Technology for solid phase synthesis of peptide by WANG strategy

A strategy and technology of synthesis method, applied in the production process field of bulk preparation of raw materials, can solve the problems of poor purity of crude products, increase the difficulty of purification, etc., and achieve the effects of reducing production cost, improving production feasibility, and improving purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

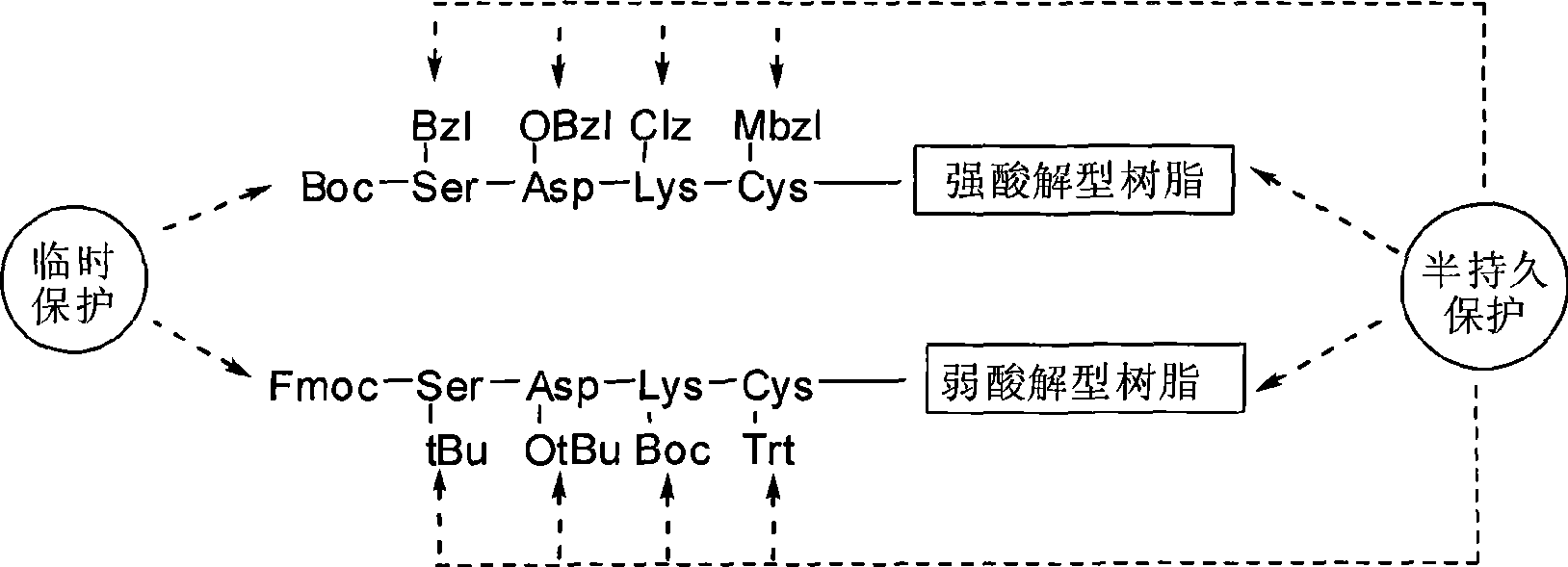

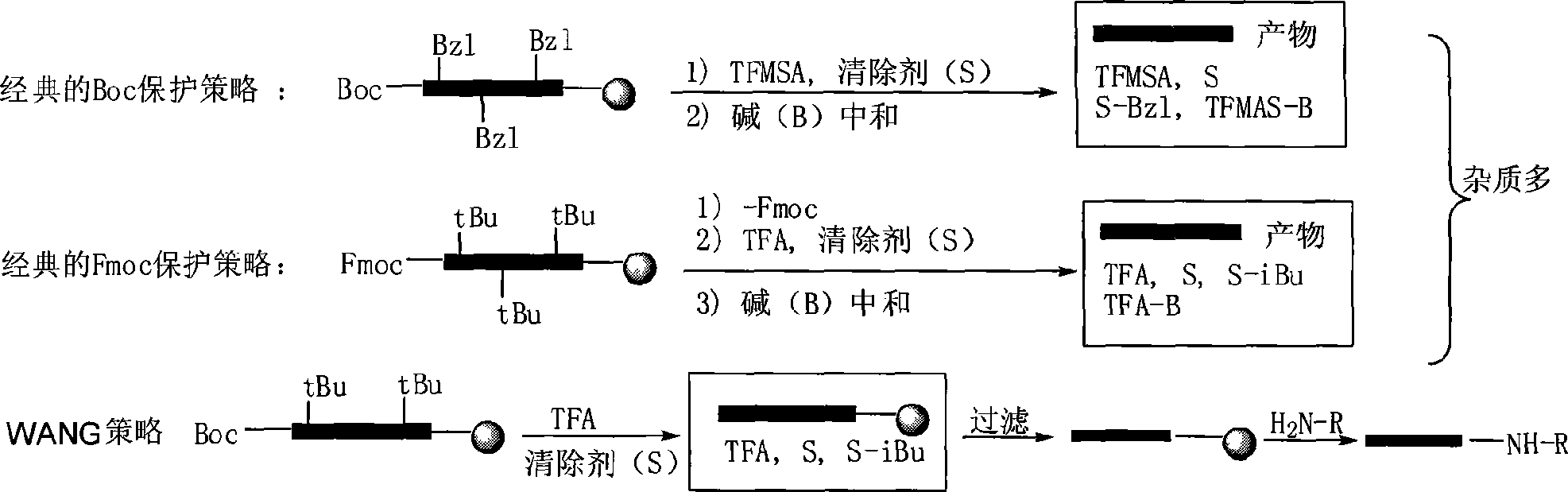

Method used

Image

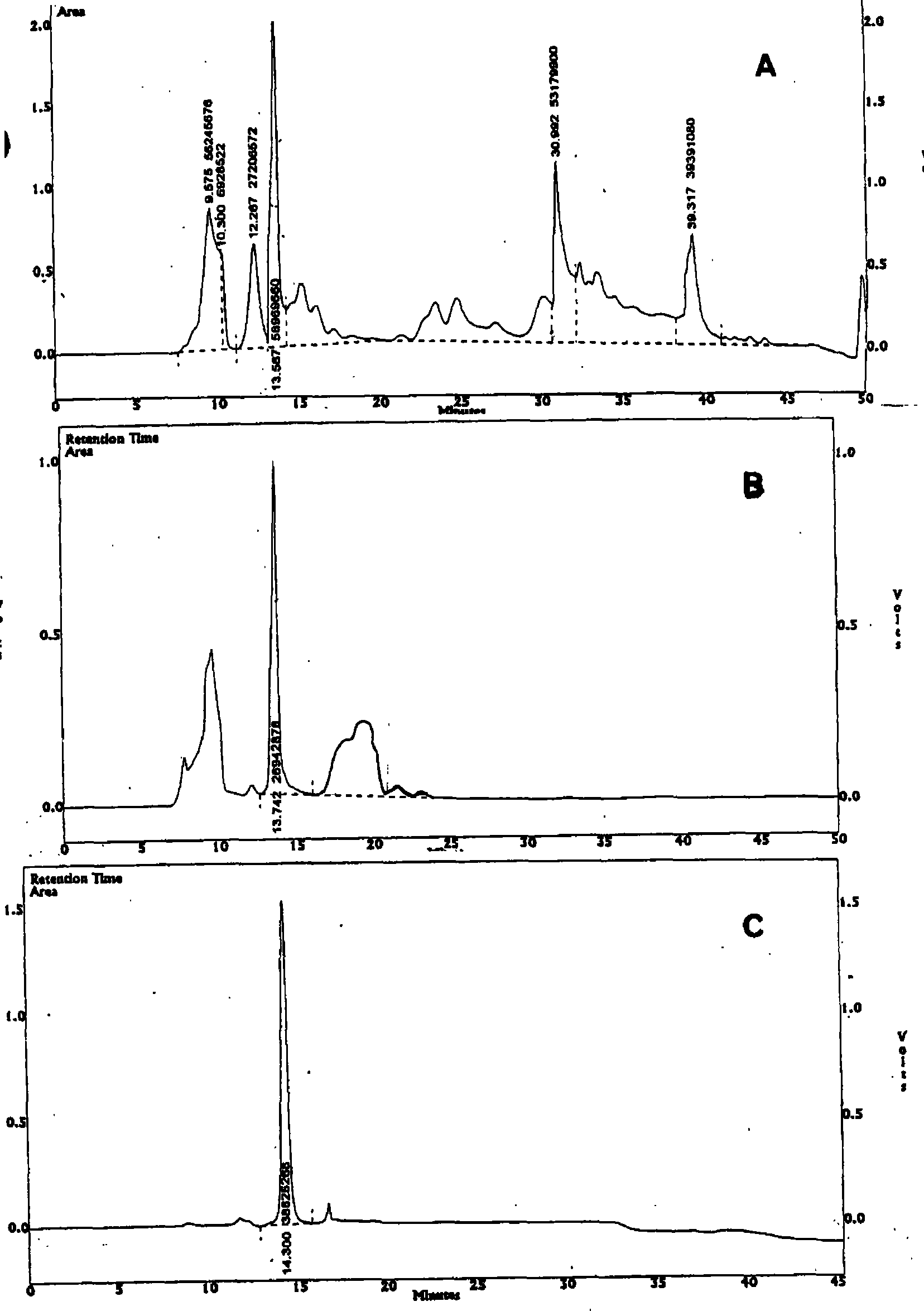

Examples

Embodiment

[0037] 1. Synthesis of TP5 Acylethylamide H-Arg-Lys-Asp-Val-Tyr-NHeT (1)

[0038] ①Boc-Tyr-OCH 2 - Preparation of polystyrene resin

[0039] Weigh 10g (10mmol) of chloromethyl (also known as Merrifield) resin (substitution equivalent 1mmol / g, particle size 100-200 mesh, cross-linking degree 1%), and three times the number of moles of Boc-Tyr-OH.K 2 CO 3 and 1 / 10 mole of KI were blended in 150mL DMF. The suspension was rotated and reacted on a hot bath at 60° C. for 25 h, and the reaction suspension was transferred to a No. G2 sand plate filter tube. Use DMF at about 60°C for diafiltration 5 times, about 50 mL each time. This was followed by diafiltration with the following solvents (× times): 95% EtOH × 3, DMF × 3, 50% EtOH / H 2 O×3, DMF×3, absolute ethanol×3. After fully drying, take out the resin and place it under an infrared lamp at about 50°C, and air-dry it to constant weight. It weighs 12.33g, and the weight gain is 2.33g (theoretical weight gain should be 2.445g)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com