Domestic waste comprehensive treatment method based on anaerobic digestion and hydrothermal carbonization

A hydrothermal carbonization and anaerobic digestion technology, which is applied in the treatment of biological organic parts, climate change adaptation, and solid waste removal, etc., can solve the problems of high operating cost and occupation of land resources for incineration treatment, and improve the potential of soil carbon sink. , The effect of low operating cost and high degree of resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

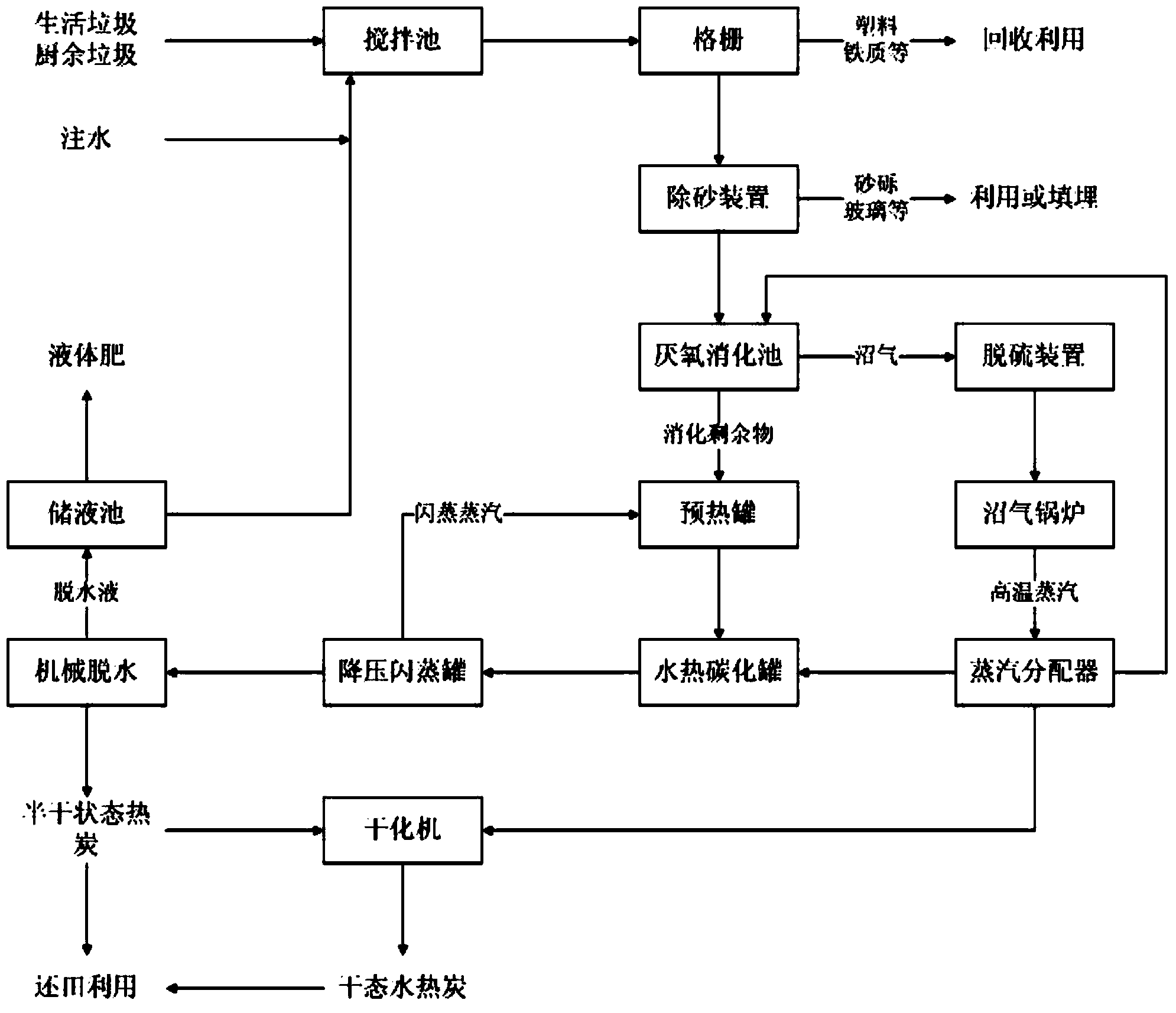

[0028] Comprehensive domestic waste treatment methods based on anaerobic digestion and hydrothermal carbonization, such as figure 1 shown, including

[0029] (1) Slurry treatment: transport domestic garbage to the mixing tank, stir and slurry treatment for 0.5h after water injection, and then transport to the grid to separate large pieces of rubber, plastic and other materials in the material, and then transport to the removal The fine sand, glass and other debris are separated in the sand device to obtain a slurry with a moisture content of 80%;

[0030] (2) Anaerobic digestion: pump the slurry into the anaerobic digestion tank for anaerobic digestion. The temperature of anaerobic digestion is controlled at 32°C. The generated biogas is first passed to the desulfurization device for treatment, and then passed to the biogas boiler for combustion to generate high temperature Steam and digested residues are transported to the preheating tank for preheating treatment for 1 hour,...

Embodiment 2

[0034] Comprehensive domestic waste treatment methods based on anaerobic digestion and hydrothermal carbonization, such as figure 1 shown, including

[0035] (1) Slurry treatment: transport domestic waste to the mixing tank, stir and slurry treatment for 1 hour after water injection, and then transport it to the grid to separate the rubber, plastic and other large pieces in the material, and then transport it to the sand removal The fine sand, glass and other debris are separated in the device to obtain a slurry with a moisture content of 90%;

[0036] (2) Anaerobic digestion: pump the slurry into the anaerobic digestion tank for anaerobic digestion. The temperature of anaerobic digestion is controlled at 38°C. The generated biogas is first passed to the desulfurization device for treatment, and then passed to the biogas boiler for combustion to generate high temperature Steam and digested residues are transported to the preheating tank for preheating treatment for 3 hours, a...

Embodiment 3

[0040] Comprehensive domestic waste treatment methods based on anaerobic digestion and hydrothermal carbonization, such as figure 1 shown, including

[0041](1) Slurry treatment: Transport domestic waste to the mixing tank, stir and slurry treatment for 0.8h after water injection, and then transport it to the grid to separate large pieces of rubber, plastic, etc. in the material, and then transport it to the removal The fine sand, glass and other sundries are separated in the sand device to obtain a slurry with a moisture content of 83%;

[0042] (2) Anaerobic digestion: pump the slurry into the anaerobic digestion tank for anaerobic digestion. The temperature of anaerobic digestion is controlled at 55°C. The generated biogas is first passed to the desulfurization device for treatment, and then passed to the biogas boiler for combustion to generate high temperature Steam and digested residues are sent to the preheating tank for preheating treatment for 1.5 hours, and the preh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com