Calcium oxide and plasma body cooperative gasified domestic garbage gasification system and equipment

A technology of plasma and domestic waste, which is applied in the field of solid organic waste disposal systems and equipment, and can solve problems such as land occupation, inability to use outlets, large-scale emissions of greenhouse gases, and hidden dangers of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

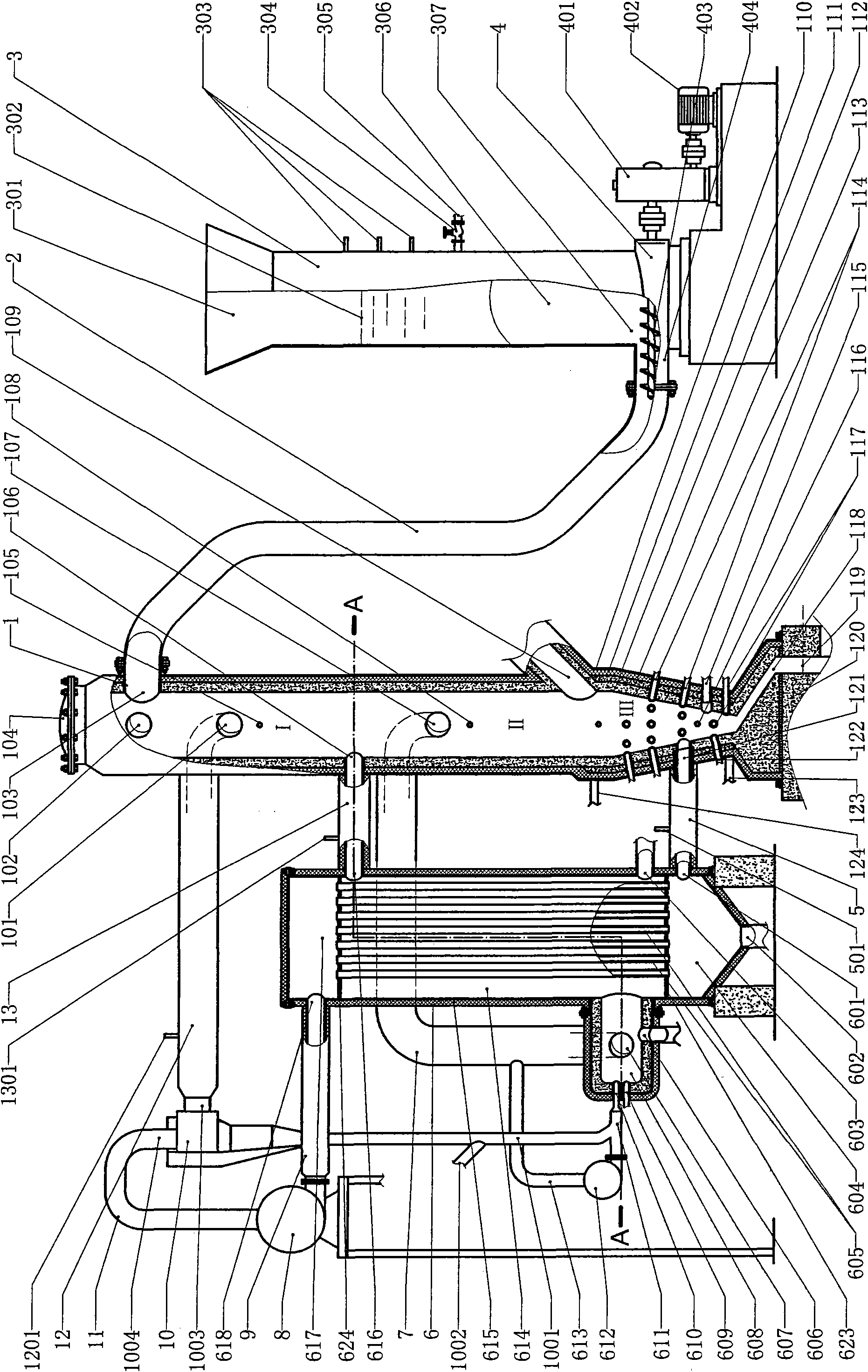

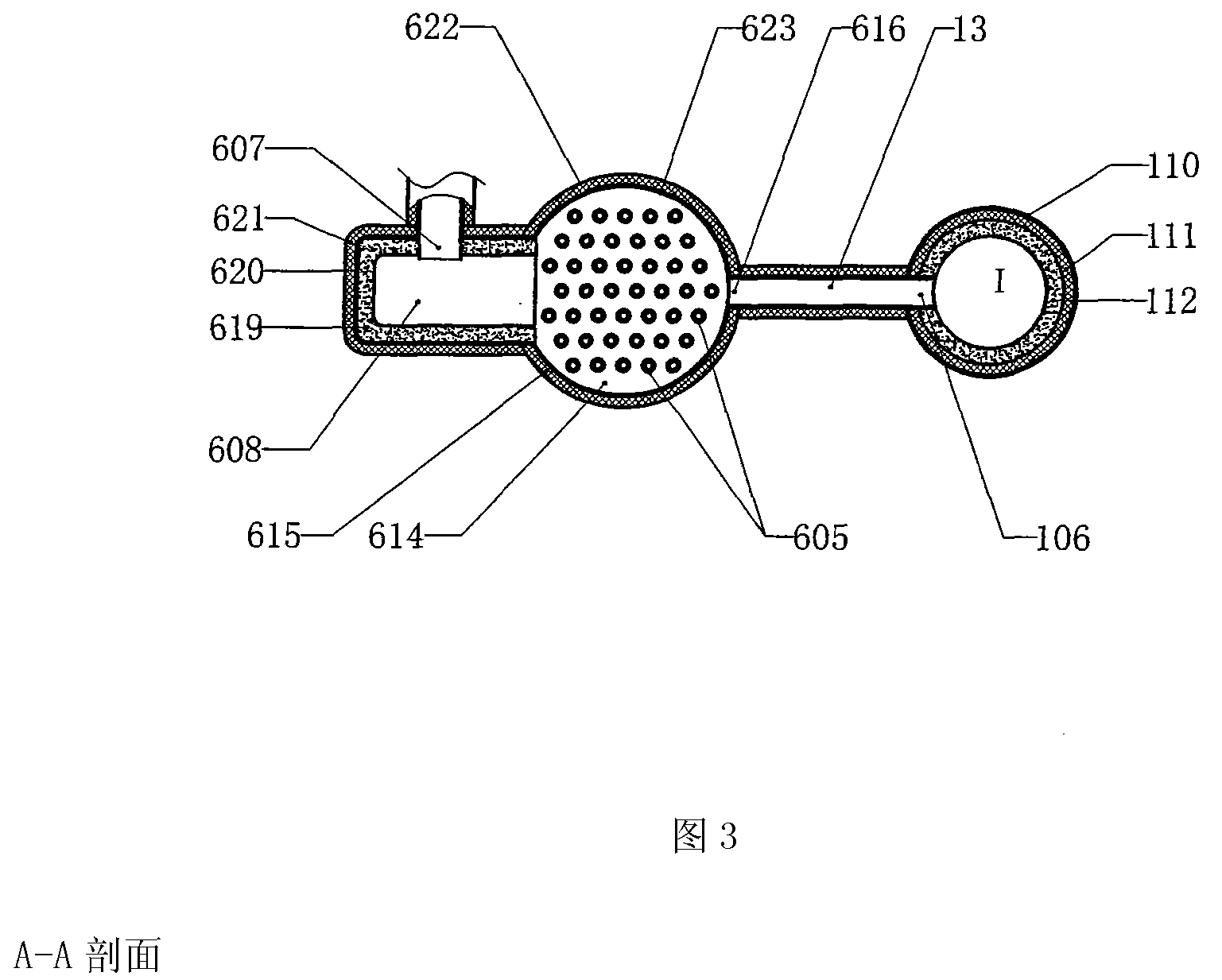

[0036] Example 1: figure 1In the shown embodiment, the domestic waste gasification system of calcium oxide and plasma cooperative gasification is mainly composed of a plasma gasifier (1), a carbon dioxide gas-sealed feeding device, a heat exchanger (6), an induced draft fan (8 ) and a cyclone separator (10), wherein: the carbon dioxide gas sealing feed device is made of a carbon dioxide gas sealing device (3) and a screw feeder (4), and the feeding port (307) of the carbon dioxide gas sealing device (3) It is connected with the feed port of the screw feeder (4), and the discharge port of the screw feeder (4) is connected to the feed port ( 103); the pyrolysis gas outlet (107) of the plasma gasification furnace (1) is connected to the carbonation reaction chamber (608) on the heat exchanger (6) through the connecting pipe (7), and the carbonation reaction chamber (608) Directly communicated with the heat exchange chamber (614), the heat carrier outlet (616) of the heat exchang...

Embodiment 2

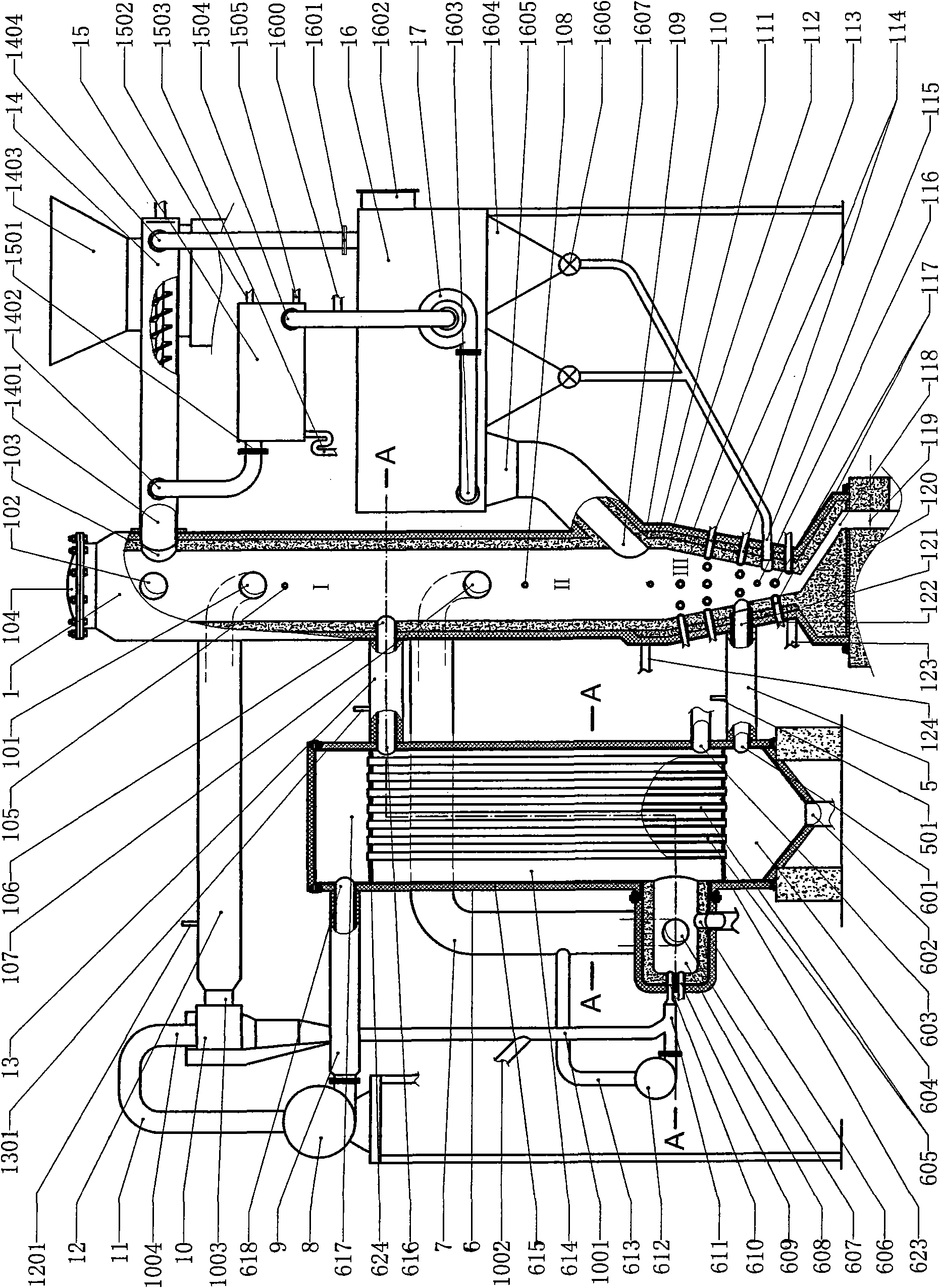

[0038] Embodiment 2: attached figure 2In the shown embodiment, replace in the previous embodiment with the feeding device that is made up of nitrogen gas seal screw feeder (14), dehumidifier (15), nitrogen preheater (16) and induced draft fan (17) A carbon dioxide air-sealed feeding device, wherein: a hopper (1403) is arranged above the nitrogen-enclosed screw feeder (14), and the outlet (1401) of the nitrogen-enclosed screw feeder (14) is connected to the plasma gasifier (1) feed port (103); the synthesis gas outlet (109) of plasma gasifier (1) is connected to the synthesis gas input interface (1605) of nitrogen preheater (16); nitrogen preheater (16) ) of the hot nitrogen outlet (1601) is connected to the hot nitrogen inlet (1404) of the nitrogen seal screw feeder (14), and the nitrogen return gas outlet (1402) of the nitrogen seal screw feeder (14) is connected to the dehumidifier (15 ), the nitrogen inlet port (1501) of the dehumidifier (15), the cold nitrogen outlet (15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com