Patents

Literature

35results about How to "Complete gasification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

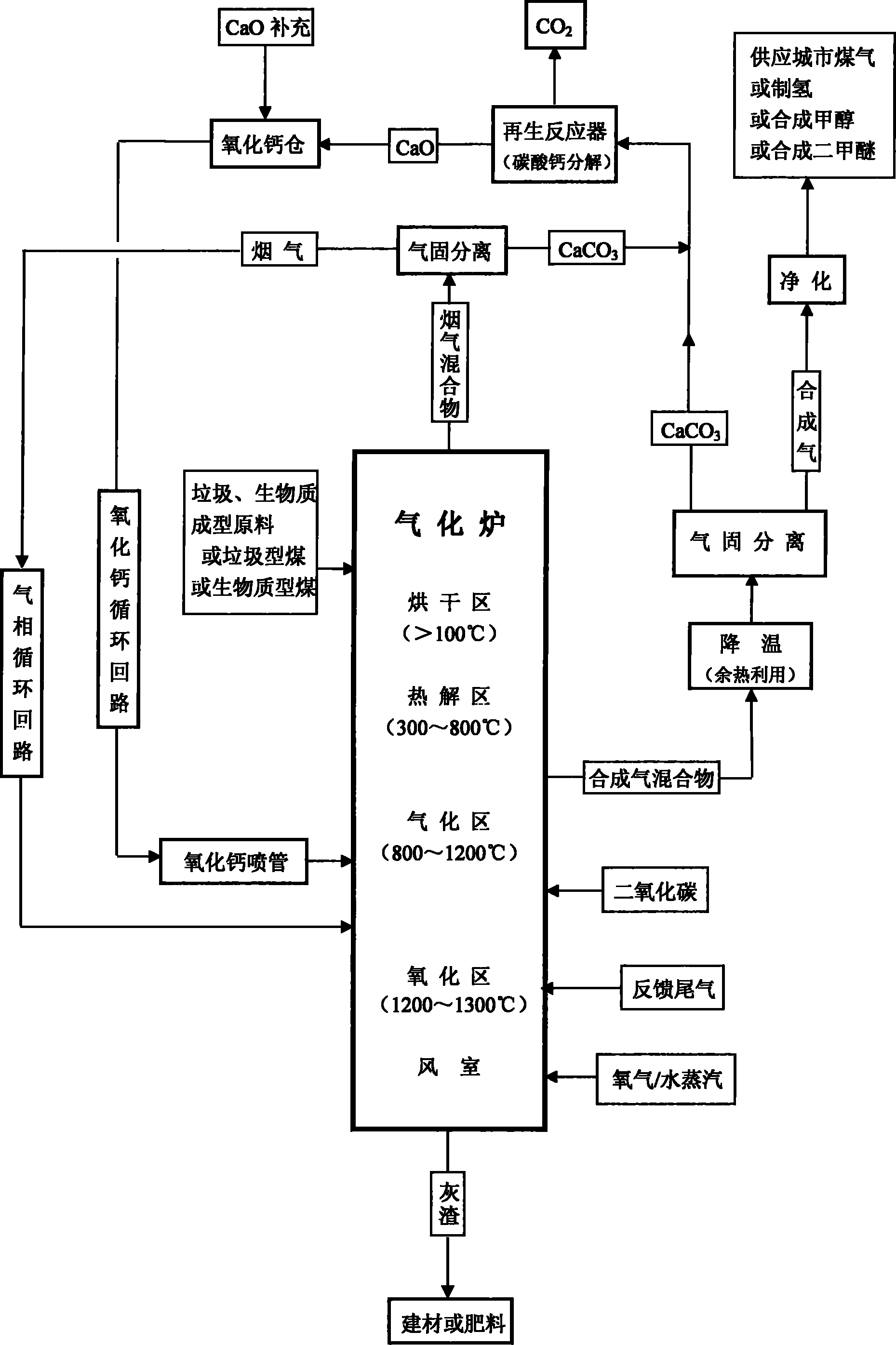

Gasification process for producing synthesis gas from garbage and biomass raw materials

InactiveCN101525118AEliminate pollutionHarmlessHydrogen productionSpecial form destructive distillationGas phaseWater vapor

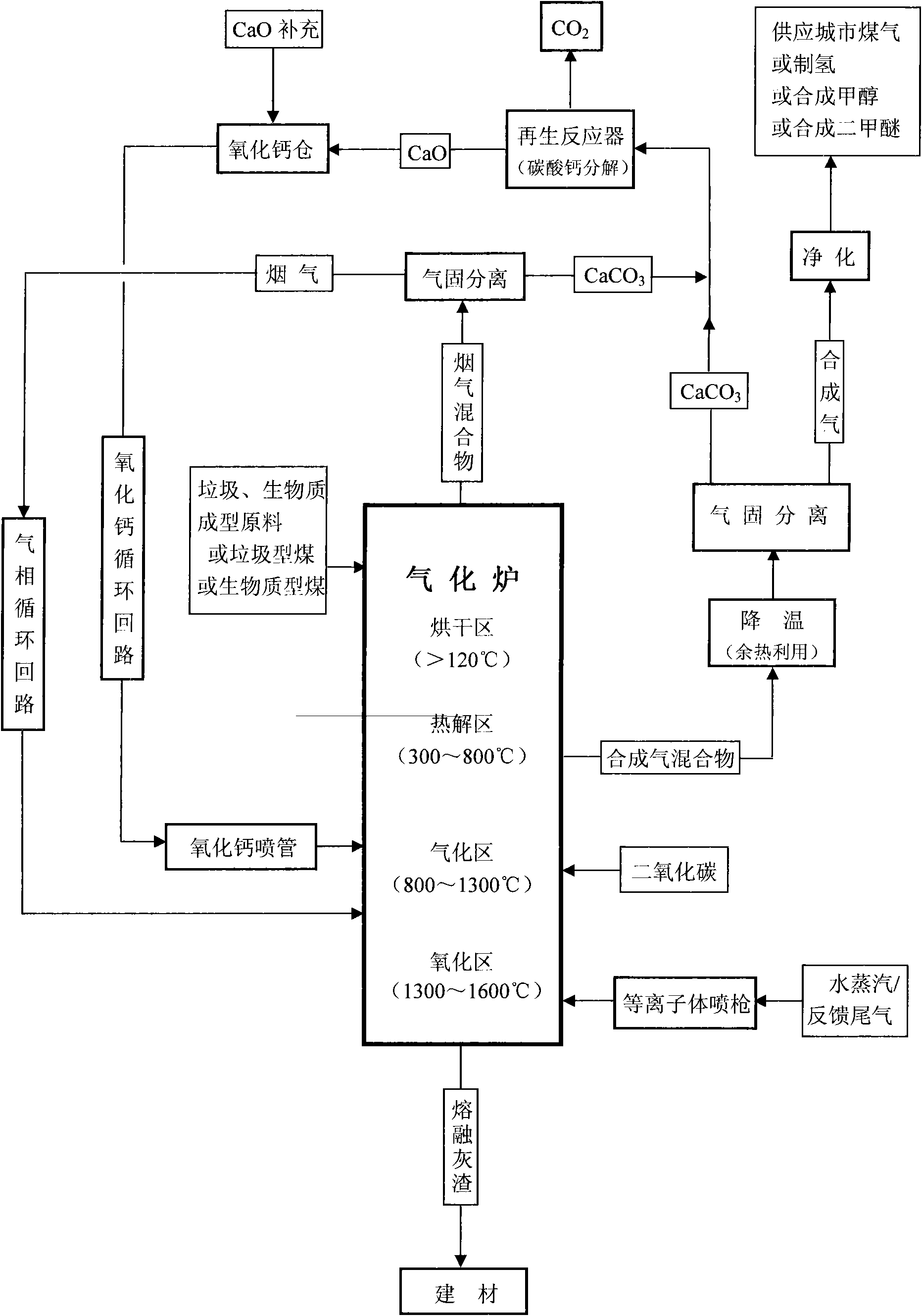

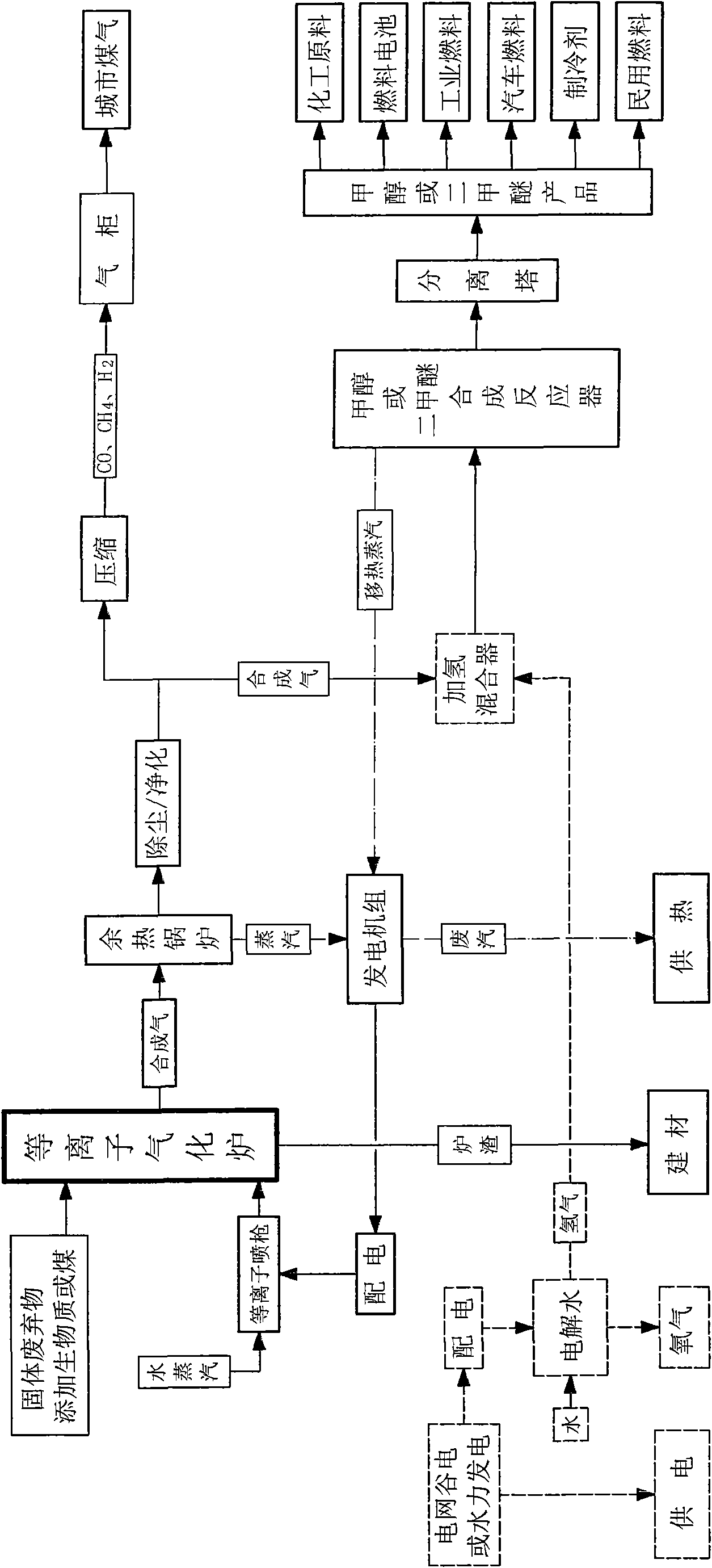

The invention provides a gasification process for producing synthesis gas from garbage and biomass raw materials, which relates to a gasification processing technique of garbage and biomasses. The gasification process is characterized in that the technological process mainly comprises a raw material solid matter process, a gas phase circulation loop, a calcium oxide circulation loop and a synthesis gas drawing process; one or a mixture of more garbage, the biomasses and coal is sent into a gasification furnace to perform gasification so as to generate the synthesis gas; and simultaneously, calcium oxide is sent into the gasification furnace, an exothermic reaction of absorbing carbon dioxide by the calcium oxide provides the heat required by the gasification reaction in the furnace, and water vapor is sent into a plasma spraying gun and is heated to more than 3,100 DEG C to generate H2, O, O2 and H2O<*> which are sprayed into the gasification furnace to perform reactions with the garbage and the biomasses and supply heat into the furnace. The gasification process adopts a measure to spray the calcium oxide into the furnace to not only greatly reduce the electric energy consumption of the plasma spraying gun, but also improve the quality and the yield of the synthesis gas, thus the aim of transforming the garbage and the biomasses into clean energy can be achieved easily.

Owner:周开根

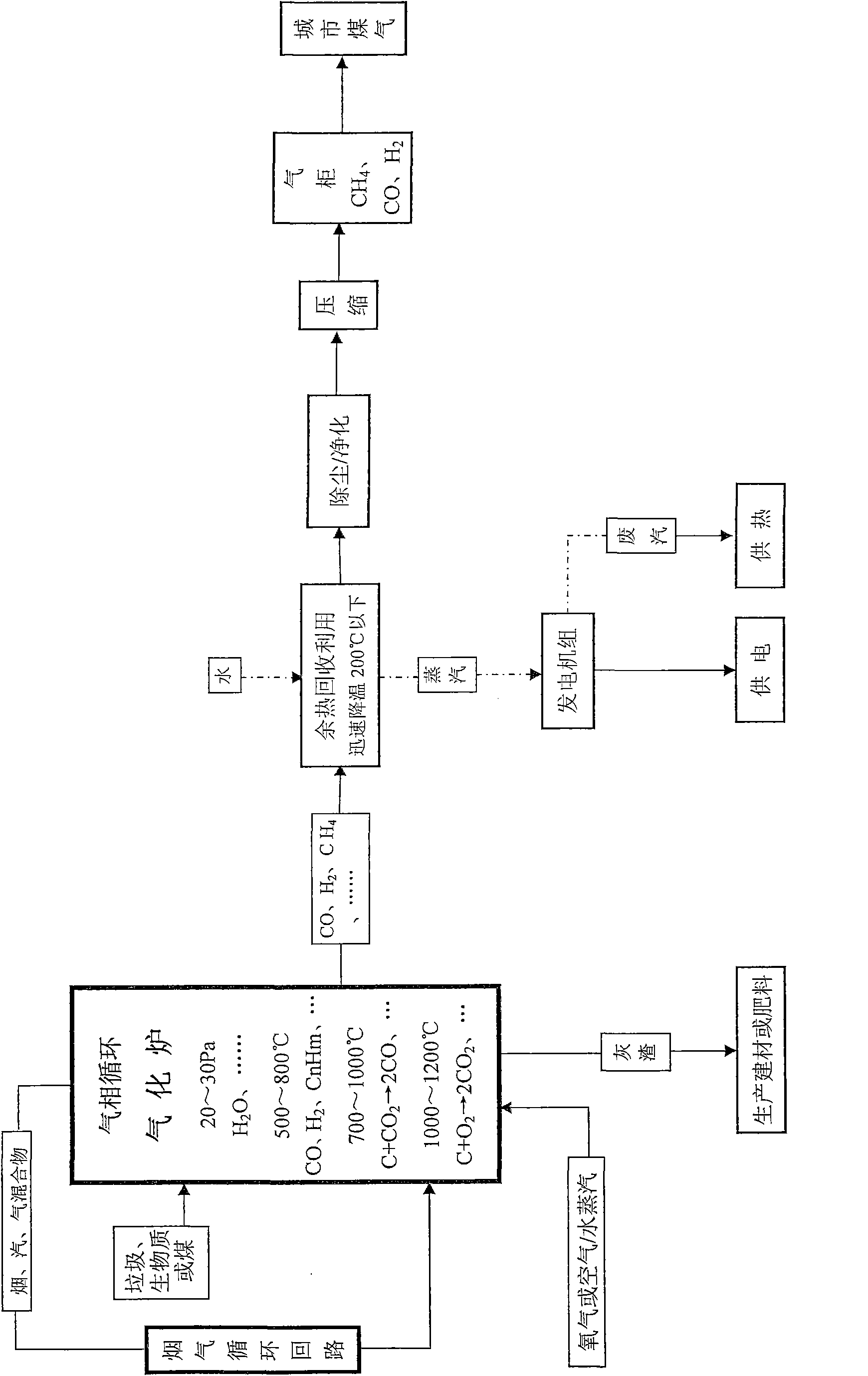

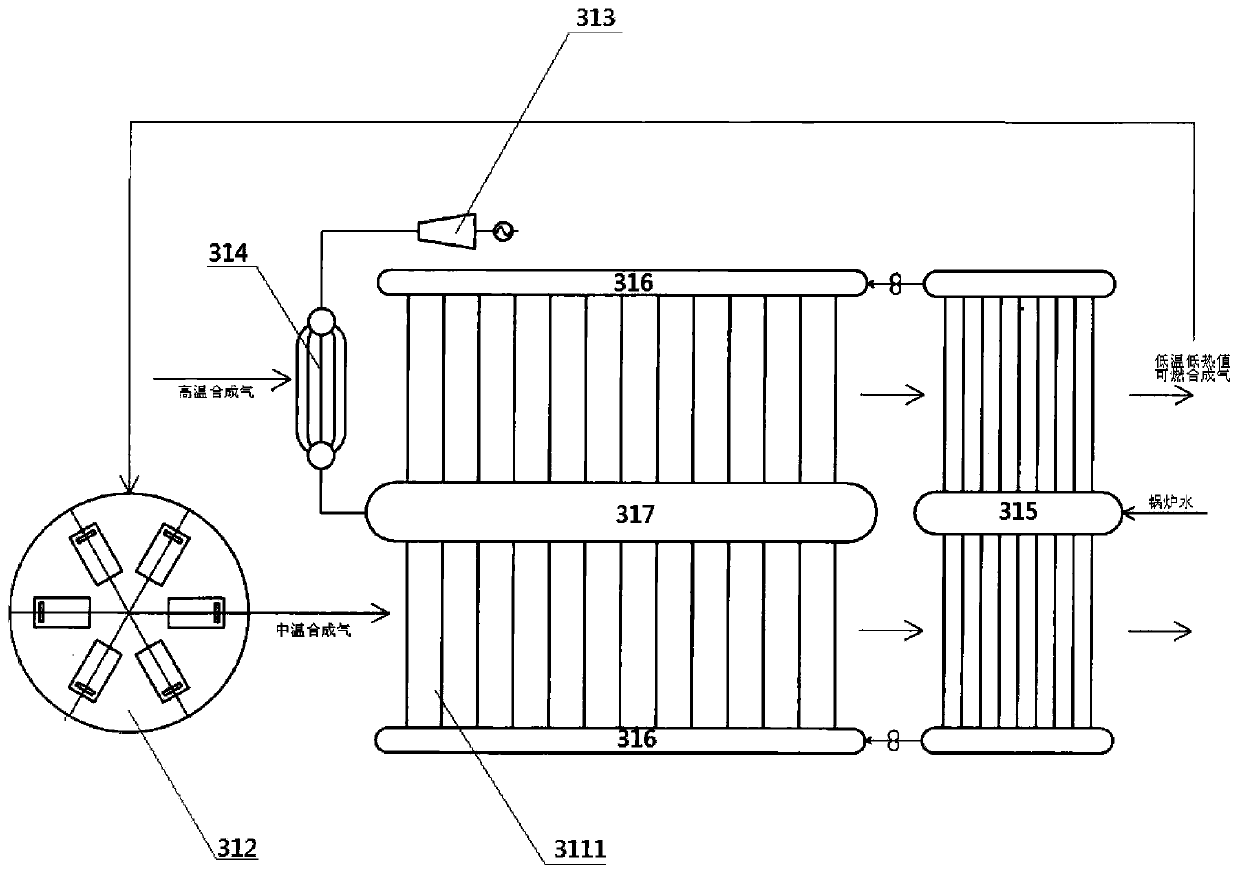

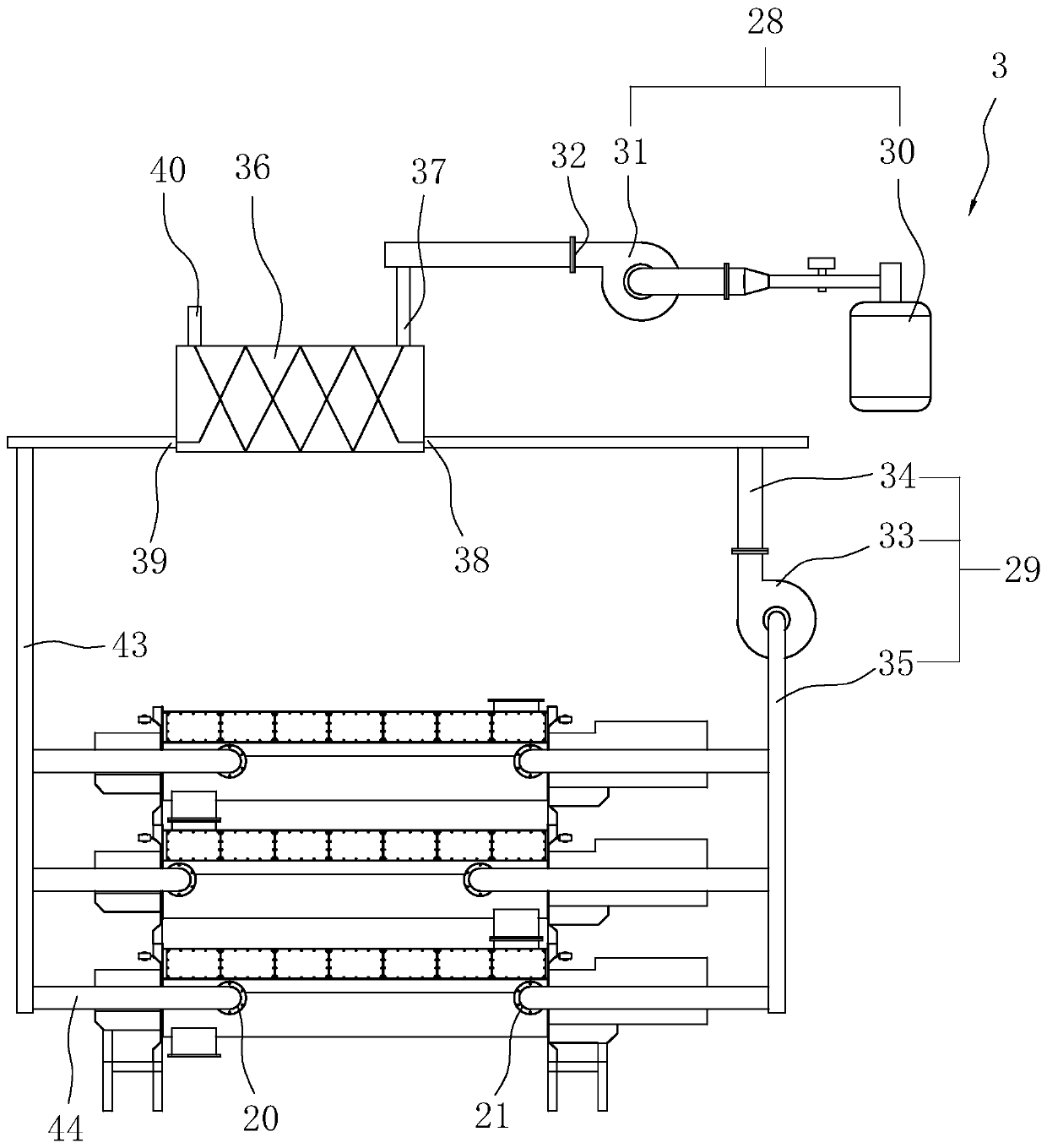

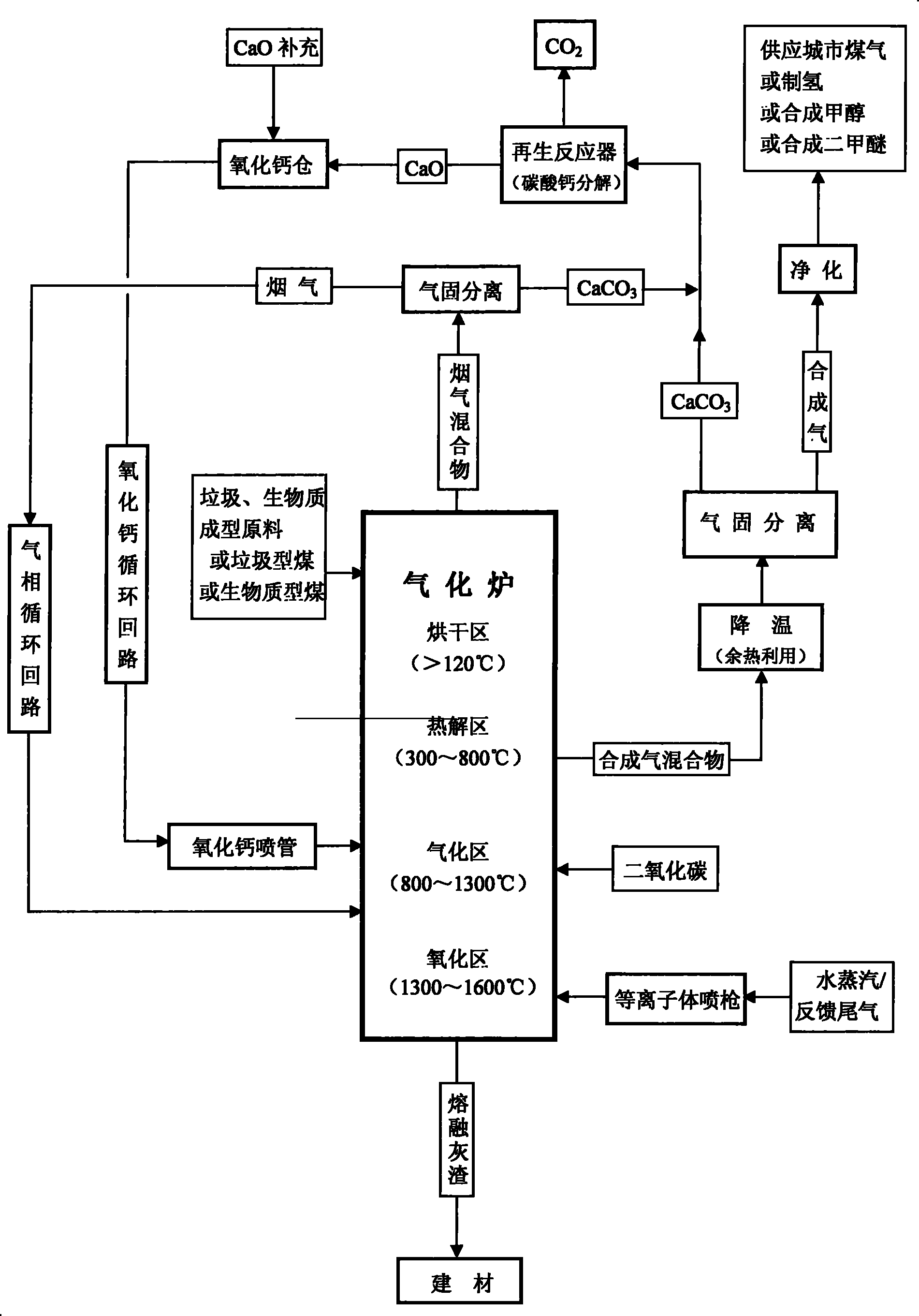

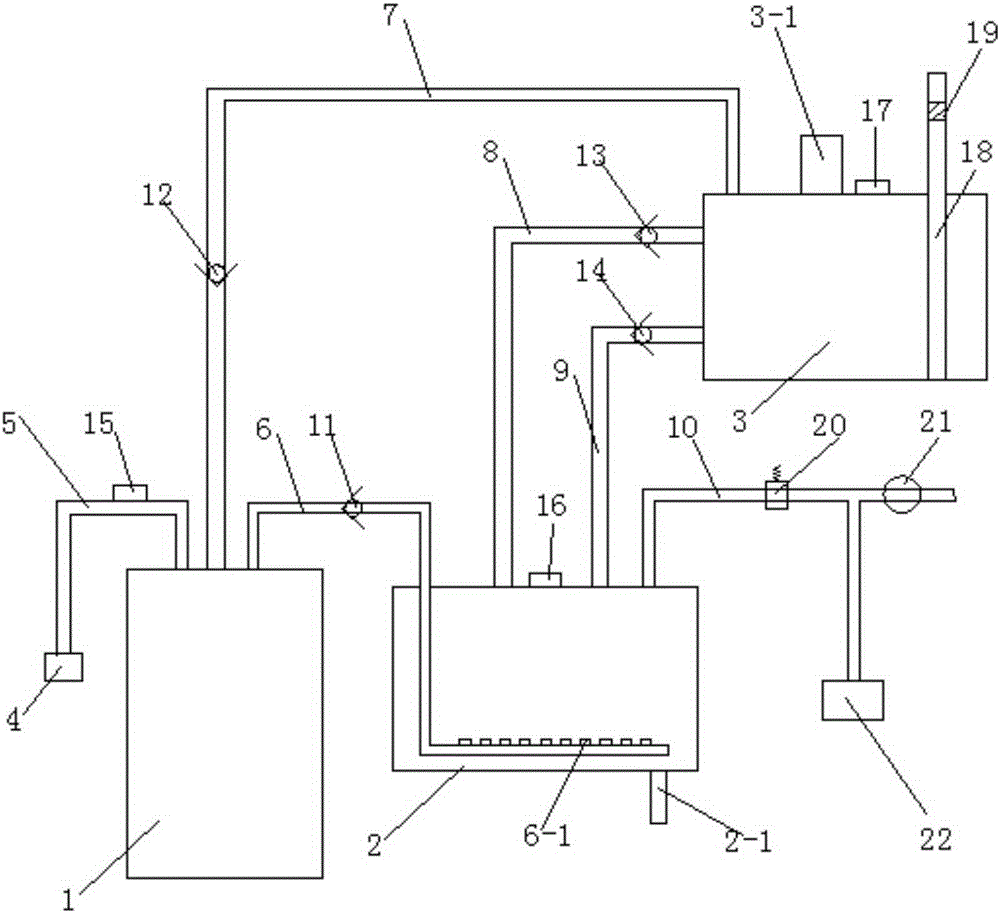

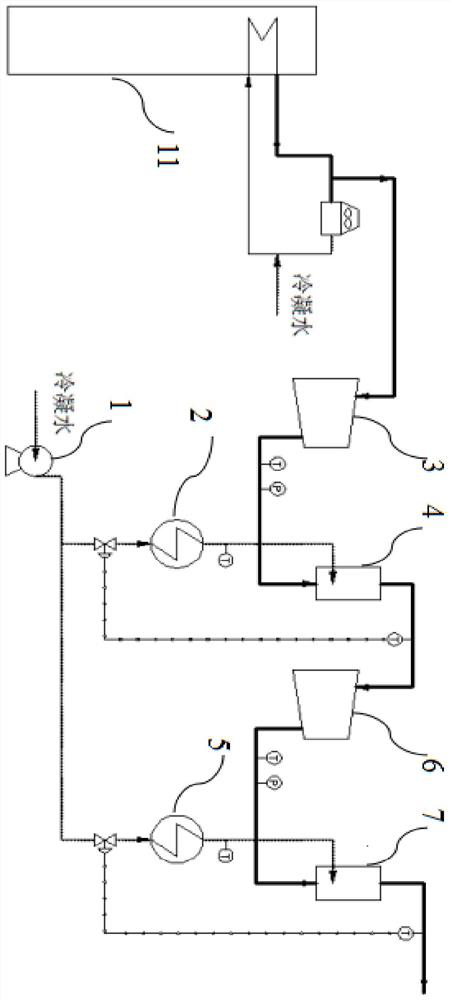

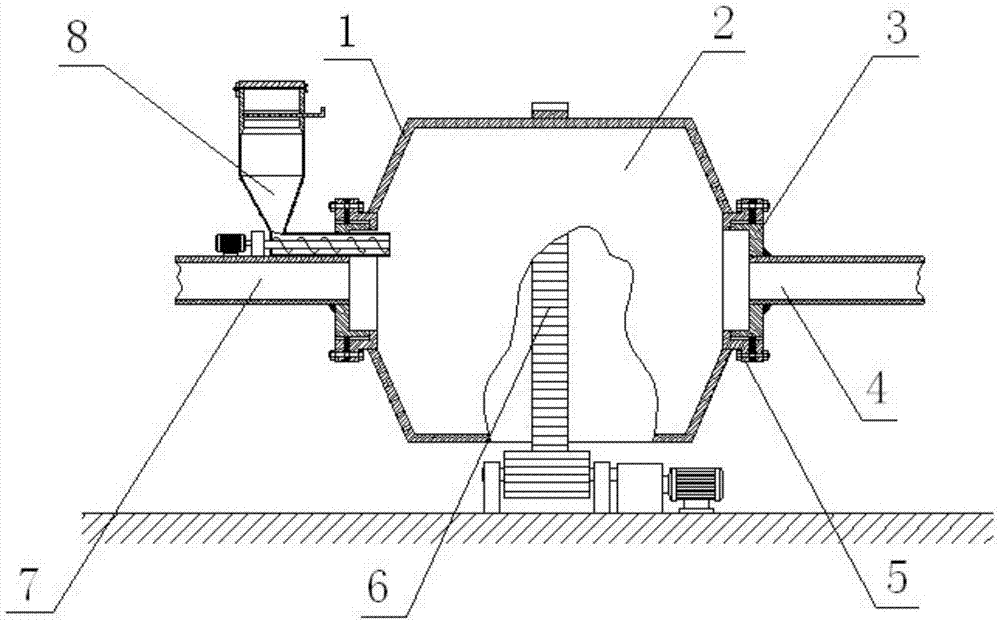

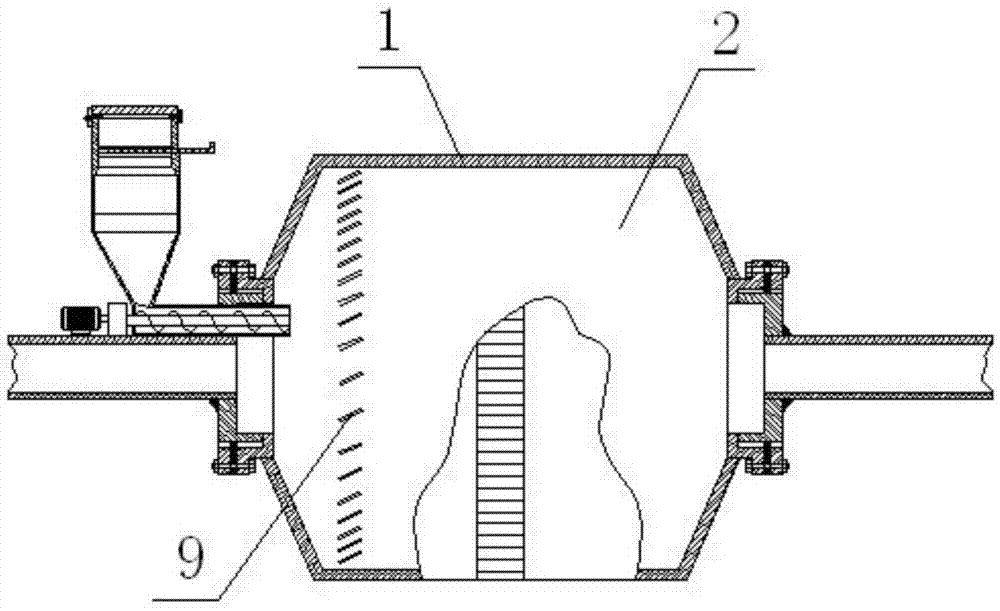

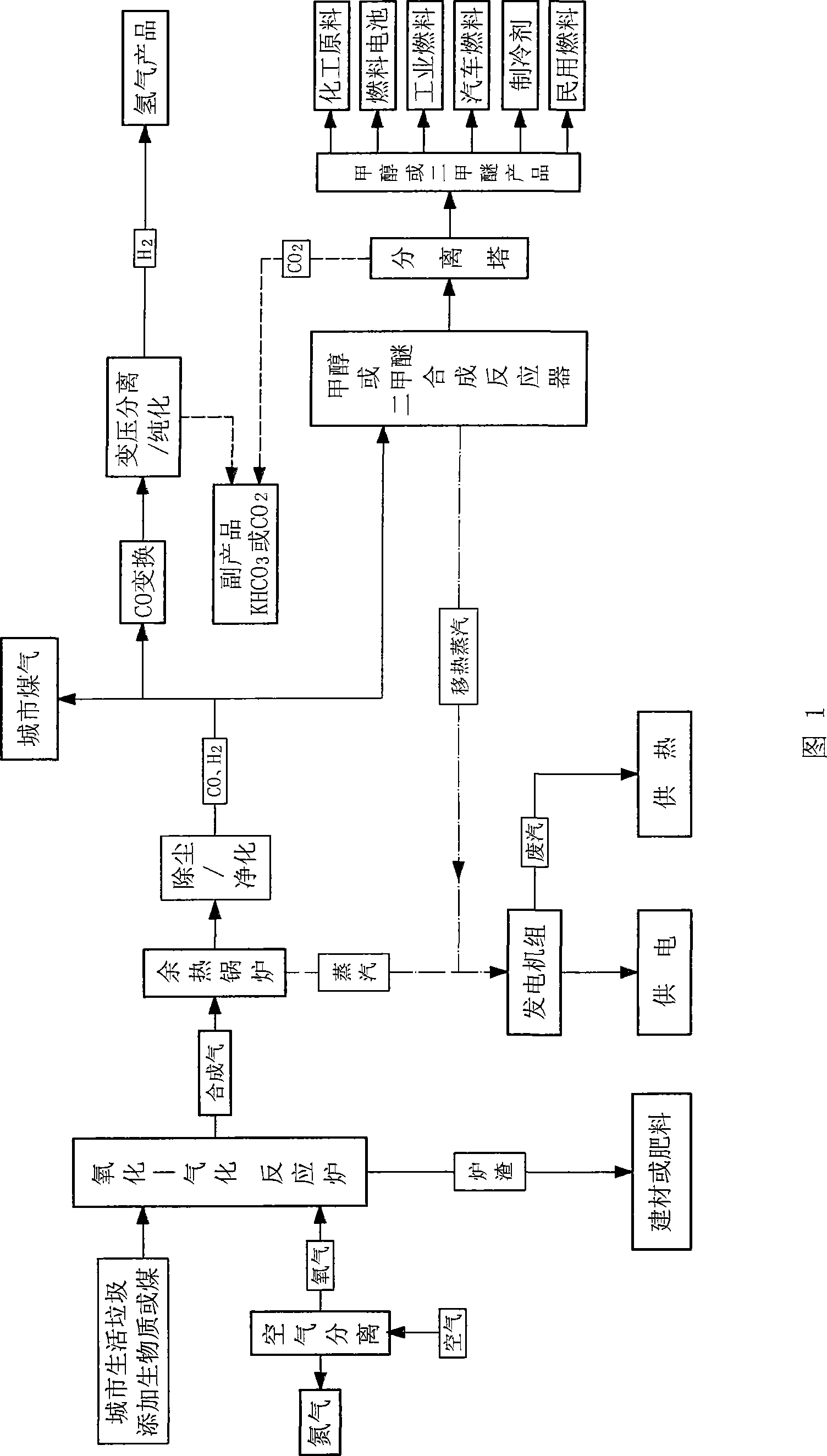

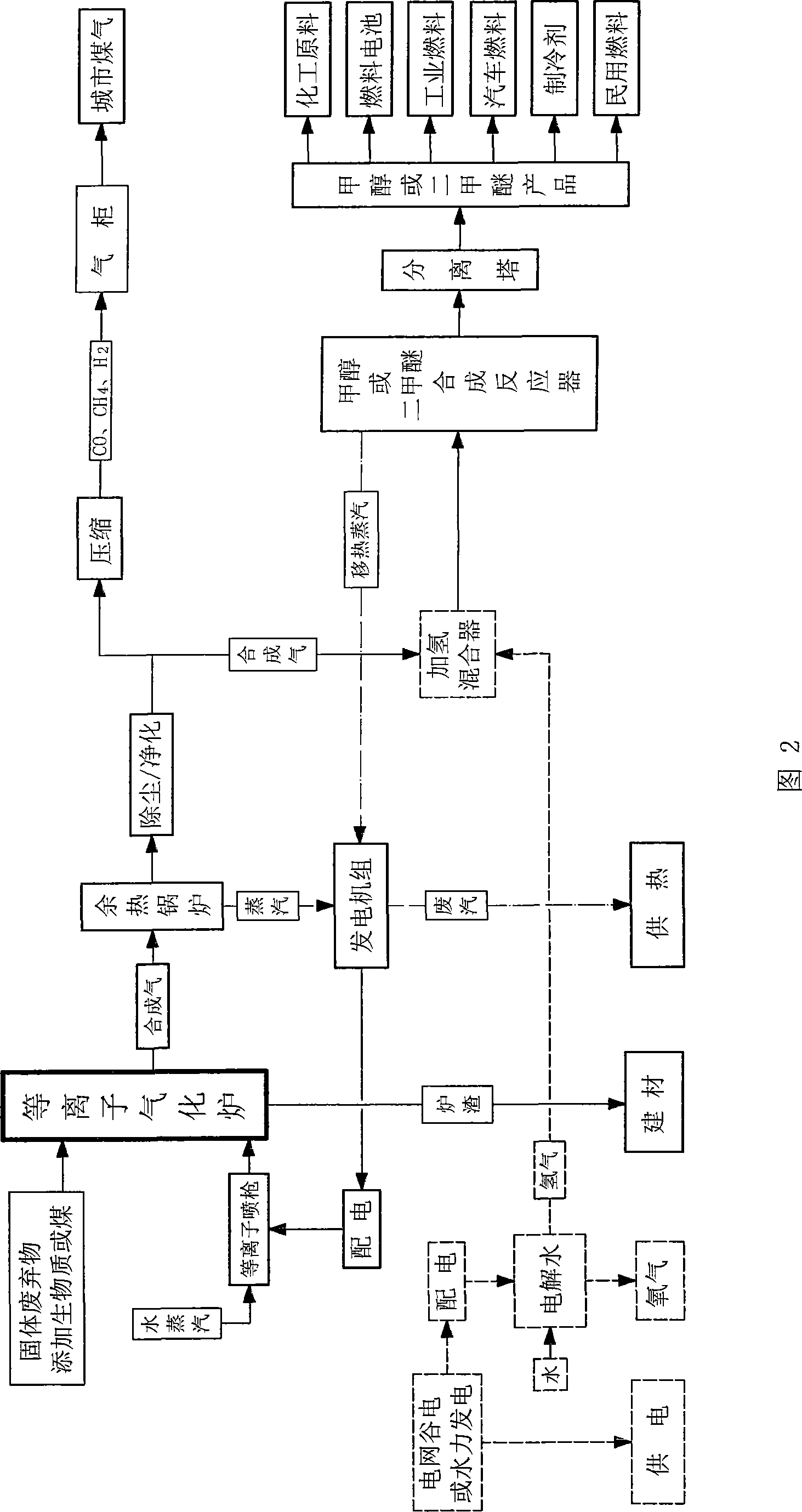

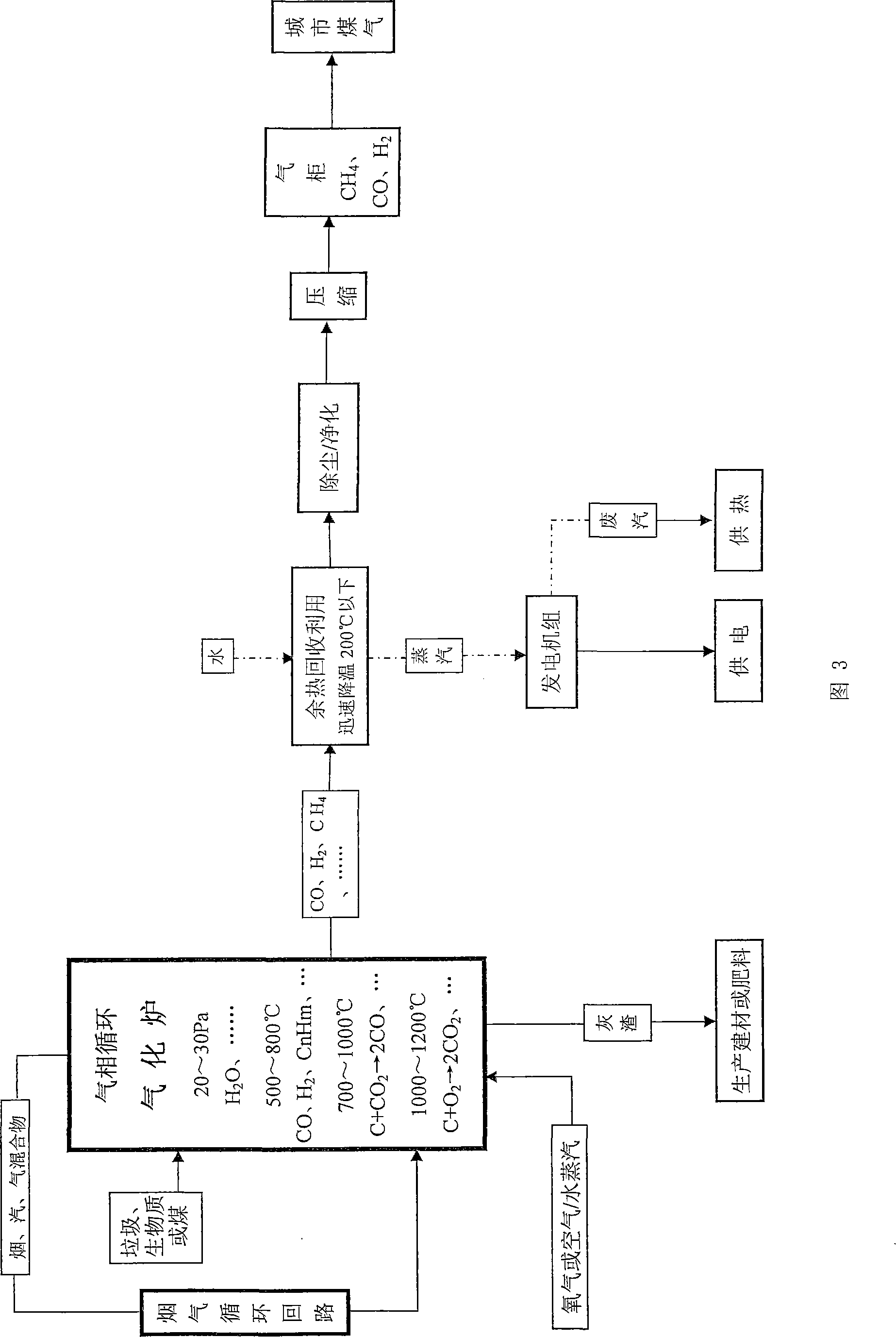

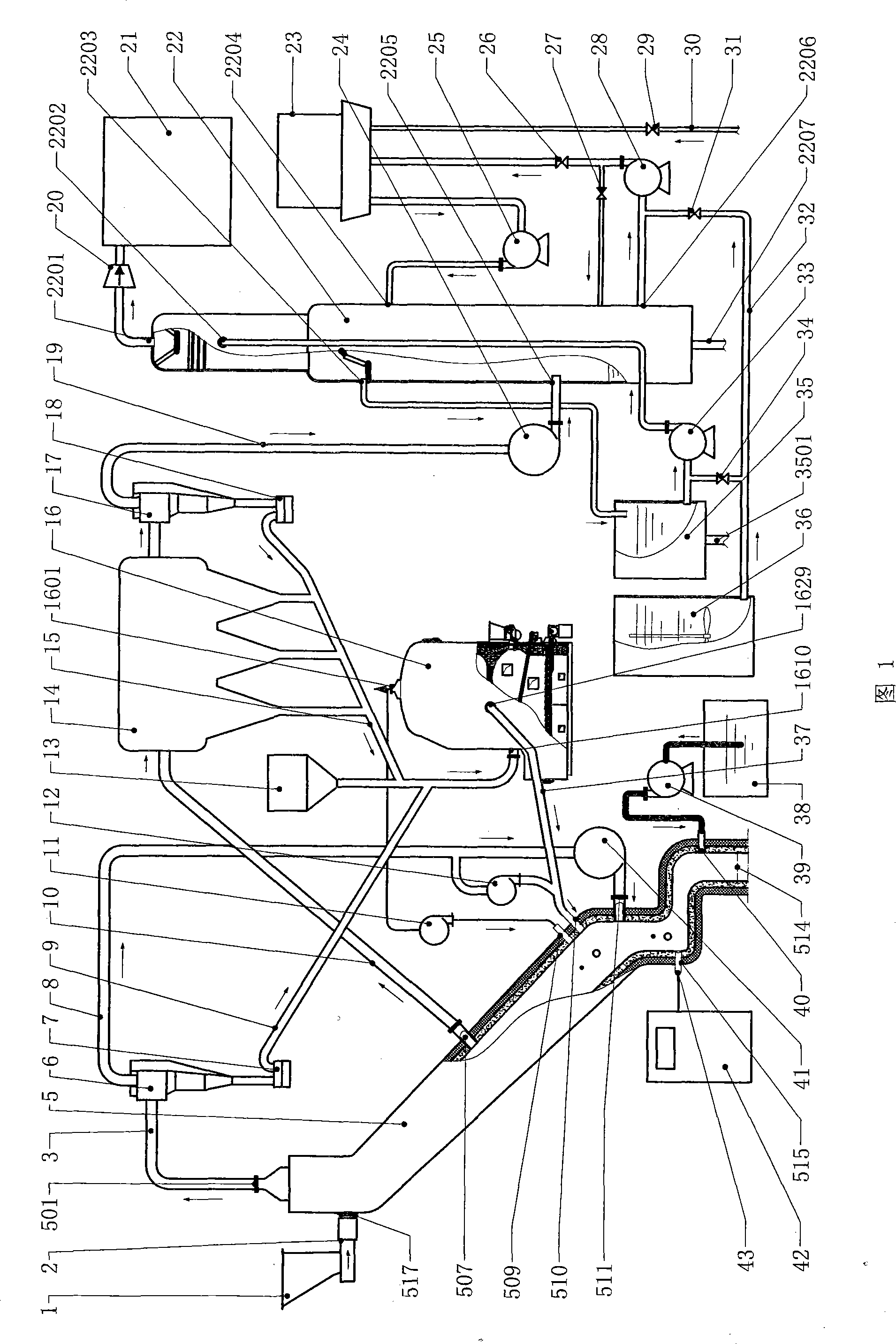

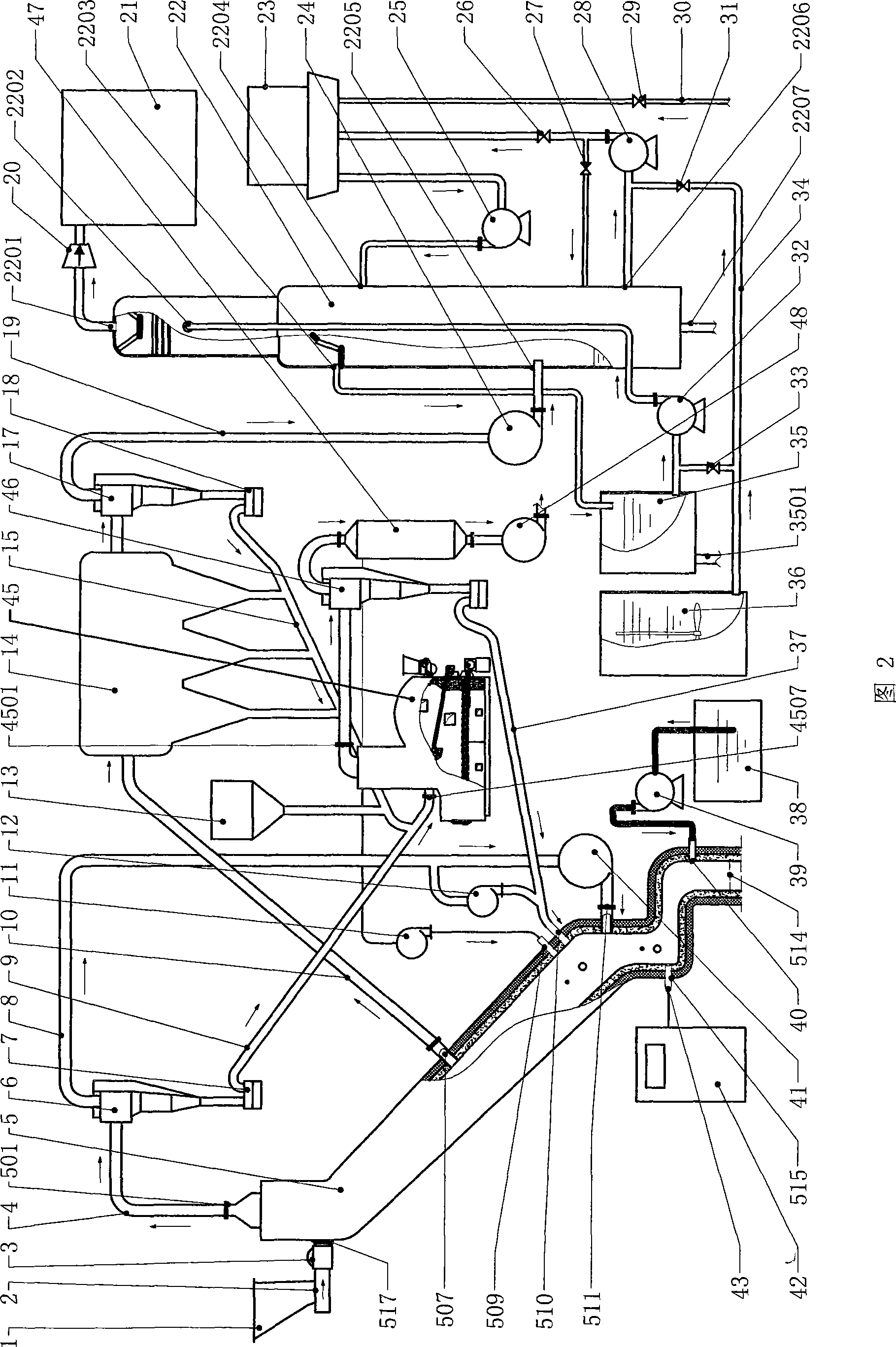

Process, system and device for waste biomass multi-production processing

ActiveCN101565629AEliminate pollutionHarmlessHydrogen separationCombustible gas catalytic treatmentEcological environmentGas phase

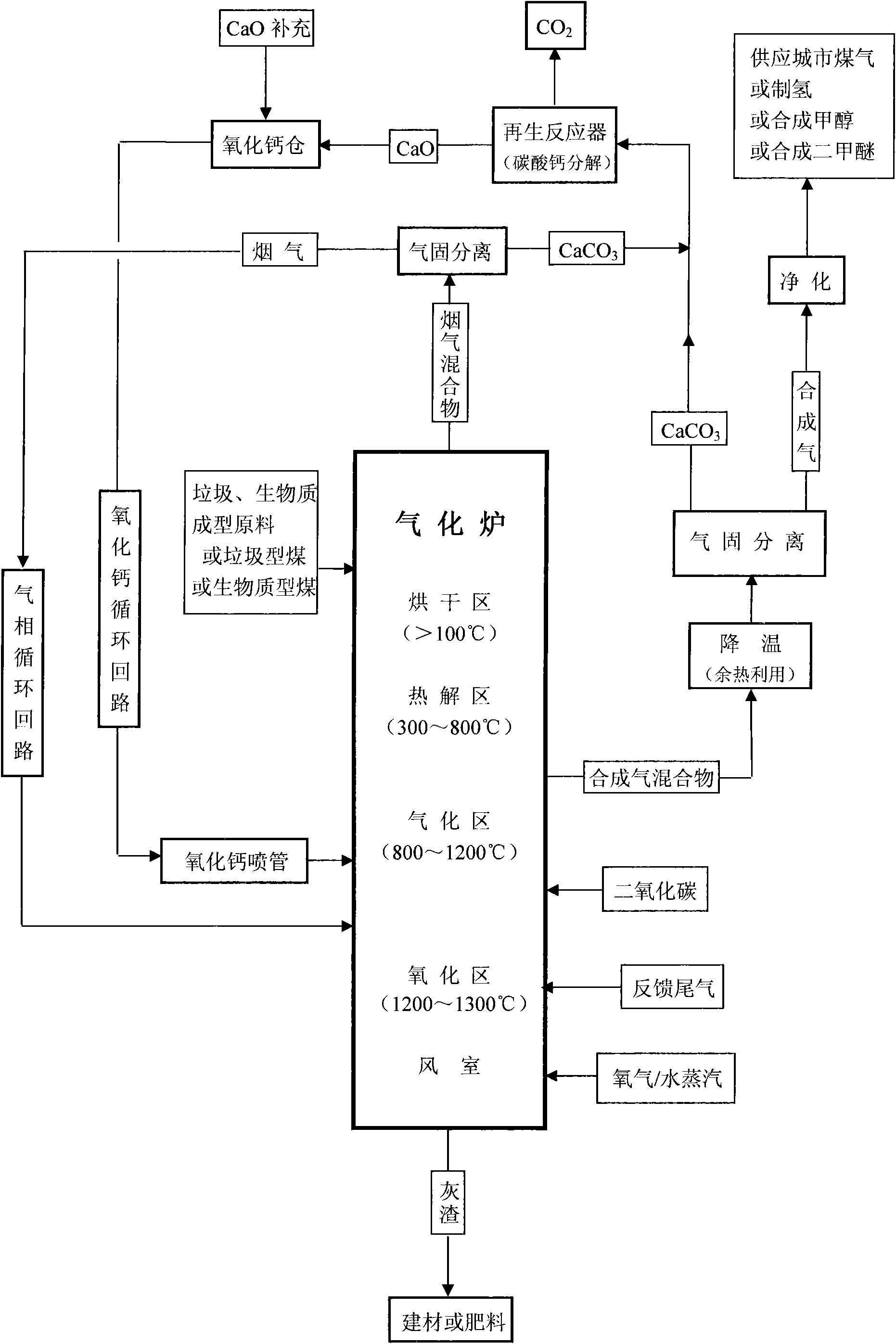

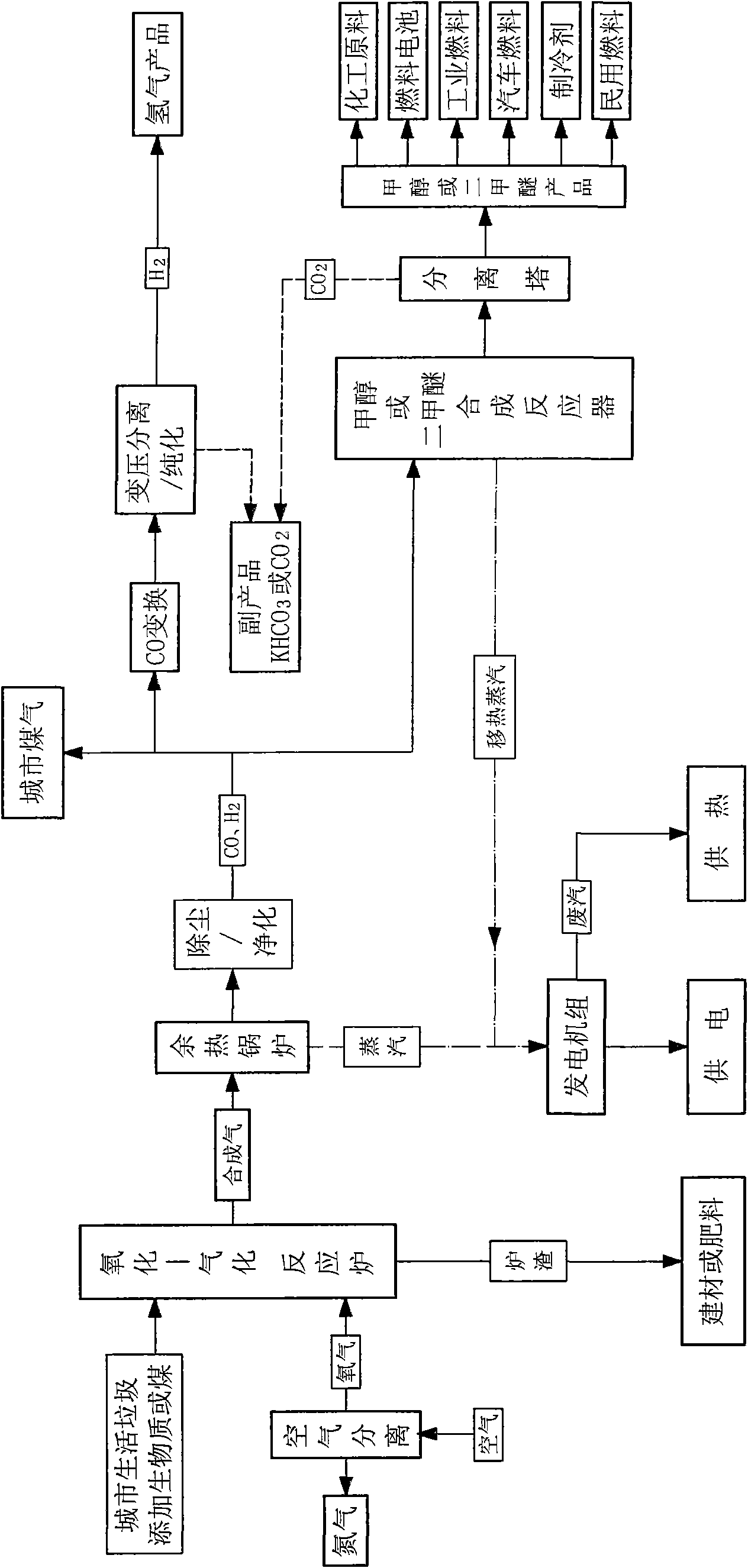

The invention relates to a process, a system and a device for waste biomass multi-production processing, in particular to a waste biomass gasification and liquefaction treatment system. The gasification treatment is performed to the waste biomass, the gas is used for producing clean energy and chemical raw materials, the furnace slag is used for producing building materials or fertilizer and the waste heat is used for electric power generation and heat supply so as to realize the environmental-friendly municipal solid waste treatment and the ecological environment protection. The system mainlycomprises a gas-phase circulation gasification furnace, a flue gas circulation air tube, a flue gas circulation fan, a dust-removal / purifying tower and a synthesis reactor and is characterized in that the gas-phase circular reaction is performed to the flue gas in the gasification furnace, the water vapor and the gaseous matter generated during the pyrolysis to obtain hydrogen-rich synthetic gas,and meanwhile, the dioxin (violent in toxicity) is broken up; and the post treatment is performed to the hydrogen-rich synthetic gas to generate city gas, methanol, dimethyl ether or hydrogen. The system has the advantages of full gasification of the solid raw material, no pollutant discharge, extremely low exhaust emission and easy purifying treatment, and the device is flexible in size and is feasible for popularization.

Owner:上海格灵迈环境科技有限公司

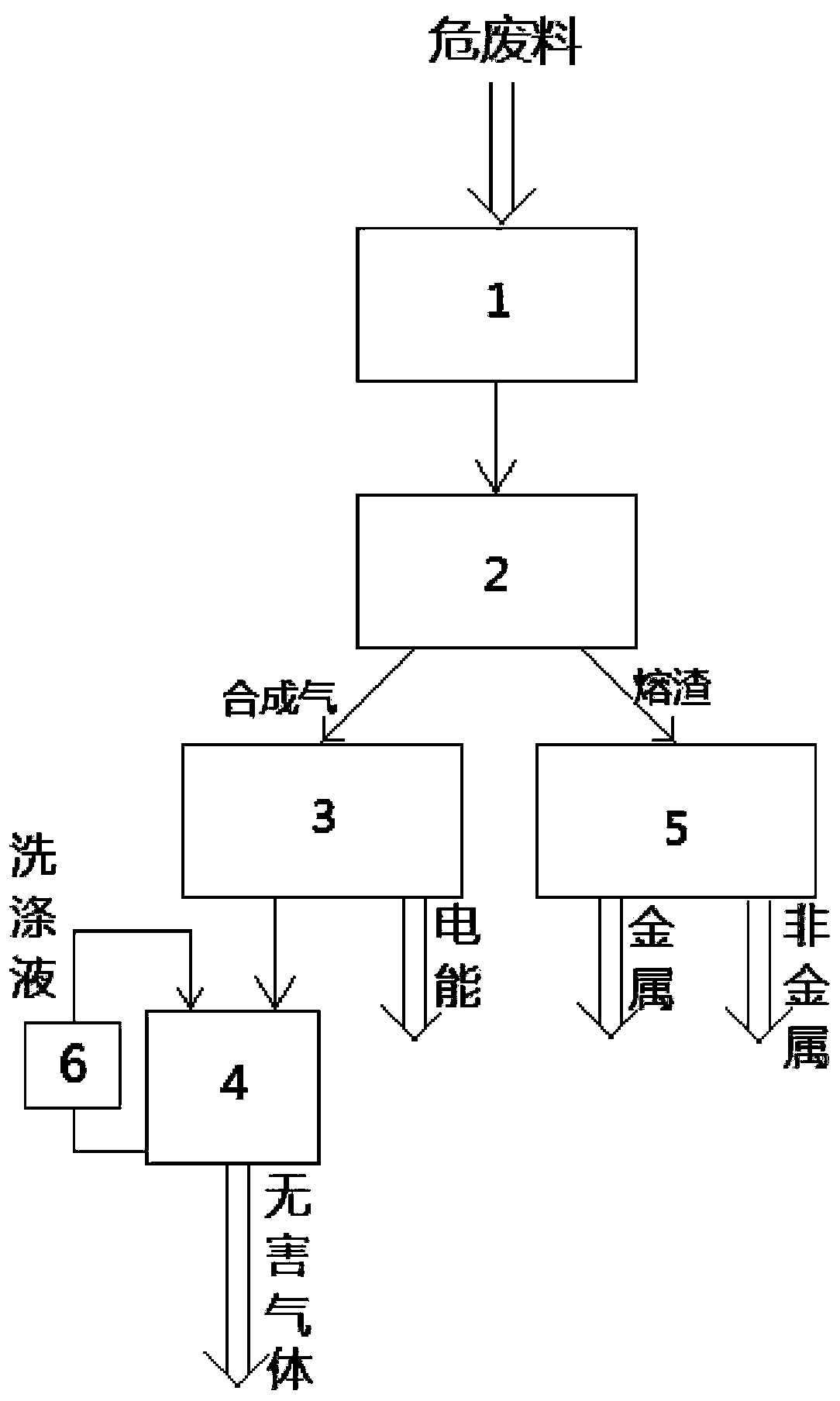

Two-stage plasma gasifying, melting and cracking method and device of waste containing organic matters

ActiveCN102000691ANo emissionsComplete gasificationSolid waste disposalGlass furnace apparatusGeneration rateHigh energy

The invention relates to a treatment method of waste containing organic matters, in particular to two-stage plasma gasifying, melting and cracking method and device of the waste containing organic matters, belonging to the field of gasifying, melting and cracking techniques. In the invention, the serious defects of high energy consumption of the waste containing organic matters and more flying ash during the plasma arc melting and cracking are solved, thereby thoroughly utilizing the energy of the organic matters and maximizing the treating efficiency, thoroughly cracking the tar, reducing the generation rate of Dioxin, obtaining synthesis gas with high quality and high heat value as much as possible, providing guarantee for the subsequent gasification power generation, the hydrogen energy recovery or the production of green liquid fuel, simultaneously finishing one-step recovery of noble metals and direct utilization of glass bodies in the field of building materials, laying foundation for the large-scale commercial development and application of the energy of the waste containing organic matters, and thoroughly solving the possible pollutant discharging problem in the gasifying process of the organic matters, particularly the dangerous waste.

Owner:HOOTECH

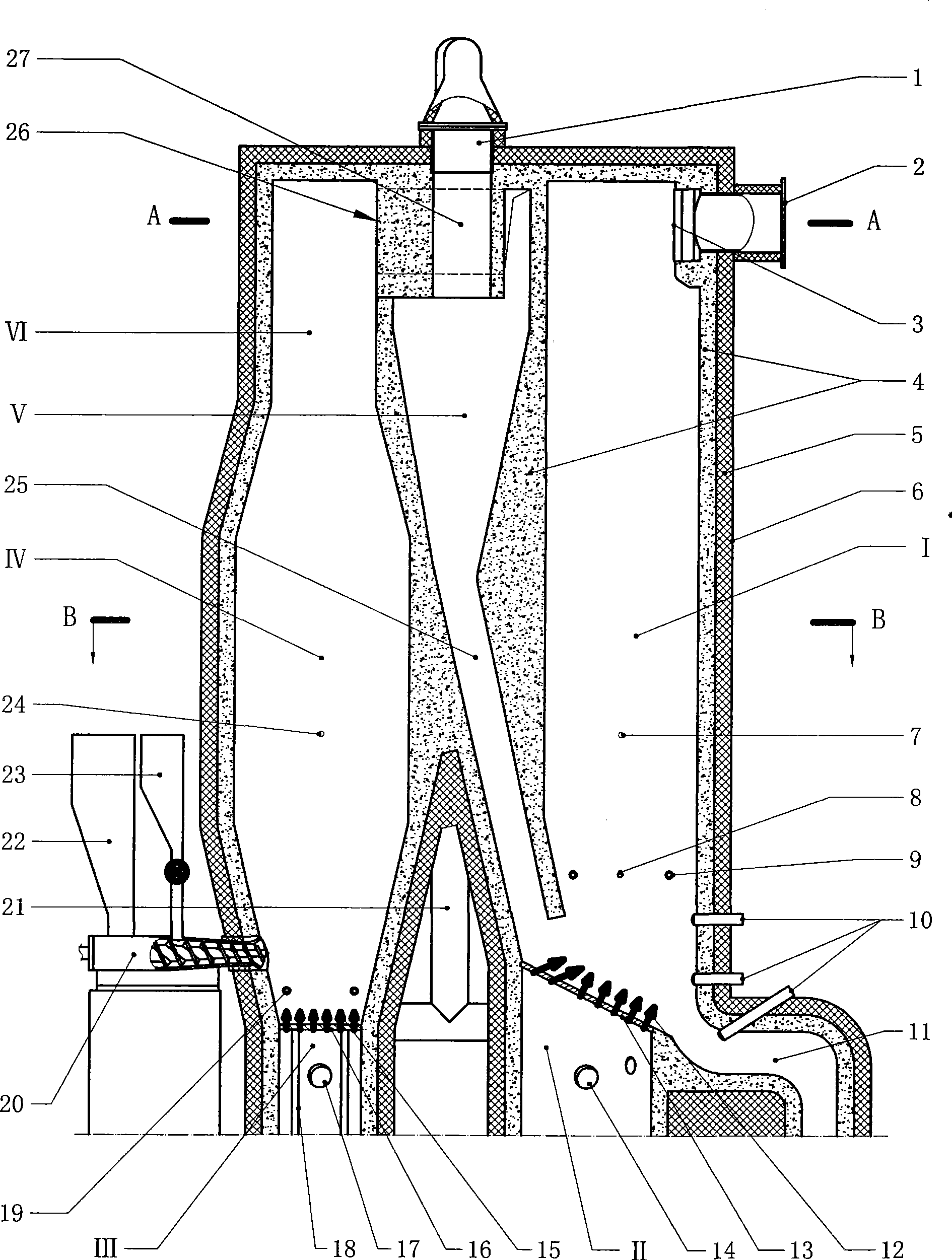

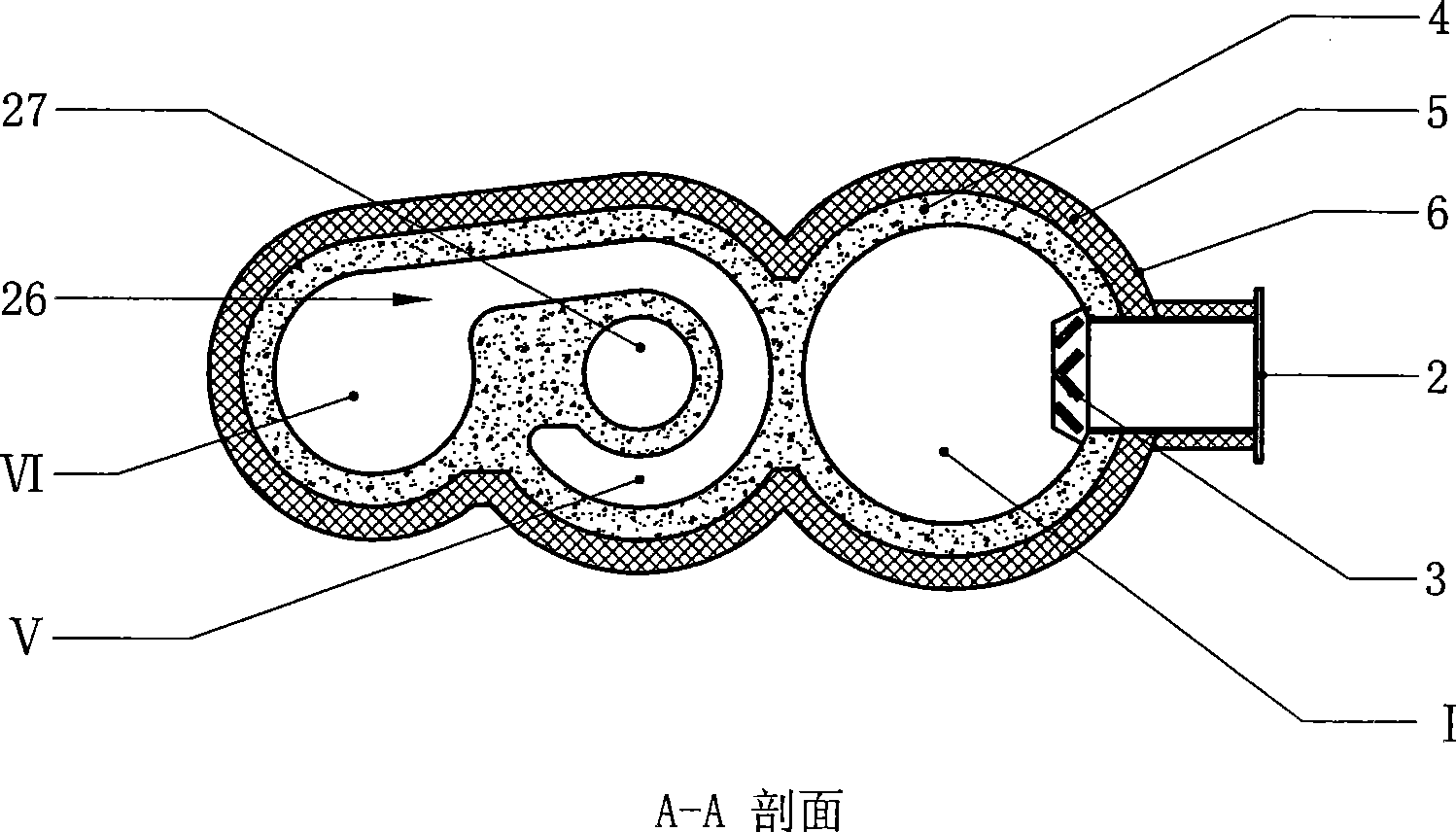

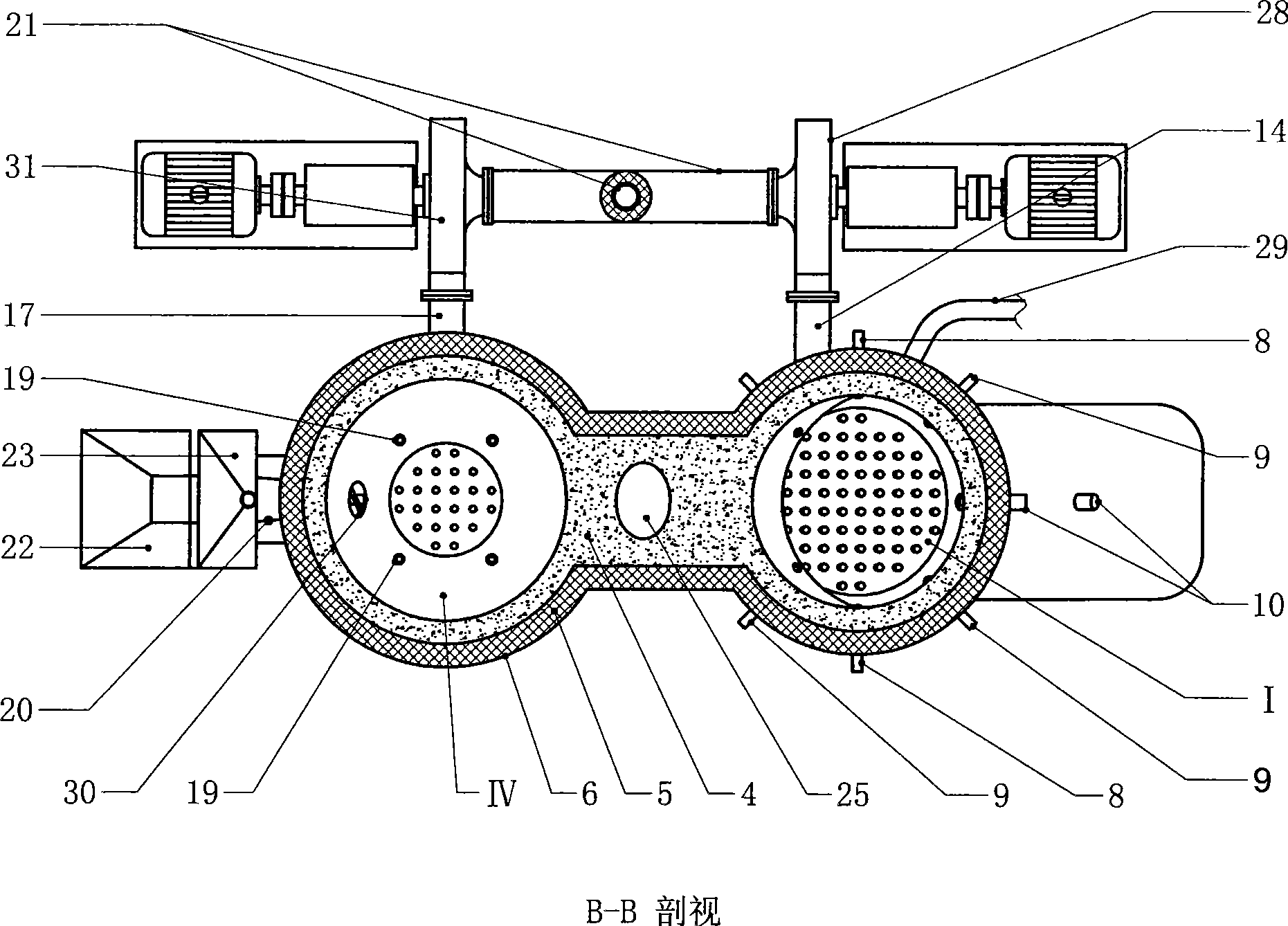

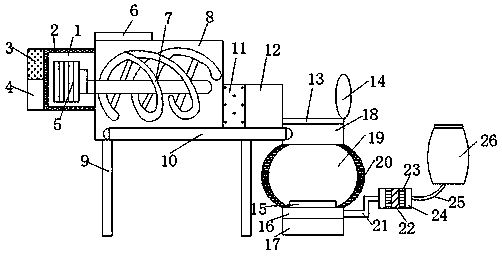

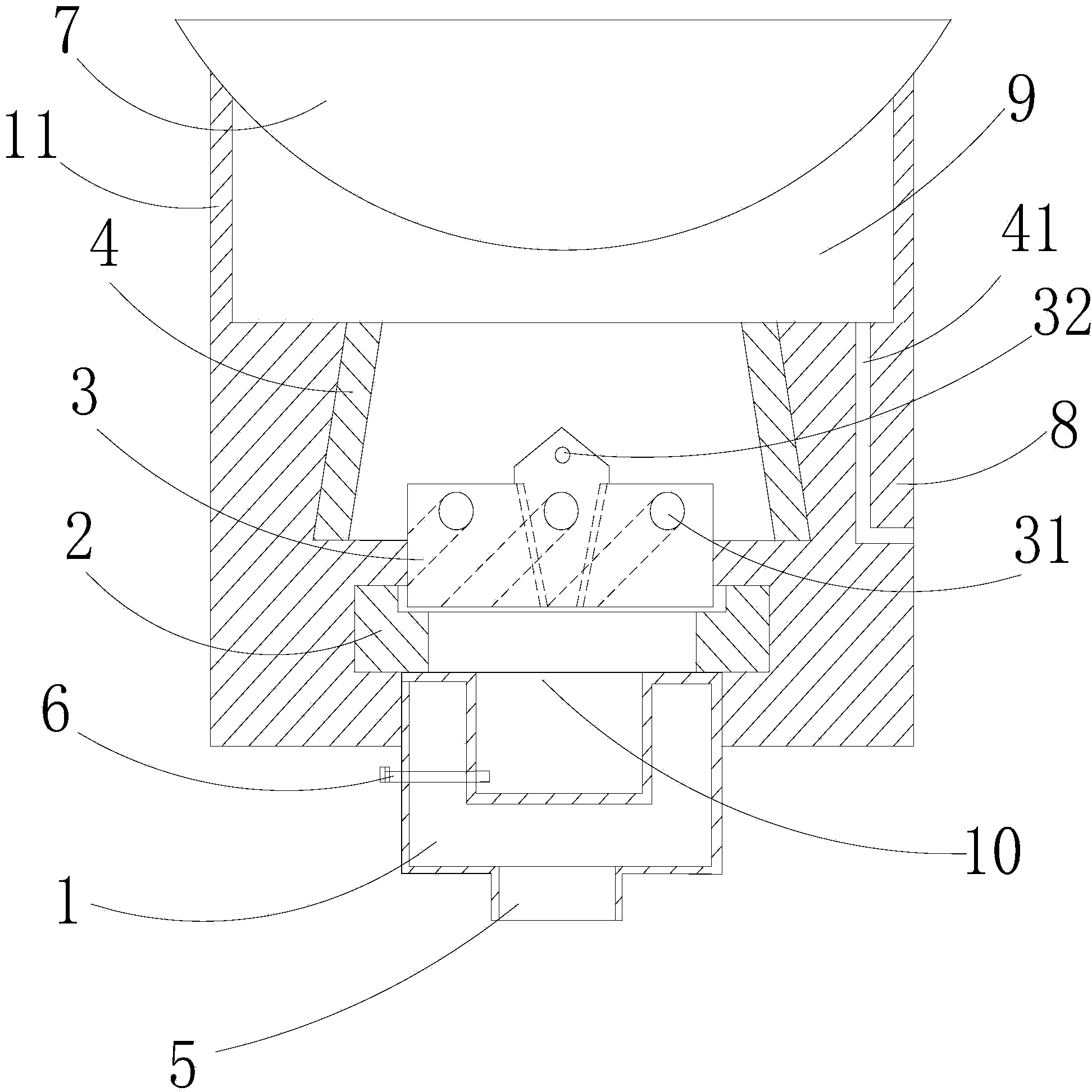

Plasma and calcium oxide cooperation-gasified rubbish biomass gasification method and equipment

InactiveCN101469865AReduce contentHigh calorific valueSpecial form destructive distillationIncinerator apparatusNew energyWater vapor

A method and apparatus for gasifying a plasma and calcium oxide cooperating with gasified rubbish biomass, relating to the rubbish processing and new energy resource field, characterized in that, the rubbish biomass is fed into a suspending fluidized bed thermal decomposition furnace, meanwhile, the heated fluidization material is circularly fed into the thermal decomposition furnace and is mixed with the raw materials to transfer heat, so that the rubbish biomass raw material is heated to decompose, and then the thermal decomposed gas and solid carbocoal is fed into a turbulent fluidized bed gasification furnace, the water vapor is heated over 3100 DEG C and is sprayed into the gasification furnace by a plasma spray gun, the water vapor is reacted with the solid carbocoal to generate carbon monoxide and hydrogen gas, the required heat of the gasification reaction in the gasification furnace can be provided by the plasma spray gun and an exothermal reaction of the calcium oxide absorbing the carbon dioxide. According to the invention, synthesis gas can be produced by rubbish and biomass raw materials under the condition without air or oxygen, the main ingredients of the synthesis gas are hydrogen gas and carbon monoxide which can be directly used for city gas or producing hydrogen gas, methanol and dimethyl ether and so on clean energies.

Owner:衢州市广源生活垃圾液化技术研究所

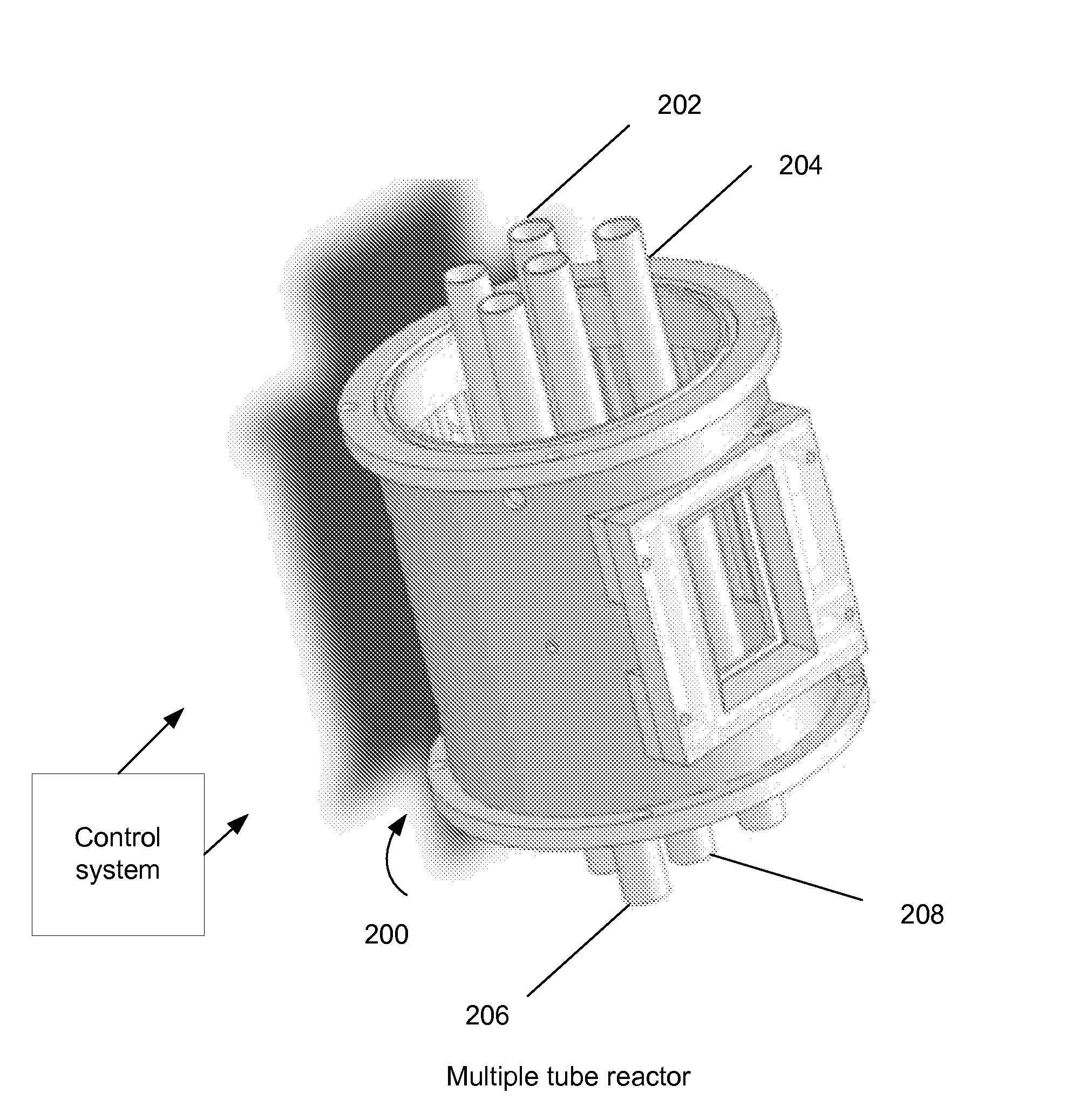

Systems and methods for biomass gasifier reactor and receiver configuration

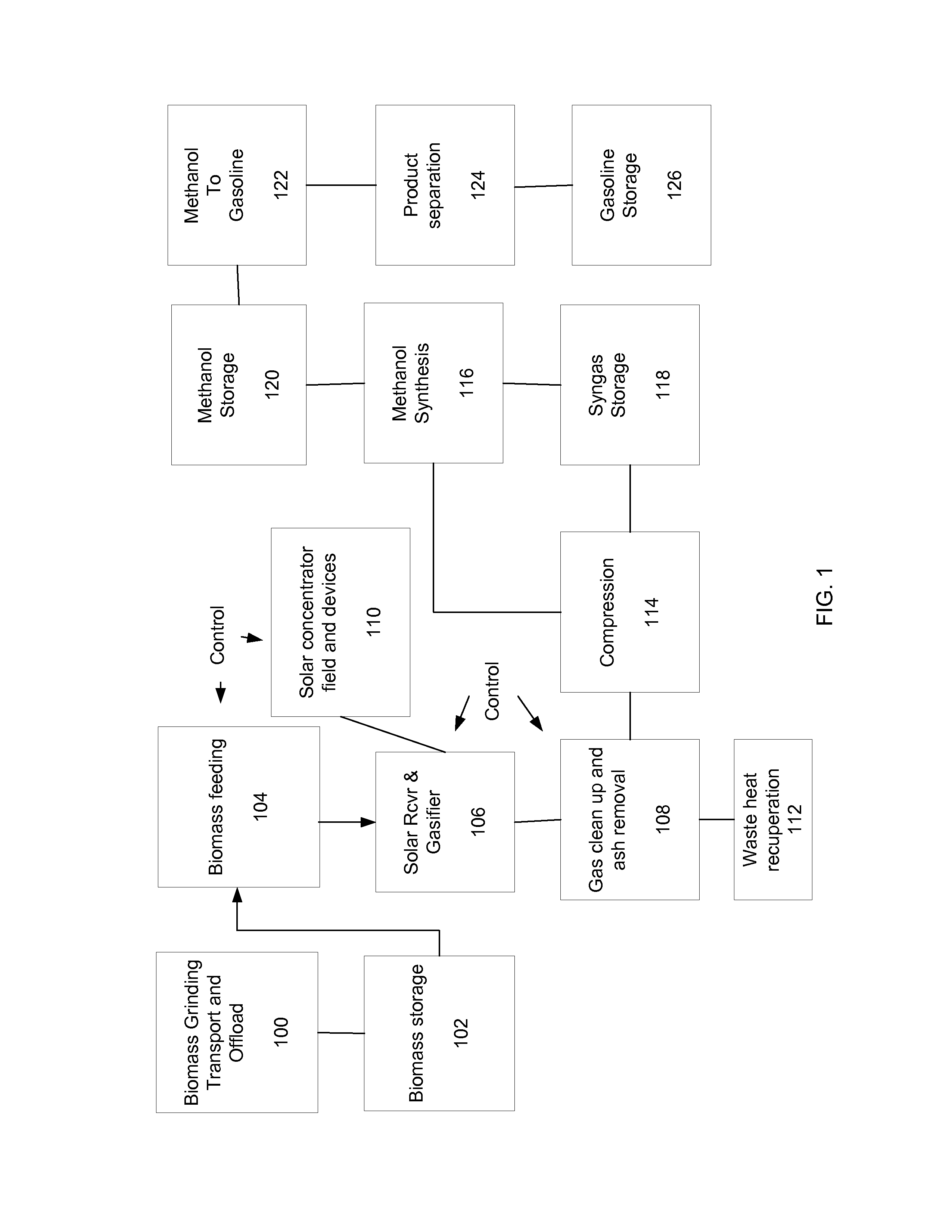

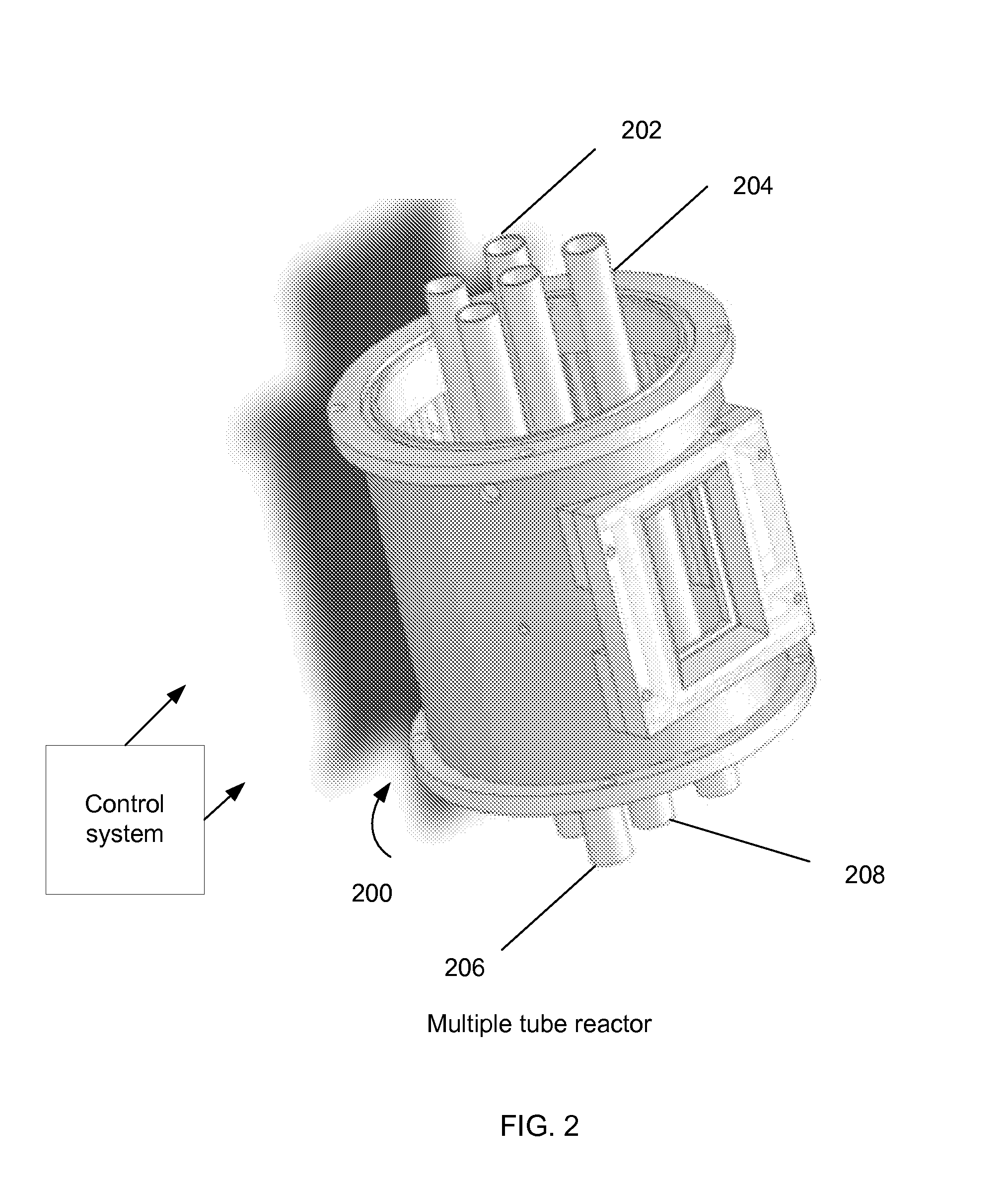

InactiveUS20100247387A1Complete gasificationProcess control/regulationSolar heating energyHydrogenHeliostat

A method, apparatus, and system for solar-driven chemical plant may include a solar thermal receiver to absorb concentrated solar energy from an array of heliostats. Additionally, some embodiments may include a solar driven chemical reactor that has multiple reactor tubes. The concentrated solar energy drives the endothermic gasification reaction of the particles of biomass flowing through the reactor tubes. Some embodiments may also include an on-site fuel synthesis reactor that is geographically located on the same site as the chemical reactor and integrated to receive the hydrogen and carbon monoxide products from the gasification reaction.

Owner:SUNDROP IP HLDG LLC

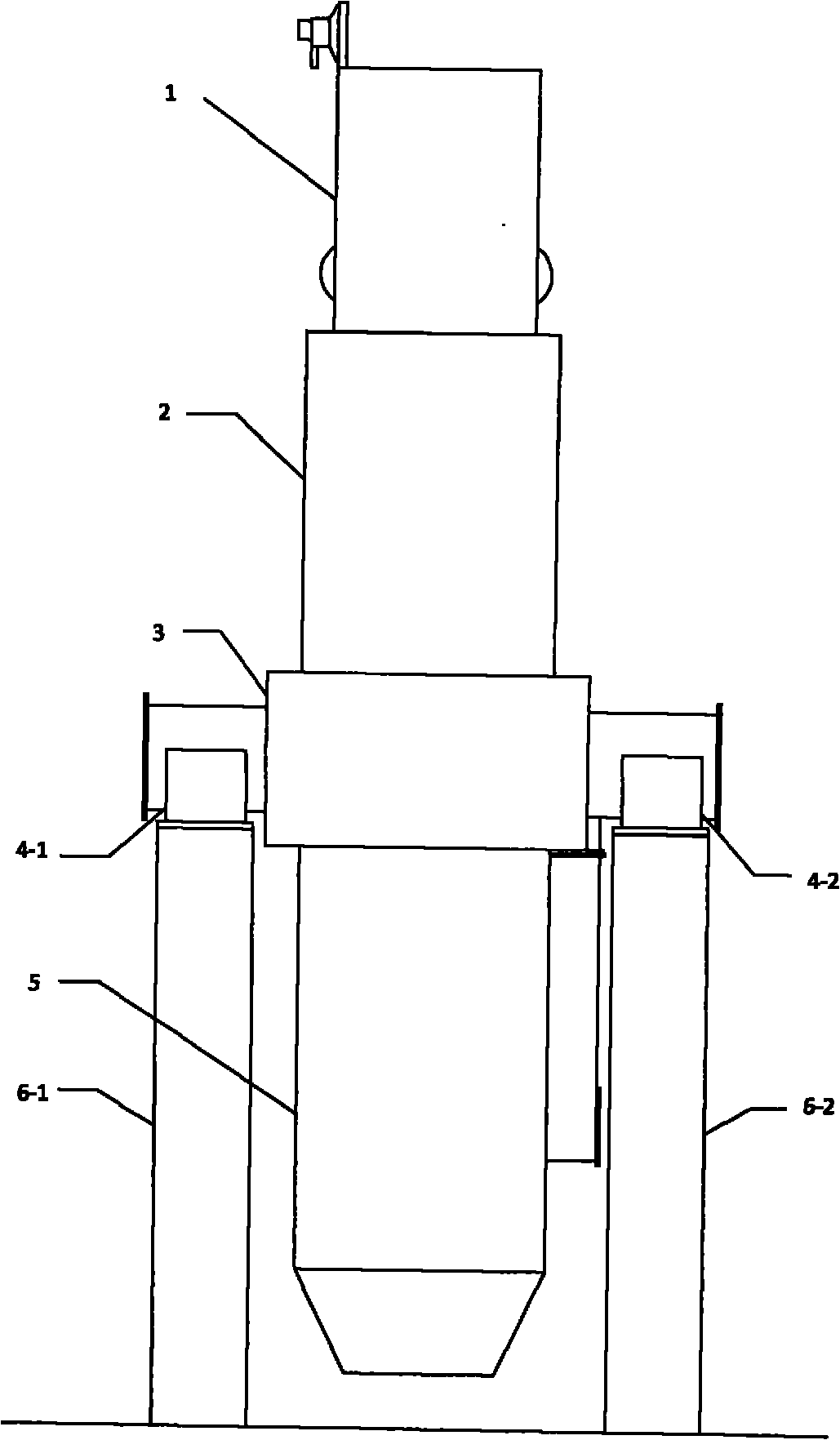

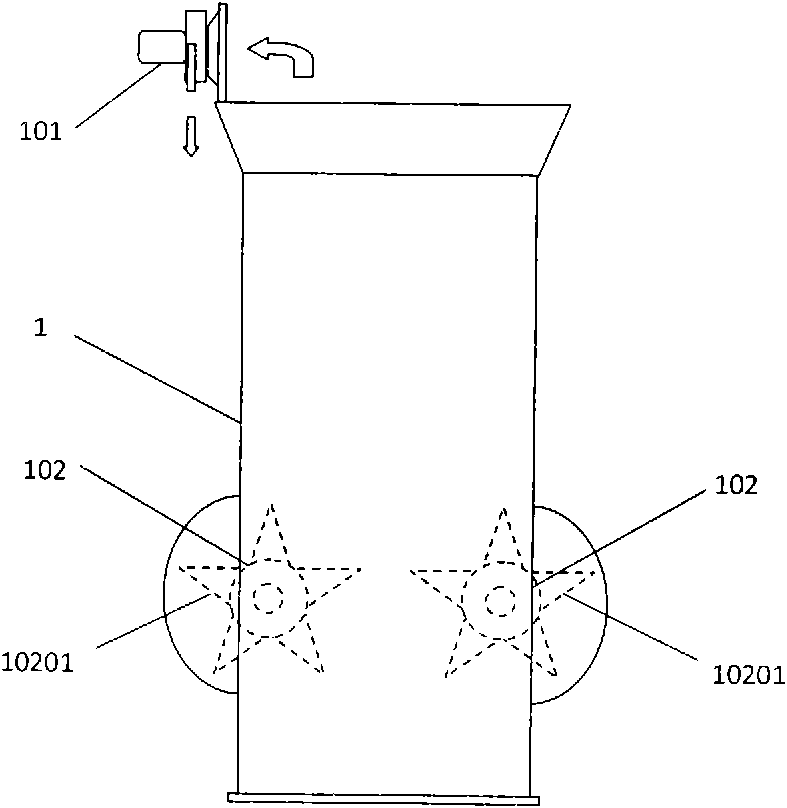

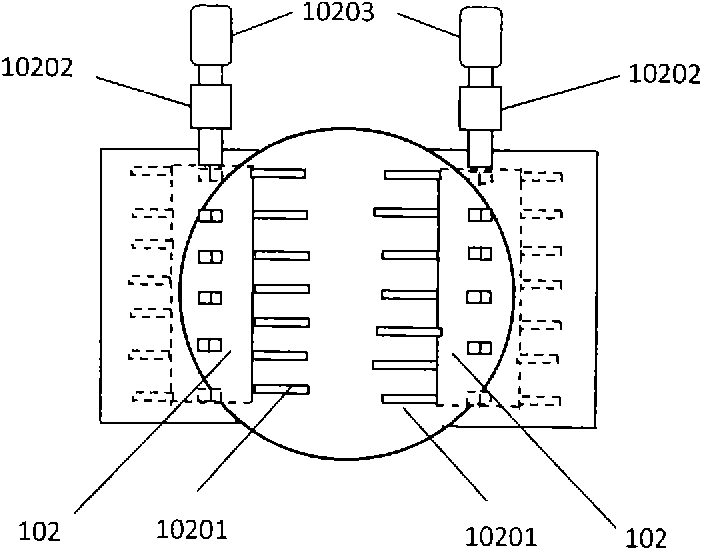

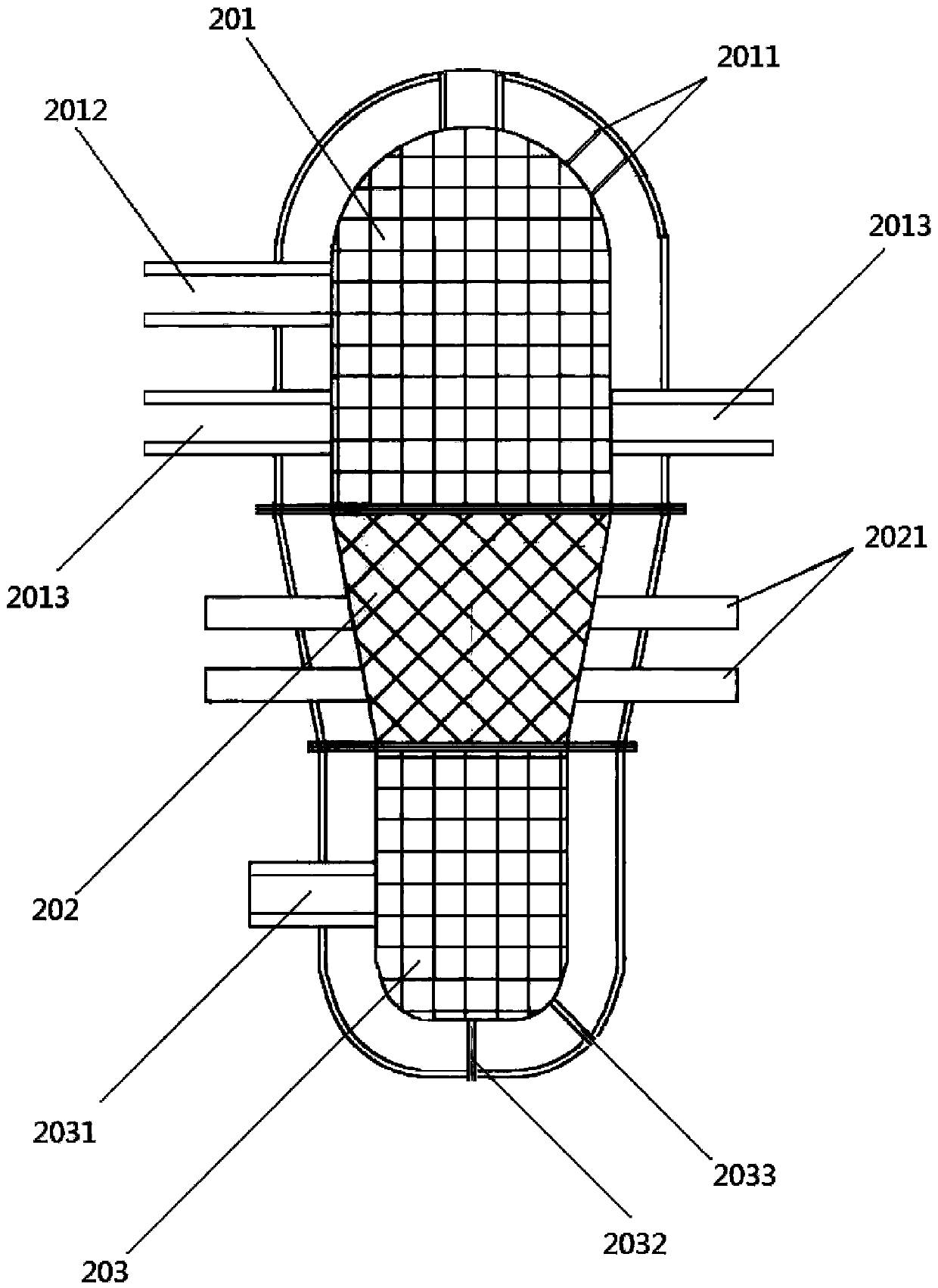

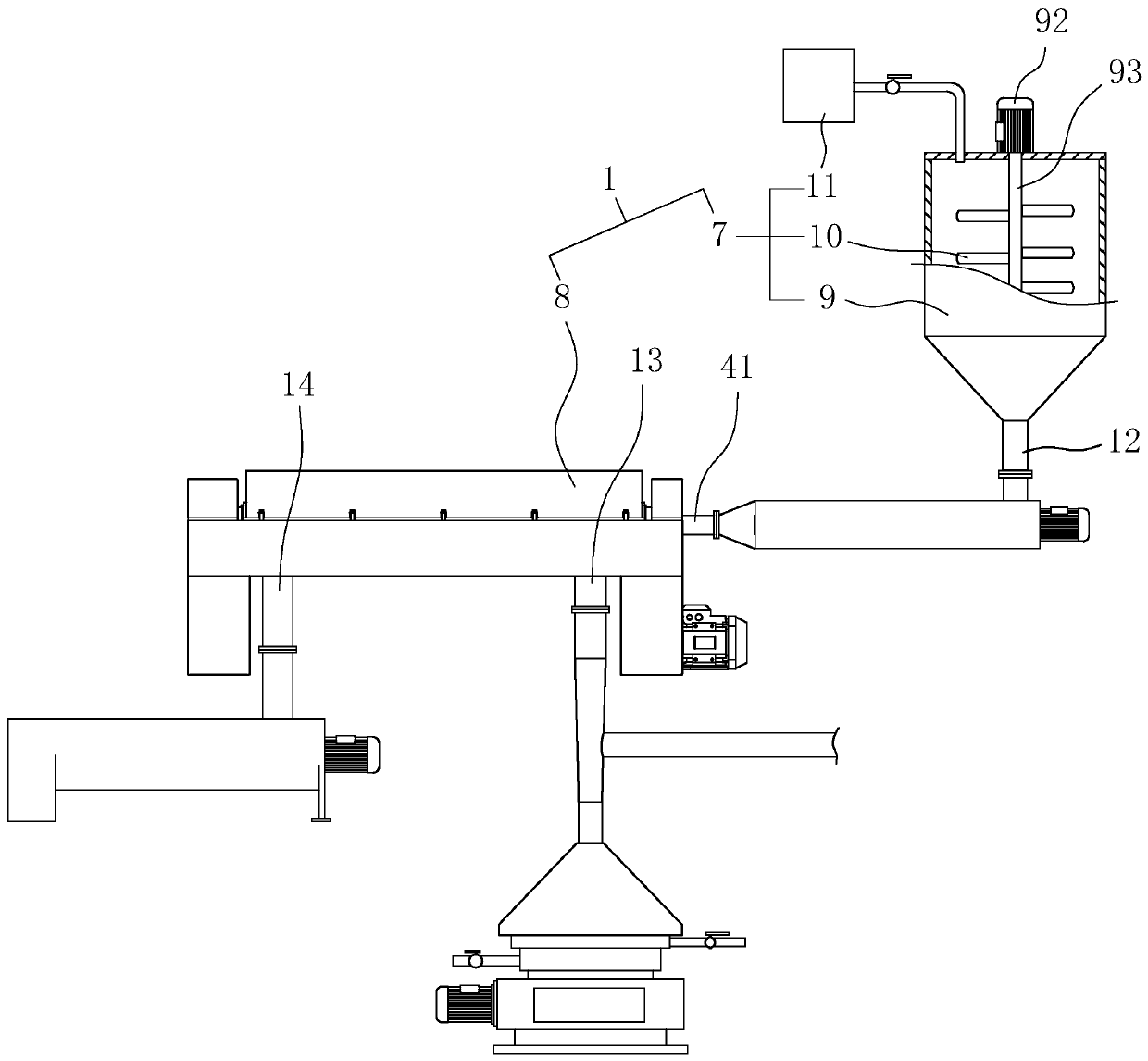

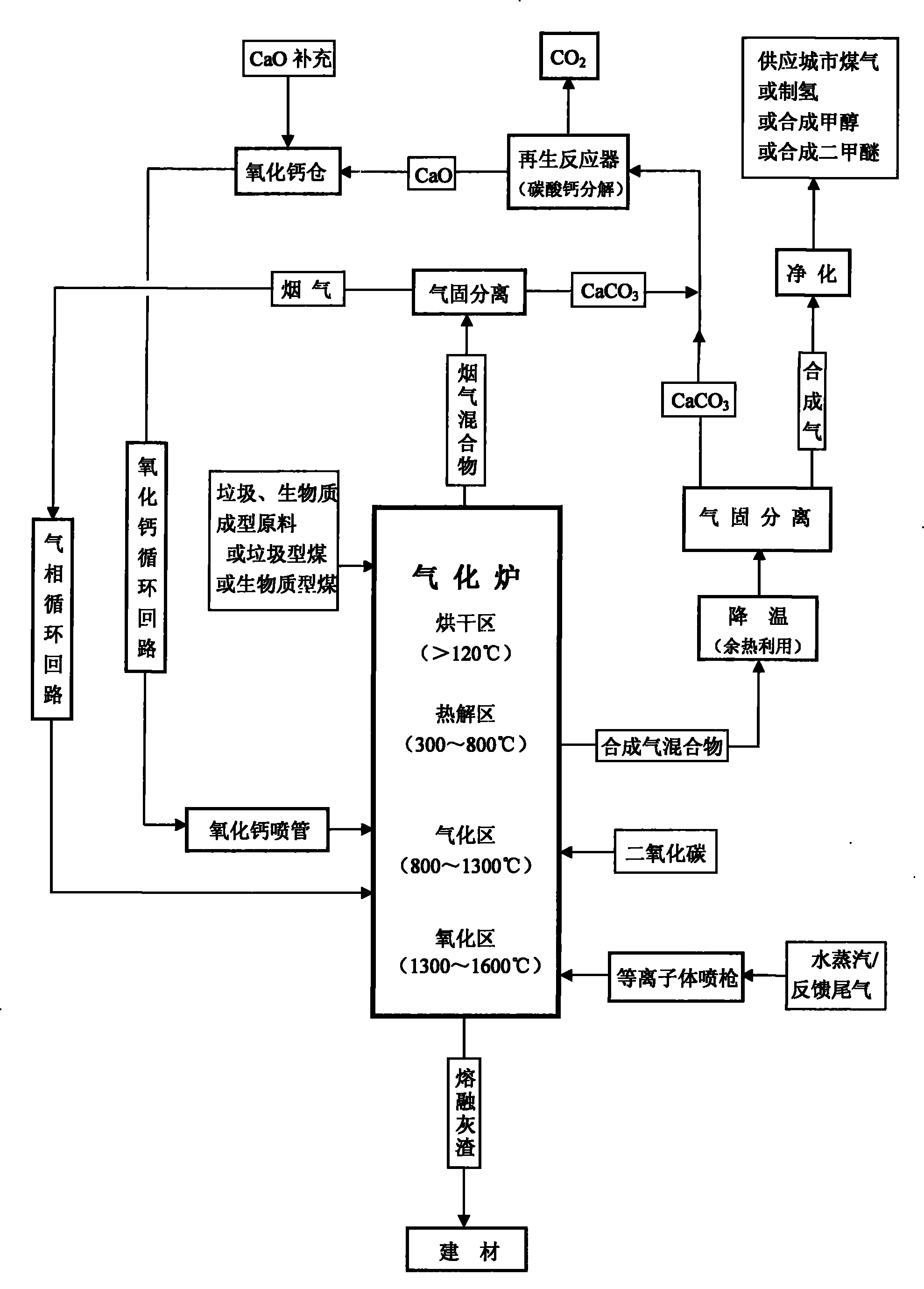

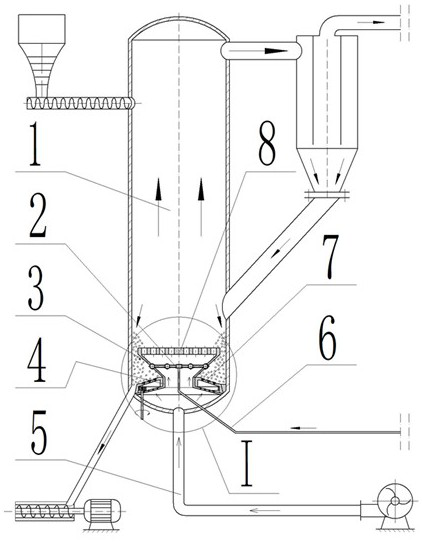

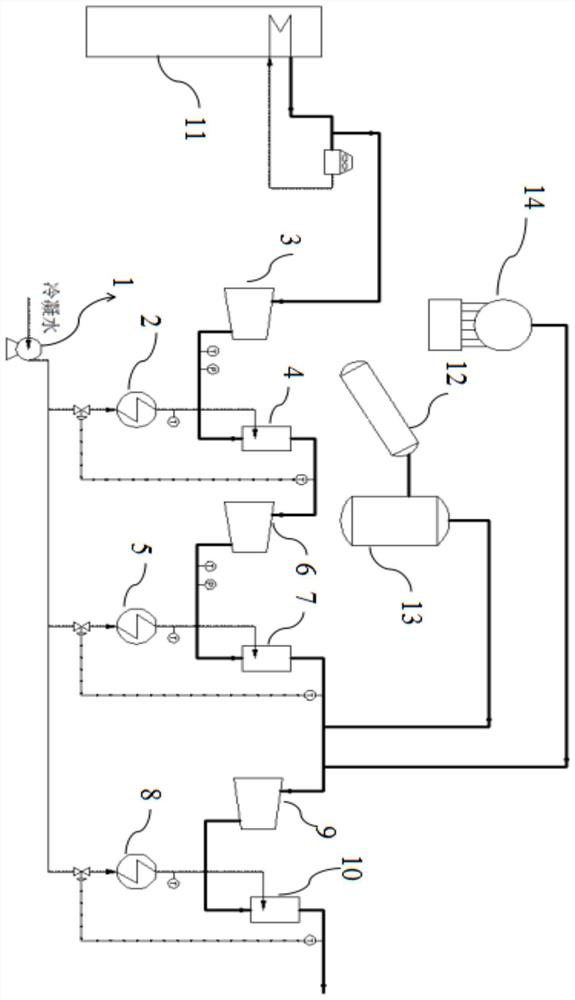

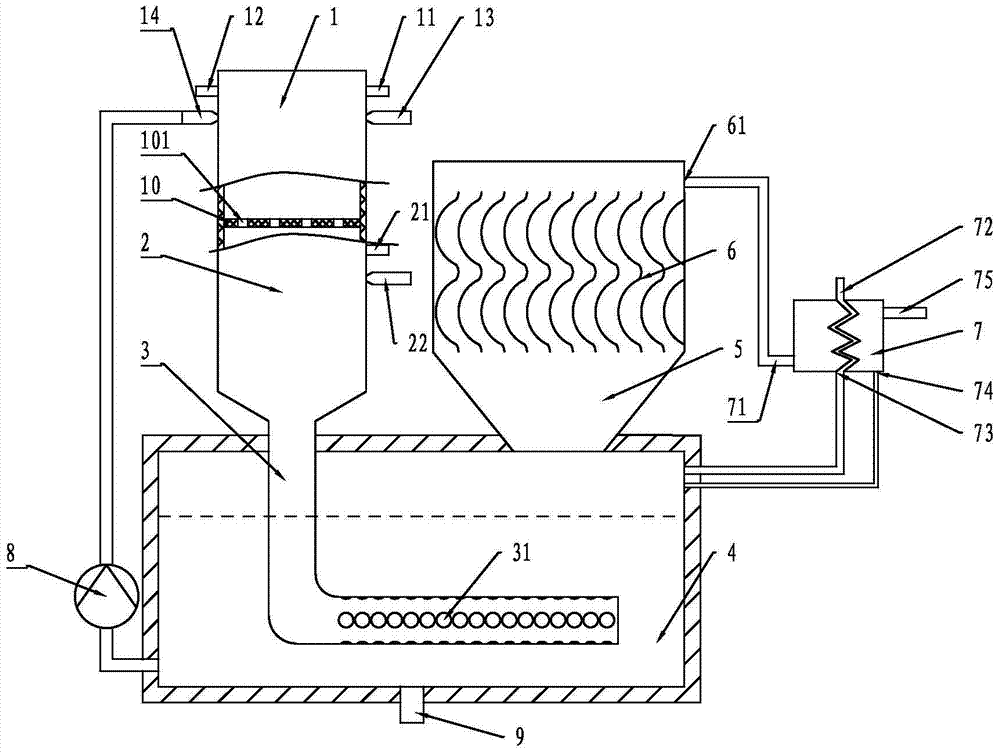

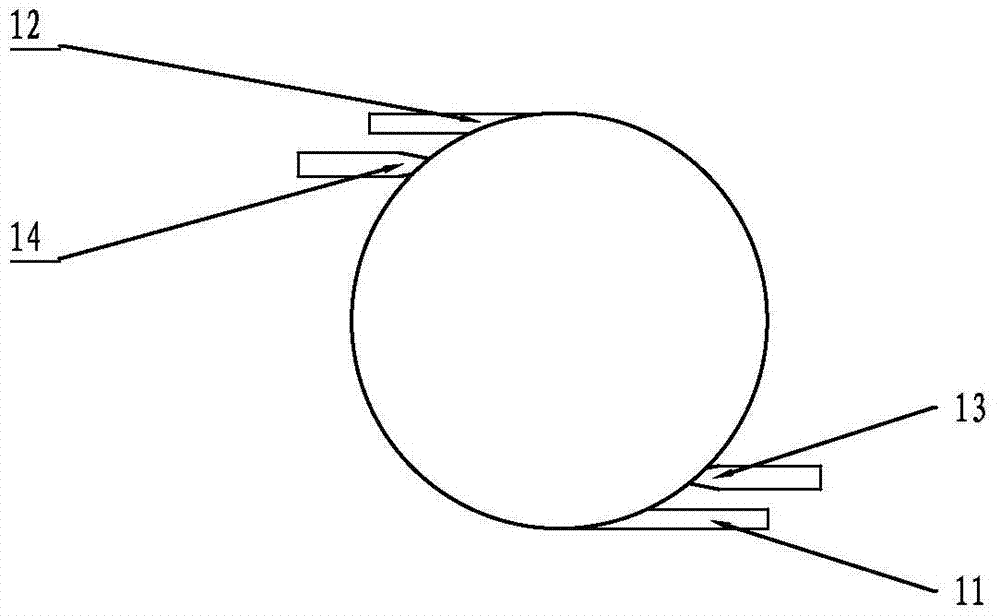

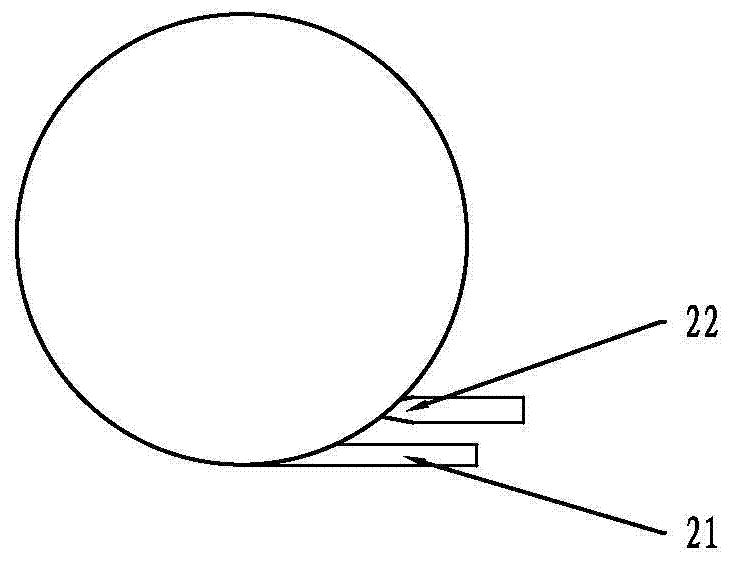

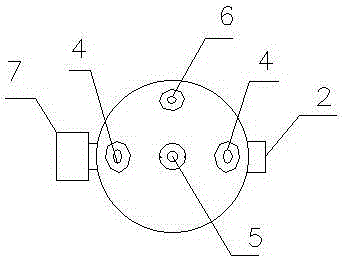

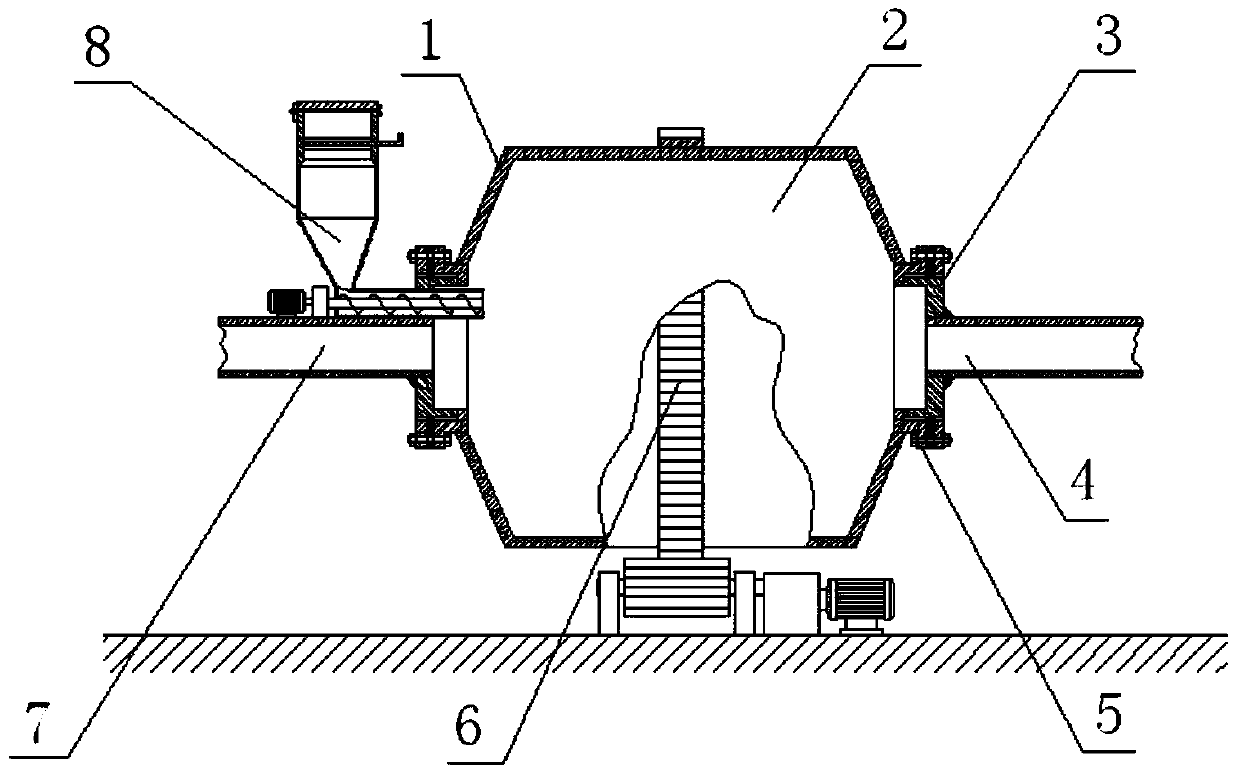

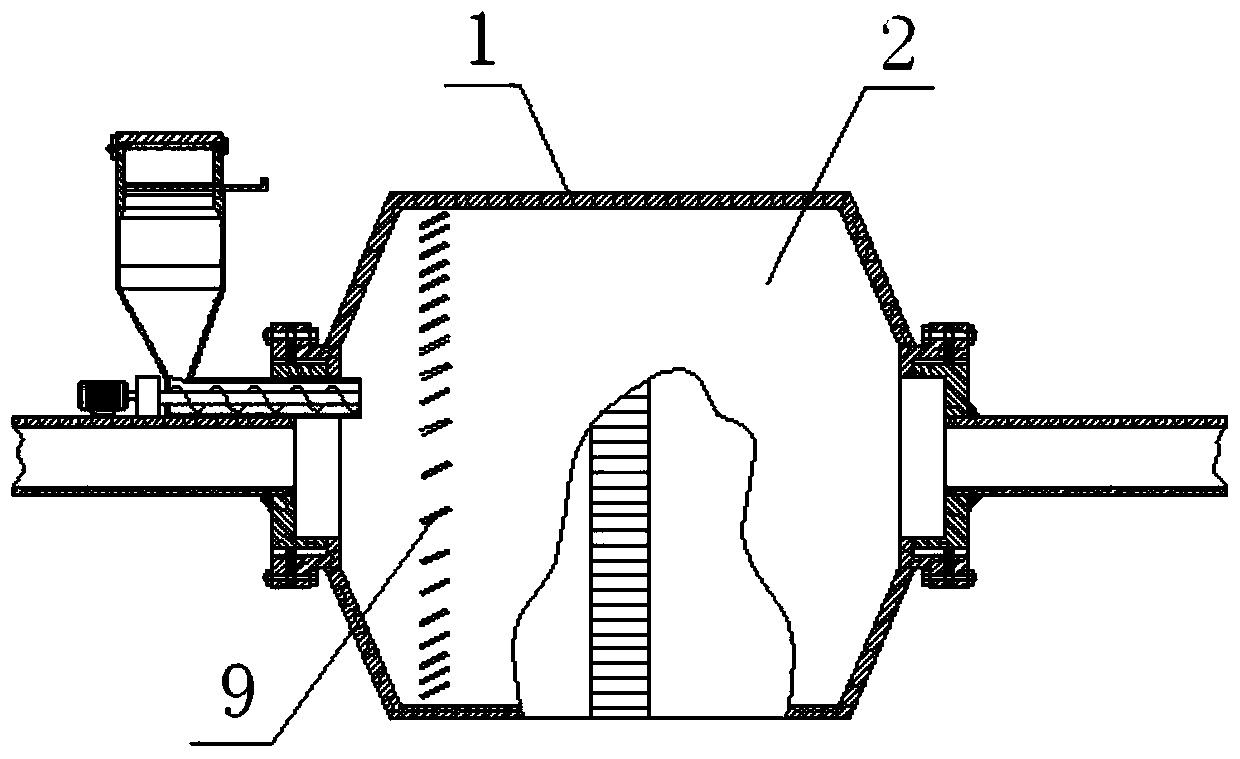

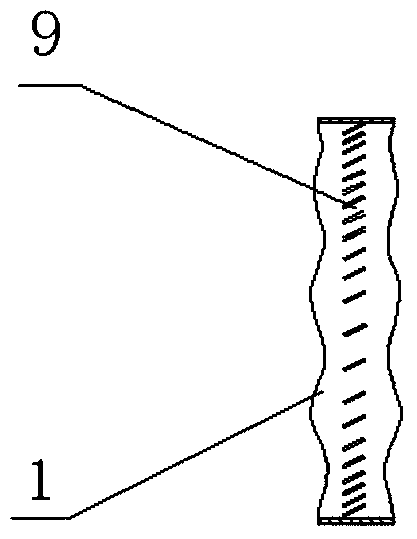

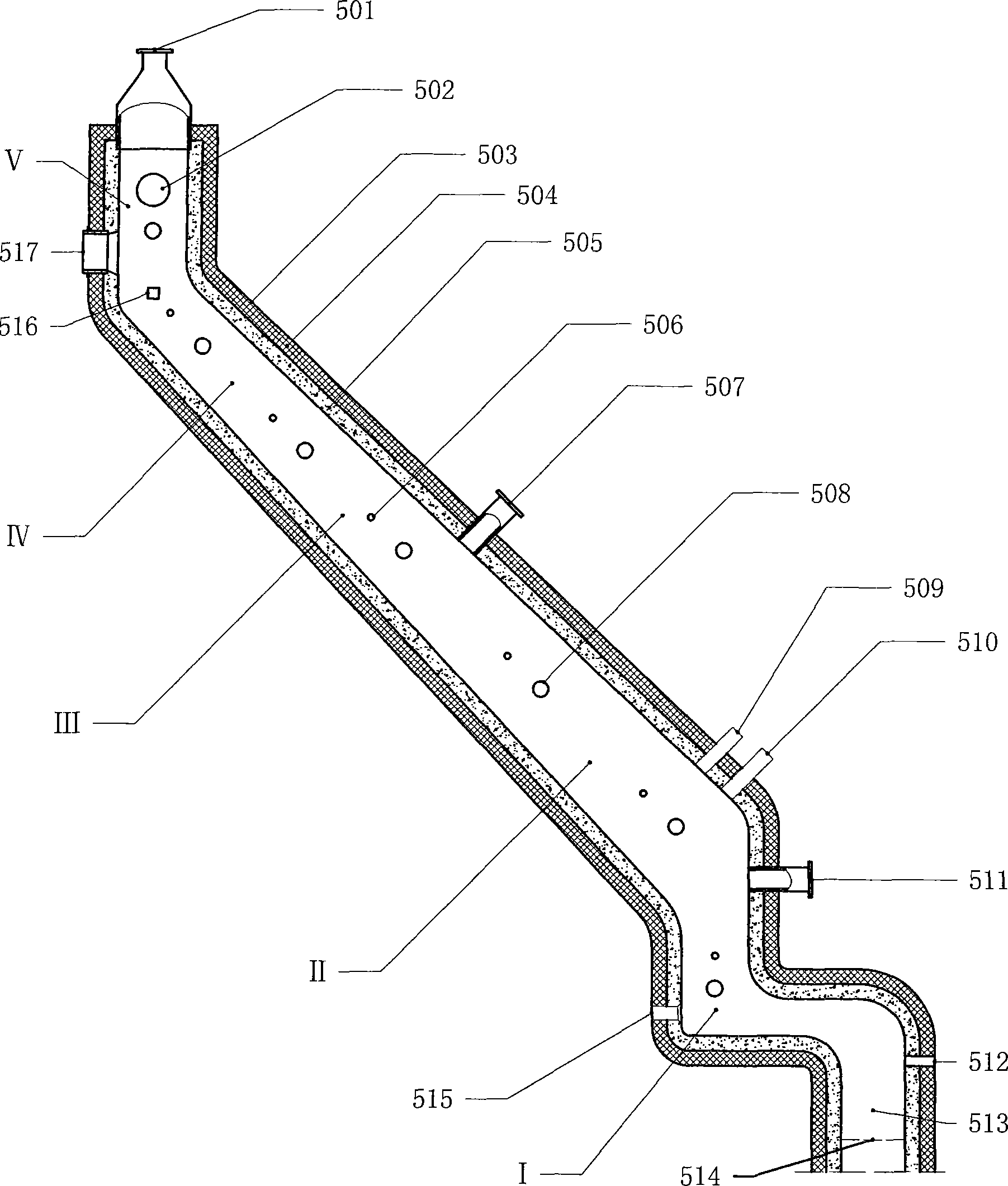

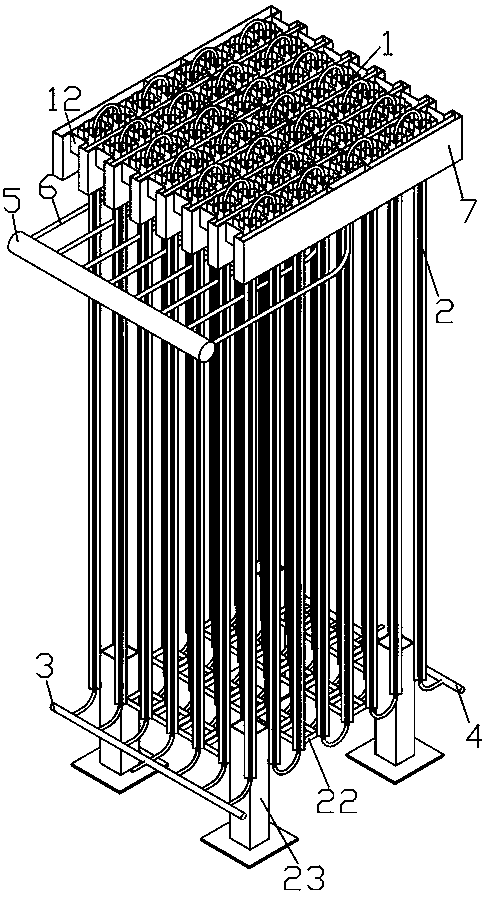

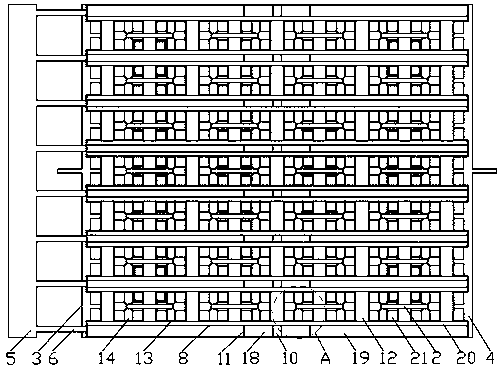

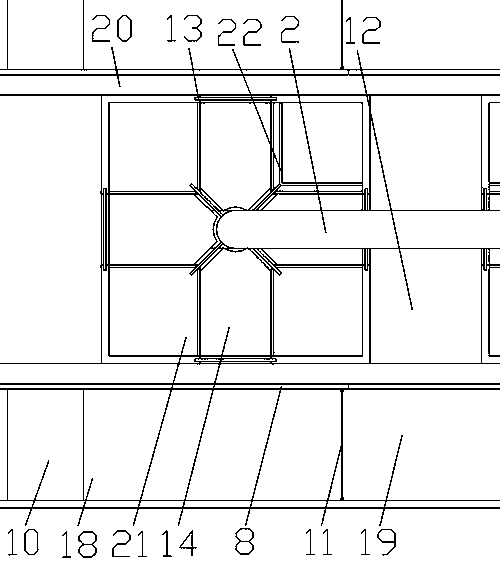

System and apparatus for producing synthesis gas from garbage and biomass raw material

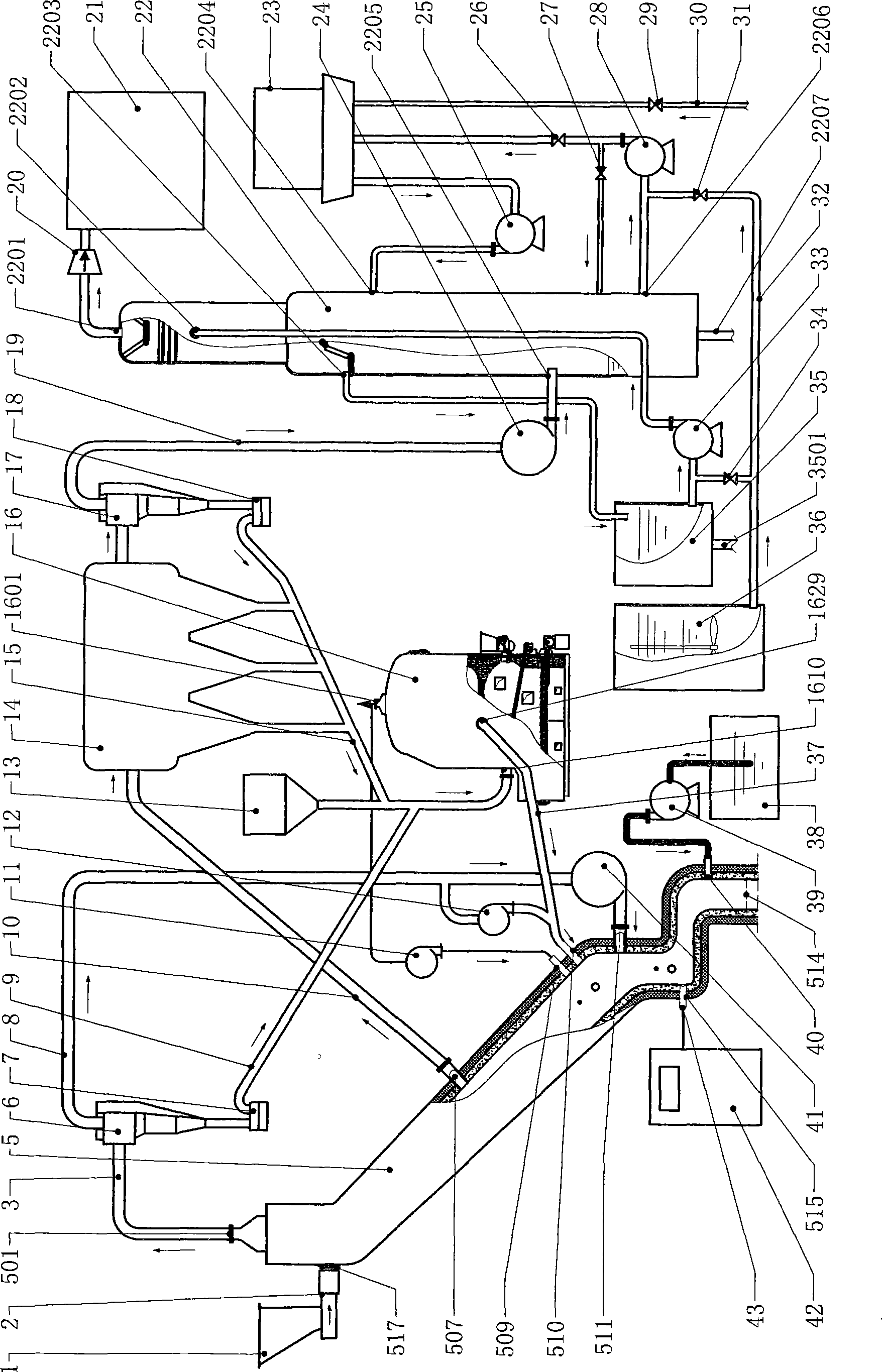

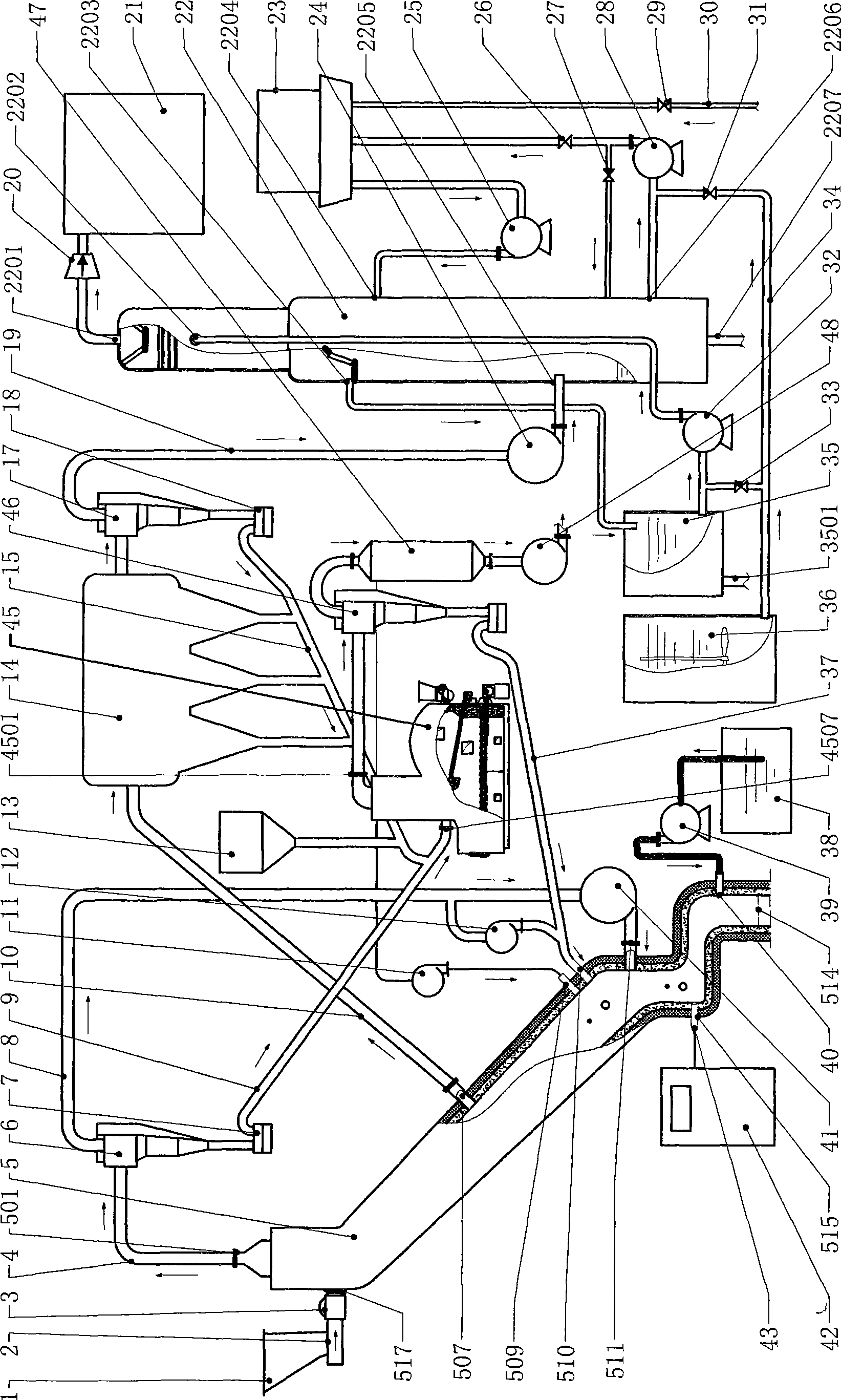

The invention provides a system and equipment for producing synthesis gas by garbage and biomass raw materials, which relates to garbage and biomass gasification equipment. The system and the equipment are characterized in that a vapor circulation loop and a calcium oxide circulation loop are arranged in the system; the garbage and the biomass raw materials are vaporized by an exothermic reaction of absorbing CO2 of the calcium oxide in a gasification furnace to cooperate with thermal plasma, so that the garbage and the biomass raw materials are converted into high heating value synthesis gas for cleaning energy or chemical raw materials. The system mainly comprises a multiphase circulation gasification furnace, a plasma spray gun, the vapor circulation loop, the calcium oxide circulation loop, a wet purification tower and a gas holder, wherein a circulation output interface of the gasification furnace is connected to a gas-solid separator; a gas outlet of the gas-solid separator is connected to a circulating fan; an air outlet of the circulating fan is connected to the vapor circulation input interface of the gasification furnace; a dipleg of the gas-solid separator is connected to a feed delivery valve; the feed delivery valve is connected to a calcium oxide calcining furnace through a solid phase conveying pipe; and a calcium oxide outlet of the calcium oxide calcining furnace is connected to a calcium oxide jet tube of the gasification furnace through a refeed line.

Owner:衢州市广源生活垃圾液化技术研究所

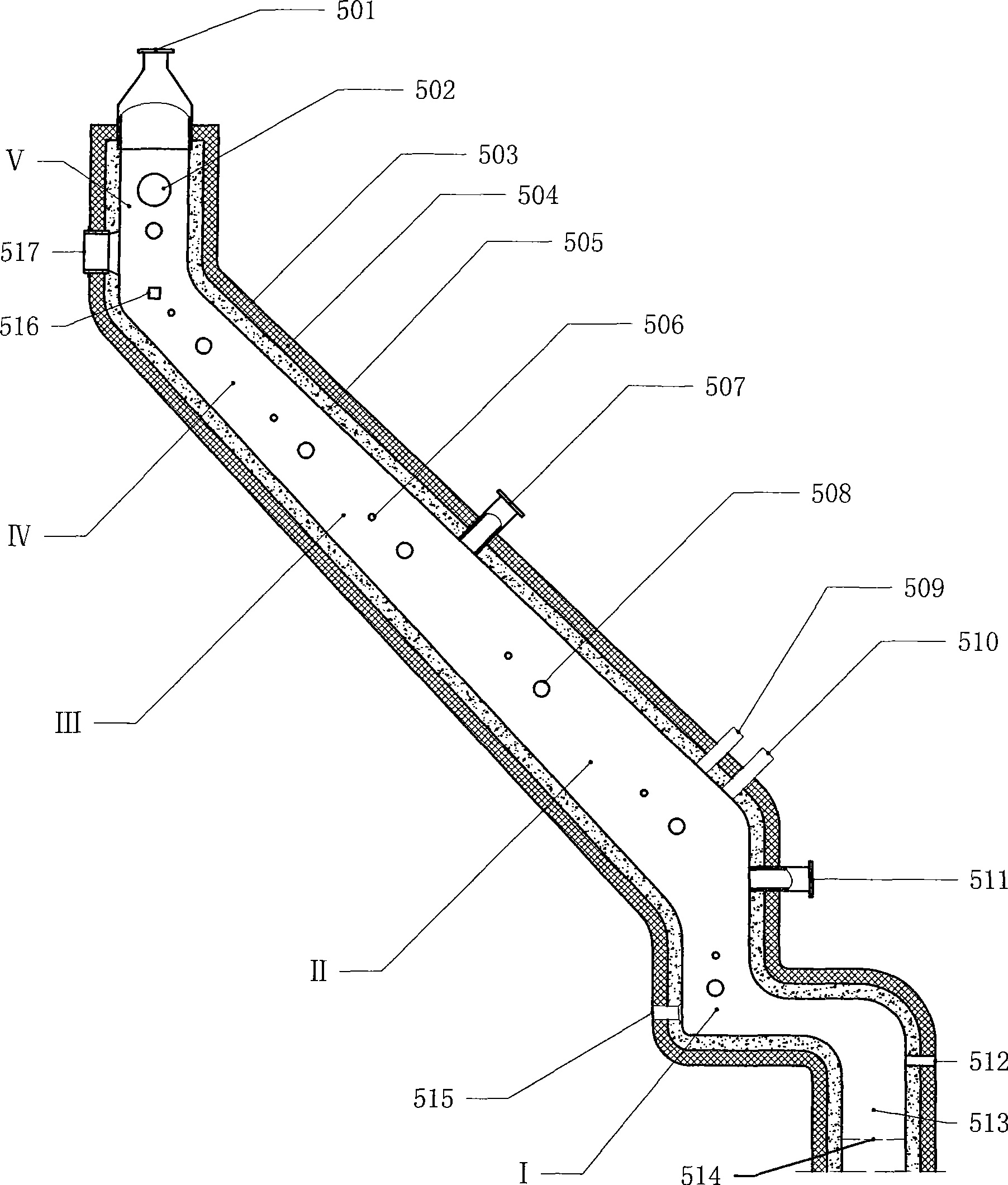

Harmless high-temperature plasma broad-spectrum waste treatment system

ActiveCN103962363AComplete gasificationEnsure diversitySolid waste disposalUsing liquid separation agentElectricitySyngas

The invention relates to the technical field of waste treatment, in particular to a waste treatment system. The harmless high-temperature plasma broad-spectrum waste treatment system comprises a feeding system, a plasmas treatment system, a synthesis gas recycling system, a residual gas treatment system, a washing circulating fluid regeneration treatment system and a waste residue treatment system, wherein the waste flows through the systems sequentially and is changed into slag and synthesis gas, the synthesis gas is recycled and used for generating electricity, produced tail gas is purified and discharged, the washing fluid is treated and recycled, and the slag is recovered and reused. With the adoption of the technical scheme, the defects of single waste treatment type and incomplete treatment by means of a conventional technology are overcome, a secondary pollution source cannot be generated, waste heat and the synthesis gas are sufficiently recovered, the treated slag can further be recycled to generate new economic benefits, resource recycling is further facilitated while the environment is protected, and the harmless high-temperature plasma broad-spectrum waste treatment system has huge social and economic values and commercial utilization prospect.

Owner:吉天师能源科技(上海)有限公司

System and method for treating high-concentration organic waste liquid

ActiveCN105066146AEasy to handleReduce consumptionLiquid fuel feeder/distributionCombustion technology mitigationHigh concentrationLiquid waste

The invention belongs to the field of wastewater treating, and particularly relates to a system and a method for treating high-concentration organic waste liquid. The organic waste liquid can be efficiently processed in a low-consumption, energy-saving and environment-friendly manner. The system for treating the high-concentration organic waste liquid comprises a gasification chamber, a combustor, a smoke pipe, a waste liquid pump, a waste liquid tank, a settling chamber, demisting baffles and a condenser. The gasification chamber is located at the top of the combustor. A primary auxiliary fuel nozzle, a waste liquid nozzle and at least one air inlet are formed in the upper portion of the side wall of the gasification chamber. A secondary air inlet and a secondary auxiliary fuel nozzle are arranged at the upper portion of the side wall of the combustor. An exhausting opening of the combustor directly extends into the waste liquid tank through the smoke pipe. The settling chamber is installed at the top of the waste liquid tank. The multiple demisting baffles are installed at the upper portion of the interior of the settling chamber. A gas outlet in the top of the settling chamber is communicated with a gas inlet of the condenser through a pipe. An inlet of a condenser heat exchanging pipe is connected with a waste liquid delivery pipe. A waste liquid outlet in the waste liquid tank is sequentially communicated with the waste liquid pump and the waste liquid nozzle through a pipe.

Owner:南京赛佳环保实业有限公司 +1

Novel alcohol-based liquid fuel and preparation method thereof

The invention relates to a novel alcohol-based liquid fuel with a high combustion heat value and no smoke and toxicity after combustion, which relates to the field of petrochemical fuels. The alcohol-based liquid fuel is composed of refined methanol, an igniting agent, a stabilizing agent, an anti-knock and a deodorant. The preparation method for the novel alcohol-based liquid fuel comprises the following steps: placing refined methanol in a container, adding the igniting agent and carrying out uniform mixing with stirring; then adding the deodorant and carrying out uniform mixing with stirring for 3 min; adding the anti-knock, carrying out uniform mixing with stirring for 5 min and then carrying out an immobility reaction for 10 min; adding the stabilizing agent and carrying out uniform mixing with stirring; and carrying out an immobility reaction in a storage tank for 24 h so as to prepare the novel alcohol-based liquid fuel. According to the invention, methanol used in the method can be converted from coal and the like, which provides a feasible approach for clean utilization of coal; production cost is low, and the method is simple and is favorable for large scale popularization and utilization; the fuel has a high heat value, as high as 25000 kJ / kg; and the fuel has the advantages of thorough gasification, full combustion, no smoke, no toxicity, no pollution to the environment, accordance with requirements of environmental protection, good anti-shock performance, safety in use and convenience in storage and transportation.

Owner:黄利

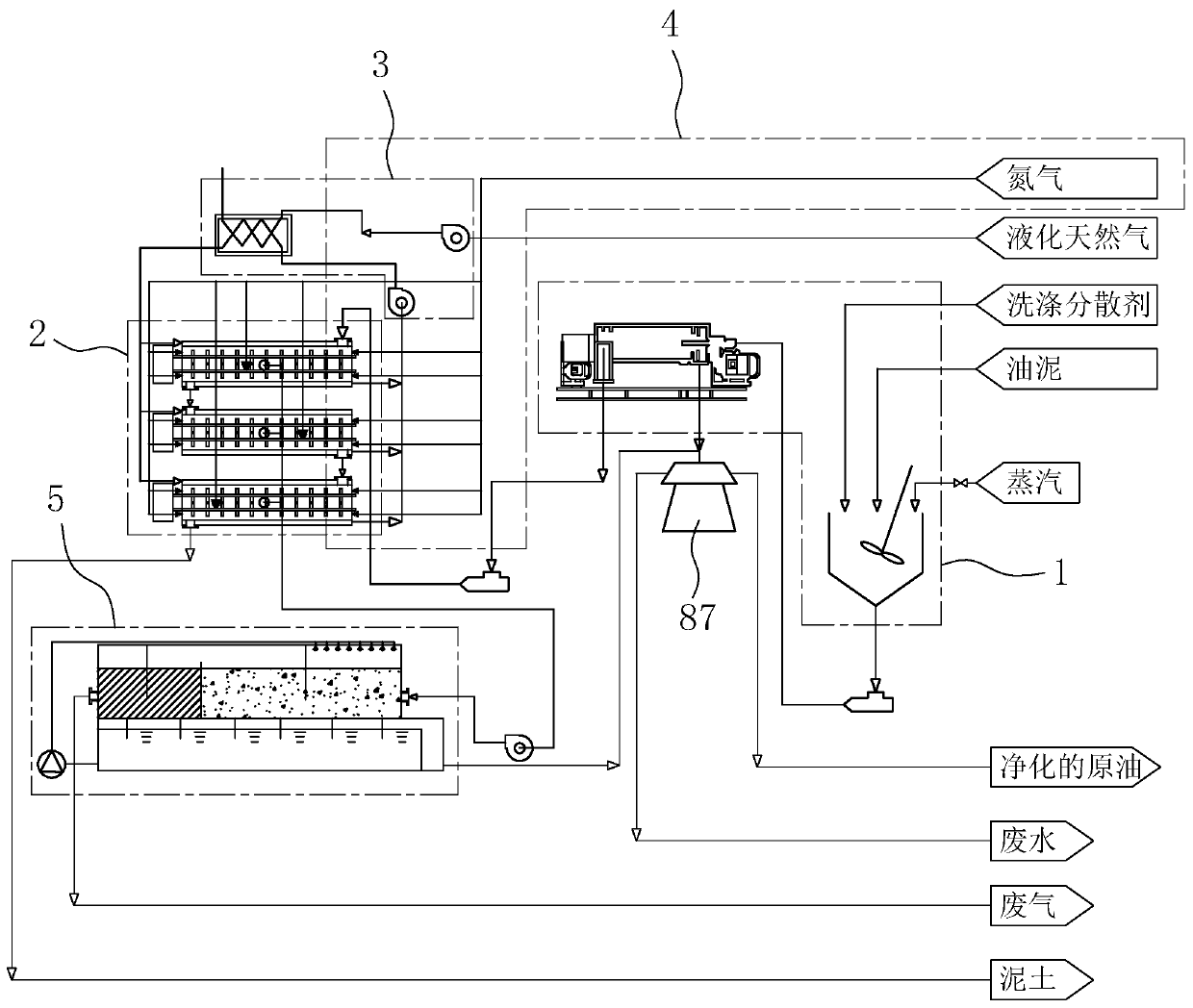

Oil sludge resource utilization system and technology

InactiveCN110194580AAvoid direct contactAvoid burnsSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningResource utilizationOil sludge

The invention discloses an oil sludge resource utilization system and technology, and applications in the technical field of oil sludge pyrolysis resource utilization. The technology is capable of solving problems in the prior art that pyrolysis residue contains heavy metals, secondary pollution is easily caused, system is complex, and equipment investment is high in conventional pyrolysis method.The oil sludge resource utilization system comprises a pyrolysis system used for pyrolysis of oil sludge, a heat supply system used for supplying the pyrolysis system with heat, an explosion-proof system used for avoiding crude oil combustion or explosion, and a condensation system. The technical effects are that: the heat supply system and the pyrolysis system are arranged independently, contactof open fire with oil sludge is avoided, and the whole housing is protected with nitrogen gas, so that pyrolysis is safer, and generation of harmful gas such as dioxins is avoided; a high efficiencyheat exchanger is adopted for heat conduction, and physical condensation is adopted by the condensation system, so that pyrolysis and condensation efficiency is higher, and more energy is saved.

Owner:上海恒埠环保科技有限公司

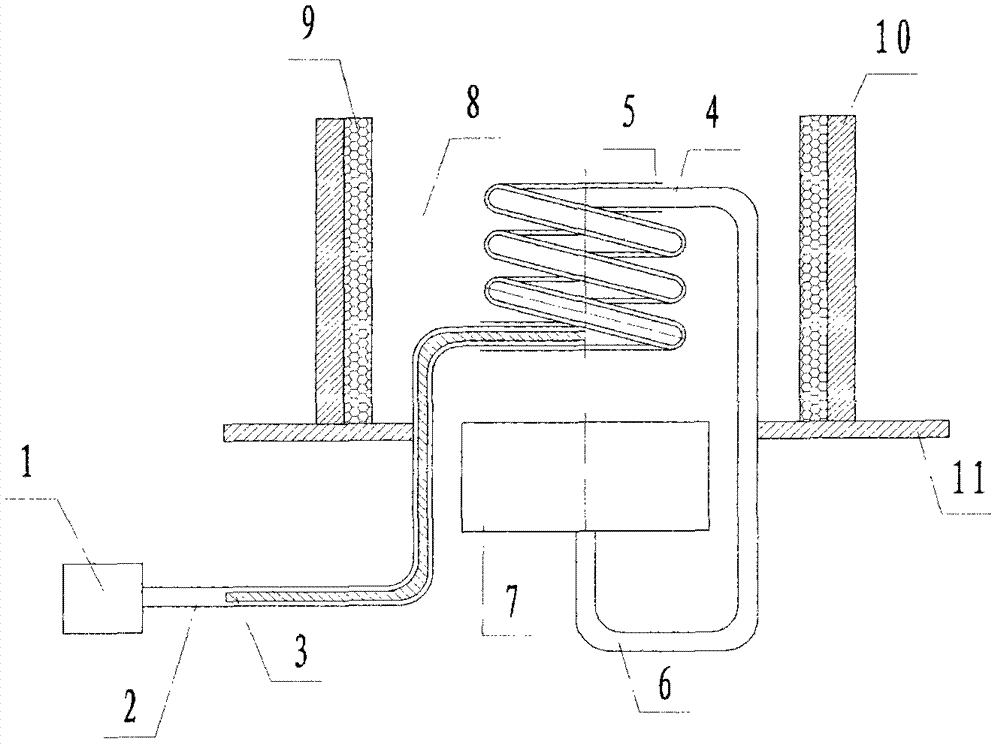

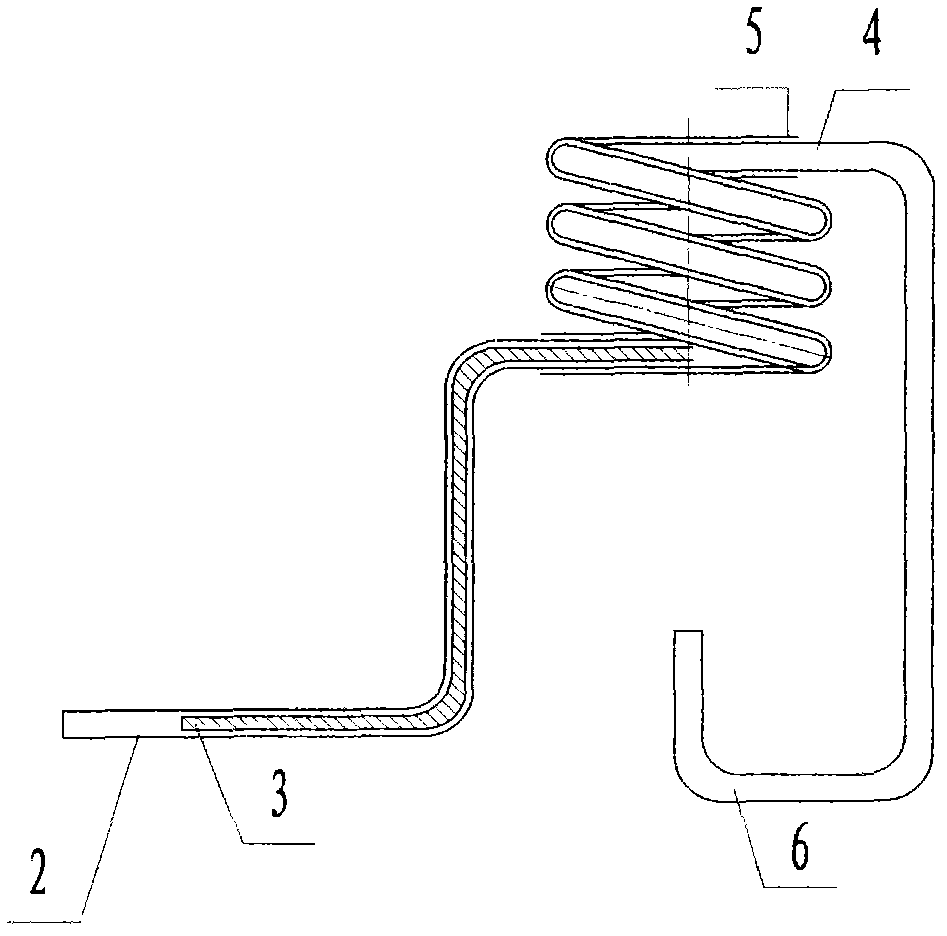

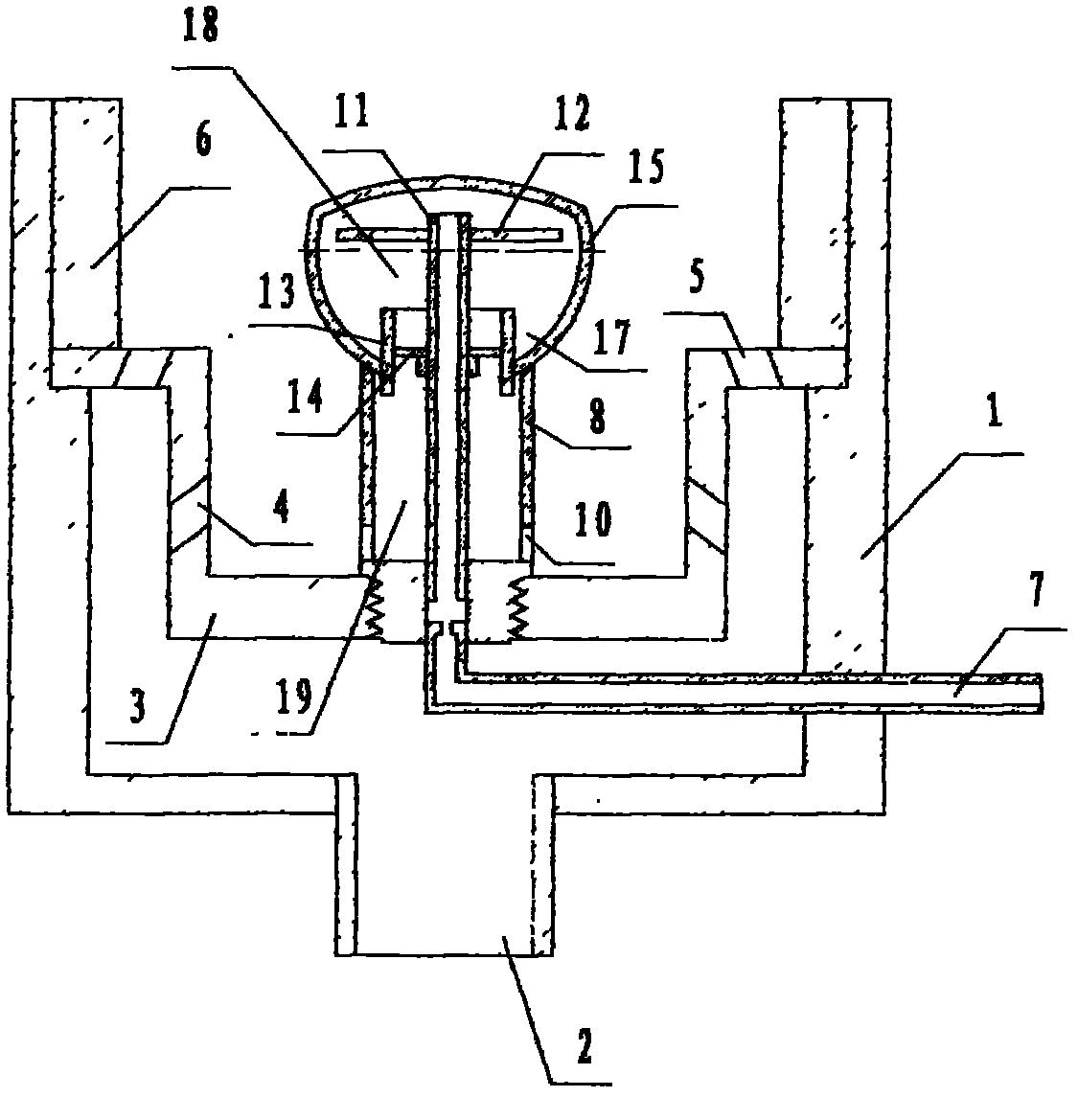

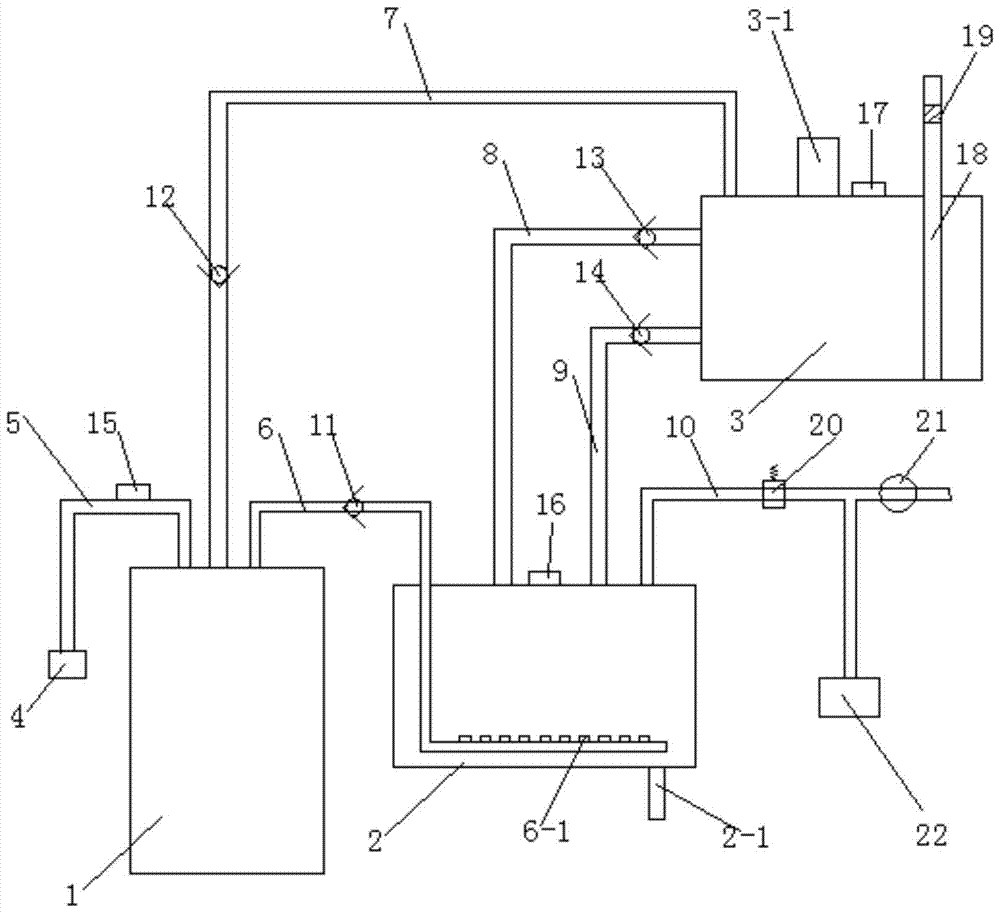

Liquid fuel gasifier

InactiveCN103090382AComplete gasificationReduce energy consumptionCombustion typesElectricityFixed frame

The invention provides a liquid fuel gasifier which is composed of a gasifying device, a burning device, a sound reducing device, a fire ring, a valve body assembly and a fixed frame. The gasifying device is placed above the burning device and is arranged in the sound reducing device. The burning device is partially or completely arranged in the sound reducing device. The gasifying device is composed of a gasifying pipe, a heat insulation pipe and a gas resistor. The gasifier is structurally characterized in that the gasifying pipe is arranged in the heat insulation pipe, the gas resistor is inserted in the gasifying pipe, the gasifying pipe and the gas resistor are combined and inserted to form a combination piece which is wound to form a spiral spring column body or a conical body, the gasifying pipe is a metal hollow pipe or a non-metal high temperature resistant hollow pipe, the heat insulation pipe is a metal hollow pipe, the length of the gas resistor and the heat insulation pipe is shorter than that of the gasifying pipe, the sound reduction device is of an annular columnar structure or a conical structure, and the sound reduction device is placed in the fire ring and surrounds the gasifying device and the burning device. The liquid fuel gasifier resolves the problem that the liquid fuel is completely gasified, enables burning to be complete, is low in energy consumption, saves energy by over 60% with flame temperature higher than 1200 DEG C, does not require a fan, is complete, convenient, electricity-saving, strong in fire and high in heating speed, simultaneously effectively controls gasifying temperature, resolves the problem of carbon accumulation and changes popularization of the liquid fuel especially alcohol group liquid fuel from ideal to reality.

Owner:李小辉

Gasification process for producing synthesis gas from garbage and biomass raw materials

InactiveCN101525118BEliminate pollutionHarmlessSolid waste disposalHydrogen productionWater vaporClean energy

The invention provides a gasification process for producing synthesis gas from garbage and biomass raw materials, which relates to a gasification processing technique of garbage and biomasses. The gasification process is characterized in that the technological process mainly comprises a raw material solid matter process, a gas phase circulation loop, a calcium oxide circulation loop and a synthesis gas drawing process; one or a mixture of more garbage, the biomasses and coal is sent into a gasification furnace to perform gasification so as to generate the synthesis gas; and simultaneously, calcium oxide is sent into the gasification furnace, an exothermic reaction of absorbing carbon dioxide by the calcium oxide provides the heat required by the gasification reaction in the furnace, and water vapor is sent into a plasma spraying gun and is heated to more than 3,100 DEG C to generate H2, O, O2 and H2O<*> which are sprayed into the gasification furnace to perform reactions with the garbage and the biomasses and supply heat into the furnace. The gasification process adopts a measure to spray the calcium oxide into the furnace to not only greatly reduce the electric energy consumptionof the plasma spraying gun, but also improve the quality and the yield of the synthesis gas, thus the aim of transforming the garbage and the biomasses into clean energy can be achieved easily.

Owner:周开根

Environmentally friendly energy-saving device for recycling straws

InactiveCN108441263AEfficient crushingAvoid leaving unshreddedChemical industryGasification processes detailsCombustible gasProduct gas

The invention discloses an environmentally friendly energy-saving device for recycling straws. The environmentally friendly energy-saving device comprises a shell and a pulverizer, wherein one side ofthe shell is connected with the pulverizer; sound-insulation cotton is arranged on the inner wall of the shell; a motor is arranged in the shell; one side of the motor is connected with an abnormal pulverizing stick; the abnormal pulverizing stick is positioned in the pulverizer; a solar cell panel is arranged on one side of the shell; and the bottom of the solar cell panel is electrically connected with a storage battery. By arrangement of the abnormal pulverizing stick, the circumstances that straws are not pulverized thoroughly, and straws which are not pulverized remain in corners are avoided; by arrangement of a dust collector and a dryer, dust of the pulverized straws is removed effectively and the pulverized straws are dried; and by arrangement of a filtering device, gas obtained by straw gasification is filtered effectively, and cleanliness of combustible gas is ensured effectively.

Owner:佛山市翔桂农机科技有限公司

Light dydrocarbon oil gas making device, light dydrocarbon oil gas making system and gas making method

ActiveCN105296032AImprove securityExtended service lifeGaseous fuelsProcess engineeringSafety coefficient

The invention relates to a light dydrocarbon oil gas making device, a light dydrocarbon oil gas making system and a gas making method. An oil inlet is formed in an oil storage tank; an air pressurizing tank is communicated with an air pump through a first pipeline; the air pressurizing tank is communicated with a bubbling reactor and the oil storage tank through a second pipeline and a third pipeline respectively; the bubbling reactor and the oil storage tank are communicated through a fourth pipeline and a fifth pipeline; the fourth pipeline and the fifth pipeline are respectively connected with the upper part and the lower part of the oil storage tank; the bubbling reactor is communicated with an output pipeline; a first one-way valve is arranged on the second pipeline; a second one-way valve is arranged on the third pipeline; a third one-way valve is arranged on the fourth pipeline; a fourth one-way valve is arranged on the fifth pipeline; the second pipeline stretches into the bottom of the bubbling reactor; and a plurality of vent holes are formed in the second pipeline. Heating is not needed, a light dydrocarbon raw material is free of residual liquid, can be completely gasified and is free of back condensation phenomenon, the safety coefficient is high, and the service life of equipment is long.

Owner:山西高阳益众新能源科技有限公司

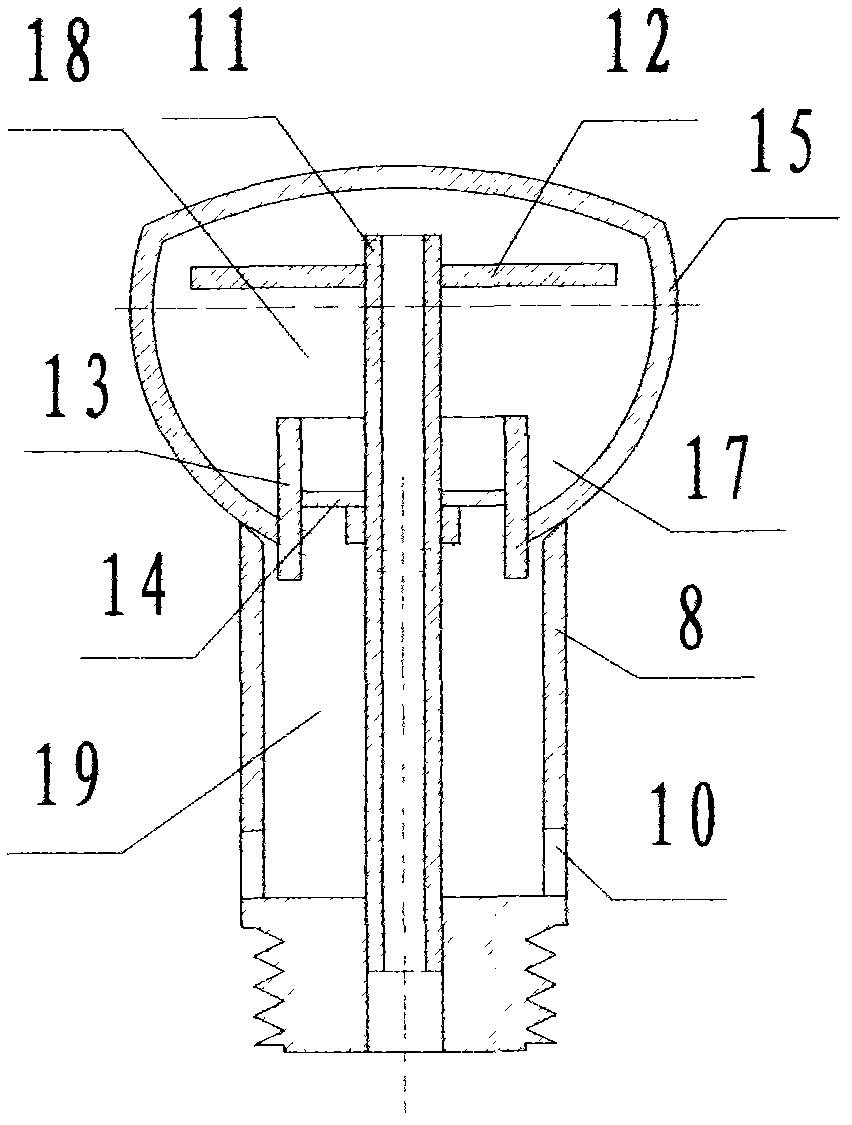

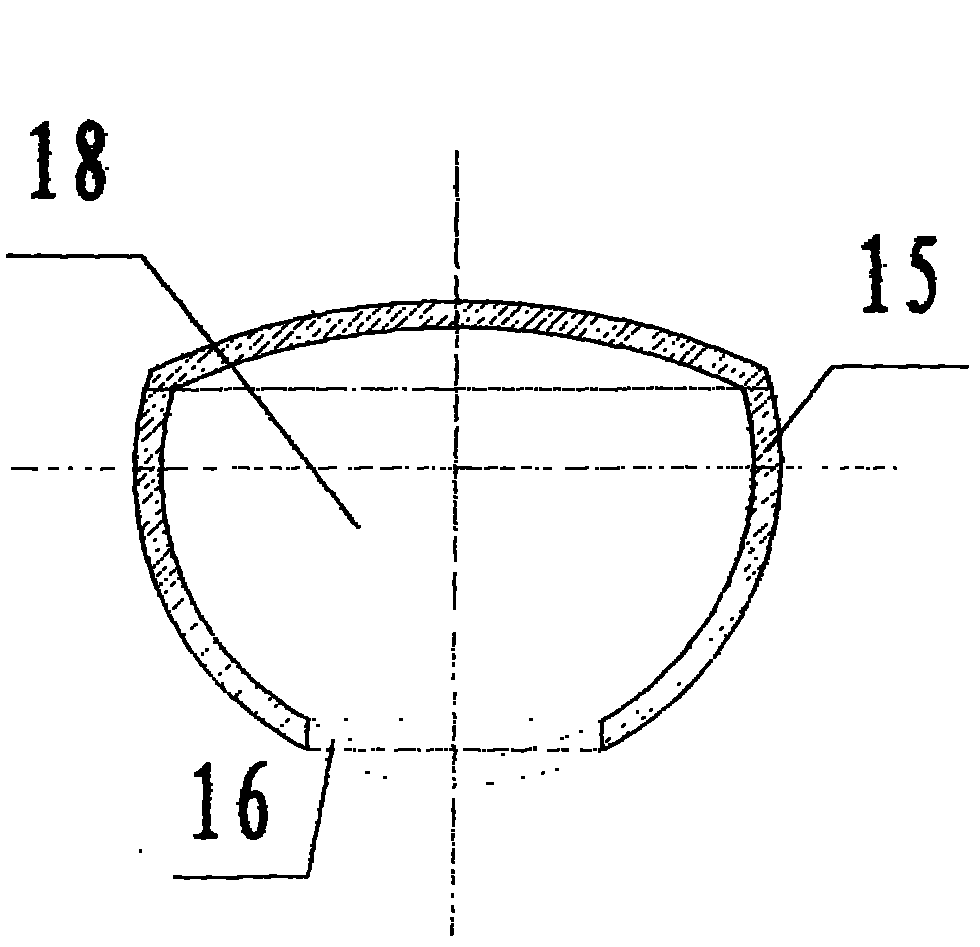

Liquid fuel gasification burner

The invention provides a liquid fuel gasification burner. The liquid fuel gasification burner comprises an air cavity outer case, an air cavity inner case, a gasifier and a fire-resistant ring; the gasifier consists of a gasification ball, an air guide cylinder, an oil outlet pipe, an oil distribution film and an oil storage ring, the liquid fuel gasification burner is characterized in that the air cavity inner case is shaped like a cup, and the gasifier is arranged on the air cavity inner case; the fire-resistant ring is arranged on the air cavity inner case, and the air cavity inner case and the air cavity outer case form a hollow air inlet cavity with a hollow cavity. The liquid fuel gasification burner can quickly change liquid fuel into gaseous fuel for burning, overcomes the defect that the liquid fuel can be only used for atomizing burning, is mainly used in industries of hotels, restaurants, industrial furnaces and the like, and is low in energy consumption, and the energy can be saved by more than 40% through tests. The flame temperature can achieve up to more than 1300 DEG C, the firepower is strong, the heating speed is fast, and the calorific value is improved in disguise; the gasification speed is fast, no preheating is needed, and the burning is stable; and the burning is sufficient, thereby being very environment-friendly. The liquid fuel gasification burner can realize the gasification burning of the liquid fuel from atomizing burning, and the popularization of the liquid fuel gasification burner can make great contribution to energy conservation for China.

Owner:李小辉

Mixed liquid gasification burner and nozzle-free water cooling gasification furnace end comprising same

The invention relates to the technical filed of gasification furnace ends and discloses a mixed liquid gasification burner and a nozzle-free water cooling gasification furnace end comprising the same. The mixed liquid gasification burner consumes 4kg of mixed liquid fuel per hour, a flame turns cyan gradually from the bottom to the top of the flame sequentially according to the power and is centralized in the direction perpendicular to the first plane. The outer flame temperature of the flame can reach 1550-1600 DEG C. The problem of kitchen waste blockage is solved, meanwhile, the mixed liquid fuel can be burned more fully, the consumption of the mixed liquid fuel can be lower, and the flame of the mixed liquid fuel can be more centralized. The nozzle-free water cooling gasification furnace end is provided with the mixed liquid gasification burner, the situation that a gas nozzle is directly exposed in the environment is avoided, the problem that the gas nozzle in the furnace end is liable to be blocked is solved, the using performance of the furnace end is improved greatly, and potential safety hazards are avoided. A tapered part and a protective part are matched, through the structure design, the temperature of the furnace end is increased, the fuel consumption is reduced, and the flame is more centralized.

Owner:株洲蓝宝新能源科技有限公司

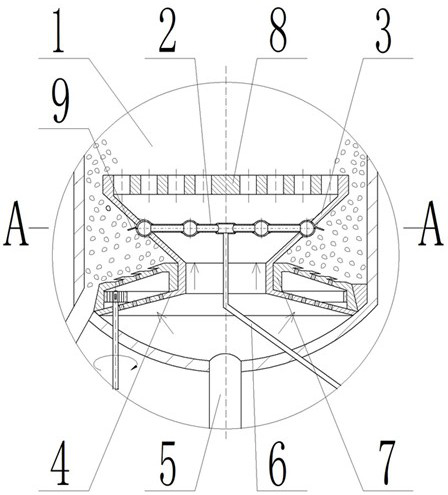

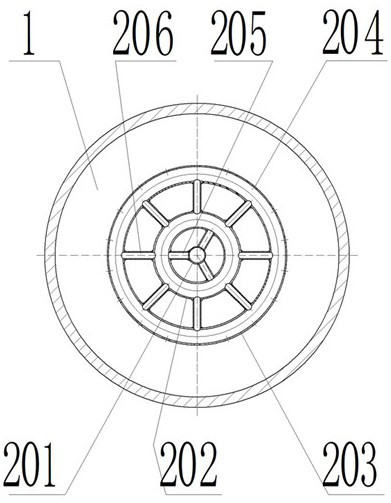

Double-bed composite coal gasifier for burning out carbon-containing fly ash

InactiveCN113684063AStable deliveryEvenly distributedGasifier feeding meansChemical industryCombustionSlag

The invention relates to a double-bed composite coal gasifier for burning out carbon-containing fly ash, wherein the double-bed composite coal gasifier is characterized in that the carbon-containing fly ash generated in a circulating fluidized bed at the upper part is separated and then fed into a high-temperature slag coke layer of a pyrolysis fixed bed arranged at the lower part of a same furnace chamber by a fly ash dispersing disc to be burnt and gasified until the carbon-containing fly ash is burnt out. The fly ash dispersing disc is composed of a first-stage ash distributing pipe, an ash distributing ring, a second-stage ash distributing pipe, an ash distributing ring and an ash spraying ring; and a fly ash input pipe is communicated with the ash distributing ring through the first-stage ash distributing pipe, the ash distributing ring is communicated with the ash spraying ring through the second-stage ash distributing pipe, the ash spraying ring is connected with a furnace core, the ash spraying ring is provided with ash spraying holes, and the ash spraying holes feed carbon-containing fly ash into a high-temperature coke slag layer of a fixed bed. The double-bed composite coal gasifier has the advantages of energy conservation, environmental protection, smooth fly ash conveying, uniform distribution in the furnace chamber, thorough combustion and gasification and the like.

Owner:ZHONGKEJUXIN CLEAN ENERGY &HOT FORGING EQUIP RES & DEV CO LTD +1

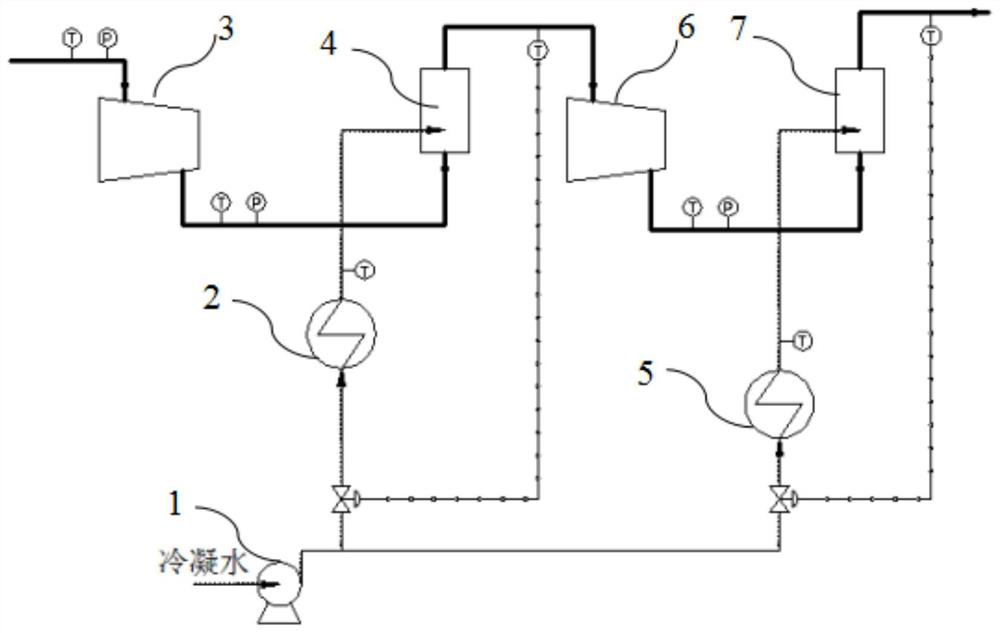

A method and device for steam recovery

ActiveCN112197613BComplete gasificationAppropriate amount of sprayChemical industryDirect contact heat exchangersThermodynamicsSteam pressure

The invention provides a steam recovery method and device, comprising the following steps: compressing the low-pressure steam in two or more stages to obtain medium-pressure steam or high-pressure steam; spraying water on the superheated steam obtained after each stage of compression to cool down , to reduce its superheat. The steam recovery method provided by the present invention enables the sprayed liquid droplets to be heated in advance to the saturation temperature under the pressure of the sprayed steam, which can realize the complete gasification of the sprayed liquid, the appropriate amount of sprayed liquid, and no liquid accumulation inside the compressor Effect. The steam recovery method and device provided by the present invention can be used to recover and utilize low-pressure steam in a melamine production device, and improve the utilization value of the low-pressure steam by-produced in a urea washing tower of the melamine production device.

Owner:SICHUAN GOLDEN ELEPHANT SINCERITY CHEM CO LTD +1

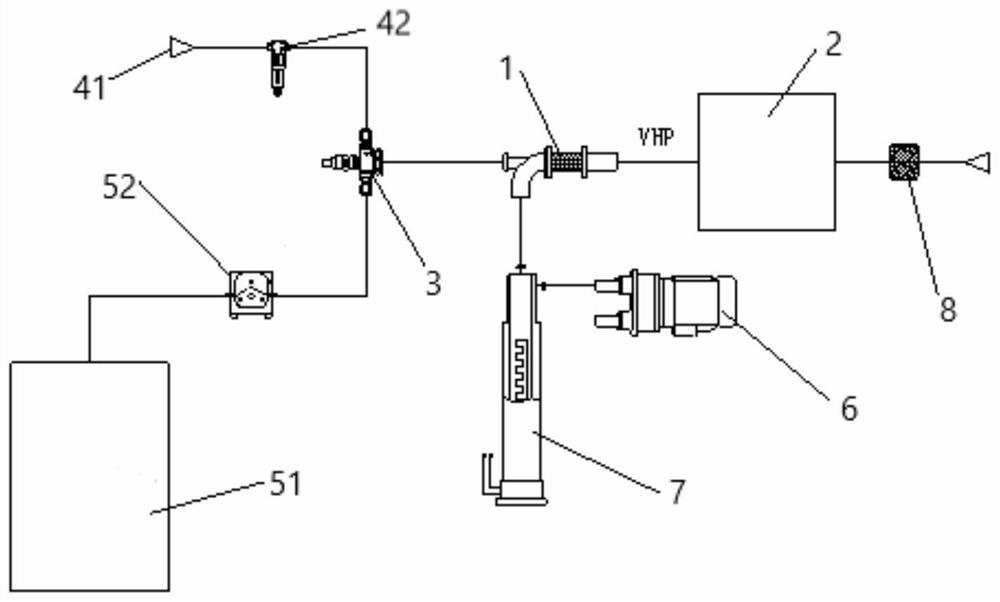

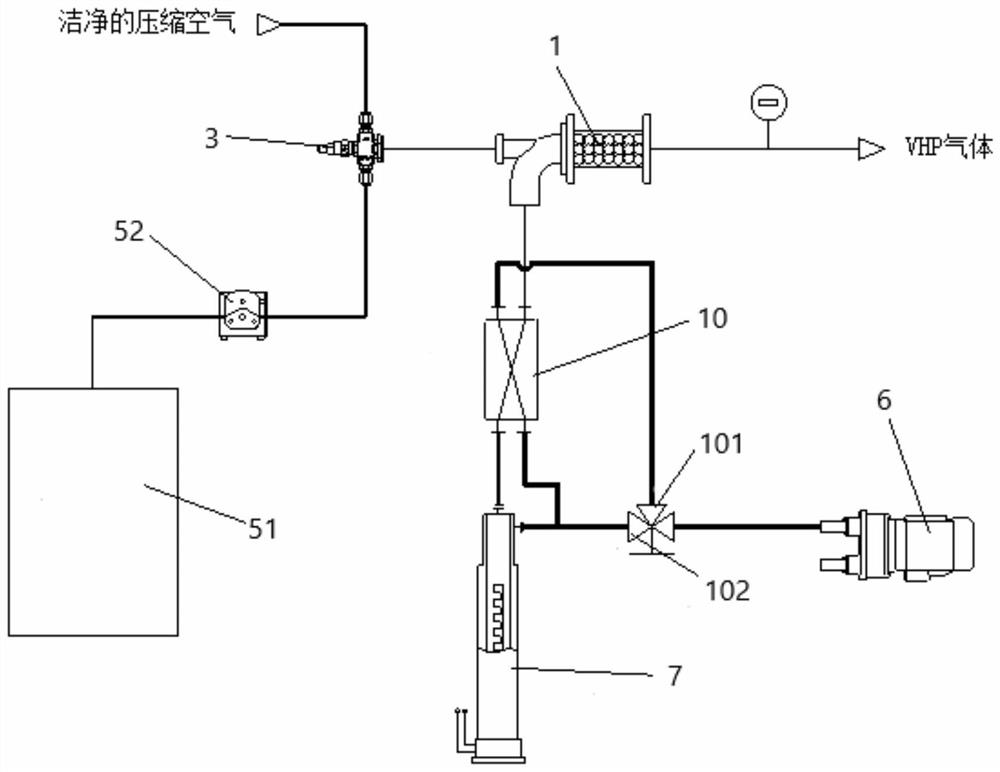

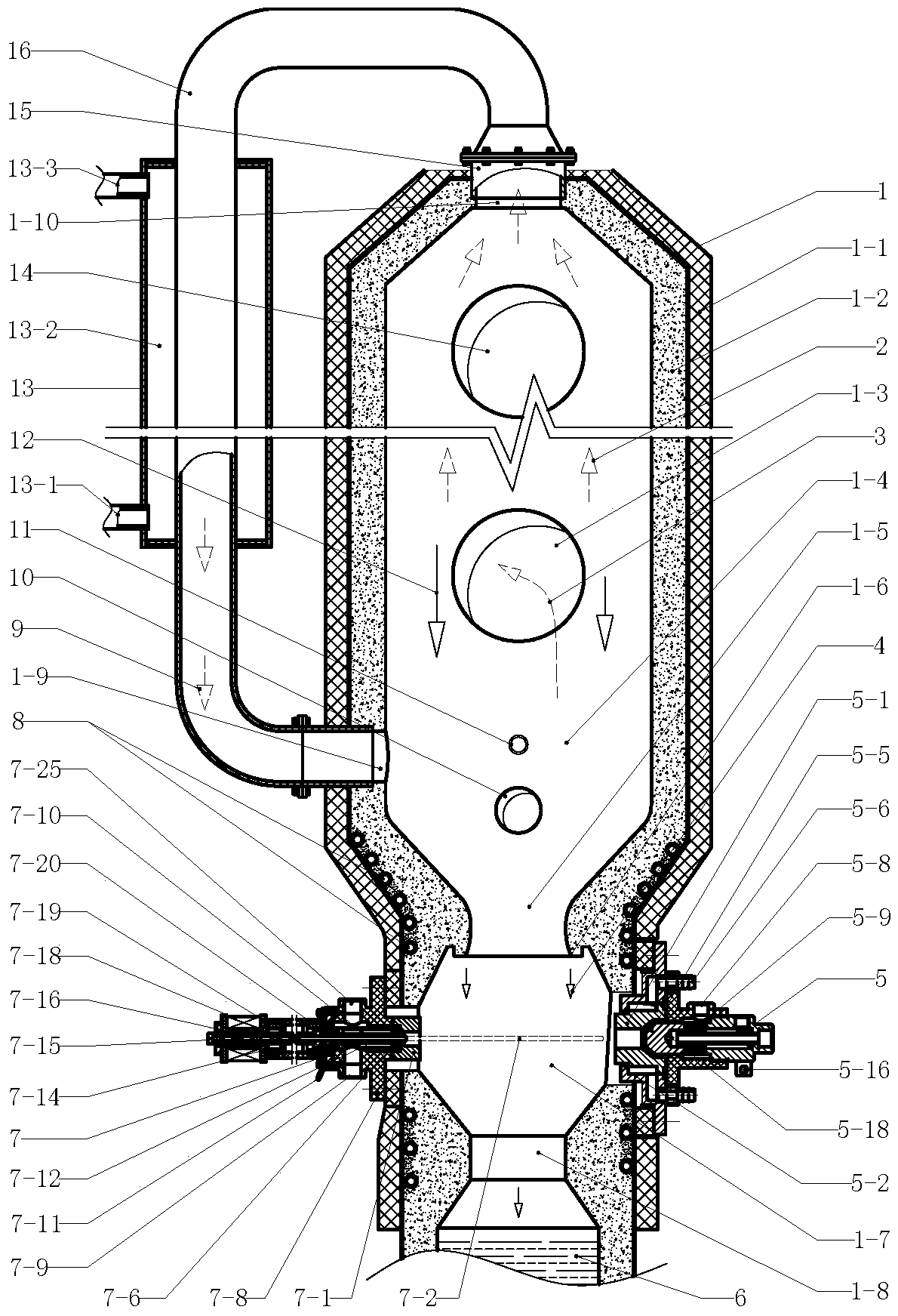

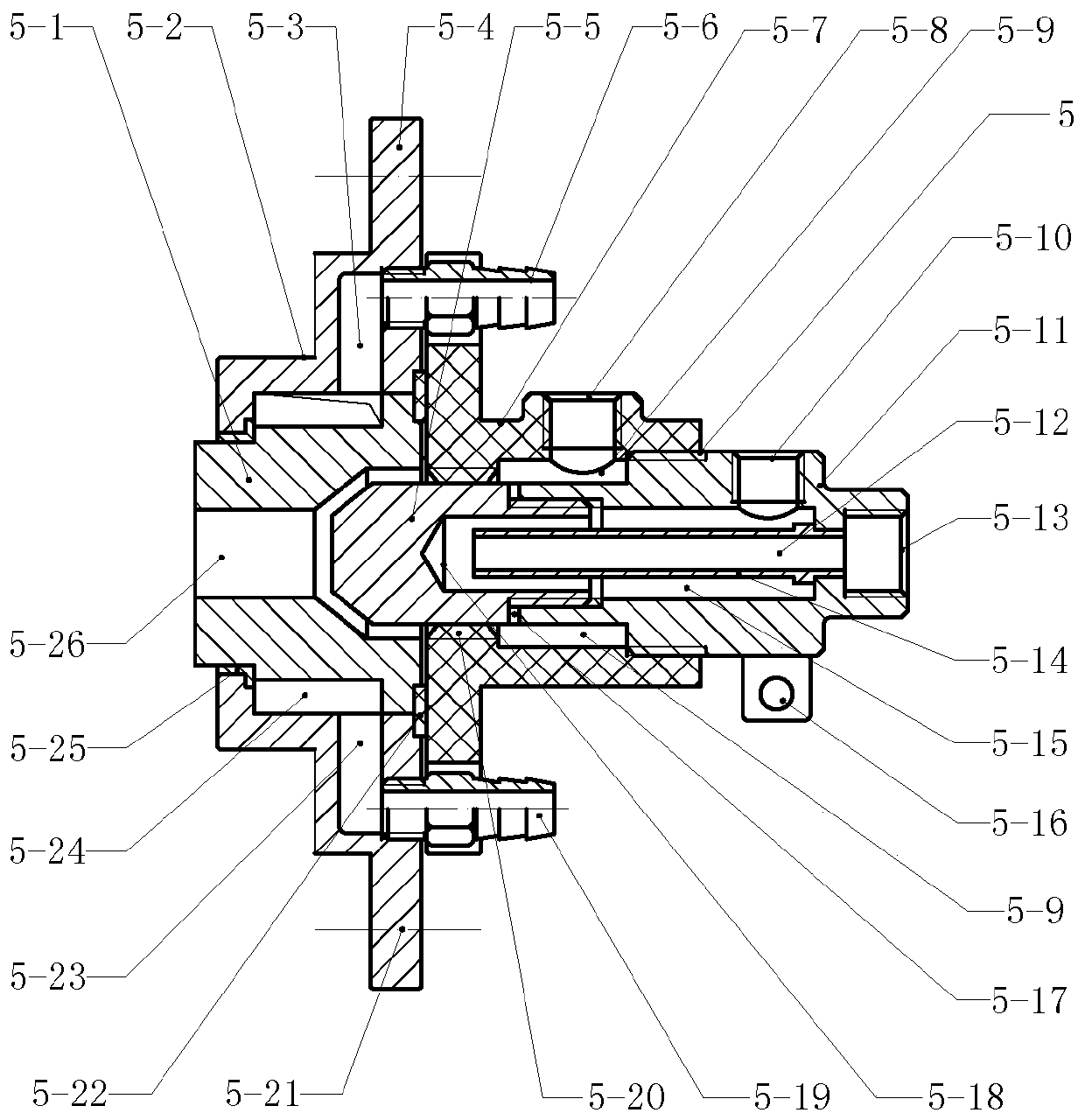

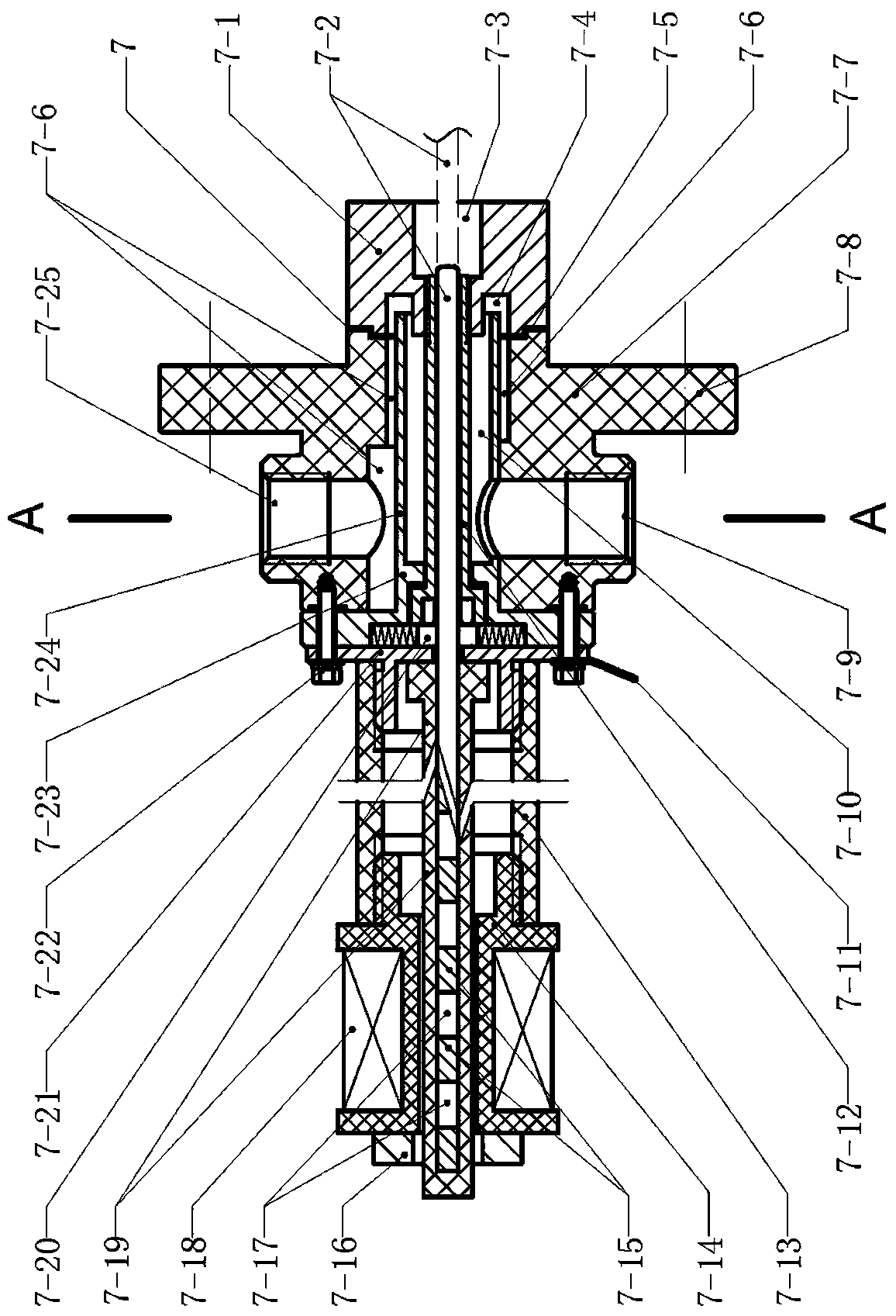

VHP sterilization generator

PendingCN113893382ASimple structureReduce the temperatureGaseous substancesAtomized substancesProcess engineeringMechanical engineering

The invention relates to a VHP sterilization generator. The VHP sterilization generator comprises a flash chamber and an atomizer, wherein a plurality of uniformly distributed beads are arranged in an internal channel of the flash chamber, one end of the flash chamber is connected with the atomizer, and one end of the atomizer is separately connected with a compressed air supply device and a hydrogen peroxide container. By adopting the technical scheme, hydrogen peroxide is gasified more thoroughly, and the killing efficiency of the system is increased.

Owner:广州市铭慧机械股份有限公司

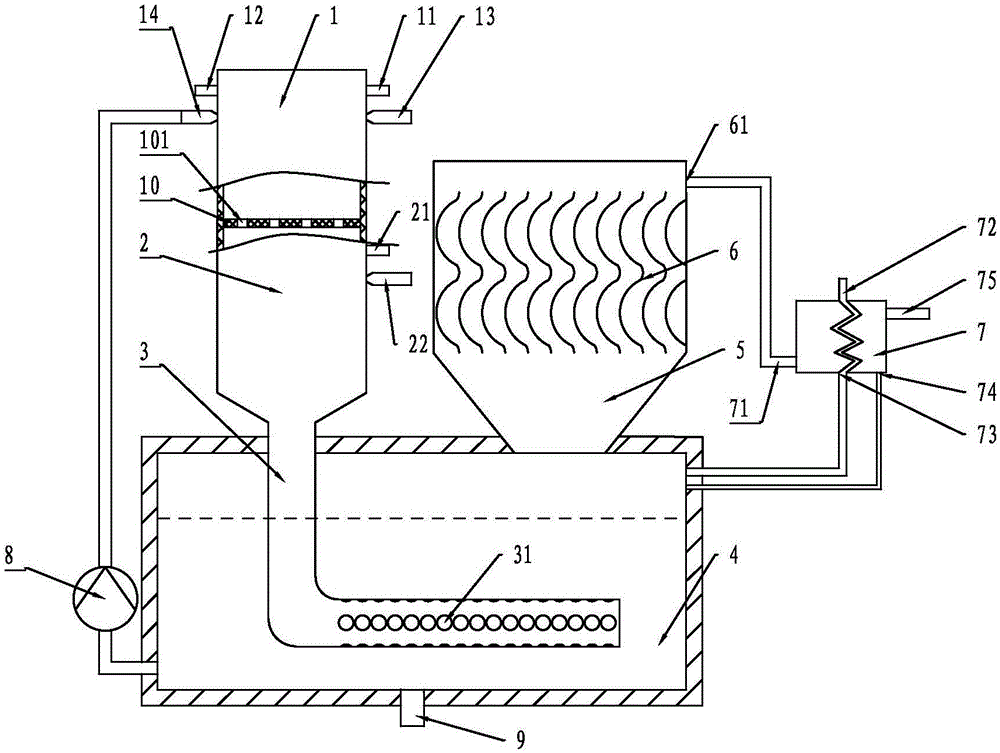

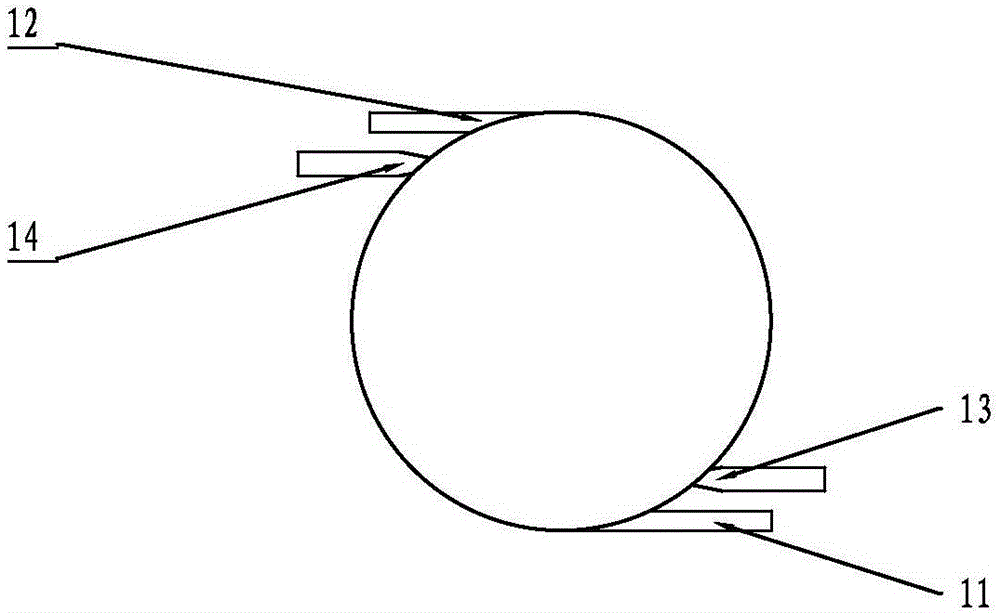

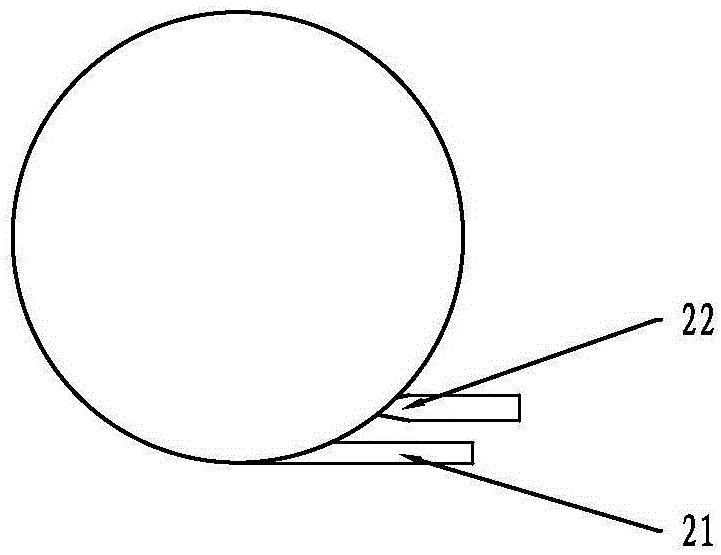

A self-circulating plasma gasifier

ActiveCN105623739BImprove decomposition efficiencyComplete gasificationGasifier electrodesGasification processes detailsHydrogenWater vapor

Owner:JINING XINRUIDA INFORMATION TECH CO LTD

Alcohol-based high-temperature gasification fire control furnace

InactiveCN103644579AEvenly heatedIncrease the heating areaBurnersDomestic stoves or rangesAlcoholCombustion chamber

The invention relates to an alcohol-based high-temperature gasification fire control furnace which comprises a furnace core, a refractory ring, a fire control cover and a fire control ring, wherein the refractory ring is arranged above the furnace core; the fire control cover is arranged above the refractory ring; a fire control ring is arranged at the periphery of the upper part of the fire control cover; a high-temperature gasification combustion chamber is formed among the furnace core, the refractory ring and the fire control cover; multiple fire outlet ducts are formed in the fire control cover; the fire outlet directions of the fire outlet ducts face an inner wall of the fire control ring. According to the alcohol-based high-temperature gasification fire control furnace, the energy can be fully utilized, the cost is saved, pungent smell, sting of eyes and odor can be avoided, carbon deposit blockage in the furnace core is avoided, and the alcohol-based high-temperature gasification fire control furnace is complete in gasification, convenient in ignition, uniform in fire distribution, strong in fire, easy to use and energy-saving.

Owner:JIANOU XINGYUAN BIOLOGICAL ALCOHOL OIL

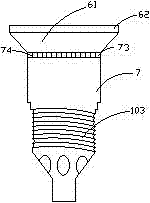

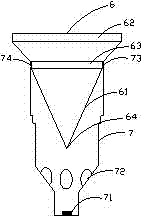

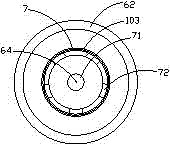

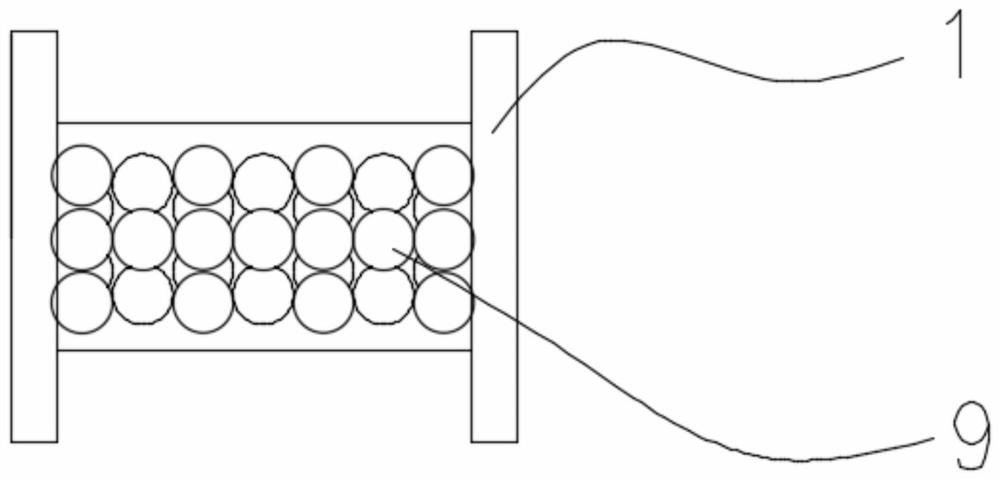

Homogeneous progressive gasification furnace

ActiveCN105441132AWill not polluteEvenly heatedChemical industryRotary drum/kiln gasifiersEngineeringEnergy analysis

The invention relates to environmental-protection energy-saving equipment, namely a homogeneous progressive gasification furnace. The homogeneous progressive gasification furnace comprises a cylindrical furnace body (1), a feed hopper, a heating pipe (7) and a collecting pipe, and is characterized in that the furnace body (1) is a rotatable revolving body; and a pushing device for pushing fuel to move from a feed end to the other end is arranged inside the furnace body (1). The invention has the following beneficial effects: fuel enters from one end of the furnace body, goes towards the other end during the process of being repeatedly turned over up and down and is heated uniformly, decomposed fully and gasified thoroughly; there is no hazard waste emission; the environment will not be polluted; the structure of the furnace is simple; cost is low; and the furnace has a considerable application prospect.

Owner:张建臣

Process, system and device for waste biomass multi-production processing

ActiveCN101565629BEliminate pollutionHarmlessHydrogen separationCombustible gas catalytic treatmentEcological environmentGas phase

The invention relates to a process, a system and a device for waste biomass multi-production processing, in particular to a waste biomass gasification and liquefaction treatment system. The gasification treatment is performed to the waste biomass, the gas is used for producing clean energy and chemical raw materials, the furnace slag is used for producing building materials or fertilizer and the waste heat is used for electric power generation and heat supply so as to realize the environmental-friendly municipal solid waste treatment and the ecological environment protection. The system mainlycomprises a gas-phase circulation gasification furnace, a flue gas circulation air tube, a flue gas circulation fan, a dust-removal / purifying tower and a synthesis reactor and is characterized in that the gas-phase circular reaction is performed to the flue gas in the gasification furnace, the water vapor and the gaseous matter generated during the pyrolysis to obtain hydrogen-rich synthetic gas,and meanwhile, the dioxin (violent in toxicity) is broken up; and the post treatment is performed to the hydrogen-rich synthetic gas to generate city gas, methanol, dimethyl ether or hydrogen. The system has the advantages of full gasification of the solid raw material, no pollutant discharge, extremely low exhaust emission and easy purifying treatment, and the device is flexible in size and is feasible for popularization.

Owner:上海格灵迈环境科技有限公司

A high-concentration organic waste liquid treatment system and treatment method

ActiveCN105066146BEasy to handleReduce consumptionLiquid fuel feeder/distributionCombustion technology mitigationHigh concentrationCombustion chamber

The invention belongs to the field of wastewater treating, and particularly relates to a system and a method for treating high-concentration organic waste liquid. The organic waste liquid can be efficiently processed in a low-consumption, energy-saving and environment-friendly manner. The system for treating the high-concentration organic waste liquid comprises a gasification chamber, a combustor, a smoke pipe, a waste liquid pump, a waste liquid tank, a settling chamber, demisting baffles and a condenser. The gasification chamber is located at the top of the combustor. A primary auxiliary fuel nozzle, a waste liquid nozzle and at least one air inlet are formed in the upper portion of the side wall of the gasification chamber. A secondary air inlet and a secondary auxiliary fuel nozzle are arranged at the upper portion of the side wall of the combustor. An exhausting opening of the combustor directly extends into the waste liquid tank through the smoke pipe. The settling chamber is installed at the top of the waste liquid tank. The multiple demisting baffles are installed at the upper portion of the interior of the settling chamber. A gas outlet in the top of the settling chamber is communicated with a gas inlet of the condenser through a pipe. An inlet of a condenser heat exchanging pipe is connected with a waste liquid delivery pipe. A waste liquid outlet in the waste liquid tank is sequentially communicated with the waste liquid pump and the waste liquid nozzle through a pipe.

Owner:南京赛佳环保实业有限公司 +1

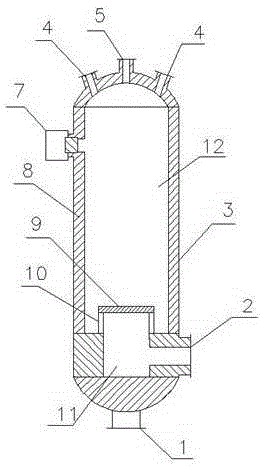

Micro negative pressure black liquor gasifier

ActiveCN103879962BIncrease contact areaIncrease contact timePulp liquors combustionCarbon layerBlack liquor

The invention discloses a micro-negative-pressure black liquor gasifier. A main body is represented as a dual-crown cover cylindrical body which is covered by a steel shell (3), wherein a supporting drum (1) is connected to a lower crown cover of the cylindrical body; a black liquor atomizing spray gun base (4), an oxygen inlet (5) and a preheated gas inlet (6) are arranged on an upper crown cover; a gasified gas and alkali melt outlet (2) is formed on the side face of the lower part of the cylindrical body, and an anti-explosion device (7) is arranged on the side face of the upper part of the cylindrical body; a liner of the steel shell (3) is a heat insulating layer (8); a carbon depositing plane (9) is constructed in an inner cavity of the black liquor gasifier through an alkali resistant and high-temperature resistant material; a carbon depositing plane support (10) is arranged below the carbon depositing plane (9); the entire inner cavity is divided into a replenishing reaction chamber (11) and a gasifying chamber (12). By mounting the carbon depositing plane on the gasifier, a contact area between coke and water vapor is increased and contact time between a carbon layer and high-temperature water vapor is prolonged, so that the black liquor is more thorough in a gasifying reaction, and yields of CO and H2 are improved.

Owner:GUANGXI UNIV

Homogeneous Progressive Gasifier

ActiveCN105441132BWill not polluteEvenly heatedChemical industryRotary drum/kiln gasifiersEngineeringEnergy analysis

The invention relates to environmental-protection energy-saving equipment, namely a homogeneous progressive gasification furnace. The homogeneous progressive gasification furnace comprises a cylindrical furnace body (1), a feed hopper, a heating pipe (7) and a collecting pipe, and is characterized in that the furnace body (1) is a rotatable revolving body; and a pushing device for pushing fuel to move from a feed end to the other end is arranged inside the furnace body (1). The invention has the following beneficial effects: fuel enters from one end of the furnace body, goes towards the other end during the process of being repeatedly turned over up and down and is heated uniformly, decomposed fully and gasified thoroughly; there is no hazard waste emission; the environment will not be polluted; the structure of the furnace is simple; cost is low; and the furnace has a considerable application prospect.

Owner:张建臣

Light hydrocarbon oil gas production device, light hydrocarbon oil gas production system and gas production method

The invention relates to a light dydrocarbon oil gas making device, a light dydrocarbon oil gas making system and a gas making method. An oil inlet is formed in an oil storage tank; an air pressurizing tank is communicated with an air pump through a first pipeline; the air pressurizing tank is communicated with a bubbling reactor and the oil storage tank through a second pipeline and a third pipeline respectively; the bubbling reactor and the oil storage tank are communicated through a fourth pipeline and a fifth pipeline; the fourth pipeline and the fifth pipeline are respectively connected with the upper part and the lower part of the oil storage tank; the bubbling reactor is communicated with an output pipeline; a first one-way valve is arranged on the second pipeline; a second one-way valve is arranged on the third pipeline; a third one-way valve is arranged on the fourth pipeline; a fourth one-way valve is arranged on the fifth pipeline; the second pipeline stretches into the bottom of the bubbling reactor; and a plurality of vent holes are formed in the second pipeline. Heating is not needed, a light dydrocarbon raw material is free of residual liquid, can be completely gasified and is free of back condensation phenomenon, the safety coefficient is high, and the service life of equipment is long.

Owner:山西高阳益众新能源科技有限公司

System and apparatus for producing synthesis gas from garbage and biomass raw material

The invention provides a system and equipment for producing synthesis gas by garbage and biomass raw materials, which relates to garbage and biomass gasification equipment. The system and the equipment are characterized in that a vapor circulation loop and a calcium oxide circulation loop are arranged in the system; the garbage and the biomass raw materials are vaporized by an exothermic reactionof absorbing CO2 of the calcium oxide in a gasification furnace to cooperate with thermal plasma, so that the garbage and the biomass raw materials are converted into high heating value synthesis gasfor cleaning energy or chemical raw materials. The system mainly comprises a multiphase circulation gasification furnace, a plasma spray gun, the vapor circulation loop, the calcium oxide circulationloop, a wet purification tower and a gas holder, wherein a circulation output interface of the gasification furnace is connected to a gas-solid separator; a gas outlet of the gas-solid separator is connected to a circulating fan; an air outlet of the circulating fan is connected to the vapor circulation input interface of the gasification furnace; a dipleg of the gas-solid separator is connected to a feed delivery valve; the feed delivery valve is connected to a calcium oxide calcining furnace through a solid phase conveying pipe; and a calcium oxide outlet of the calcium oxide calcining furnace is connected to a calcium oxide jet tube of the gasification furnace through a refeed line.

Owner:衢州市广源生活垃圾液化技术研究所

Mixed heating LNG gasifier

InactiveCN110319345ASuppress vibration phenomenonReduce heat pollutionFluid handledPressure vesselsStable stateEngineering

The invention provides a mixed heating LNG gasifier. The mixed heating LNG gasifier is composed of a hot water distributor, a finned tube, an LNG distribution tank, an NG gas collecting tank and the like. The hot water distributor comprises a hot water distribution box, a water inlet pipe, a hot water tank, a convex overflow plate, a cylindrical buffer, a buffer cover plate, a distribution plugboard, a trough type channel, an overflow plugboard and a drainage board, wherein the hot water tank is divided into a buffer area, a distribution area, an overflow area and a heat exchange area by the distribution plugboard and the overflow plugboard, the non-communication of the buffer area and the heat exchange area ensures that the hot water in the heat exchange area is in a stable state, so thathot water forms a uniformly-distributed hot water solution film on the outer surface of the finned tube through a flow guide plate. When the temperature in the daytime is high, the LNG is heated by taking air as a heat source. When the temperature at night is low, the LNG is heated by utilizing plant hot water, so that the gasification efficiency of LNG is improved.

Owner:HARBIN UNIV OF SCI & TECH

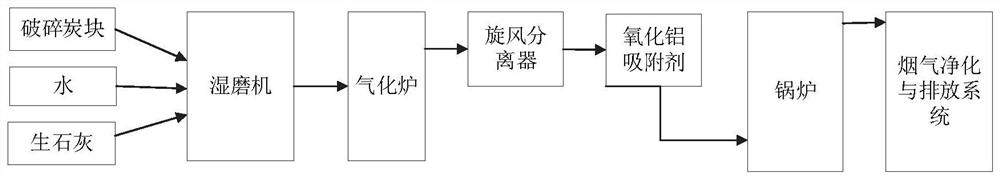

A method of gasification and reburning denitrification of electrolytic aluminum waste cathode carbon blocks

ActiveCN111892963BNon-flammableComplete gasificationGasification processes detailsLiquid carbonaceous fuelsSlurryFluoride

The invention discloses a gasification and reburning denitrification method of electrolytic aluminum waste and old cathode carbon block, which comprises the following steps: crushing electrolytic aluminum waste and old cathode carbon, mixing with quicklime and water and ball milling to make carbon slurry; gasifying the carbon slurry, gasifying The melting temperature is above the melting temperature of cryolite and below 1500°C. The method realizes the recycling of alumina and fluoride of the carbon block ash, the gasification gas is used as a clean fuel, or is used as a reburning fuel in a coal-fired boiler, and the disposal amount of the carbon block is large, and the process is clean and efficient.

Owner:山东魏桥铝电有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com