Food residue and sludge mixing anaerobic treatment method and system

A technology for catering waste and anaerobic treatment, which is applied in the direction of biological sludge treatment, biomass pretreatment, biological organic part treatment, etc., can solve the problems of no mixed treatment process and system, and achieve the goal of overcoming the lack of alkalinity and nutrients, The effect of increasing the processing capacity and improving the effect of biogas fermentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

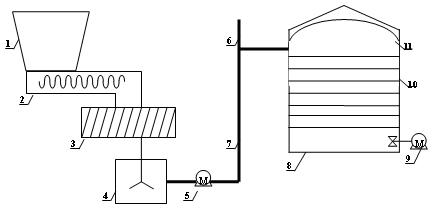

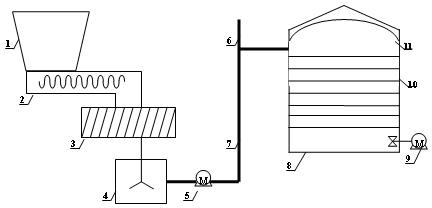

[0023] figure 1 Shown is an anaerobic treatment system for mixing food waste and sludge, including food waste pretreatment and anaerobic digestion;

[0024] The catering waste pretreatment part includes catering waste storage tank 1, material conveyor 2, crushing and separating device 3, slurry storage tank 4, and slurry lifting pump 5; the outlet of the catering waste storage tank is connected to the material conveyor, and the outlet of the material conveyor is connected to the crushing The inlet of the separation device, the outlet of the crushing and separation device are connected to the slurry storage tank, and the outlet of the slurry storage tank is connected to the feeding pipe of the food waste of the anaerobic digestion device. A slurry lift is installed between the slurry storage tank and the feeding pipe of the food waste. Pump;

[0025] The anaerobic digestion part includes sludge feed pipe 6, catering waste feed pipe 7, anaerobic digestion device 8, agitator 9, ...

Embodiment 2

[0029] Adopt the anaerobic treatment system that the food waste of embodiment 1 mixes with sludge to process, and specific process comprises food waste pretreatment and anaerobic digestion treatment:

[0030] Catering waste pretreatment: Catering waste and urban sludge are transported to the treatment plant by transport vehicles. Catering waste with an oil content of less than 8% enters the catering waste storage tank 1 after unloading, and the gate valve is opened to transport the materials in the waste storage tank through the material. The machine 2 is sent to the crushing and separating machine 3 for crushing and separation, crushing to a particle size below 30mm, so that the impurities are separated from the food waste, the treated slurry part enters the slurry storage tank 4, and the impurity part enters the slag tanker;

[0031] Anaerobic digestion treatment: the slurry enters the anaerobic digestion device 8 through the slurry lifting pump 5, and the municipal sludge en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com