Patents

Literature

66results about How to "Easy purification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

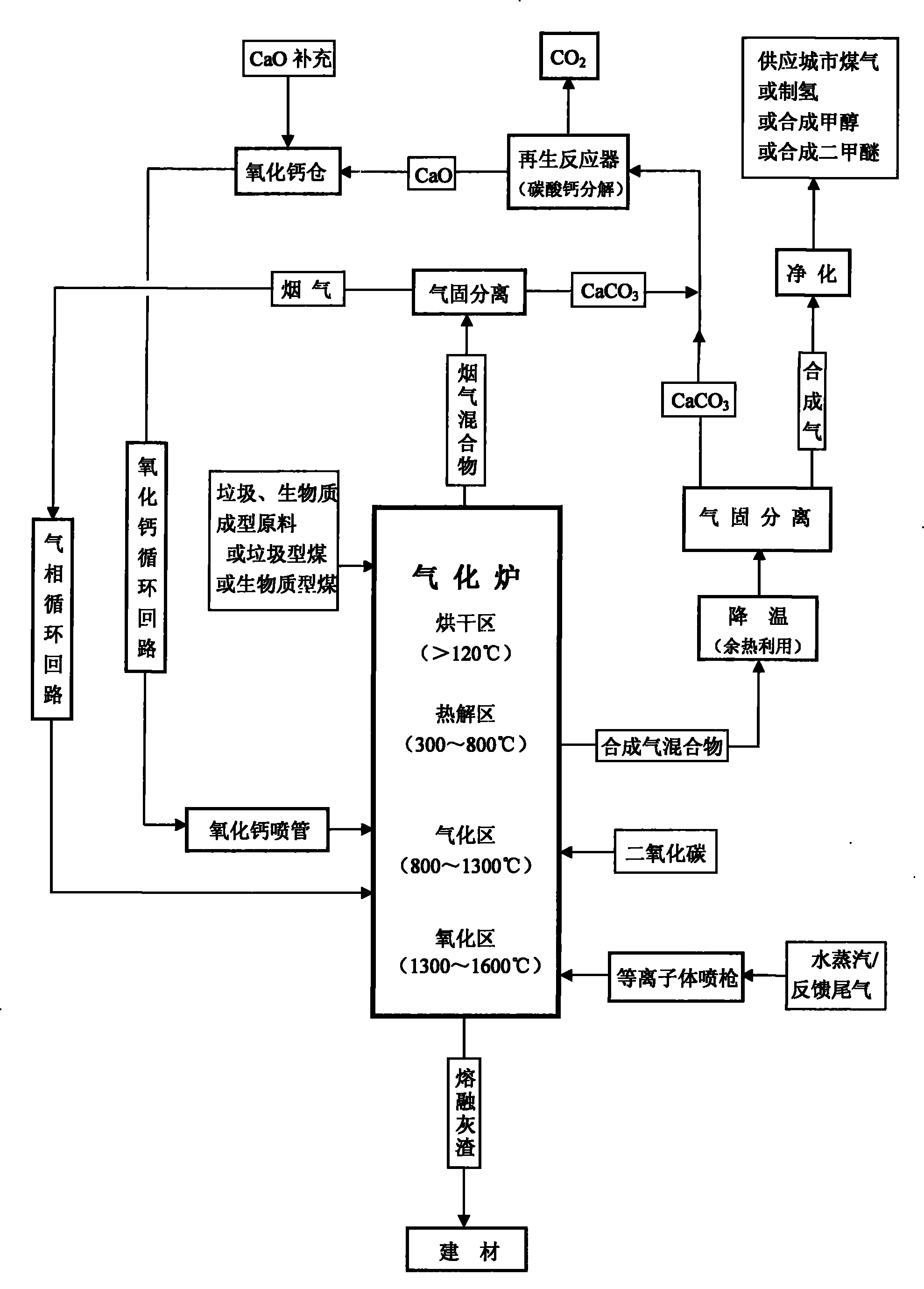

Gasification process for producing synthesis gas from garbage and biomass raw materials

InactiveCN101525118AEliminate pollutionHarmlessHydrogen productionSpecial form destructive distillationGas phaseWater vapor

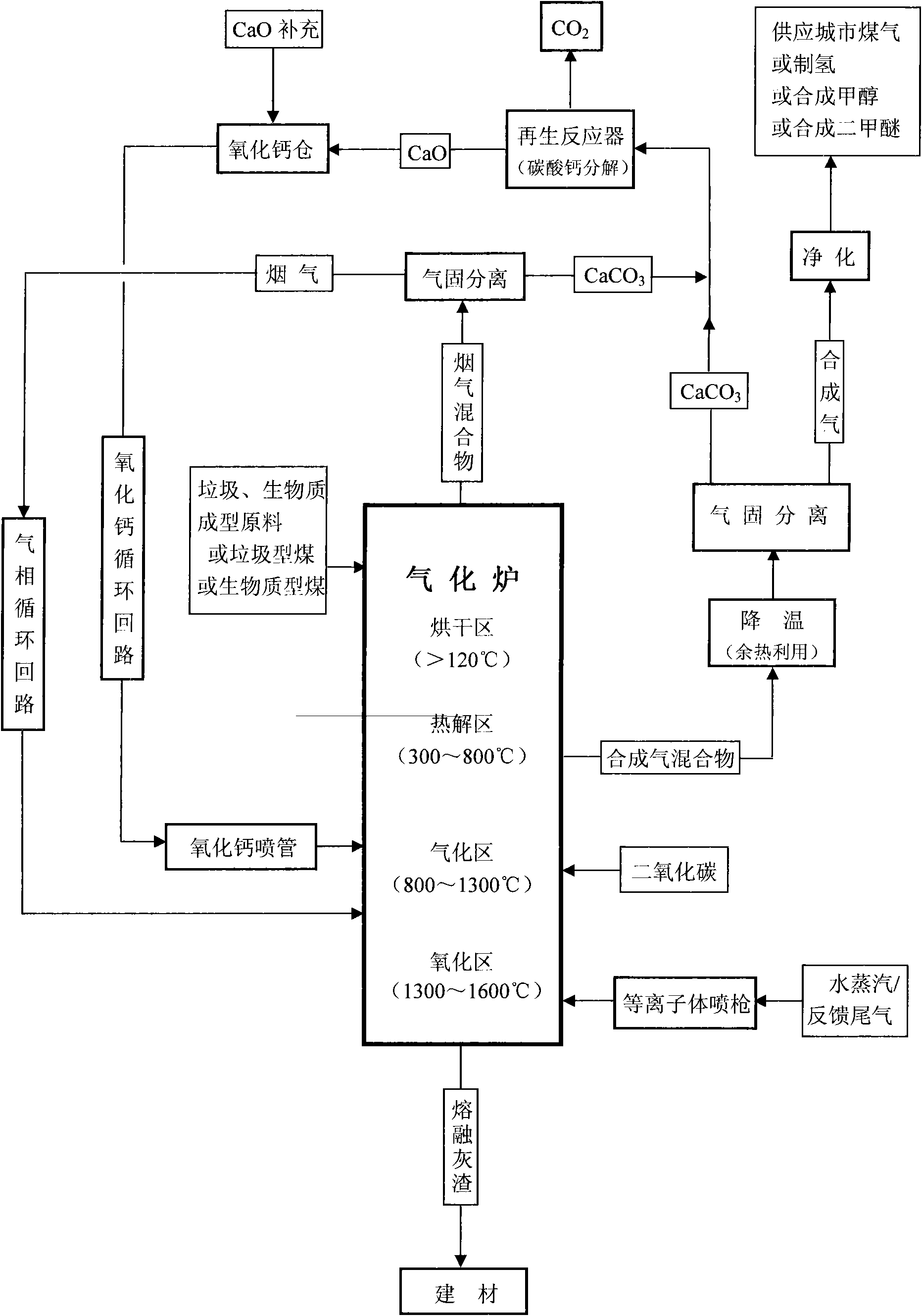

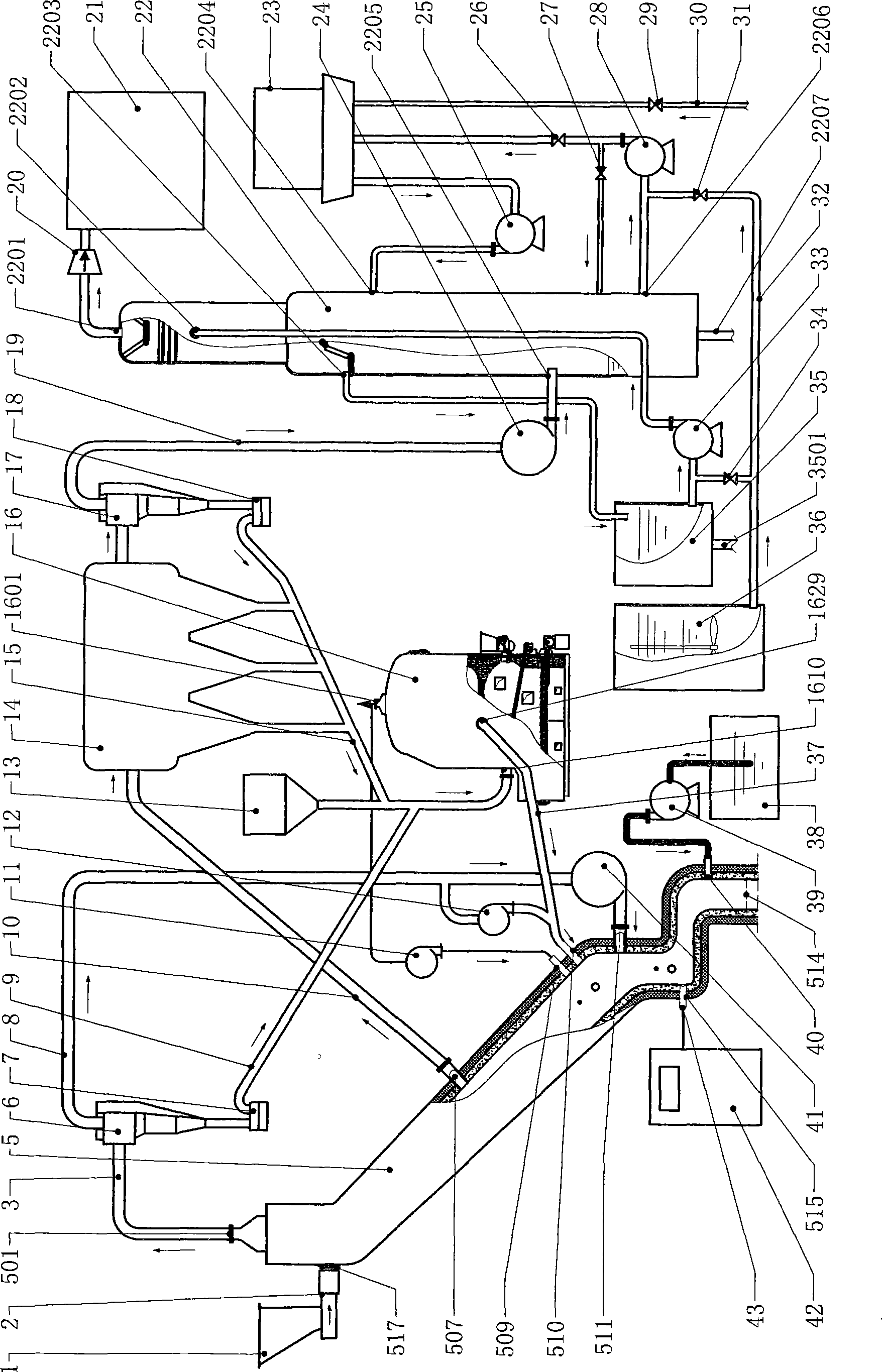

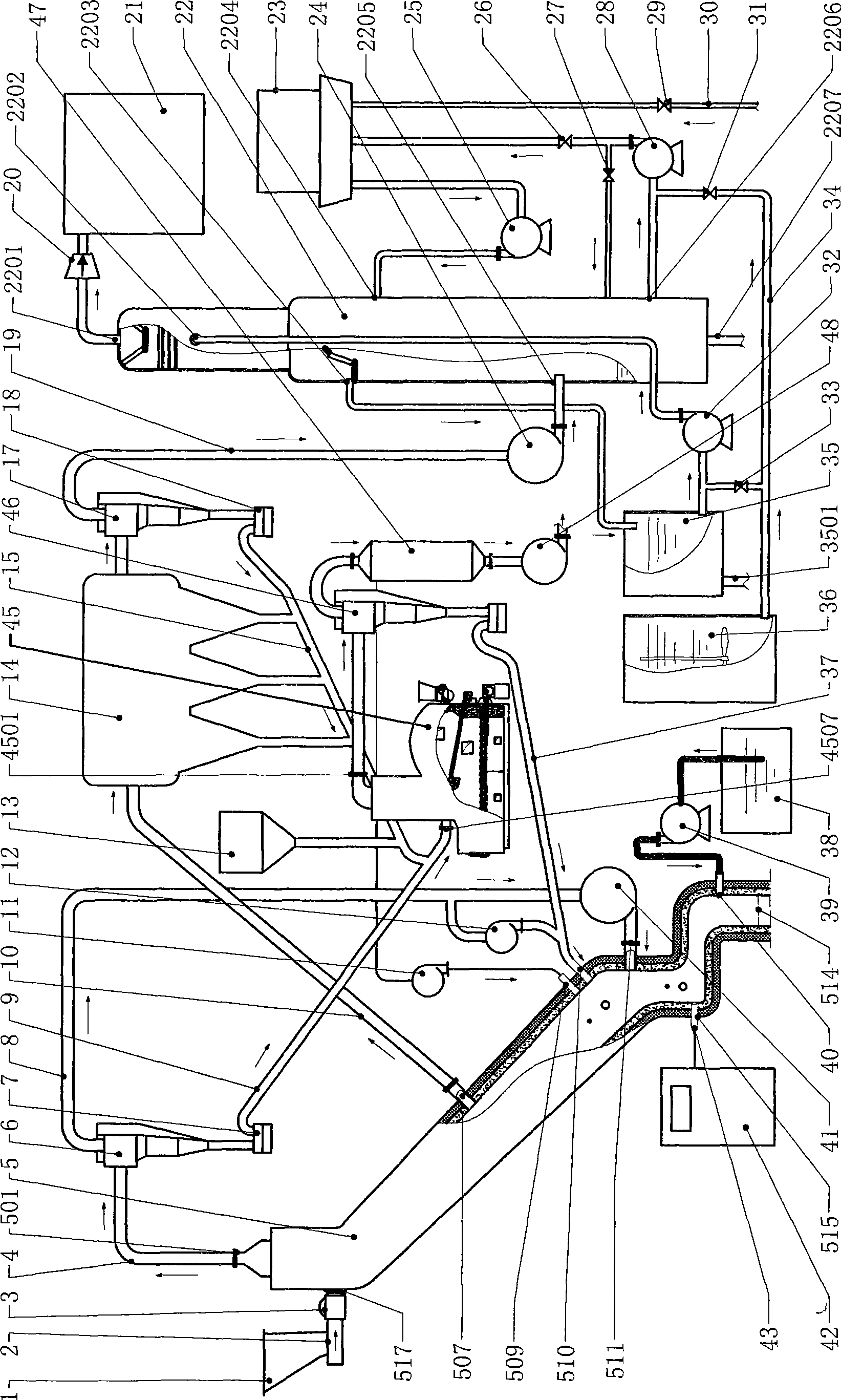

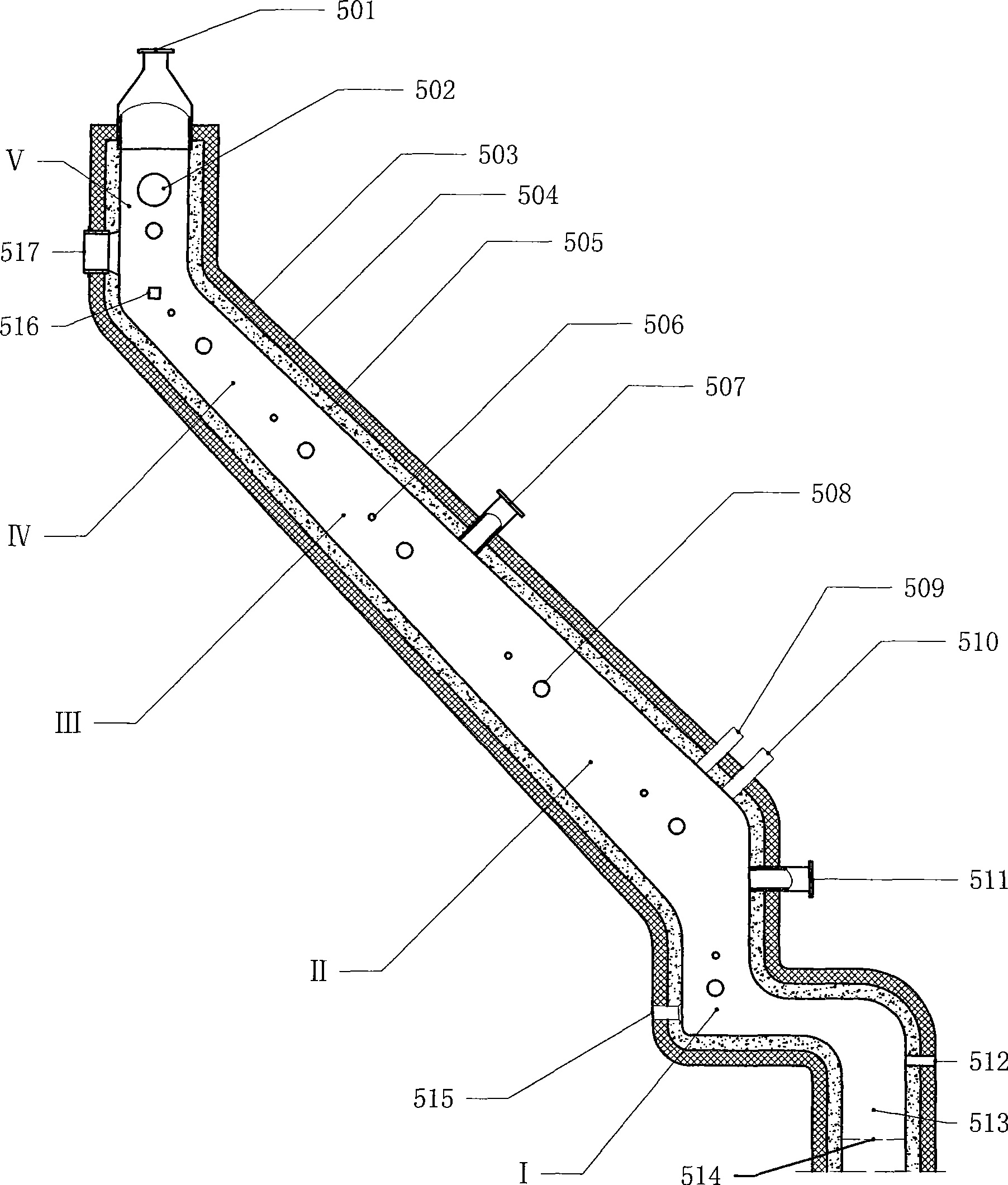

The invention provides a gasification process for producing synthesis gas from garbage and biomass raw materials, which relates to a gasification processing technique of garbage and biomasses. The gasification process is characterized in that the technological process mainly comprises a raw material solid matter process, a gas phase circulation loop, a calcium oxide circulation loop and a synthesis gas drawing process; one or a mixture of more garbage, the biomasses and coal is sent into a gasification furnace to perform gasification so as to generate the synthesis gas; and simultaneously, calcium oxide is sent into the gasification furnace, an exothermic reaction of absorbing carbon dioxide by the calcium oxide provides the heat required by the gasification reaction in the furnace, and water vapor is sent into a plasma spraying gun and is heated to more than 3,100 DEG C to generate H2, O, O2 and H2O<*> which are sprayed into the gasification furnace to perform reactions with the garbage and the biomasses and supply heat into the furnace. The gasification process adopts a measure to spray the calcium oxide into the furnace to not only greatly reduce the electric energy consumption of the plasma spraying gun, but also improve the quality and the yield of the synthesis gas, thus the aim of transforming the garbage and the biomasses into clean energy can be achieved easily.

Owner:周开根

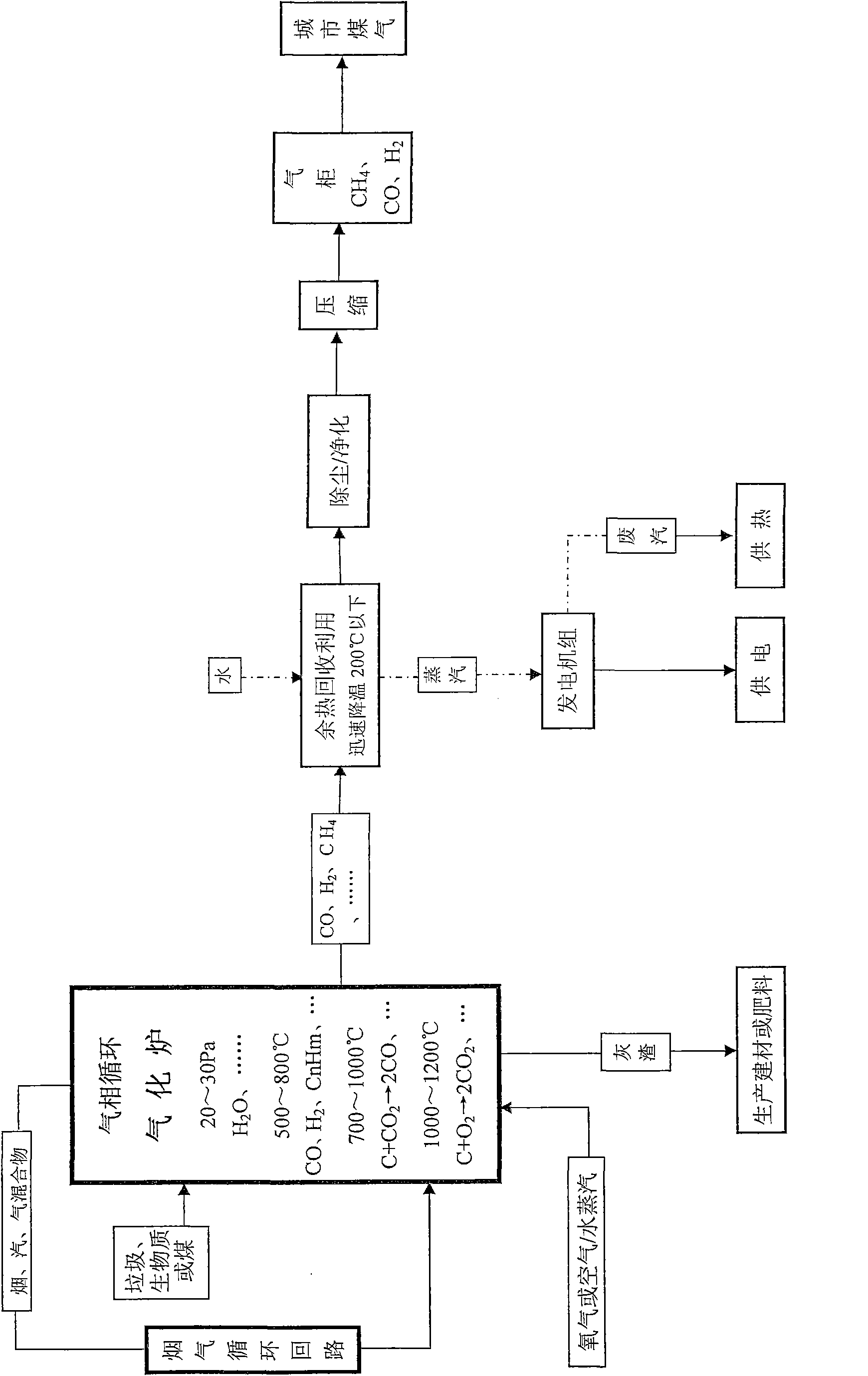

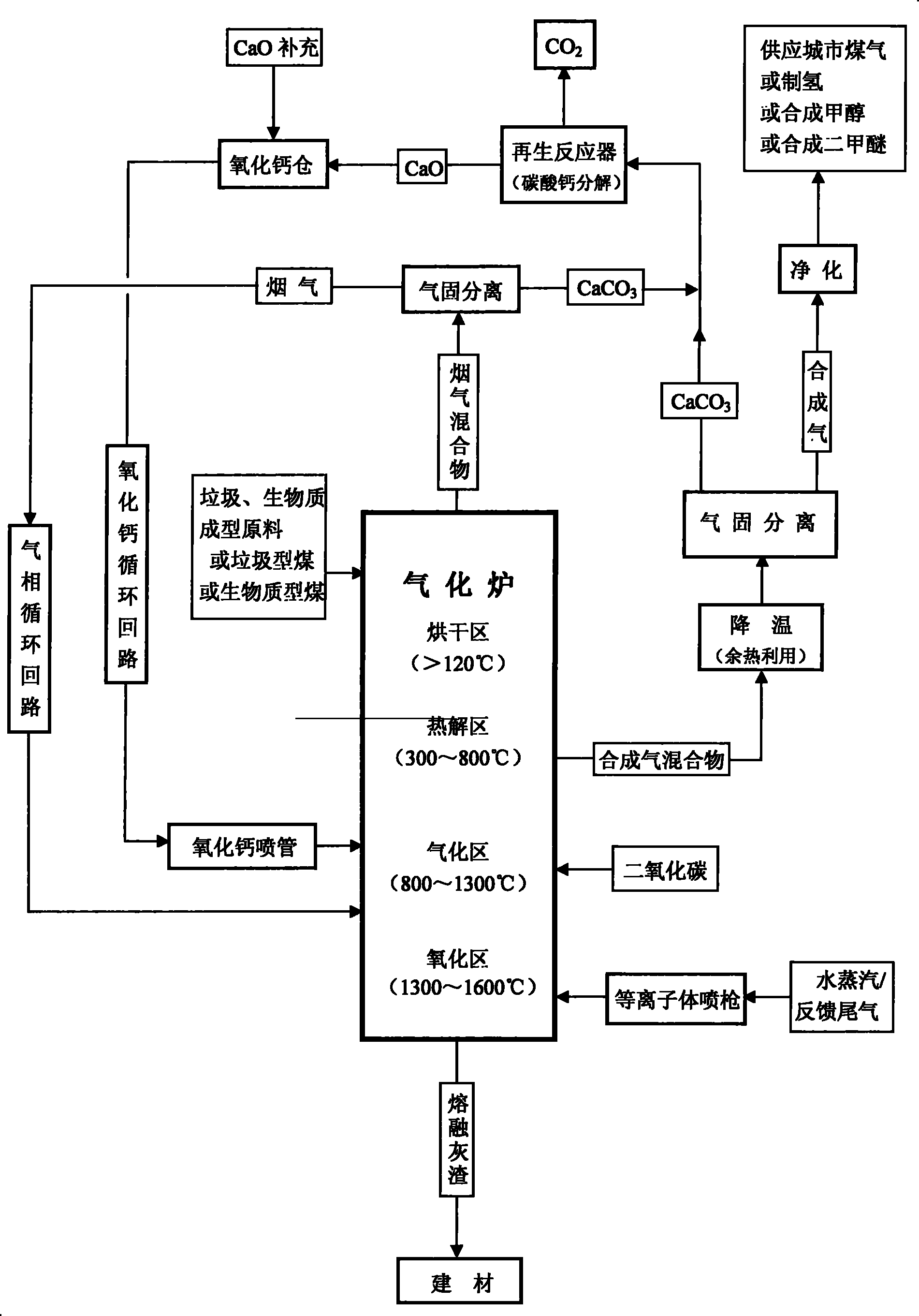

Process, system and device for waste biomass multi-production processing

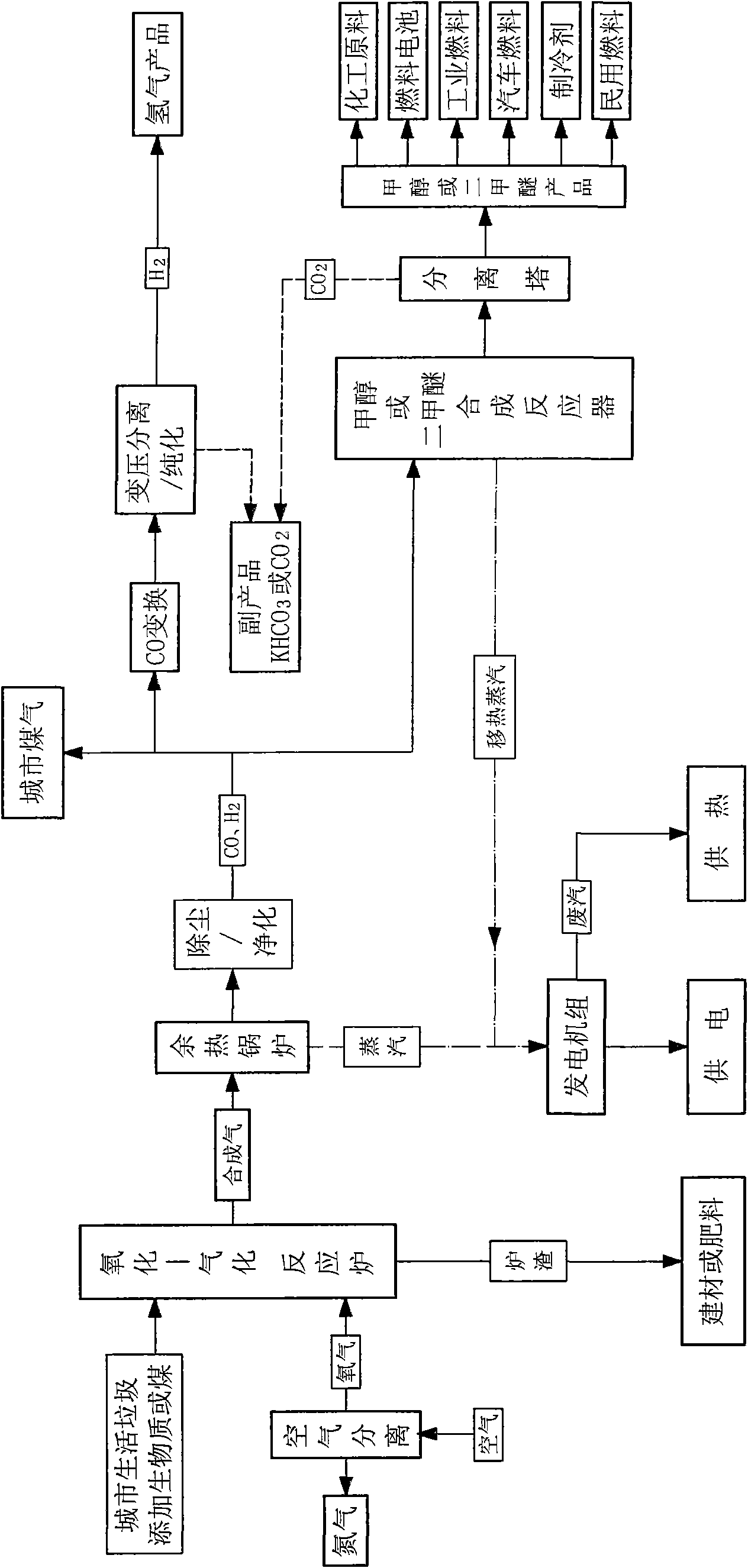

ActiveCN101565629AEliminate pollutionHarmlessHydrogen separationCombustible gas catalytic treatmentEcological environmentGas phase

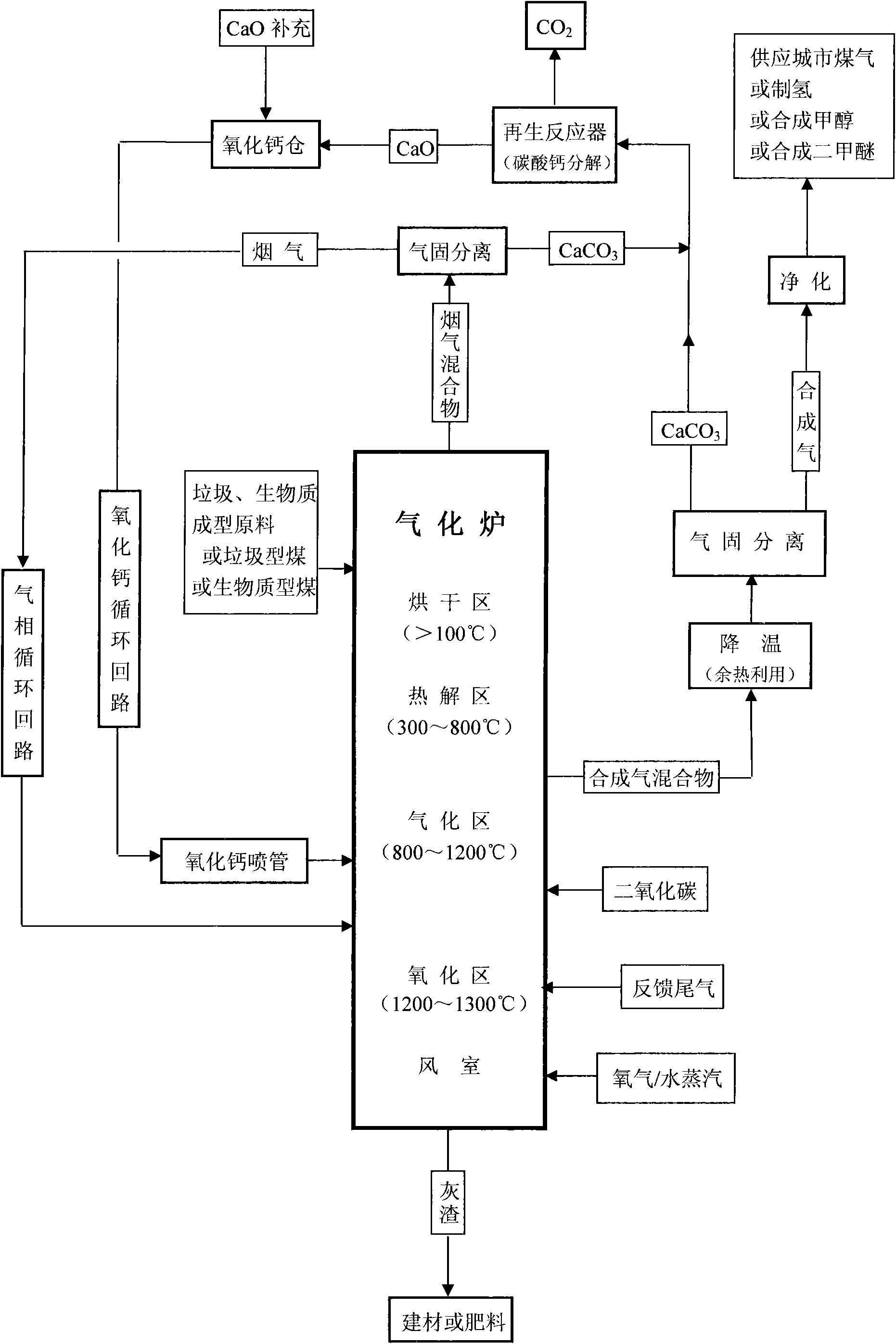

The invention relates to a process, a system and a device for waste biomass multi-production processing, in particular to a waste biomass gasification and liquefaction treatment system. The gasification treatment is performed to the waste biomass, the gas is used for producing clean energy and chemical raw materials, the furnace slag is used for producing building materials or fertilizer and the waste heat is used for electric power generation and heat supply so as to realize the environmental-friendly municipal solid waste treatment and the ecological environment protection. The system mainlycomprises a gas-phase circulation gasification furnace, a flue gas circulation air tube, a flue gas circulation fan, a dust-removal / purifying tower and a synthesis reactor and is characterized in that the gas-phase circular reaction is performed to the flue gas in the gasification furnace, the water vapor and the gaseous matter generated during the pyrolysis to obtain hydrogen-rich synthetic gas,and meanwhile, the dioxin (violent in toxicity) is broken up; and the post treatment is performed to the hydrogen-rich synthetic gas to generate city gas, methanol, dimethyl ether or hydrogen. The system has the advantages of full gasification of the solid raw material, no pollutant discharge, extremely low exhaust emission and easy purifying treatment, and the device is flexible in size and is feasible for popularization.

Owner:上海格灵迈环境科技有限公司

Plasma and calcium oxide cooperation-gasified rubbish biomass gasification method and equipment

InactiveCN101469865AReduce contentHigh calorific valueSpecial form destructive distillationIncinerator apparatusNew energyWater vapor

A method and apparatus for gasifying a plasma and calcium oxide cooperating with gasified rubbish biomass, relating to the rubbish processing and new energy resource field, characterized in that, the rubbish biomass is fed into a suspending fluidized bed thermal decomposition furnace, meanwhile, the heated fluidization material is circularly fed into the thermal decomposition furnace and is mixed with the raw materials to transfer heat, so that the rubbish biomass raw material is heated to decompose, and then the thermal decomposed gas and solid carbocoal is fed into a turbulent fluidized bed gasification furnace, the water vapor is heated over 3100 DEG C and is sprayed into the gasification furnace by a plasma spray gun, the water vapor is reacted with the solid carbocoal to generate carbon monoxide and hydrogen gas, the required heat of the gasification reaction in the gasification furnace can be provided by the plasma spray gun and an exothermal reaction of the calcium oxide absorbing the carbon dioxide. According to the invention, synthesis gas can be produced by rubbish and biomass raw materials under the condition without air or oxygen, the main ingredients of the synthesis gas are hydrogen gas and carbon monoxide which can be directly used for city gas or producing hydrogen gas, methanol and dimethyl ether and so on clean energies.

Owner:衢州市广源生活垃圾液化技术研究所

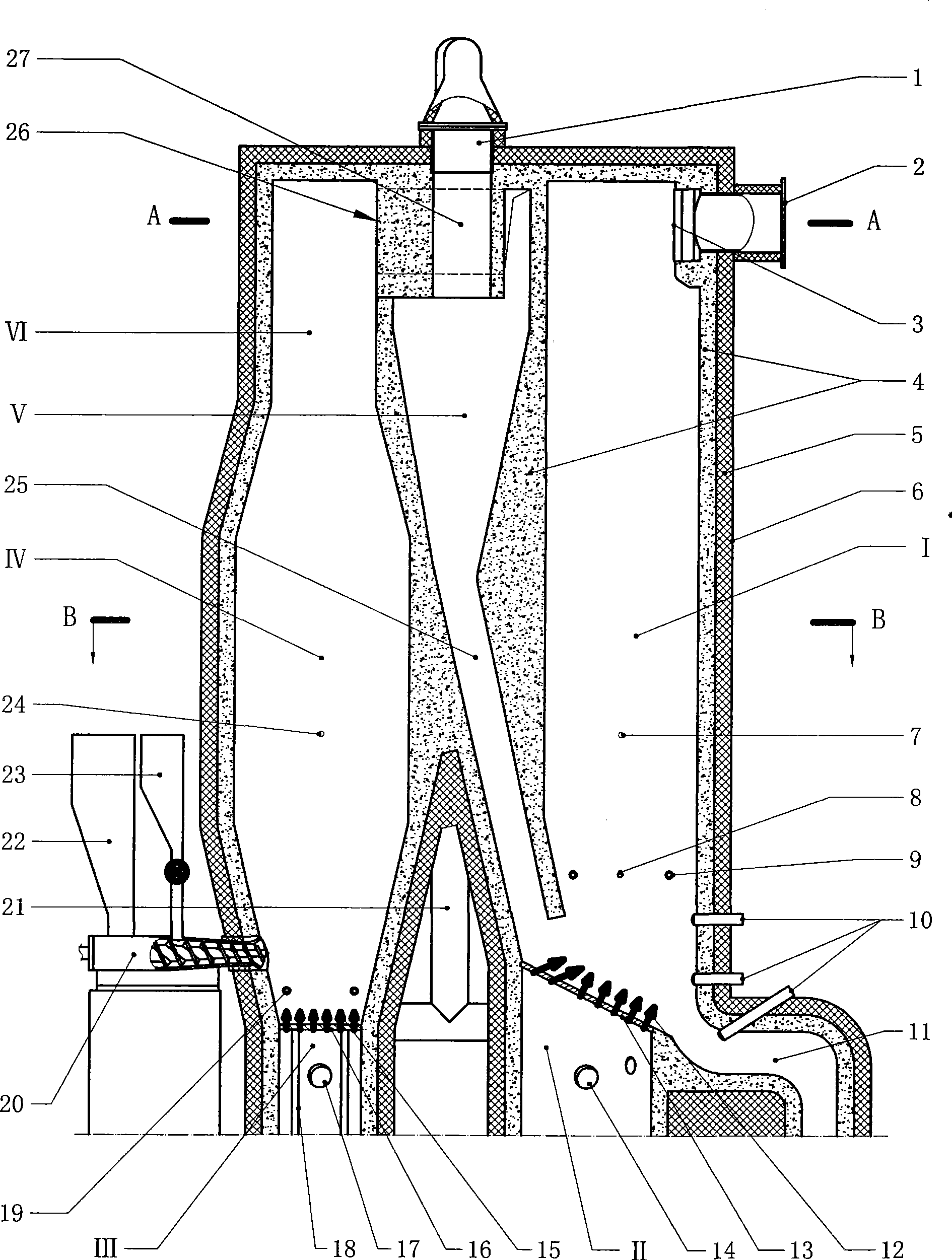

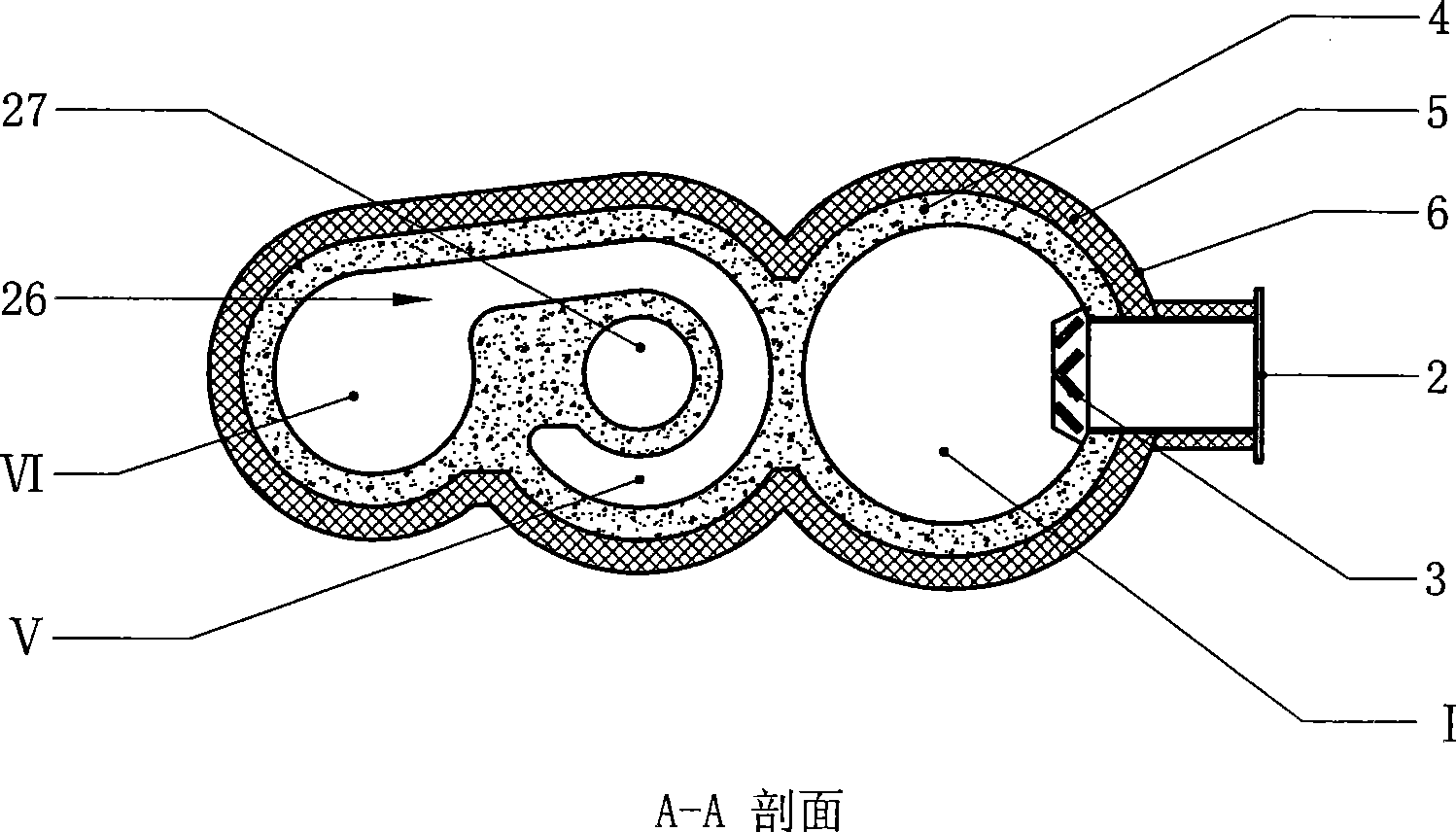

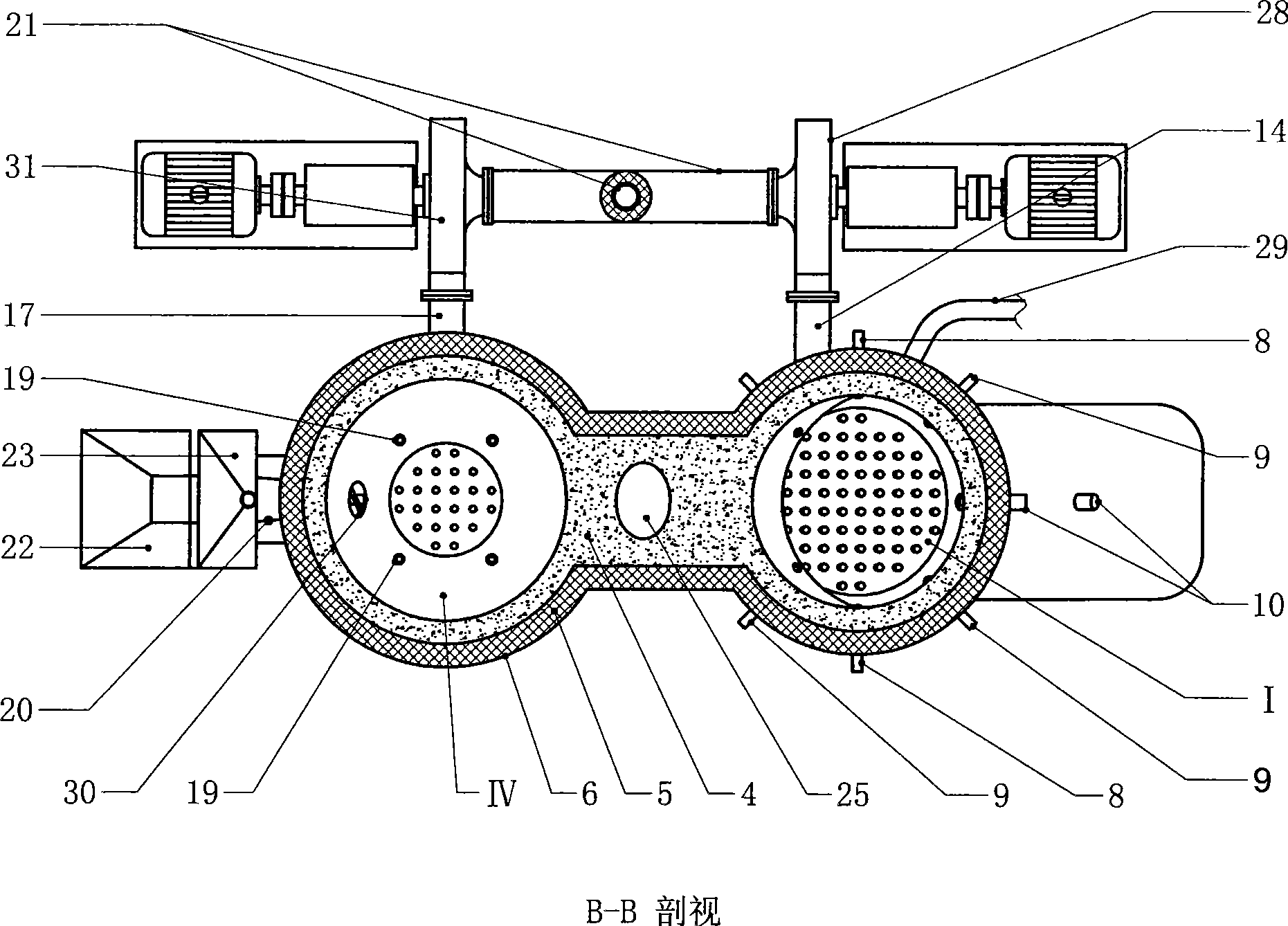

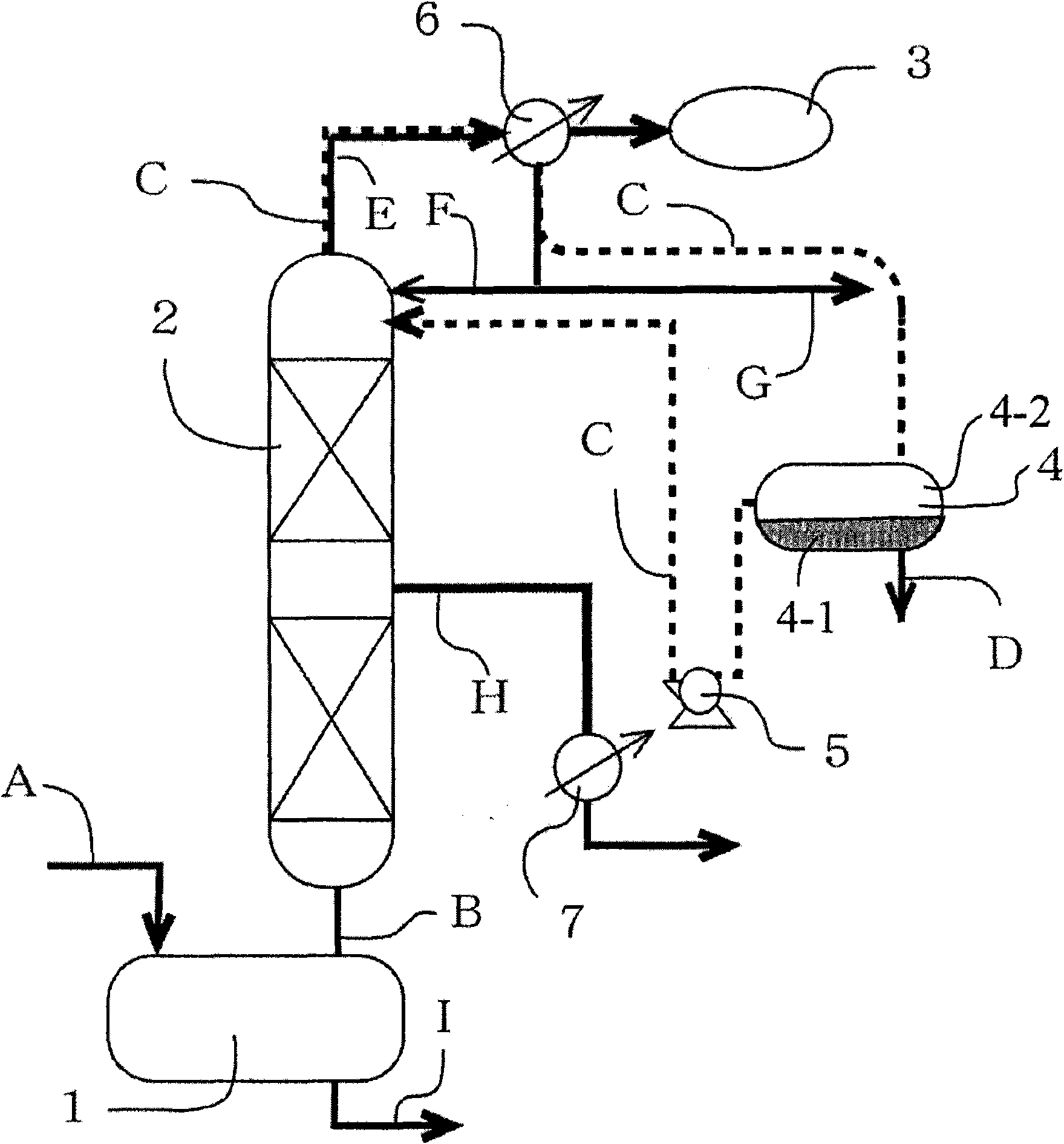

System and apparatus for producing synthesis gas from garbage and biomass raw material

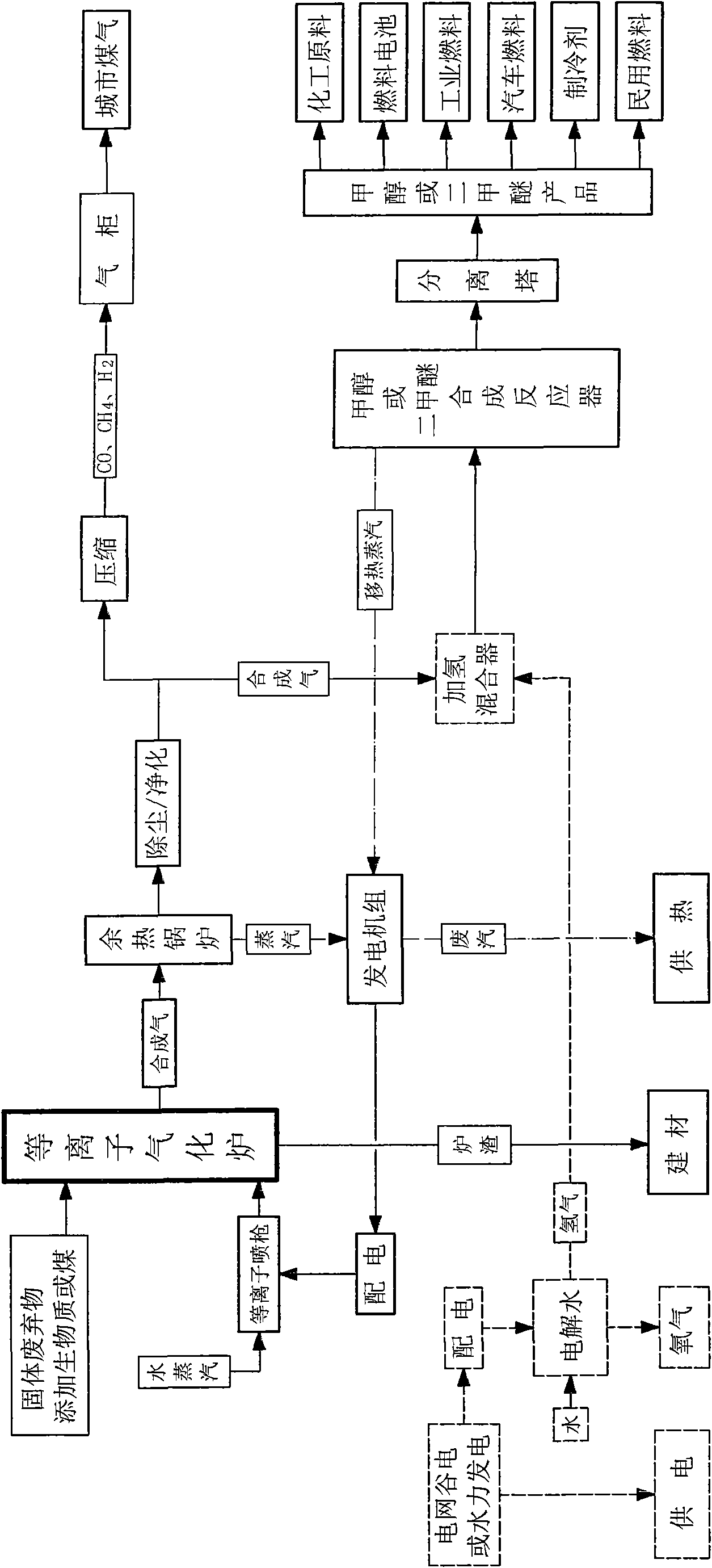

The invention provides a system and equipment for producing synthesis gas by garbage and biomass raw materials, which relates to garbage and biomass gasification equipment. The system and the equipment are characterized in that a vapor circulation loop and a calcium oxide circulation loop are arranged in the system; the garbage and the biomass raw materials are vaporized by an exothermic reaction of absorbing CO2 of the calcium oxide in a gasification furnace to cooperate with thermal plasma, so that the garbage and the biomass raw materials are converted into high heating value synthesis gas for cleaning energy or chemical raw materials. The system mainly comprises a multiphase circulation gasification furnace, a plasma spray gun, the vapor circulation loop, the calcium oxide circulation loop, a wet purification tower and a gas holder, wherein a circulation output interface of the gasification furnace is connected to a gas-solid separator; a gas outlet of the gas-solid separator is connected to a circulating fan; an air outlet of the circulating fan is connected to the vapor circulation input interface of the gasification furnace; a dipleg of the gas-solid separator is connected to a feed delivery valve; the feed delivery valve is connected to a calcium oxide calcining furnace through a solid phase conveying pipe; and a calcium oxide outlet of the calcium oxide calcining furnace is connected to a calcium oxide jet tube of the gasification furnace through a refeed line.

Owner:衢州市广源生活垃圾液化技术研究所

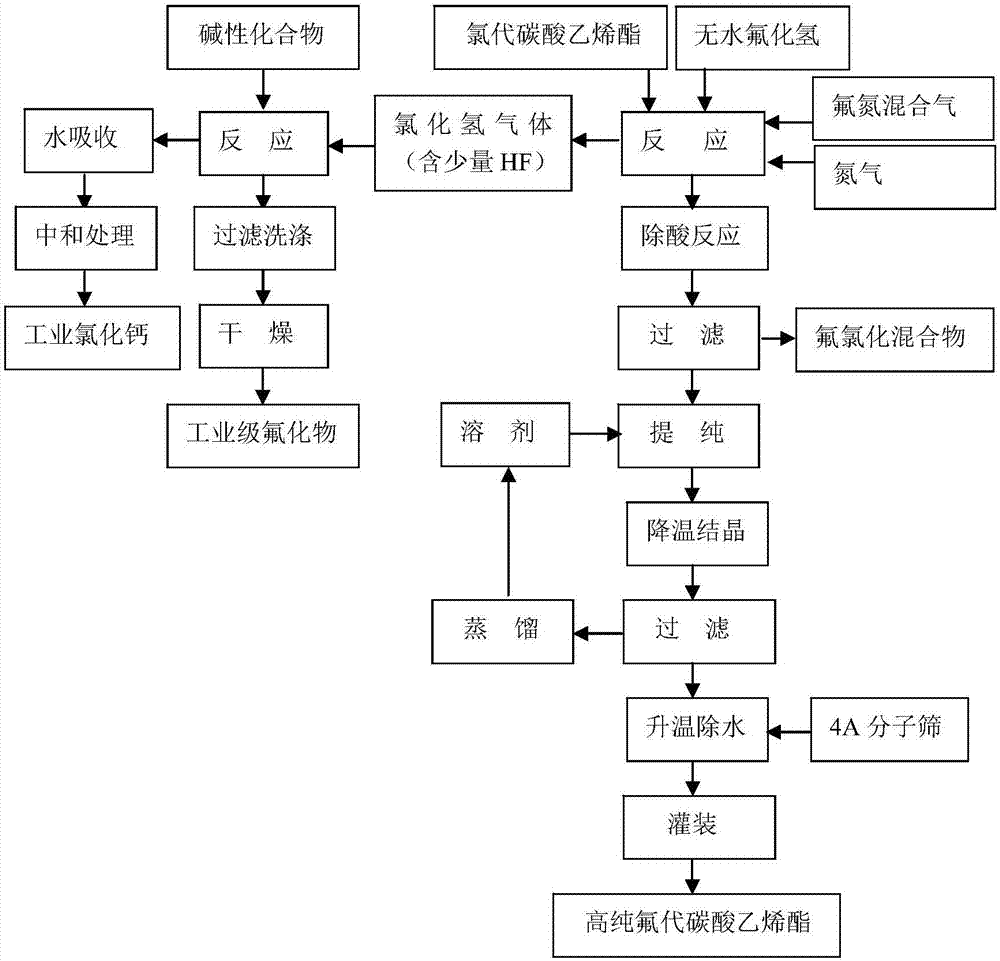

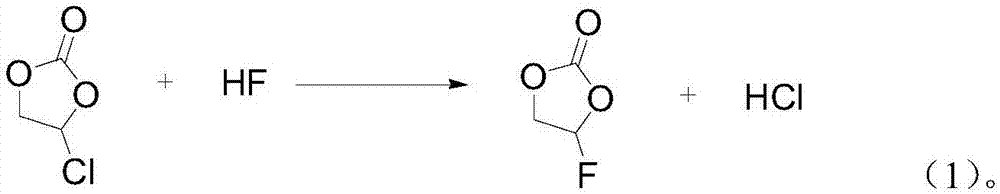

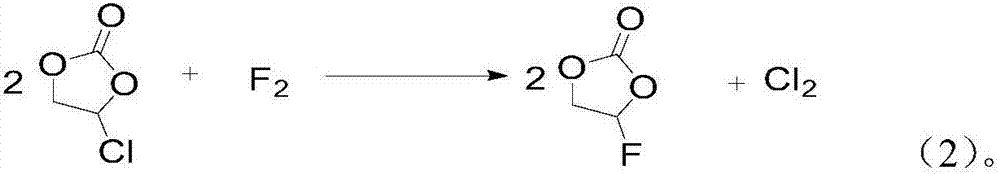

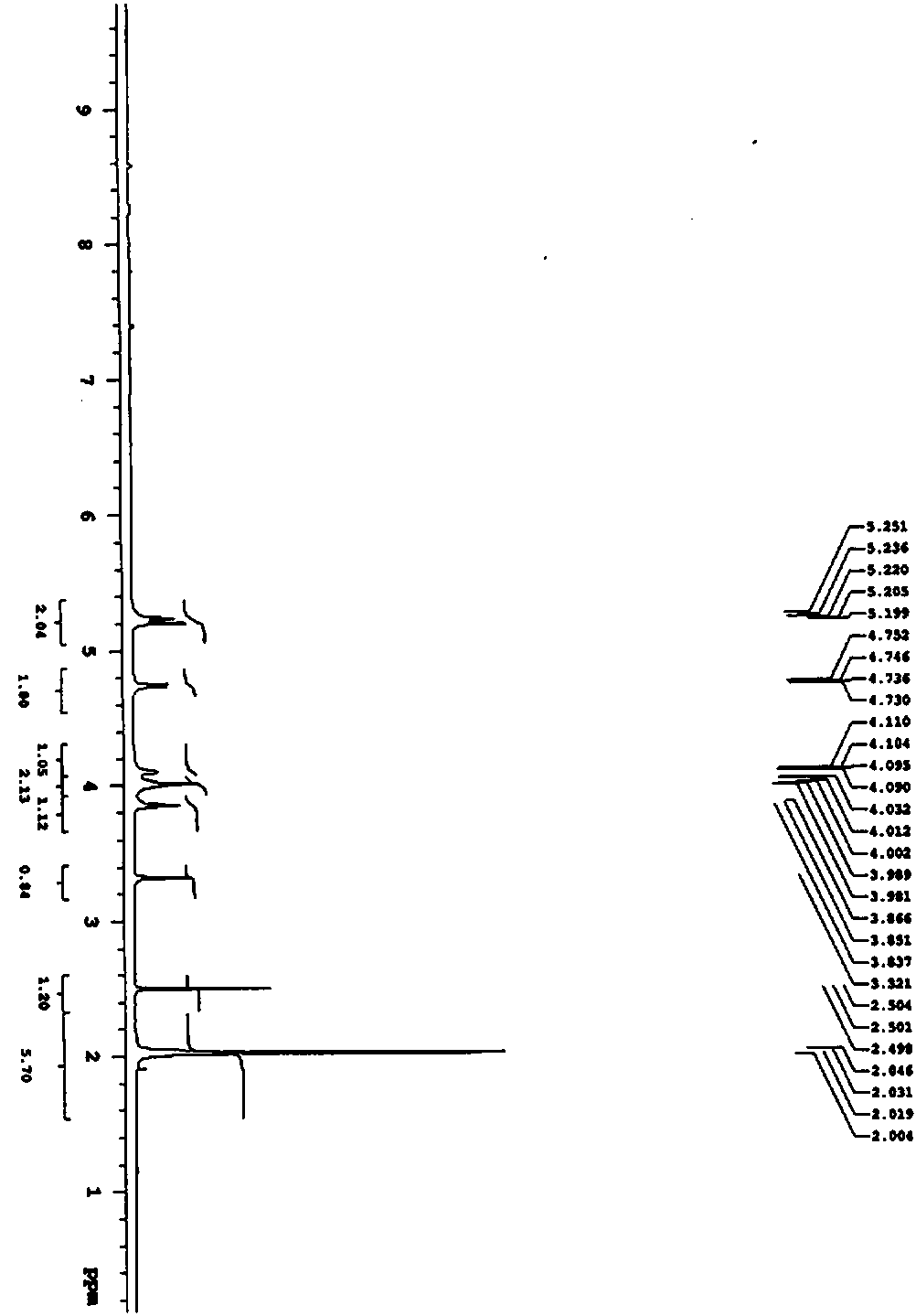

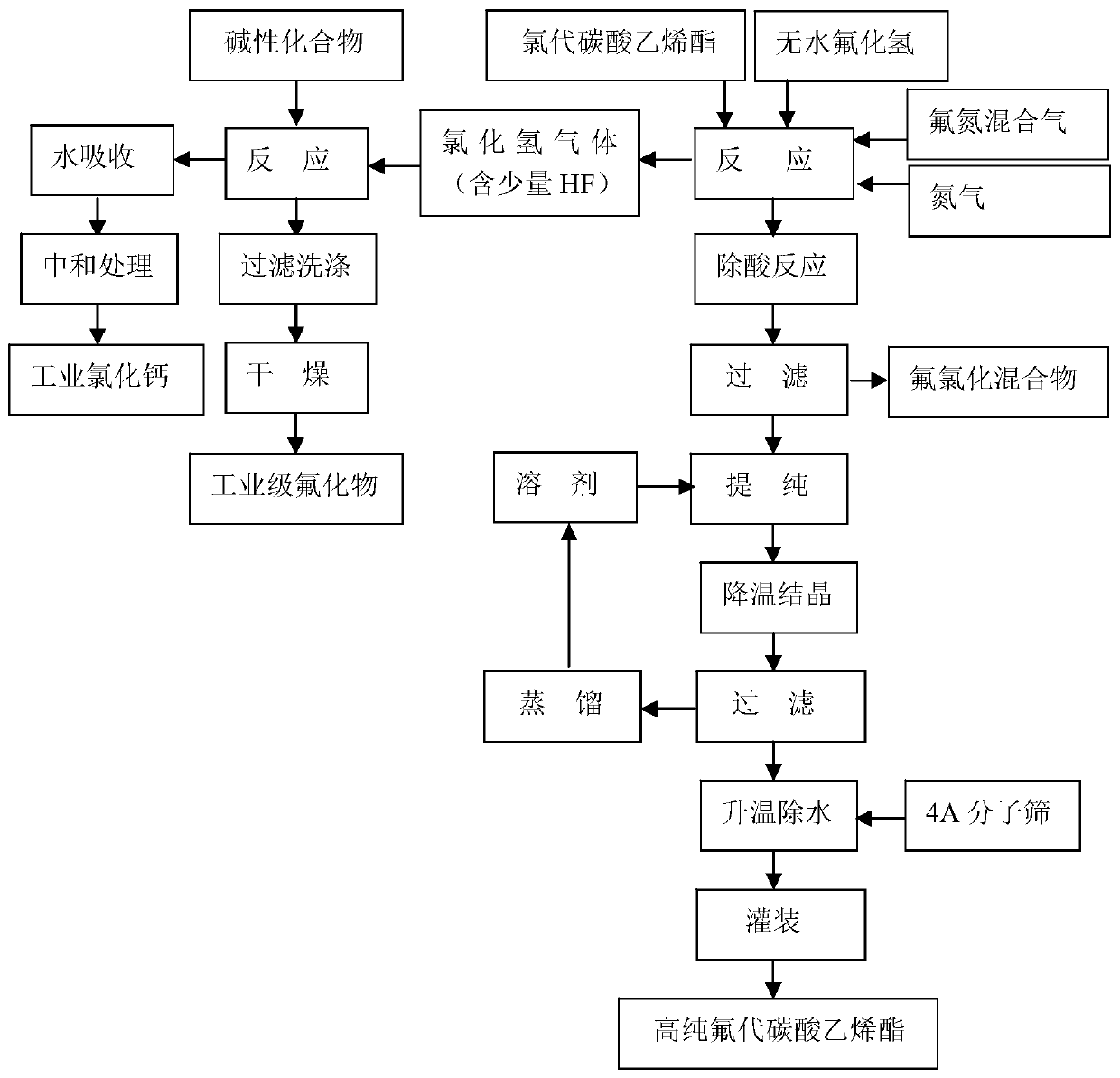

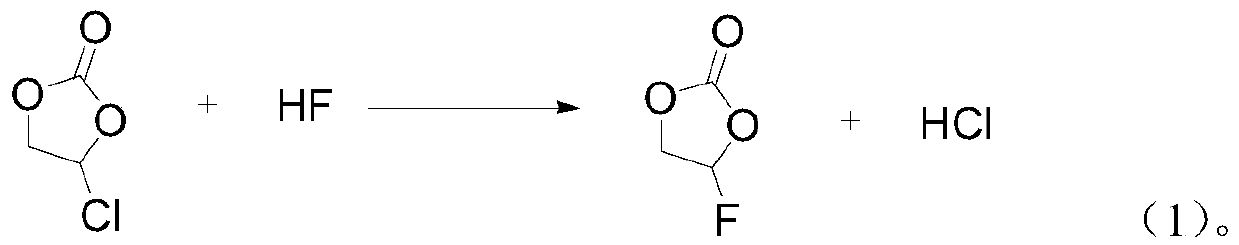

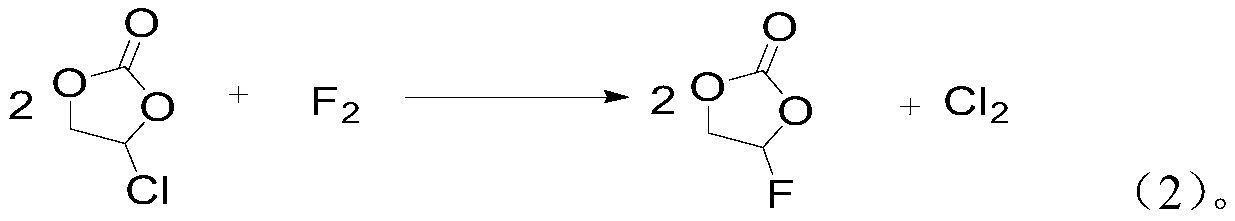

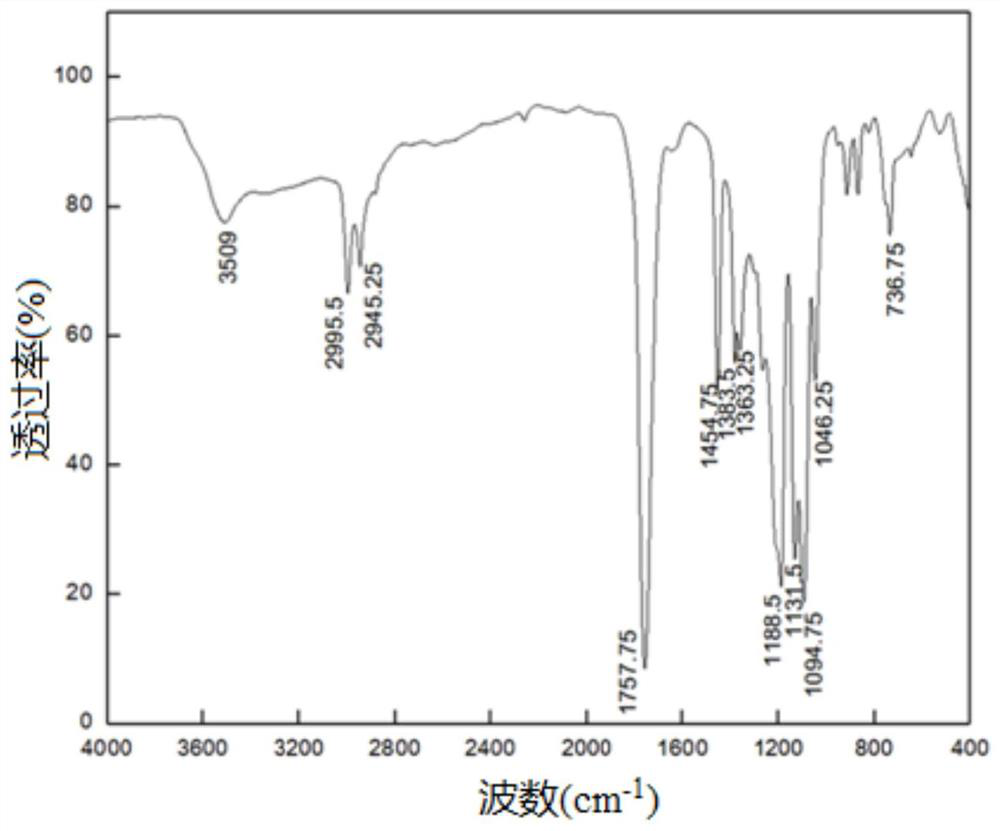

Preparing method of high-purity fluoroethylene carbonate

The invention relates to a preparing method of high-purity fluoroethylene carbonate. The preparing method includes the following steps that 1), a chloroethylene carbonate material and hydrogen fluoride liquid react to obtain a mixture; 2), metallic oxide is added into the mixture to conduct disacidifying reaction, and filter liquor is obtained through filtration; 3), solvent is added into the filter liquor and mixed, fluoroethylene carbonate crystal is obtained through cooling crystallization, and high-purity fluoroethylene carbonate is obtained through dehydration. In the preparing method of high-purity fluoroethylene carbonate, chloroethylene carbonate and hydrogen fluoride liquid are used as the raw materials to conduct liquid-liquid reaction, high-purity fluoroethylene carbonate is prepared through disacidifying reaction, cooling crystallization and heating dehydration, and the purity of the obtained product is 99.5% or more. The preparing method is simple in process control and includes few side reactions, and the reaction product is easy to purify, high in purity, low in cost and convenient to produce industrially.

Owner:DO FLUORIDE CHEM CO LTD

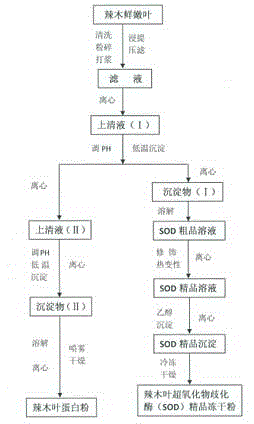

Technology for extracting proteins and superoxide dismutase (SOD) from horseradish tree leaves

InactiveCN104611310AImprove solubilityImprove leaching ratePeptide preparation methodsOxidoreductasesThermal denaturationActive enzyme

The invention discloses a technology for extracting proteins and superoxide dismutase (SOD) from horseradish tree leaves. The technology comprises the following steps: smashing and pulping fresh horseradish tree leaves, and performing digestion, pressure filtering, isoelectric precipitation and centrifugation to obtain precipitates and supernate; performing modification protection, thermal denaturation reaction and freeze drying on the precipitates to obtain SOD freeze-dry powder; performing isoelectric precipitation, centrifugation and spray drying on the supernage to obtain leaf protein powder. By the adoption of the technical methods such as normal-temperature digestion, isoelectric precipitation, centrifugal separation, the original functional characteristics of the proteins and the activity of enzyme are retained to the maximum extent, and the yield of the proteins and that of active enzyme are greatly increased; the obtained leaf protein powder is bright in color, high in protein content and stable in quality; the obtained SOD is high in activity, and the practical value and the economical benefit are higher. The technology is easy to operate, low in production cost, safe, reliable and suitable for industrial production.

Owner:陈石良

Synthesis method of sodium sugammadex

The invention provides a synthesis method of sodium sugammadex. The synthesis method includes: using gamma-cyclodextrin as a raw material, and subjecting the raw material sequentially to halogenationreaction, acetylation reaction, etherification reaction, alcoholysis and hydrolysis to obtain high-purity sodium sugammadex. Yield of the method is up to 70%, the method is simple in technical process, low in energy consumption, pollution-free, easy-to-get in raw materials, simple in industrial operation, low in cost, safe, environment-friendly and easy for industrial production, and sodium sugammadex up to higher than 99% in purity can be obtained without membrane dialysis operation.

Owner:河北坤安药业有限公司

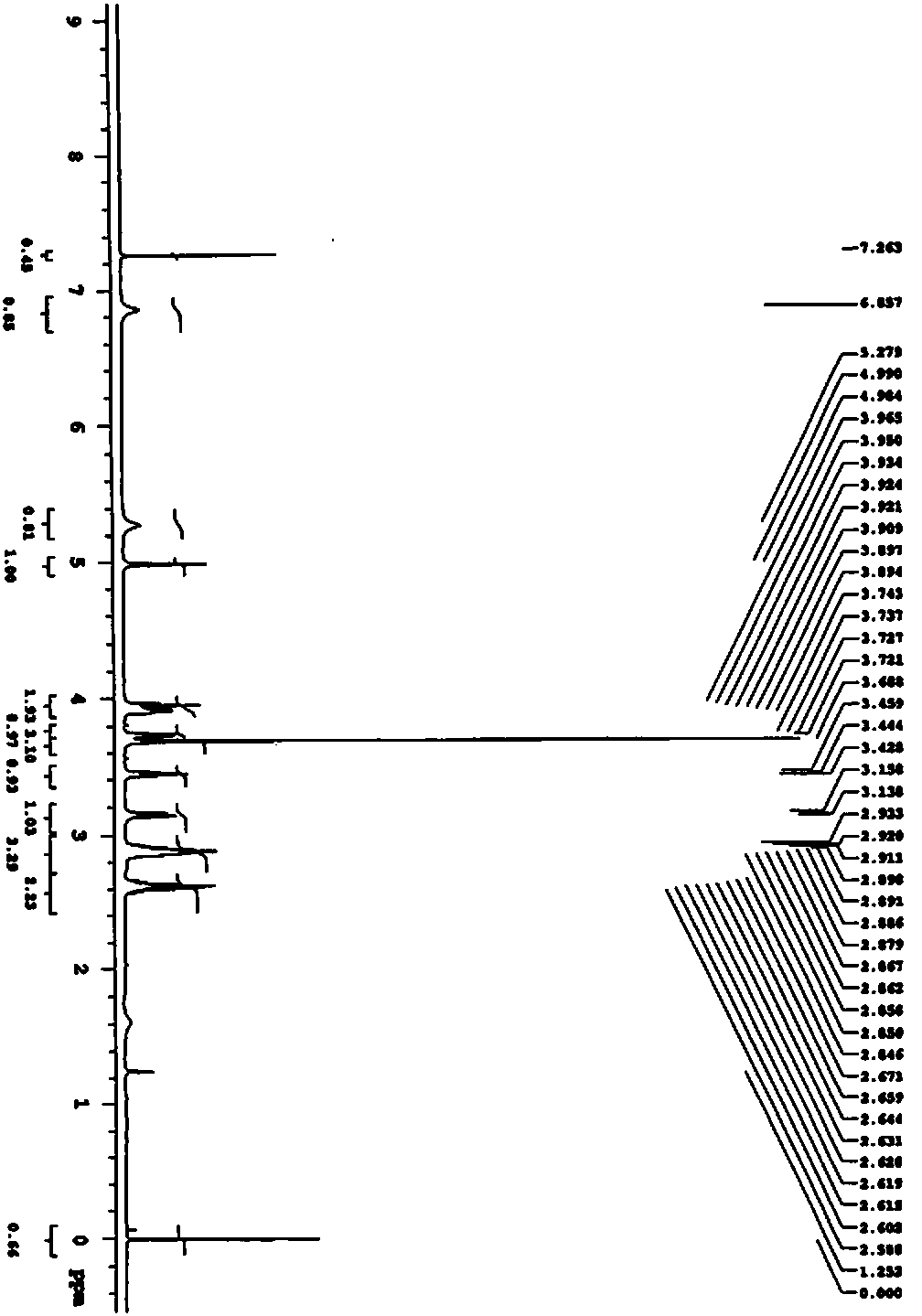

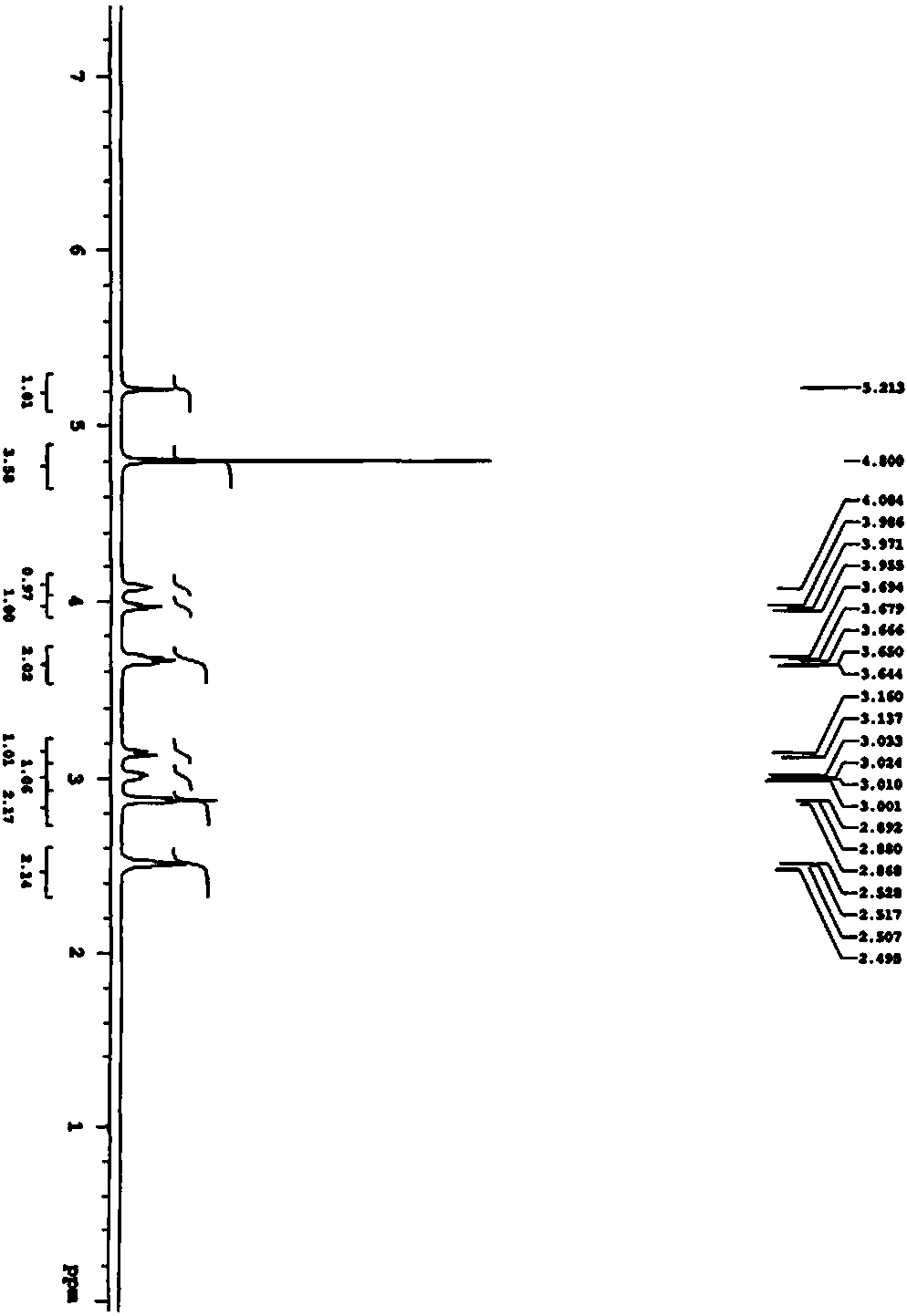

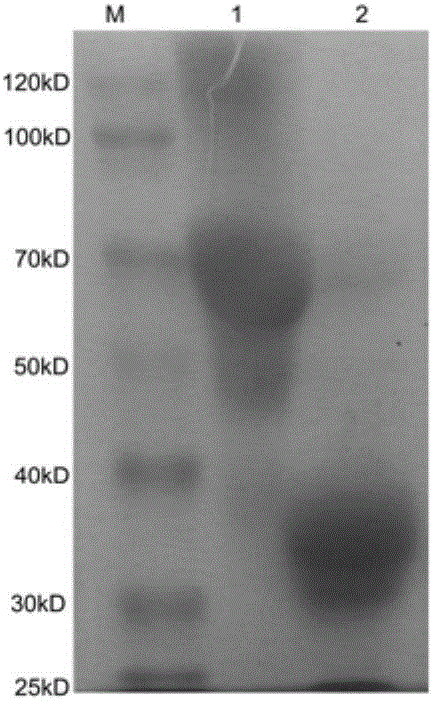

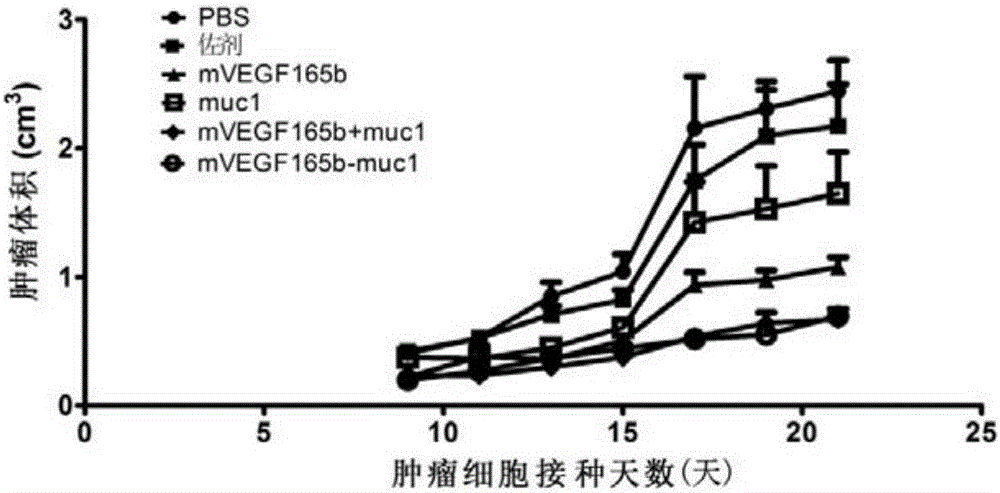

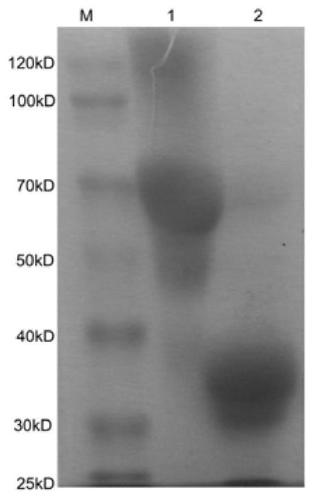

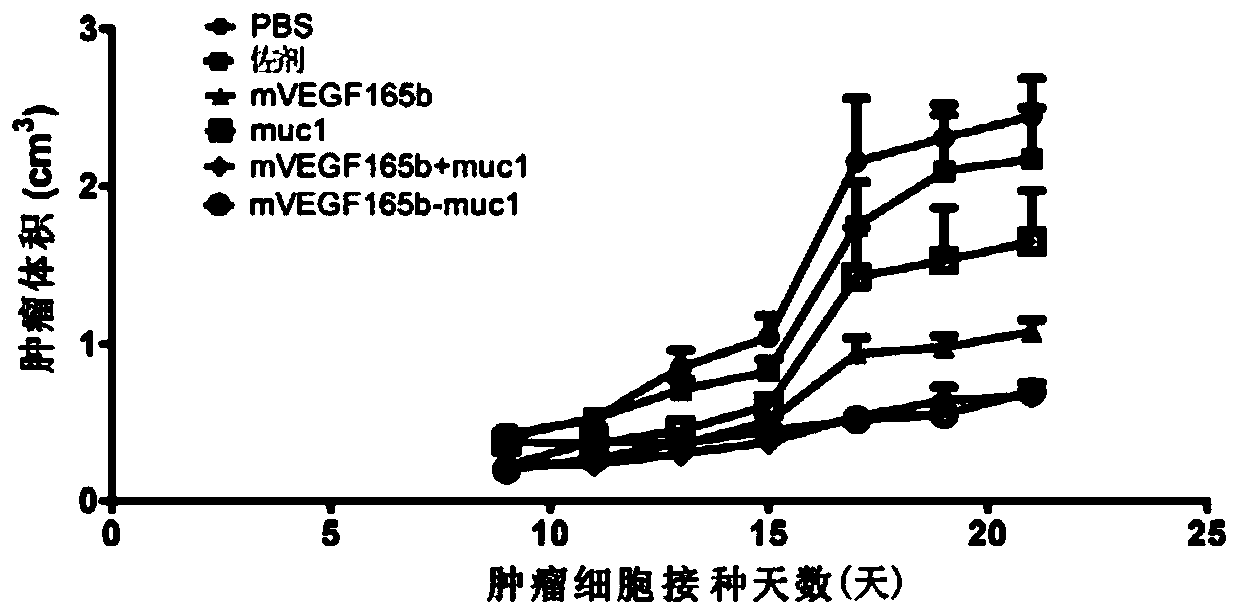

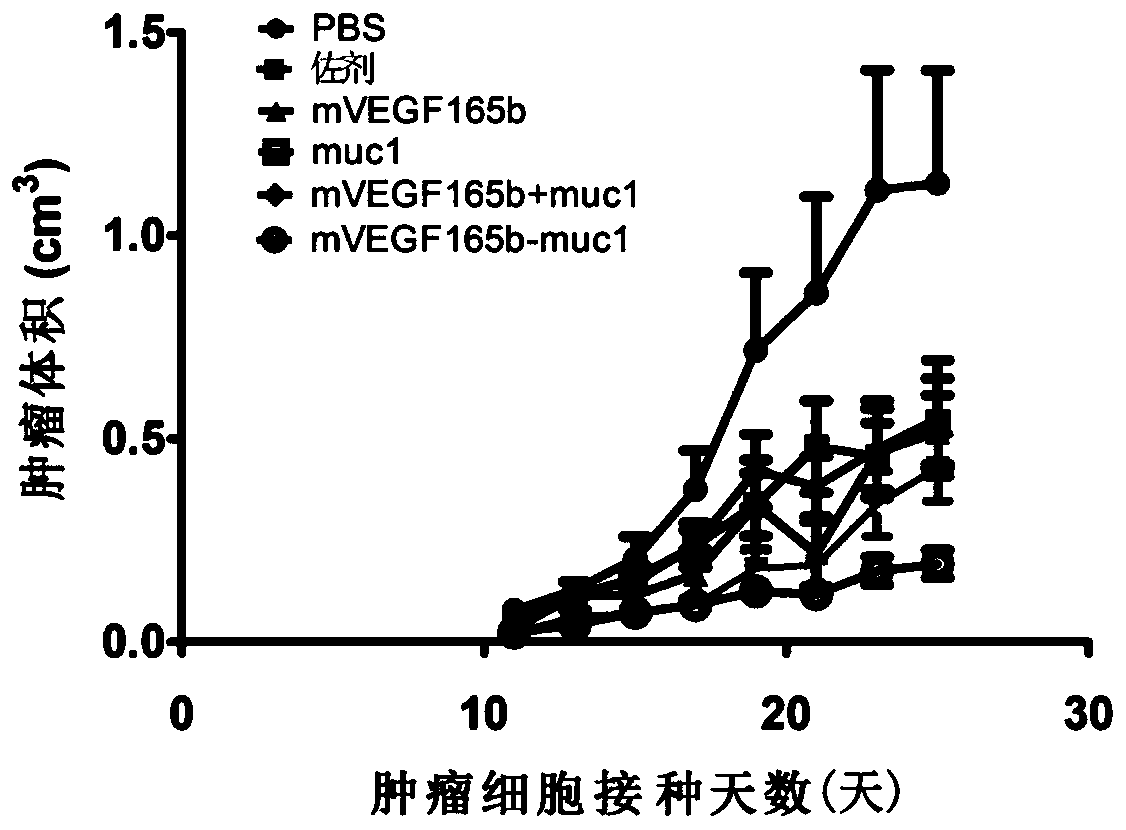

Antitumor vaccine, encoding gene, expression vector, expression engineering bacteria and application of targeted VEGF and mucin1

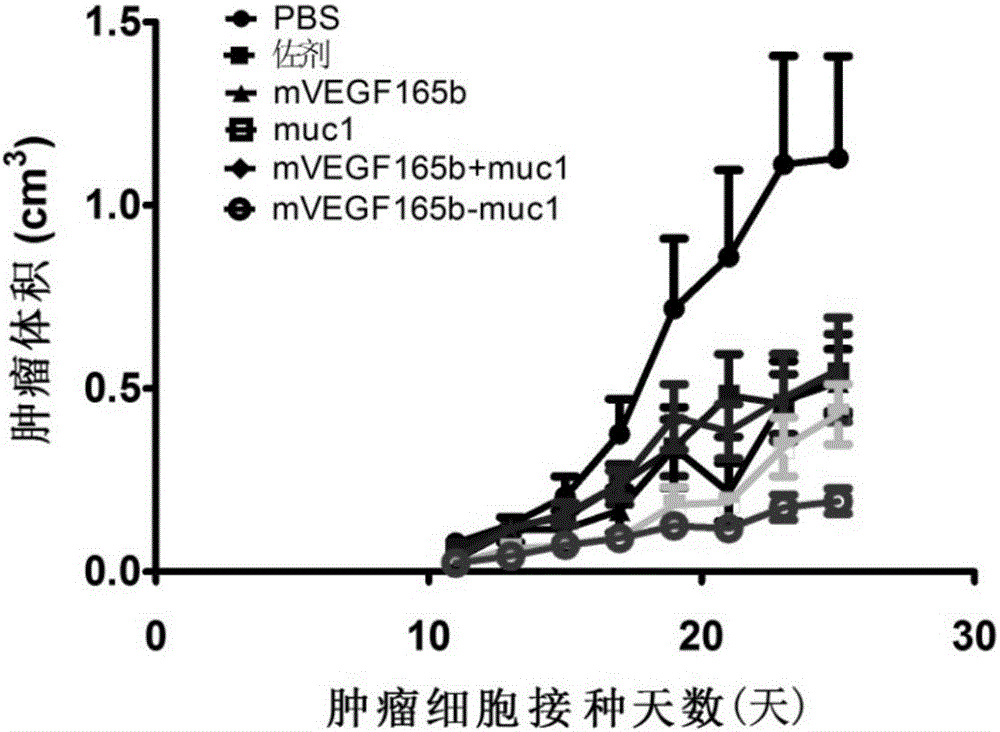

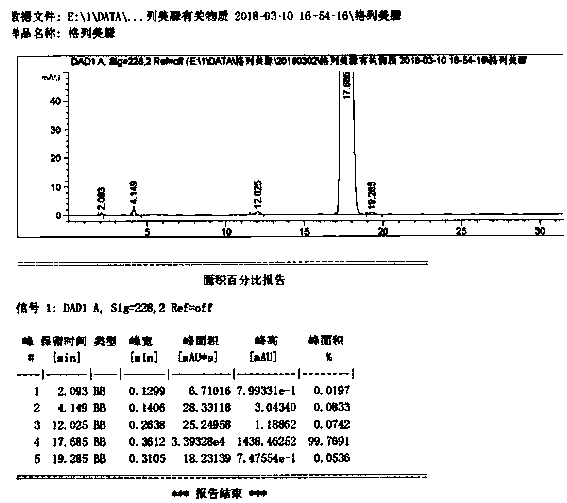

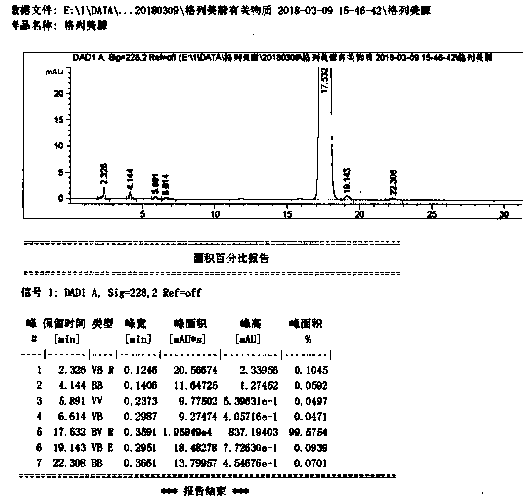

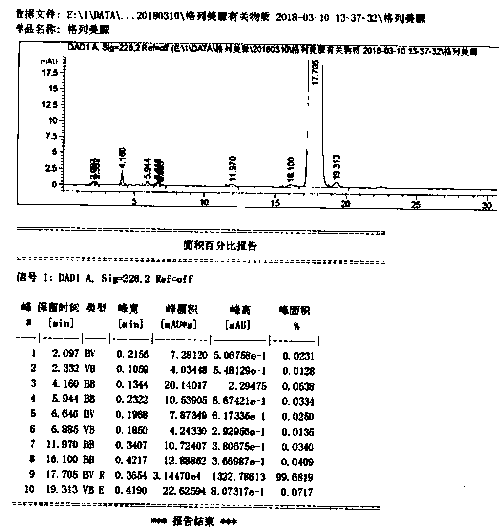

ActiveCN106279435AAffinity chromatography is convenientAffinity Chromatography ExpressFungiTumor rejection antigen precursorsTumor vesselMutant

The invention discloses an antitumor vaccine, an encoding gene, an expression vector, an expression engineering bacteria and application of targeted VEGF and mucin1, and belongs to the technical field of biology. An antitumor vaccine fusion protein adopts VEGF165, VEGF165b or corresponding modified VEGF mutants as an epitope vector, at least one section of epitope peptide of tumor related antigen mucin1 is connected to an end N or an end C of the vector to form the antitumor vaccine having a double target effect. The VEGF in the vaccine can be used as the epitope vector to improve the antigenicity of the mucin1 epitope connected with the VEGF, the over-expressed mucin1 tumor cells are killed, the VEGF can also be used as an antigen to produce an antibody for VEGF so as to inhibit the generation of tumor vessels and cut off the nutrient supply of the tumor. Meanwhile, the epitope vector has a heparin-binding domain which can be bond with heparin sepharose, thereby facilitating the subsequent protein purification.

Owner:XINXIANG MEDICAL UNIV

Process for synthesizing glimepiride raw material medicine

InactiveCN108383768AReduce lossesReduce generationOrganic active ingredientsOrganic chemistryKetoneGlimepiride

The invention discloses a process for synthesizing a glimepiride raw material medicine. A compound A, namely 3-ethyl-4-methyl-3-pyrroline-2-ketone and a compound B, namely 2-phenethyl isocyanate are taken as start raw materials. The process is characterized in that when an intermediate 1 is synthesized, filtrate is applied mechanically, so that the loss of the intermediate 1 can be reduced, the yield can be increased, and the production efficiency can be improved; when an intermediate 2 is synthesized, hydrochloric ether is adopted as a solvent, so that isomer impurities can be greatly reduced, the content of the isomer impurities can be reduced to 0.5% or less from 8%, and later purification procedures can be simple to operate; when a glimepiride metallic salt is synthesized, acetonitrileis adopted as a solvent, sufficient reactions can be achieved, the reaction time can be greatly shortened, the residue of an intermediate 3 is reduced to 0.2% or less from 5-10%, in addition, a highsolvent recycling rate can be achieved. The process disclosed by the invention is simple and safe, low in production cost, high in yield, stable in intermediate and finished product quality and applicable to industrial large-scale production and hypoglycemic drug, namely glimepiride, synthesis processes with relatively great social, economic and environmental-friendly benefits.

Owner:江西博雅欣和制药有限公司

HMB-Ca production process method

InactiveCN108129294AEasy to operateOptimizationOrganic compound preparationCarboxylic acid salt preparationFood additiveOrganic solvent

The invention discloses HMB-Ca production process method, which comprises the following steps that HMB is dissolved in water; calcium salt is added; stirring, filtering and concentration are performedto obtain an HMB-Ca crude product; the HMB-Ca crude product is added into an alcohol solvent; after stirring, filtering and concentration are performed, an organic solvent is added; stirring and filtering are performed; solid drying is performed to obtain an HMB-Ca product; during the filtering, the hole diameter is 1 to 100 micrometers. The HMB-Ca production process method has the advantages that the production operation and purification filtering conditions of the HMB-Ca product are optimized; the mechanical impurities and the metal ion residues in the HMB-Ca product are effectively reduced; the safety when the HMB-Ca product is used as a health care product and food additive is improved; the process conditions are mild; the operation is easy; the production operation safety degrade isreduced; green and environment-friendly effects are achieved; the industrialization is favorably realized.

Owner:穆云

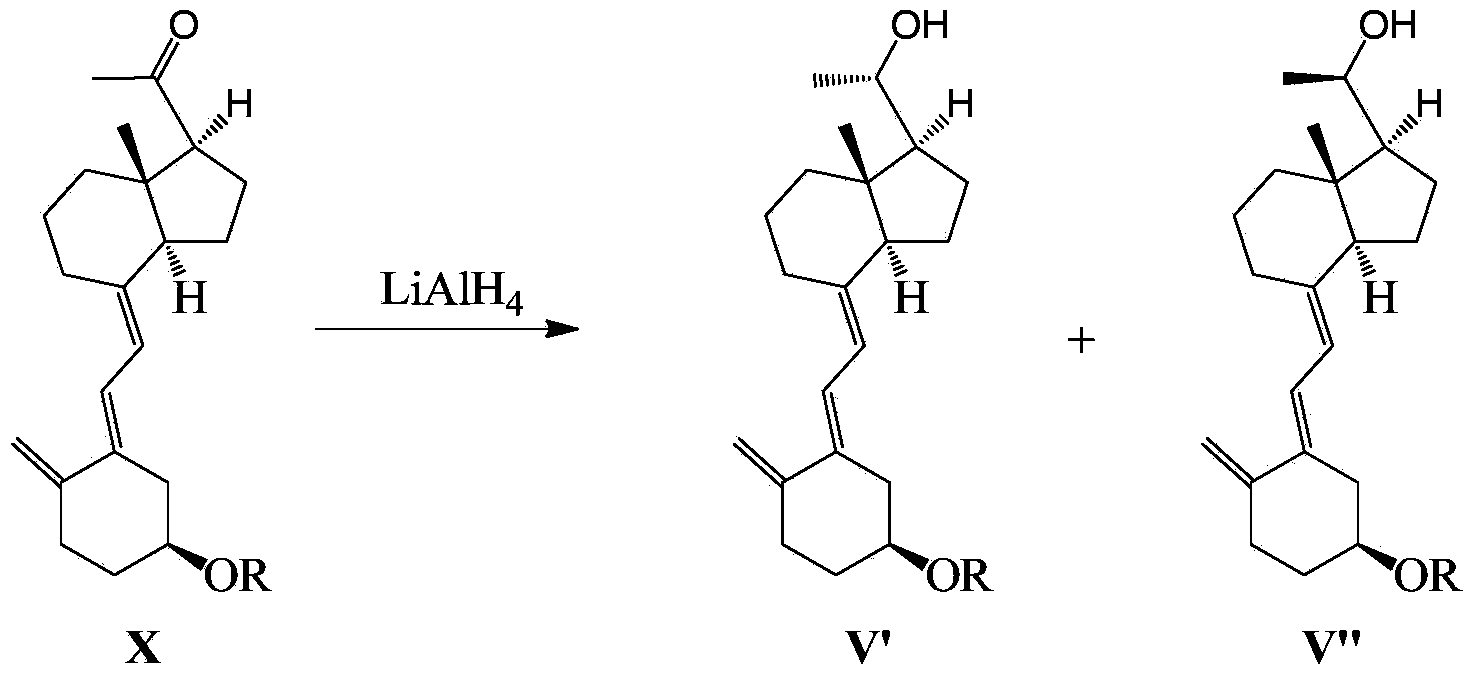

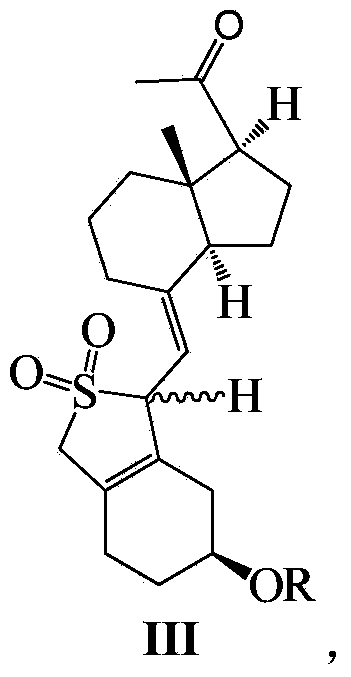

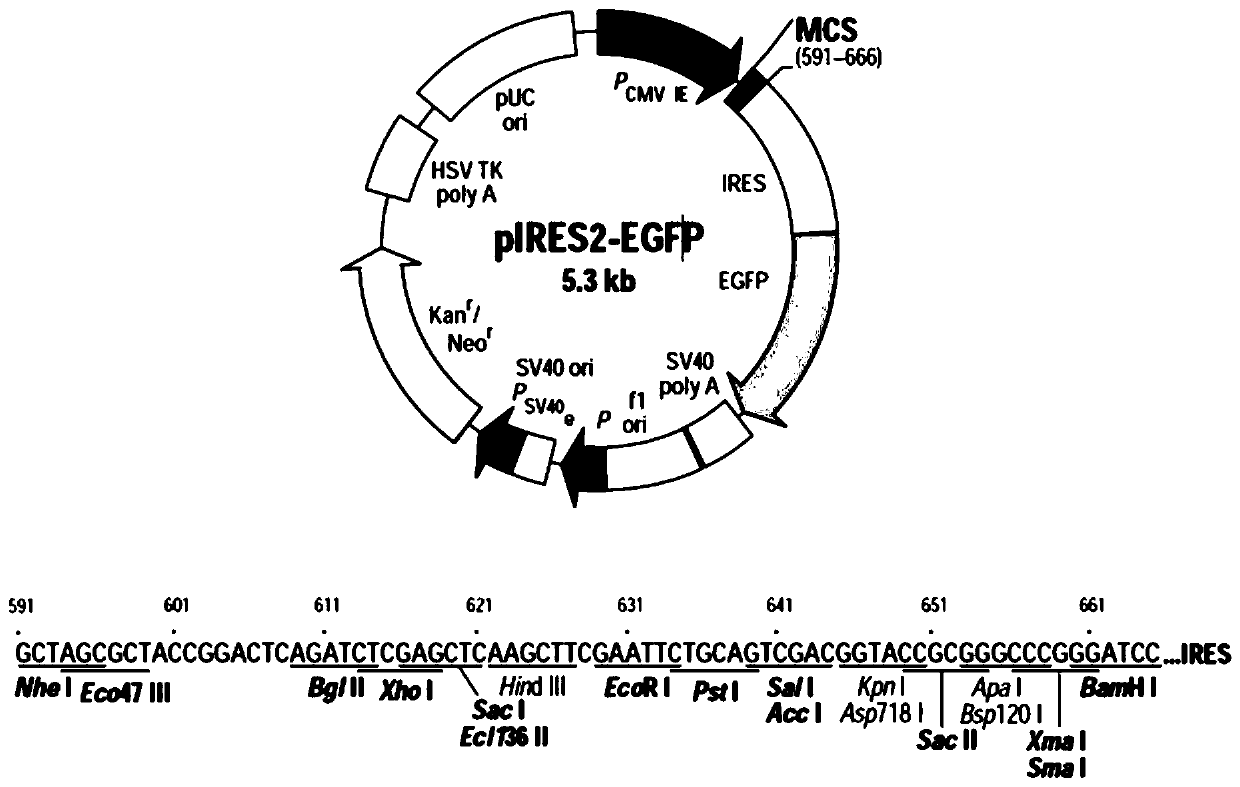

Maxacalcitol synthesizing intermediate and preparation method and application thereof

InactiveCN103508999AHigh reaction yieldHigh synthesis efficiencyGroup 4/14 element organic compoundsDermatological disorderVitamina D2Side chain

The invention provides a new method for synthesizing maxacalcitol and an intermediate thereof. According to the method, the maxacalcitol is creatively synthesized through the steps of taking vitamin D2 as an initial raw material, obtaining a compound shown as a formula II, oxidizing, chirally reducing, connecting a side chain, introducing a hydroxyl group to a C-1 position, photochemically overturning and the like.

Owner:ZHEJIANG HISUN PHARMA CO LTD

Method for producing and purifying enoxaparin sodium

The invention relates to a method for producing and purifying enoxaparin sodium. The finished enoxaparin sodium which satisfies the pharmacopeia standards can be obtained through carrying out centrifugal separation and alcohol precipitation purification. The method is high in yield, simple and convenient to operate and good in product clarity, and is capable of satisfying the requirements of the pharmaceutical industry.

Owner:SUZHOU ERYE PHARMA CO LTD

Method for preparing and purifying enoxaparin sodium

The invention discloses a method for preparing and purifying enoxaparin sodium. After a crude enoxaparin sodium product is subjected to centrifugal separation and alcohol precipitation impurity removal, the finished enoxaparin sodium product meeting pharmacopeia standards can be obtained. The method is high in yield and easy and convenient to implement, and the product is good in clarity and capable of meeting requirements of the pharmaceutical industry.

Owner:QINGDAO JIULONG BIO PHARMA

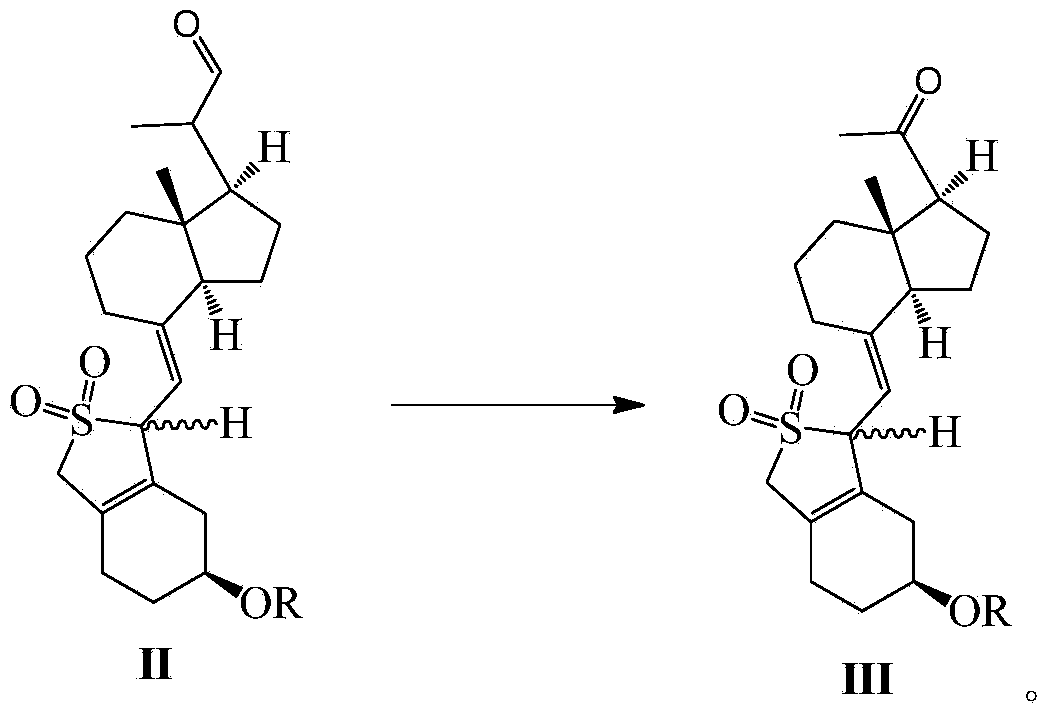

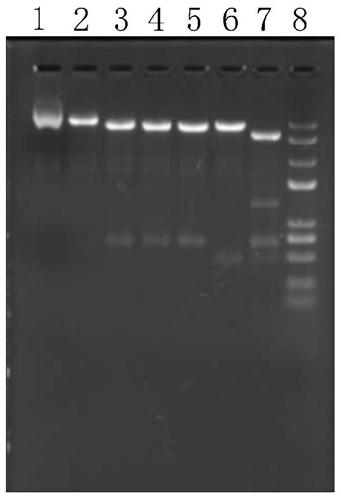

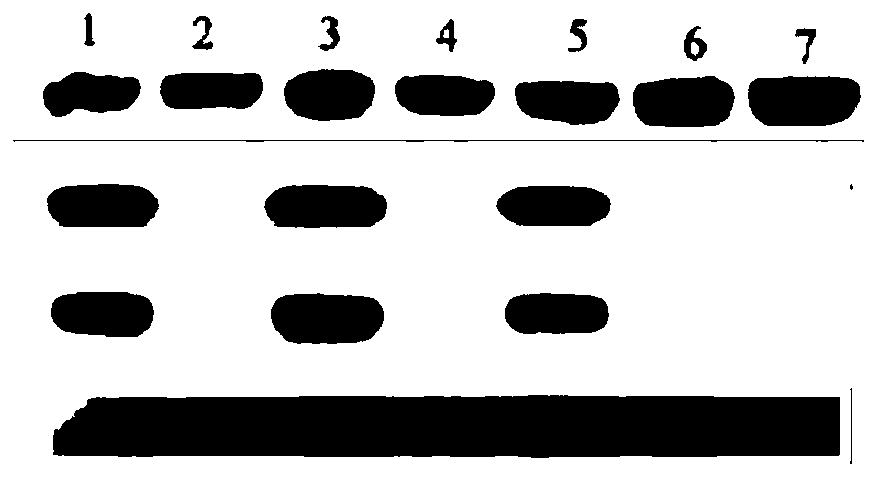

African swine fever virus tandem gene, coexpression vector, construction method and application

ActiveCN110218732AStrong and effective specific immune responseStrong and effective immune responseViral antigen ingredientsVirus peptidesDiseaseEscherichia coli

The invention belongs to the technical field of genetic engineering vaccines, and particularly relates to an African swine fever virus tandem gene, a coexpression vector, a construction method and application. The recombinant vector is obtained through the steps that an artificially synthesized polygene clone expression element is connected to the portion between the BglII and BamHI restriction enzyme cutting sites in a pIRES2-egfp vector, and oriR101 is inserted in the portion behind the XbaI site of 1986 nt of the pIRES2-egfp vector, wherein the nucleotide sequence of the gene clone expression element is shown in SEQ ID NO: 1; the recombinant vector is transformed into escherichia coli competent cells, screening and cultivation enlargement are conducted, then polygenic protein is collected and purified, and a subunit vaccine against the African swine fever disease is obtained; the recombinant vector is transformed into lactobacillus competent cells, and after screening and cultivation enlargement are conducted, a lactobacillus vaccine is obtained. The prepared vaccine stimulates the body to generate an antibody in different levels and different gradations, stimulates the body toproduce a strong and effective specific immune response, exerts high-efficiency immune protection, and makes an immune response against the African swine fever virus.

Owner:YANAN UNIV

A kind of preparation method of high-purity fluoroethylene carbonate

Owner:DO FLUORIDE CHEM CO LTD

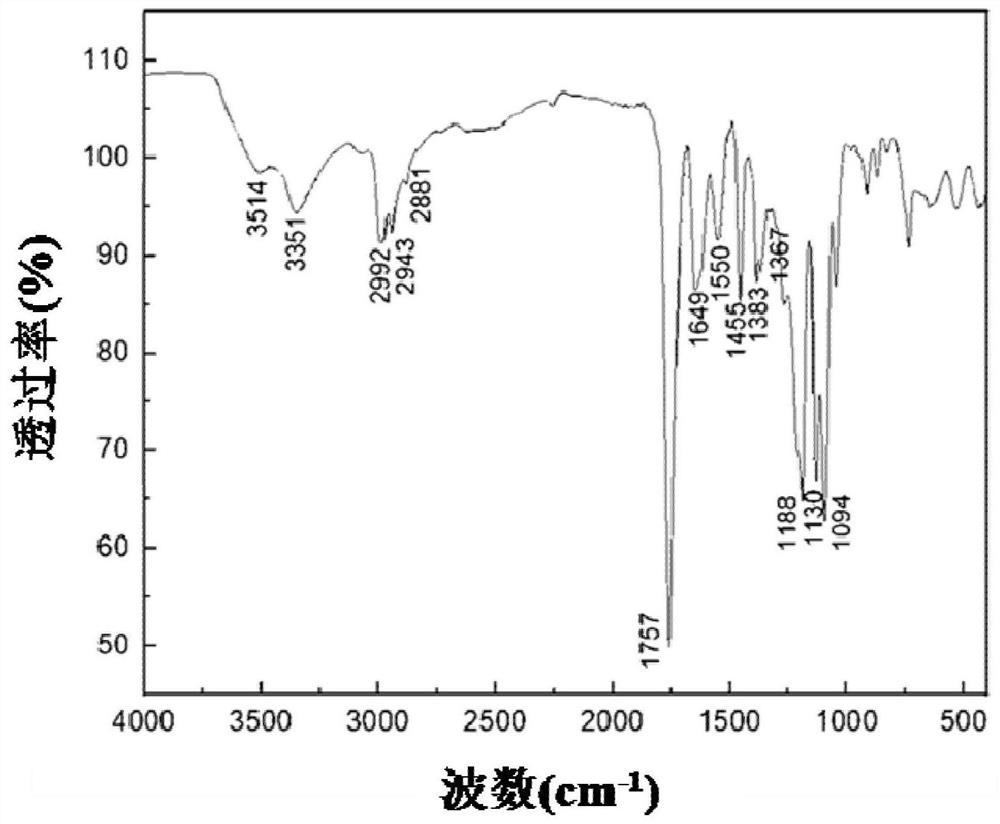

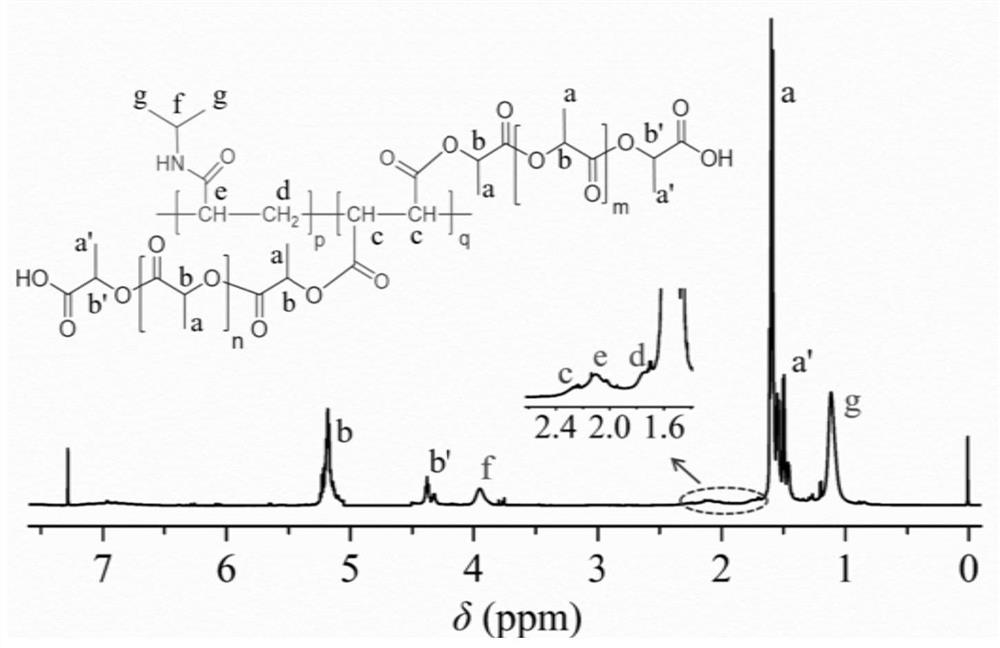

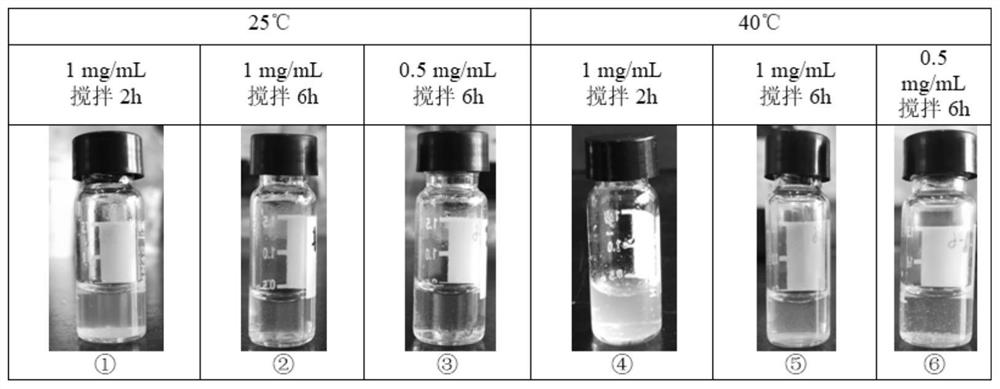

Thermo-sensitive polylactic acid high-molecular material and preparation method and application thereof

The invention discloses a thermo-sensitive polylactic acid high-molecular material and a preparation method and application thereof, the structural formula of the thermo-sensitive polylactic acid high-molecular material is shown in the specification, R is a polymerization chain segment of a thermo-sensitive polymer monomer, n is an integer between 10 and 100, q is an integer between 10 and 10, and m is an integer between 10 and 100. The novel polylactic acid high-molecular material is obtained by carrying out copolymerization reaction on cheap and easily available bio-based lactic acid monomers, simple maleic anhydride and temperature-sensitive polymer monomers through direct melt polycondensation by a one-pot method, and the polylactic acid high-molecular material has temperature sensitivity and biodegradability. The material is expected to be used as a carrier of small molecular drugs or antibacterial drugs, or can be directly used as a wound dressing base material in a form of powder, which is blended with a solvent into a gel form or spun into a fibrous form.

Owner:SOUTH CHINA NORMAL UNIVERSITY

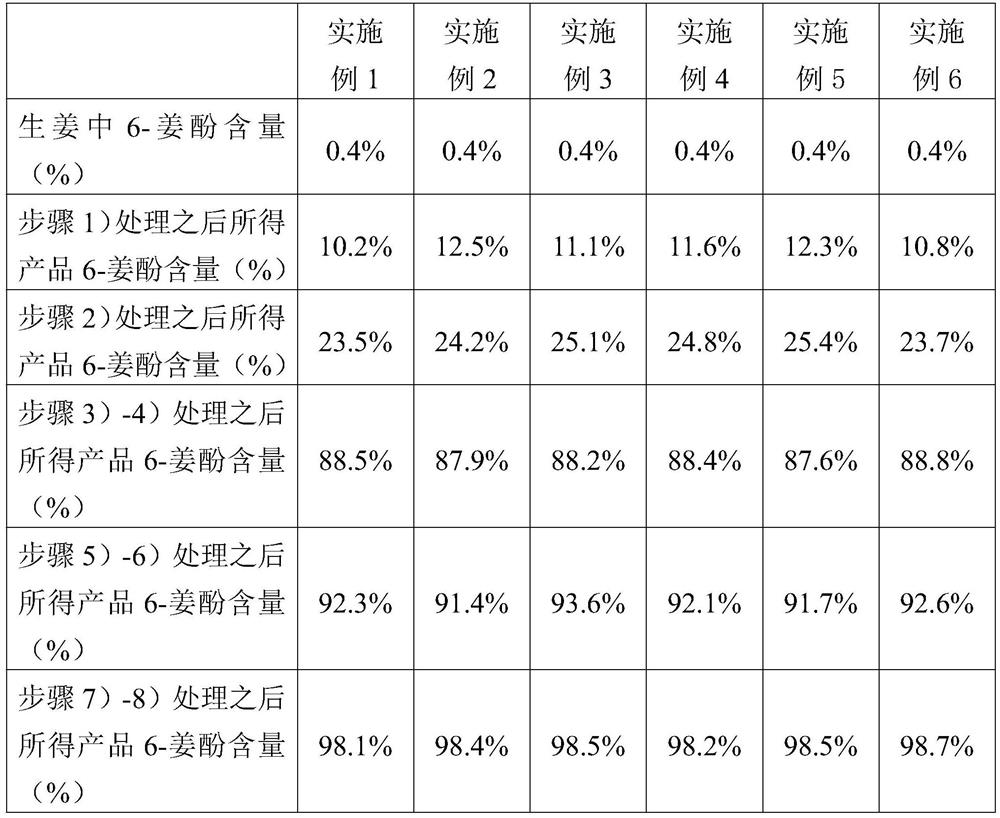

Method for extracting 6-gingerol with content greater than or equal to 98%

ActiveCN112920034AIncrease productivityExtraction method is fast and efficientOrganic compound preparationCarbonyl compound separation/purificationActivated carbonAlcohol ethyl

The invention belongs to the field of 6-gingerol extraction, and particularly relates to a method for extracting 6-gingerol with the content larger than or equal to 98%. The method for extracting 6-gingerol with the content larger than or equal to 98% comprises the following steps: crushing fresh ginger, adding ethyl alcohol for flash extraction, and separating out a filtrate; concentrating the obtained filtrate, carrying out alumina column chromatography, and collecting an alumina column chromatography eluent; adsorbing the alumina column chromatography eluent through a macroporous resin column, eluting with alkali-containing ethanol, acid-containing ethanol and 50-60 vt% ethanol in sequence, collecting 50-60 vt% ethanol eluent, and concentrating to prepare a concentrated solution with the baume degree of 10-15; mixing the obtained concentrated solution with an organic solvent, adjusting the alcohol concentration to 55-60 vt%, adding activated carbon, and filtering with an organic membrane; and performing gradient elution separation on the obtained filtrate by using macroporous resin through 50-60 vt% ethanol and 65-70 vt% ethanol in sequence, respectively collecting each gradient eluent, concentrating and drying to obtain the required 6-gingerol. The original extraction method is replaced by flash extraction, so that the production efficiency is greatly improved, and various data of series macroporous resin purification are optimized to achieve the maximum efficiency.

Owner:GUILIN NATURAL INGREDIENTS CORP

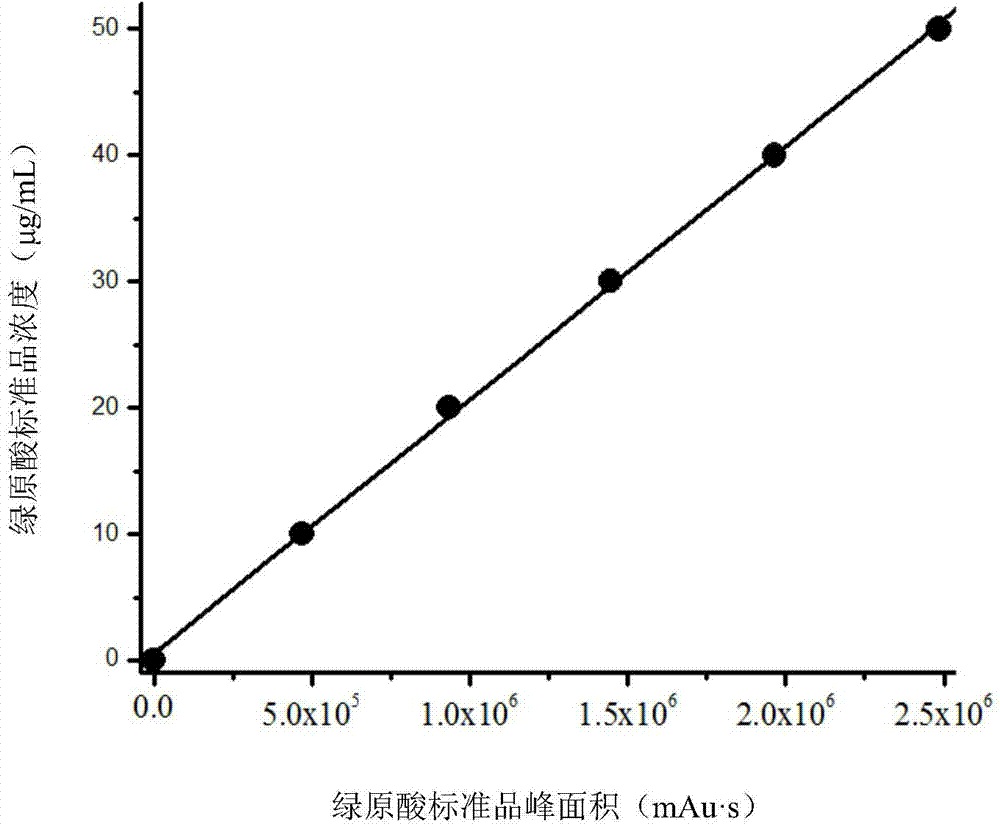

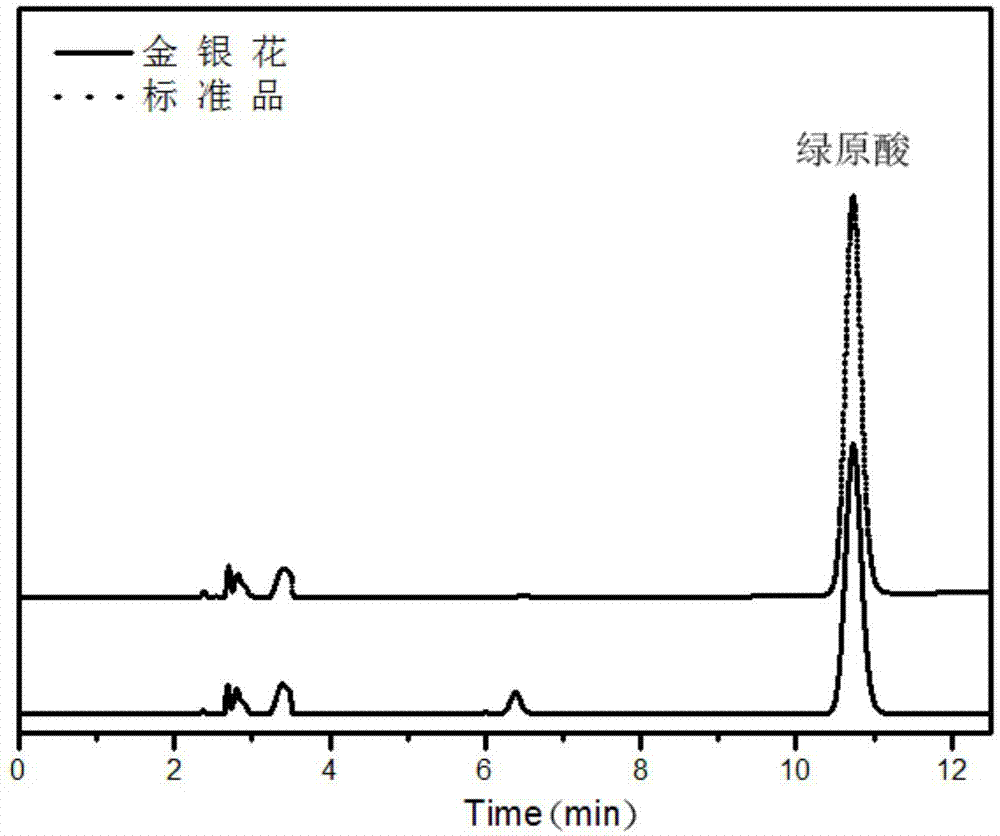

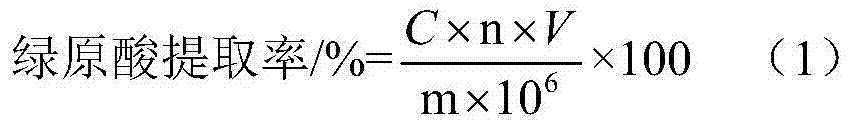

Method for extracting chlorogenic acid from honeysuckle flower

InactiveCN104288204AAvoid pollutionEasy to operateOrganic compound preparationCarboxylic acid esters separation/purificationChlorogenic acidPollen

The invention discloses a method for extracting chlorogenic acid from honeysuckle flower, and belongs to the technical field of extraction of effective components from medicinal plants. The method adopts a methanol solution to extract chlorogenic acid from honeysuckle flower at a temperature of 70-130DEG C under closed conditions to solve the disadvantages of a water extraction method, an ethanol reflux method, a supercritical extraction method and an ultrasonic extraction method. The method disclosed in the invention includes the following steps: 1, adding crushed honeysuckle flower powder of 80-100 meshes into a methanol solution with the concentration of 25-75%, and adjusting the pH value of the obtained mixed solution to 4-7; and 2, extracting under closed conditions for 10-60min, centrifuging, taking the obtained supernatant, and detecting the extraction rate of chlorogenic acid to be 3.32-4.19%. The extraction method has the advantages of simple operation, short extraction time, good repeatability, high stability, and avoiding of environment pollution caused by organic solvent volatilization due to the implementation of the whole extraction process in a closed system.

Owner:HENAN UNIV OF SCI & TECH

Preparation method of p-methylsulfonyl benzaldehyde

InactiveCN106966932AThe synthesis process is simplePost-processing is simpleOrganic chemistryOrganic compound preparationBenzaldehydeEconomic benefits

The invention relates to a preparation method of p-methylsulfonyl benzaldehyde. The preparation method includes: dissolving p-methylsulfonyl methylbenzene and a catalyst in water; mixing for reaction to obtain p-methylsulfonyl benzaldehyde, wherein the catalyst is 1, 4-dichloro-1, 4-diazacyclo [2, 2, 2] octane. The preparation method has the advantages of simplicity, easiness in operation, suitability for large-scale industrial production and high economic benefit.

Owner:FUJIAN YIMING MEDICAL TECH CO LTD

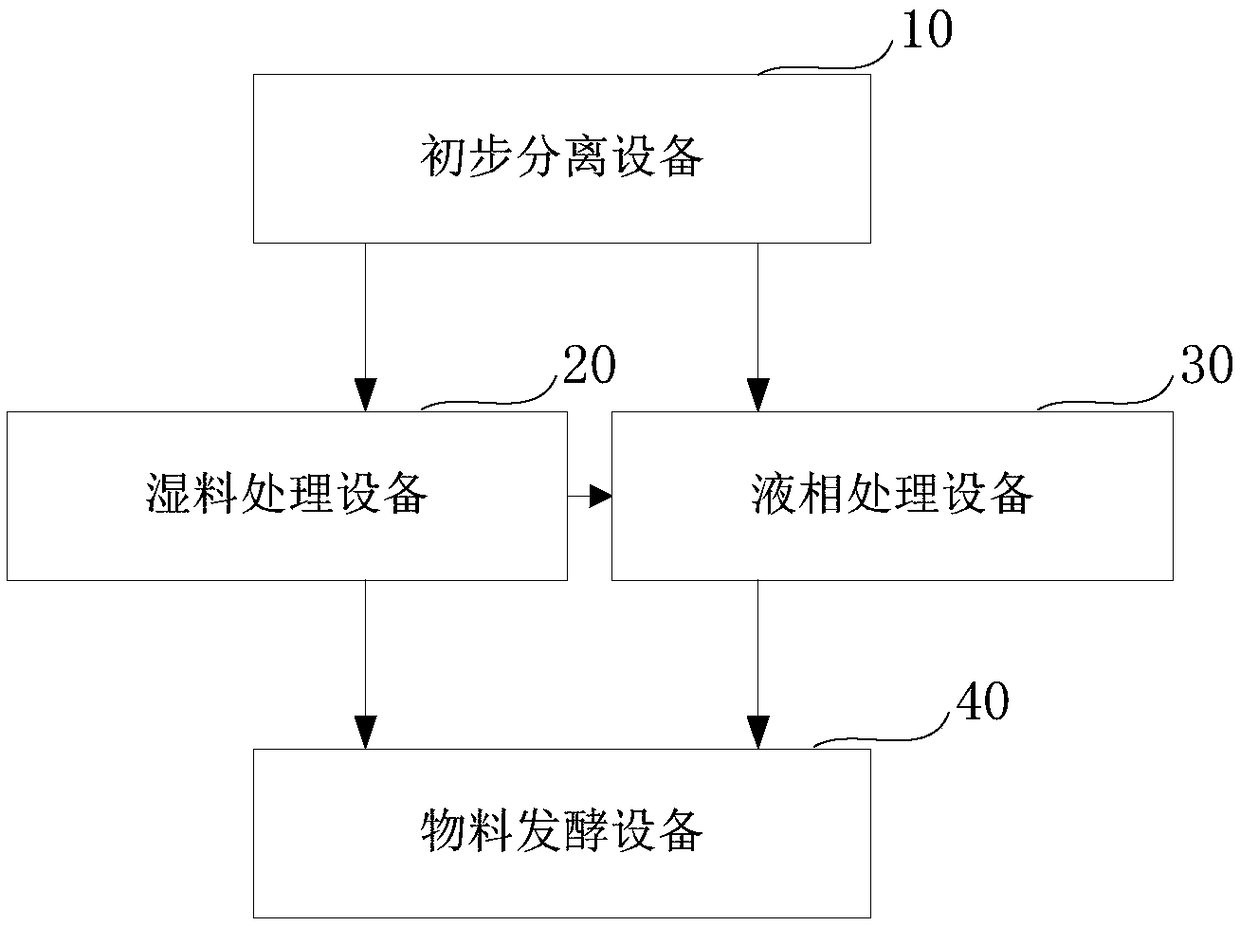

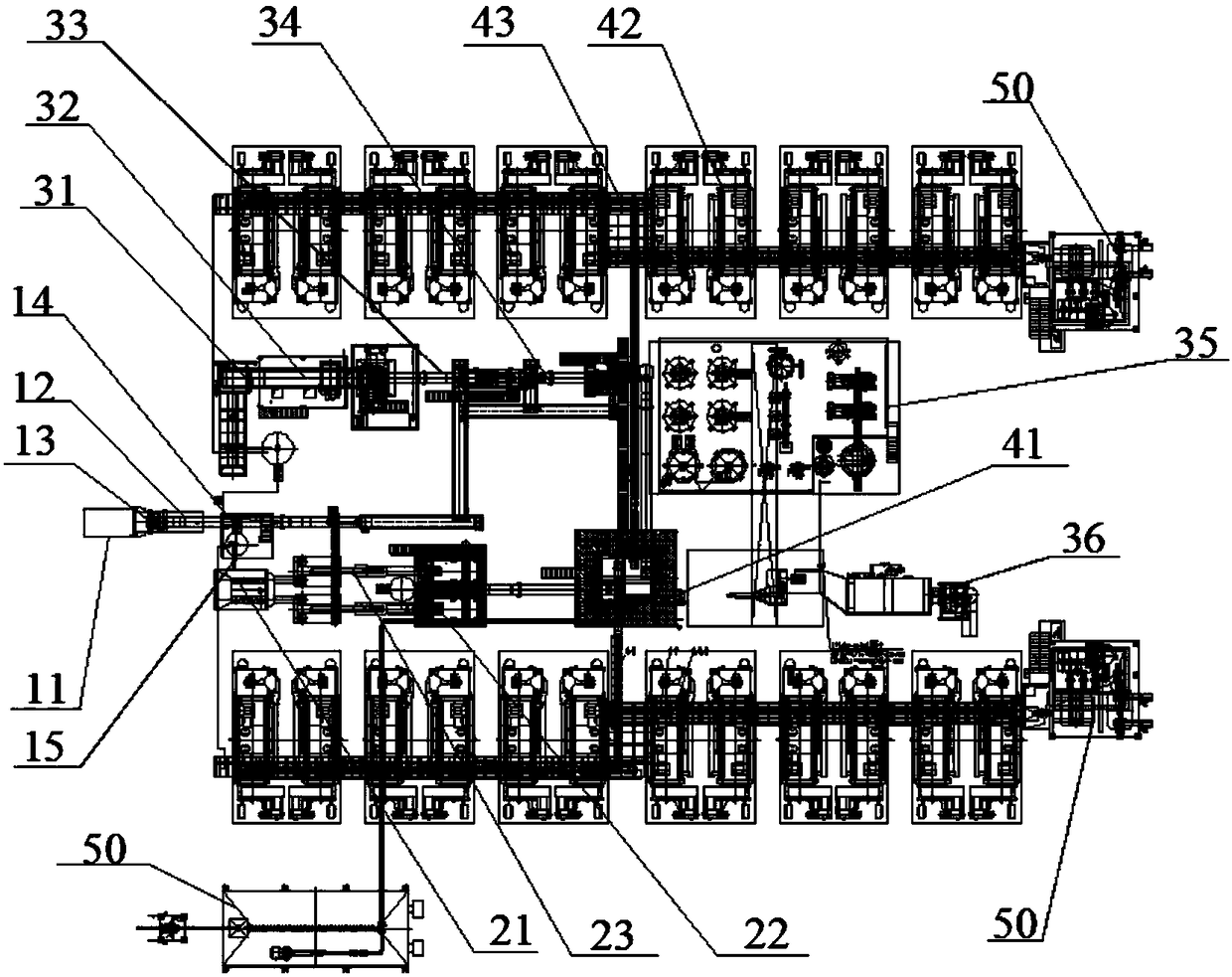

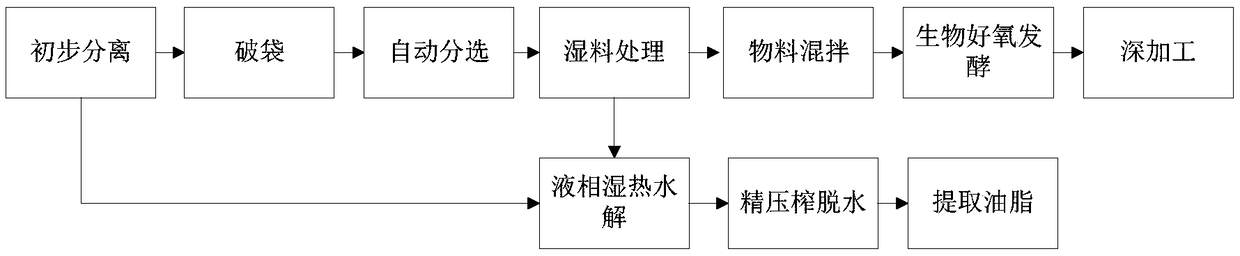

Kitchen waste treatment system

PendingCN108704923AIncrease profitSimple purificationSolid waste disposalTransportation and packagingOil and greaseLitter

The invention relates to the technical field of kitchen waste treatment, in particular to a kitchen waste treatment system. The kitchen waste treatment system comprises preliminary separation equipment, wet material treating equipment, liquid phase treatment equipment and material fermenting equipment, wherein the preliminary separation equipment is used for receiving kitchen waste and separatingthe kitchen waste into percolate, solid waste and wet materials preliminarily, the wet material treating equipment is used for receiving the wet materials, carrying out squeezing and dewatering treatment on the wet materials, and obtaining wet material liquid phases and wet material solid phases, the liquid phase treatment equipment is used for receiving percolate and the wet material liquid phases and further separating mixed liquid of the percolate and the wet material liquid phases into grease, organic matter and liquid phase impurities, and the material fermenting equipment is used for receiving the wet material solid phases and the organic matter, mixing the wet material solid phases and the organic matter with auxiliary materials to form a fermenting raw material, and fermenting thefermenting raw material into biological yeast. The kitchen waste treatment system can treat the kitchen waste fast and efficiently, and solve the problem that when the kitchen waste is treated throughthe prior art, secondary pollution to the environment is caused.

Owner:BEIJING GOLDENWAY BIO TECH

Process for preparation of esters solvent

InactiveCN101514157AAvoid mixingReduce alkali metal contentOrganic compound preparationCarboxylic acid esters preparationAlcoholBoiling point

The present invention provides high boiling point esters solvent with low content of sodium and acid and high-efficiency industry method for preparing the same. The esters solvent can be used in electronic material field with requirement of high-purity quality. Process for preparation of esters solvent is, at the presence of acid catalyst, putting the esterification reaction stock solution got from esterification of alcohol and acid into distilling tower and distilling to get esters solvent, wherein, the reaction stock solution used for distil purifying without neutralization treatment, and after removing low boiling point ingredients by distillation, distilling off the esters solvent via sidetrack distillate pipe disposed in central part of the distilling tower.

Owner:DAICEL CHEM IND LTD

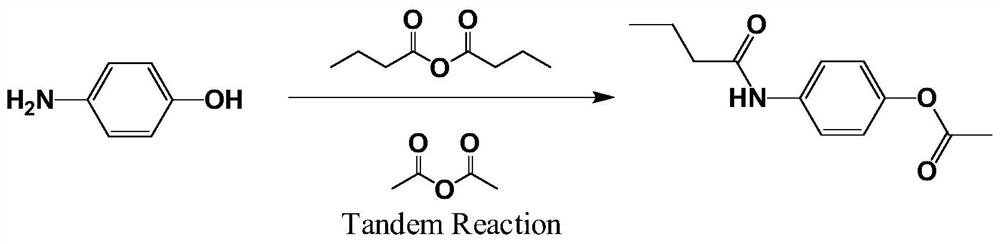

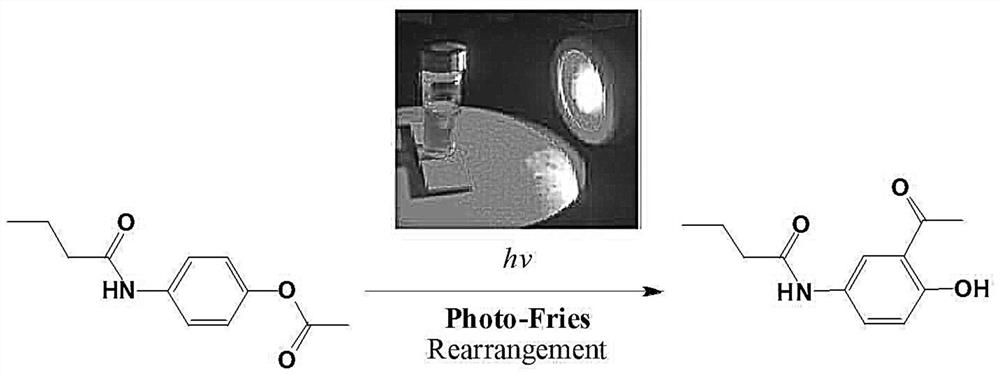

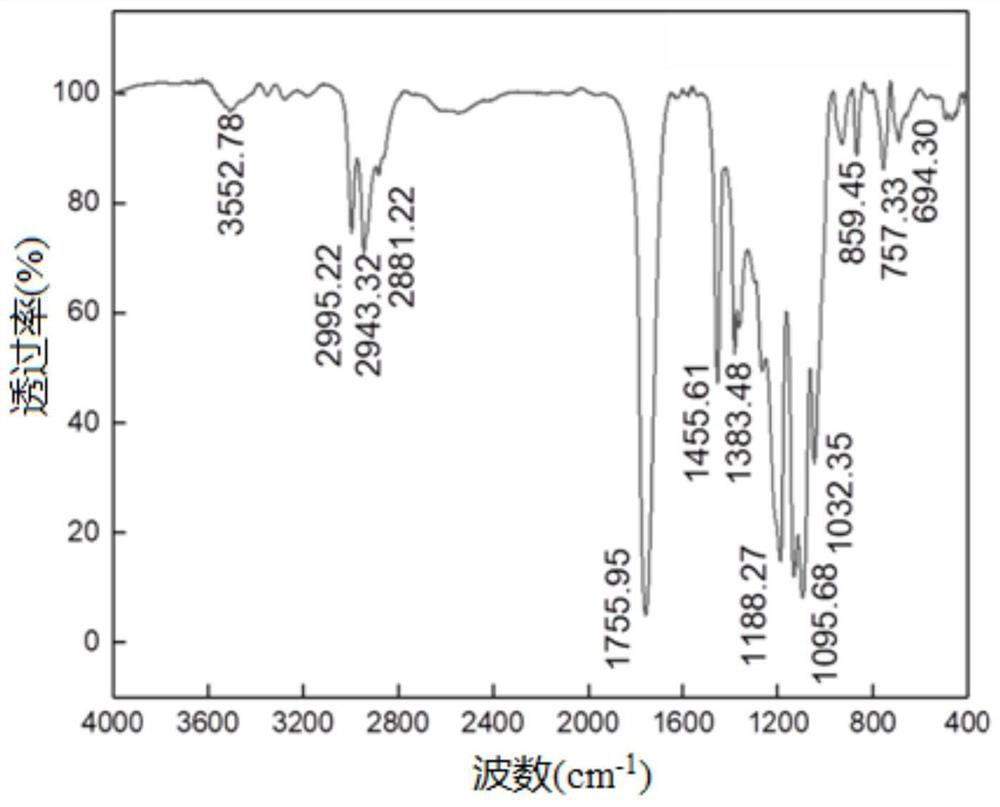

Beta receptor blocker Acebutolol intermediate synthesized by photochemical Fries rearrangement

PendingCN113527123ASynthetic method is simpleLow pollution and cheapOrganic compound preparationCarboxylic acid amide separation/purificationM-aminophenolButyric anhydride

The invention belongs to the field of organic photochemistry and medicinal chemistry, and particularly relates to a beta receptor blocker Acebutolol intermediate synthesized by photochemical Fries rearrangement. An efficient continuous acetylation synthesis method is adopted, raw materials including p-aminophenol and n-butyric anhydride are mixed and subjected to a water diversion reaction with a water-carrying agent, then the water-carrying agent is removed through distillation, reactants are cooled, water is added as a dispersing agent, then liquid caustic soda is added for a reaction, phenate is generated, acetic anhydride is dropwise added, the mixture is stirred for a reaction, ester is generated, recrystallizing is carried out to generate a first-step product N-(4-acetoxyphenyl) butyrylamide; and in the step 2 photochemical Fries liquid phase rearrangement reaction is adopted, the product in the first step is dissolved in an organic solvent, then Fries rearrangement is carried out by irradiation of ultraviolet-visible light with a specific wavelength, the solvent is heated and evaporated after the reaction is completed, and the important intermediate 2-acetyl-4-n-butyryl aminophenol of Acebutolol is obtained after recrystallization. The method is simple and easy to implement, and low-toxicity, efficient and cheap green chemical reagents are used in the synthesis process.

Owner:山东盛安贝新材料有限公司

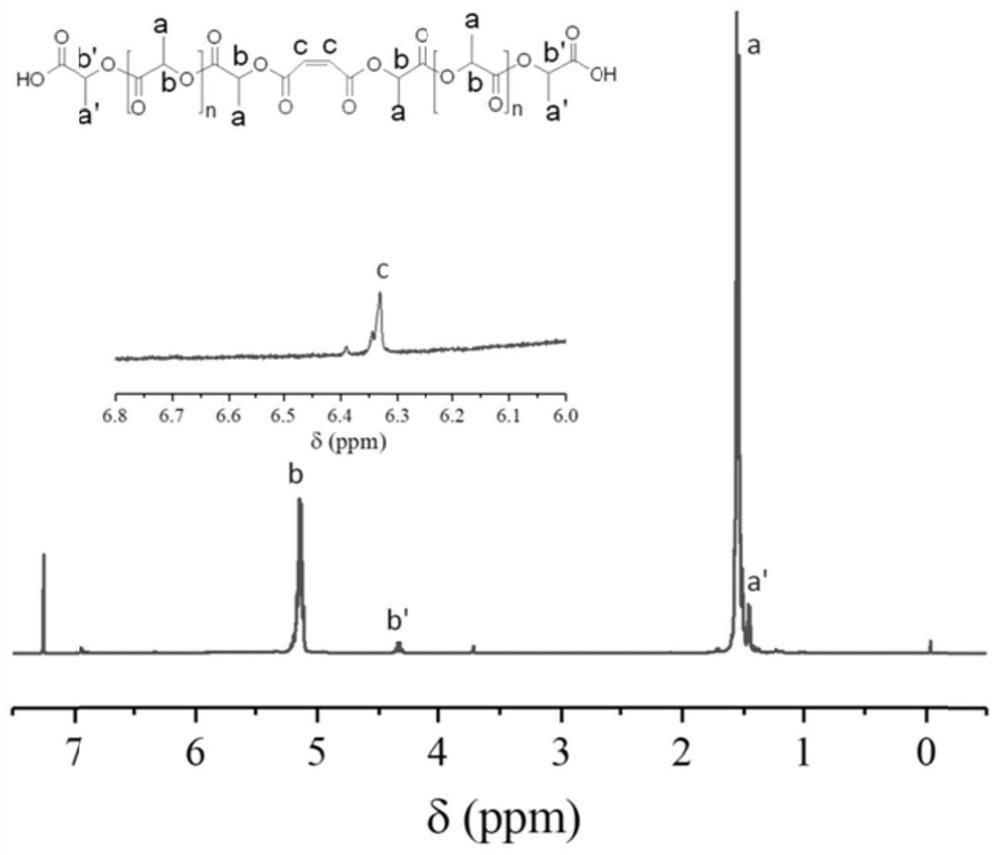

Polylactic acid-based macromonomer as well as preparation method and application thereof

The invention discloses a polylactic acid-based macromonomer as well as a preparation method and application thereof. The structural formula of the polylactic acid-based macromonomer is as follows: n represents an integer between 10 and 200, p represents an integer between 1 and 200, m represents an integer between 10 and 200, and R1 and R2 are independently selected from H or alkyl. According to the preparation method, the cheap and easily available bio-based lactic acid monomer is directly subjected to copolymerization reaction with maleic anhydride, acrylic acid and ester thereof, and direct melt polycondensation is performed through a one-pot method to obtain the novel polylactic acid-based macromonomer which has certain active sites, and can be used as a macromonomer for free radical polymerization, polycondensation and other reactions; meanwhile, the thermal property and crystallization property of the polylactic acid-based macromonomer can be adjusted, and the polylactic acid-based macromonomer is expected to be used in 3D printing, toughening rubber and other materials, and even in the field of biomedical materials.

Owner:SOUTH CHINA NORMAL UNIVERSITY

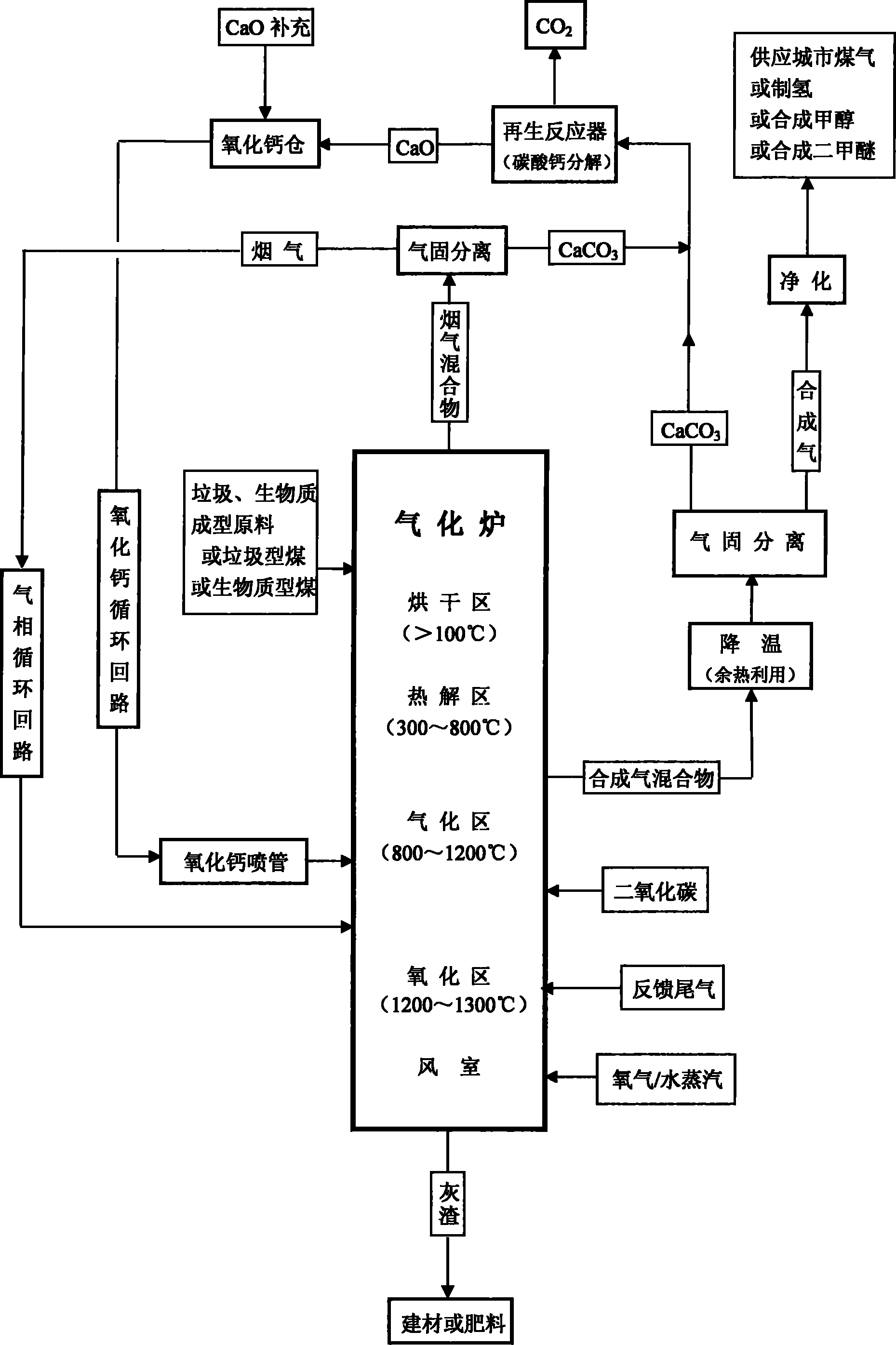

Gasification process for producing synthesis gas from garbage and biomass raw materials

InactiveCN101525118BEliminate pollutionHarmlessSolid waste disposalHydrogen productionWater vaporClean energy

The invention provides a gasification process for producing synthesis gas from garbage and biomass raw materials, which relates to a gasification processing technique of garbage and biomasses. The gasification process is characterized in that the technological process mainly comprises a raw material solid matter process, a gas phase circulation loop, a calcium oxide circulation loop and a synthesis gas drawing process; one or a mixture of more garbage, the biomasses and coal is sent into a gasification furnace to perform gasification so as to generate the synthesis gas; and simultaneously, calcium oxide is sent into the gasification furnace, an exothermic reaction of absorbing carbon dioxide by the calcium oxide provides the heat required by the gasification reaction in the furnace, and water vapor is sent into a plasma spraying gun and is heated to more than 3,100 DEG C to generate H2, O, O2 and H2O<*> which are sprayed into the gasification furnace to perform reactions with the garbage and the biomasses and supply heat into the furnace. The gasification process adopts a measure to spray the calcium oxide into the furnace to not only greatly reduce the electric energy consumptionof the plasma spraying gun, but also improve the quality and the yield of the synthesis gas, thus the aim of transforming the garbage and the biomasses into clean energy can be achieved easily.

Owner:周开根

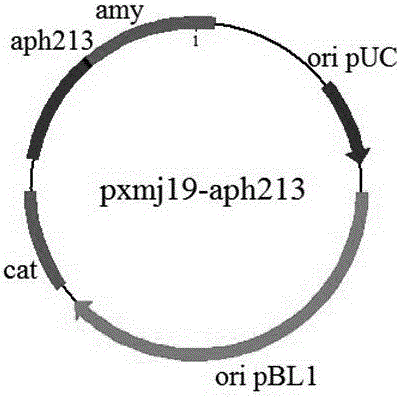

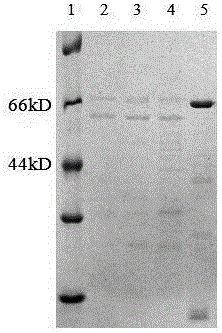

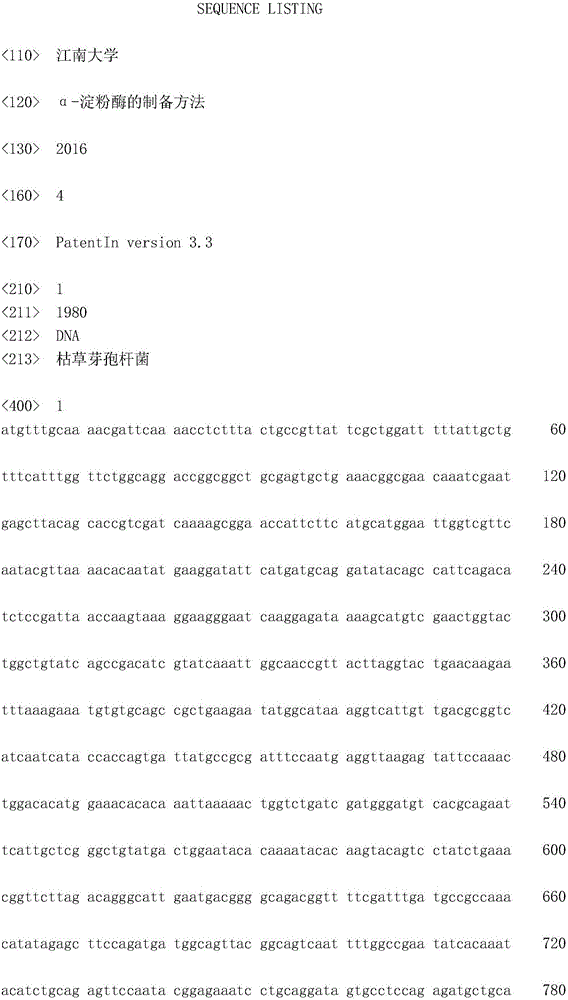

Preparation method of Alpha-amylase

ActiveCN106566820AGood securityEasy purificationNucleic acid vectorVector-based foreign material introductionAmylase preparationChemistry

The invention provides a preparation method of Alpha-amylase. The preparation method can solve the technical problems that in the prior art, when the Alpha-amylase is prepared form bacillus subtilis, the later-period purification steps are complicated, and the pure product cannot be easily obtained. The method comprises the following steps of (2) adding an e3 SD sequence at the upstream of an Alpha-amylase gene, adding a histidine tag at the downstream part of the Alpha-amylase gene, and obtaining the modified Alpha-amylase gene; (3) connecting the modified Alpha-amylase gene onto a vector pxmj19-aph213, and obtaining a recombinant expression vector pxmj19-aph213-amy; (4) transferring the recombinant expression vector pxmj19-aph213-amy into corynebacterium glutamicum to obtain recombinant bacteria; (5) culturing the recombinant bacteria, and performing secretory expression on the Alpha-amylase; and (6) performing Alpha-amylase purification: performing affinity chromatography on supernatant containing the Alpha-amylase, wherein the medium is a nickel column.

Owner:SHENZHEN INNOVATION CENT OF SMALL MOLECULE DRUG DISCOVERY CO LTD

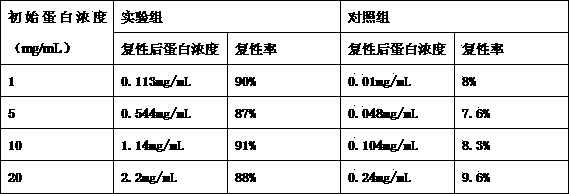

Recombinant protein renaturation buffer solution as well as preparation method and application thereof

InactiveCN103626834ALess volume increaseConcentration dilution is smallPeptide preparation methodsBuffer solutionBeta-Cyclodextrins

The invention relates to a recombinant protein renaturation buffer solution as well as a preparation method and an application thereof. The buffer solution consists of a basis solution, 0.5% of beta-mercaptoethanol, 1% of tween-20, 10mM of beta-cyclodextrin, 1M of L-cysteine and 4M of urea. The preparation method comprises the following steps: firstly, adding 4M of urea into the basis solution, secondly, adding 0.5% of beta-mercaptoethanol, 1% of tween-20, 10mM of beta-cyclodextrin and 1M of L-cysteine according to volume ratio, so as to form the recombinant protein renaturation buffer solution. The buffer solution provided by the invention is applied to recombinant protein renaturation with the primary protein concentration greater than 1mg / mL, is simple to operate, low in cost and convenient in industrial production, the volume after renaturation is slightly increased, the protein concentration is slightly diluted, and the renaturation rate is high.

Owner:JIANGSU ACAD OF AGRI SCI

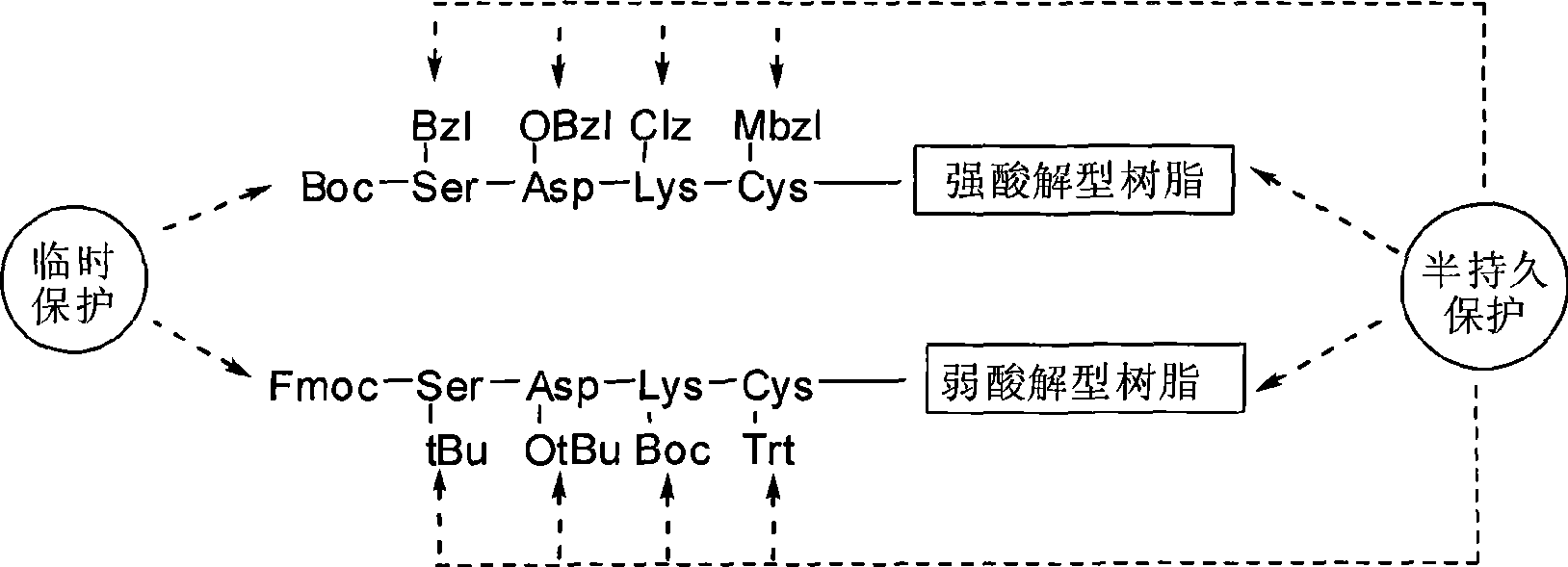

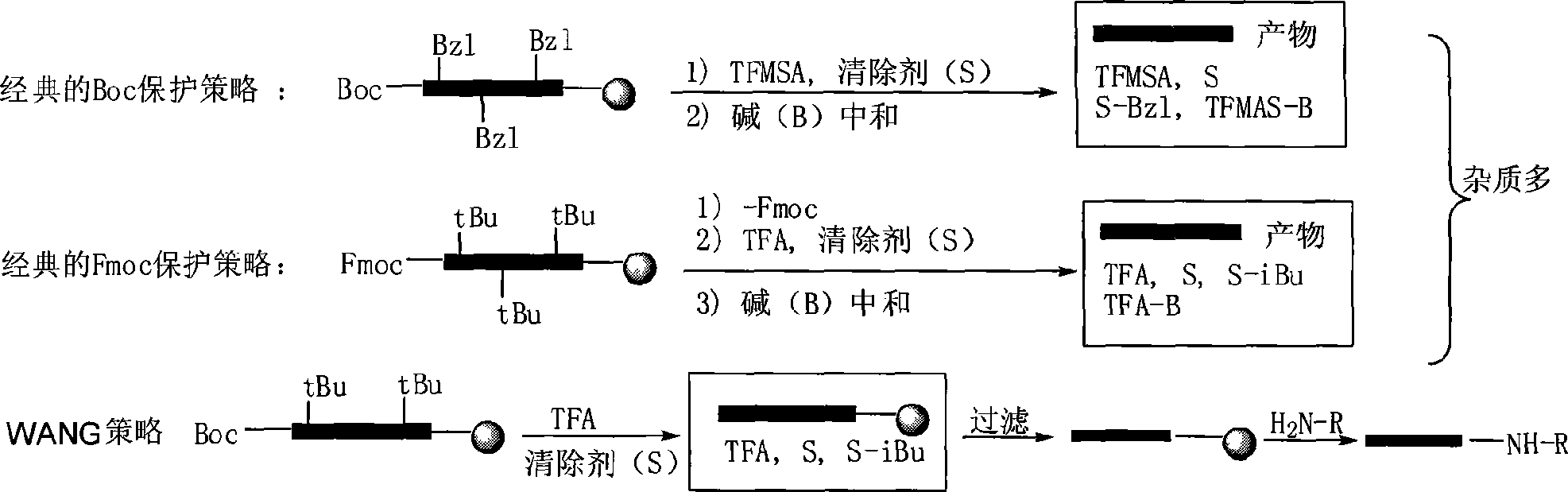

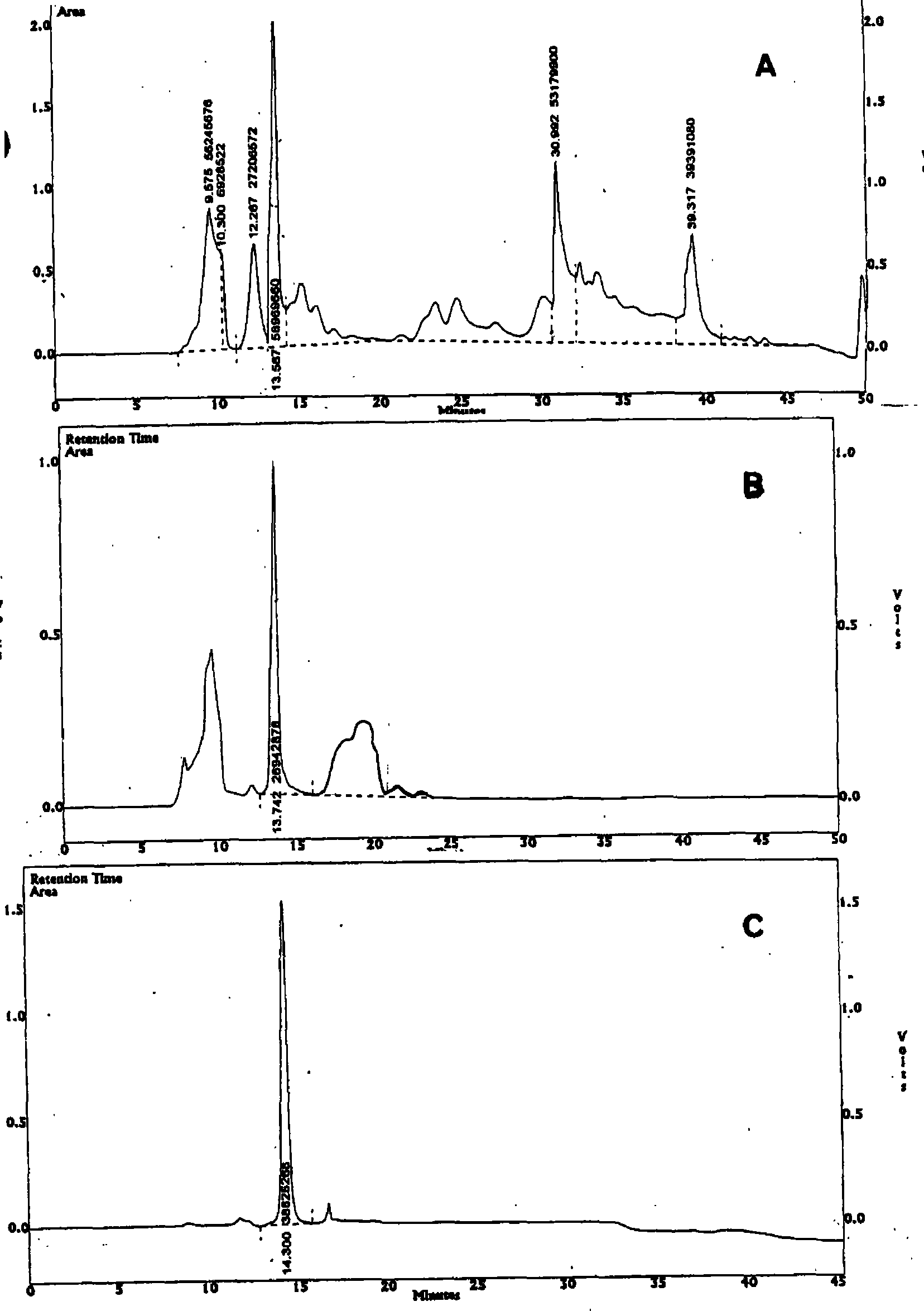

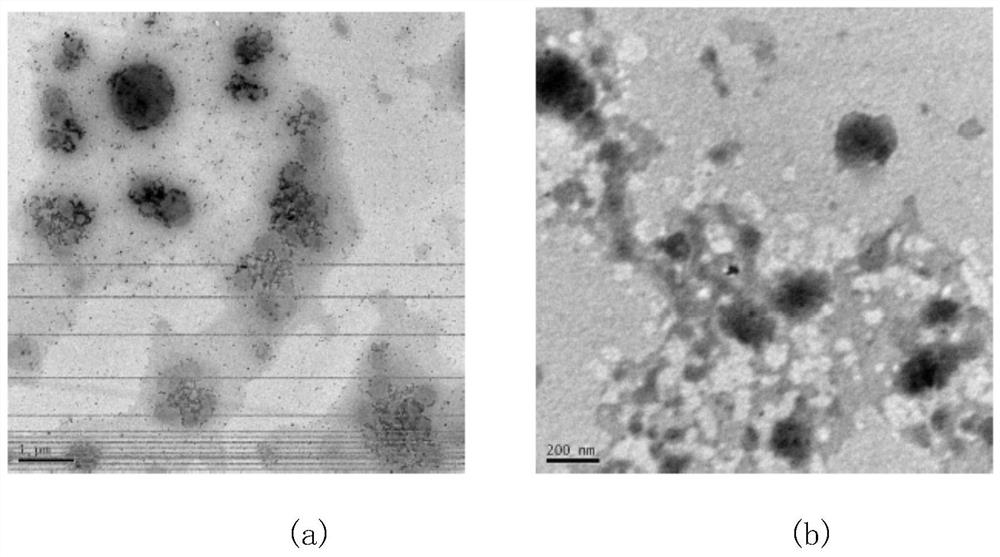

Technology for solid phase synthesis of peptide by WANG strategy

InactiveCN101463070AHigh purityReduce manufacturing costPeptide preparation methodsLibrary creationSolid phasesStrong acids

The invention relates to solid phase synthetic peptide technology by a WANG strategy, in particular to the synthetic mode taking six active oligopeptide as the target structure and adopting cross-matching of Boc-amino acid / strong acid-cleavage resin and Fmoc-amino acid / weak acid-cleavage resin, WANG (without acid-cleavage and nice gain) strategy for short, is adopted; finally the product with satisfactory yield and more lower cost is obtained.

Owner:INST OF MATERIA MEDICA AN INST OF THE CHINESE ACAD OF MEDICAL SCI

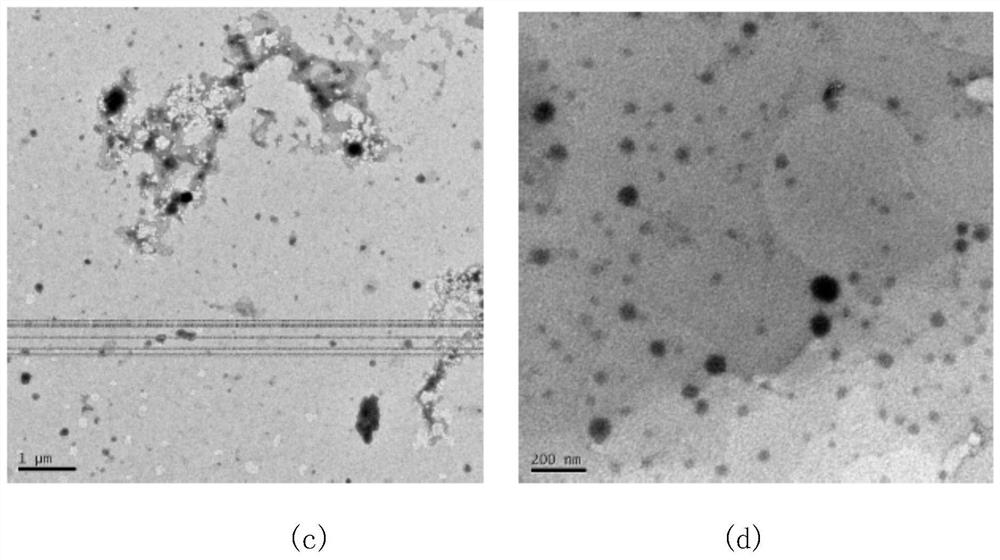

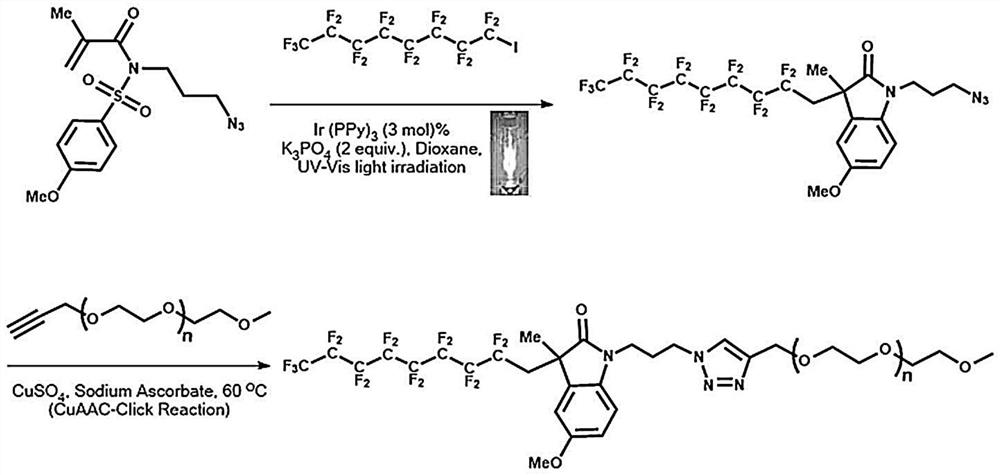

Nitrogen-containing heterocyclic fluorocarbon surfactant synthesized by adopting photoreaction-click reaction method and preparation of water-phase micelle of nitrogen-containing heterocyclic fluorocarbon surfactant

ActiveCN113527264AReduce dosageLow toxicityOrganic chemistryTransportation and packagingSodium ascorbateActive agent

The invention belongs to the crossing field of organic photochemistry, organic fluorine chemistry and medicinal surfactant chemistry, and particularly relates to a nitrogen-containing heterocyclic fluorocarbon surfactant synthesized by adopting a photoreaction-click reaction method and preparation of a water-phase micelle of the nitrogen-containing heterocyclic fluorocarbon surfactant. An intermediate 1-N-(3-azidopropyl)-3-methyl-3-perfluorooctyl-5-methoxyl-indolone is synthesized by adopting a photoreaction, photochemical intramolecular ring-closure reaction is carried out by using ultraviolet-visible light irradiation, and under the catalysis of copper sulfate / sodium ascorbate, the intermediate and monopropynyl-monomethyl-polyethylene glycol are subjected to a click reaction, and the nitrogen heterocyclic ring fluorocarbon surfactant is prepared. The green synthesis method is simple and easy to implement, low-toxicity, efficient and commercialized green chemical reagents are used in the synthesis process, and the synthesis method is atom-economical. The preparation method passes a small-amount synthesis test in a laboratory and is successful. Then, water-phase micelles of the nitrogen-containing heterocyclic fluorocarbon surfactant are prepared and are characterized.

Owner:山东盛安贝新材料有限公司

Enoxaparin sodium purifying method

The invention relates to an enoxaparin sodium purifying method and belongs to the field of biological engineering. The process is simple in operation, safe, controllable and high in yield. The needs of the pharmaceutical industry can be met.

Owner:QINGDAO JIULONG BIO PHARMA

Anti-tumor vaccines, coding genes, expression vectors, expression engineering bacteria and applications targeting vegf and mucin1

ActiveCN106279435BAffinity chromatography is convenientAffinity Chromatography ExpressFungiTumor rejection antigen precursorsTumor vesselMutant

Owner:XINXIANG MEDICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com