Method for extracting 6-gingerol with content greater than or equal to 98%

A technology of gingerol and content, applied in chemical instruments and methods, preparation of organic compounds, separation/purification of carbonyl compounds, etc., can solve the problem that the quality cannot reach high quality, the key production points are not well controlled, and the large-scale production products are not available. and other problems, to achieve the effect of shortening the purification cycle, no pesticide residues, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

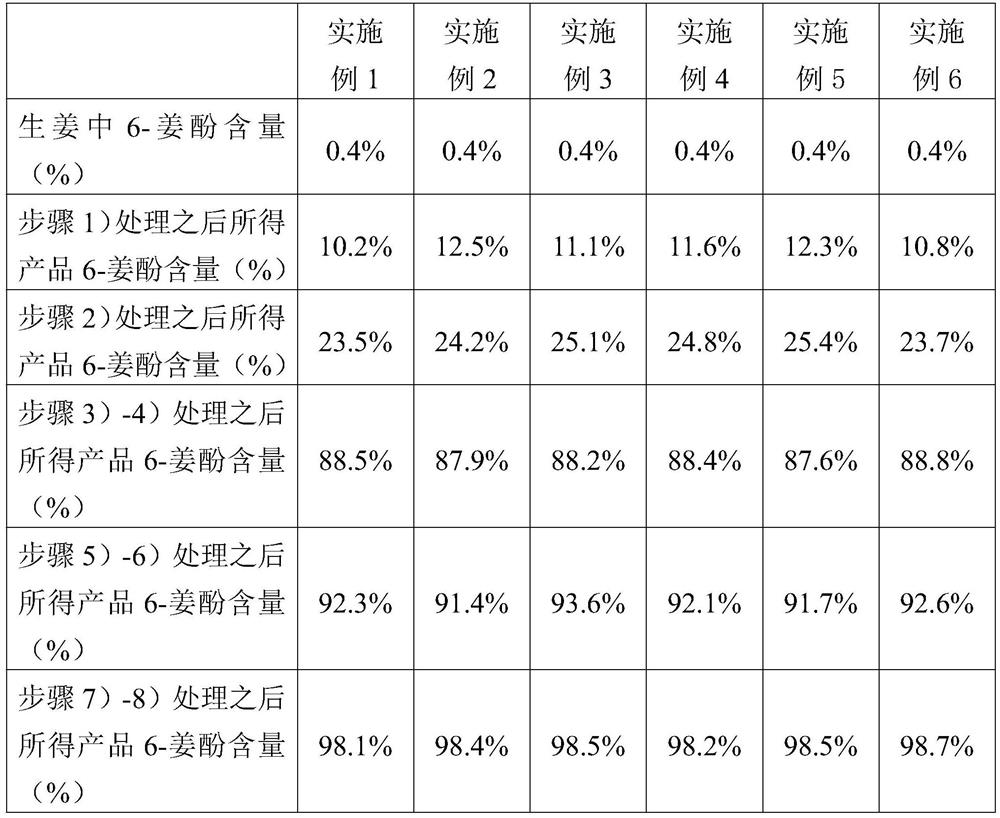

Examples

Embodiment 1

[0029] 1) Get 2kg of dried ginger (the content of 6-gingerol detected by HPLC is 0.4%), be pulverized to 100 orders, and the material is put into a flash extractor, and extracted with 75vt% ethanol (vt% is percent volume concentration) Solvent, adding 18 times the weight of ginger, extracting at room temperature for 3 minutes at a motor speed of 5000r / min, and extracting 3 times, each time for one minute. Rest for 2 minutes between extractions. The filtrate was separated, and the filtrates extracted 3 times were combined to obtain the total filtrate;

[0030] 2) Concentrate the total filtrate membrane to 2000ML, adjust the ethanol concentration of the concentrate to 50vt% with 96vt% ethanol, stir evenly, enter the alumina column chromatography, the alumina and ginger mass ratio contained in the chromatography column is 2 : 1, the alumina is neutral alumina, the number of meshes is 100 meshes, and the flow rate of the concentrated solution into the column is 1BV / h. After the c...

Embodiment 2

[0038] 1) Get 2kg of dried ginger (the content of 6-gingerol detected by HPLC is 0.4%), pulverize to 150 orders, put the material into a flash extractor, use 78vt% ethanol as the extraction solvent, add 19 times the solvent of ginger weight , under the condition of motor speed 5500r / min, extract at room temperature for 3 minutes, extract 3 times, each time for one minute. Rest for 2 minutes between extractions. The filtrate was separated, and the filtrates extracted 3 times were combined to obtain the total filtrate;

[0039]2) Concentrate the total filtrate through membrane to 2000ML, adjust the ethanol concentration of the concentrated solution to 55vt% with 98vt% ethanol, stir evenly, enter the alumina column chromatography, the mass ratio of alumina and ginger contained in the chromatography column is 2.5 : 1, the alumina is neutral alumina, the number of meshes is 150 meshes, and the flow rate of the concentrated solution into the column is 1.2BV / h. After the column is c...

Embodiment 3

[0047] 1) Get 2kg of dried ginger (the content of 6-gingerol detected by HPLC is 0.4%), be pulverized to 200 orders, and the material is put into a flash extractor, and 80vt% ethanol (vt% is volume percentage concentration) is used as extraction Solvent, add 20 times the weight of ginger, extract at normal temperature for 4 minutes under the condition of motor speed 6000r / min, extract 4 times, each time for one minute. Rest for 2 minutes between extractions. Separating the filtrate, merging the filtrates extracted for 3-4 times to obtain the total filtrate;

[0048] 2) Concentrate the total filtrate membrane to 2000ML, adjust the ethanol concentration of the concentrate to 60vt% with 97vt% ethanol, stir evenly, enter the alumina column chromatography, the mass ratio of alumina and ginger contained in the chromatography column is 3 : 1, the alumina is neutral alumina, the number of meshes is 200 meshes, the flow rate of the concentrated solution into the column is 1.5BV / h, aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com