Light hydrocarbon oil gas production device, light hydrocarbon oil gas production system and gas production method

A light hydrocarbon oil and oil storage tank technology, which is applied to liquid light hydrocarbon oil gas production equipment, light hydrocarbon oil gas production system and gas production field, and can solve problems such as equipment aging, pipe network back-condensation, and poor safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

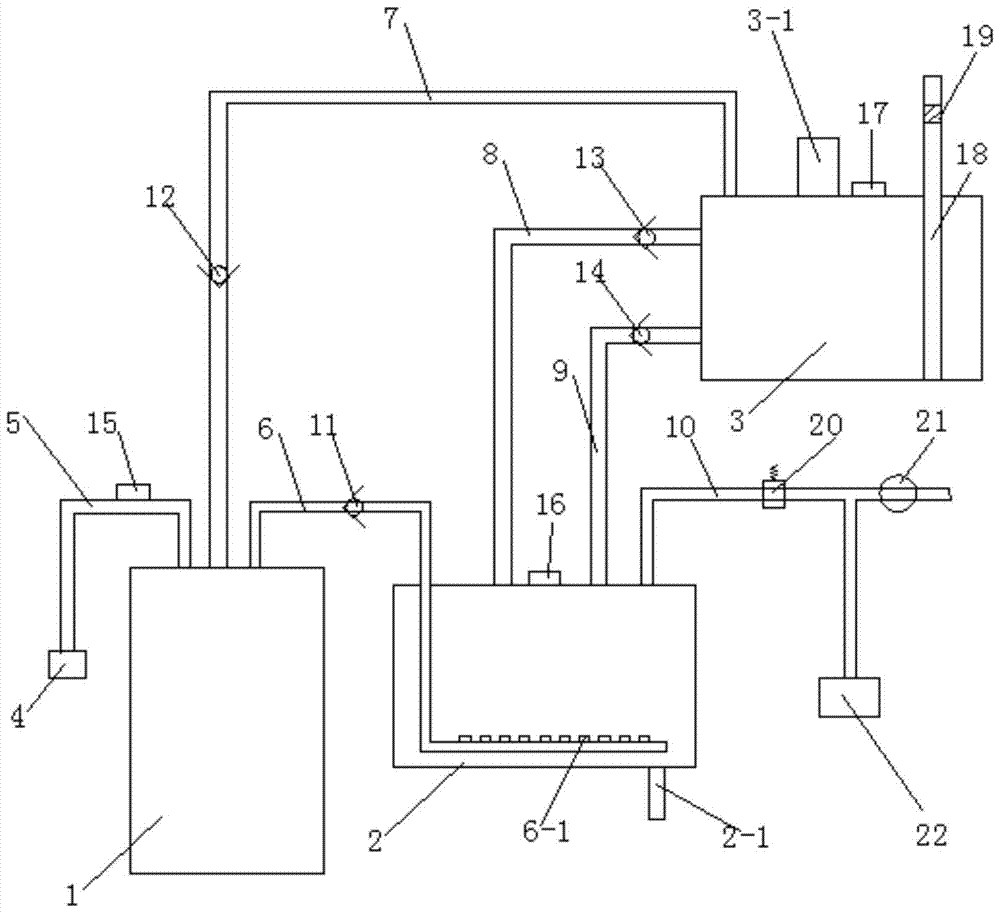

[0010] The present invention is described in further detail below in conjunction with the embodiment that accompanying drawing provides.

[0011] see figure 1 As shown, a light hydrocarbon oil gas production device includes an air pressurized tank 1, a bubbling reactor 2, an oil storage tank 3 and an air pump 4, and the oil storage tank 3 is provided with an oil inlet 3-1, The air pressurized tank 1 communicates with the air pump 4 through the first pipeline 5, and the air pressurized tank 1 communicates with the bubbling reactor 2 and the oil storage tank 3 respectively through the second pipeline 6 and the third pipeline 7, and the bubbling The reactor 2 and the oil storage tank 3 communicate through the fourth pipeline 8 and the fifth pipeline 9, the fourth pipeline 8 and the fifth pipeline 9 are respectively connected to the upper and lower parts of the oil storage tank 3, and the bubble reactor 2 communicates with the output pipeline 10, and the second pipeline 6 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com