Treatment method of organic solid waste

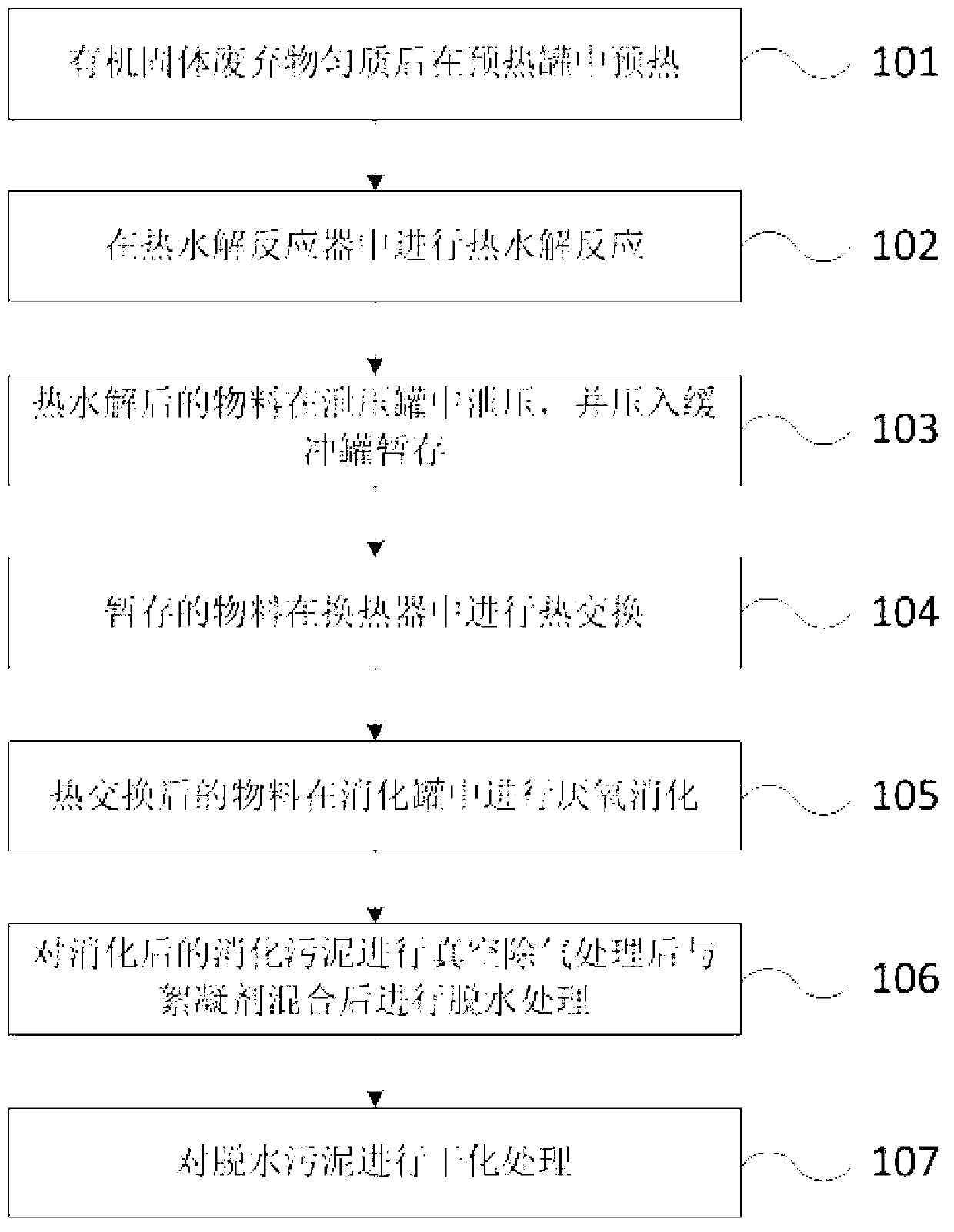

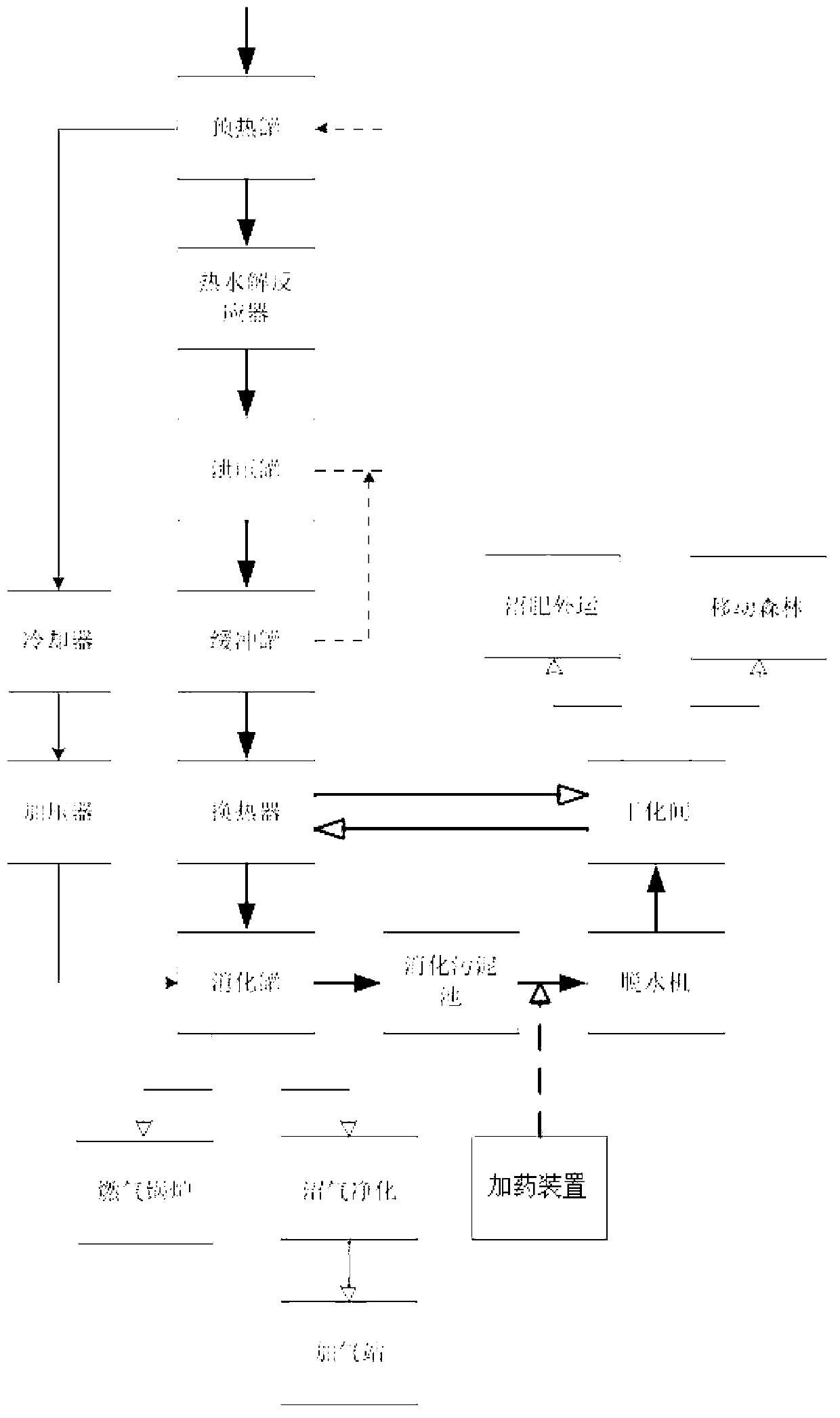

A technology of organic solids and treatment methods, which is applied in the field of environmental engineering, can solve the problems of low treatment efficiency of organic solid waste, low digestion rate of anaerobic digestion method, and waste of a lot of resources by incineration method, so as to improve the biochemical performance and reduce the Hazards of land use and landscaping use, effects of shorter dwell times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Example 1, the organic solid waste is animal husbandry waste, the steps are as above, wherein the thermal hydrolysis reaction temperature is 130°C, the thermal hydrolysis reaction pressure is 2bar, the thermal hydrolysis reaction time is 38min, and the temperature in the digestion process is 40°C, the digestion time is 15 days, the pH value during the digestion process is 7.9, the mass percentage of water in the formed dewatered sludge is 62%, and the water content of the generated biogas residue is 23%; the treatment effect of organic solid waste Significantly enhanced, the reduction of organic solid waste is significantly improved, and the treatment time is significantly reduced, the biogas production is increased by more than 50% compared with the existing process, and the construction cost is further reduced due to the 50% reduction in the volume of the digested sludge tank.

Embodiment 2

[0058] Example 2, the organic solid waste is agricultural straw, the steps are as above, wherein the thermal hydrolysis reaction temperature is 150°C, the thermal hydrolysis reaction pressure is 4bar, the thermal hydrolysis reaction time is 60min, and the temperature during the digestion process is 38 ℃, the digestion time is 20 days, the pH value during the digestion process is 7.8, the mass percentage of water in the formed dewatered sludge is 65%, and the water content of the generated biogas residue is 30%; the treatment effect of organic solid waste is relatively Enhanced, the reduction of organic solid waste has been improved, and the treatment time has been reduced, the biogas production has increased by more than 50% compared with the existing process, and the construction cost has been further reduced due to the 50% reduction in the volume of the digested sludge tank.

Embodiment 3

[0059] Example 3, the organic solid waste is sludge, and the steps are as above, wherein the thermal hydrolysis reaction temperature is 170°C, the thermal hydrolysis reaction pressure is 7bar, the thermal hydrolysis reaction time is 15min, and the temperature during the digestion process is 42 ℃, the digestion time is 11 days, the pH value during the digestion process is 8.0, the mass percentage of water in the formed dewatered sludge is 60%, and the water content of the generated biogas residue is 20%; the treatment effect of organic solid waste is relatively Enhanced, the reduction of organic solid waste is significantly improved, and the treatment time is greatly reduced, the biogas production is increased by more than 50% compared with the existing process, and the construction cost is further reduced due to the 50% reduction in the volume of the digested sludge tank.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com