Method for preparing hydrophobic silicon oxide aerogel based on inorganic salt aqueous solution

A technology of inorganic salt solution and water silicon oxide, which is applied in the direction of inorganic chemistry, chemical instruments and methods, silicon compounds, etc., can solve the problems of high material cost, achieve the effects of low preparation cost, shorten the preparation cycle, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

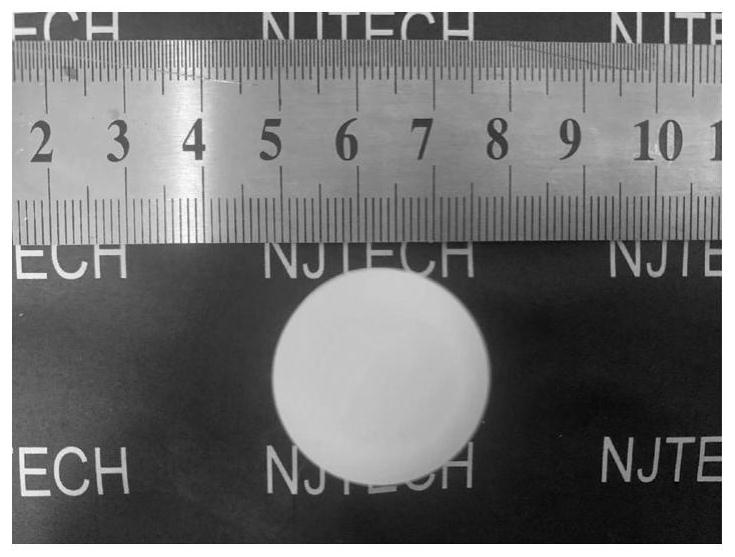

[0026] 30 parts of sodium methylsilicate and 200 parts of water were mixed and stirred for 3 hours to obtain a mixed solution. Mix and stir 5 parts of water glass with a modulus of 3.3 and 30 parts of water for 0.5 h to obtain a silica sol, mix and stir the mixed solution and the silica sol at a ratio of 1:1 for 0.5 h to obtain a mixed sol, first add oxalic acid to adjust the pH of the mixed solution 6 was mixed and stirred for 0.1 h, and the mixed solution was gelatinized at 50° C. to obtain a wet gel. The obtained wet gel was immersed in an ammonia solution with a pH of 10 and aged at 90 °C for 6 h, and then an ethanol solution was added for solvent replacement 6 times for 3 h each time. The wet gel after the replacement is subjected to carbon dioxide supercritical drying, and the silica aerogel obtained by drying is heat-treated in an air atmosphere of 350° C. for 3 hours to obtain a hydrophobic silica aerogel. The obtained hydrophobic silica aerogel sample picture is as f...

example 2

[0028] 10 parts of potassium methyl silicate and 50 parts of water were mixed and stirred for 1 h to obtain a mixed solution. Mix and stir 10 parts of water glass with a modulus of 1.5 and 80 parts of water for 1.5 hours to obtain a silica sol. The mixed solution and the silica sol are mixed and stirred at a ratio of 2:1 for 2.5 hours to obtain a mixed sol. First, add hydrochloric acid to adjust the pH of the solution to 5. After mixing and stirring for 0.3 h, the mixed solution was gelatinized at 70° C. to obtain a wet gel. The obtained wet gel was immersed in a pH 7 ammonia solution and aged at 50°C for 12h. Then add methanol solution for solvent replacement 3 times, 1h each time. The wet gel after the replacement is vacuum-dried, and the silica aerogel obtained by drying is heat-treated in an air atmosphere of 150° C. for 1 h to obtain a hydrophobic silica aerogel. The density of the hydrophobic silica aerogel material is 0.2g / cm3, the specific surface area is 600m2 / g, an...

example 3

[0030] 15 parts of sodium methylsilicate and 100 parts of water were mixed and stirred for 1.5 h to obtain a mixed solution. Mix and stir 8 parts of water glass with modulus 2 and 60 parts of water for 0.8 h to obtain silica sol, mix and stir the mixed solution and silica sol at a ratio of 3:1 for 1.5 h to obtain a mixed sol, first add acetic acid to adjust the pH of the solution to 7 After mixing and stirring for 0.2 h, the mixed solution was gelatinized at 20° C. to obtain a wet gel. The obtained wet gel was immersed in a pH 8 ammonia solution and aged at 60°C for 10h. Then water was added to perform solvent replacement 6 times, 3h each time. The wet gel after the replacement is freeze-dried, and the silica aerogel obtained by drying is heat-treated in an air atmosphere of 180° C. for 1.5 h to obtain a hydrophobic silica aerogel. The density of the hydrophobic silica aerogel material is 0.12g / cm3, the specific surface area is 635m2 / g, and the hydrophobic angle is 131°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com