Homogeneous Progressive Gasifier

A gasifier and furnace body technology, applied in the field of environmental protection and energy-saving equipment, can solve the problems of low pyrolysis efficiency, uneven heating, insufficient gasification, etc., and achieve the effects of considerable application prospects, sufficient decomposition and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

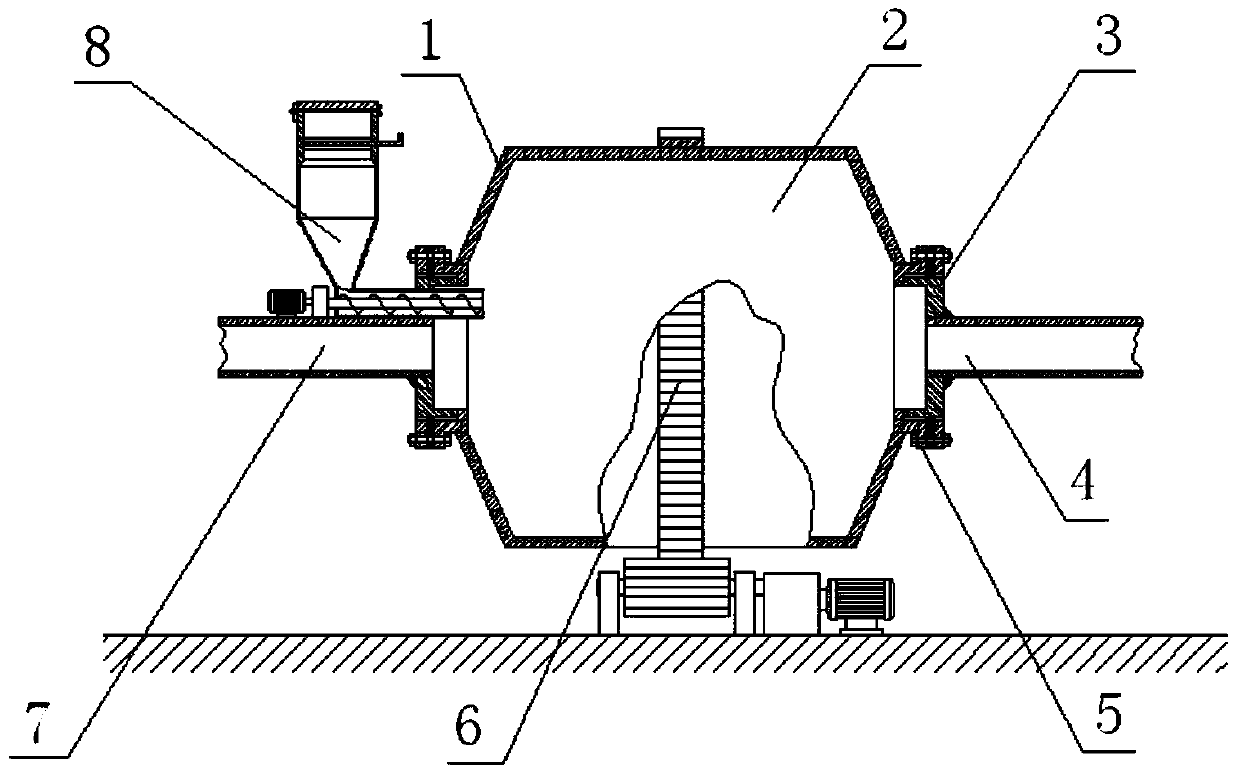

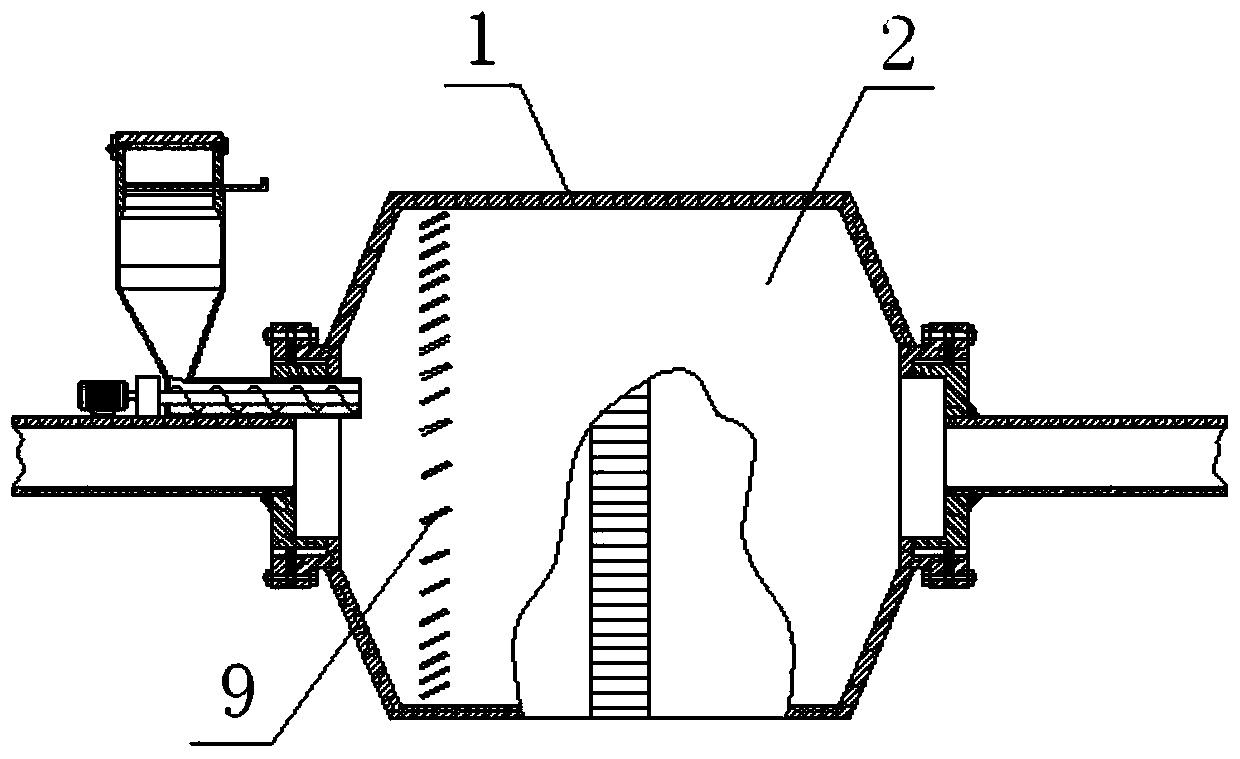

[0036] The first embodiment: figure 1 A homogeneous progressive gasification furnace is introduced, which includes a cylindrical furnace body 1, a fuel hopper 8, a heat supply pipe 7 and a collection pipe 4. The push device that moves the feed end to the other end. Furnace body 1 is a rotary furnace that can rotate around a flat axis. There are transfer discs 5 at both ends of the rotary furnace. The devices on both sides are connected, and the adapter plate 5 can be a splint-shaped flange plate, and there is packing between the splints, and the packing and the splicing plate 3 rotate and cooperate to achieve the purpose of sealing and rotating. A rotary gear 6 is arranged on the periphery of the rotary furnace, and the rotary gear 6 is transmitted with the driving gear driven by the power machine.

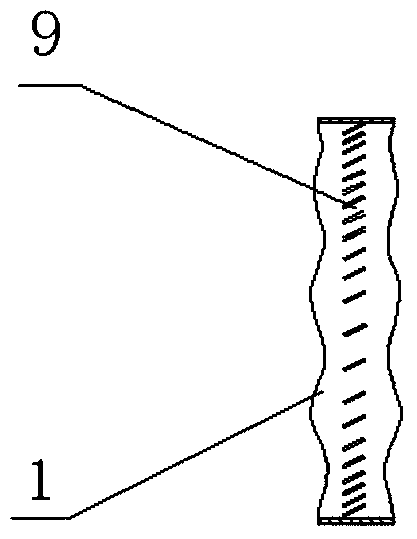

[0037] Said pusher device here has multiple, and a kind of exemplifying among the figure is that screw blade 9 is installed on the inner wall of the furnace. Spiral sheet 9 can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com