Patents

Literature

221results about How to "High degree of resource utilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

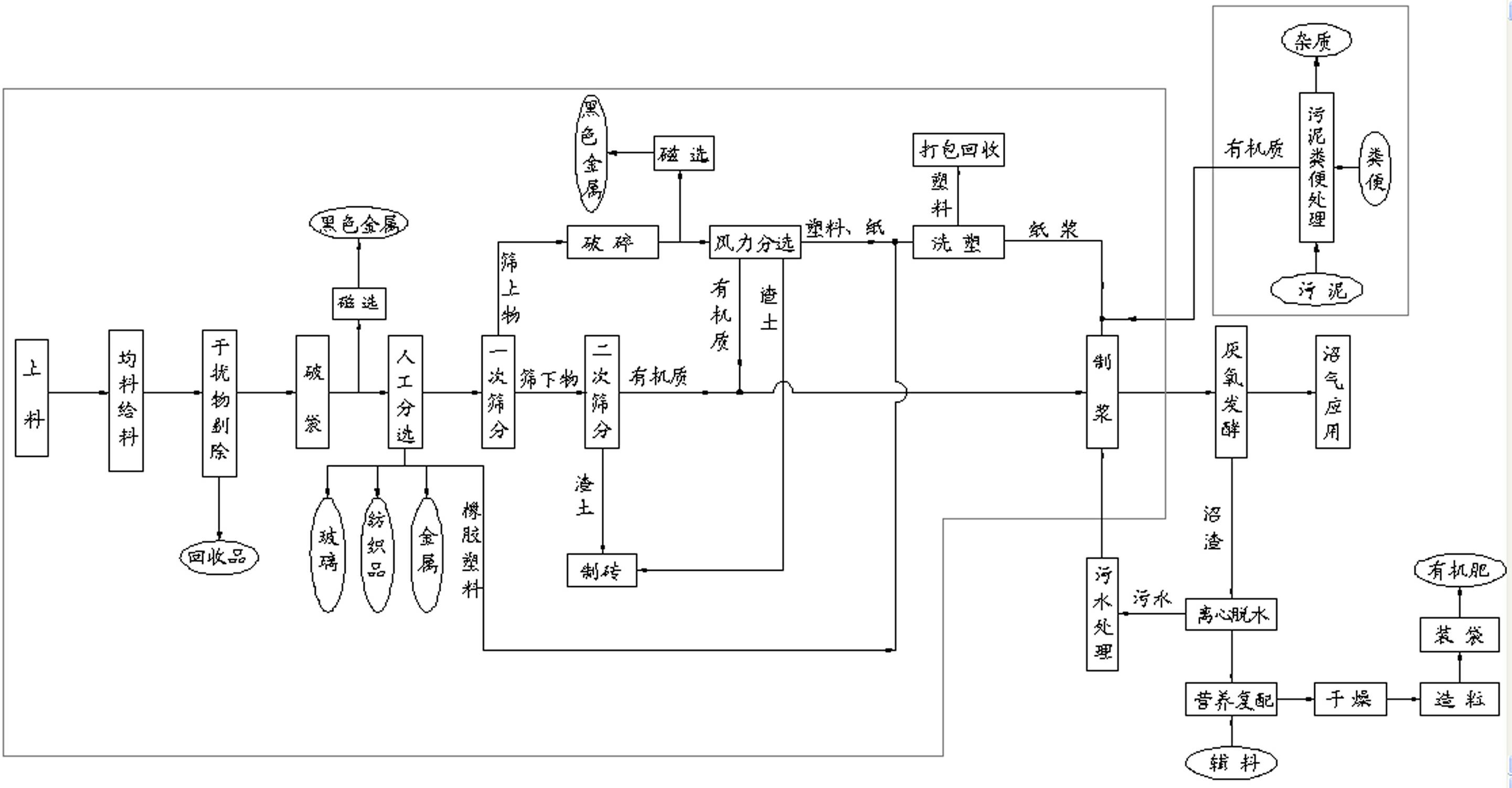

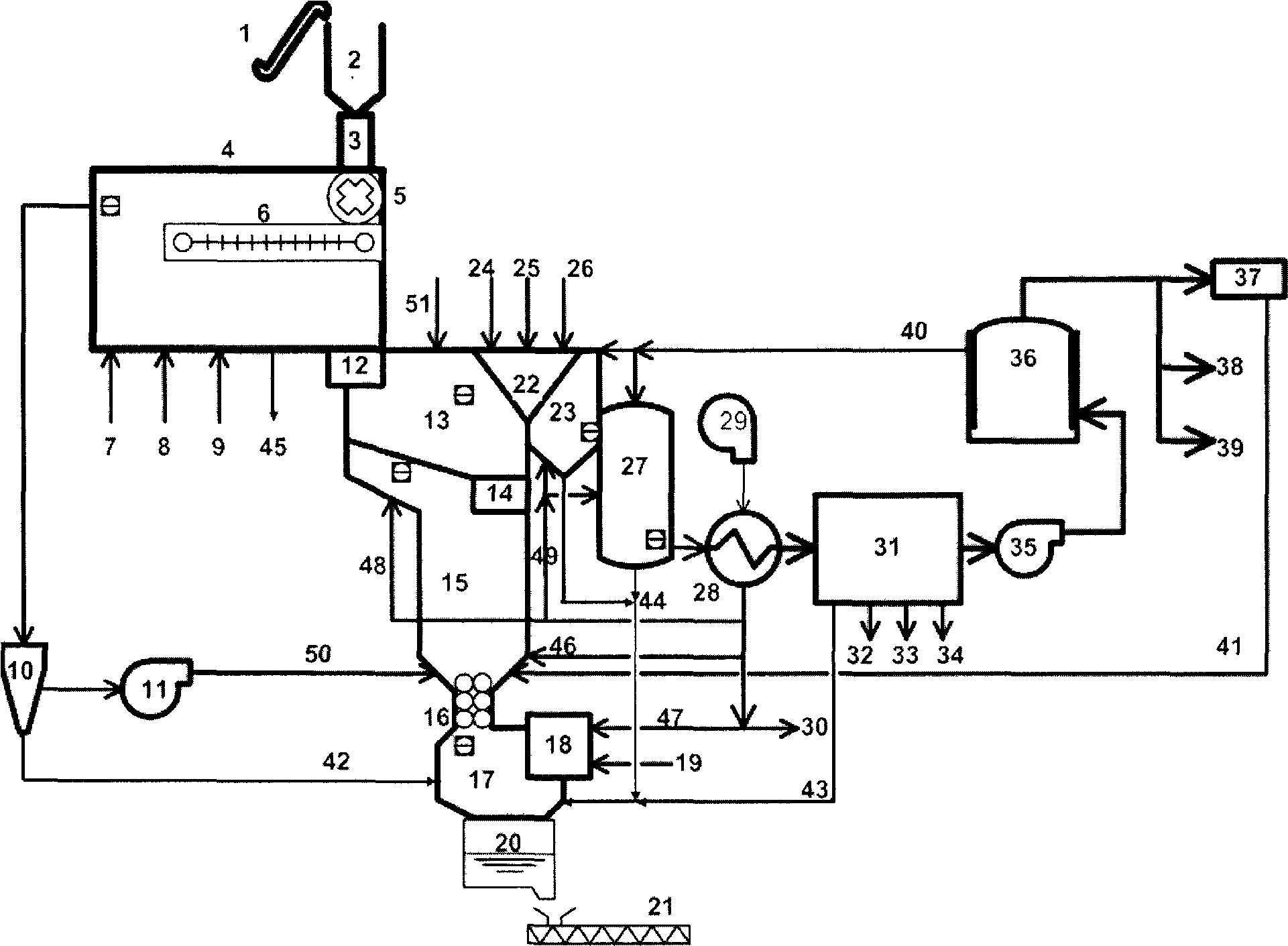

Comprehensive treating system for domestic wastes

InactiveCN102527701AIncrease productionImprove qualityBio-organic fraction processingWaste processingSludgeOrganic manure

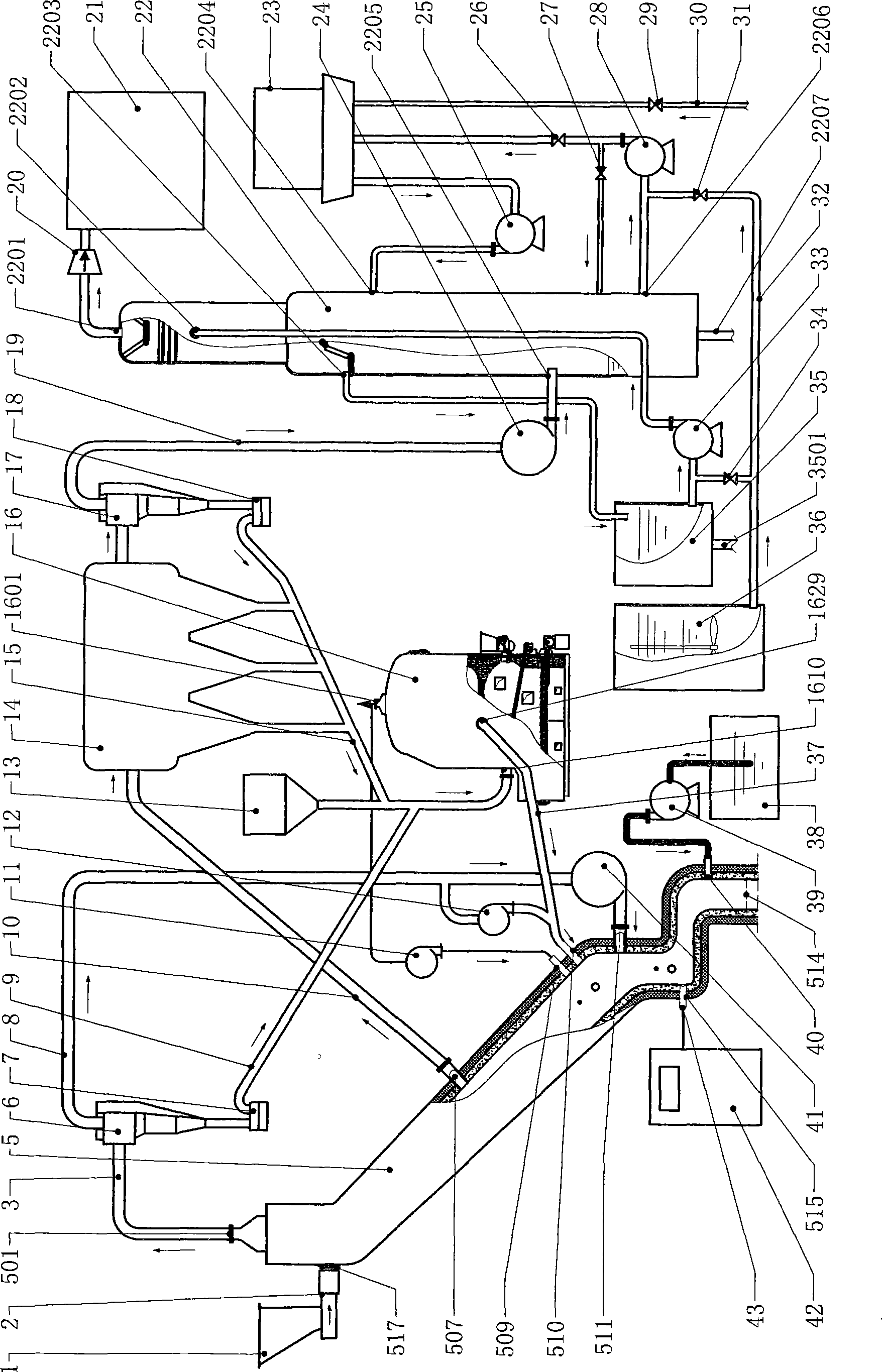

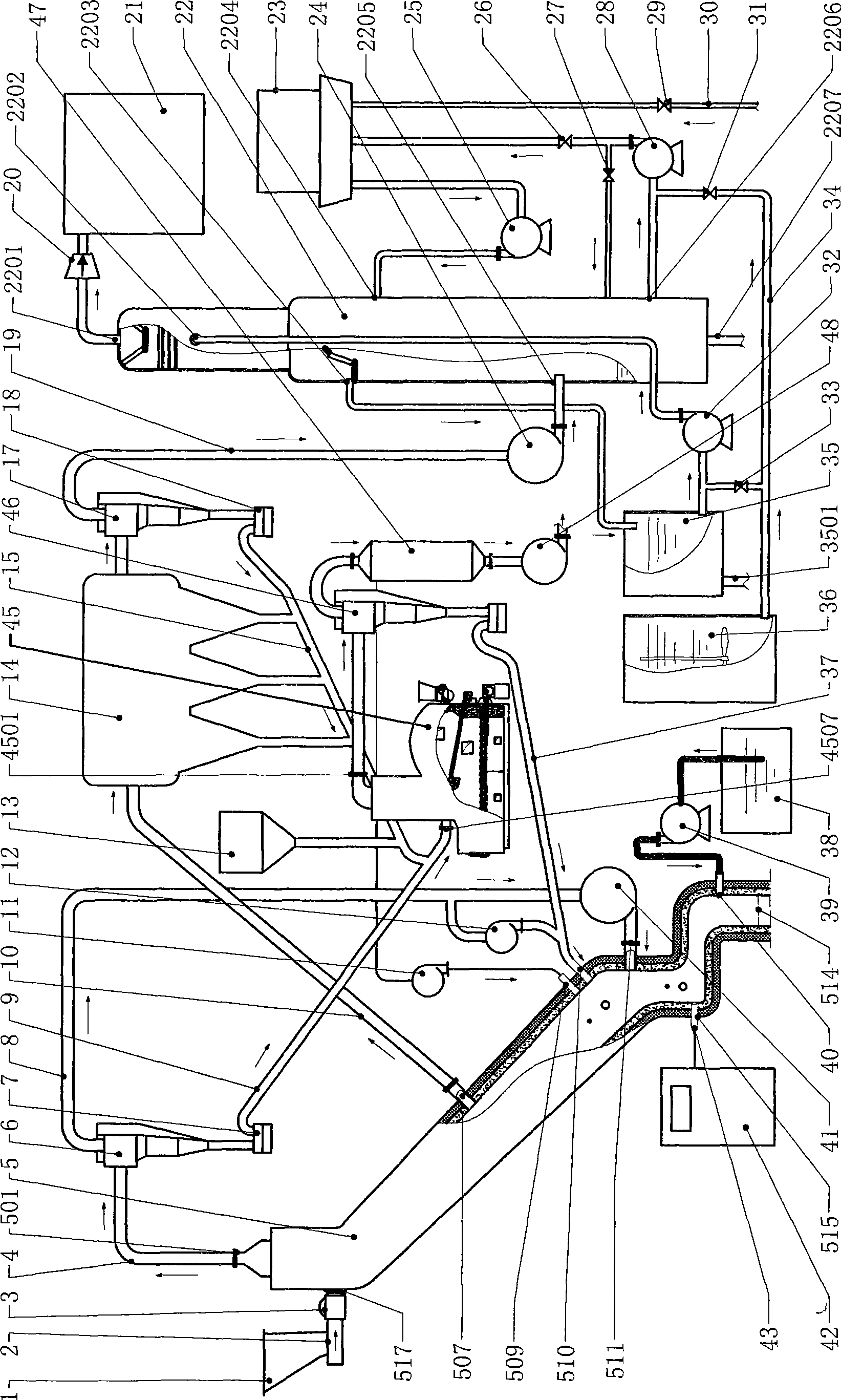

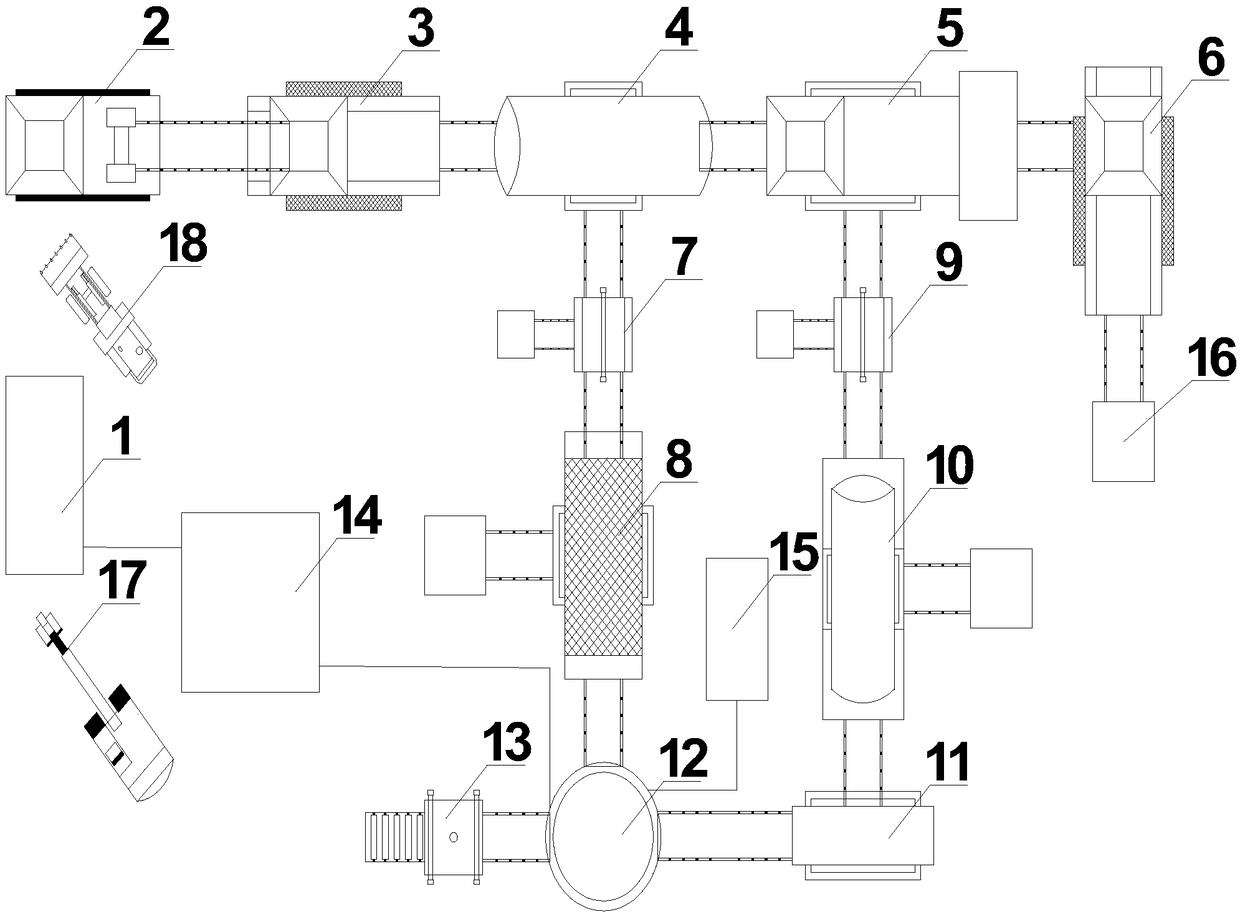

The invention discloses a comprehensive treating system for domestic wastes. Reutilizing comprehensive treatment for mixed wastes is realized by the system according to a comprehensive sorting technology and a combined anaerobic fermentation technology, wherein the advanced sorting techniques, such as, crushing, magnetic separating, sieving, air classifying, and the like, are adopted in the comprehensive sorting technology; reutilized products, such as metal, plastics, organic matters, and the like, are screened out; the screened organic matters are prepared into slurry together with sludge and excrements and are then subjected to the combined anaerobic fermentation; the reutilized products, such as methane, organic fertilizer, and the like, can be produced under the action of anaerobic fermentation; and after the methane is purified, the methane is used for generating power, domestic fuel or vehicle-mounted fuel. According to the technology, the intensified treatment for organic wastes, such as domestic wastes, sludge, excrements, kitchen wastes, and the like, can be realized. The comprehensive treating system is high in mechanical and automated degree. Compared with the prior art, the comprehensive treating system has the advantages of simplification, effectiveness, less labor power, and the like.

Owner:BEIJING HAOHAI TIANJI TECH +1

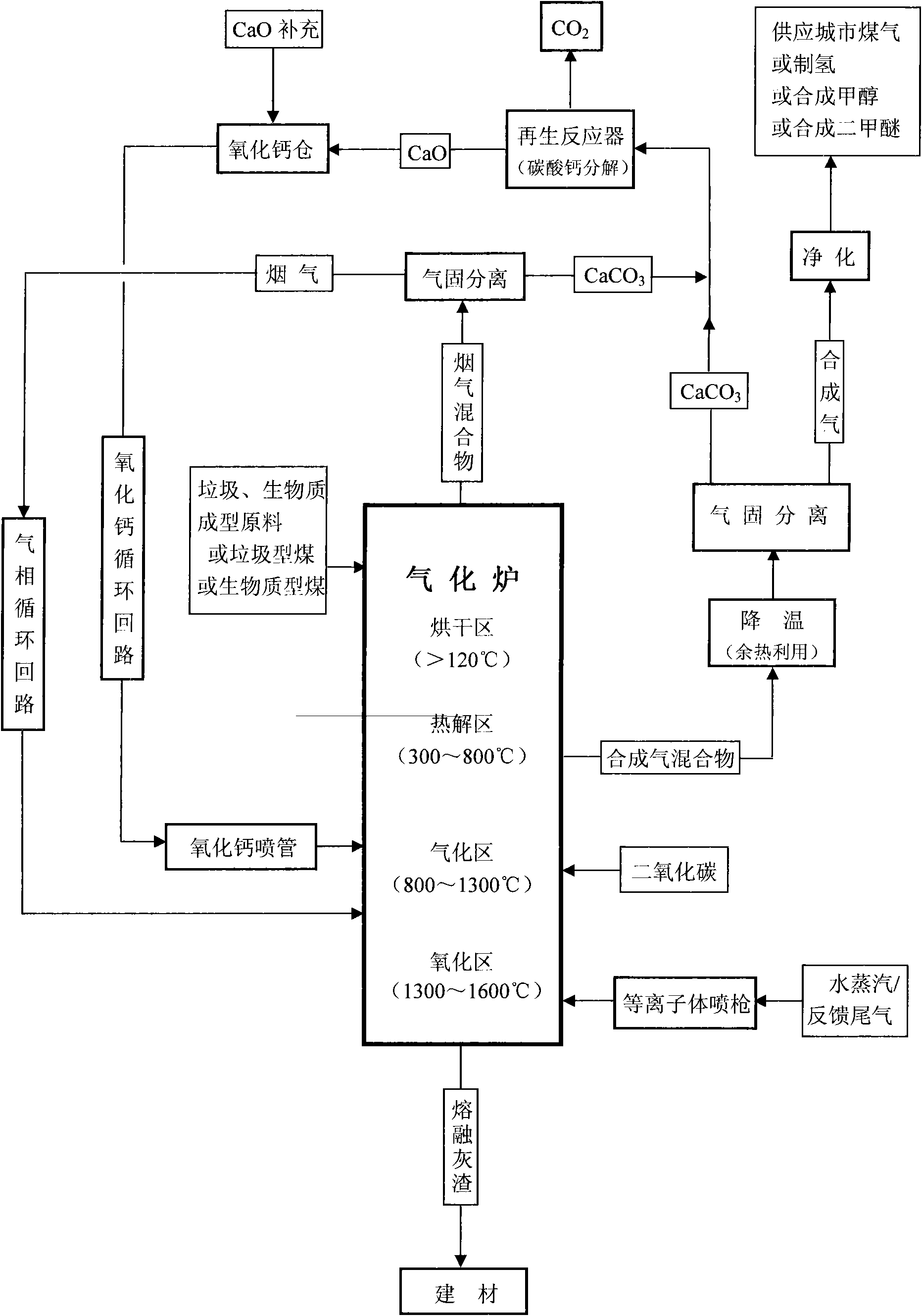

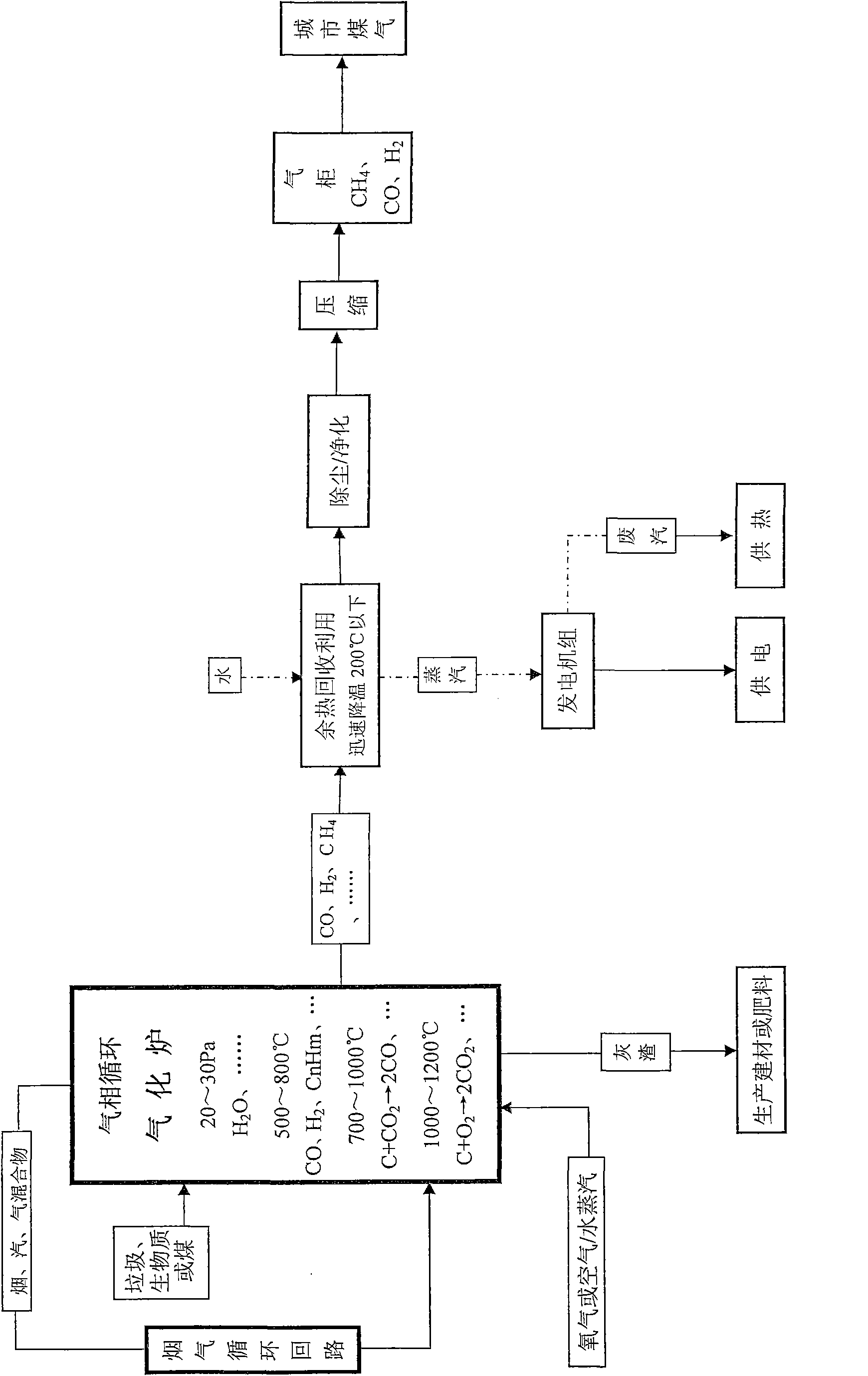

Gasification process for producing synthesis gas from garbage and biomass raw materials

InactiveCN101525118AEliminate pollutionHarmlessHydrogen productionSpecial form destructive distillationGas phaseWater vapor

The invention provides a gasification process for producing synthesis gas from garbage and biomass raw materials, which relates to a gasification processing technique of garbage and biomasses. The gasification process is characterized in that the technological process mainly comprises a raw material solid matter process, a gas phase circulation loop, a calcium oxide circulation loop and a synthesis gas drawing process; one or a mixture of more garbage, the biomasses and coal is sent into a gasification furnace to perform gasification so as to generate the synthesis gas; and simultaneously, calcium oxide is sent into the gasification furnace, an exothermic reaction of absorbing carbon dioxide by the calcium oxide provides the heat required by the gasification reaction in the furnace, and water vapor is sent into a plasma spraying gun and is heated to more than 3,100 DEG C to generate H2, O, O2 and H2O<*> which are sprayed into the gasification furnace to perform reactions with the garbage and the biomasses and supply heat into the furnace. The gasification process adopts a measure to spray the calcium oxide into the furnace to not only greatly reduce the electric energy consumption of the plasma spraying gun, but also improve the quality and the yield of the synthesis gas, thus the aim of transforming the garbage and the biomasses into clean energy can be achieved easily.

Owner:周开根

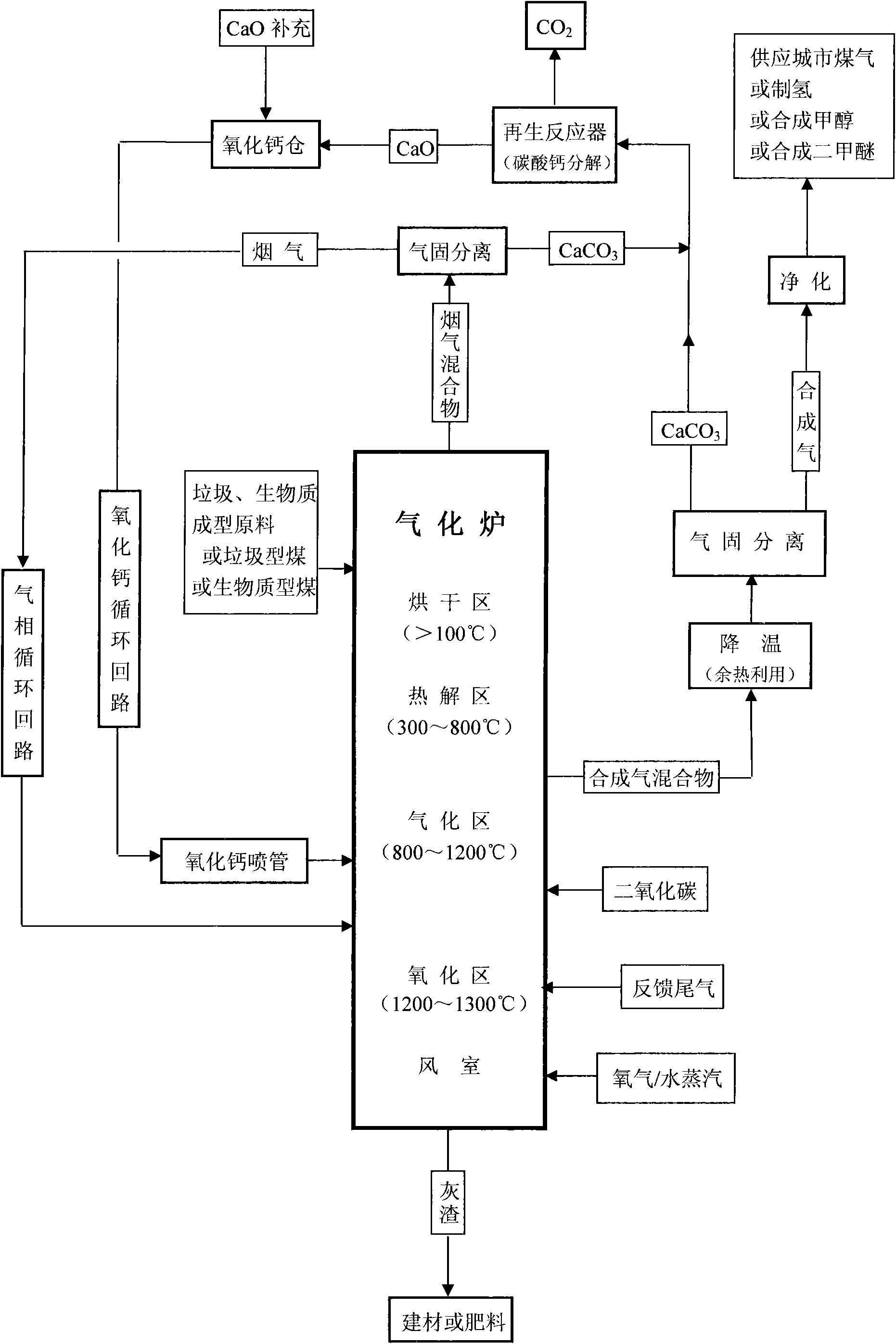

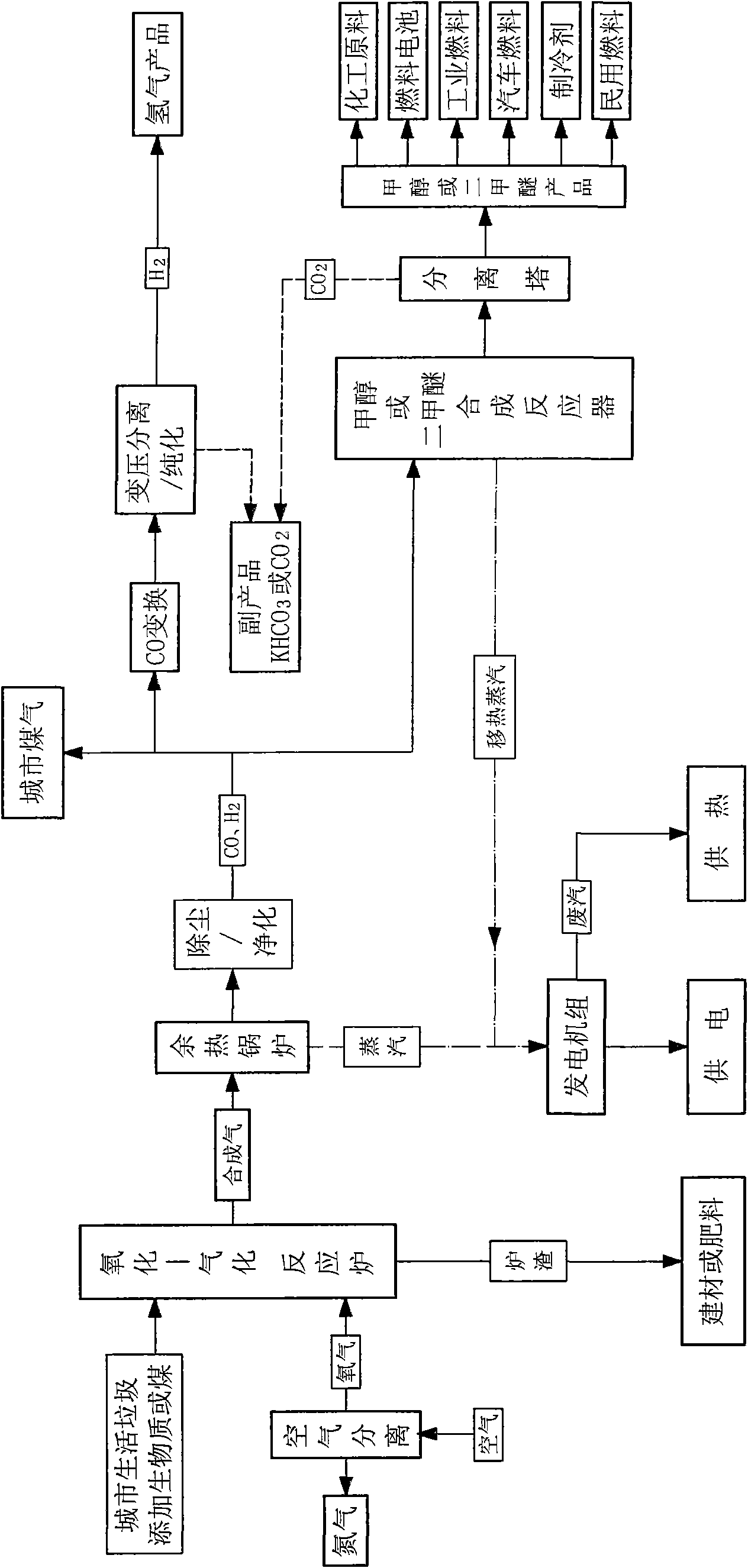

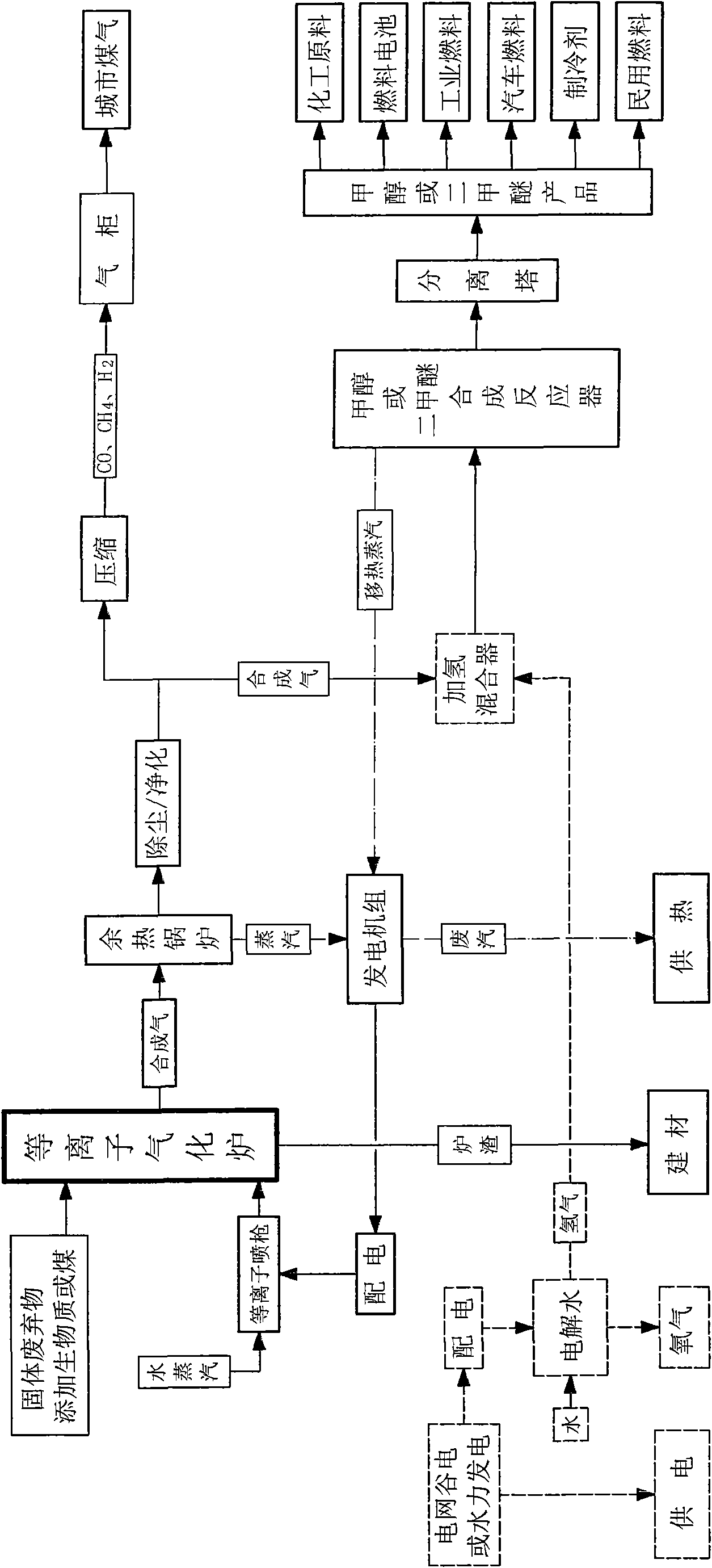

Process, system and device for waste biomass multi-production processing

ActiveCN101565629AEliminate pollutionHarmlessHydrogen separationCombustible gas catalytic treatmentEcological environmentGas phase

The invention relates to a process, a system and a device for waste biomass multi-production processing, in particular to a waste biomass gasification and liquefaction treatment system. The gasification treatment is performed to the waste biomass, the gas is used for producing clean energy and chemical raw materials, the furnace slag is used for producing building materials or fertilizer and the waste heat is used for electric power generation and heat supply so as to realize the environmental-friendly municipal solid waste treatment and the ecological environment protection. The system mainlycomprises a gas-phase circulation gasification furnace, a flue gas circulation air tube, a flue gas circulation fan, a dust-removal / purifying tower and a synthesis reactor and is characterized in that the gas-phase circular reaction is performed to the flue gas in the gasification furnace, the water vapor and the gaseous matter generated during the pyrolysis to obtain hydrogen-rich synthetic gas,and meanwhile, the dioxin (violent in toxicity) is broken up; and the post treatment is performed to the hydrogen-rich synthetic gas to generate city gas, methanol, dimethyl ether or hydrogen. The system has the advantages of full gasification of the solid raw material, no pollutant discharge, extremely low exhaust emission and easy purifying treatment, and the device is flexible in size and is feasible for popularization.

Owner:上海格灵迈环境科技有限公司

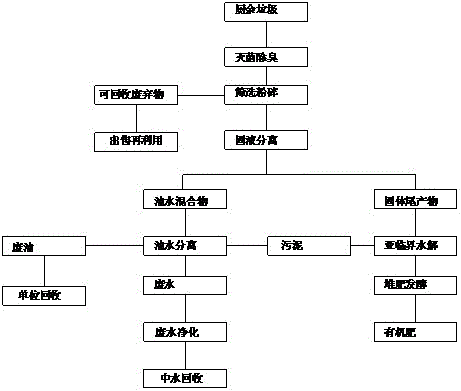

Kitchen garbage disposal method

InactiveCN102873078AStrong processing abilityHigh degree of resource utilizationSolid waste disposalPulverizerSewage

A kitchen garbage disposal method is characterized by including steps of 1, sterilizing, deodorizing, and adding hydrolyzing protease into kitchen waste; 2, screening and crushing the kitchen garbage, sorting wastes such as glass and ceramics which cannot be disposed from deodorized garbage automatically, crushing the residual waste by a crusher; 3, performing solid and liquid separation, separating suspended matters with thickness of 2mm at least and solids and squeezing to dewater to form a tailing product, and discharging oil water into an oil and water separator; 4, performing oil and water separation to separate heavy oil, light oil, sewage and sludge and the like in waste water of the kitchen garbage, feeding the separated oil, sewage and sludge into an oil storage barrel, a sewage treatment device and a sludge collection barrel respectively; 5, purifying sewage by details of feeding the separated sewage into a sewage purifying system which is provided with air flotation and reverse osmosis devices; and 6, treating the tailing solid products by details of hydrolyzing the tailing solid subcritically, subjecting dynamic fermentation to the tailing solid products for two to three days after subcritical hydrolysis treatment, and finally obtaining an organism modifier for soil.

Owner:ZHEJIANG AIKELE ENVIRONMENTAL PROTECTION

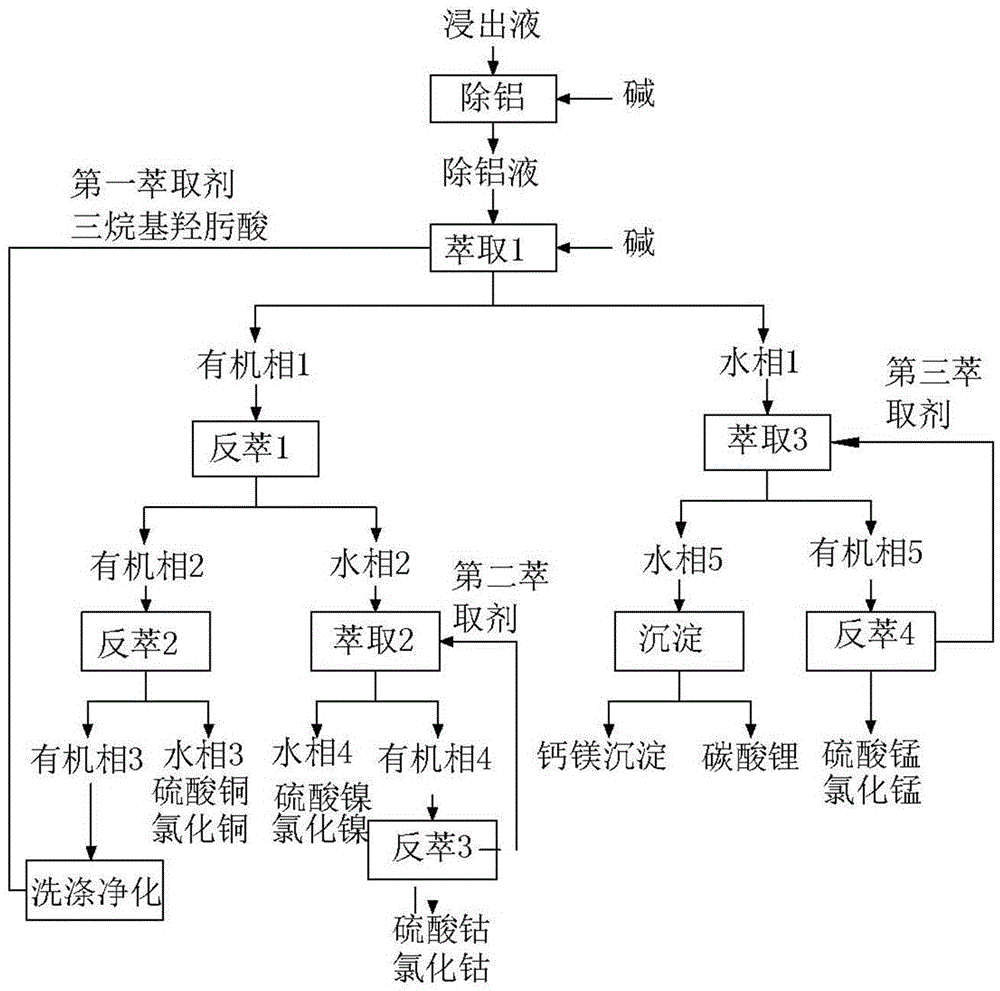

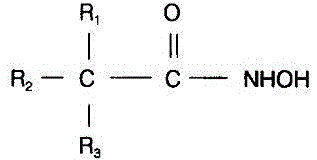

Separation and recovery method for leaching solutions of waste battery material containing nickel, cobalt and manganese

ActiveCN105483382AReduce consumptionEasy to separateWaste accumulators reclaimingProcess efficiency improvementLithiumRecovery method

The invention provides a separation and recovery method for leaching solutions of waste battery material containing nickel, cobalt and manganese. The method comprises the steps of adopting trialkyl hydroxamic acid for extracting solutions to be treated for obtaining organic phases 1 and aqueous phases 1, wherein the nickel and the cobalt are extracted into the organic phases 1, and manganese ions and lithium ions are left in the aqueous phases 1; adopting sulfuric acid or hydrochloric acid for carrying out reverse extraction on the organic phases 1 for obtaining organic phases 2 and aqueous phases 2, wherein the nickel and the cobalt are reversely extracted into the aqueous phases 2; adopting a second extraction agent for extracting the aqueous phases 2 for obtaining organic phases 4 and aqueous phases 4, wherein the cobalt is extracted into the organic phases 4 and the nickel is left in the aqueous phases 4 for forming nickel solutions; adopting the sulfuric acid or hydrochloric acid for carrying out reverse extraction on the organic phases 4 for obtaining cobalt solutions; adopting a third extraction agent for extracting the aqueous phases 1 for obtaining organic phases 5 and aqueous phases 5 after phase splitting, wherein the manganese is extracted into the organic phases 5 and the lithium ions are left in the aqueous phases 5; adopting the sulfuric acid or hydrochloric acid for carrying out reverse extraction on the organic phases 5 for obtaining manganese solutions.

Owner:TSINGHUA UNIV

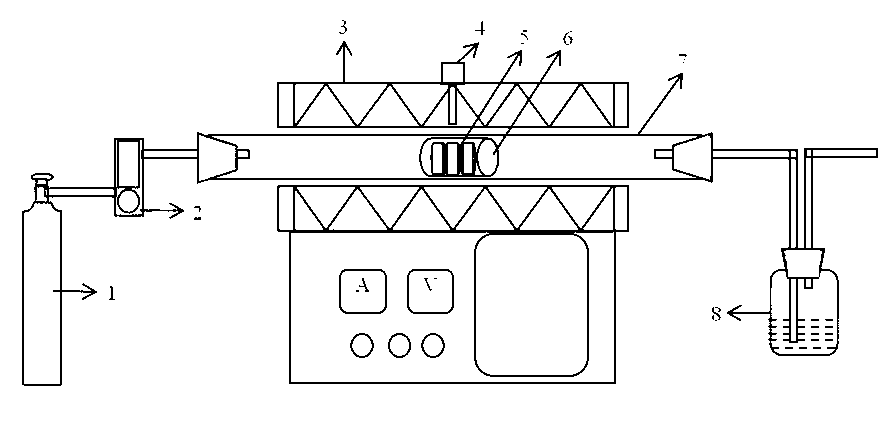

Two-stage plasma gasifying, melting and cracking method and device of waste containing organic matters

ActiveCN102000691ANo emissionsComplete gasificationSolid waste disposalGlass furnace apparatusGeneration rateHigh energy

The invention relates to a treatment method of waste containing organic matters, in particular to two-stage plasma gasifying, melting and cracking method and device of the waste containing organic matters, belonging to the field of gasifying, melting and cracking techniques. In the invention, the serious defects of high energy consumption of the waste containing organic matters and more flying ash during the plasma arc melting and cracking are solved, thereby thoroughly utilizing the energy of the organic matters and maximizing the treating efficiency, thoroughly cracking the tar, reducing the generation rate of Dioxin, obtaining synthesis gas with high quality and high heat value as much as possible, providing guarantee for the subsequent gasification power generation, the hydrogen energy recovery or the production of green liquid fuel, simultaneously finishing one-step recovery of noble metals and direct utilization of glass bodies in the field of building materials, laying foundation for the large-scale commercial development and application of the energy of the waste containing organic matters, and thoroughly solving the possible pollutant discharging problem in the gasifying process of the organic matters, particularly the dangerous waste.

Owner:HOOTECH

Plasma and calcium oxide cooperation-gasified rubbish biomass gasification method and equipment

InactiveCN101469865AReduce contentHigh calorific valueSpecial form destructive distillationIncinerator apparatusNew energyWater vapor

A method and apparatus for gasifying a plasma and calcium oxide cooperating with gasified rubbish biomass, relating to the rubbish processing and new energy resource field, characterized in that, the rubbish biomass is fed into a suspending fluidized bed thermal decomposition furnace, meanwhile, the heated fluidization material is circularly fed into the thermal decomposition furnace and is mixed with the raw materials to transfer heat, so that the rubbish biomass raw material is heated to decompose, and then the thermal decomposed gas and solid carbocoal is fed into a turbulent fluidized bed gasification furnace, the water vapor is heated over 3100 DEG C and is sprayed into the gasification furnace by a plasma spray gun, the water vapor is reacted with the solid carbocoal to generate carbon monoxide and hydrogen gas, the required heat of the gasification reaction in the gasification furnace can be provided by the plasma spray gun and an exothermal reaction of the calcium oxide absorbing the carbon dioxide. According to the invention, synthesis gas can be produced by rubbish and biomass raw materials under the condition without air or oxygen, the main ingredients of the synthesis gas are hydrogen gas and carbon monoxide which can be directly used for city gas or producing hydrogen gas, methanol and dimethyl ether and so on clean energies.

Owner:衢州市广源生活垃圾液化技术研究所

Multilevel-control polyradical biomass-gasification energy regeneration system

ActiveCN101519604AImprove gasification efficiencyHigh reforming efficiencyBiofuelsEnergy inputOxygenMoisture

The invention provides a multilevel-control free-polyradical biomass-gasification energy regeneration system, which can transform extensive biomass and carbon-containing raw materials, including energy crops, agriculture-forestry byproducts, organic waste, industrial and dangerous waste and the like, into high-grade energy. The system is designed for continuous operation. Gasification comprises the following steps of performing pretreatment, performing pyrolysis, transforming carbon, fusing ash, cracking tar, reforming syngas and utilizing waste heat, wherein the steps are precisely controlled one by one and integrated so as to achieve optimum; moisture from the pretreatment of the materials is led into a carbon-transforming unit so as to realize oxygen-free pyrolysis; gasification gas is in contact with a large number of free polyradicals in a free-polyradical reaction-accelerating unit; and the obtained product is purified and then enters downstream application, such as power generation, hydrogen production and biomass methanol / ethanol production. The system has the advantages of needing no auxiliary fuel, maximizing gasification efficiency and thoroughly cracking tar and clearing pollutants, and is an upstream technique for the application of biomass renewable energy. As energy utilization meets all strict environmental protection standards, the system is also an energy-saving environment-friendly technique for non-incineration harmless treatment.

Owner:浙江瑞拓展泰再生能源有限公司

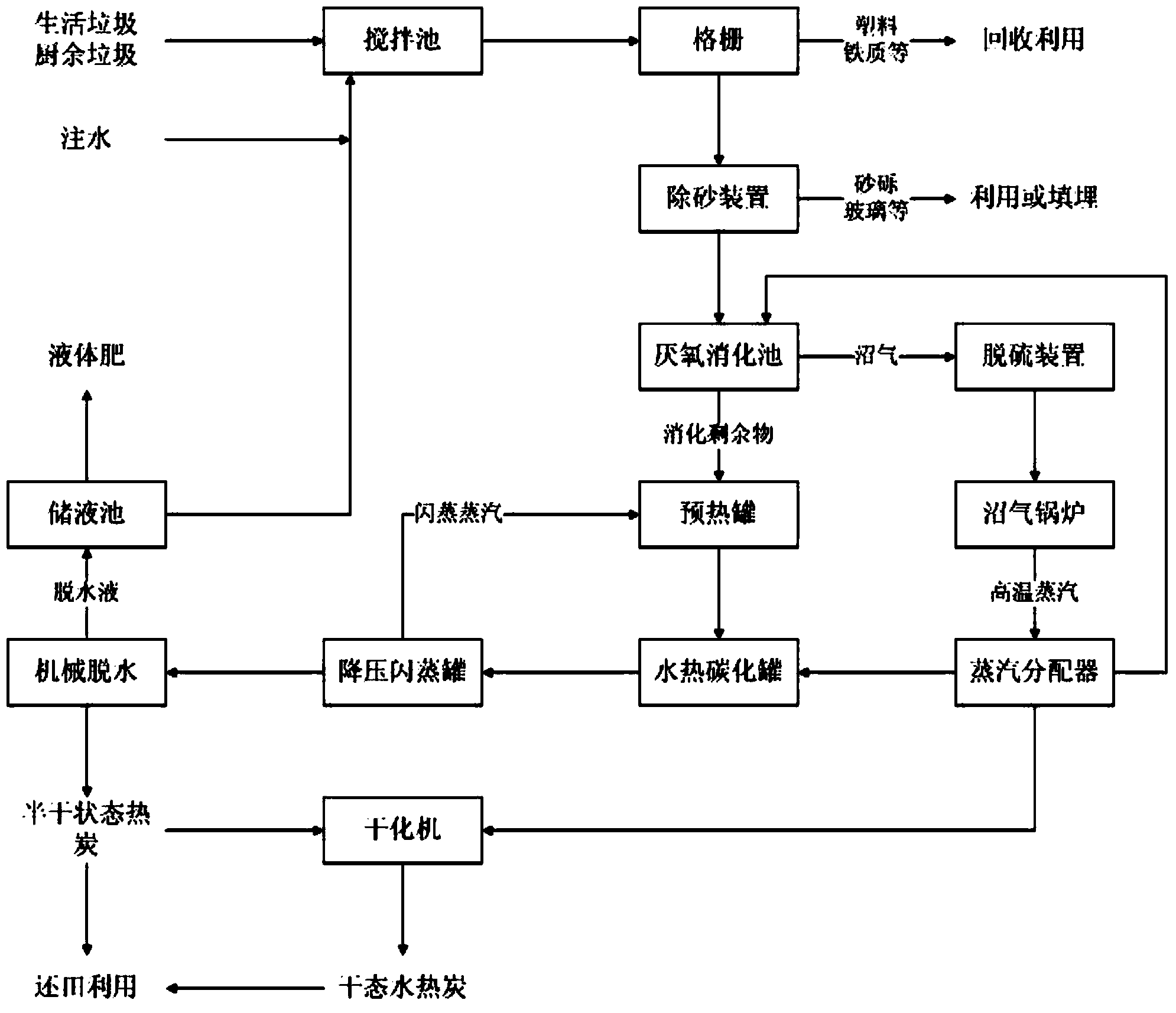

Domestic waste comprehensive treatment method based on anaerobic digestion and hydrothermal carbonization

ActiveCN103722002AIncrease energy densityHigh agronomic valueBio-organic fraction processingSolid waste disposalResource recoveryEnergy regeneration

The invention relates to a municipal solid waste reduction, energy regeneration and recycling method, and discloses a domestic waste comprehensive treatment method based on anaerobic digestion and hydrothermal carbonization. The domestic waste comprehensive treatment method comprises the following steps: slurry treatment, anaerobic digestion, hydrothermal carbonization, dewatering and drying. The domestic waste and kitchen waste are subjected to reduction, energy regeneration and recycling treatment, so that the domestic waste comprehensive treatment method is high in resource recycling degree, low in operation cost, clean and environment-friendly, and can ensure that pathogenic microorganisms in the wastes are completely killed, so that repugnant substances are converted and decomposed, and the domestic waste comprehensive treatment method has good economic value and social value.

Owner:HANGZHOU HUHUI ENVIRONMENTAL PROTECTION TECH

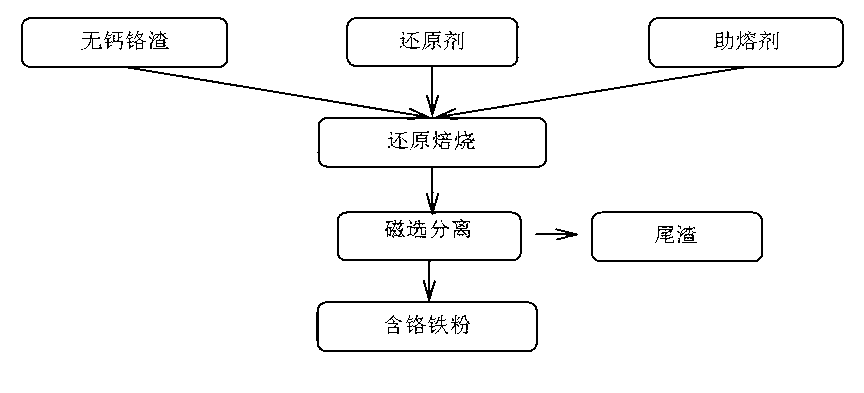

Method for preparing chromium-containing iron powder by direct reduction of calcium-free chromium slag

ActiveCN102796879AHigh degree of resource utilizationEfficient separationProcess efficiency improvementIron powderMixed materials

The invention discloses a method for preparing chromium-containing iron powder by direct reduction of calcium-free chromium slag, which belongs to the technical field of comprehensive utilization of chromium slag. The method comprises the following steps of: firstly, material preparation, wherein the calcium-free chromium slag is mixed with a reducing agent and fluxing agents comprising alumina, and the four-element alkalinity m(MgO+CaO) / m(SiO2+Al2O3) of the mixed material is equal to 0.9 to 1.3; secondly, agglomeration, wherein the mixed material is pressed or pelletized to obtain agglomerates; thirdly, reduction roasting, wherein the agglomerates are roasted in reducing atmosphere at a reduction temperature of 1,250 to 1,350 DEG C for 30 to 240 minutes; fourthly, crushing and fine grinding, wherein the roasted agglomerates are crushed and ground to be fine; and fifthly, magnetic separation, wherein the finely ground powder is subjected to magnetic separation at magnetic induction intensity of 100 to 200 mT, thereby separating the chromium-containing iron powder. According to the method, the calcium-free chromium slag is completely detoxified and fully recycled, the grade sum of calcium and iron in the prepared chromium-containing iron powder is over 80 percent, the chromium recovery rate and the iron recovery rate are respectively over 78 percent, and the method is low in energy consumption and free from secondary pollution.

Owner:HUBEI ZHENHUA CHEMICAL CO LTD +1

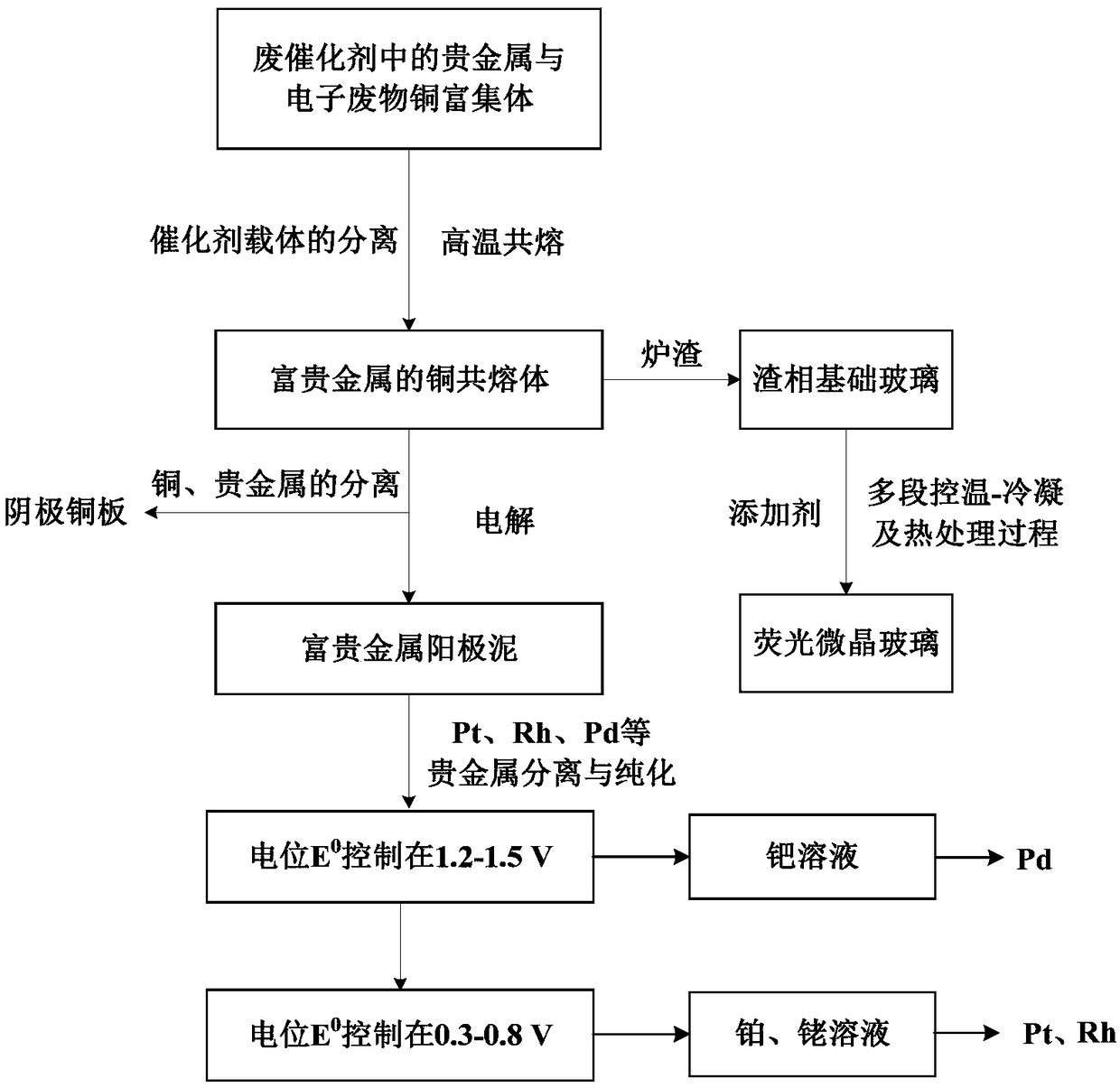

Method for collaborative resource between waste circuit board and automobile tail gas waste catalyst

ActiveCN109136532AEasy to separateEnable co-processingProcess efficiency improvementElectrostatic separationEngineering

The invention discloses a method for collaborative resource between a waste circuit board and an automobile tail gas waste catalyst. The method comprises the following steps: firstly, obtaining a copper-rich collective through performing crushing, magnetic separation and high voltage electrostatic separation on the waste circuit board; crushing the automobile tail gas waste catalyst to obtain waste catalyst powder; mixing the copper-rich collective and the waste catalyst powder to obtain mixed powder; adding a reagent in a certain amount of mixed powder in proportion, placing in a high-temperature muffle furnace for reaction and cooling to a room temperature after the completion of the reaction to obtain a product of which an upper layer is a glass layer, and a lower layer is a copper layer; separating the copper layer from the glass layer, taking out, crushing, then placing the glass layer in the muffle furnace for heat treatment; after the completion of the treatment, pouring microcrystalline glass liquid into a mold while the microcrystalline glass liquid is still hot, reducing the temperature and forming; after a room temperature is lowered, preparing out fluorescent microcrystalline glass. In the process, the recovery rate of precious metals exceeds 98 percent, the precious metals are enriched for 20 times or more, and the obtained fluorescent microcrystalline glass can betaken as an LED fluorescent lamp and other materials. To sum up, the method has the characteristics of being efficient, environmentally friendly and high in resource degree and is suitable for large-scale industrial application.

Owner:SHANGHAI JIAO TONG UNIV

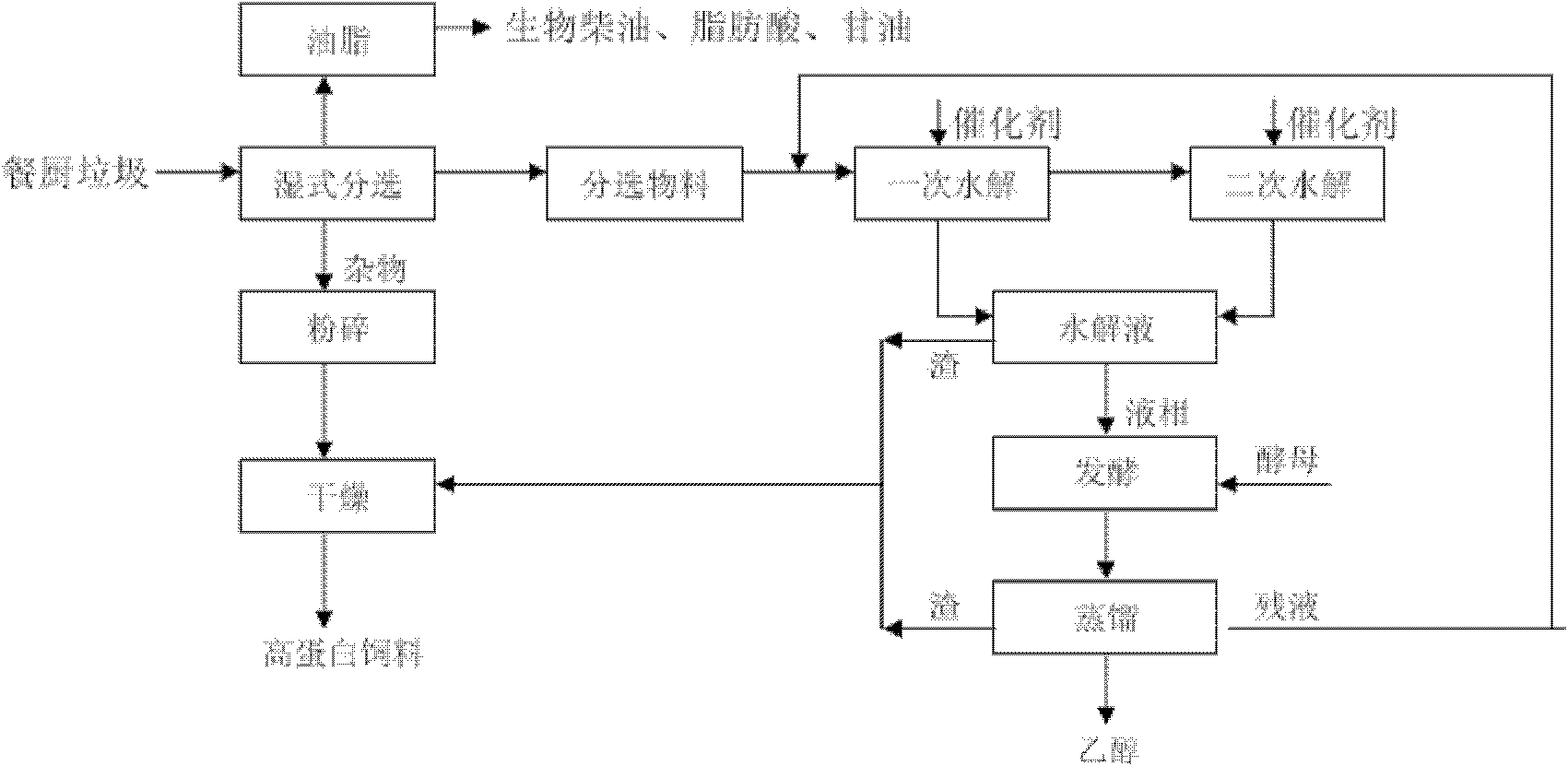

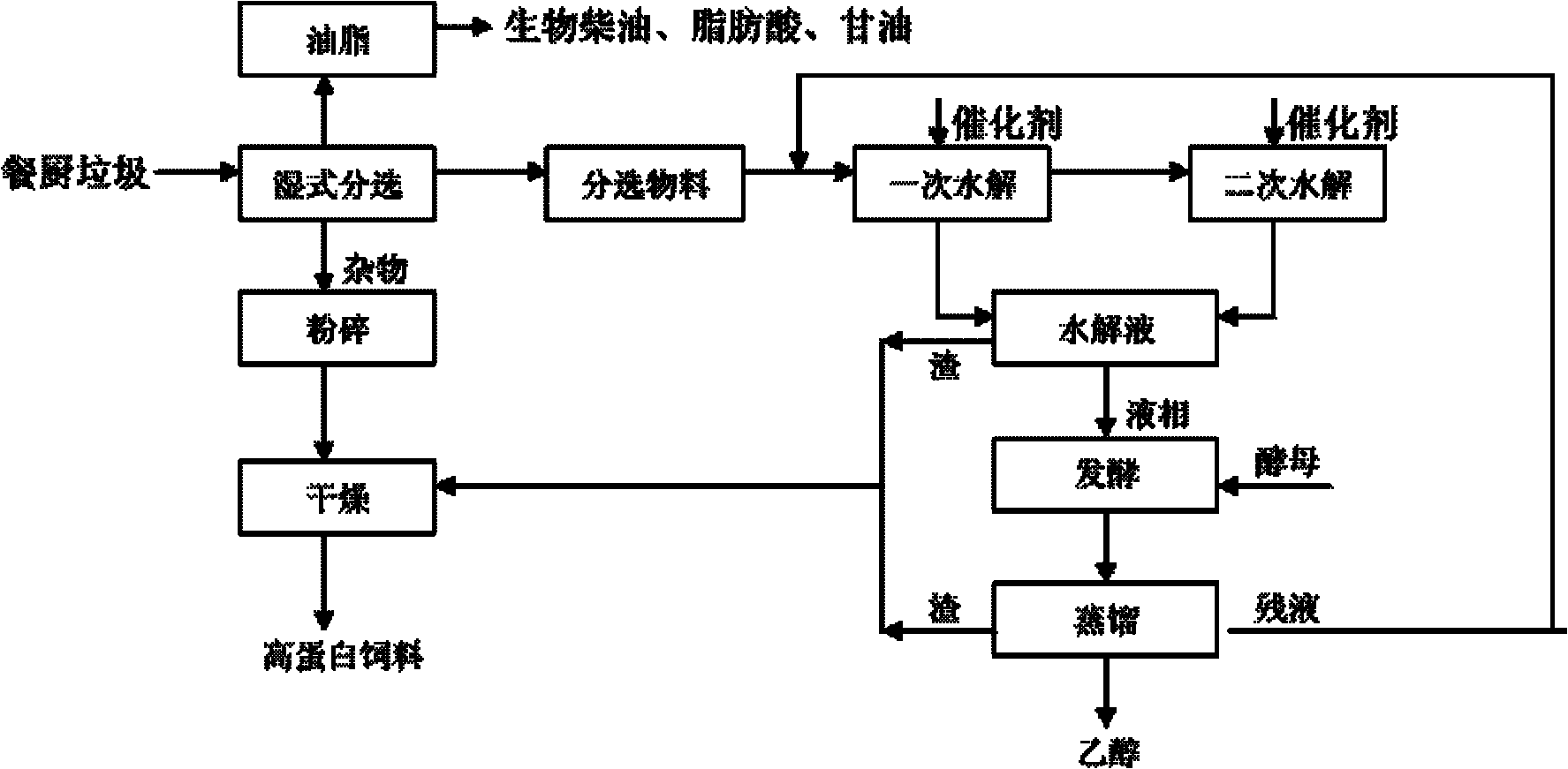

Recycling method for cleaning and processing kitchen waste

InactiveCN101890423AIncrease the degree of hydrolysisCompletely hydrolyzedFatty oils/acids recovery from wasteSolid waste disposalOil and greaseOperational costs

The invention relates to a waste processing method, in particular to relate to a recycling method for cleaning and processing kitchen waste and comprising the following steps: sorting, separating and recovering grease, performing secondary hydrolysis on materials after grease separation and recovery, further fermenting hydrolysis liquid and preparing solid residue obtained by sorting, hydrolysis and fermentation into feed. The invention has the following beneficial effects: economic and reasonable technologies suitable for industrialized application are adopted, thus greatly lowering processing cost; regenerative recycled products can be prepared with wide application and high additional value; and the production process is clean and environment-friendly, closed cycle of materials can be realized, secondary pollutants are prevented, and the recycled products have wide application, low operation cost and high economic benefit.

Owner:武汉市金书环保科技股份有限公司

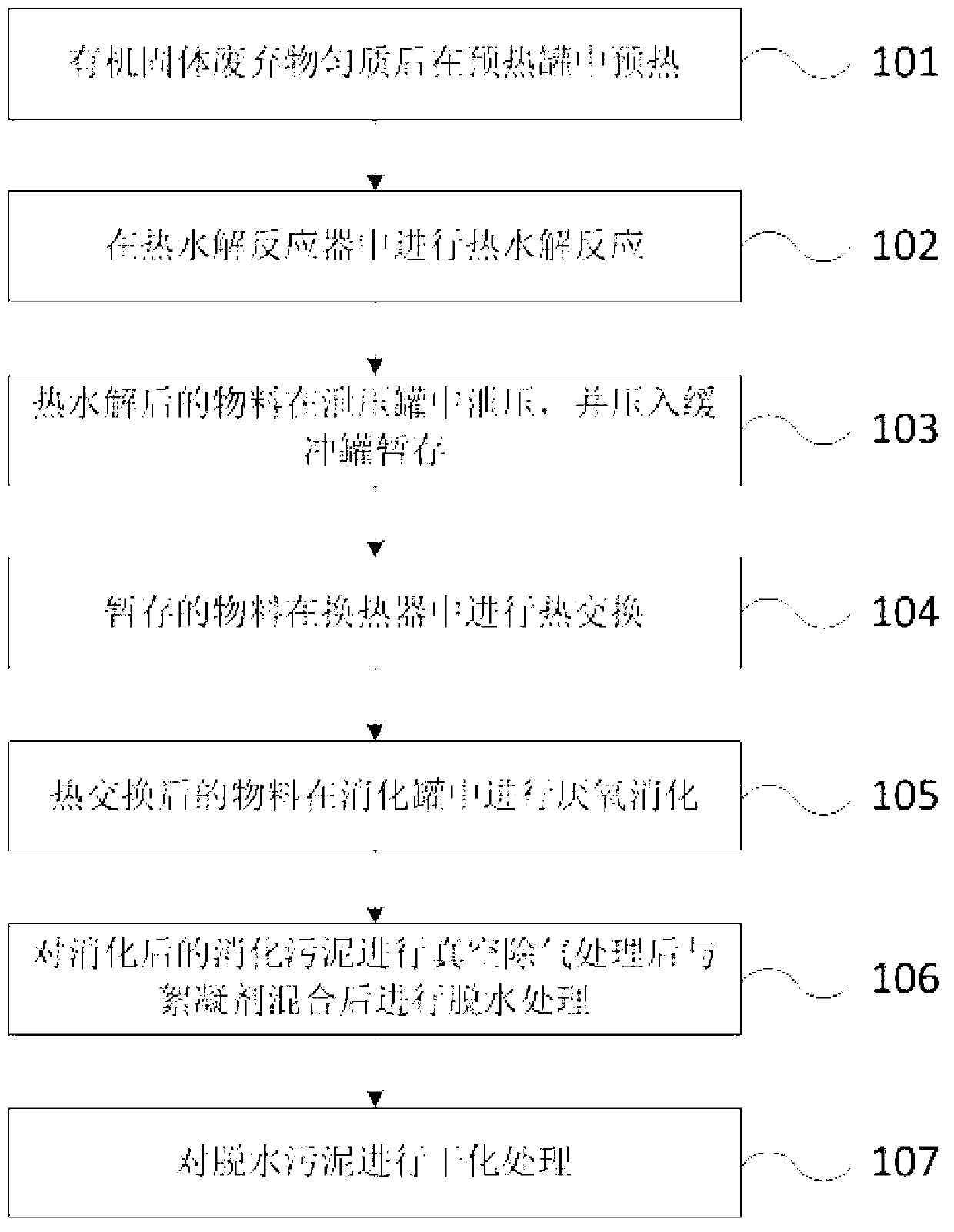

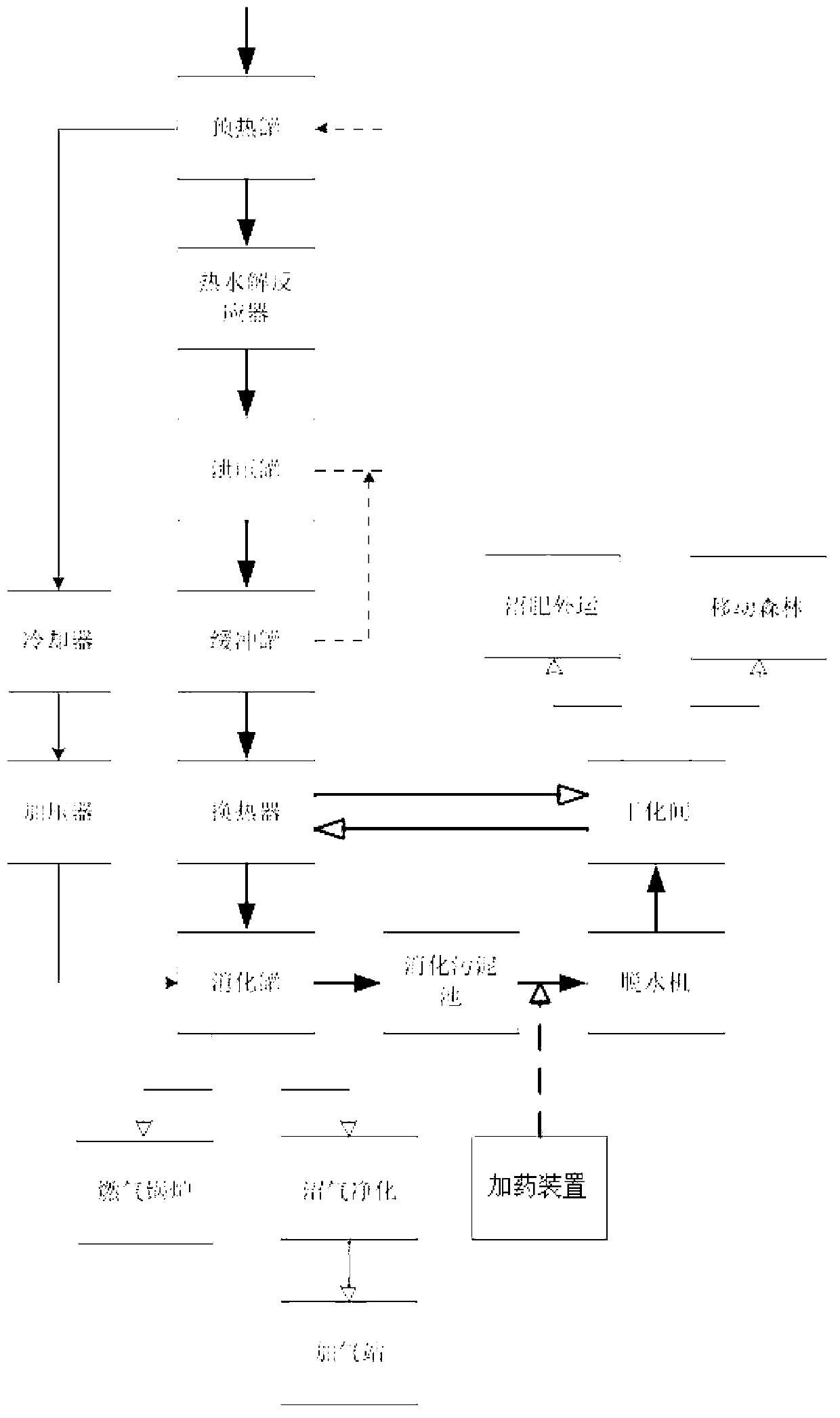

Treatment method of organic solid waste

InactiveCN103274572AImprove dehydration efficiencyIncrease drynessSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisBuffer tankAerobic digestion

The invention relates to a treatment method of organic solid waste. The treatment method comprises the following steps of: homogenizing the organic solid waste and then preheating, carrying out a thermal hydrolysis reaction on the preheated organic solid waste, then pushing the material into a depressurization tank and a buffer tank to be subjected to primary depressurization and secondary depressurization and then temporary storage, then carrying out heat exchange on the material, carrying out anaerobic digestion on the material subjected to heat exchange, carrying out vacuum degassing treatment on digested sludge in a digested sludge tank, dehydrating the treated digested sludge to form dehydrated sludge, conveying the dehydrated sludge to a drying room to be dried, and producing dried biogas residue. According to the treatment method of the organic solid waste, high temperature hydrolysis and anaerobic digestion technologies are adopted, the problems that resource is wasted when a burning method is adopted and secondary pollution can be easily caused when a burying method is adopted can be avoided, digestive efficiency in follow-up anaerobic digestion is improved, standing time of an anaerobic digestion process is also reduced, and sludge subjected to anaerobic digestion is subjected to vacuum degassing, so that carbon dioxide and ammonium nitrogen in the digested sludge can be effectively removed, and sludge dehydration efficiency is improved.

Owner:HUBEI GUOXIN TIANHUI ENERGY

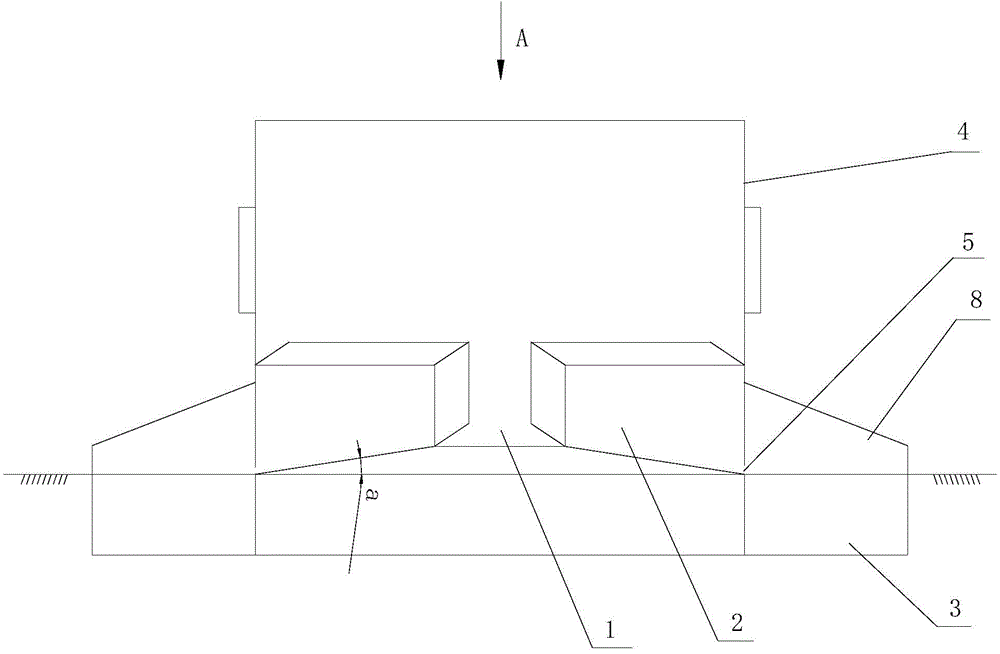

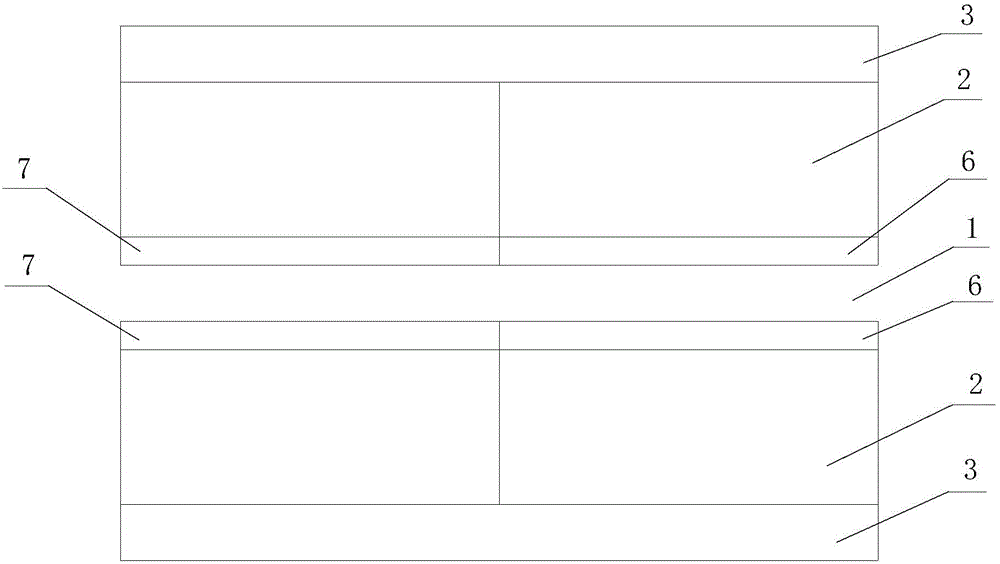

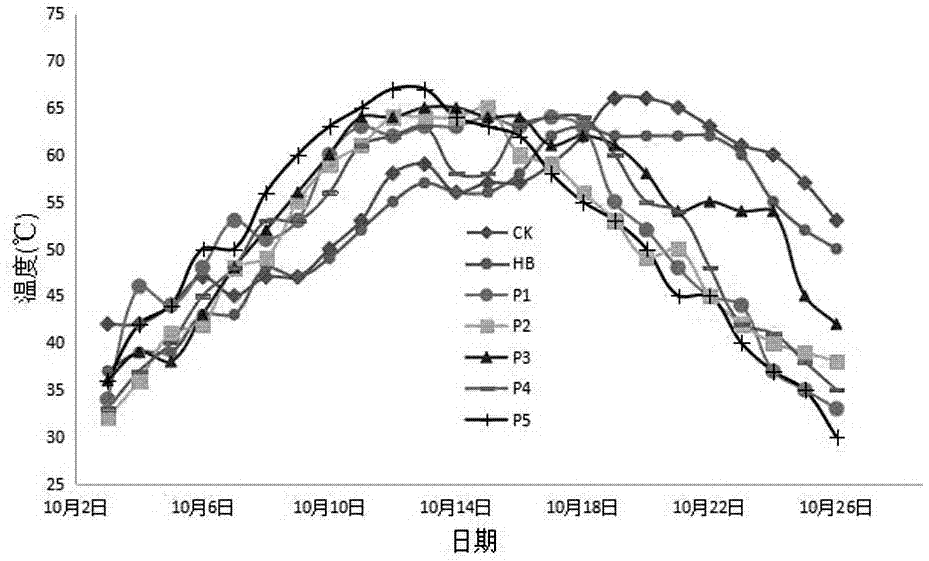

Hog house structure with external fermentation bed and manufacturing method of padding layer for fermentation bed

InactiveCN103947567AOvercoming technical difficulties in swine mold poisoningImprove cleanlinessAnimal housingEngineeringSewage

The invention discloses a hog house structure with an external fermentation bed and a manufacturing method of a padding layer for the fermentation bed. The hog house structure comprises a passage, a swine bed and a fermentation bed, wherein the passage and the swine bed are arranged indoor, the fermentation bed is arranged outdoor, the passage is arranged on the inner side of the swine bed, a hog house external wall is arranged on the outer side of the swine bed, the fermentation bed is arranged at the exterior of the exterior wall of the hog house and is parallel to the swine bed, a wall body sewage outlet is formed in the bottom of the exterior wall of the hog house, and the fermentation bed is communicated with the swine bed through the wall body sewage outlet; a padding layer is paved in the fermentation bed. The padding layer is formed through mixing, fermenting and paving saw dust chips, corn straws, bergmeal and an auxiliary leavening agent. According to the hog house structure, the fermentation bed and the swine bed are arranged in a separated way, the manufacturing method for components in the padding layer is changed, the cleanliness of the swine bed is effectively maintained, various germs affected by hogs due to the direct contact with a fermentation bed can be avoided, and the technical difficulty of mycetism of the hogs due to the fact that the hogs eat mycete-carried padding of the fermentation bed can be overcome.

Owner:HUNAN AGRICULTURAL UNIV

Food residue and sludge mixing anaerobic treatment method and system

InactiveCN102352380AAffects oil contentSolve processing problemsBio-organic fraction processingBiological substance pretreatmentsElectricityOil and grease

The invention belongs to the technical field of food residue and municipal sludge treatment. A food residue and sludge mixing anaerobic treatment method comprises a food residue pretreatment and anaerobic digestion treatment, wherein the food residue pretreatment is that: the food residue with the grease content less than 8% is transferred to a breaking and separating unit to break and separate, and is broken until the granular is less than 30mm, and the serous liquid is obtained for spare use; and the anaerobic digestion treatment is that: the serous liquid which is obtained after the food residue pretreatment is transferred to an anaerobic digestion device, meanwhile, the sludge also enters the anaerobic digestion device, the solid content of the mixing material is 8-12%, stirring and mixing are carried out in the anaerobic digestion device, so the anaerobic digestion is carried out. The invention has the following characteristics: 1, the food residue which is not classified can be treated, the invention is in accordance with the urban food residue source classification current situation in China; 2, the food residue does not need oil-water separation, is directly mixed with sludge to enter the anaerobic digestion system, so that biodegradation is carried out for producing methane, the technological equipment is simple, and the recycling degree is high; and the heat and electricity consumption are saved, and the operation cost is low.

Owner:LIDA ENVIRONMENT ENG DALIAN ECONOMIC TECH DEV ZONE

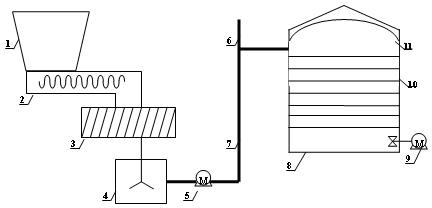

Comprehensive recycling method for high-arsenic soot

The invention discloses a comprehensive recycling method for high-arsenic soot. The method specifically comprises the following steps that two-stage leaching is conducted on the high-arsenic soot; two-stage leaching liquid enters a cyclone electrolytic system for extracting copper, and a copper product is obtained through two-stage deep decoppering; then arsenic removal is conducted, and copper-arsenic slag and a zinc sulfate solution are obtained; the copper-arsenic slag is subjected to alkaline leaching, oxidization-crystallization, prereduction and the cyclone electrolytic technology, and simple substance arsenic is produced; lead and silver in high-pressure leaching residuals are subjected to lead conversion through ammonium bicarbonate and ammonium hydroxide, the lead is made to enter feed liquid, and a lead-containing solution is obtained after solid-liquid separation to recycle the lead; and the leaching residuals are leached through thiourea, a silver-containing solution is obtained, and silver powder is obtained through replacement. According to the comprehensive recycling method, various valuable metals in the high-arsenic soot are recycled through different techniques; and meanwhile, the techniques are combined organically, basically no waste slag or waste water or waste gas or other matter is generated from the whole system, the recycling degree is high, the techniques are advanced, the recycling rate is high, the recycling cost is low, and the comprehensive recycling method has quite remarkable environment protection significance.

Owner:浙江科菲科技股份有限公司

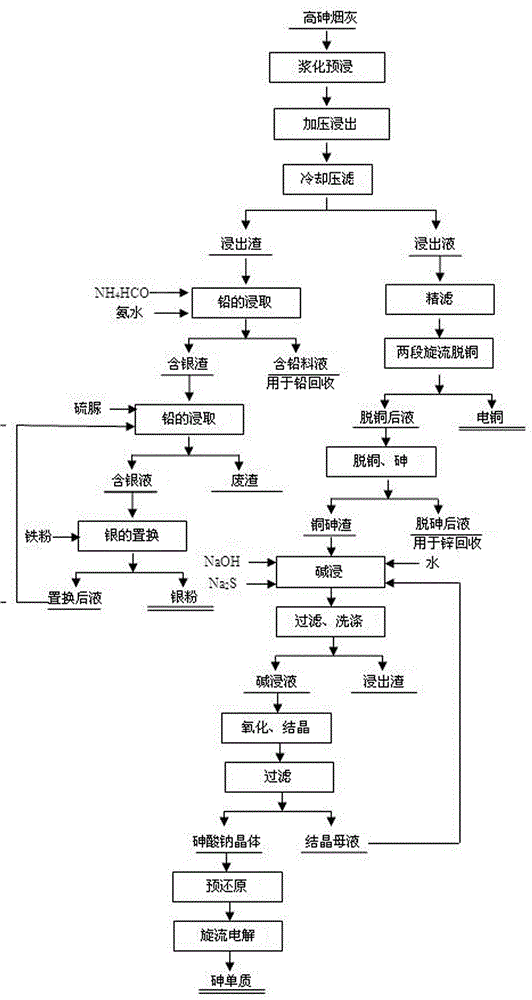

Comprehensive treatment technology for municipal domestic sludge

InactiveCN104446683AImprove resource utilization efficiencyEliminate pollutionBio-organic fraction processingClimate change adaptationDigestion TreatmentSoil organic matter

The invention provides a comprehensive treatment technology for municipal domestic sludge. The comprehensive treatment technology comprises the following steps: (1), the municipal domestic sludge is subjected to anaerobic fermentation and digestion treatment; and (2), residual sludge after anaerobic fermentation and digestion treatment is subjected to high-temperature aerobic fermentation. After two treatment processes, the municipal domestic sludge is thoroughly decomposed, finally changed to nutrient soil containing high organic matters and total NPK (nitrogen, phosphorus and potassium) nutrients, and can be used for producing various organic fertilizer products through processing. By means of the comprehensive treatment technology, not only can the municipal domestic sludge be thoroughly reduced and harmless, but also a series of environmental pollution for the air, the earth's surface, the water body and the like due to the municipal domestic sludge can be eliminated completely, the resource utilization rate of the municipal domestic sludge is increased, biogas can be produced and prepared at the anaerobic fermentation stage, sludge decomposed nutrient soil can be used for processing various organic fertilizers for landscaping, agriculture and the like at the high-temperature aerobic fermentation stage, the soil organic matters are increased, and the soil structure is improved.

Owner:新疆天物生态环保股份有限公司

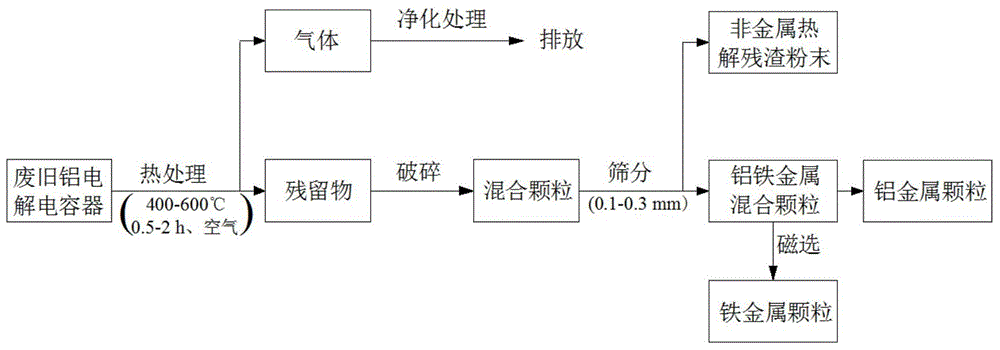

Processing and recycling method for waste aluminum electrolytic capacitor

InactiveCN104624605ARealize recycling of resourcesHigh recovery rateWaste processingSolid waste disposalRecovery methodElectrolysis

The invention discloses a processing and recycling method for a waste aluminum electrolytic capacitor. The processing and recycling method comprises the following steps: putting the waste aluminum electrolytic capacitor into a thermal treatment device to perform pyrolysis of nonmetal components, wherein the pyrolysis temperature is 400-600 DEG C, the pyrolysis time is 0.5-2 hours, and the pyrolysis treatment atmosphere is air; then, crushing obtained pyrolysis residues until metal components and nonmetal components are completely dissociated; screening crushed mixed particles through a screen of 0.1-0.3 mm to respectively obtain nonmetal pyrolysis residue powder and aluminum-iron metal mixed particles; performing magnetic separation on the aluminum-iron metal mixed particles and completely separating and recycling the iron metal particles and the aluminum metal particles. The processing and recycling method realizes recycling with high recovery rate and high purity of the aluminum and the iron, is clean in a processing process, does not discharge any toxic and harmful substances to an environment, has the characteristics of being simple and convenient to operate, short in flow, efficient, environment-friendly and high in recycling degree, and is suitable for large-scale industrial application.

Owner:SHANGHAI JIAO TONG UNIV

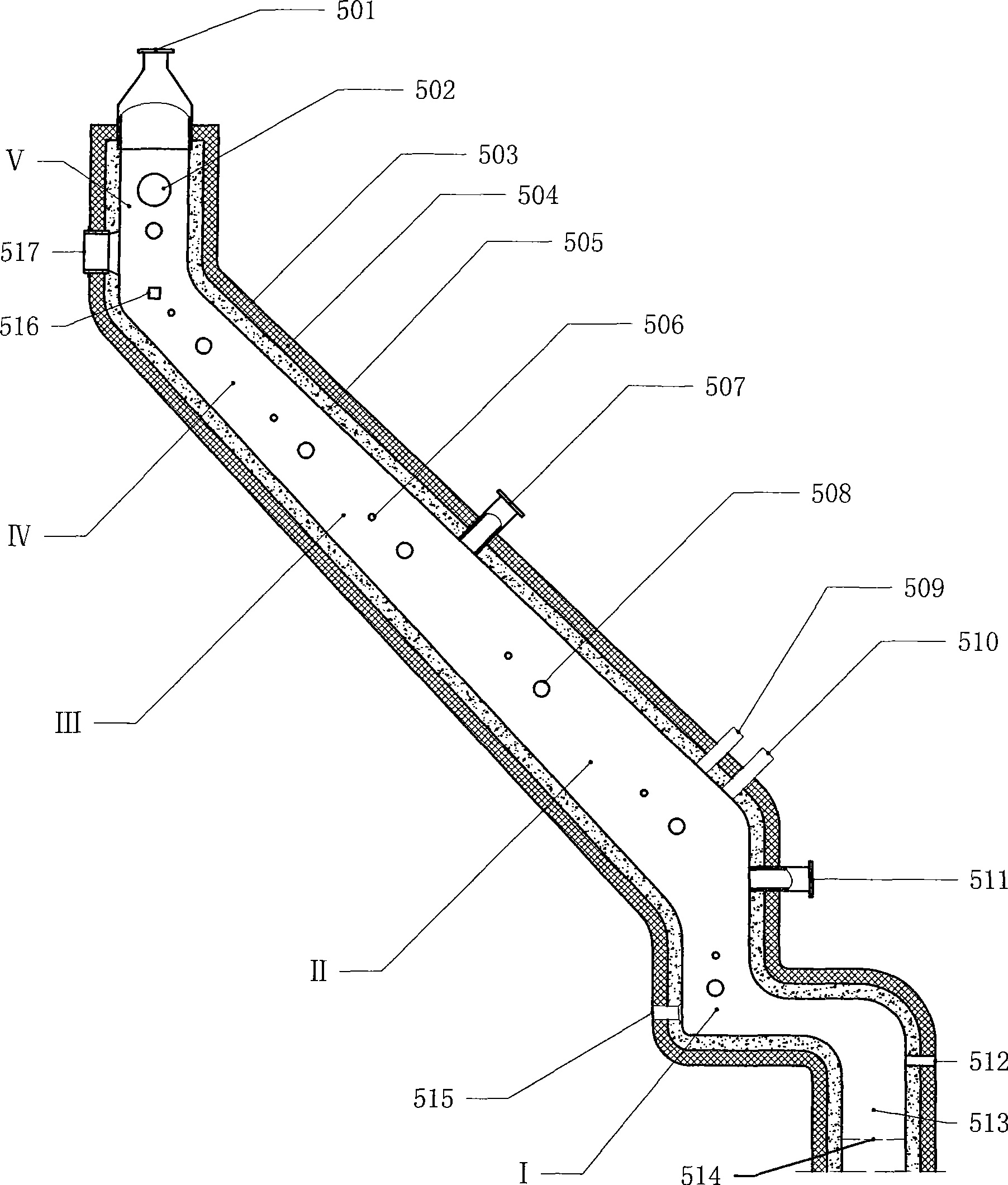

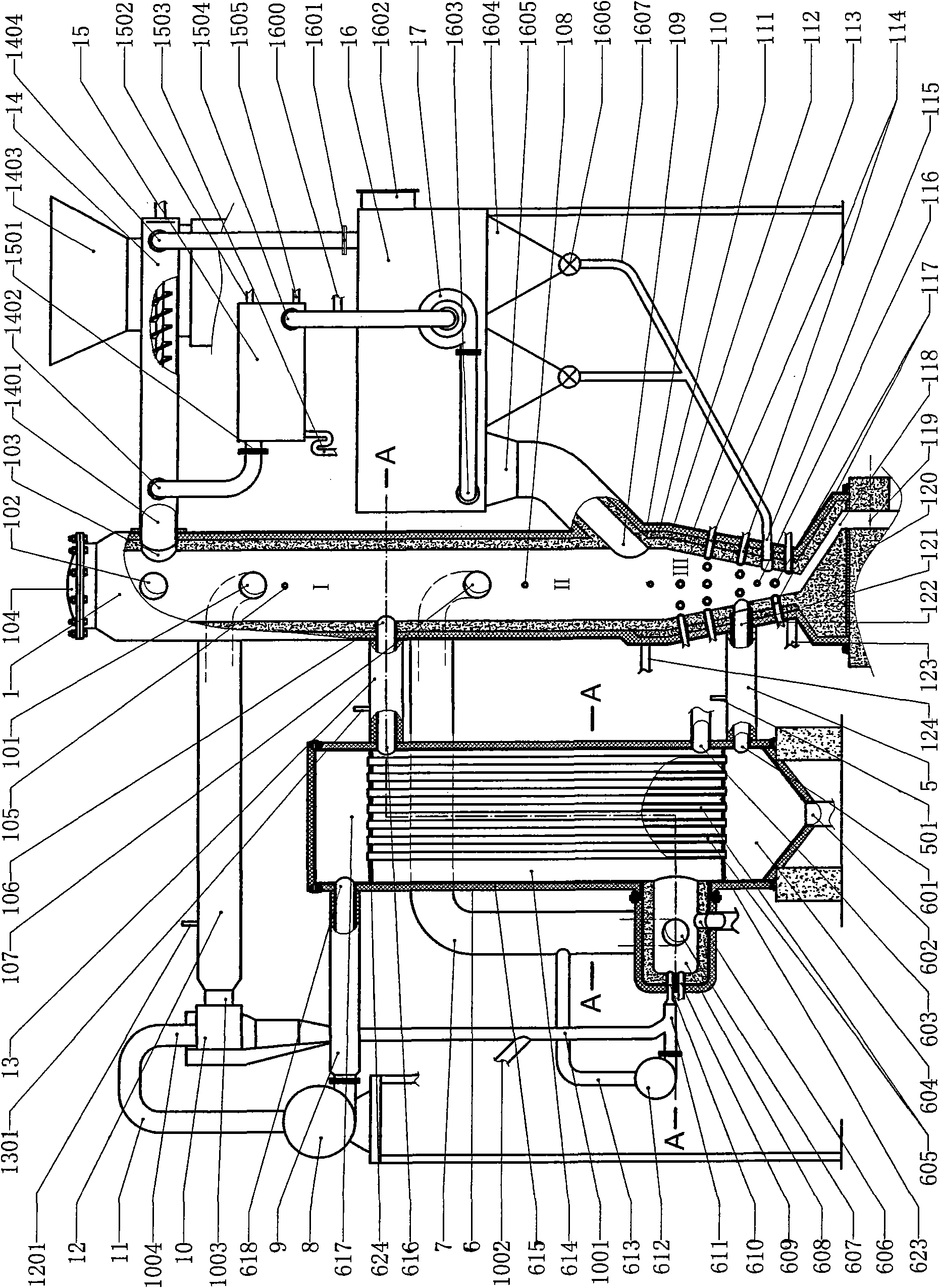

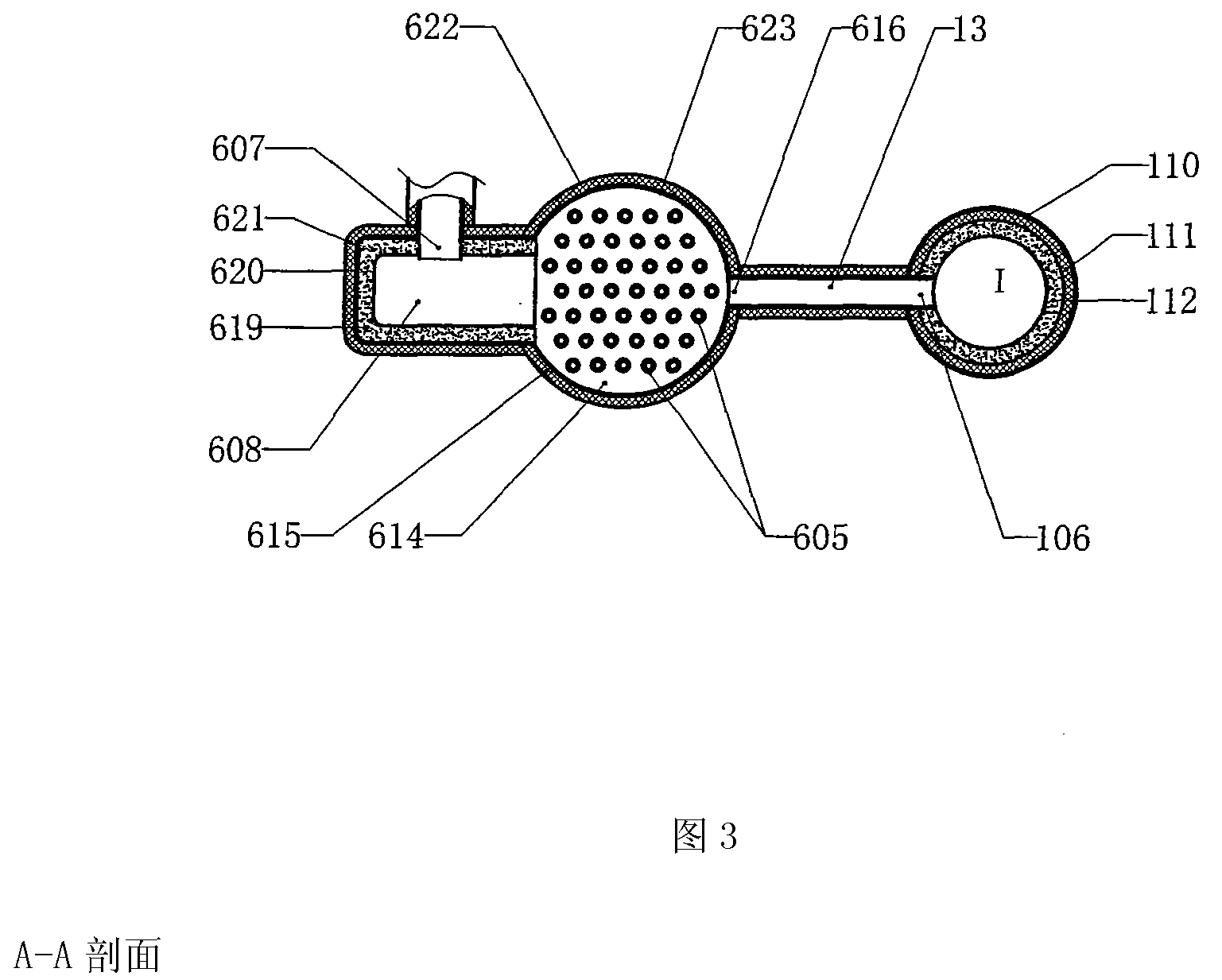

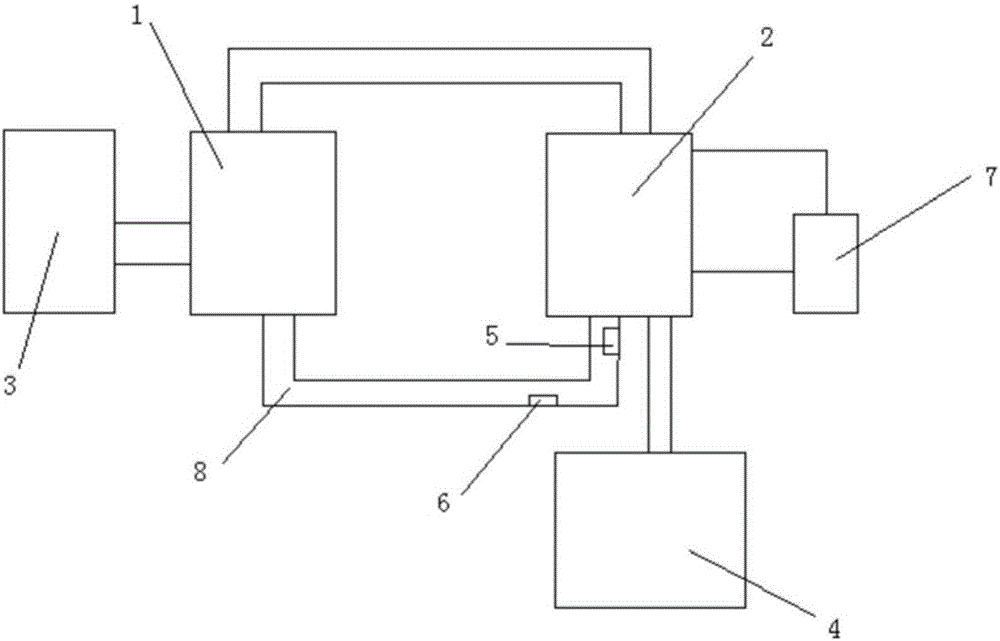

System and apparatus for producing synthesis gas from garbage and biomass raw material

The invention provides a system and equipment for producing synthesis gas by garbage and biomass raw materials, which relates to garbage and biomass gasification equipment. The system and the equipment are characterized in that a vapor circulation loop and a calcium oxide circulation loop are arranged in the system; the garbage and the biomass raw materials are vaporized by an exothermic reaction of absorbing CO2 of the calcium oxide in a gasification furnace to cooperate with thermal plasma, so that the garbage and the biomass raw materials are converted into high heating value synthesis gas for cleaning energy or chemical raw materials. The system mainly comprises a multiphase circulation gasification furnace, a plasma spray gun, the vapor circulation loop, the calcium oxide circulation loop, a wet purification tower and a gas holder, wherein a circulation output interface of the gasification furnace is connected to a gas-solid separator; a gas outlet of the gas-solid separator is connected to a circulating fan; an air outlet of the circulating fan is connected to the vapor circulation input interface of the gasification furnace; a dipleg of the gas-solid separator is connected to a feed delivery valve; the feed delivery valve is connected to a calcium oxide calcining furnace through a solid phase conveying pipe; and a calcium oxide outlet of the calcium oxide calcining furnace is connected to a calcium oxide jet tube of the gasification furnace through a refeed line.

Owner:衢州市广源生活垃圾液化技术研究所

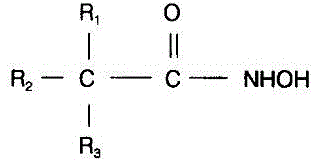

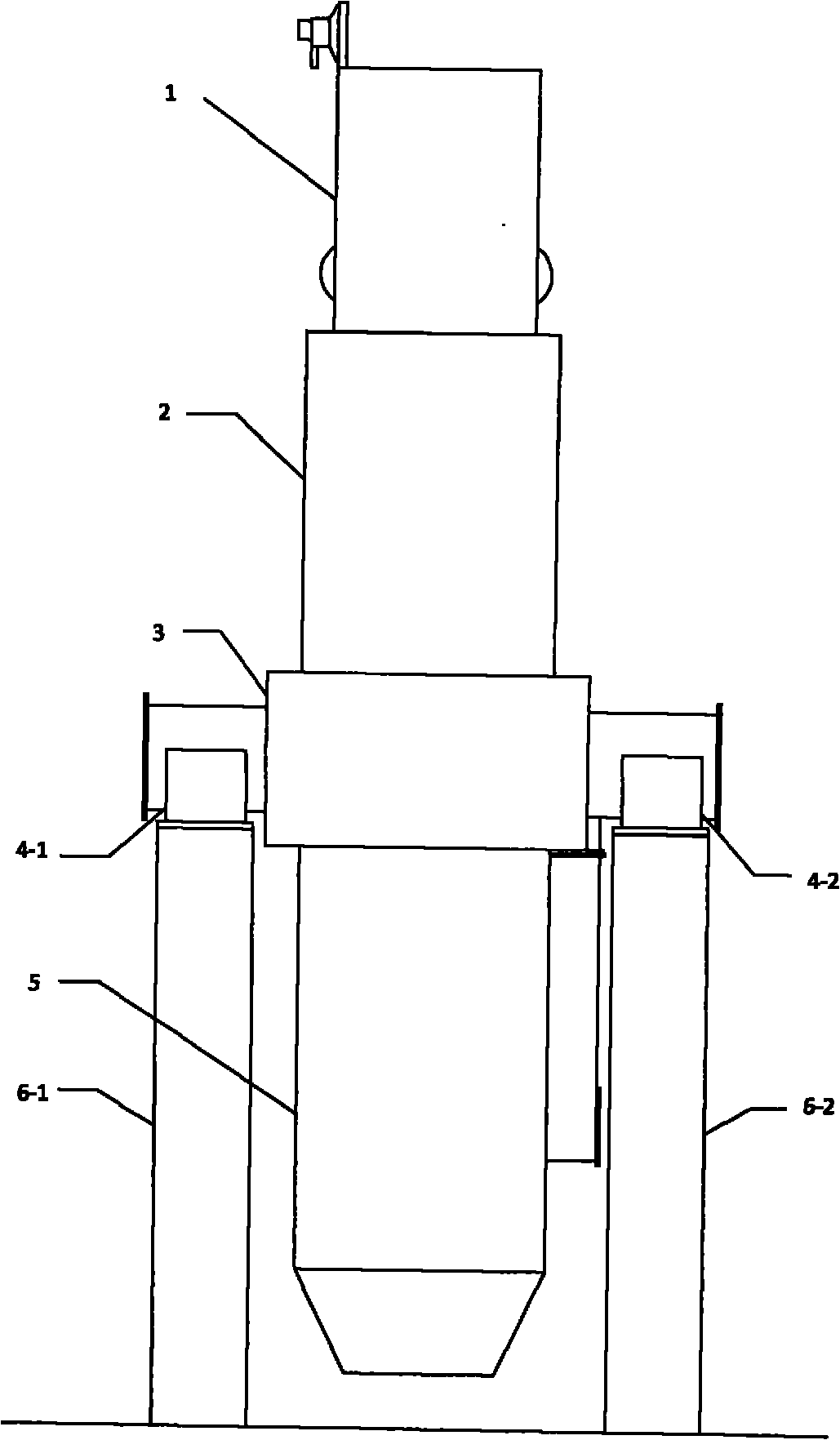

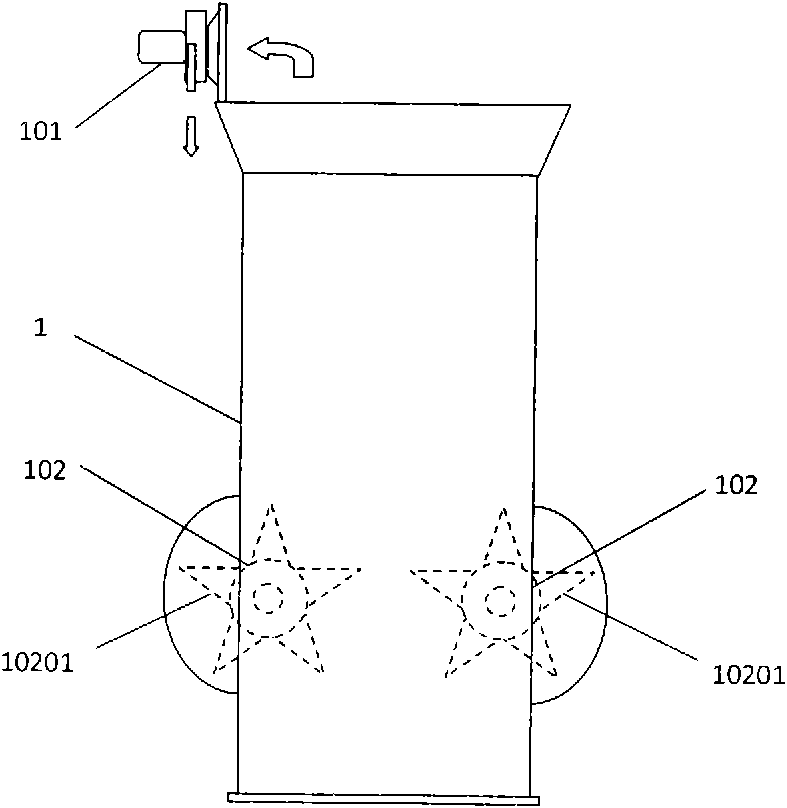

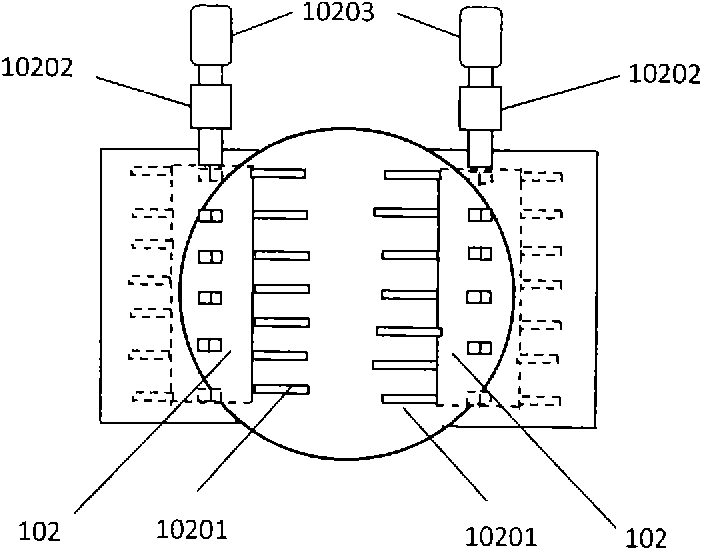

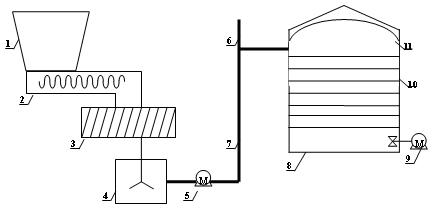

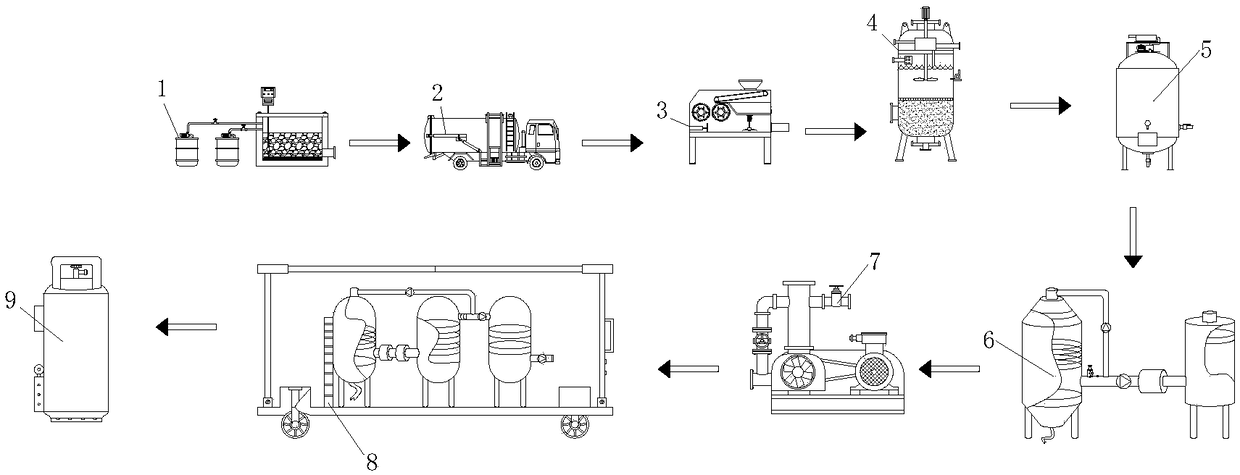

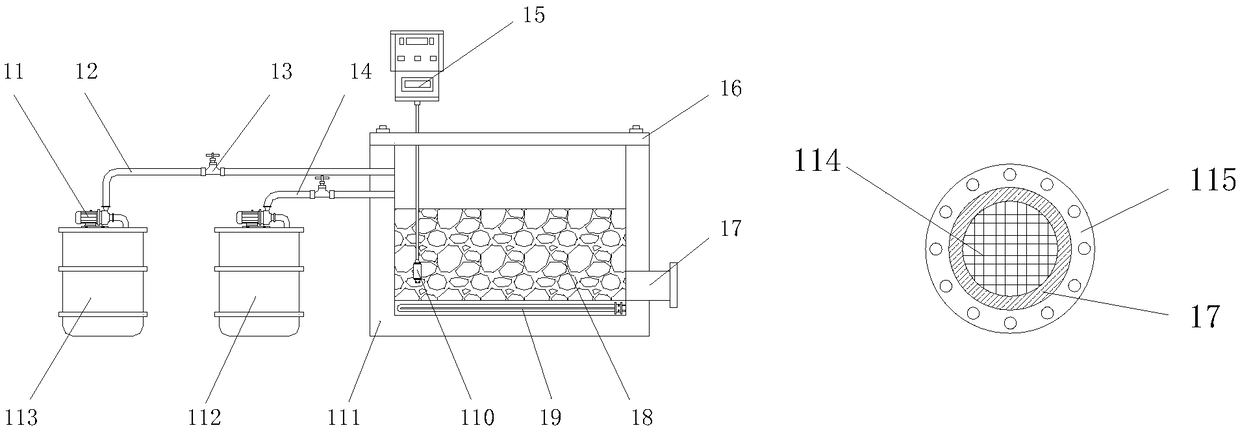

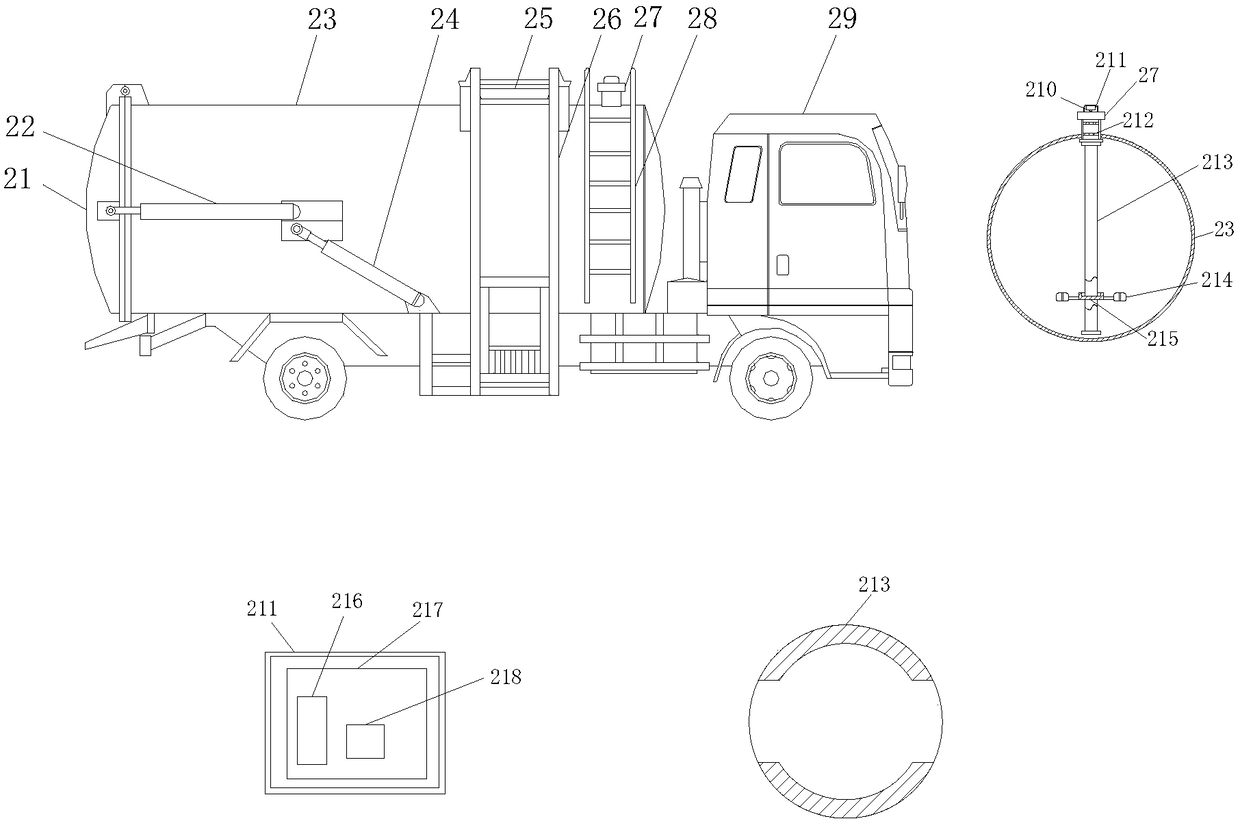

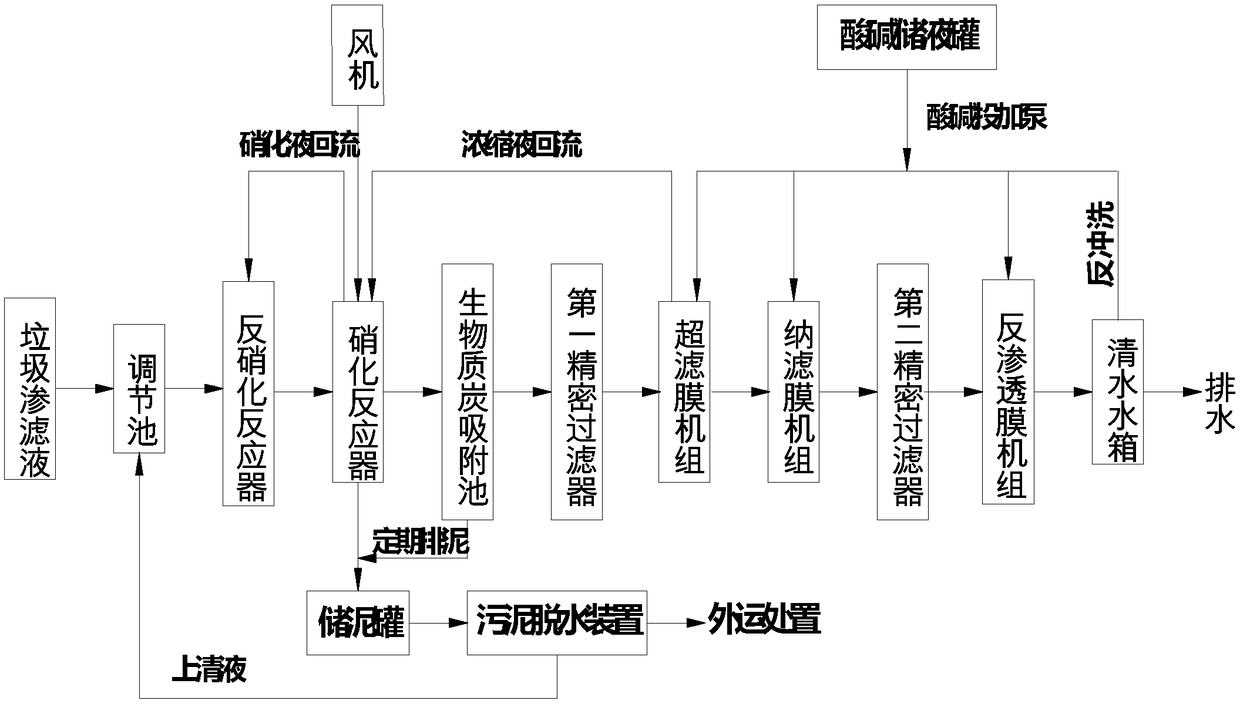

Marsh gas preparation method of system for preparing marsh gas from domestic garbage

InactiveCN108085249AHigh activityHigh degree of resource utilizationBioreactor/fermenter combinationsBiological substance pretreatmentsReturn periodFermentation

The invention relates to the field of environmental protection facilities and equipment, in particular to a marsh gas preparation method of a system for preparing marsh gas from domestic garbage. Themarsh gas preparation method comprises the following steps: pretreating, by a pretreatment apparatus on garbage, storing and transporting the pretreated garbage by virtue of a storage and transportation apparatus, transporting the garbage to a crushing apparatus, crushing the garbage, fermenting the crushed garbage by virtue of a fermentation apparatus, storing the fermented garbage by virtue of astorage apparatus, desulphurizing and dehydrating the stored garbage by virtue of a desulphurization and dehydration apparatus, pressurizing the desulphurized and dehydrated garbage by virtue of a pressurizing apparatus, purifying by virtue of a purifying apparatus, and finally storing the purified marsh gas in a storage tank. By adopting the marsh gas preparation method, the recycling degree ofthe garbage can be maximally increased, the equipment is simple, the garbage is thorough in treatment, the cost is low, the investment return period is short, the energy utilization rate is high, thewaste utilization is realized by preparing the marsh gas from the garbage, the living fuel and electric charge can be saved, and the application prospect is promising.

Owner:苏州浩长空环保科技有限公司

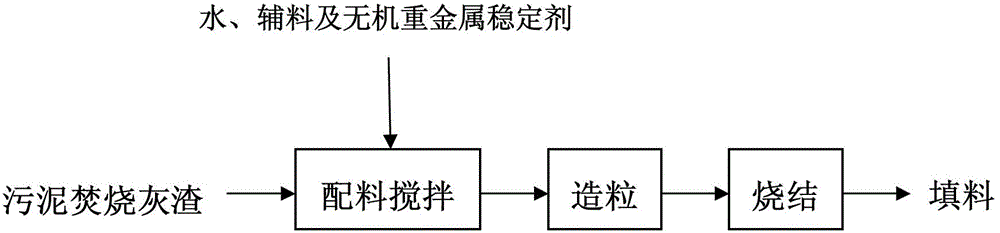

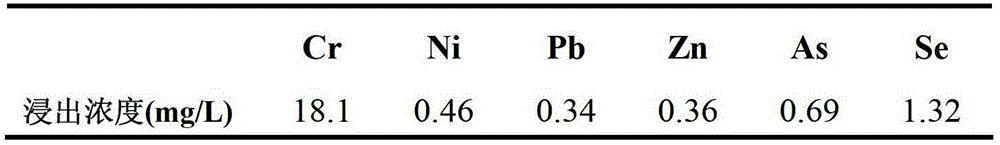

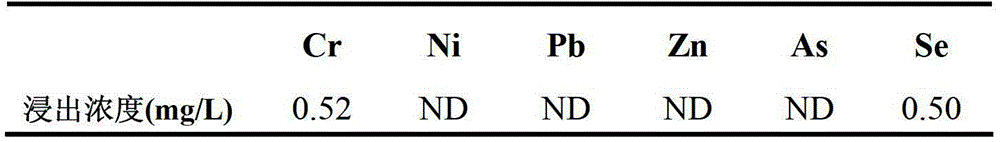

Heavy metal stabilizing method in process of preparing filler by chemical sludge burning ash

ActiveCN103145403AImprove stabilityLow leaching rateCeramic materials productionClaywaresPhosphateSludge

The invention relates to a heavy metal stabilizing method in a process of preparing filler by chemical sludge burning ash. An inorganic heavy metal stabilizer is prepared by using calcium oxide and potassium dihydrogen phosphate to prepare a calcium potassium phosphate cementing material supplemented by bentonite; the chemical sludge burning ash is used as a raw material, clay or shale is used as an auxiliary material, and a small amount of the inorganic heavy metal stabilizer is doped; and the raw material, the auxiliary material and the inorganic heavy metal stabilizer are mixed according to a certain proportion and stirred by adding water, pelletted and sintered to prepare the filler with small heavy metal leaching rate. The invention provides the heavy metal stabilizing method which is in good stabilizing effect and has universality to different heavy metal components and shapes. The process for preparing the filler by using the chemical sludge burning ash doped with the inorganic heavy metal stabilizer has the advantages of low operating cost, short disposal period, small secondary pollution, high degree of resources and the like compared with the conventional chemical sludge treatment and disposal manner.

Owner:NANJING UNIV OF TECH

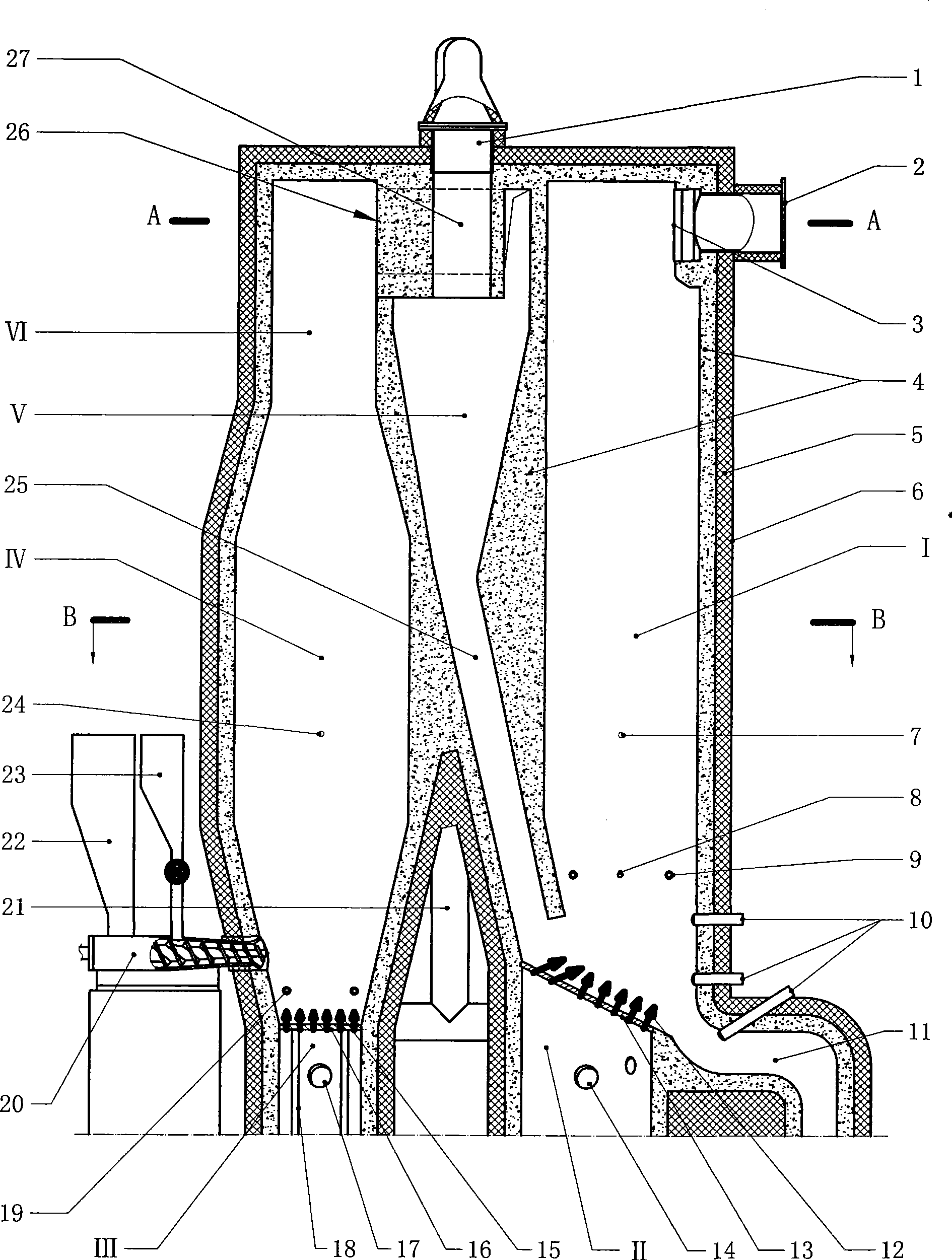

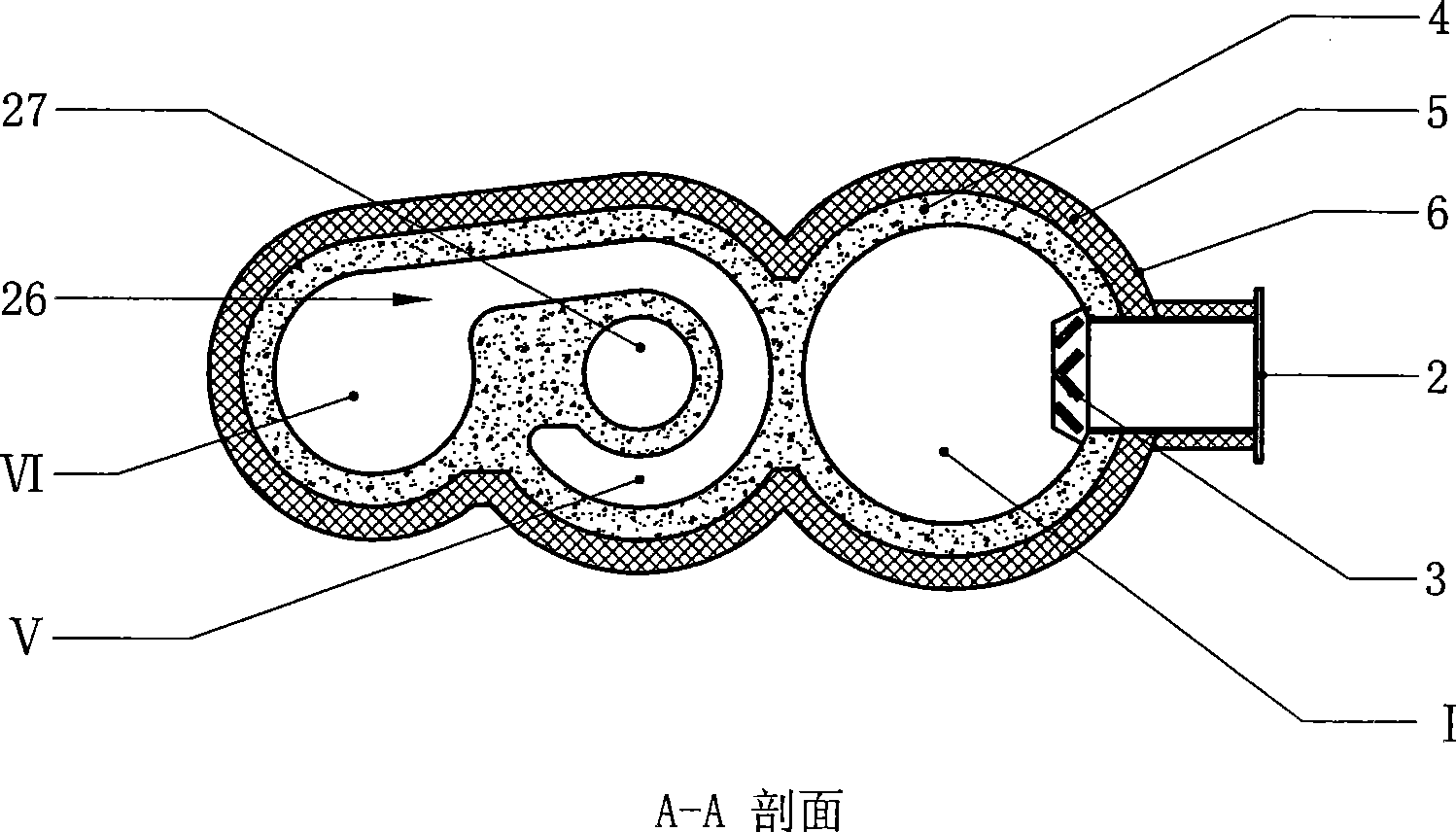

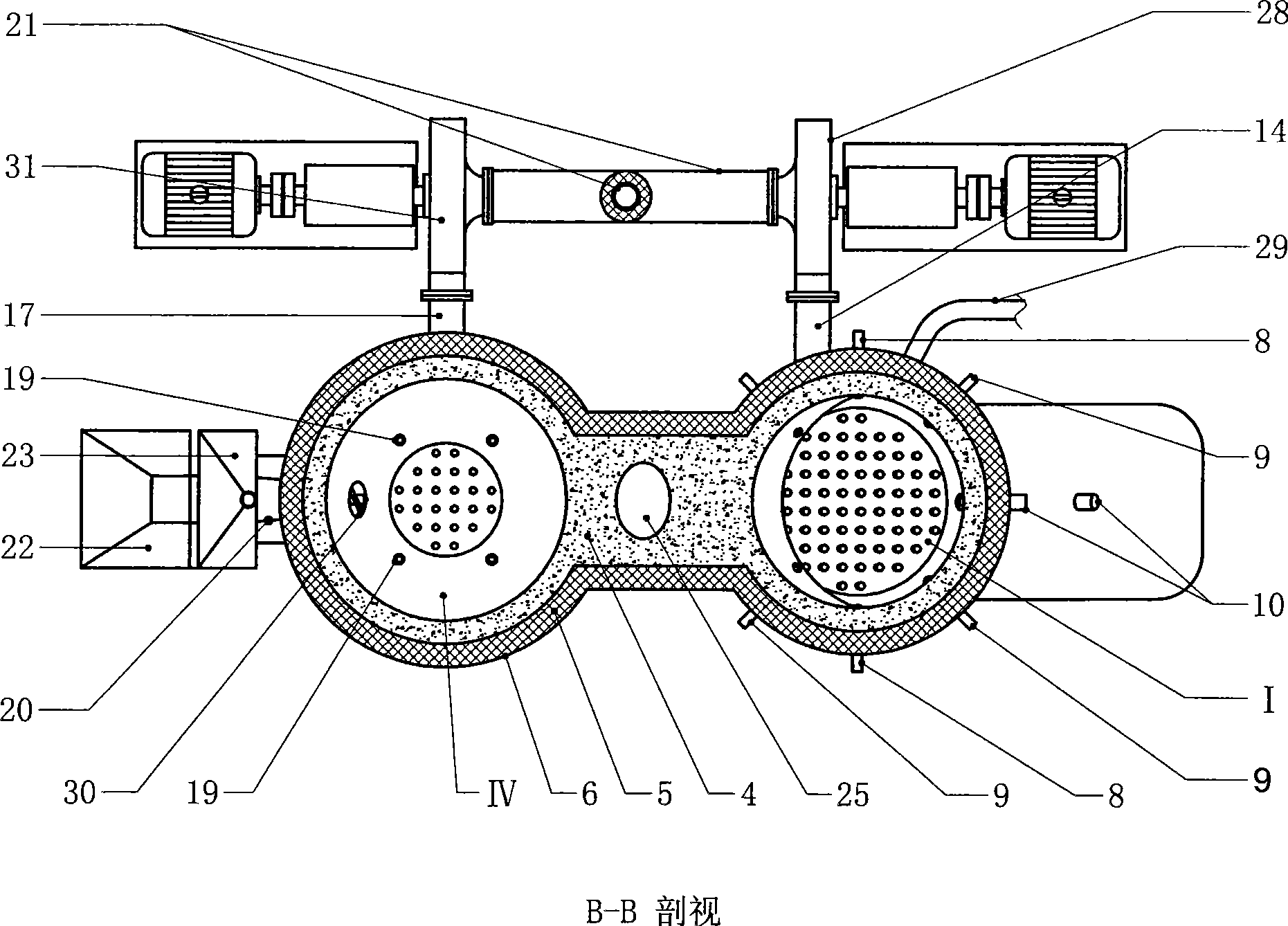

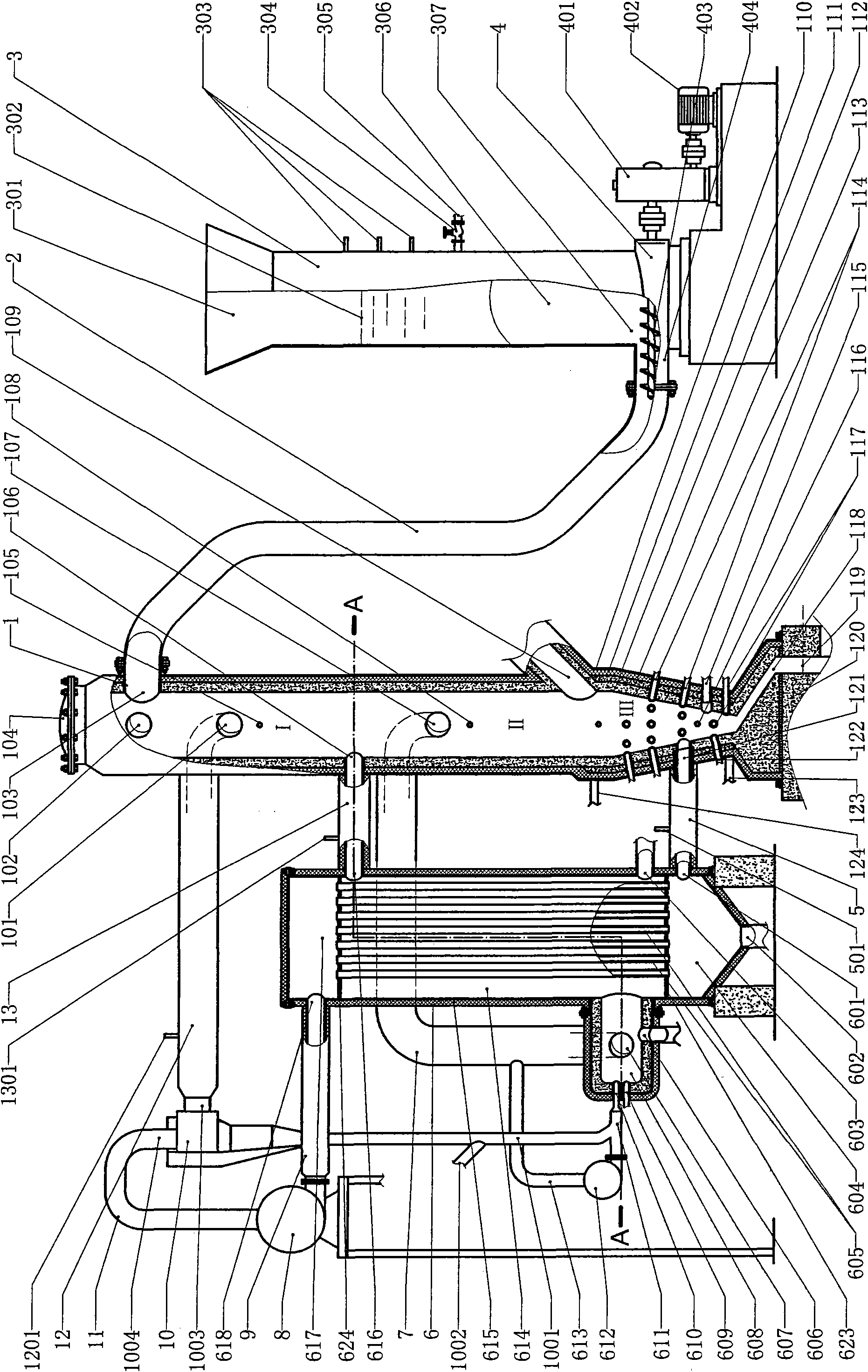

Calcium oxide and plasma body cooperative gasified domestic garbage gasification system and equipment

ActiveCN101880551ANo financial pressureReduce financial pressureOrganic compound preparationSolid waste disposalCo operativeWaste material

The invention provides a calcium oxide and plasma body cooperative gasified domestic garbage gasification system and equipment, which relate to solid organic waste disposal equipment. The gasification system consists of a plasma body gasification furnace, an air sealing material feeding device, a heat exchanger, a draught fan and a cyclone separator, wherein a material outlet of the air sealing material feeding device is connected to a material inlet of the gasification furnace, a thermolytical air outlet of the gasification furnace is connected to a carbonatation reaction chamber of the heat exchanger, a hot carrier outlet of the heat exchanger is connected to a hot carrier inlet of the gasification furnace, the hot carrier outlet of the gasification furnace is connected to the cyclone separator, the cyclone separator is connected to the draught fan, the draught fan is connected to a thermolytical air inlet of the heat exchanger, a thermolytical air outlet of the heat exchanger is connected to a thermolytical air inlet of the gasification furnace, and a synthesis air outlet is connected out at the engagement position of a thermolytical region and a gasification region. The system can realize the domestic garbage disposal without discharge or pollution, and is applicable to the harmless disposal of urban domestic garbage, rural domestic garbage, medical garbage, industrial high molecular waste materials and the like.

Owner:上海格灵迈环境科技有限公司

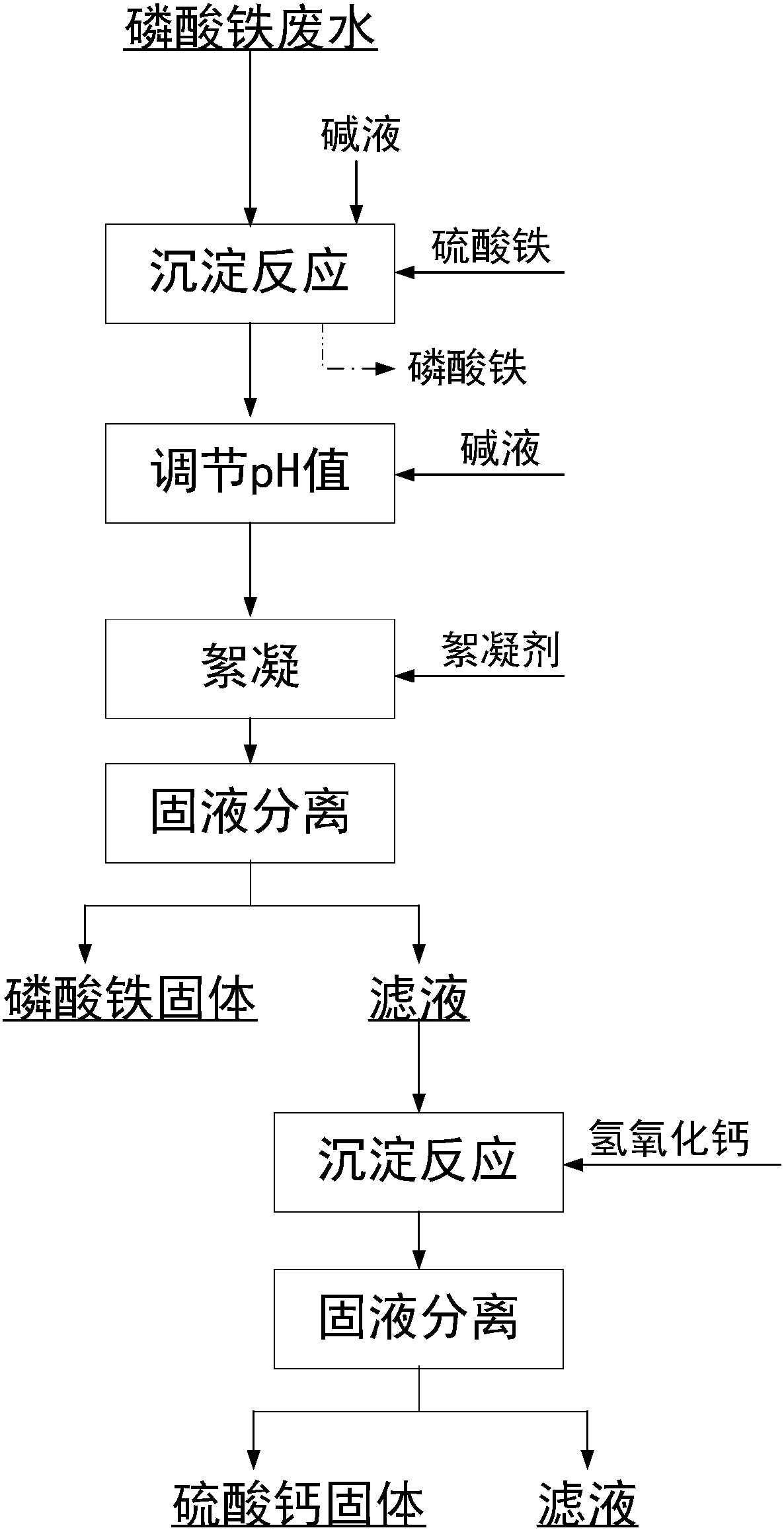

Stepwise removing method of phosphate and sulfate radicals in iron phosphate wastewater

ActiveCN108975469AHigh degree of resource utilizationOvercome the technical difficulties of step-by-step removal and recoveryWater contaminantsTreatment involving filtrationCalcium hydroxidePhosphate

The invention relates to a stepwise removing method of phosphate and sulfate radicals in iron phosphate wastewater. The method comprises the following steps of: (1) adding alkali liquor to the iron phosphate wastewater to adjust the pH (potential of Hydrogen) value to 4-11; (2) adding iron sulfate to carry out precipitation reaction; (3) adding the alkali liquor again to adjust the pH value to 3-9; (4) adding a flocculating agent, stirring and standing to obtain a filtrate and an iron phosphate-containing solid via solid-liquid separation; and (5) adding calcium hydroxide to the filtrate obtained in the step (4) and carrying out the precipitation reaction to obtain filtrate and a calcium sulfate-containing solid via the solid-liquid separation, wherein the alkali liquor comprises any one or a combination of at least two of sodium hydroxide, potassium hydroxide or ammonia water. The method has the advantages that the phosphate and sulfate radicals are separately removed, the calcium sulfate is recovered and the resource utilization degree is higher than that of the prior art; and in the final effluent, the content of the phosphate radical is less than 0.5 g / L and the content of thesulfate radical is less than 1.5 g / L.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

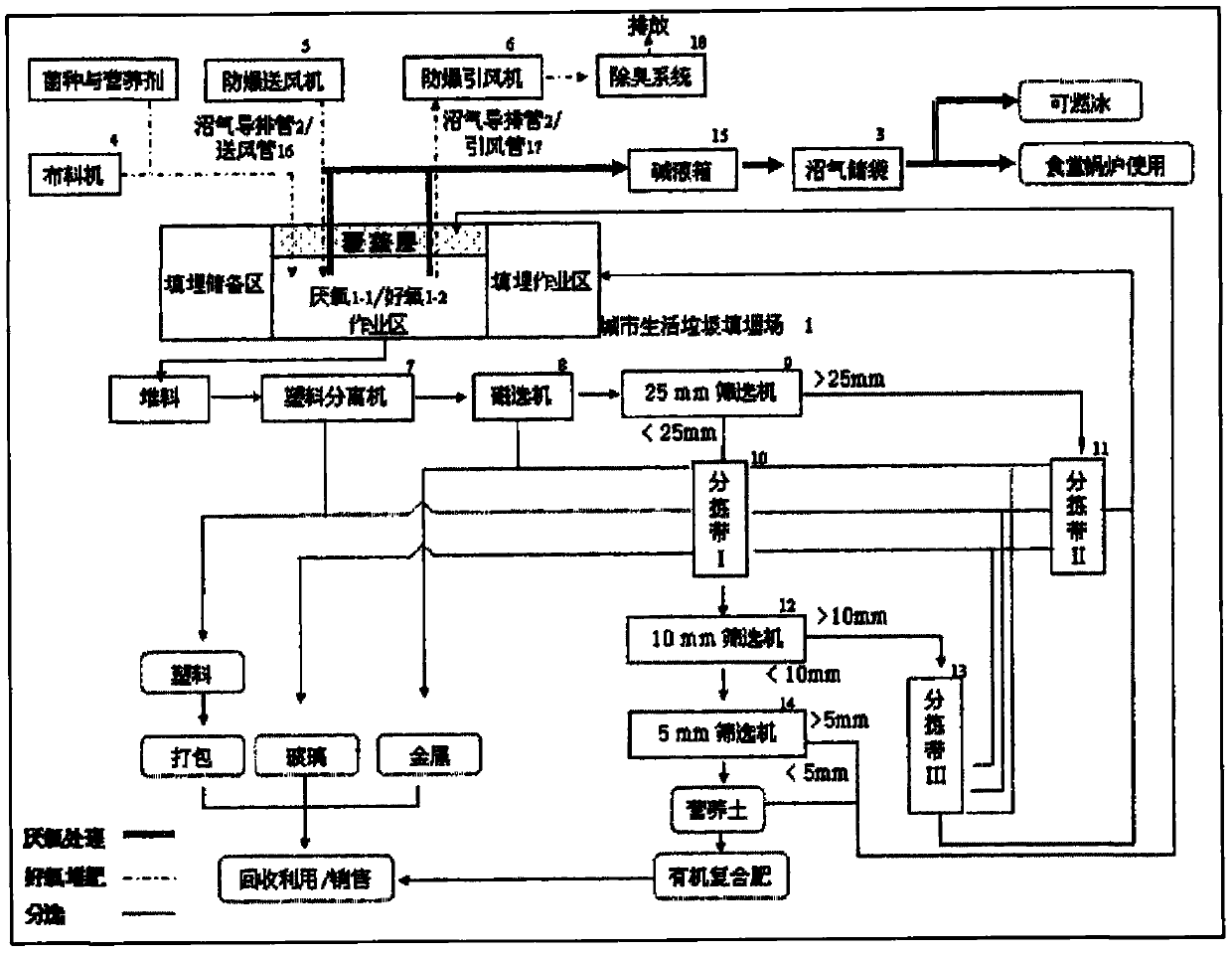

Active landfill method of urban domestic garbage

ActiveCN101804417AHigh degree of resource utilizationExtended service lifeSolid waste disposalLitterEnvironmental engineering

The invention relates to an active landfill method of urban domestic garbage, which comprises the following steps of: adopting subarea operation for garbage landfill, carrying out anaerobic treatment on the landfilled garbage, carrying out aerobic treatment on the landfilled garbage after the anaerobic treatment, sorting the garbage after the aerobic treatment and sorting unusable residues for landfill treatment. By the steps, 100% of hazard-free treatment, 75.5% of reduction and 45.5%recycling of the urban domestic garbage are realized. The use time of a garbage landfill field is prolonged by 75.5%, thereby the sustainable landfill is farthest realized.

Owner:北京昊业怡生科技有限公司

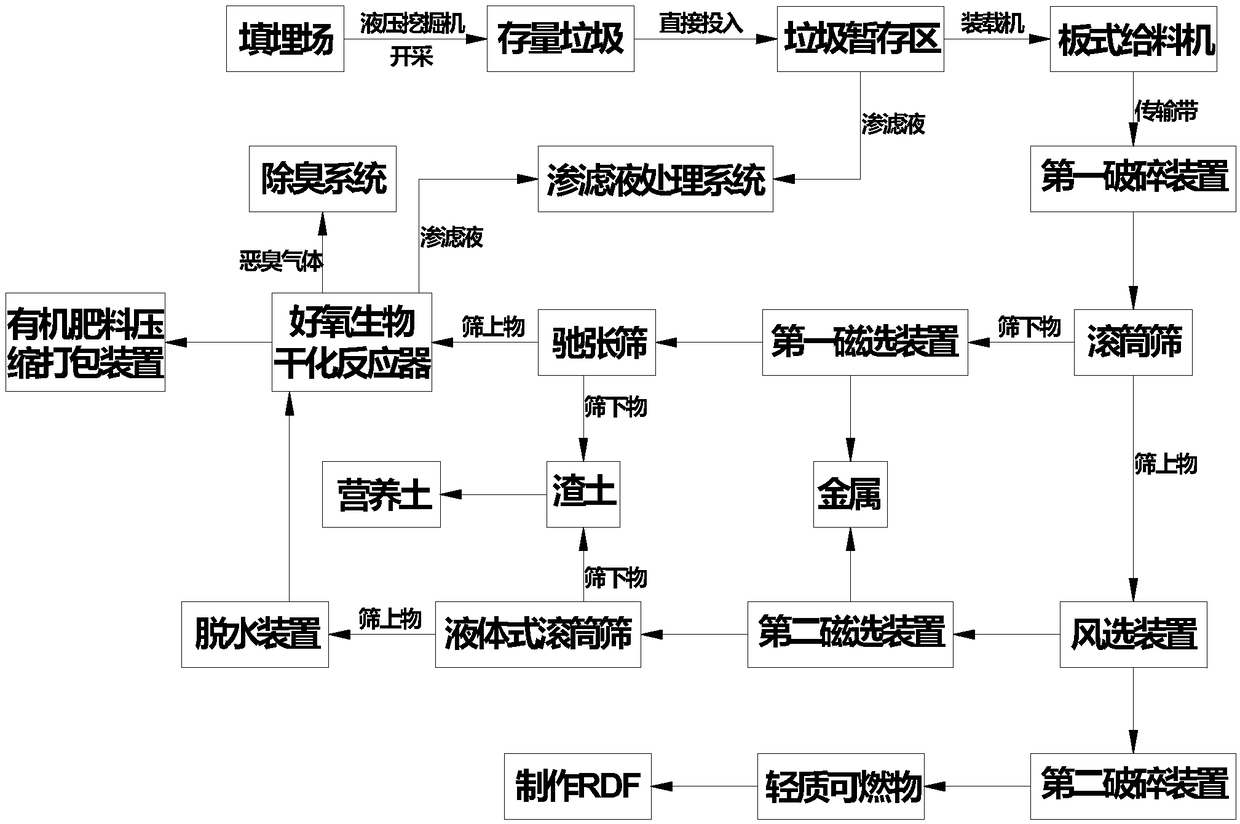

Stock garbage in-situ resourceful treatment method and stock garbage in-situ resourceful treatment system

ActiveCN108787699ARealize high resource utilizationReduce landfill volumeSolid waste disposalDispersed particle separationAir separationOrganic fertilizer

The invention discloses a stock garbage in-situ resourceful treatment method and a stock garbage in-situ resourceful treatment system. The system comprises a garbage temporary storage area, a plate feeder, a first breaking device, a drum screen, an air separation device, a second breaking device, a first magnetic separation device, a tension and relaxation screen, an aerobic biological drying reactor, an organic fertilizer compressing and packing device, a second magnetic separation device, a liquid type drum screen, a dewatering device, a percolating liquid treatment system and a deodorization system; garbage in the garbage temporary storage area is transported to the plate feeder; the plate feeder is sequentially connected with the first breaking device and the drum screen; a first outlet of the drum screen is connected with the air separation device; a first outlet of the air separation device is connected with the second breaking device; a second outlet of the air separation deviceis sequentially connected with the second magnetic separation device, the liquid type drum screen and the dewatering device; an outlet of the dewatering device is connected with a first inlet of theaerobic biological drying reactor; a second outlet of the drum screen is connected with the first magnetic separation device and the tension and relaxation screen; an outlet of the tension and relaxation screen is connected with a second inlet of the aerobic biological drying reactor; an outlet of the aerobic biological drying reactor is connected with the organic fertilizer compressing and packing device; the aerobic biological drying reactor is further connected with the percolating liquid treatment system and the deodorization system; and the garbage temporary storage area is further connected with the percolating liquid treatment system. Production of secondary pollution can be completely prevented, and highly-resourceful utilization of the stock garbage can be achieved.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

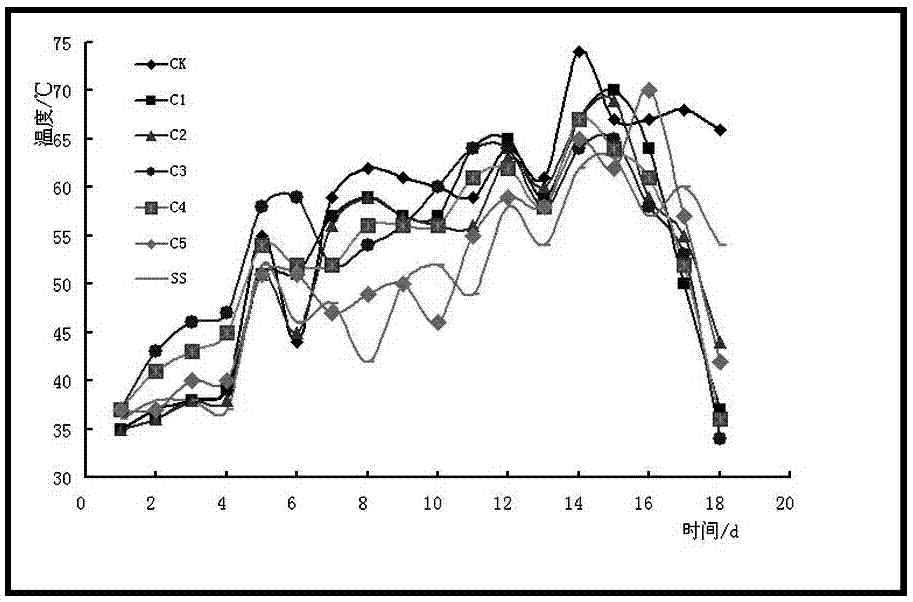

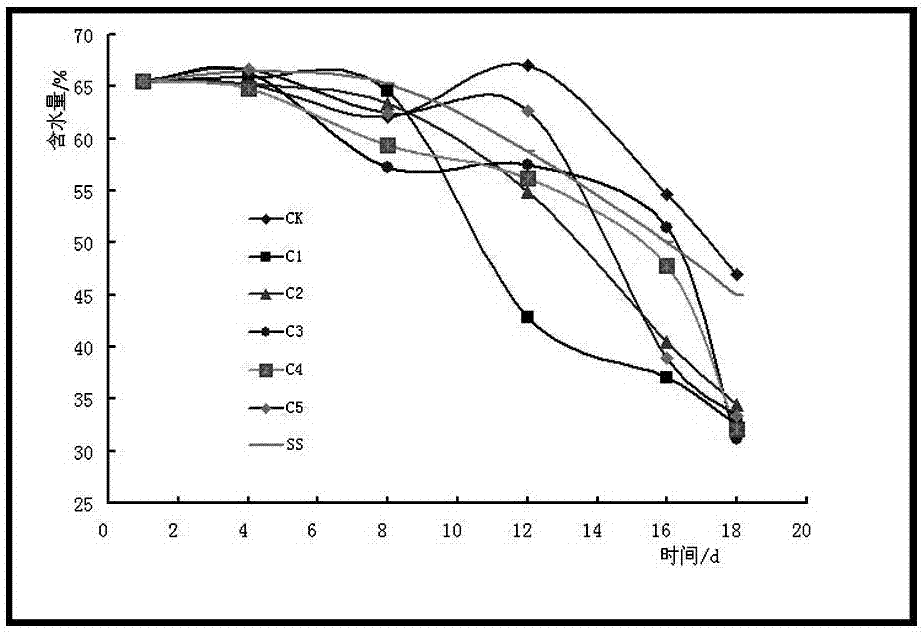

Organic fertilizer fermenting agent

The invention discloses an organic fertilizer fermenting agent. The organic fertilizer fermenting agent comprises, by weight, 2-7 parts of bacteria preparations, 2-8 parts of mycete preparations, 2 parts of saccharomycetes preparations and 1-3 parts of actinomyces preparations. A preparation method of the organic fertilizer fermenting agent is simple, a finished fermenting agent is green and safe, by adding the organic fertilizer fermenting agent in excrement of livestock, organic substances in the excrement can be decomposed quickly, the temperature of the excrement can be risen quickly by generated heat, harmful microorganisms and worm eggs in the excrement can be killed, decomposing of the excrement of livestock is accelerated, and the excrement is enabled to be turned into organic fertilizer. The organic fertilizer fermenting agent has the advantages that by adopting the pointed organic fertilizer fermenting agent to ferment the excrement of the livestock, a fermenting period is shortened to 1 / 3-1 / 2 as that of a natural fermenting manner, the problems that a production field for large-scale organic fertilizer production is occupied for a long time and an production index cannot be achieved quickly are solved, and various indexes of the produced organic fertilizer accord with the national standards.

Owner:ZHENGZHOU UNIV

Method for recycling waste FCC catalyst

ActiveCN108993531AImprove pore structureLarger than surfaceMetal/metal-oxides/metal-hydroxide catalystsWater/sewage treatment by oxidationResource utilizationCatalytic oxidation

The invention discloses a method for recycling a waste FCC catalyst. The method comprises the following technical scheme: taking 50 to 70 wt% of the waste FCC catalyst, 25 to 45 wt% of clay and 2 to 5wt% of TiO2 as catalyst materials, mixing the raw materials, drying a mixture, and grinding the mixture; placing the mixture into a disc granulator, spraying 10 to 15% by weight of a transition metalsalt aqueous solution of the catalyst raw material while rotating, rotating a disk grain making machine to form spherical catalyst particles having a particle diameter of 3 to 5 mm; and drying and sintering the material at 1080 to 1200 DEG C for 15 to 30 minutes to prepare an ozone catalyst. A catalytic oxidation tower or a reaction tank is filled with an ozone catalyst according to a filling volume of the ozone catalyst being 45 to 60% of the effective volume of the catalytic oxidation tower or the reaction tank, the dosage of ozone is 50-75 mg / L, the reaction is 15-30min, and the COD of difficultly degraded industrial wastewater after deep treatment is subjected to standardized discharge. The method has the advantages of simple process, low cost and high degree of resource utilization,and the prepared ozone catalyst has stable catalytic performance and high catalytic activity.

Owner:WUHAN UNIV OF SCI & TECH

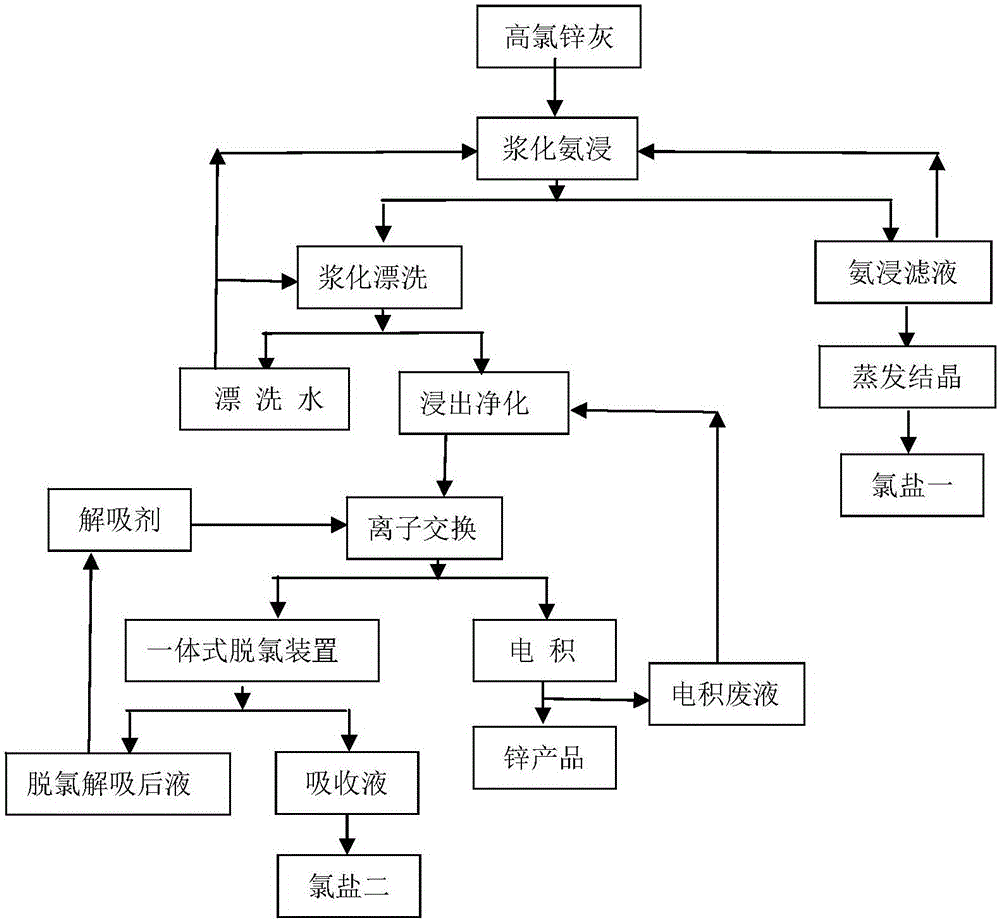

Method for producing electrolytic zinc through high-chloride zinc ash material ammonia leaching ion exchange combined process

InactiveCN106399715AIncreased concentration of chloride ionsReduce water volumeChloride preparationPhotography auxillary processesLiquid wasteFiltration

The invention discloses a method for producing electrolytic zinc through a high-chloride zinc ash material ammonia leaching ion exchange combined process. The method comprises the steps that (1) high-chloride zinc ash is made into slurry, ammonia is added to conduct ammonia leaching; ammonia leaching filter residues and ammonia leaching filtrate are obtained after filtration; if the concentration of chloride ions in the filtrate is less than 80 g / L, slurrying and ammonia leaching are conducted again; and if the concentration of chloride ions in the filtrate is greater than 80 g / L, a way is opened, and chlorine salt I is recovered; the ammonia leaching filter residues are rinsed to obtain rinsing water and after-rinsed zinc ash, the after-rinsed zinc ash is subjected to sulfuric acid leaching to obtain a zinc sulfate solution and leaching residues, and the leaching residues are used for recovery of zinc and lead; chloride ions are removed from the zinc sulfate solution by using ion exchange resin, the zinc sulfate solution is subjected to electrodeposition sending and zinc is recovered after dechlorination, and an ion exchange desorption after-solution is subjected to dechlorination to generate chlorine salt II and returns to the ion exchange resin as a desorption reagent. Through the method, high-efficiency and low-cost impurity removal and harm removal of high-chloride zinc ash with the treatment effect which is several times higher than the treatment limit effect obtained through an existing dechlorination process is realized; a new acceptable raw material source is provided for production of electrolytic zinc; emissions of waste liquor and waste residues are avoided, and the environmental protection effect and economic and social benefits are remarkable.

Owner:吉首市金湘资源科技开发有限公司

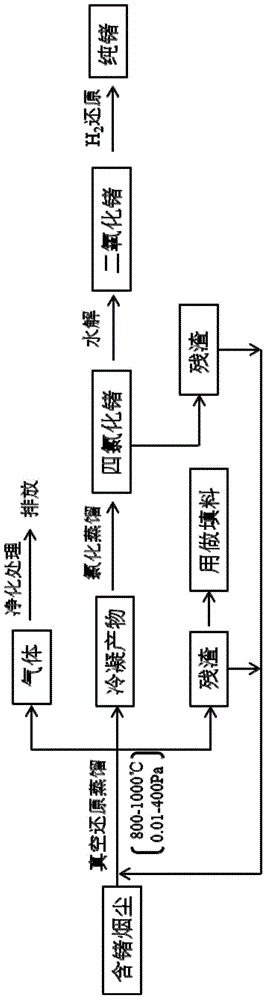

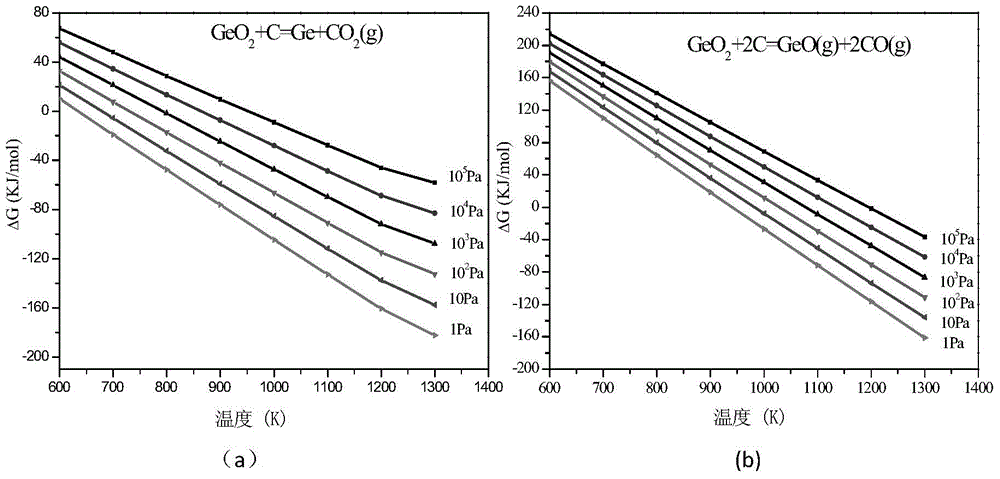

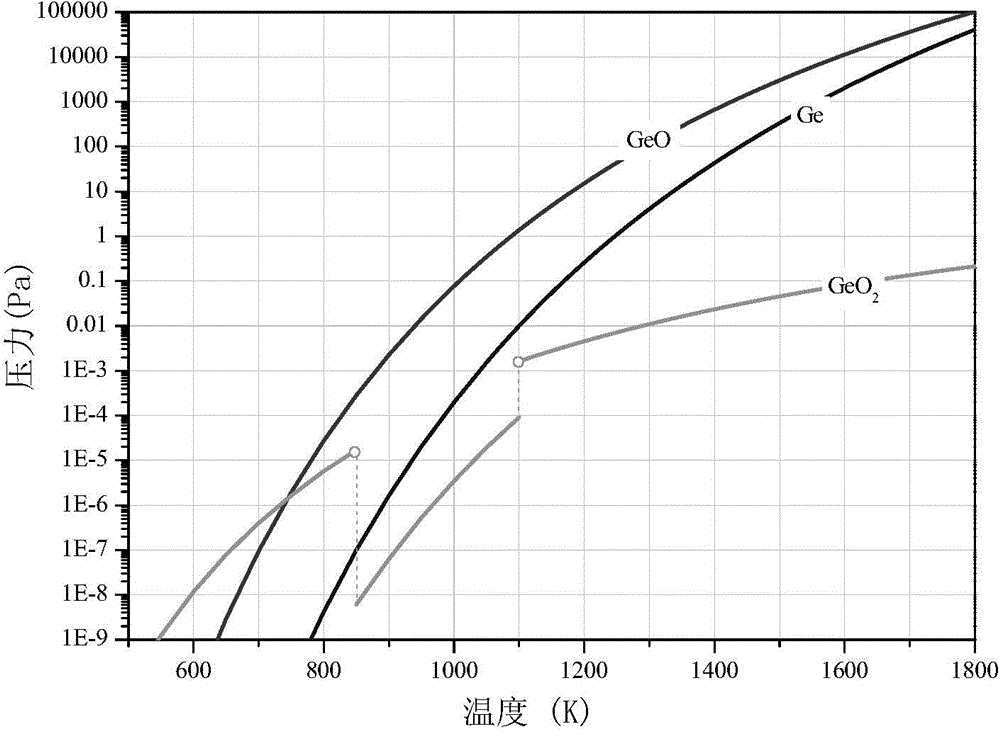

Method for recovering germanium in lignite smoke

InactiveCN104911363AHigh degree of resource utilizationSuitable for large-scale industrial applicationsProcess efficiency improvementDistillationHeating furnace

The invention discloses a method for recovering germanium in lignite smoke by virtue of a vacuum reduction-chlorination distillation technology. The method comprises the following steps: firstly, placing the lignite smoke and 5-25wt% of coke in a vacuum heating furnace, and carrying out a vacuum reduction reaction at 800-1000 DEG C to obtain a product containing metal Ge, GeO and some impurities, for example, the condensation product of As2O3; secondly, carrying out chlorination distillation on the condensation product to obtain pure GeCl4 with a purity of more than 90%; thirdly, carrying out a hydrolysis reaction on GeCl4 to obtain pure GeO2; finally, carrying out the reaction of reducing the pure GeO2 by H2 to obtain metal Ge with a purity of more than 90%. The method achieves the recovery rates of 90% or above respectively, has the characteristics of being efficient, environment-friendly and high in recycling degree, and is suitable for large-scale industrialized applications.

Owner:SHANGHAI JIAO TONG UNIV

Method of using red mud to prepare firing-free lightweight aggregate

InactiveCN107129238AHigh degree of resource utilizationSimple manufacturing methodRed mudToxic industrial waste

The invention discloses a method of using red mud to prepare firing-free lightweight aggregate and relates to the technical field of solid waste recycling. The method includes steps: adding water to well stir the red mud, cement and fine sand according to a proportion of 5:2:3 and a water-solid ratio of 0.22:1; using a ball pressing machine to make balls of 5-10mm, and curing indoors for three days to go out a factory. The method is simple and easy to implement, low in cost, energy-saving, environment-friendly and easy to popularize and use, and recycling degree of industrial waste is increased.

Owner:HENAN POLYTECHNIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com