Preparation of highly efficient water phase system non-organic silicon defoaming agent

A defoamer, non-organic technology, applied in the field of preparation of high-efficiency non-organic silicon defoamer, can solve the problems of production difficulties, defoaming and anti-foaming performance decline, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 10 parts of higher fatty alcohol, 2 parts of glycerol monostearate, 5 parts of higher fatty alcohol polyether (structural formula is i-C 13 h 27 O(EO) 5 (PO) 7 H), 10 parts of white oil, 2 parts of S-60 and 1 part of T-60 are added to the reaction flask, the system is heated up to 80°C, stirred for a while, so that the components are mixed evenly; then slowly add 70 parts of water, water After the addition, grind and disperse through a colloid mill until the particle size of the emulsion is less than 15um to obtain defoamer A.

Embodiment 2

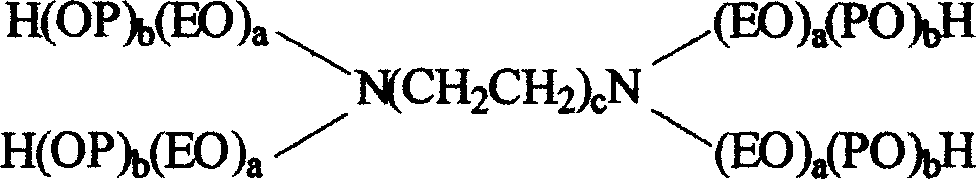

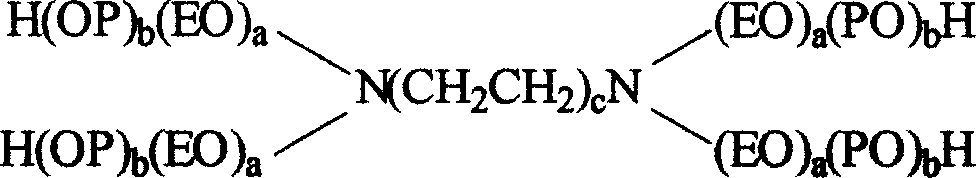

[0022] Mix equal amounts of crude liquid wax and white carbon black, stir and disperse evenly as the active component (1).

[0023] Add 5 parts of higher fatty alcohols, 5 parts of higher fatty alcohol polyethers (structural formula is C 18 h 37 O(PO) 10 H), 4 parts of nitrogen-containing polyethers (a=10 in the structural formula, b=15, c=1), 6 parts of active components (1), 6 parts of behenyl stearate, 2 parts of TX- 10. 2 parts of TX-3, then the system was heated up to 70°C and kept for 10 minutes, then 70 parts of water was added. After the water was added, it was ground and dispersed by a colloid mill so that the particle size of the emulsion was less than 15 minutes, and the defoamer B was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com