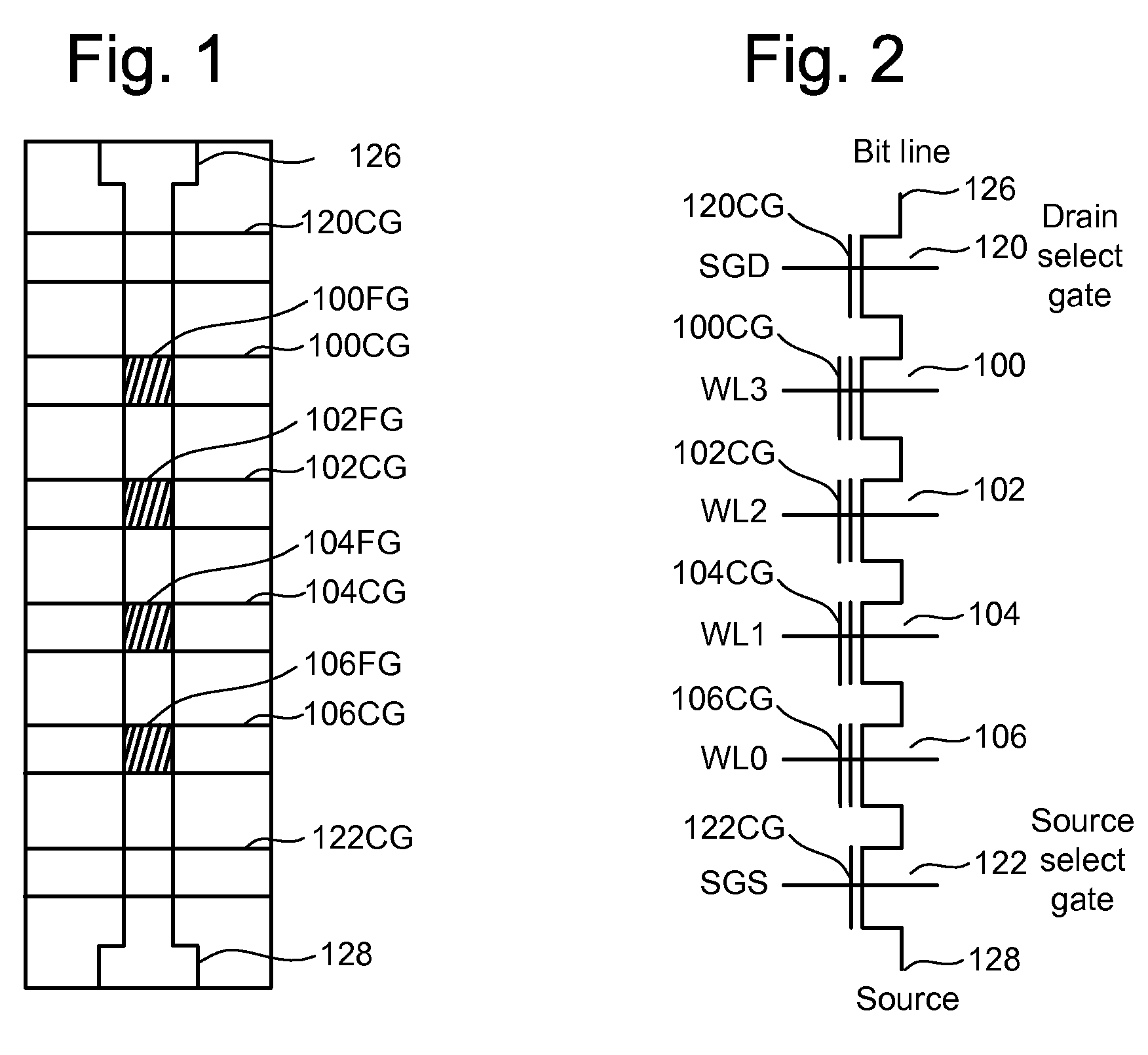

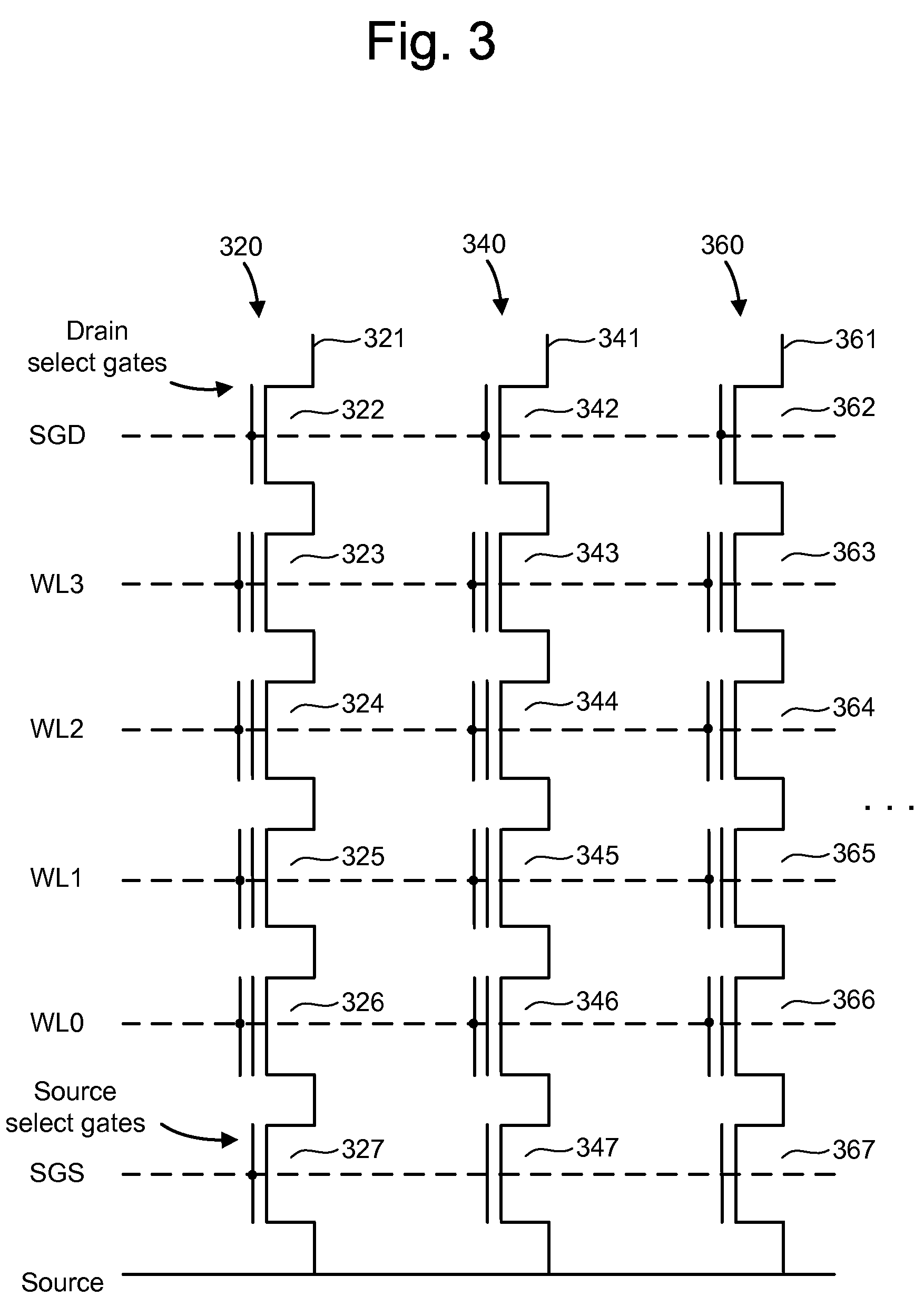

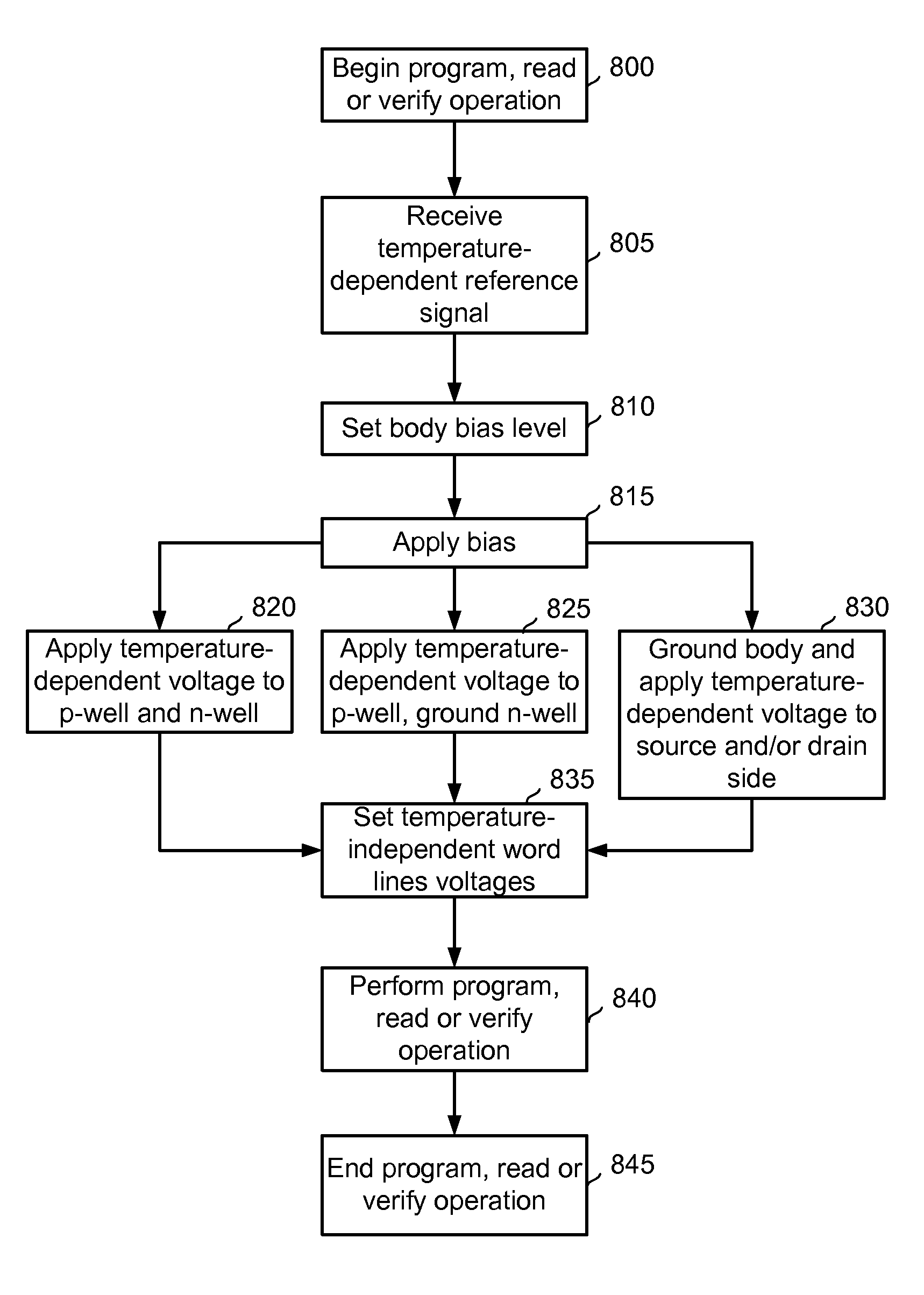

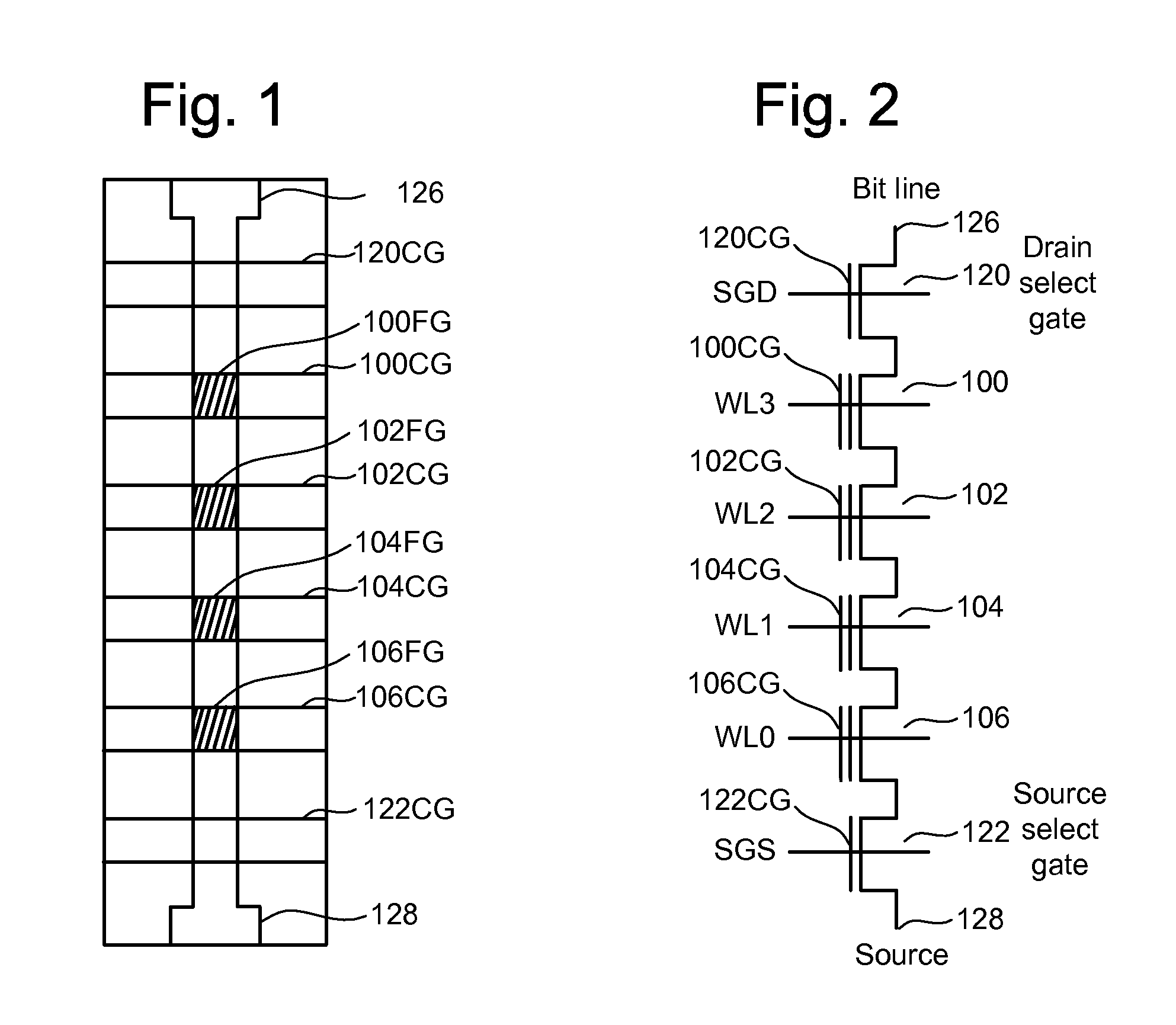

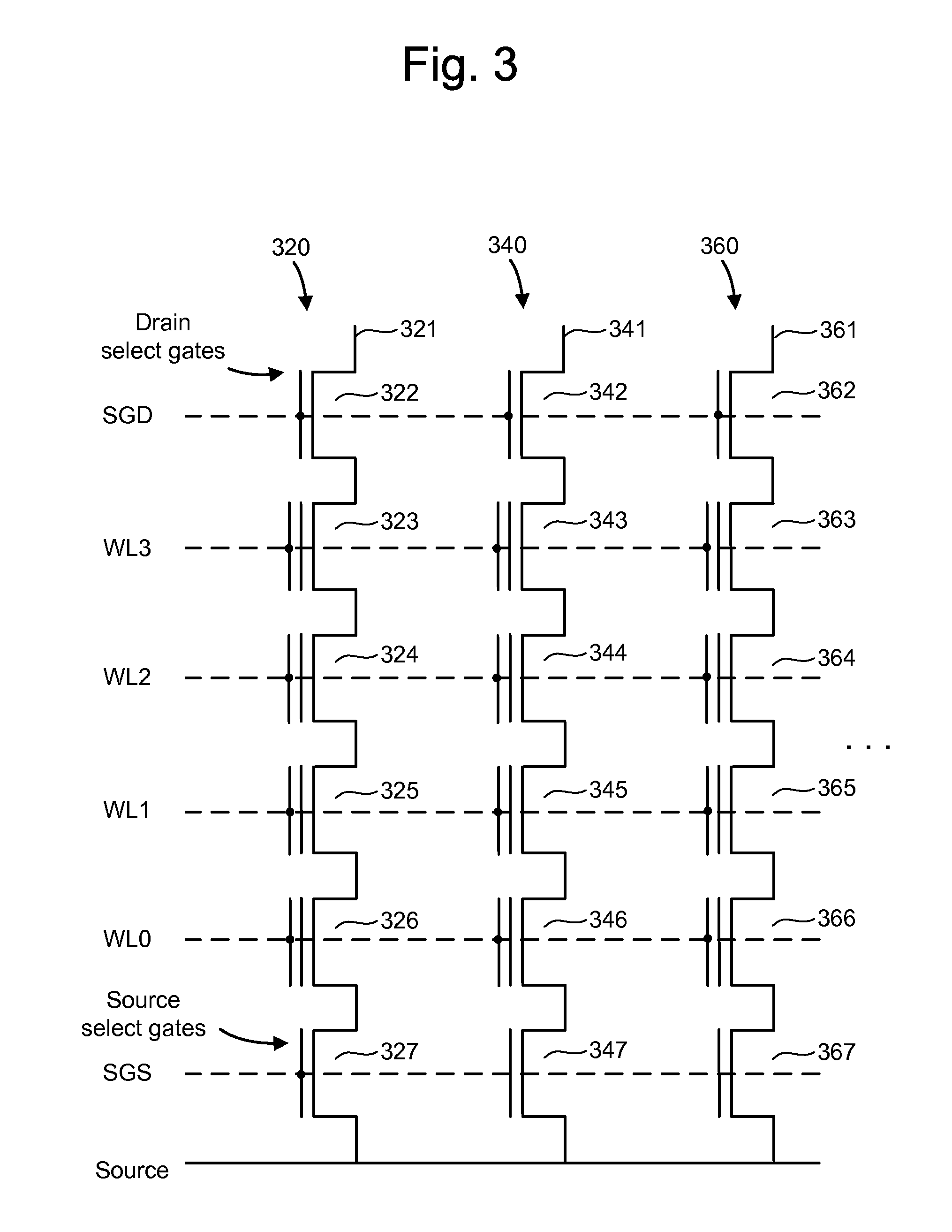

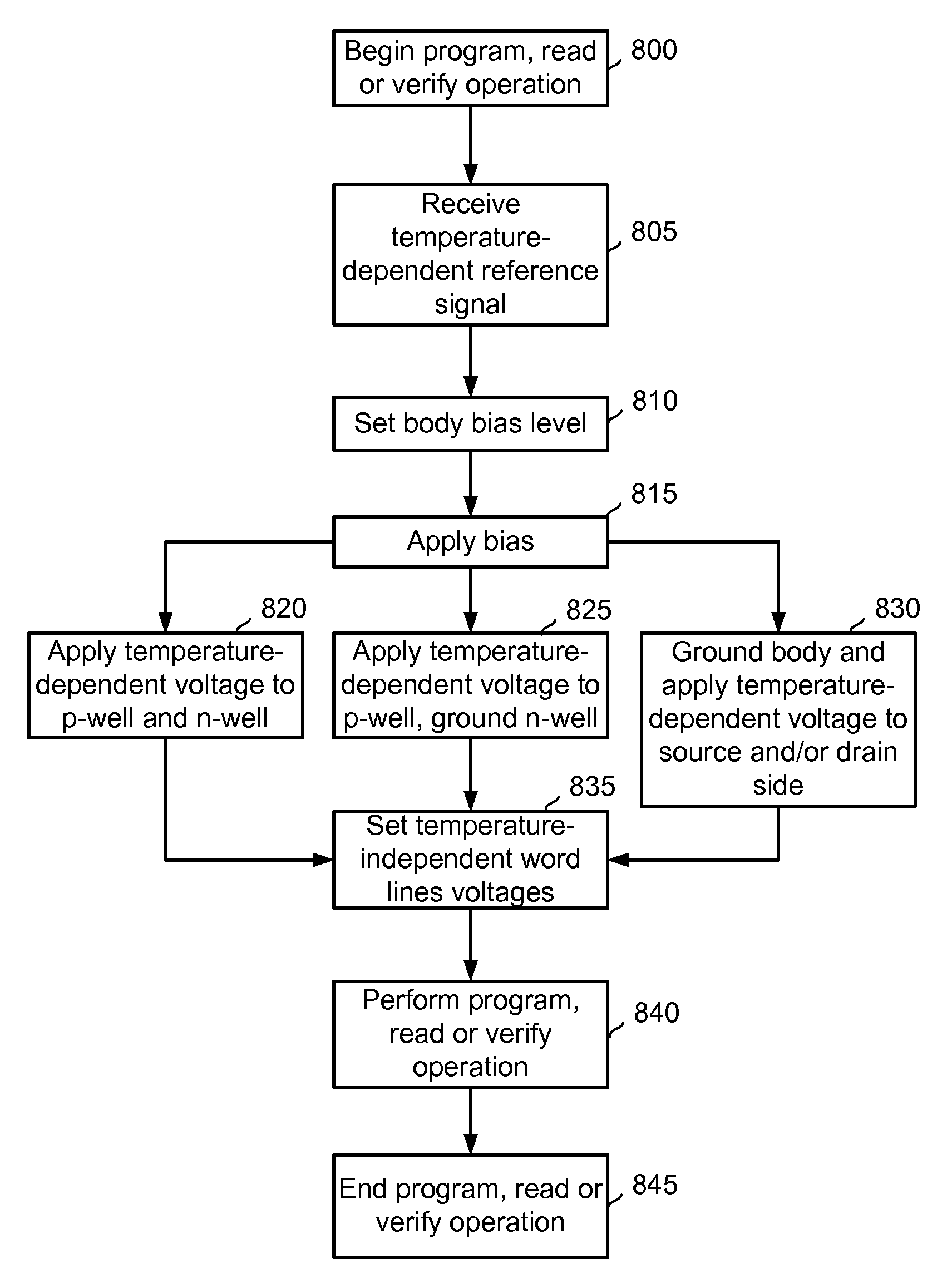

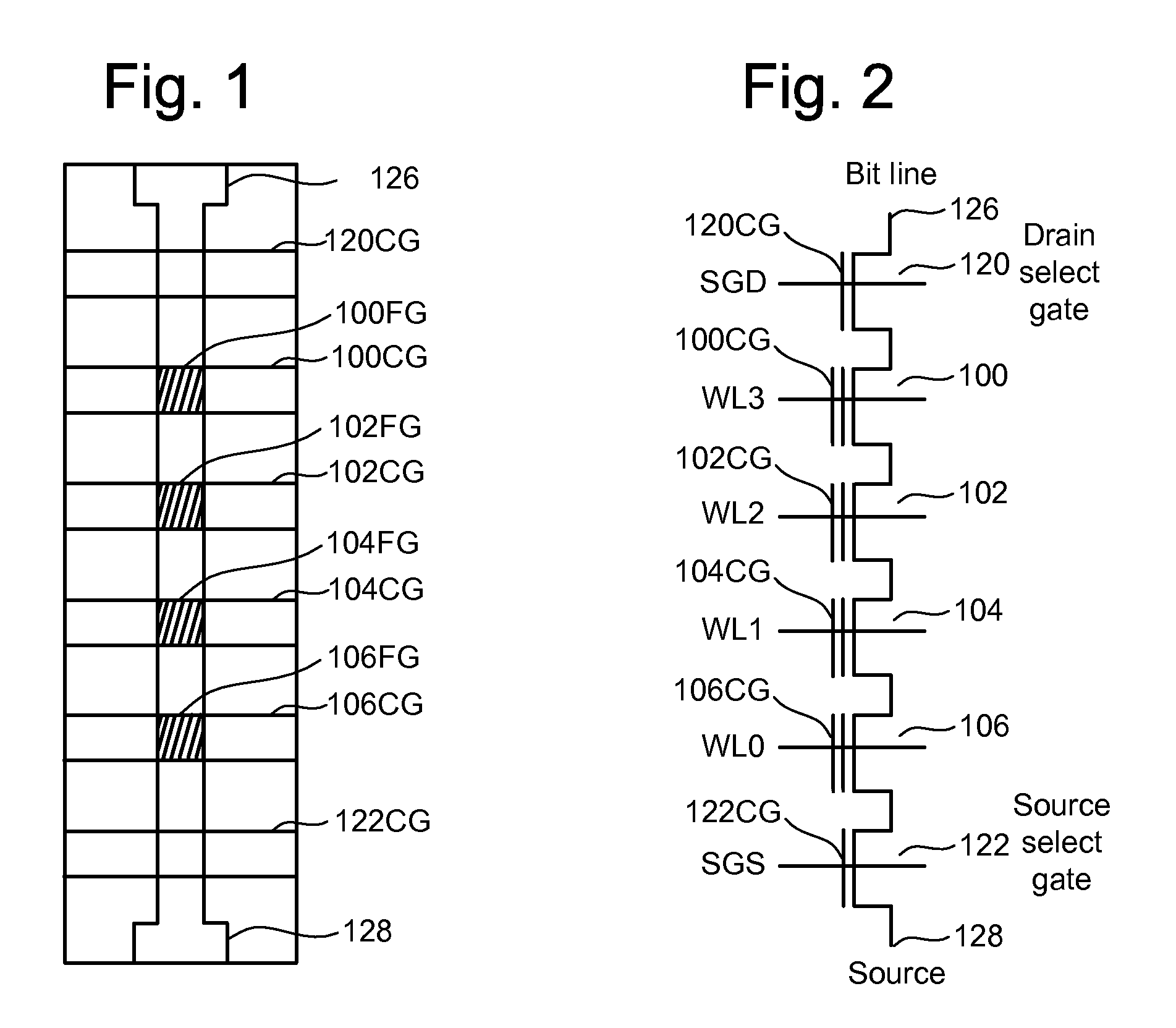

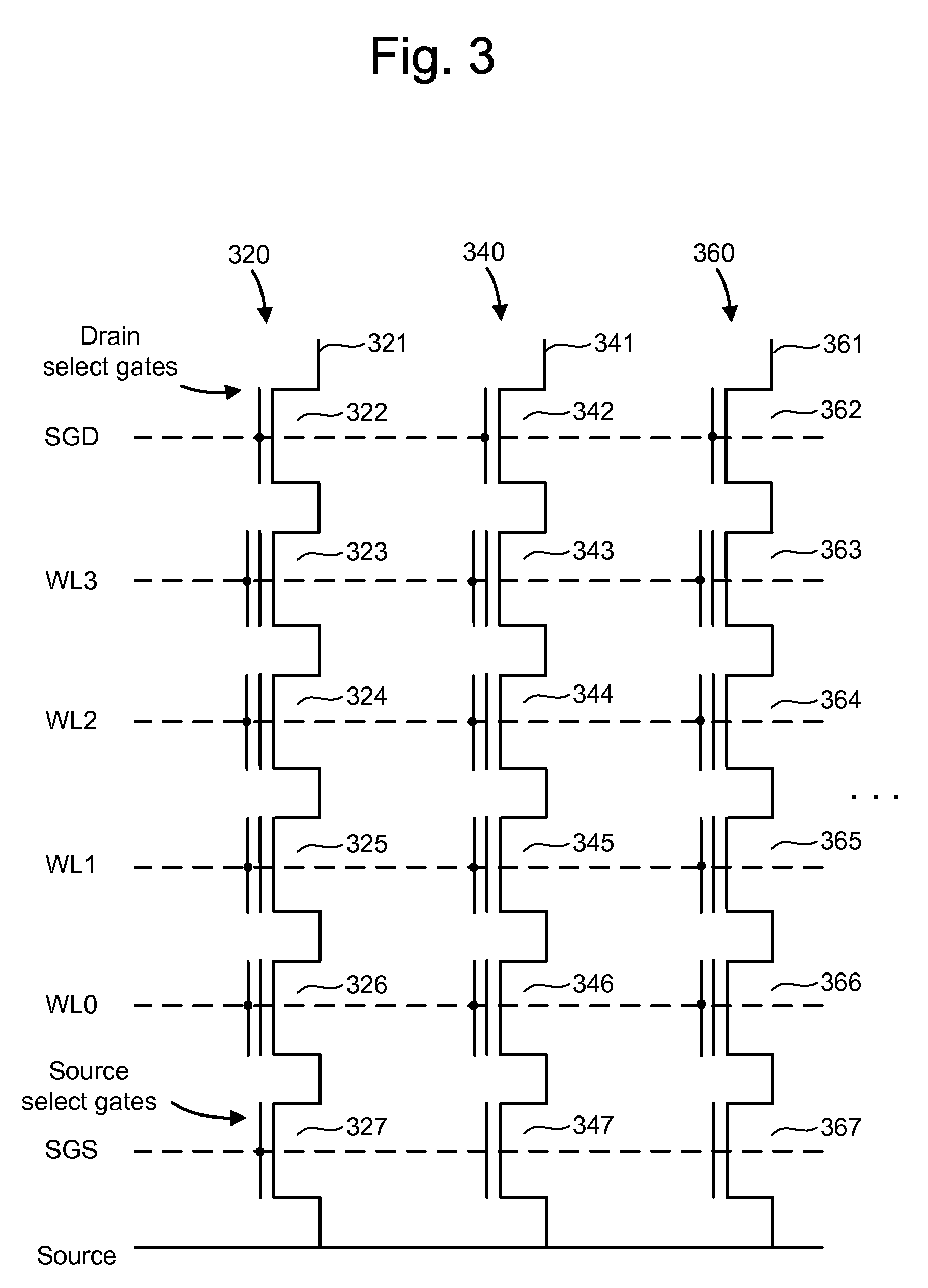

Biasing non-volatile storage to compensate for temperature variations

A body bias is applied to a non-volatile storage system to compensate for temperature-dependent variations in threshold voltage, sub-threshold slope, depletion layer width and / or 1 / f noise. A desired bias level is set based on a temperature-dependent reference signal. In one approach, a level of the biasing can decrease as temperature increases. The body bias can be applied by applying a voltage to a p-well and n-well of a substrate, applying a voltage to the p-well while grounding the n-well, or grounding the body and applying a voltage to the source and / or drain of a set of non-volatile storage elements. Further, temperature-independent and / or temperature-dependent voltages can be applied to selected and unselected word lines in the non-volatile storage system during program, read or verify operations. The temperature-dependent voltages can vary based on different temperature coefficients.

Owner:SANDISK TECH LLC

System for measuring a rise-over-thermal characteristic in a communication network

InactiveUS20060045045A1Accurate measurementConducive to loadPower managementRadio/inductive link selection arrangementsTransmitted powerRise over thermal

A system for measuring a rise-over-thermal (RoT) characteristic in a communication network includes controlling a transmitting station to maintain its transmit power at a substantially constant level for a first time interval, and measuring a first received power level. The transmitting station is then controlled to adjust its transmit power by a selectable amount for a second time interval, and a second received power level is measured. The first and second received power levels are then processed to determine the RoT characteristic.

Owner:QUALCOMM INC

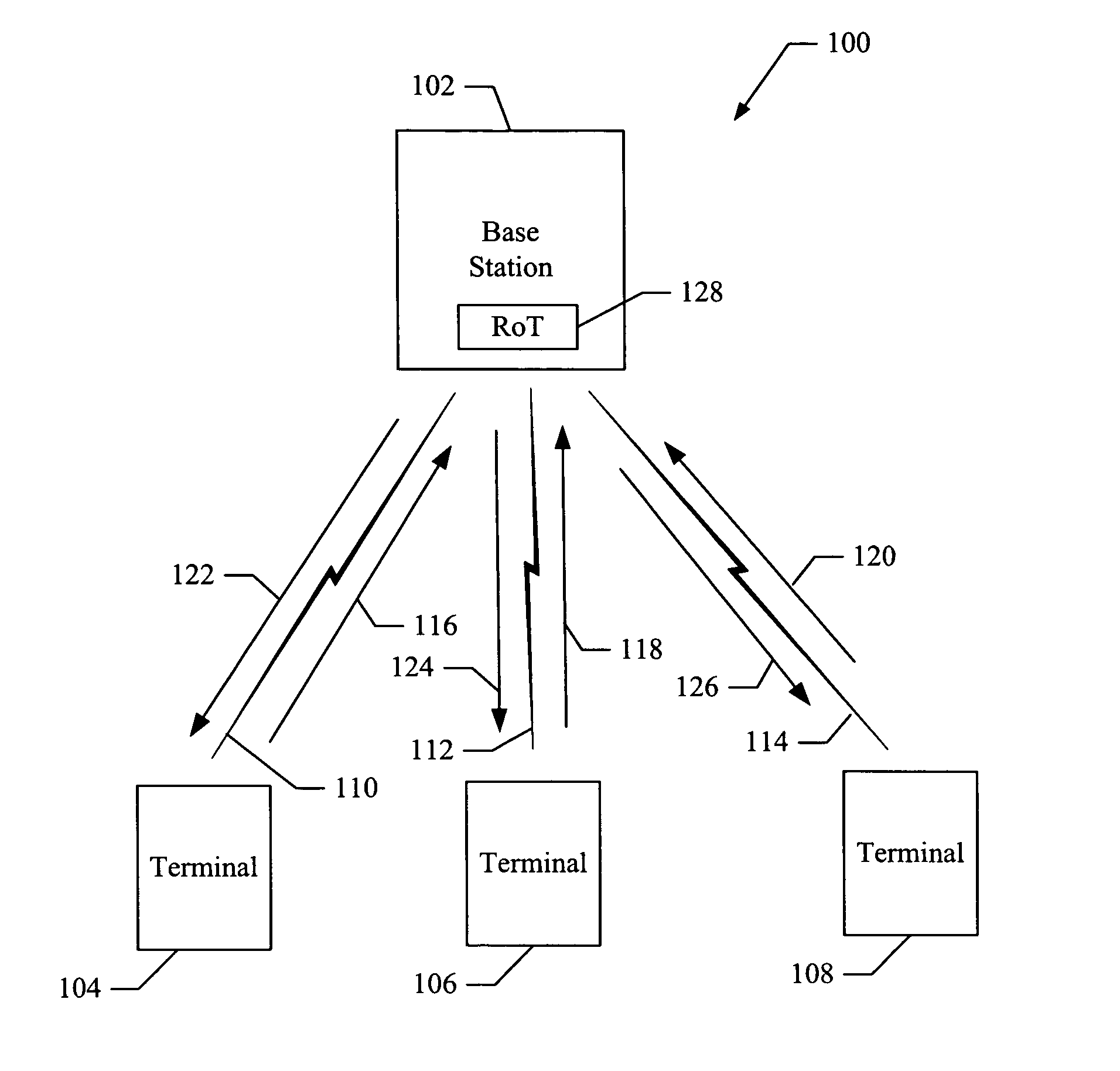

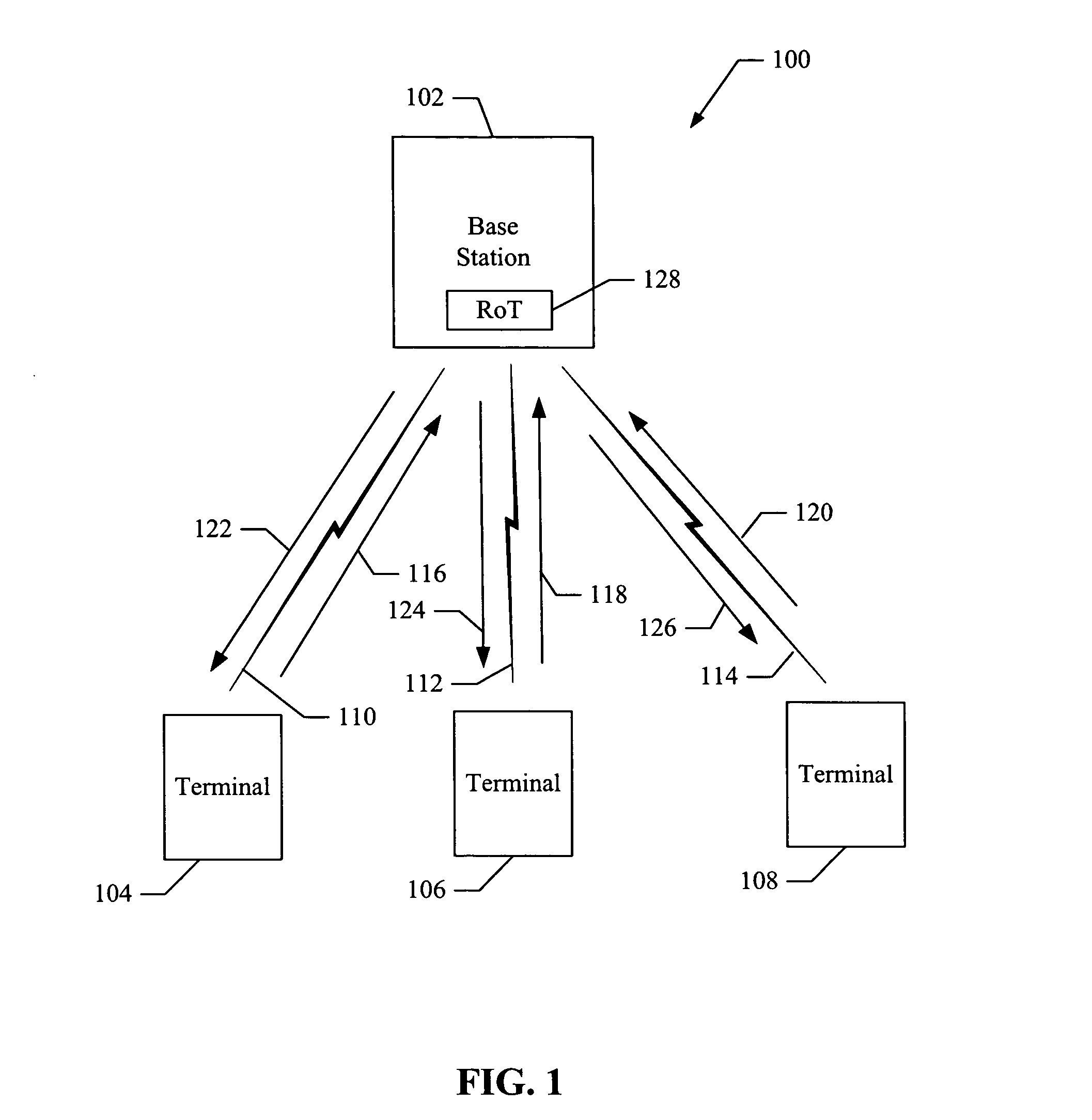

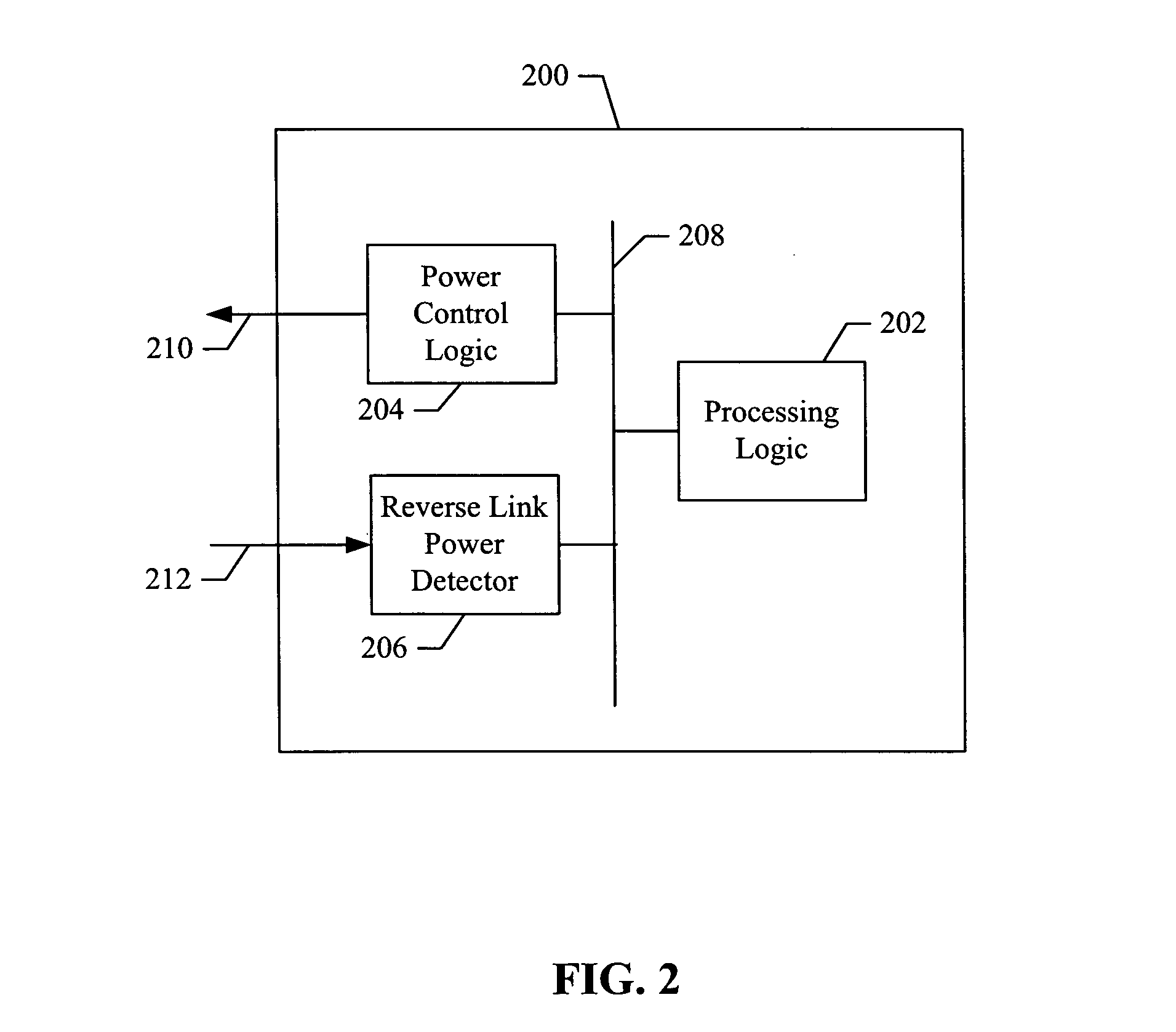

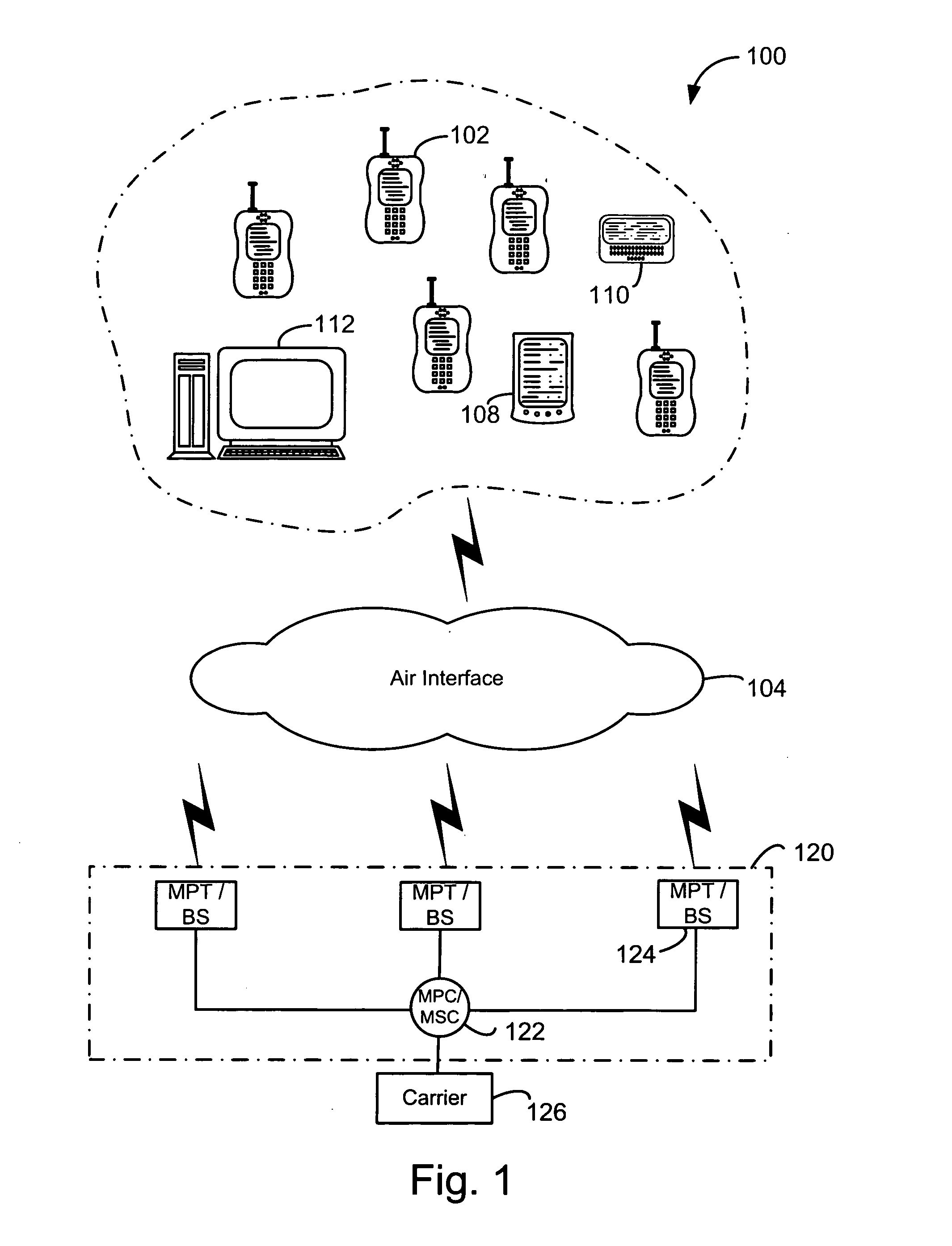

Method and apparatus for uplink interference cancellation in wireless mobile communication system

InactiveUS20110195731A1Improve uplink performancePower managementRadio transmissionTransmitted powerData rate

An apparatus of a Base Station (BS) and a method for cancelling uplink interference in a wireless mobile communication system are provided. The method includes estimating interference to be exerted by each User Equipment (UE) on a plurality of neighbor cells based on a Rise over Thermal (RoT) level for the plurality of the neighbor cells, determining a transmit power change for each UE based on the estimated interference to be exerted on the neighbor cells, and transmitting the transmit power change for the UE to each UE. The cell coverage is maintained by maintaining the interference exerted on the neighbor cell at a proper level, and the average data rate is enhanced.

Owner:SAMSUNG ELECTRONICS CO LTD

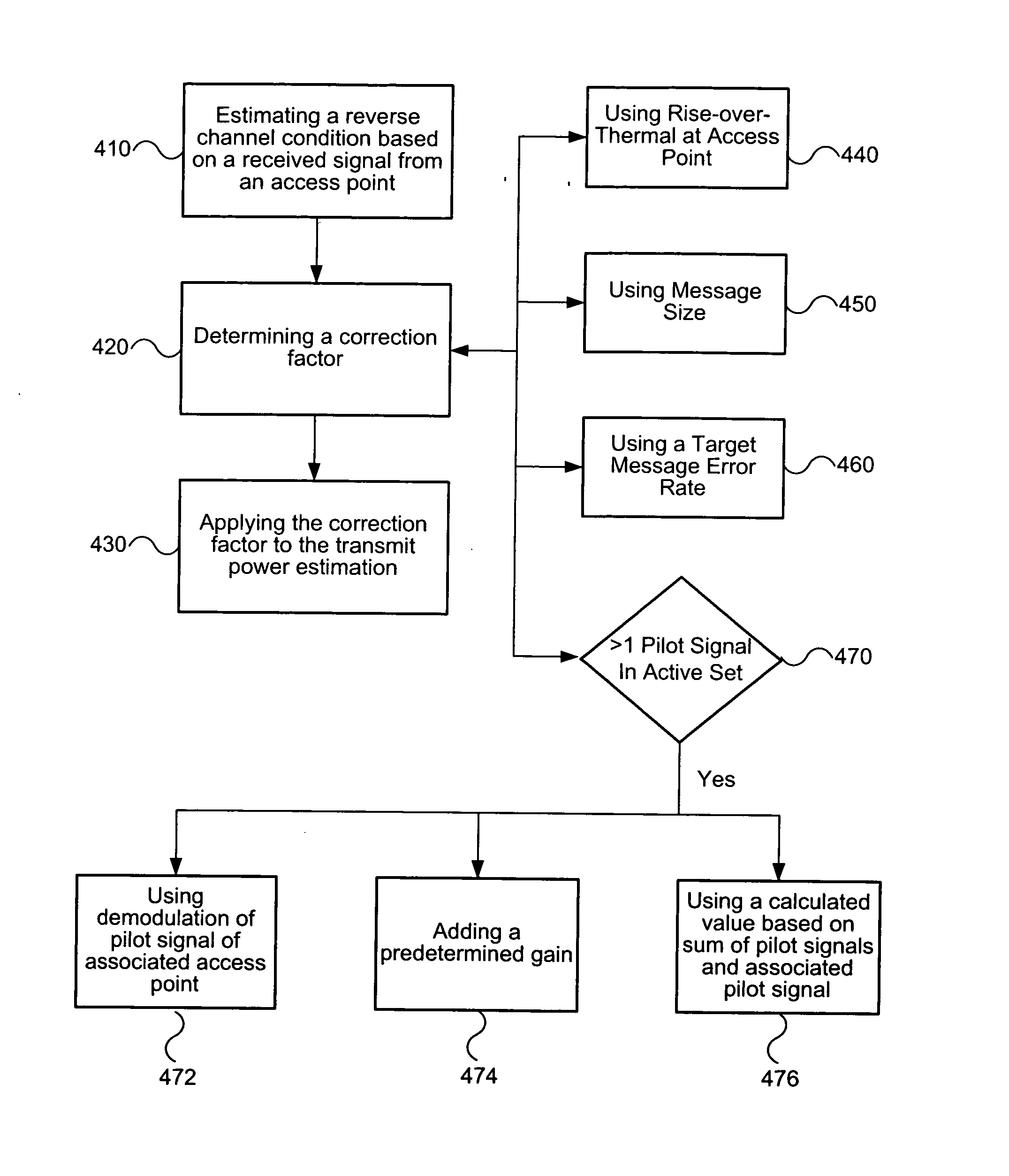

Power control in communication systems

InactiveUS20070201405A1Convenient power controlPower managementRadio transmissionCommunications systemTransmitted power

Systems and methods for estimating transmit power in a communication system are disclosed. An estimate of a reverse channel condition is based on a received signal from an access point. A correction factor is determined based on at least one of the number of access points detected, a Rise-over-Thermal (RoT) at the access point, a message error rate, and a message size. Then the correction factor is applied to the transmit power determination.

Owner:QUALCOMM INC

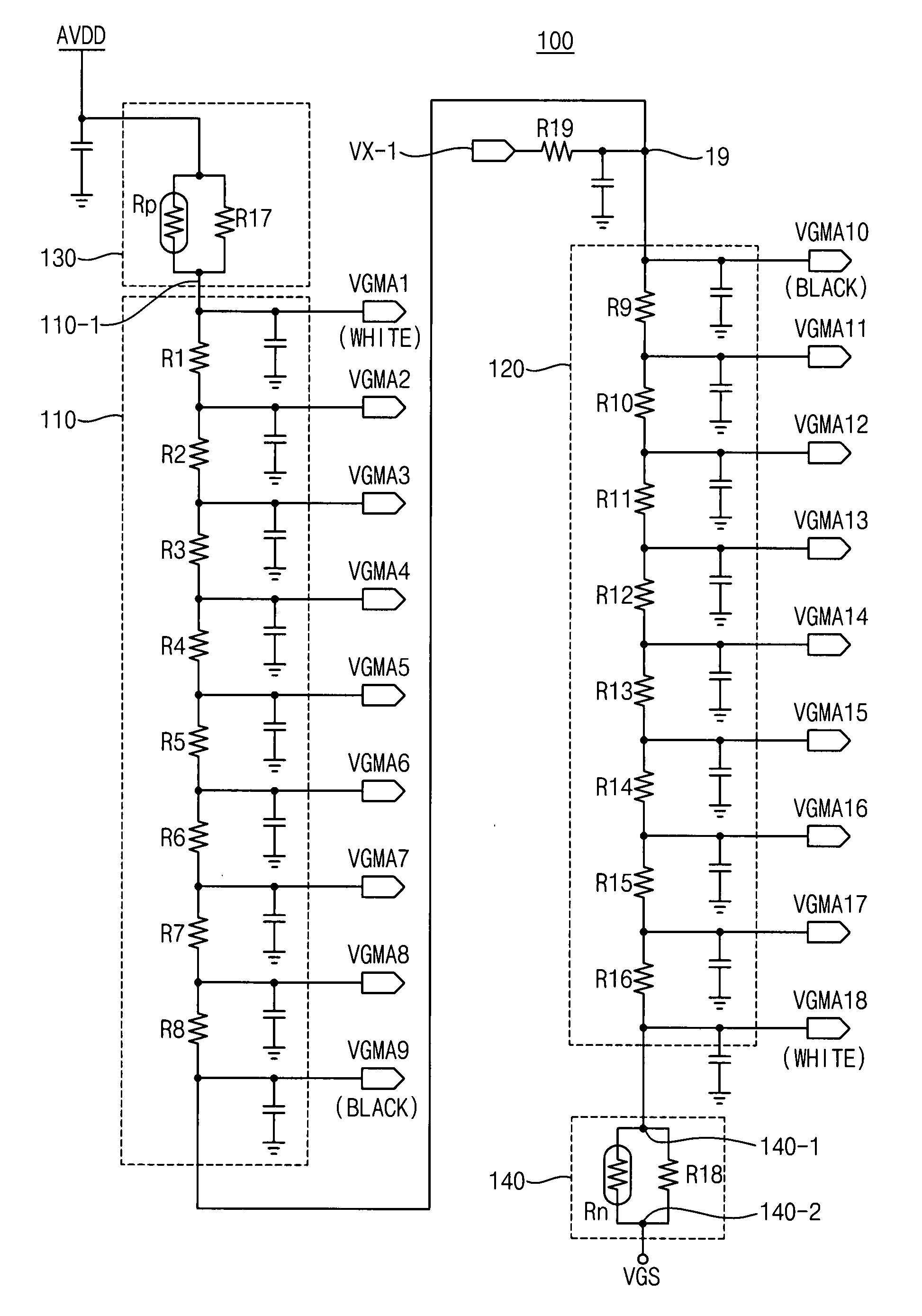

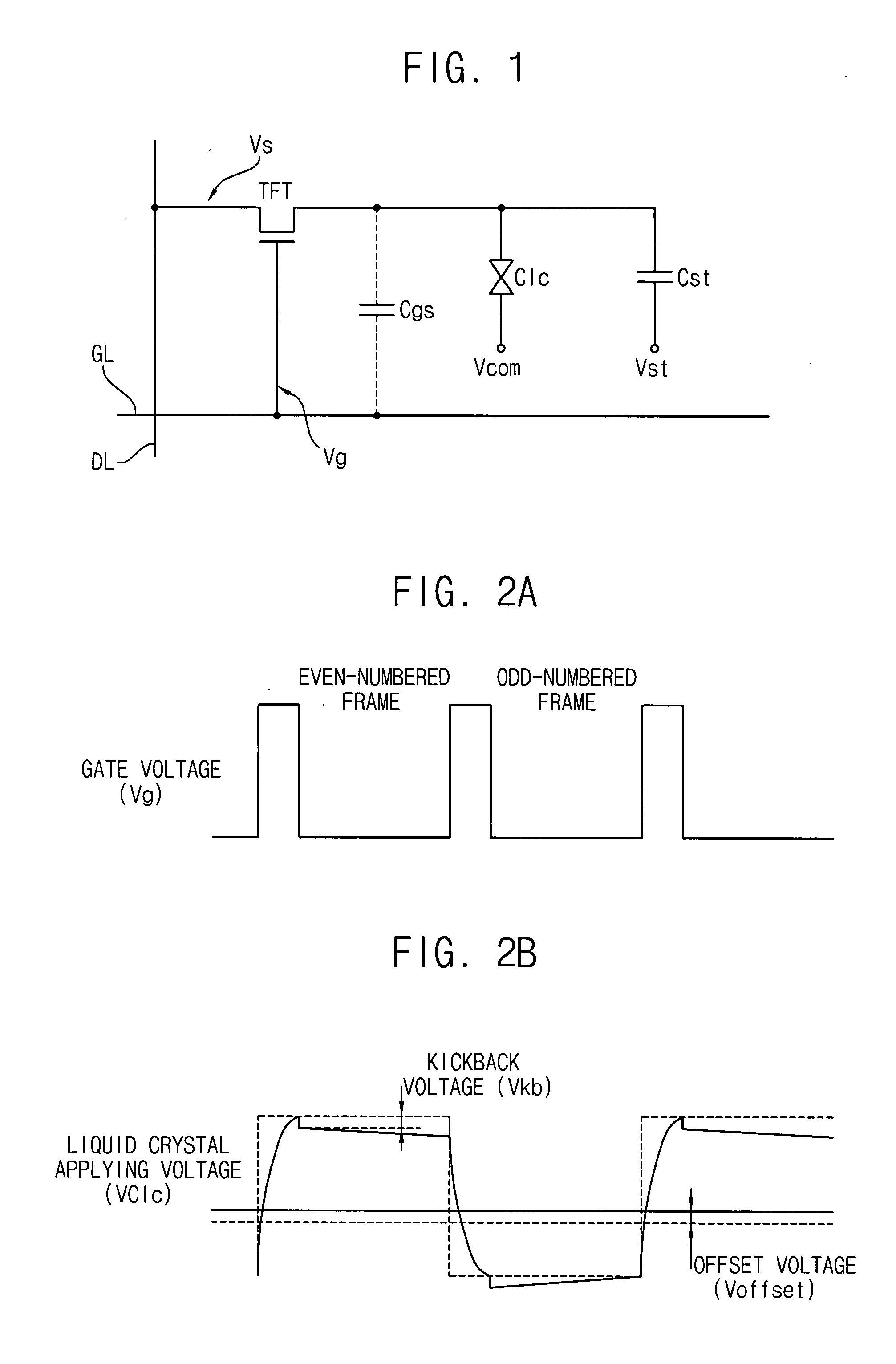

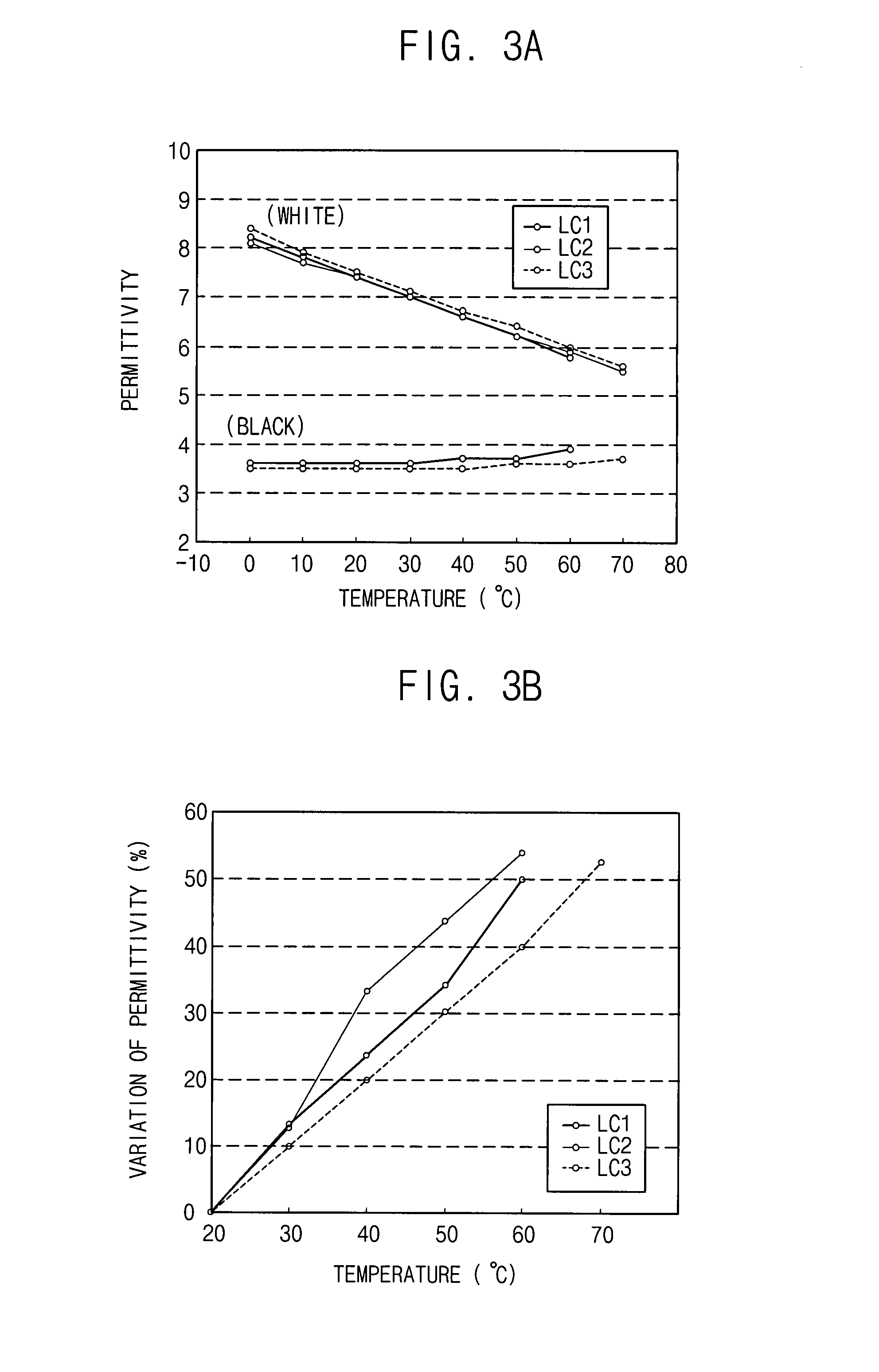

Gamma-reference-voltage generating circuit and apparatus for generating gamma-voltages and display device having the circuit

ActiveUS20070188430A1Reducing kickback voltageReduce biasStatic indicating devicesNon-linear opticsElectrical resistance and conductanceDisplay device

A first resistor string provides a plurality of first polarity gamma-reference-voltages. A second resistor string provides a plurality of second polarity gamma-reference-voltages. A first main-thermal compensation section exhibits a resistance value that increases with an increase of temperature. A second main-thermal compensation section has a resistance value that is decreases with an increase of temperature. Thus, gamma-reference-voltages corresponding to white gradation are decreased and gamma-reference-voltages corresponding to black gradation are maintained, so that a deviation of kickback voltage corresponding to the white gradation is decreased.

Owner:SAMSUNG DISPLAY CO LTD

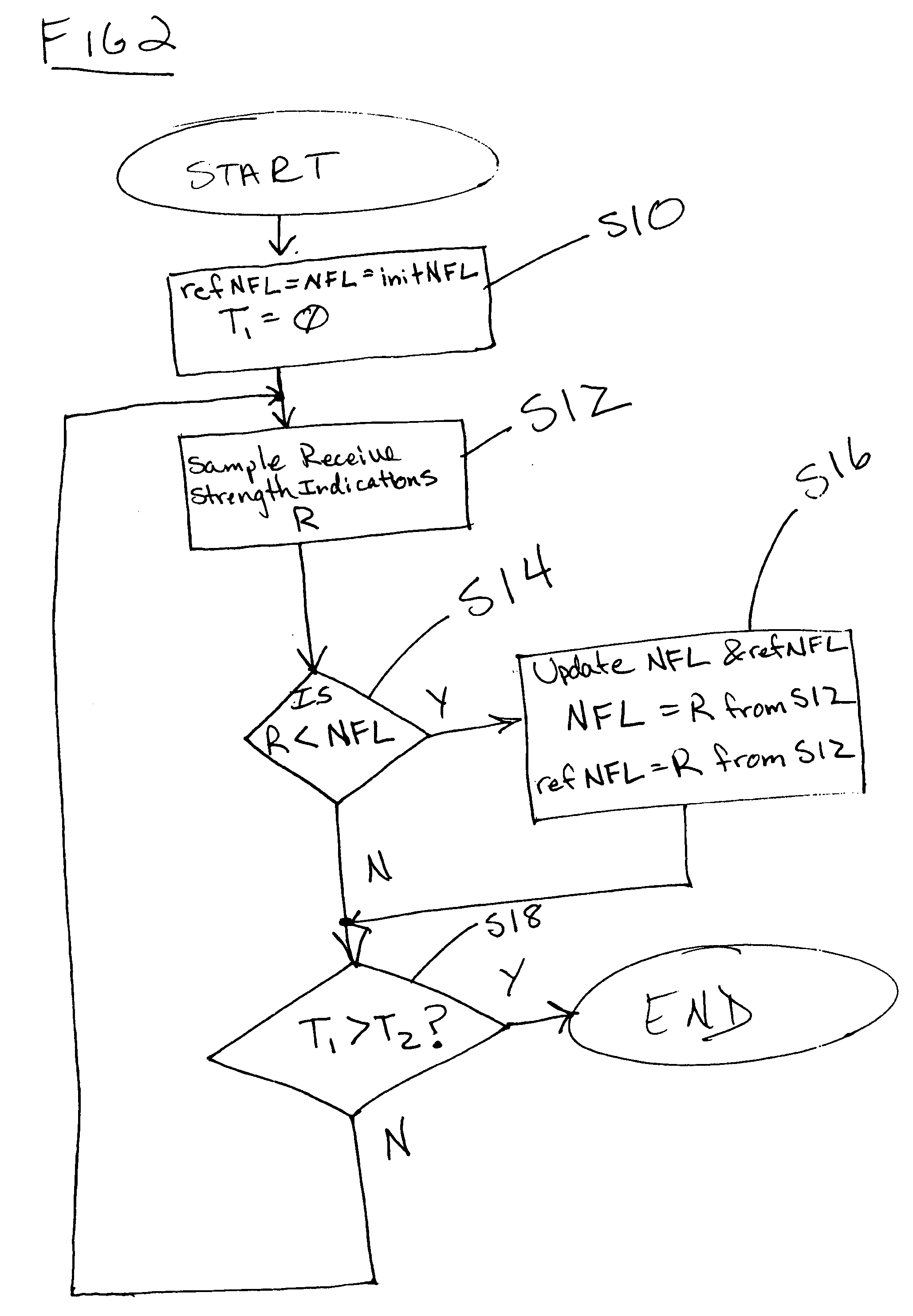

Method for dynamically estimating noise floor and rise over thermal (ROT)

ActiveUS20060068717A1Easy maintenanceAssess restrictionTransmission monitoringCommunications systemRise over thermal

A method for controlling access of a subscriber station to a wireless communications system facilitates the maintenance of a performance target of the reverse link and desired geographic coverage of the reverse link. The method for controlling access of a subscriber station to a wireless communications system includes measuring a first performance indicator and a second performance indicator for a reverse link associated with a subscriber station seeking access to a wireless communications system. A blocking threshold value is established based upon the measured second performance indicator and may be adjusted to allow more or less blocking based on any additional metrics that characterize the performance of the current subscriber stations. The decision to grant or deny access of the subscriber station to the wireless communications system is determined based on a comparison of the measured first performance indicator to the established blocking threshold value.

Owner:ALCATEL-LUCENT USA INC +1

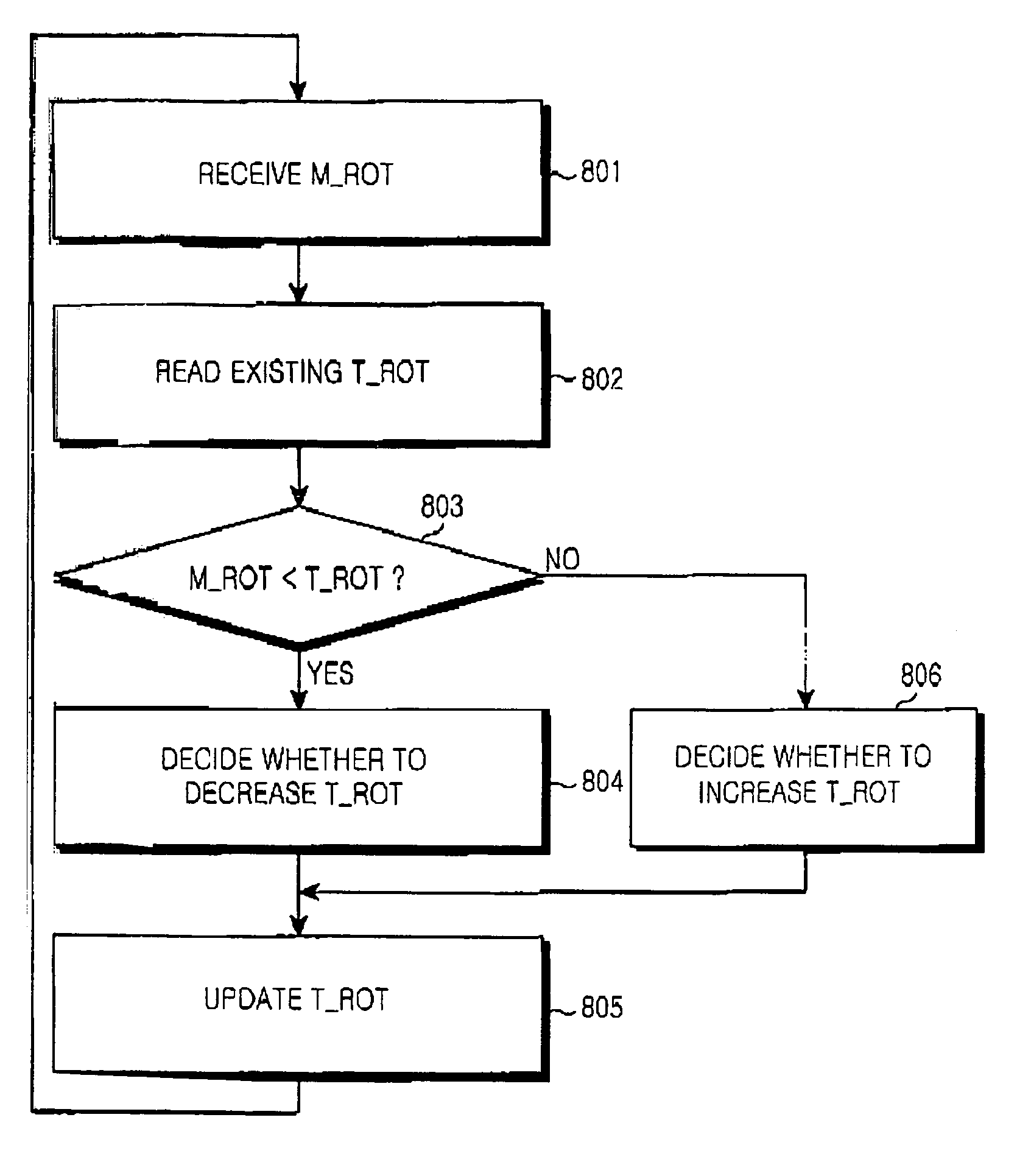

Scheduling apparatus and method for determining a desired noise rise over thermal noise in a CDMA mobile communication system

ActiveUS7324821B2Improve system performancePerformance maximizationRadio/inductive link selection arrangementsRadio transmission for post communicationAsynchronous cdmaCommunications system

There are disclosed an apparatus and method for determining or changing a target ROT for a target cell according to measurement ROTs from its neighbor cells in Node B controlled scheduling for improving enhanced uplink dedicated channels in an asynchronous CDMA communication system. The present invention proposes novel signaling procedures for the purpose of determining or changing the target ROT for the target cell.

Owner:HUAWEI TECH CO LTD

Preparation of highly efficient water phase system non-organic silicon defoaming agent

InactiveCN1762532AEliminate effectiveNot affected by temperatureTransportation and packagingMixingEmulsionNitrogen

The defoamer in this invention mainly comprises the following components: higher fatty alcohol, higher fatty alcohol polyether, polyether containing nitrogen, fatty acid ester, the mixture of dewatering particle and mineral oil, emulsifier and water. The preparing process is as follows: premixing the defoaming active substance with the emulsifier, heating the systematic temperature to a certain temperature, adding water slowly into it, determining whether passing the colloid grinder in accordance with the emulsion diameter, generally, the emulsion diameter is smaller than 15 um. The defoamer in this invention mainly solves the problem of the weakening of the property of the high temperature emulsifying and defoamer with the elevation of temperature, the product is safe and high effective, and suit for the paper making coating and paper bladder defoaming.

Owner:JIANGSU SIXIN SCI-TECH APPL RES INST CO LTD

Non-volatile storage with bias for temperature compensation

ActiveUS20080158975A1Level of biasing decreaseLower Level RequirementsRead-only memoriesDigital storageSub thresholdTemperature coefficient

A non-volatile storage system in which a body bias is applied to a non-volatile storage system to compensate for temperature-dependent variations in threshold voltage, sub-threshold slope, depletion layer width and / or 1 / f noise. A desired bias level is set based on a temperature-dependent reference signal. In one approach, a level of the biasing can decrease as temperature increases. The body bias can be applied by applying a voltage to a p-well and n-well of a substrate, applying a voltage to the p-well while grounding the n-well, or grounding the body and applying a voltage to the source and / or drain of a set of non-volatile storage elements. Further, temperature-independent and / or temperature-dependent voltages can be applied to selected and unselected word lines in the non-volatile storage system during program, read or verify operations. The temperature-dependent voltages can vary based on different temperature coefficients.

Owner:SANDISK TECH LLC

High-temperature-resistant salt-resistant fluid loss agent and preparation method thereof

The invention discloses a high-temperature-resistant salt-resistant fluid loss agent which is prepared by polymerizing the following components in parts by weight: 40-60 parts of 2-acrylamido-2-methylpropanesulfonic acid, 10-40 parts of acrylamide, 10-40 parts of alkyl substituted acrylamide or N-vinyl-2-pyrrolidone, 5-30 parts of unsaturated carboxylic acid and 5-20 parts of sodium p-styrenesulfonate, and an initiator which accounts for 0.1-1.0 wt% of the five components above. The invention also provides a preparation method of the fluid loss agent. The fluid loss agent has better high temperature resistance, and the maximum normal use temperature can reach 200 DEG C. The fluid loss agent has higher salt resistance, and can resist a saturated NaCl solution. The cement mortar with the fluid loss agent has the advantages of high system stability and high compression strength, and does not have the phenomenon of longer thickening time along with the temperature increase.

Owner:CNPC BOHAI DRILLING ENG

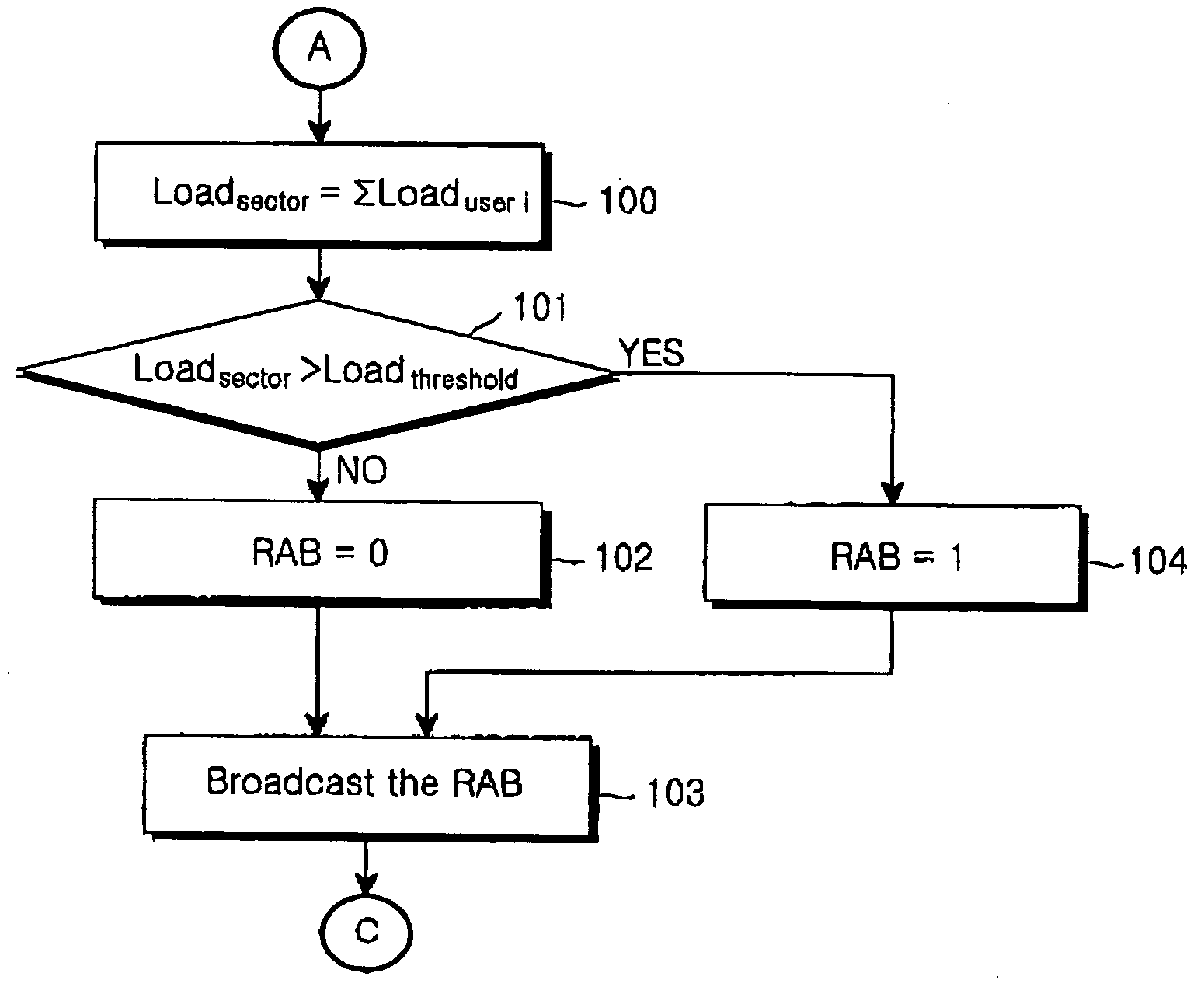

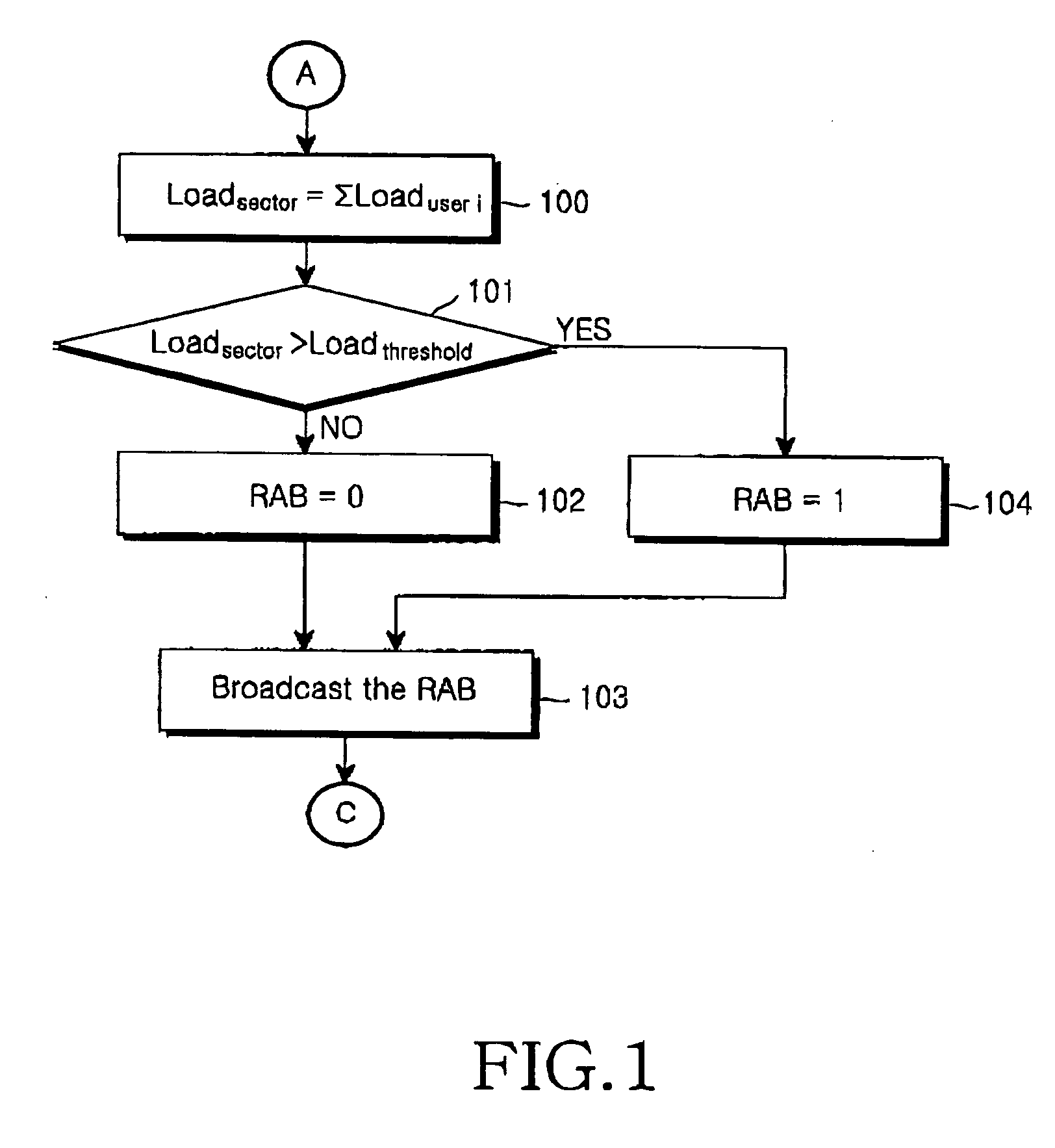

Method for controlling a data transfer rate in a reverse link of a mobile communication system

InactiveUS20050047365A1Improve data transfer rateReduce data transfer rateNetwork traffic/resource managementRadio/inductive link selection arrangementsMobile communication systemsData transmission

A method for controlling a Base Station (BS) to control a reverse data transfer rate in a mobile communication system includes the steps of: measuring a total user load value of a reverse link in a sector and an Rise Over Thermal (ROT) value; comparing the measured total user load value with a predetermined load threshold value, and comparing the measured ROT value with a predetermined ROT threshold value if it is determined that the measured total user load value is greater than the predetermined load threshold value; and increasing the data transfer rate if it is determined that the measured ROT value is less than or equal to the predetermined ROT threshold value.

Owner:SAMSUNG ELECTRONICS CO LTD

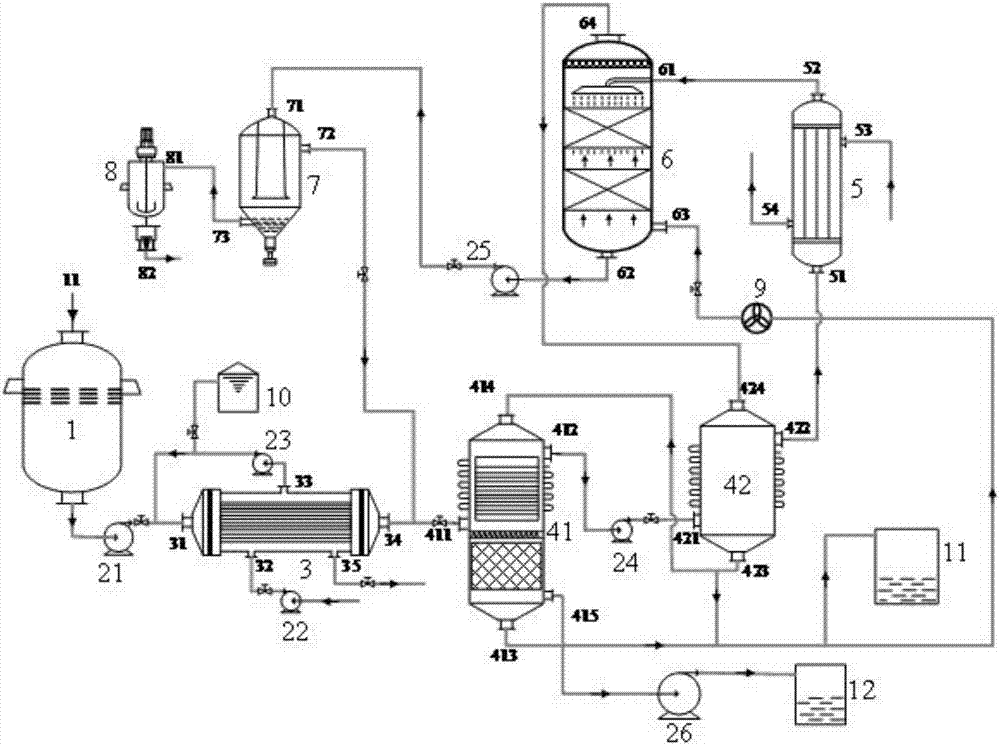

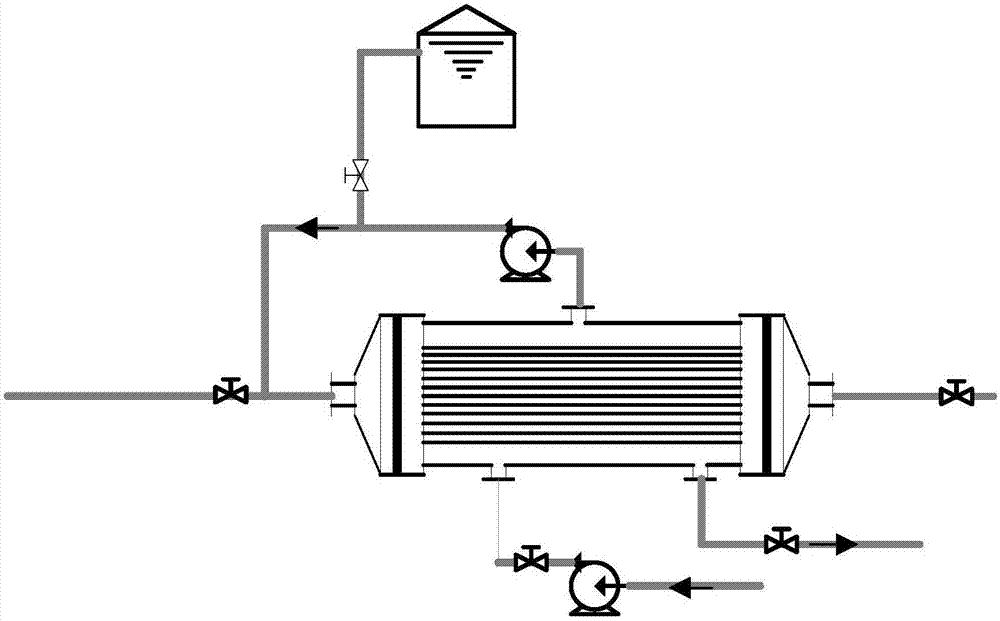

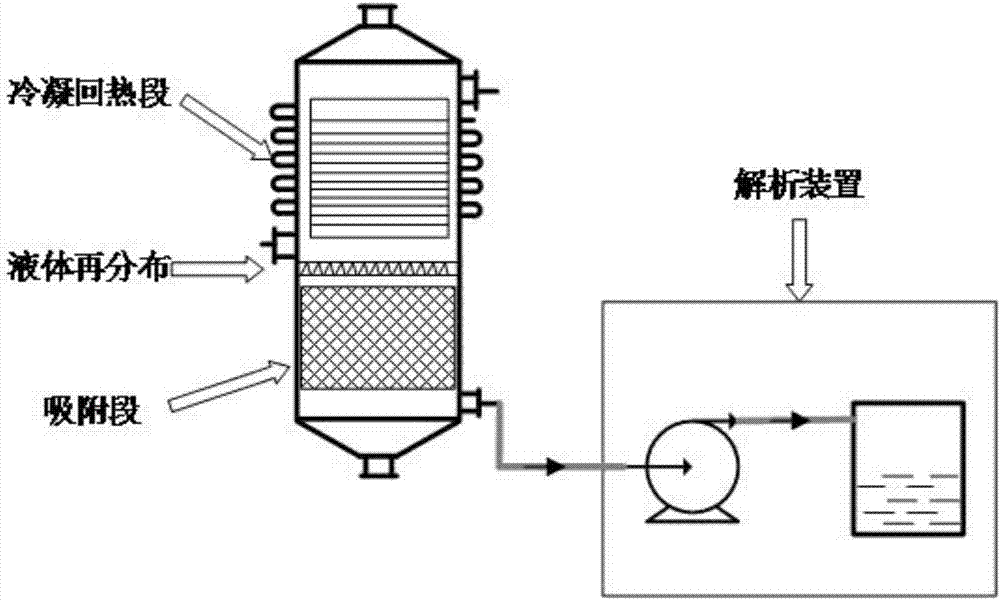

High salt content organic wastewater treatment device

ActiveCN106986486AIncrease productivityEasy to sort and recycleWater contaminantsMultistage water/sewage treatmentChemical industryChemical oxygen demand

The invention discloses a high salt content organic wastewater treatment device. The device comprises an ultrafiltration pretreatment part, a low-temperature evaporation part and a high-efficiency adsorption and condensation part. According to the wastewater treatment method disclosed by the invention, moisture recovery in a low-temperature environment is realized by utilizing the characteristic that the moisture carrying capacity of air is obviously improved along with temperature rise, the evaporated steam and volatile organic compounds pass through the condenser and are condensed to enter an adsorber to be adsorbed, so that the BOG (Boil Off Gas) and COD (Chemical Oxygen Demand) are further reduced, and the recovery standard is reached. According to the device disclosed by the invention, the high salt content organic wastewater produced in the production processes of chemical industries such as petrochemical engineering, food industry, superfine processing and the like can be effectively solved. The device has the advantages of low energy consumption, zero pollution, high production efficiency and the like and has a good application prospect.

Owner:NANJING TECH UNIV

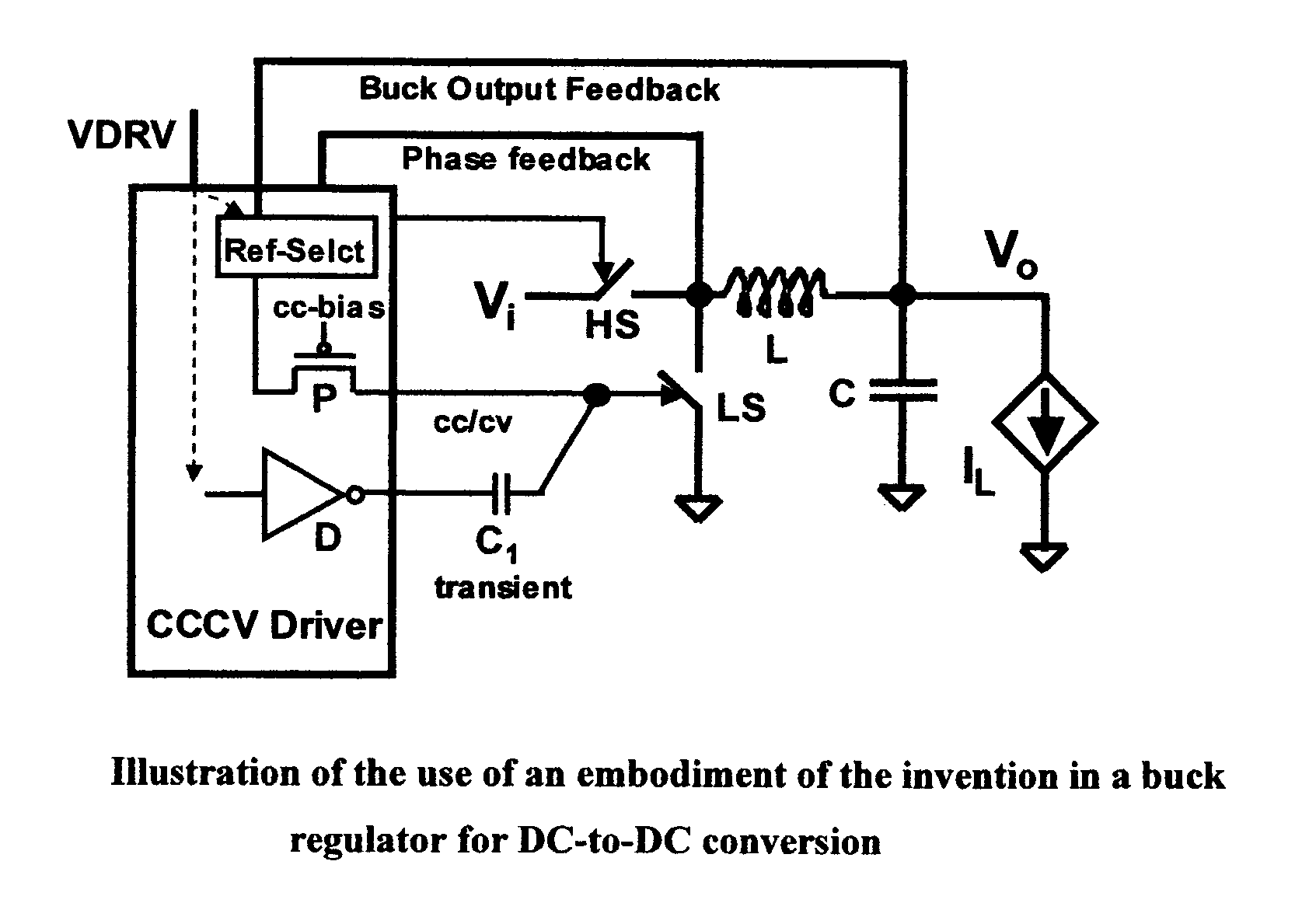

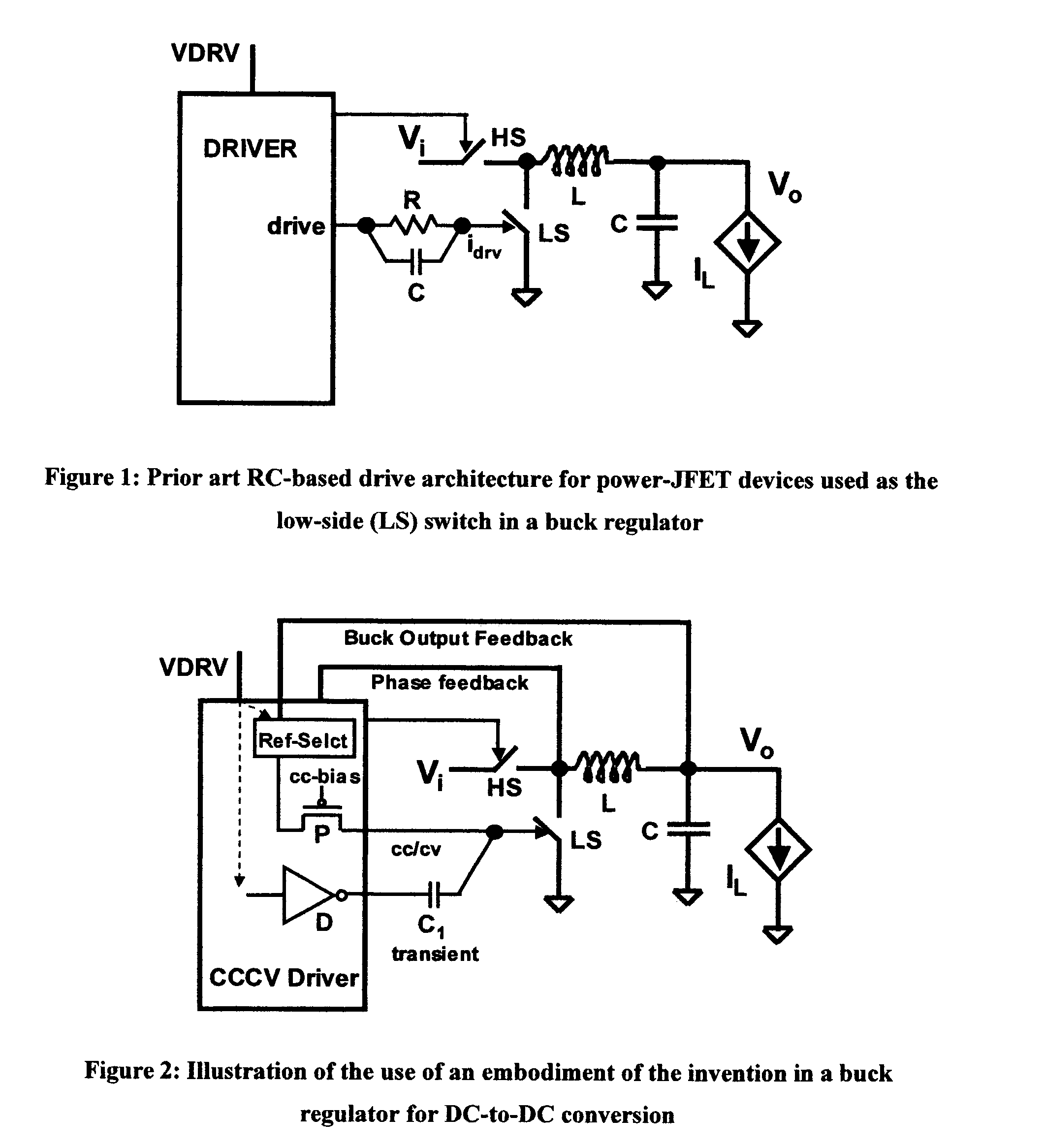

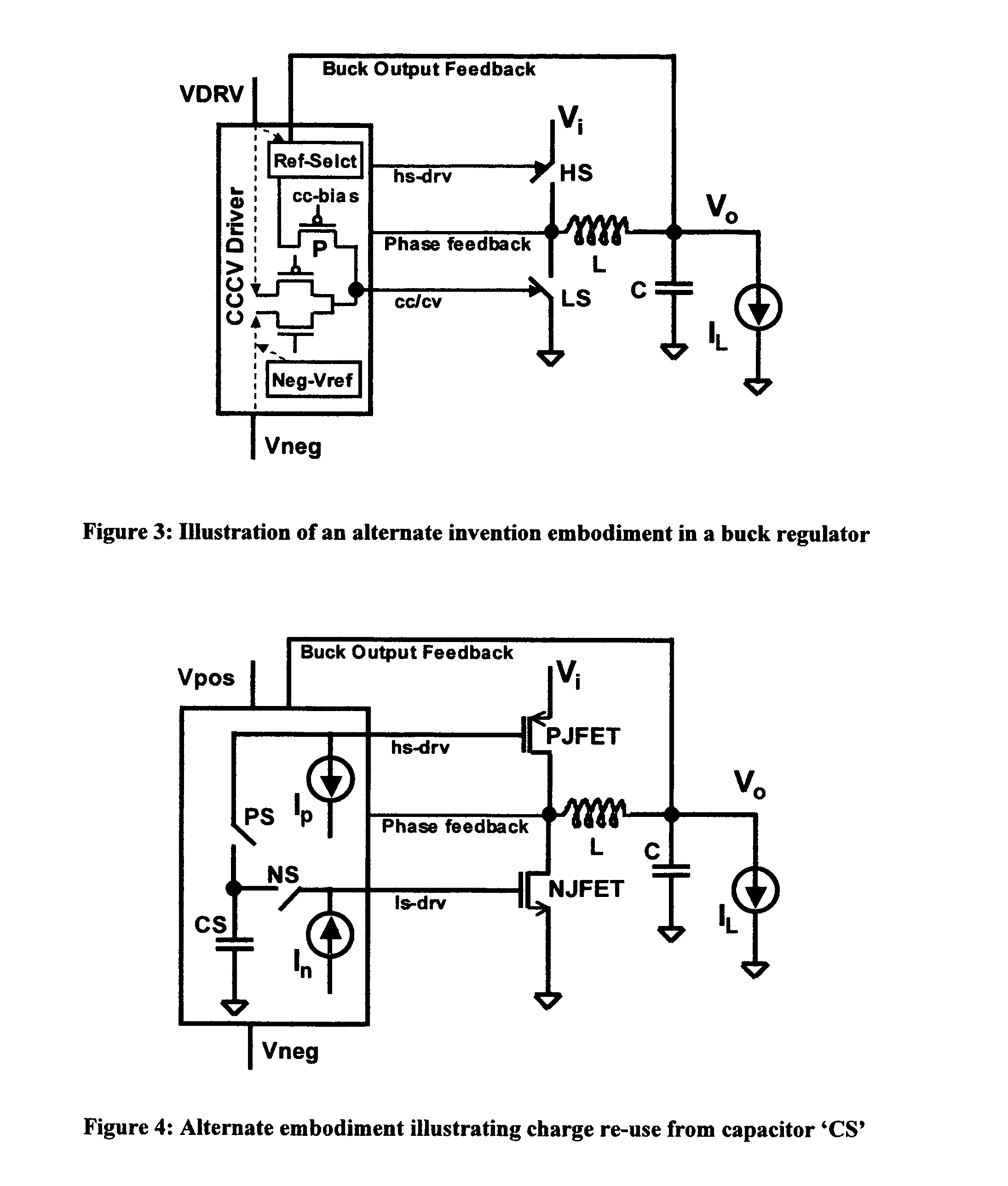

Method and apparatus for driving low input impedance power transistor switches

InactiveUS7126387B2Minimizes additional energy expenseEasy to changeEfficient power electronics conversionDc-dc conversionEnergy expenditureLow input

An adaptable, low-power drive circuit for transistor switches requiring control input current is disclosed. In one embodiment of the invention, a current source output replaces the prior art voltage drive circuits and associated external current-limiting resistor. The current-source drive circuit provides both a high impedance as well as variability. The high impedance of the current-source drive circuit enables a reduction in the value of the resistance-bypass capacitor employed in the prior art. The variability in the output current provided by the current-source circuit allows the drive circuits to optimize the control current flowing into the switch device as the characteristics of the switch device change with operating temperature. The drive circuit is capable of providing as output either a desired current, at a high output impedance, or a desired voltage, at a low output impedance, employing a shared amplifier and output transistor. The drive circuit also derives current from the much lower output voltage of the buck conversion system that the invention is used in. This minimizes the static power dissipated in driving the switch, and also minimizes the energy expenditure incurred in increasing the output current to modulate the power switch resistance that increases with increasing temperature.

Owner:NAIR RAJENDRAN

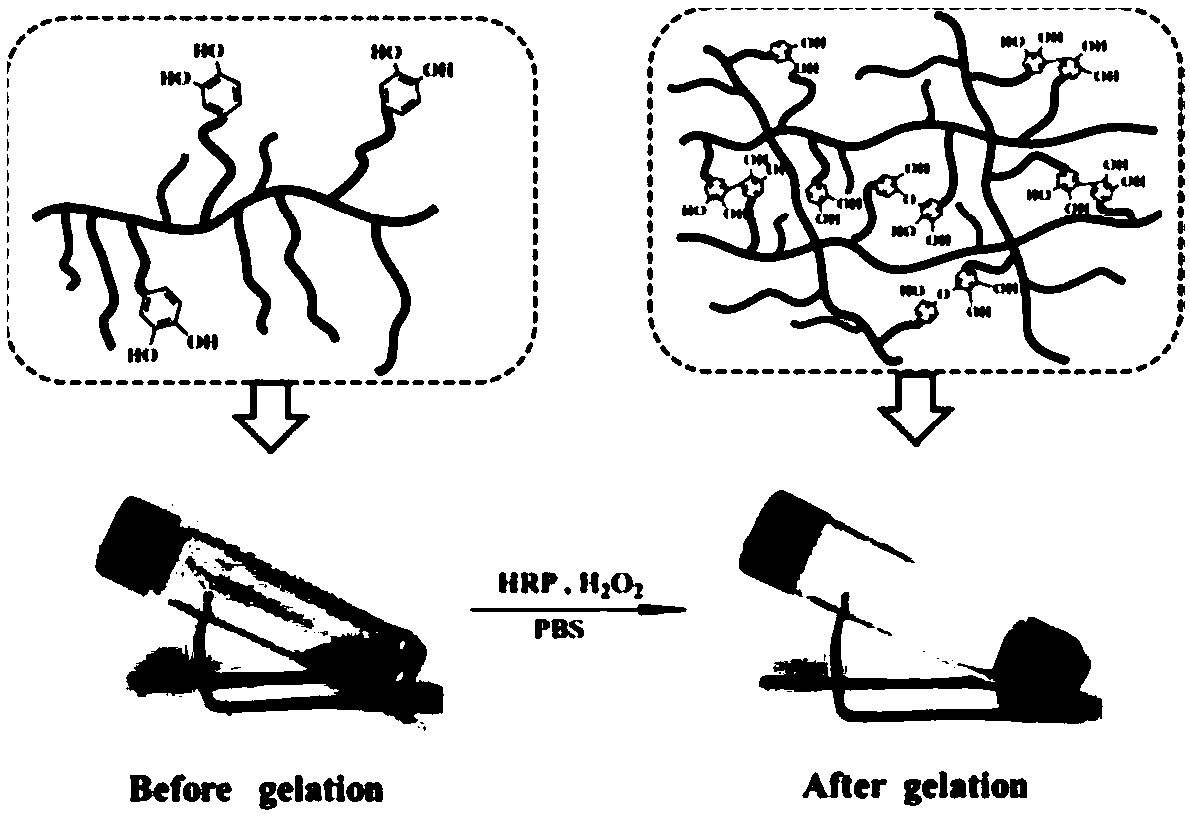

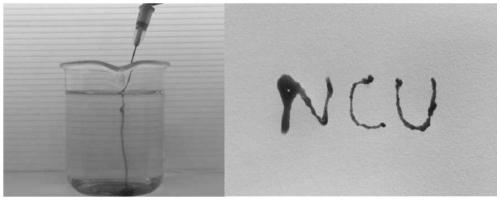

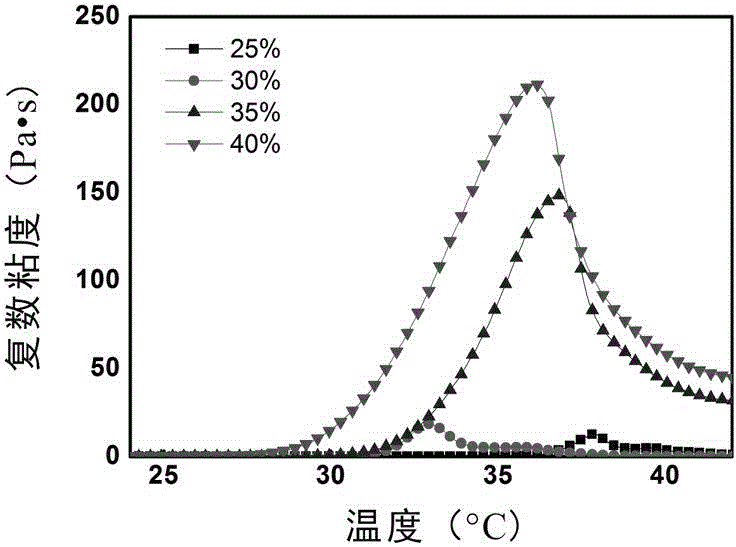

Method for preparing temperature-responsive adhesive injectable hydrogel

ActiveCN108929412AGel time controlImprove adhesion strengthSurgical adhesivesAerosol deliveryMethacrylateWound dressing

The invention provides a method for preparing a temperature-responsive adhesive injectable hydrogel. The method comprises the following steps: synthesizing a temperature-responsive polymer with different dopamine contents from dopamine methacrylamide used as an adhesive monomer and ethyl 2-(2-methoxyethoxy)methacrylate and oligo(ethylene glycol)methyl ether methacrylate as temperature-sensitive monomers, and carrying out enzyme catalytic crosslinking on the polymer and a dopamine group under the catalysis of horseradish peroxidase and hydrogen peroxide to prepare the temperature-responsive adhesive hydrogel. The hydrogel prepared in the invention has the characteristics of fastness in gel formation, realization of in-situ injection molding, realization of regulating the gelation time and the gel strength by regulating the concentrations of the polymer, horseradish peroxidase and hydrogen peroxide, and convenience in use; and the adhesion strength of the hydrogel is enhanced with the rising of the temperature, so the temperature-responsive characteristic makes the obtained hydrogel applied to fields of tissue adhesives, wound dressings, cell culture media and drug controlled releasecarriers.

Owner:NANCHANG UNIV

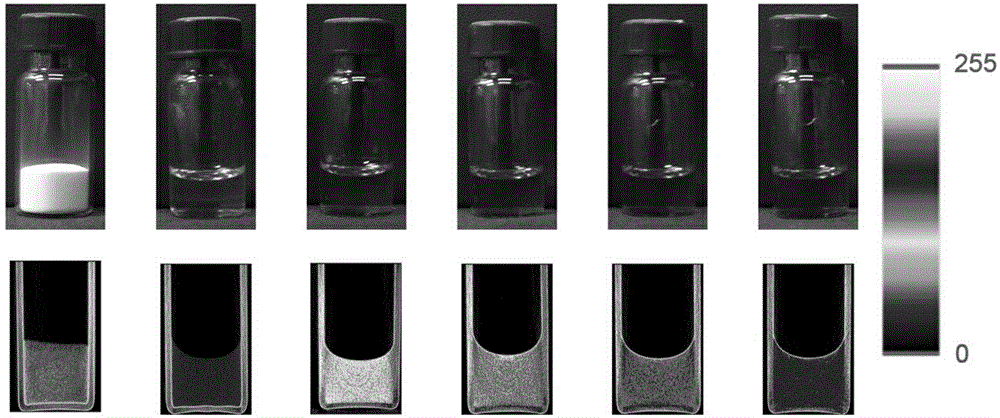

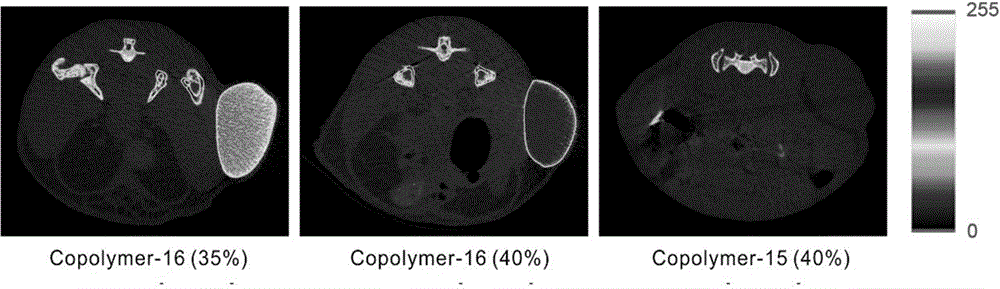

X-ray developing thermotropic hydrogel and preparation method thereof

ActiveCN104645356APossesses thermally induced gelation propertiesGood injectabilityAerosol deliverySurgeryTissue repairEmbolization Agent

The invention belongs to the technical field of medical polymer materials and in particular relates to X ray developing thermotropic hydrogel and a preparation method thereof. The X ray developing thermotropic hydrogel comprises an iodine-containing amphiphilic block copolymer and a solvent, wherein the iodine-containing amphiphilic block copolymer is obtained by bonding an iodine-containing micromolecule and an amphiphilic block copolymer by virtue of a covalent bond, and thermotropic gelatinization phase transformation can be carried out on a water system of the X ray developing thermotropic hydrogel along with temperature increase. The thermotropic hydrogel can be implanted under the skin and implanted into an abdominal cavity, an articular cavity and other specific parts of a human body in a mode of injection, and in situ formed hydrogel has good X ray developing performance, clear positioning and long-term tracing observation can be carried out on the hydrogel by adopting an X ray radiography technique. The thermotropic hydrogel also can serve as a medicine controlled release carrier, a tissue repairing support, a blood vascular embolization agent, a tissue marker and the like and can be used for realizing integration of diagnosis and treatment.

Owner:FUDAN UNIV

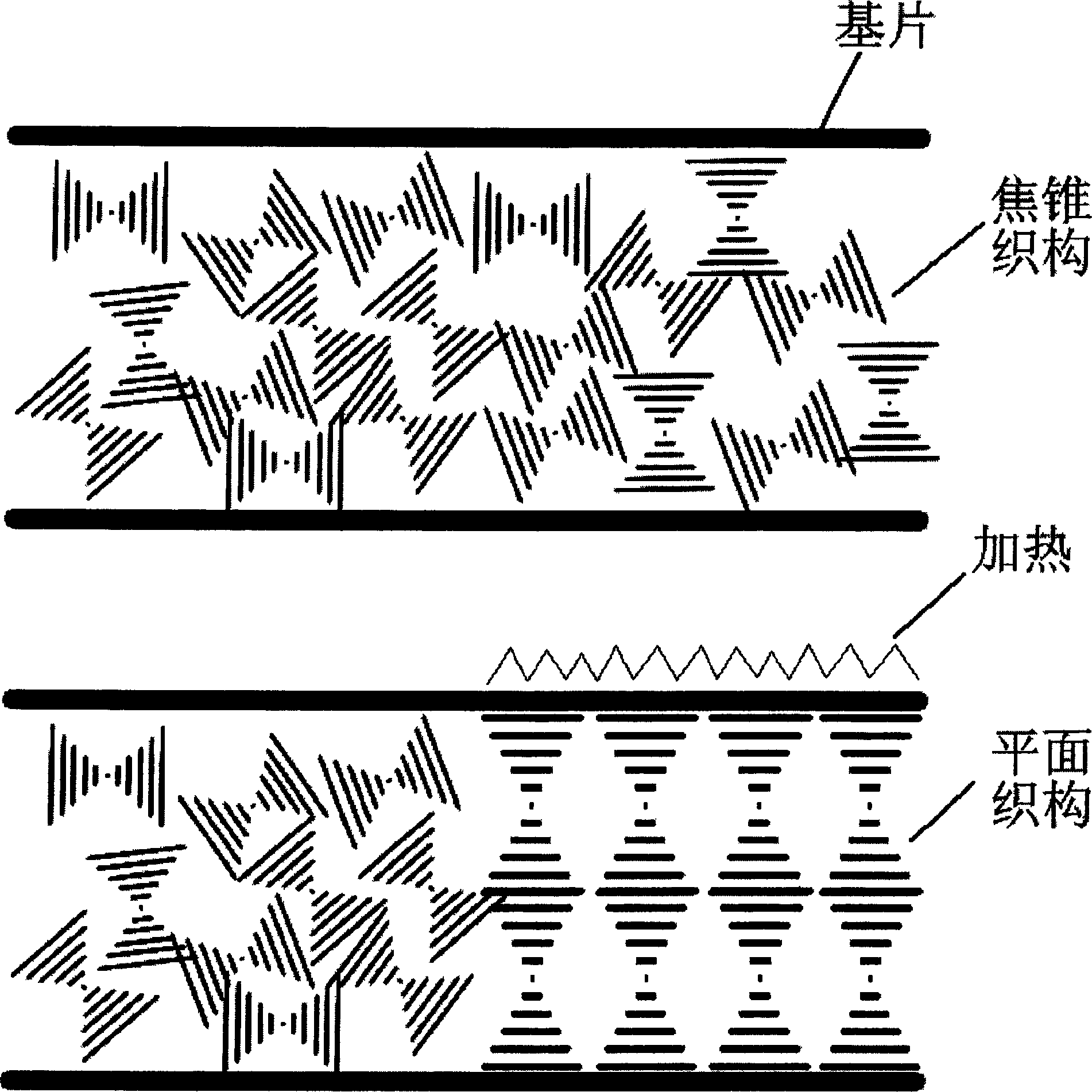

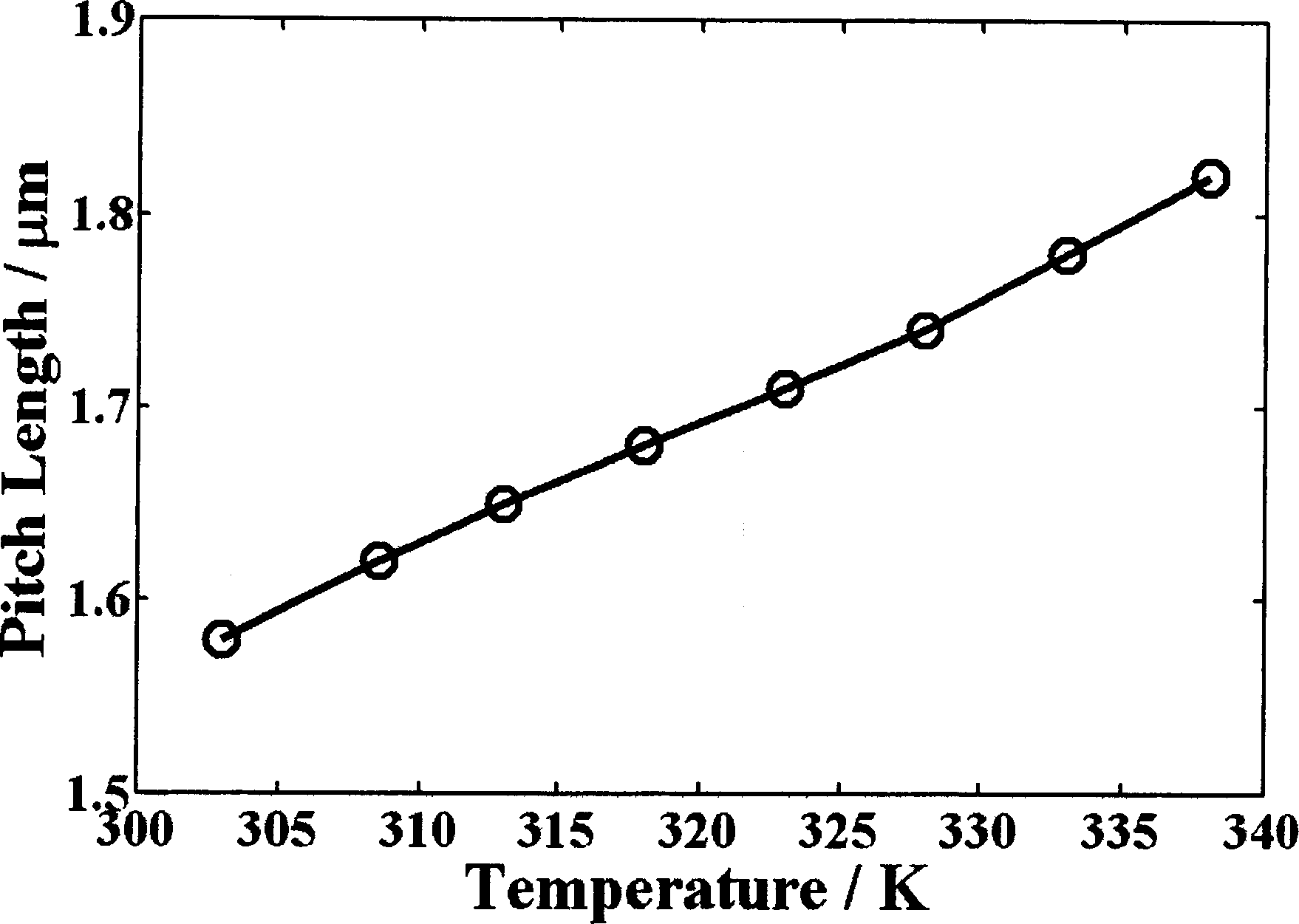

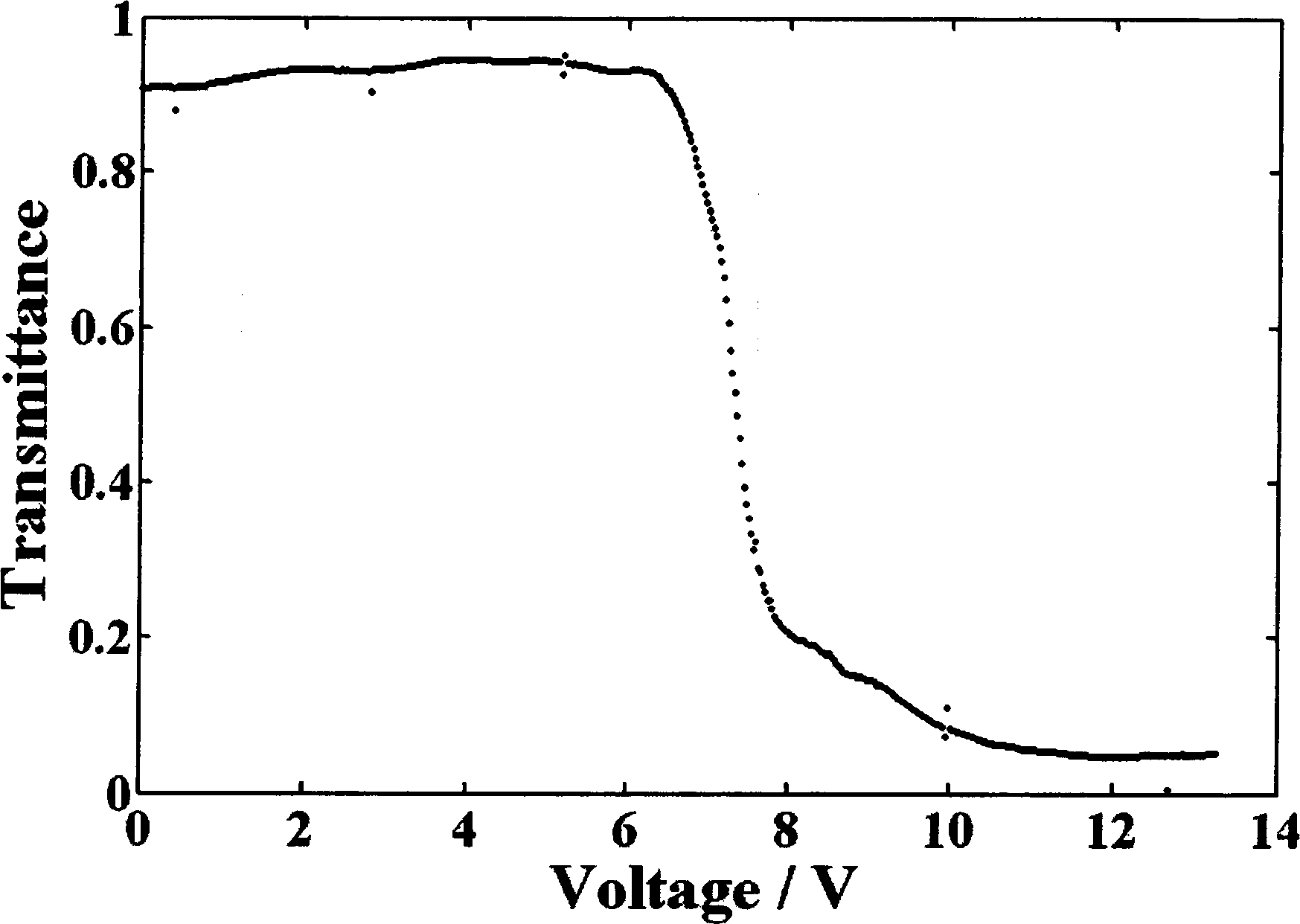

Method for erazing or writing cholesteryl phase liquid crystal stored information

The present invention provides a method capable of thermally erasing information stored in the cholesteryl liquid crystal and writing information into said cholesteryl liquid crystal, belonging to the field of liquid crystal display technology. Said invention uses a chiral compound whose helical torque force can be continuously reduced with that the temperature is continuously risen, and mixes it with nematic phase liquid crystal so as to obtain the cholesteryl liquid crystal, in which the mass percent of the chiral compound is 0.1%-20%. Said invention also provides a concrete technological process to implement thermal erasion or writing-in of cholesteryl liquid crystal.

Owner:UNIV OF SCI & TECH BEIJING

Membrane electrode assembly and fuel cell using same

InactiveUS20130029242A1Excellent power generation characteristicsWater management in fuel cellsSolid electrolyte fuel cellsEvaporationEngineering

A membrane electrode assembly having a temperature responsive layer whose material permeability is reduced with temperature rise, on a laminate including an anode catalyst layer, an electrolyte membrane and a cathode catalyst layer in this order, and a fuel cell using the same are provided. The temperature responsive layer may be composed of a porous layer containing a temperature responsive material whose moisture content changes at a phase transition temperature. It is possible to repress increase in fuel supply amount to the anode catalyst layer in association with temperature rise, and moisture evaporation from the electrolyte membrane in association with temperature rise, and to prevent excessive temperature rise and thermal runaway of the fuel cell.

Owner:SHARP KK

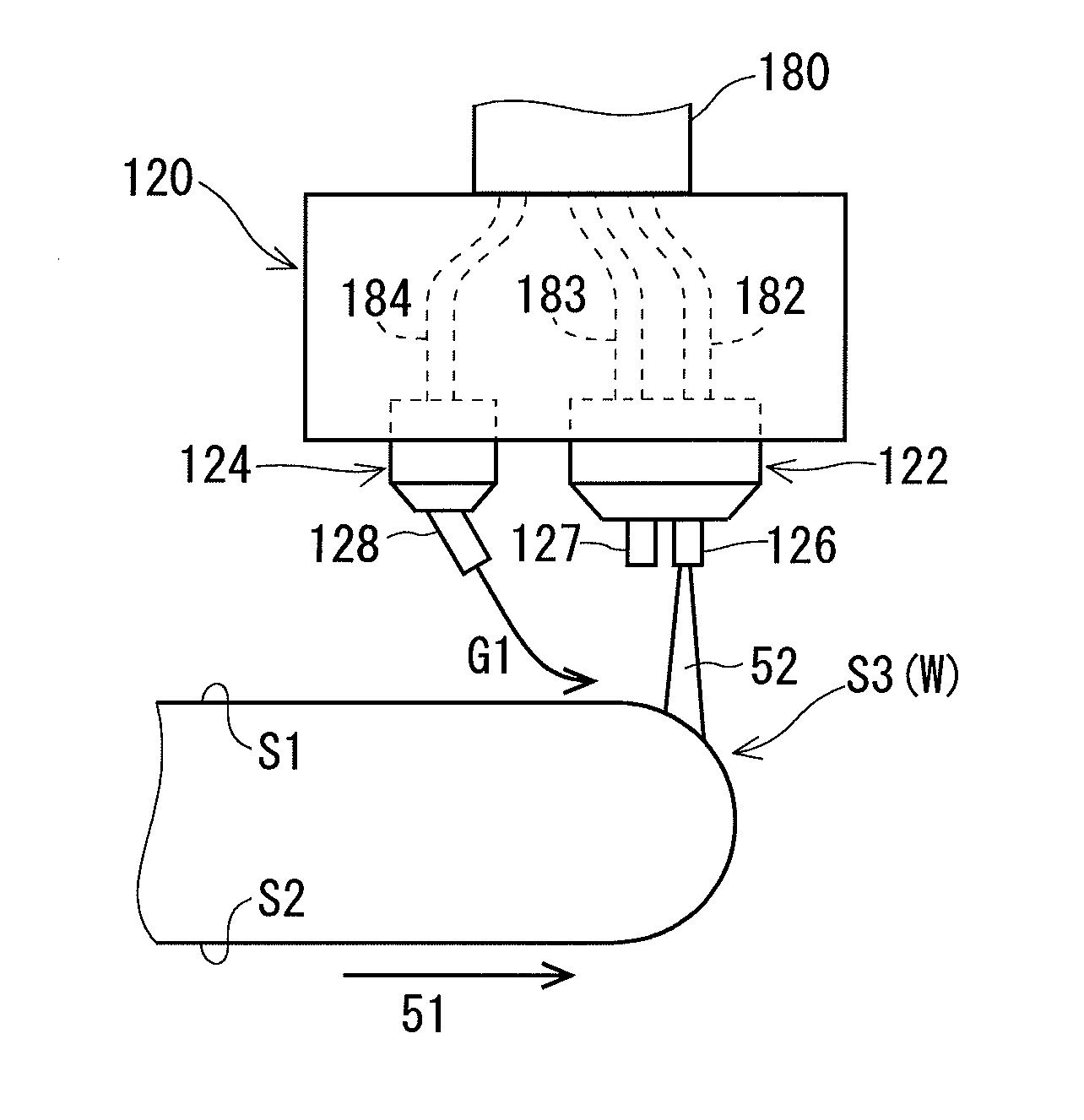

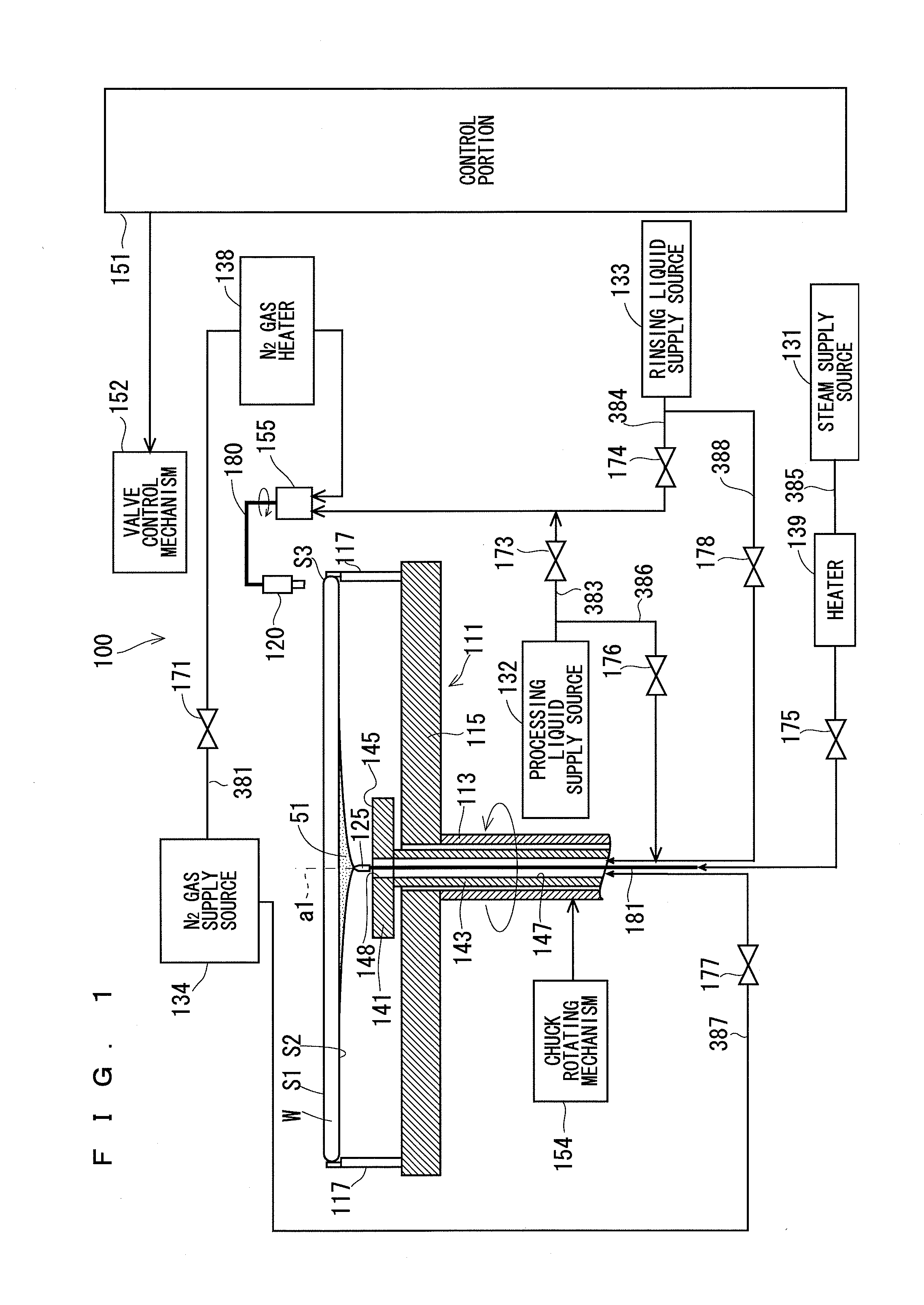

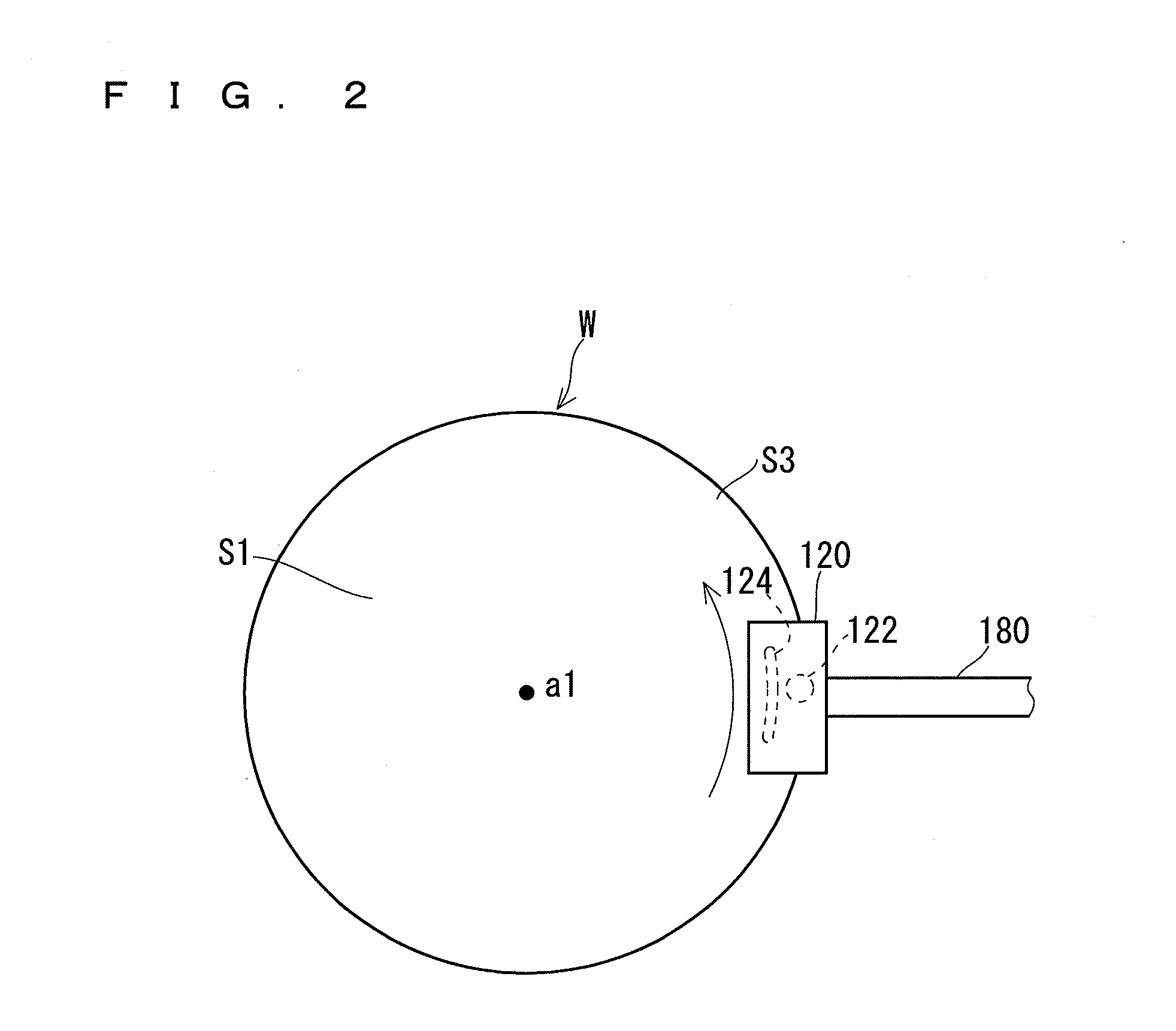

Substrate processing device and substrate processing method for carrying out chemical treatment for substrate

InactiveUS20140051259A1Reducing chemical treating widthInhibit deteriorationSemiconductor/solid-state device manufacturingChemical treatmentReaction rate

It is an object to reduce a chemical treating width in a peripheral edge part of a substrate while suppressing deterioration in each of uniformity of the chemical treating width and processing efficiency. In order to achieve the object, a substrate processing device for carrying out a chemical treatment for a substrate using a processing liquid having a reaction rate increased with a rise in temperature includes a substrate holding portion, a rotating portion for rotating the substrate held in the substrate holding portion in a substantially horizontal plane, a heating portion for injecting heating steam to a central part of a lower surface of the substrate to entirely heat the substrate, and a peripheral edge processing portion for supplying the processing liquid from above to a peripheral edge part of the substrate heated by the heating portion, thereby carrying out a chemical treatment for the peripheral edge part.

Owner:DAINIPPON SCREEN MTG CO LTD

Biasing non-volatile storage to compensate for temperature variations

A body bias is applied to a non-volatile storage system to compensate for temperature-dependent variations in threshold voltage, sub-threshold slope, depletion layer width and / or 1 / f noise. A desired bias level is set based on a temperature-dependent reference signal. In one approach, a level of the biasing can decrease as temperature increases. The body bias can be applied by applying a voltage to a p-well and n-well of a substrate, applying a voltage to the p-well while grounding the n-well, or grounding the body and applying a voltage to the source and / or drain of a set of non-volatile storage elements. Further, temperature-independent and / or temperature-dependent voltages can be applied to selected and unselected word lines in the non-volatile storage system during program, read or verify operations. The temperature-dependent voltages can vary based on different temperature coefficients.

Owner:SANDISK TECH LLC

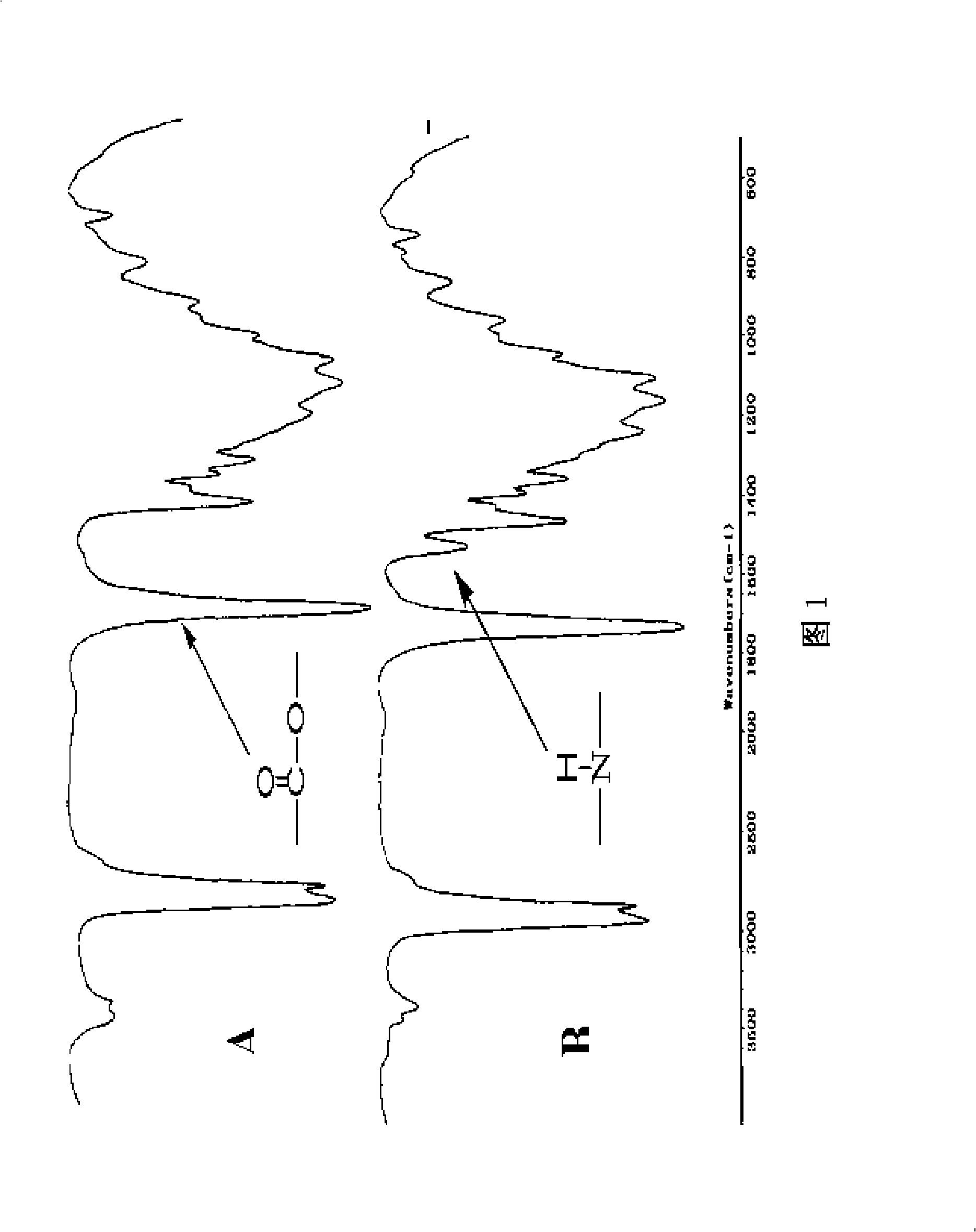

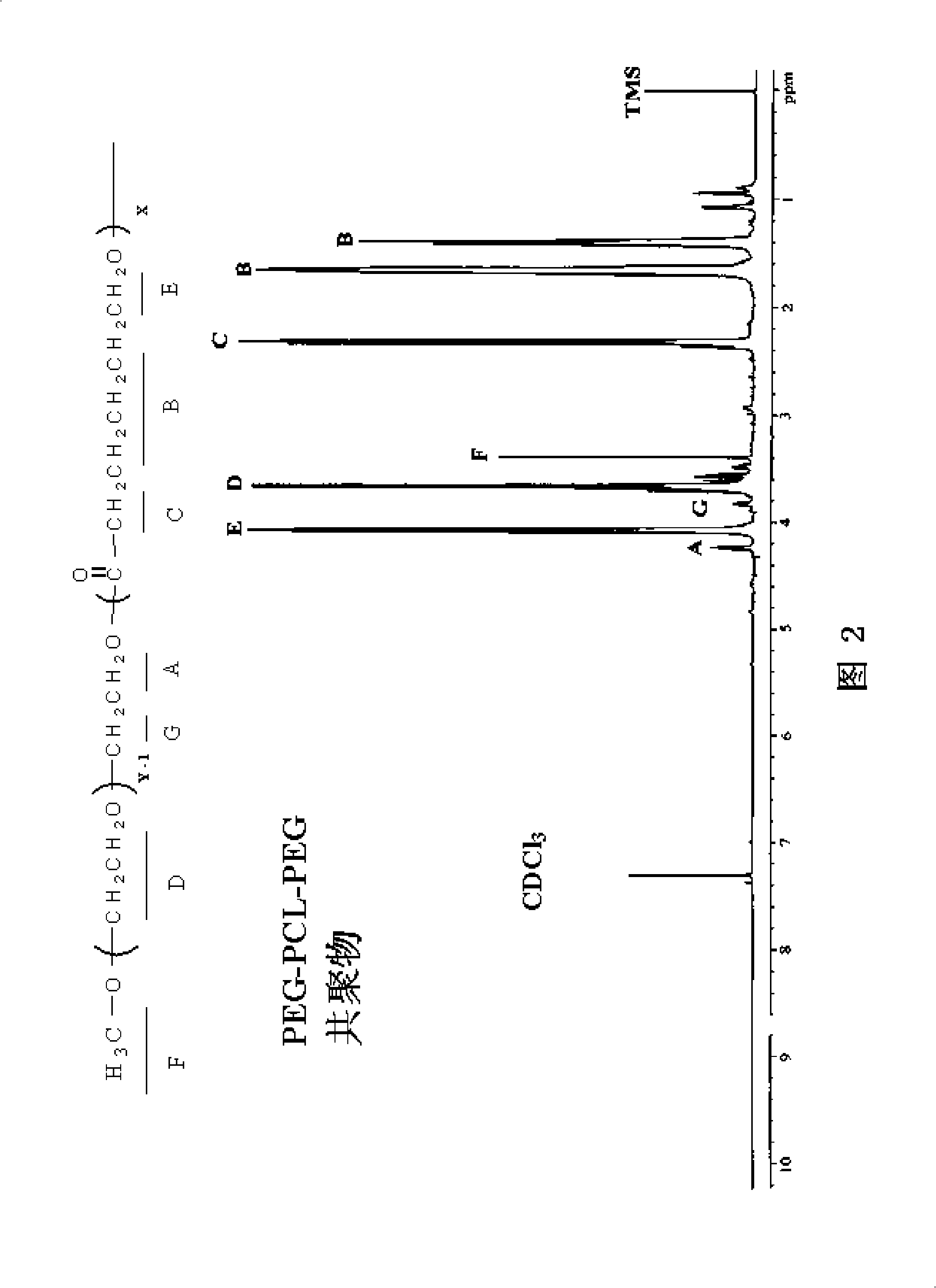

Thermo-sensitive tri-block copolymer having sol-gel conversion characteristic and preparation thereof

InactiveCN101255235AAdjustable intensityGood biocompatibilitySurgeryPharmaceutical non-active ingredientsPEG-PCL-PEGMolecular materials

The invention relates to medical polymers field, especially a temperature sensitive and biodegradable triblock copolymer with gel-sol transformation characteristics and preparation method thereof and usage. The triblock copolymer is PEG-PCL-PEG copolymer, the aqueous solution thereof performs Sol-Gel phase transformation along with the temperature rise and the phase transformation temperature is 25-35 degree. The PEG-PCL-PEeG copolymer has a variety of excellent features to provide a new choice in field which is in need of temperature sensitive material.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com