High-temperature-resistant salt-resistant fluid loss agent and preparation method thereof

A water loss reducing agent and high temperature resistant technology, applied in the field of oil drilling, can solve the problems of poor stability of cement slurry and easy delamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

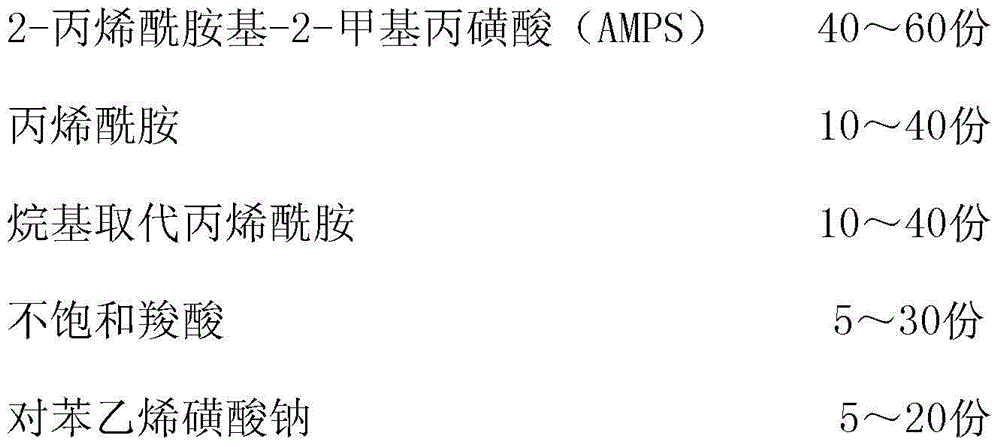

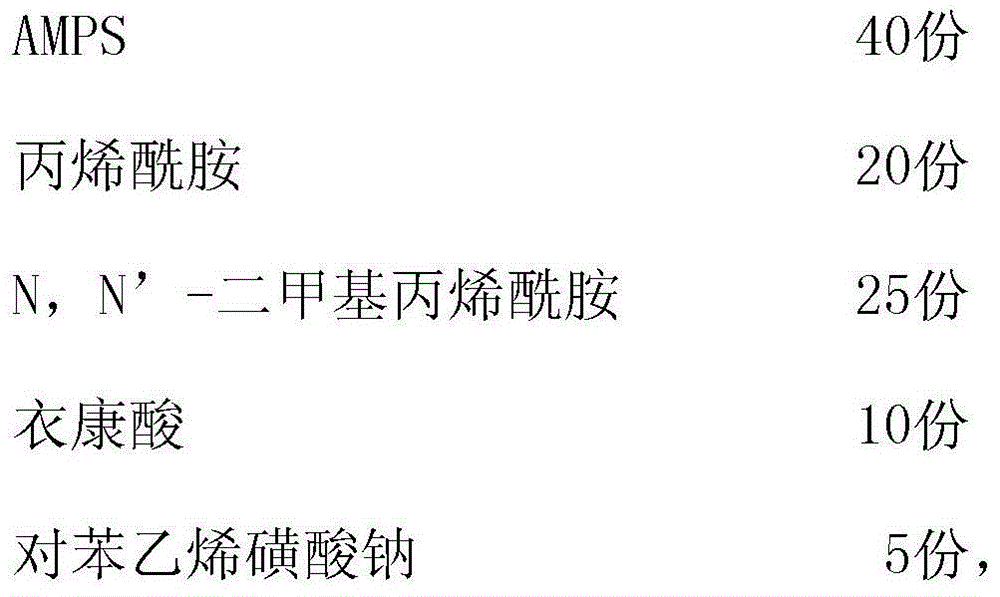

[0019] Take by weight the following 5 components:

[0020]

[0021] Dissolve the above 5 monomers in 400 parts of water; use sodium hydroxide solution to adjust the pH value of the solution to 2; add the solution to the three-necked flask, 40 ℃ constant temperature water bath, and stir, when the solution temperature in the three-necked flask reaches After 40°C, add 1 part of ammonium persulfate initiator, continue the reaction for 6 hours, dry and pulverize to obtain the product.

Embodiment 2

[0023] Take by weight the following 5 components:

[0024]

[0025] Dissolve the above 5 monomers in 566 parts of water; use sodium hydroxide solution to adjust the pH value of the solution to 4; add the solution to the three-necked flask, 50 ° C constant temperature water bath, and stir, when the temperature of the solution in the three-necked flask reaches After 50°C, add 0.5 parts of ammonium persulfate initiator, continue the reaction for 4 hours, dry and pulverize to obtain the product.

Embodiment 3

[0027] Take by weight the following 5 components:

[0028]

[0029] Dissolve the above-mentioned 5 monomers in 900 parts of water; adjust the pH value of the solution to 5 with sodium hydroxide solution; add the solution into the three-necked flask, put it in a constant temperature water bath at 60°C, and stir it. When the temperature of the solution in the three-necked flask reaches After 60°C, add 0.1 part of ammonium persulfate initiator, continue the reaction for 2 hours, dry and pulverize to obtain the product.

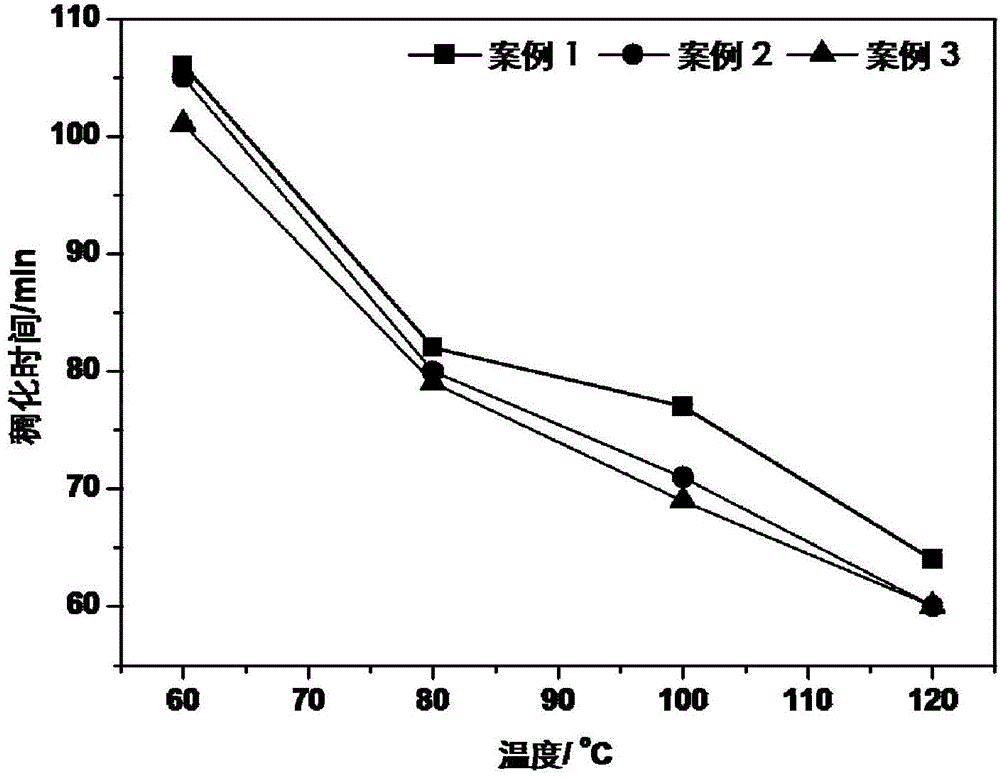

[0030] 2. Performance evaluation of fluid loss reducer:

[0031] The cement slurry was prepared according to GB / T19139-2003 and its properties such as water loss, thickening time and compressive strength were measured. The specific cement paste formula is as follows:

[0032] The formula of table 16 kinds of cement slurry systems

[0033]

Recipe 1

Recipe 2

Recipe 3

Recipe 4

Recipe 5

Recipe 6

G grade oil well cement

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com