Thermo-sensitive polylactic acid high-molecular material and preparation method and application thereof

A technology of polymer material and temperature-sensitive polymer, which is applied in the field of temperature-sensitive polylactic acid polymer material and its preparation, can solve the problems of high cost, difficult application, complicated preparation process of temperature-sensitive polymer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

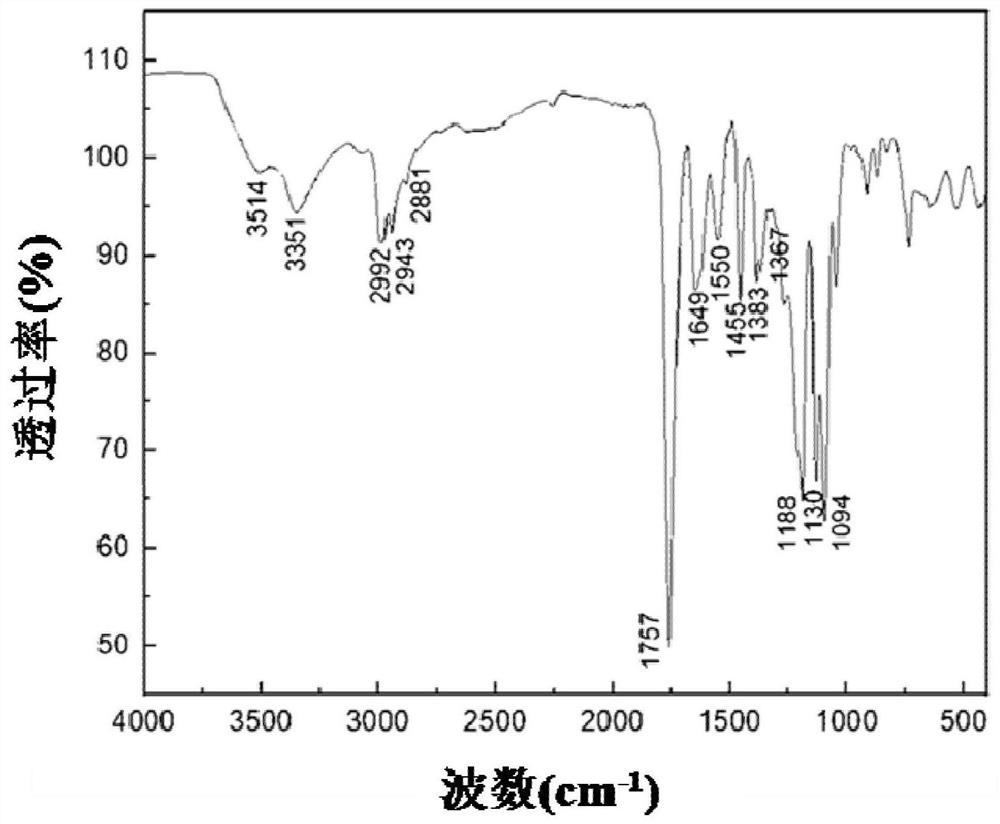

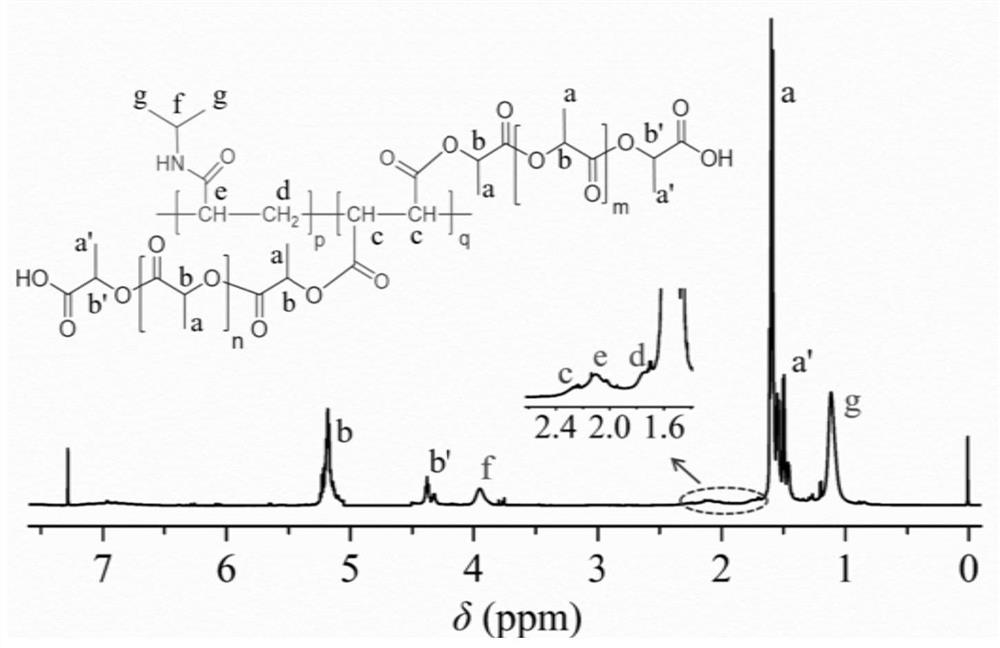

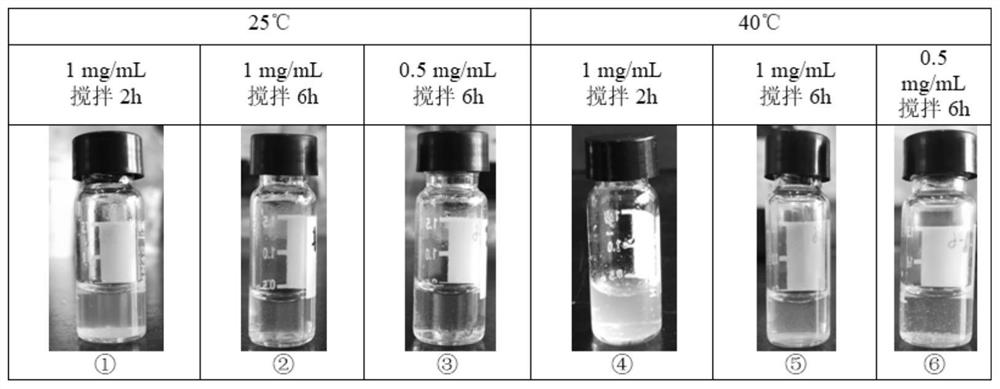

[0045] The invention provides a temperature-sensitive polylactic acid polymer material, the preparation method of which is as follows:

[0046] Firstly, the prepolymer is prepared by a one-time feeding method, a magnetic stirrer is placed in a fully dry reaction flask, lactic acid monomer and maleic anhydride are added to the reaction flask, and the electromagnetic stirring is turned on. Dehydration at normal pressure first, and then vacuum prepolymerization to obtain prepolymer.

[0047] Then, a catalyst is added to the prepolymer to catalyze direct melt polymerization. Next, remove the vacuum, add temperature-sensitive polymer monomers and initiators into the above reaction system, and start electromagnetic stirring to carry out the reaction.

[0048] Finally, purify the product, first dissolve the product with a solvent, heat the product if necessary, and then use deionized water to precipitate and wash it. After filtering, the filter residue is heated and dried in a vacuu...

Embodiment 1

[0054] Copolymer PLAMN 4 Synthesis:

Embodiment 2

[0057] Copolymer PLAMN 7 Synthesis:

[0058] Put a magnetic stirring bar into the reaction flask, add about 3.6g (40mmol) of lactic acid monomer and 0.2g (2mmol) of maleic anhydride into the reaction flask, and start stirring. Under normal pressure, dehydrate at 130°C for 6 hours, then vacuumize with a circulating water vacuum pump, and prepolymerize for 8 hours. After the prepolymerization, add 0.01g catalyst SnO, vacuumize with a rotary vane vacuum oil pump, and polymerize at 140°C for 3h. Release the vacuum, add 1.6g (14mmol) of N-isopropylacrylamide and 0.02g of potassium persulfate, and polymerize at 100°C for 4h. After the polymerization, the product was dissolved with methanol, and then precipitated and washed with deionized water. After filtration, the filter residue was dried in a vacuum oven at 45°C for 24 hours to obtain the copolymer PLAMN 7 , the yield was 49%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com