Double-bed composite coal gasifier for burning out carbon-containing fly ash

A technology for coal gasification and gasification furnace, which is applied in the field of coal gasification, can solve the problems of difficult handling of carbon-containing fly ash, etc., and achieve the effects of smooth transportation, thorough combustion and gasification, and uniform distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

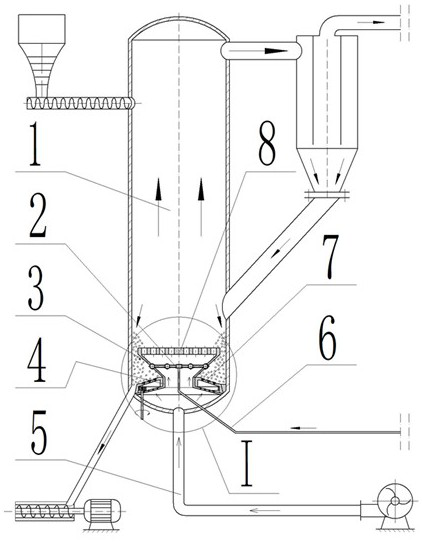

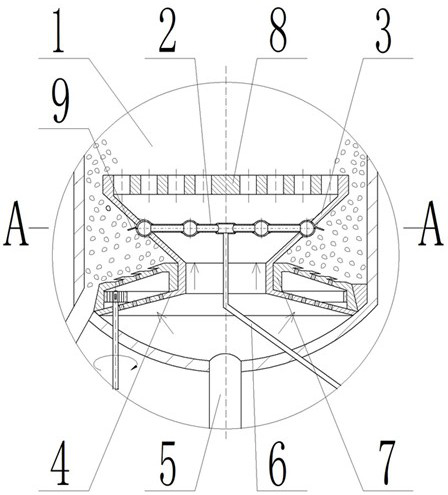

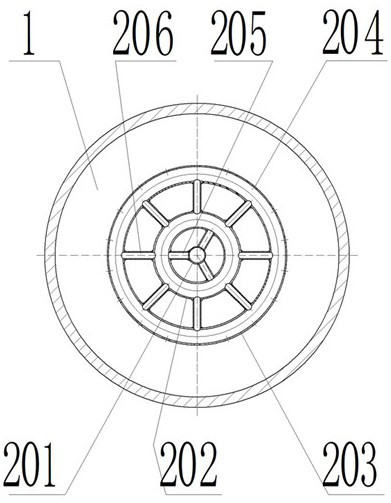

[0016] As shown in the accompanying drawings, the fly ash dispersion disc 2 is arranged as a planar net-like embodiment. as attached figure 1 As shown, the raw coal is burned and gasified in the gasifier 1, and semi-coke, carbon-containing fly ash and coal gas are produced. After the fly ash gathers, a fly ash air flow is formed under the action of high-pressure nitrogen gas, and the fly ash air flow enters the fly ash conveying pipeline 6, and then enters the fly ash input pipe 201 from the fly ash conveying pipeline 6, and the fly ash input pipe 201 sends the fly ash air flow into a Fractional ash pipe 205, the first-stage ash separation pipe 205 sends the fly ash airflow to the ash separation circle 202, and the ash separation circle 202 sends the fly ash airflow to the second-stage ash separation pipe 206, and the second-stage ash separation pipe 206 sends the fly ash airflow Send it into the ash spray ring 203, and the fly ash airflow is sprayed into the high-temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com