Method for preparing temperature-responsive adhesive injectable hydrogel

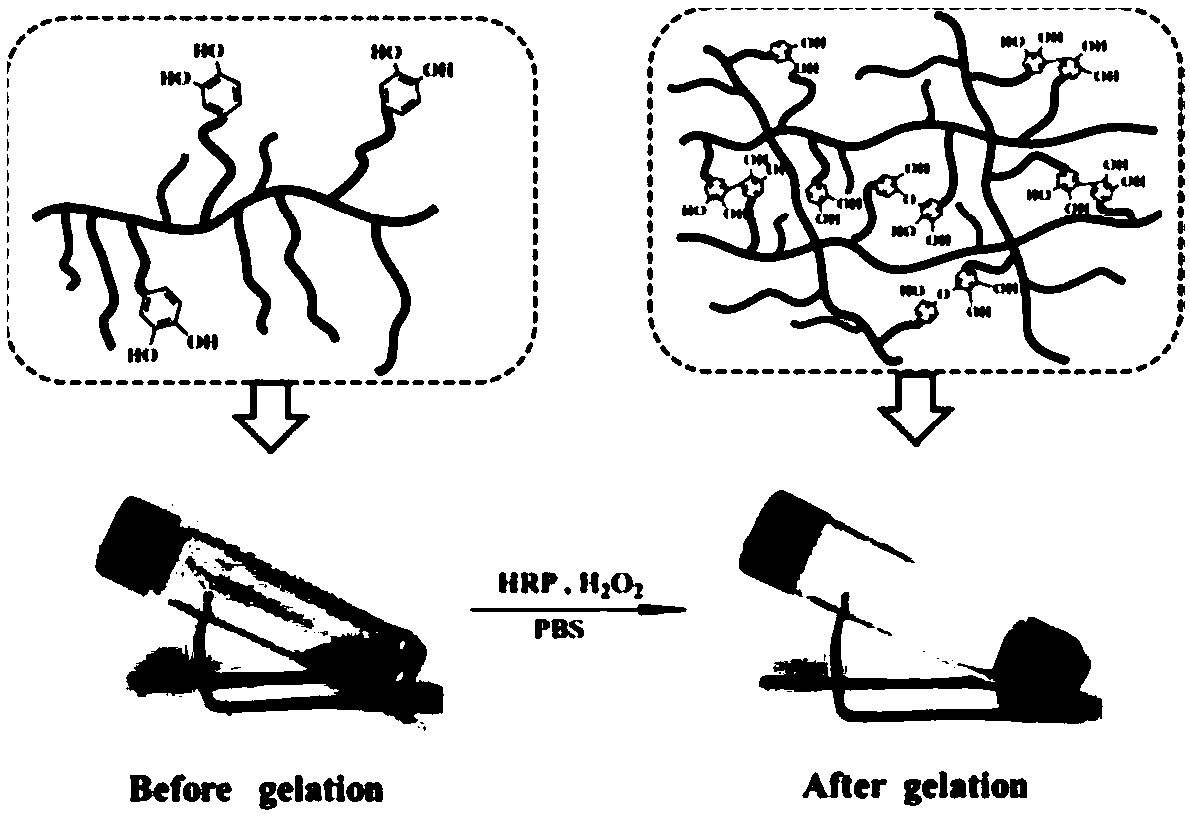

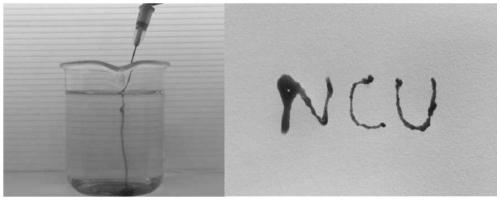

A technology of temperature response and adhesion, which is applied in the field of preparation of adhesive injectable hydrogels, can solve the problems of weak strength, regulation, and inability to effectively regulate the structure and adhesion of hydrogels, and achieve control structure and strength, good biocompatibility, and the effect of rapid in-situ injection molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation of embodiment 1 dopamine methacrylamide (DMA)

[0030] 8g NaHCO 3 and 20g Na 2 B 4 o 7 10H 2Dissolve O in 200mL of distilled water, remove oxygen by bubbling with nitrogen for 30 minutes, add 10g of dopamine hydrochloride, stir to dissolve, take 9.4mL of methacrylic anhydride, dissolve in 50mL of tetrahydrofuran, and add dropwise to the above mixture with a constant pressure funnel , adjust the pH of the mixture to >8 with 1M NaOH, stir the reaction at room temperature for 16 hours and filter with suction to remove insoluble NaHCO 3 and Na 2 B 4 o 7 10H 2 O, the filtrate was washed with 100mL ethyl acetate, and adjusted to pH4 Dry overnight, filter to remove MgSO 4 , concentrated by rotary evaporation to about 50 mL, recrystallized drop by drop into 450 mL of ice n-hexane under vigorous stirring, filtered by suction, and dried in vacuum to obtain dopamine methacrylamide;

Embodiment 2

[0031] The preparation of the temperature-responsive polymer of embodiment 2 different dopamine group contents

[0032] (1) Preparation of polymer PMOD-1: 2-(2-methoxyethoxy)ethyl methacrylate (3.00mL, 16.3mmol), oligo(ethylene glycol) methyl ether methacrylic acid Ester (2.51mL, 5.43mmol), dopamine methacrylamide (0.4803g, 2.17mmol) prepared in Example 1 and azobisisobutyronitrile (0.0589g, 0.358mmol) were added to a 15mL N, N - Dimethylformamide was stirred in a round-bottomed flask to fully dissolve it, bubbled with nitrogen for 30 minutes to remove oxygen, and continued to react in an oil bath at 65°C for 5 hours. The reaction solution was dissolved / precipitated three times with tetrahydrofuran / glacial ether, After vacuum drying at room temperature for 48 hours, the polymer PMOD-1 was obtained.

[0033] Polymer PMOD-1 measures the degree of polymerization of each structural unit by proton nuclear magnetic spectrum: x=77.4, y=22.6, z=8.8, gel permeation chromatography dete...

Embodiment 3

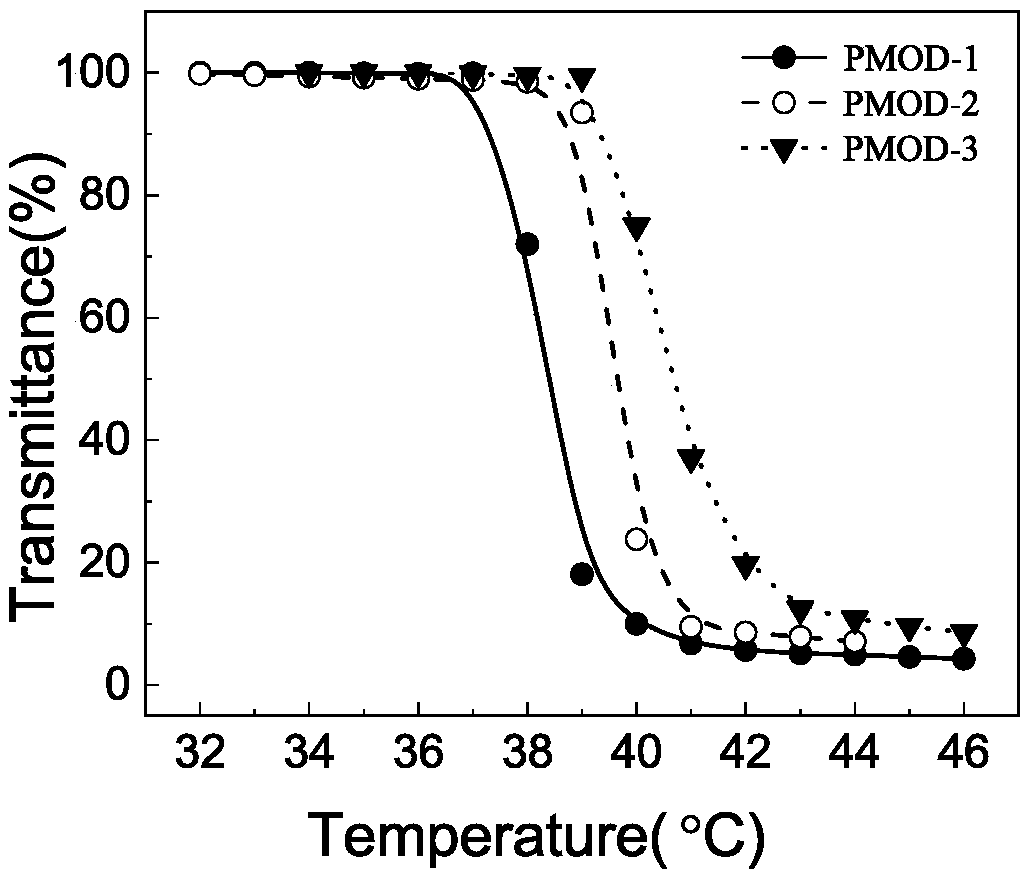

[0038] Example 3 Polymer temperature responsiveness measurement

[0039] Each polymer prepared in Example 2 was dissolved in a PBS buffer solution of 7.4, and its concentration was fixed at 5 mg / mL. Pipette 3 mL of the solution into a quartz cuvette and seal it, and keep the solution temperature at the set temperature value for 10 min. , through the UV-3100 ultraviolet-visible spectrophotometer equipped with a constant temperature water bath circulation device to record the light transmittance at 600nm at each temperature, and determine the change of the light transmittance of the polymer solution with temperature. Among them, the lower critical solution temperature (LCST) is defined as the temperature at which the light transmittance drops to 50% of the initial value. See the test results figure 1 .

[0040] From figure 1 It can be obtained that the LCST of the polymers PMOD-1, PMOD-2 and PMOD-3 are 38.4°C, 39.6°C and 40.7°C, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com