Novel application of waste agents

A waste agent and application technology, applied in the field of organic matter conversion process, can solve the problems of environmental hazards, low economic and environmental benefits of biomass liquefaction process, and achieve the effects of reducing production costs, reducing landfill volume, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

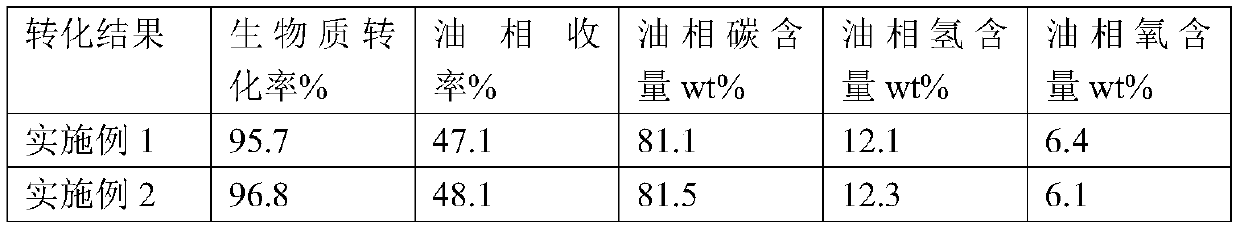

Examples

Embodiment 1

[0471] An embodiment of the present invention provides a waste FeOOH desulfurizer, wherein, based on the total mass of the FeOOH desulfurizer, the content of amorphous iron oxyhydroxide in the FeOOH desulfurizer is 60%, and the content of the carrier diatomite is The content of binder cellulose powder is 10%.

[0472] The above-mentioned catalyst is used as the desulfurization process of coal pyrolysis gas, which is summarized as follows:

[0473] (1) The compressed coal pyrolysis gas is cooled to 30-35°C, mixed with the air from the air pump, and enters the rough desulfurization tower. The process of entering from the bottom and exiting from the top is adopted to avoid liquid water entering the desulfurizer bed. Here only crude hydrogen sulfide removal and part of R-SH and thiophene removal are carried out.

[0474] (2) The gas after rough desulfurization is heated to 110-125°C for hydrolysis, and most of COS and CS2 are hydrolyzed into H2S.

[0475] (3) The temperature of ...

Embodiment 2

[0478] An embodiment of the present invention provides a waste FeOOH desulfurizer, wherein, based on the total mass of the FeOOH desulfurizer, the content of amorphous iron oxyhydroxide in the FeOOH desulfurizer is 80%, and the content of the carrier aluminum oxide is The content is 15%, and the content of the binder scallop powder is 5%. The desulfurization process of gas field water by the above-mentioned catalyst is as follows:

[0479] The above catalyst is loaded in a fixed bed reactor, and the gas field water containing H2S is fully contacted and reacted with it. The contact conditions are: temperature 35°C, pressure 0.2MPa and volume space velocity 10000h-1, the spent catalyst after desulfurization of gas field water The agent is the waste agent of FeOOH desulfurization agent of the present application.

Embodiment 3

[0481] An embodiment of the present invention provides a waste FeOOH desulfurizer, wherein, based on the total mass of the FeOOH desulfurizer, the content of γ-FeOOH in the FeOOH desulfurizer is 45%, and the content of α-FeOOH is 35%. , the content of the carrier molecular sieve is 15%, and the content of the binder scallop powder is 5%.

[0482] The above catalyst removes H from exhaust gas 2 The matrix process of S includes the following steps: 2 S content is 5500mg / cm 3 exhaust gas at 3000h -1 The space velocity is passed into the desulfurization section, and the desulfurization reaction is carried out at 30°C. In the outlet gas of the desulfurization section, H 2 When the content of S is less than or equal to 0.01ppm, the waste in the desulfurization section is collected and used as a catalyst for the liquefaction reaction of biomass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com