Patents

Literature

64results about How to "Increase the total output value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

RGB to RGBW color decomposition method and system

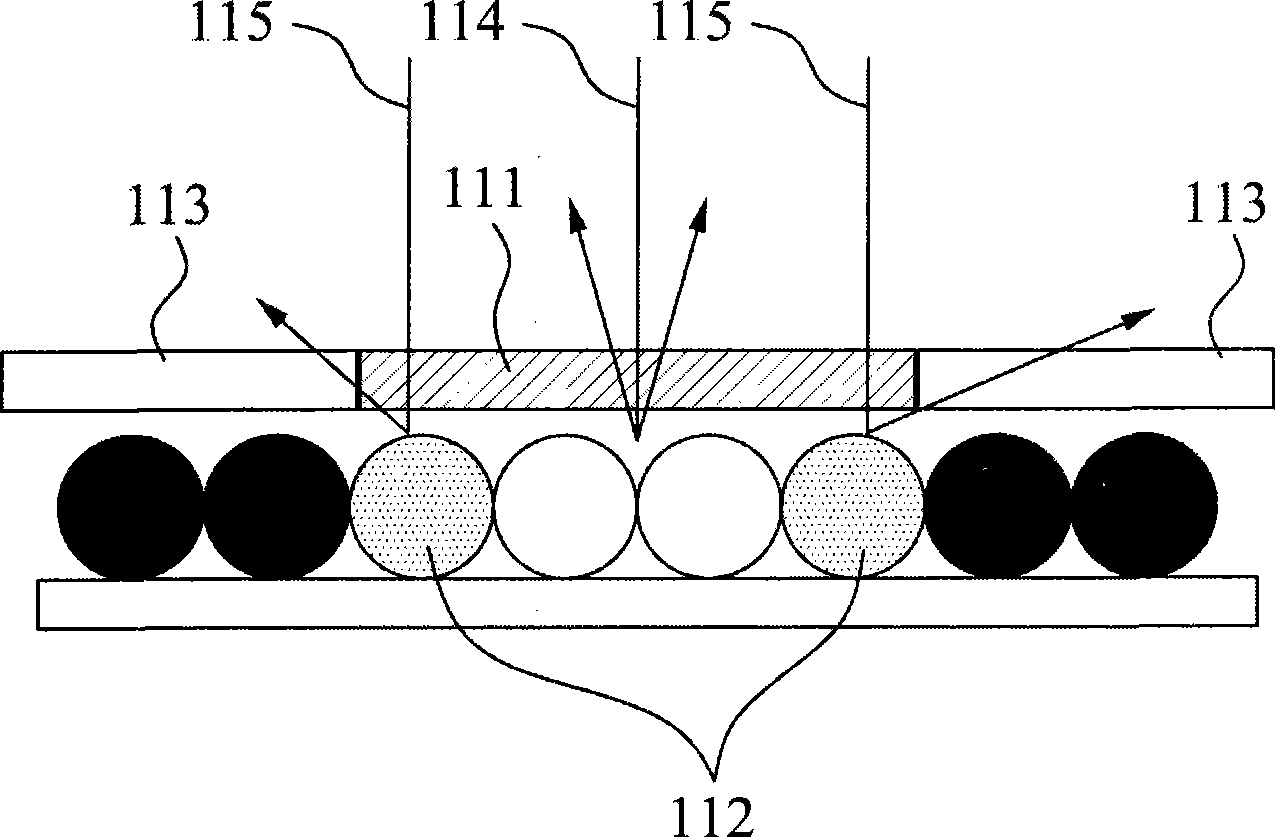

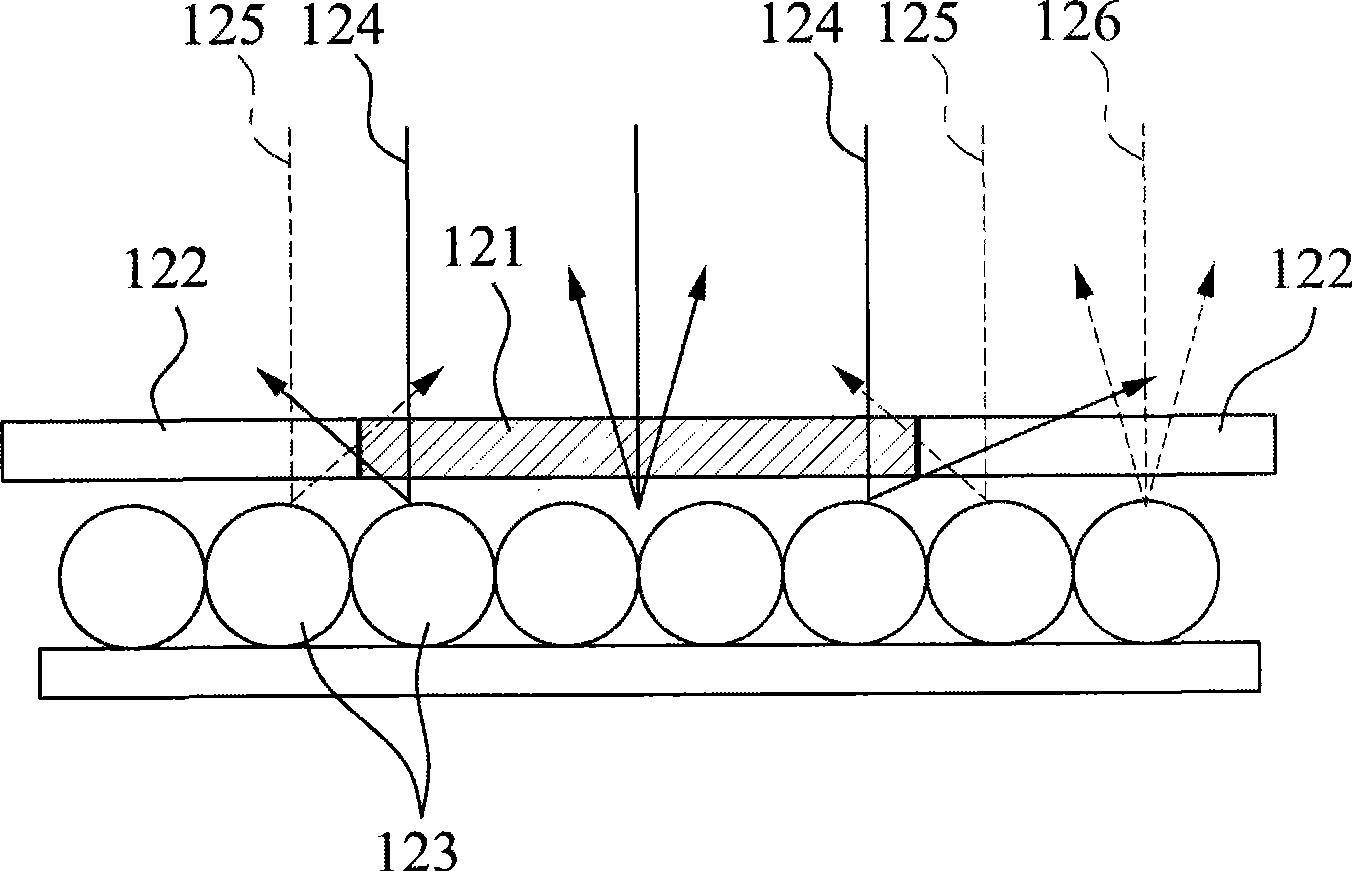

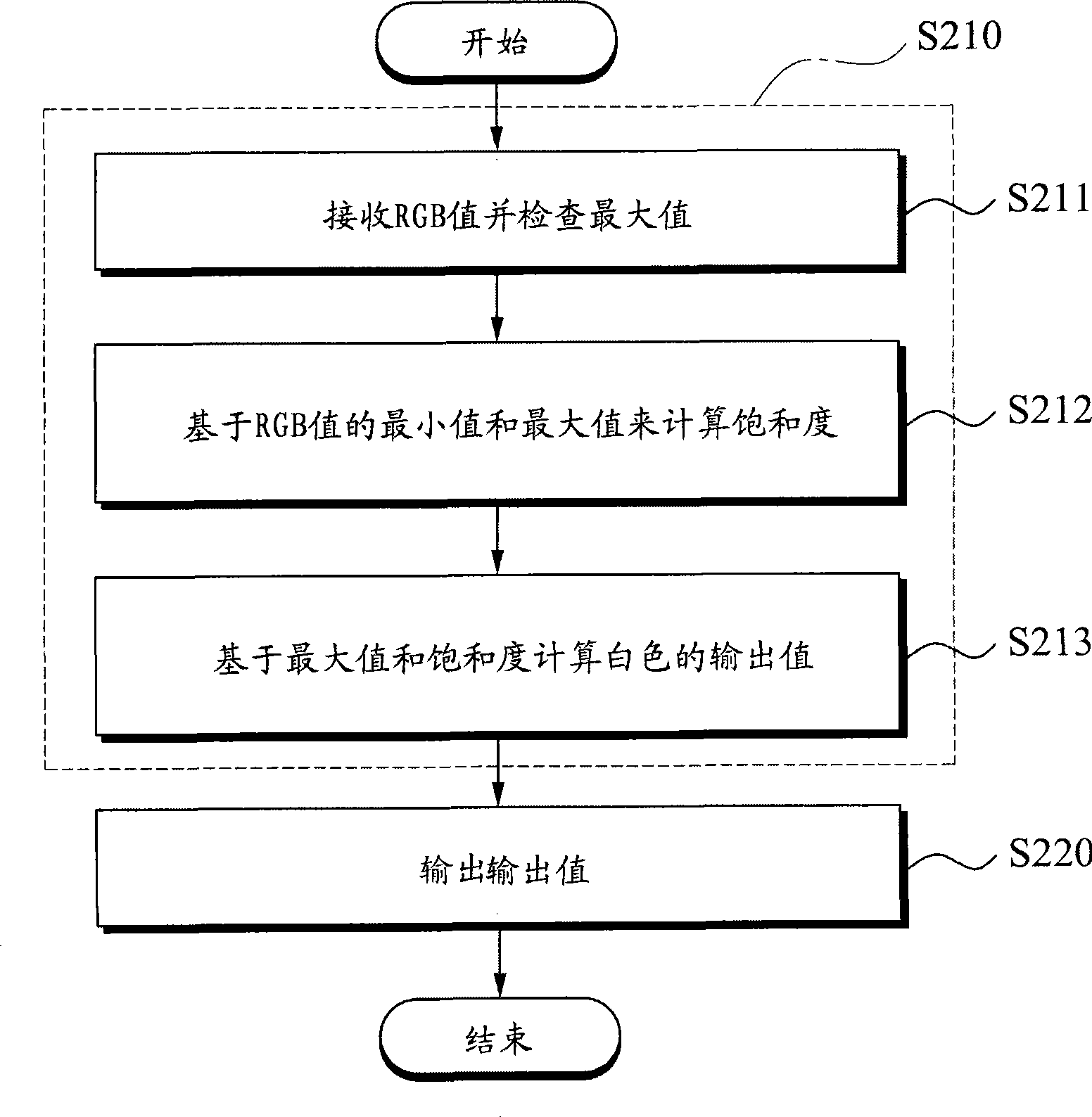

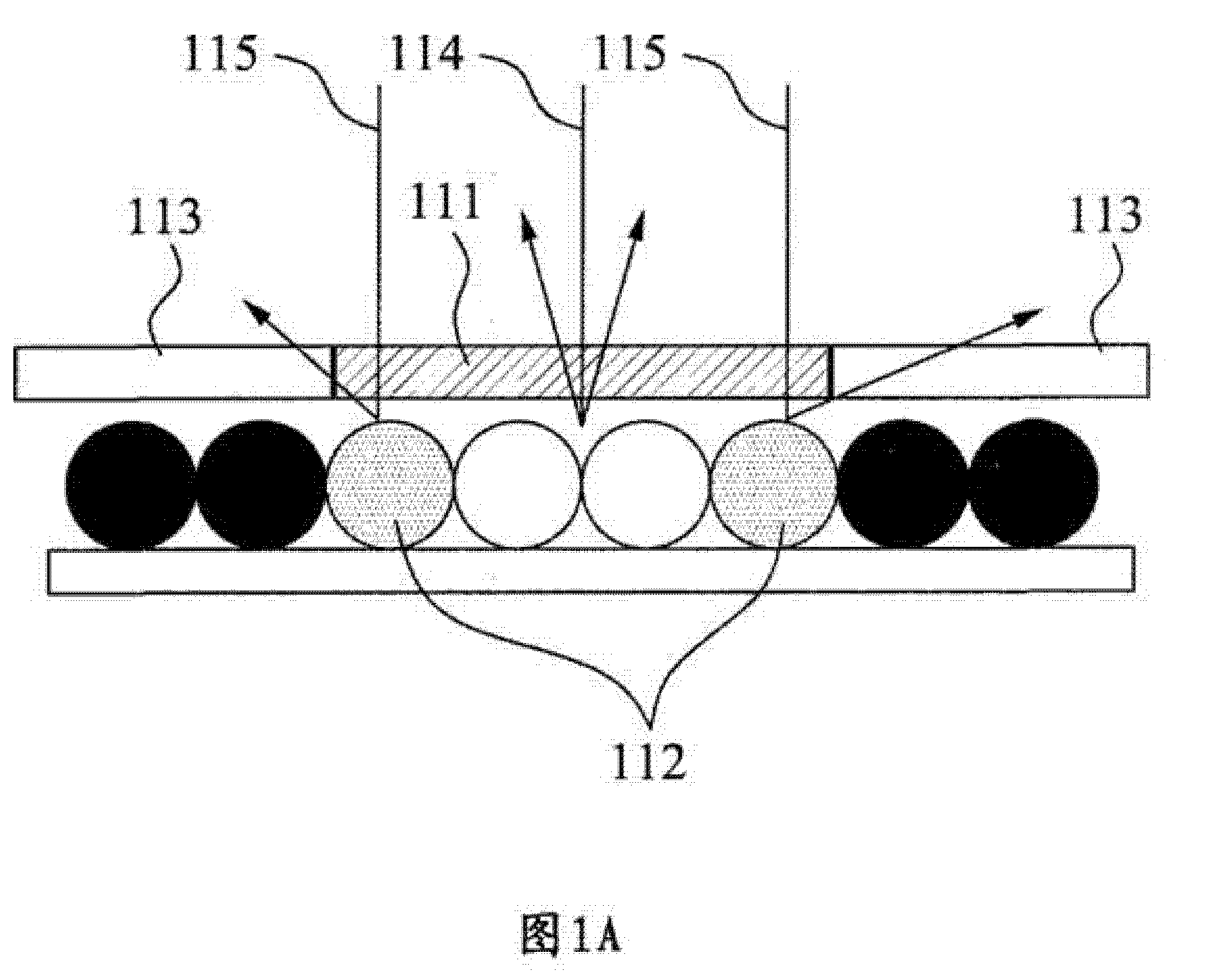

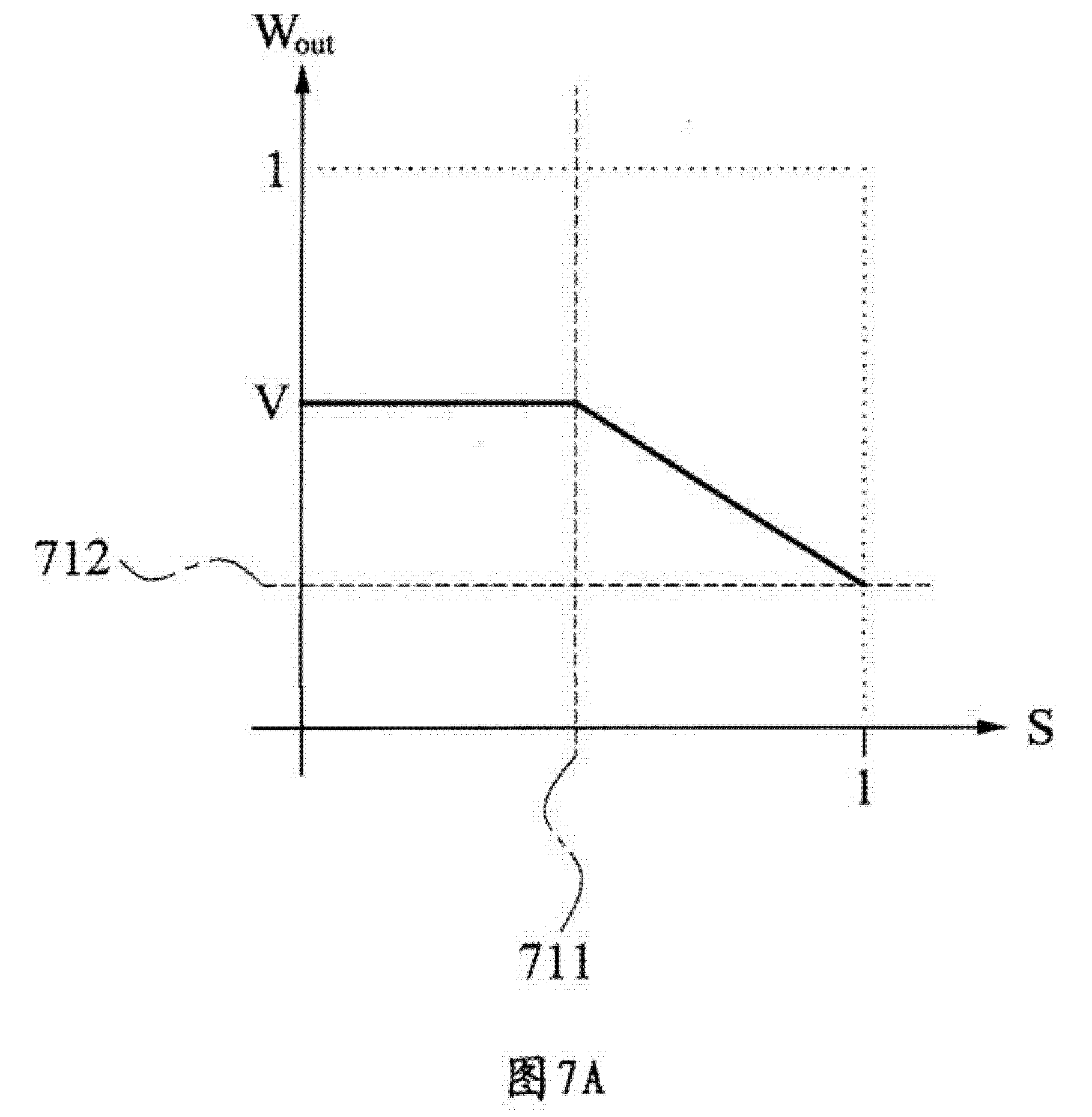

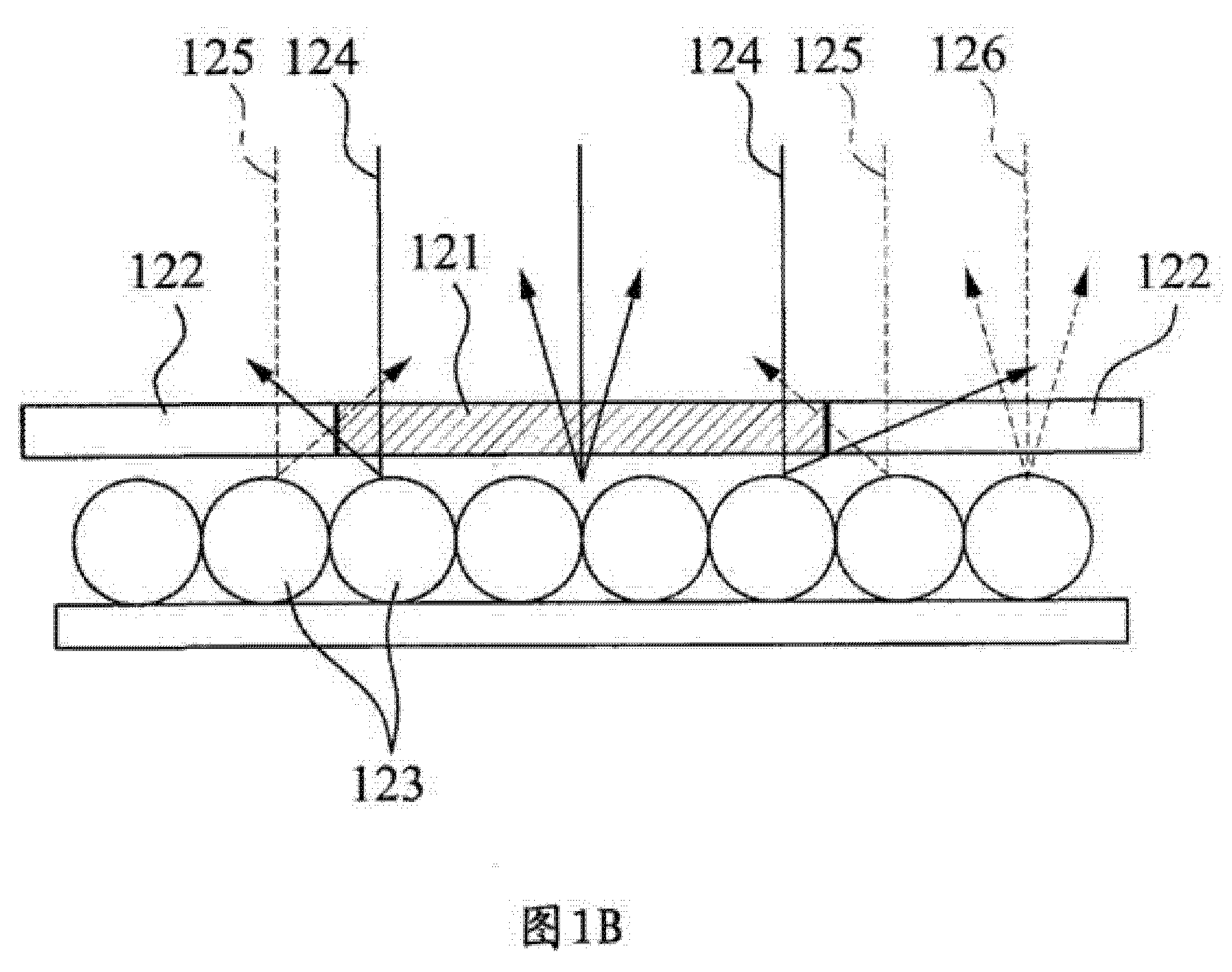

ActiveCN101370148AImprove reflectivityDesaturationColor signal processing circuitsCathode-ray tube indicatorsPattern recognition

A Red Green Blue-to-Red Green Blue White (RGB-to-RGBW) color decomposition method and system. The RGB-to-RGBW color decomposition method includes: determining an output value of white based on inputted RGB values and a saturation; and outputting the output value when an input color is a pure color.

Owner:SAMSUNG ELECTRONICS CO LTD

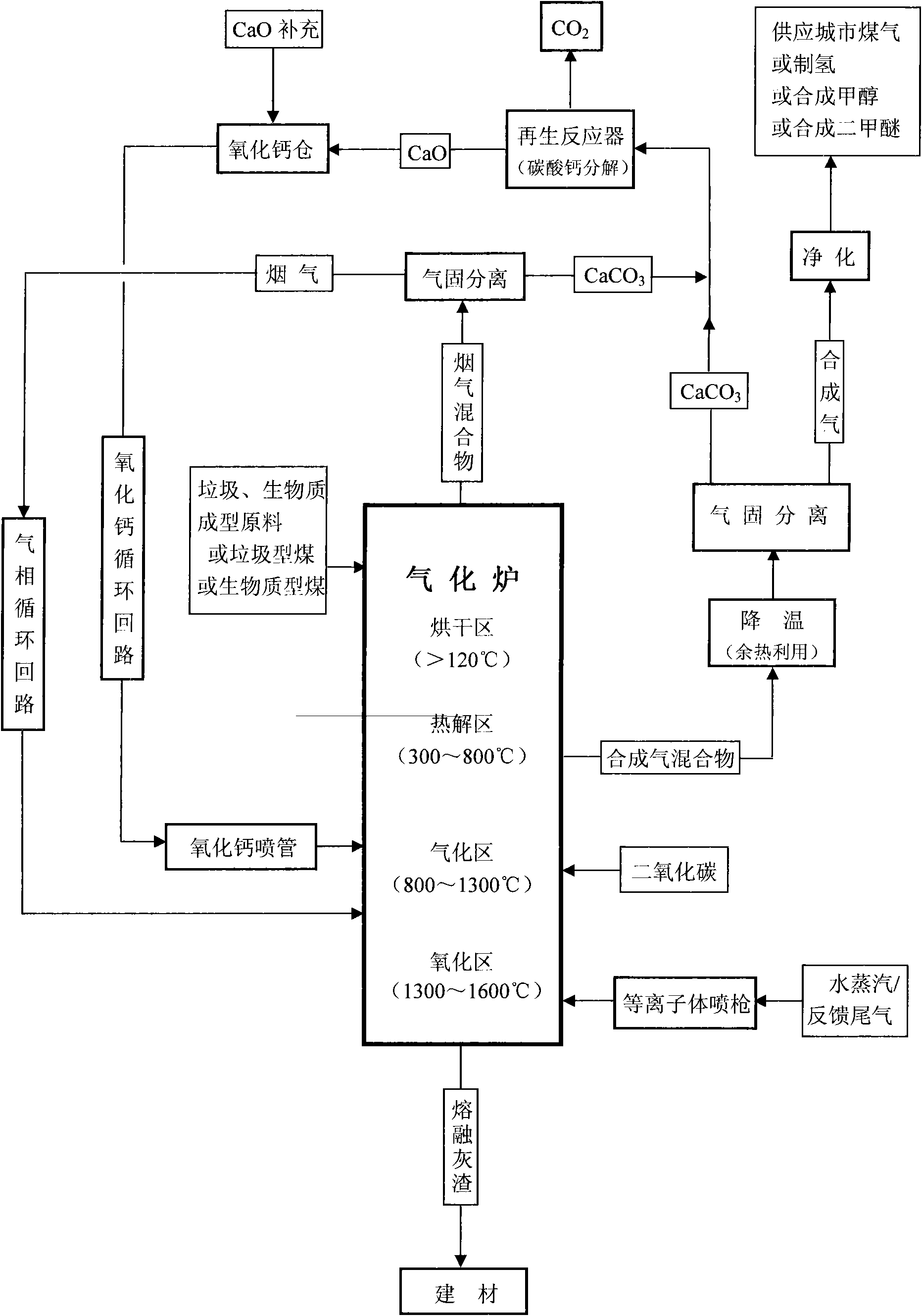

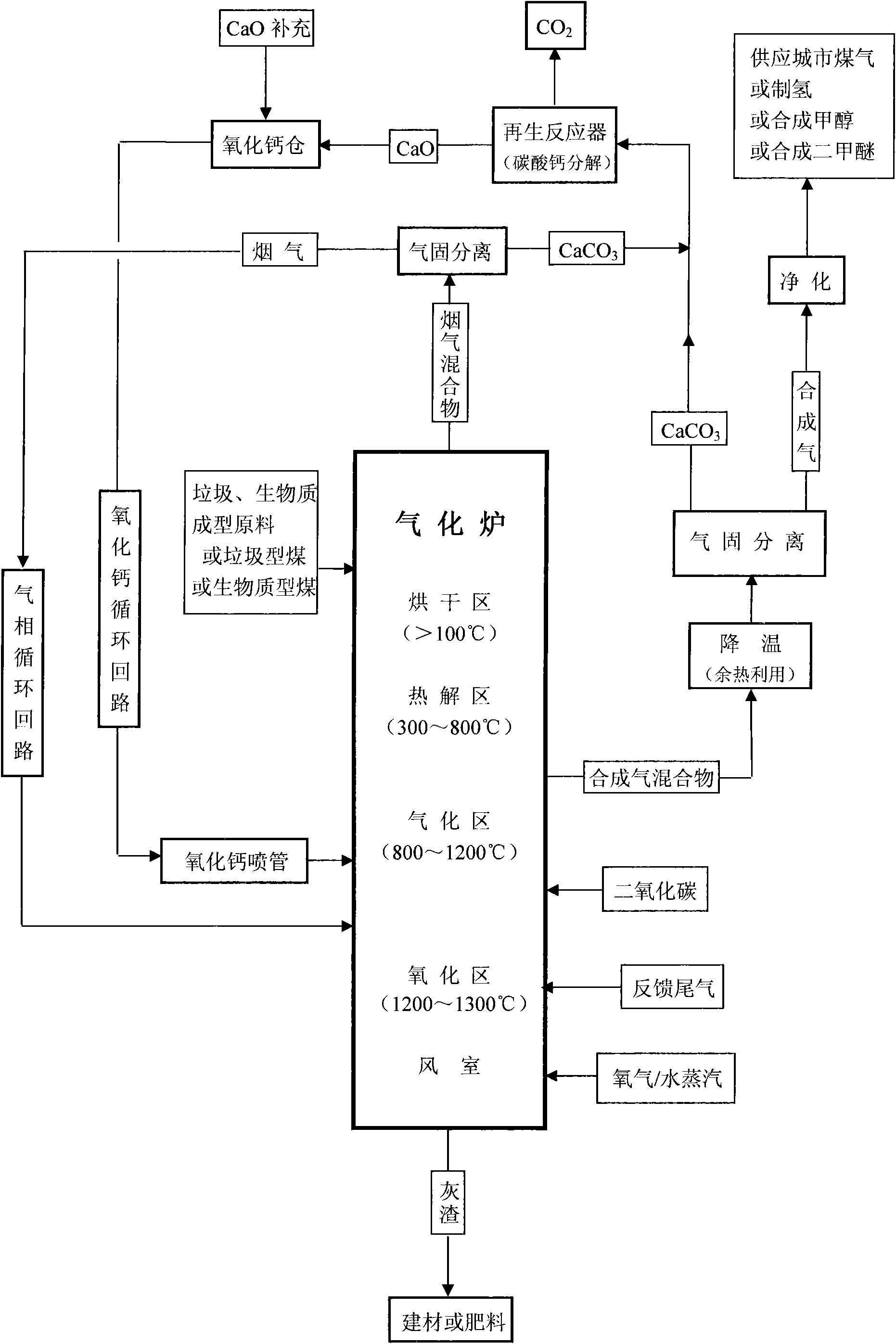

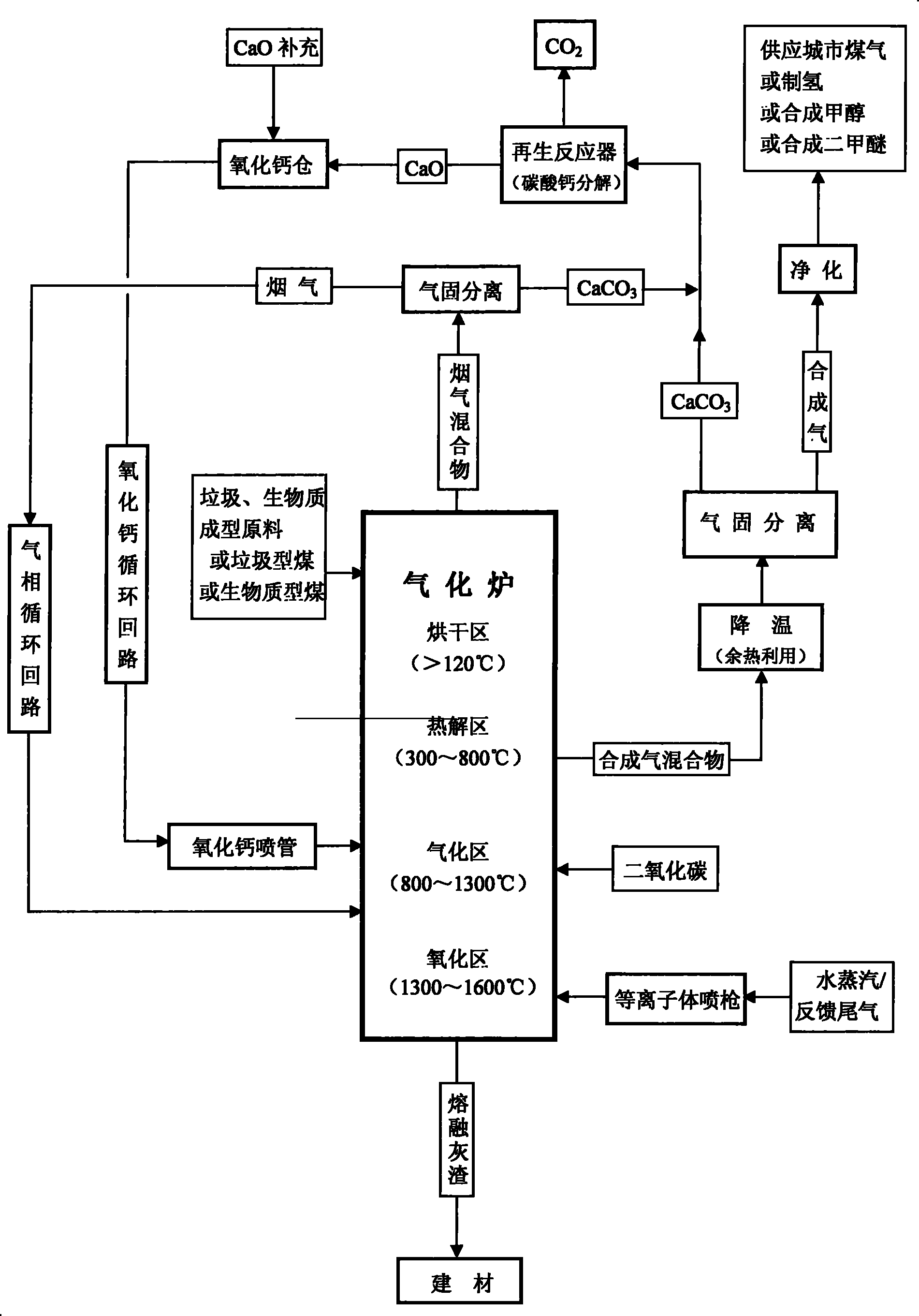

Gasification process for producing synthesis gas from garbage and biomass raw materials

InactiveCN101525118AEliminate pollutionHarmlessHydrogen productionSpecial form destructive distillationGas phaseWater vapor

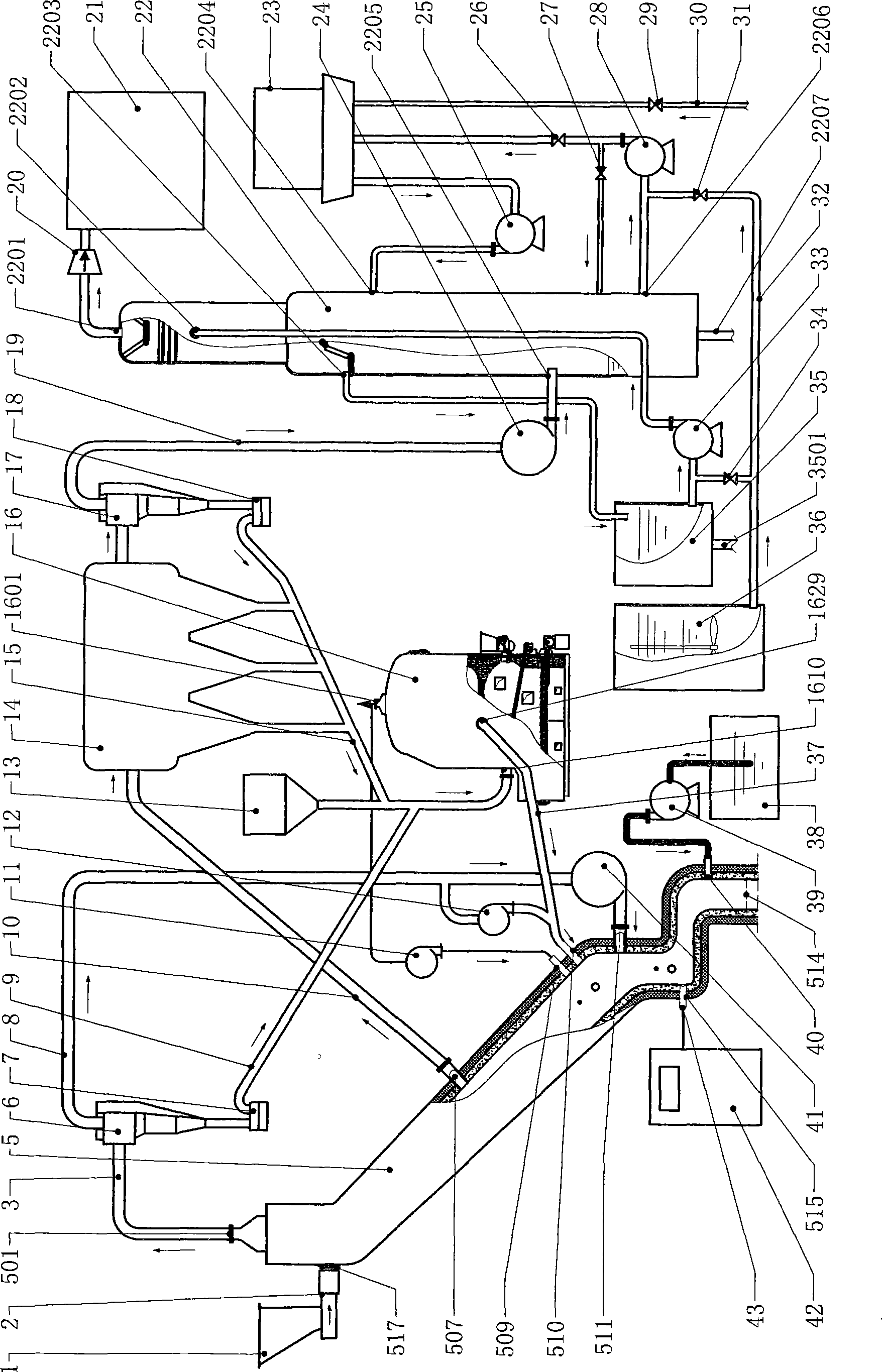

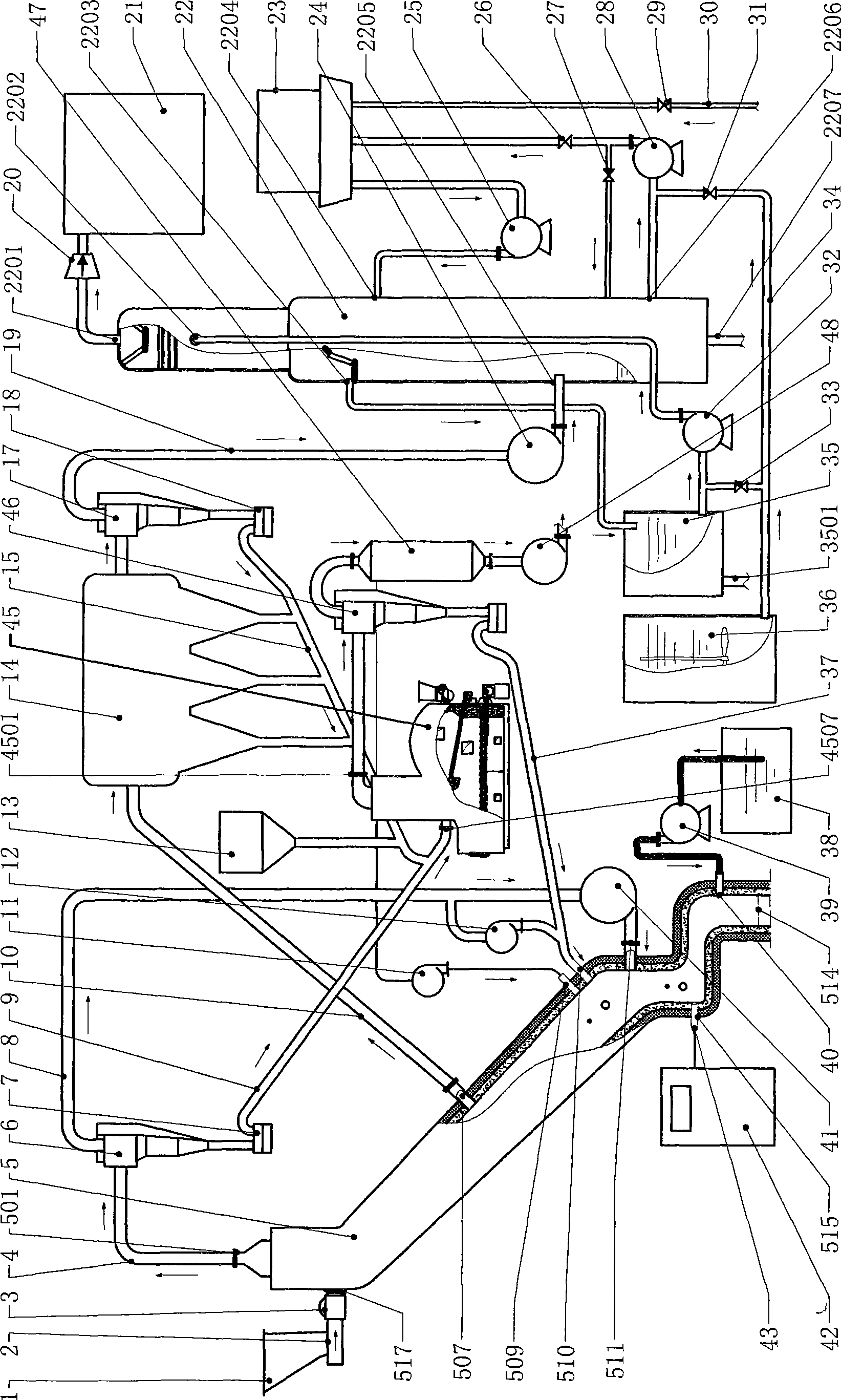

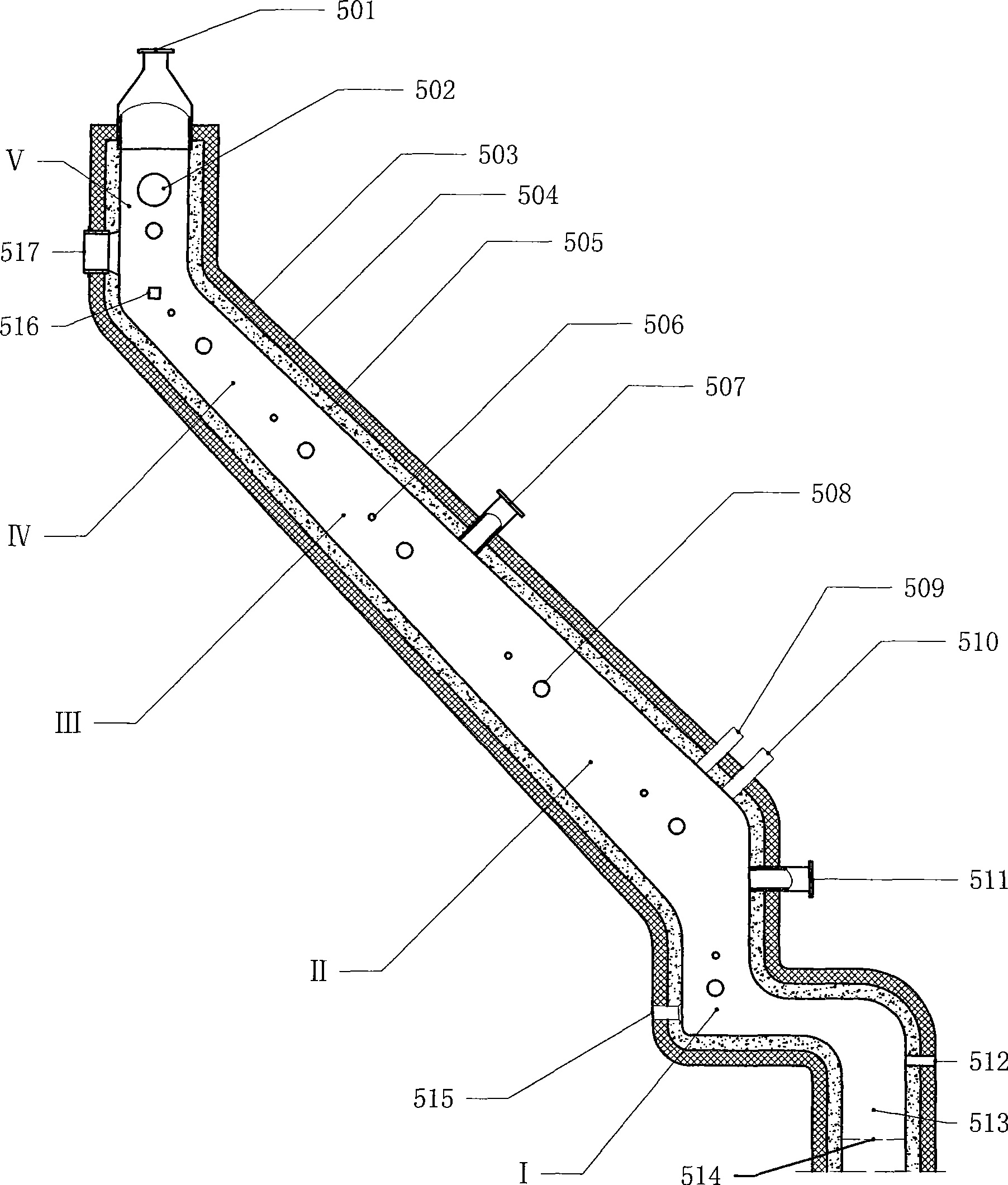

The invention provides a gasification process for producing synthesis gas from garbage and biomass raw materials, which relates to a gasification processing technique of garbage and biomasses. The gasification process is characterized in that the technological process mainly comprises a raw material solid matter process, a gas phase circulation loop, a calcium oxide circulation loop and a synthesis gas drawing process; one or a mixture of more garbage, the biomasses and coal is sent into a gasification furnace to perform gasification so as to generate the synthesis gas; and simultaneously, calcium oxide is sent into the gasification furnace, an exothermic reaction of absorbing carbon dioxide by the calcium oxide provides the heat required by the gasification reaction in the furnace, and water vapor is sent into a plasma spraying gun and is heated to more than 3,100 DEG C to generate H2, O, O2 and H2O<*> which are sprayed into the gasification furnace to perform reactions with the garbage and the biomasses and supply heat into the furnace. The gasification process adopts a measure to spray the calcium oxide into the furnace to not only greatly reduce the electric energy consumption of the plasma spraying gun, but also improve the quality and the yield of the synthesis gas, thus the aim of transforming the garbage and the biomasses into clean energy can be achieved easily.

Owner:周开根

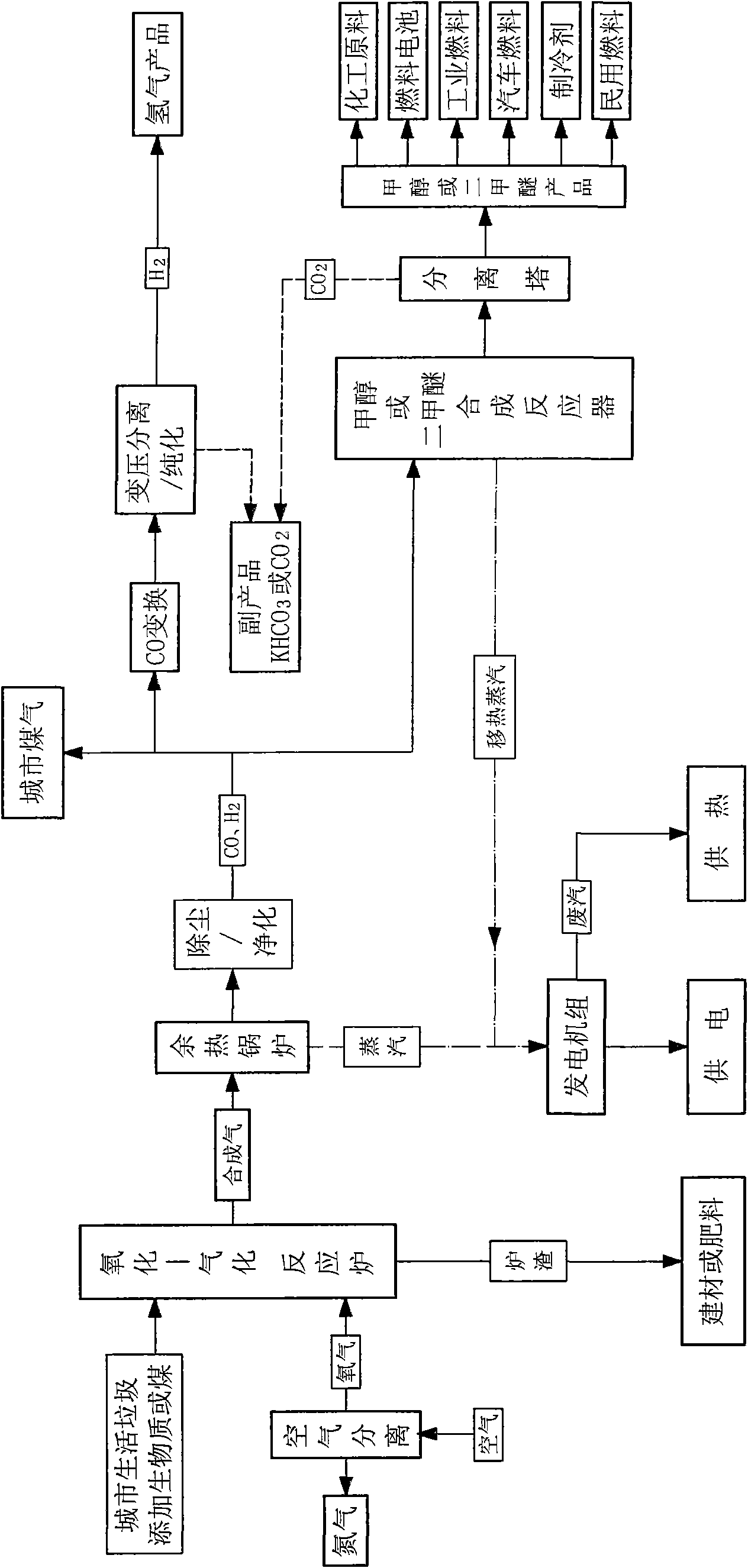

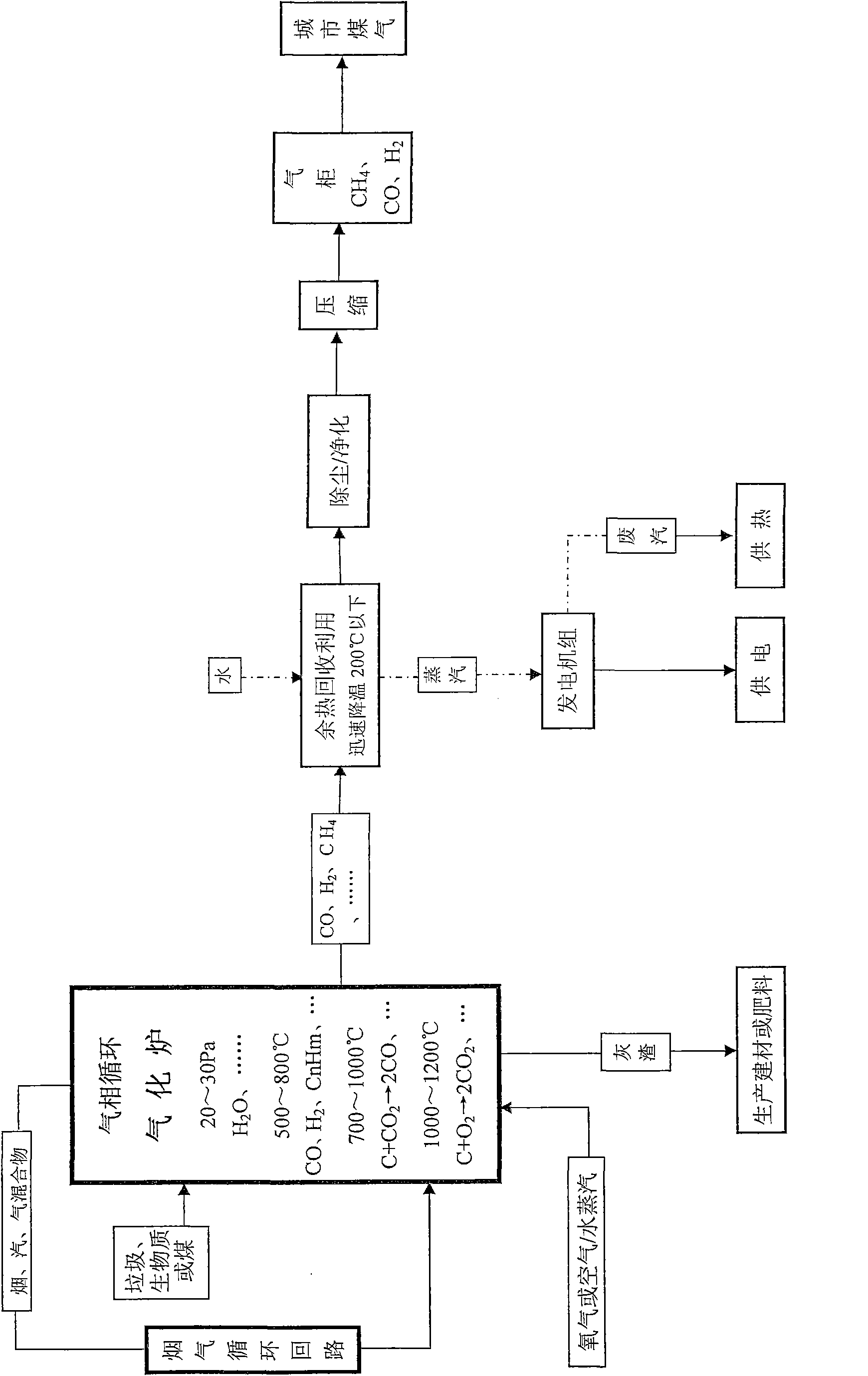

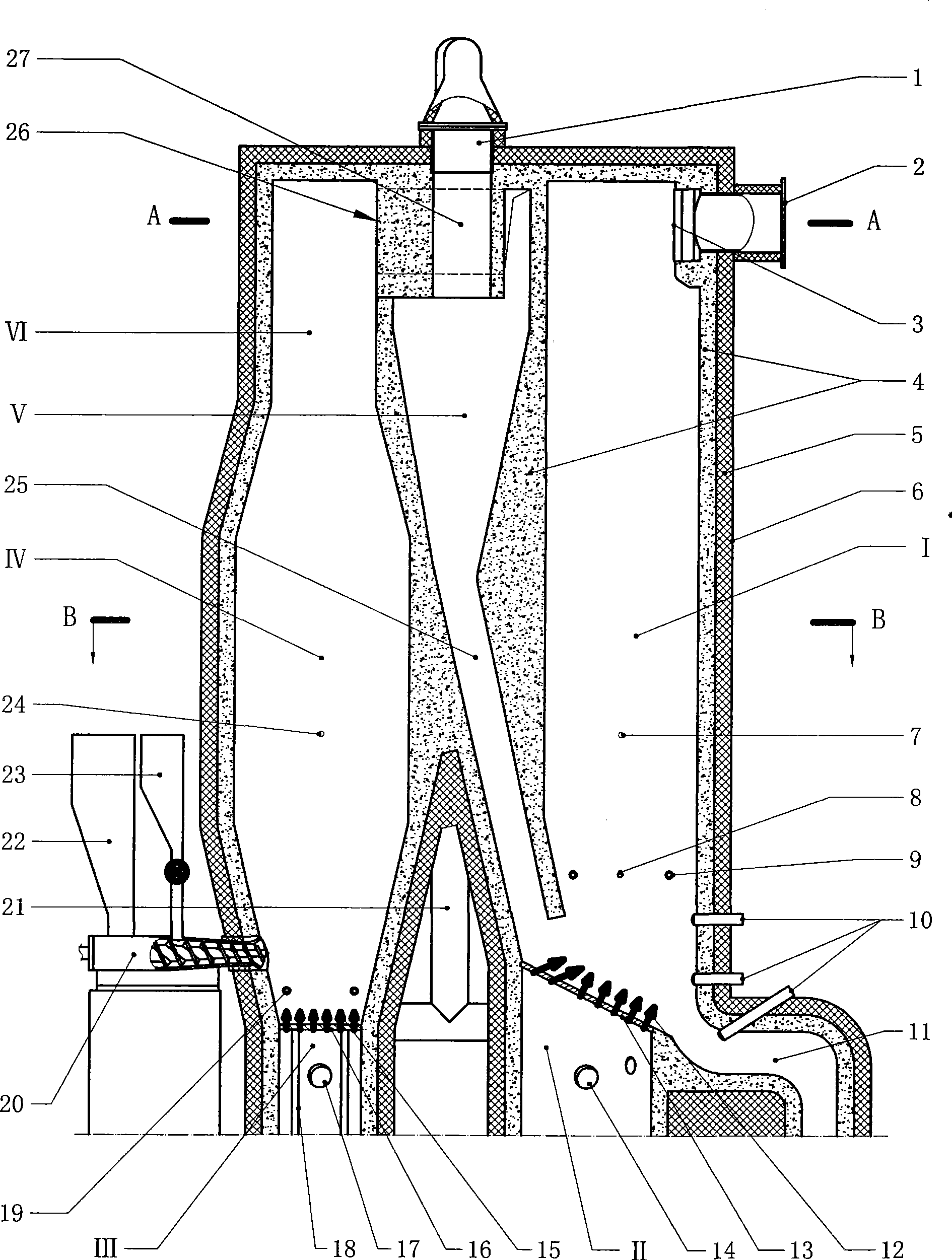

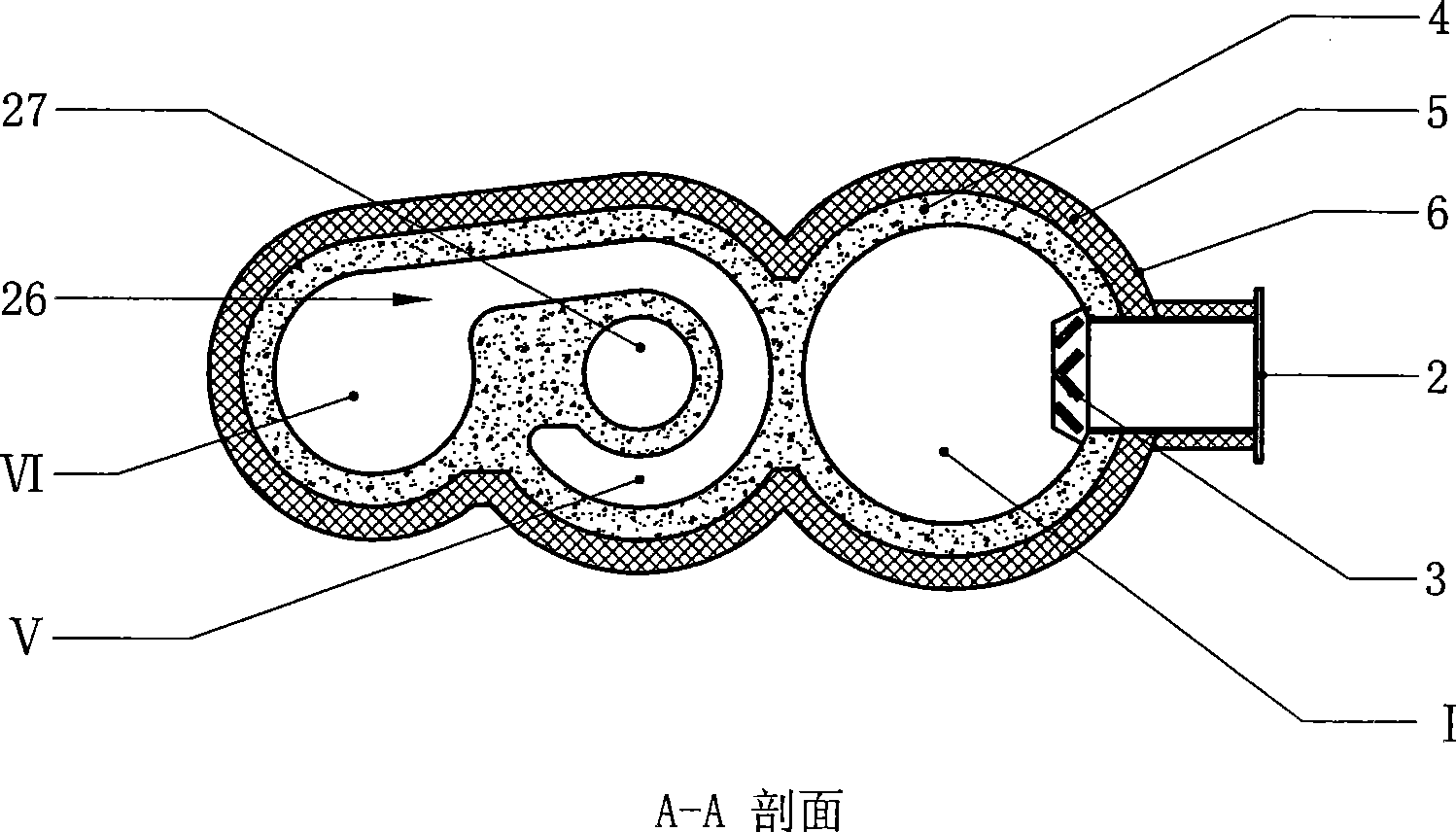

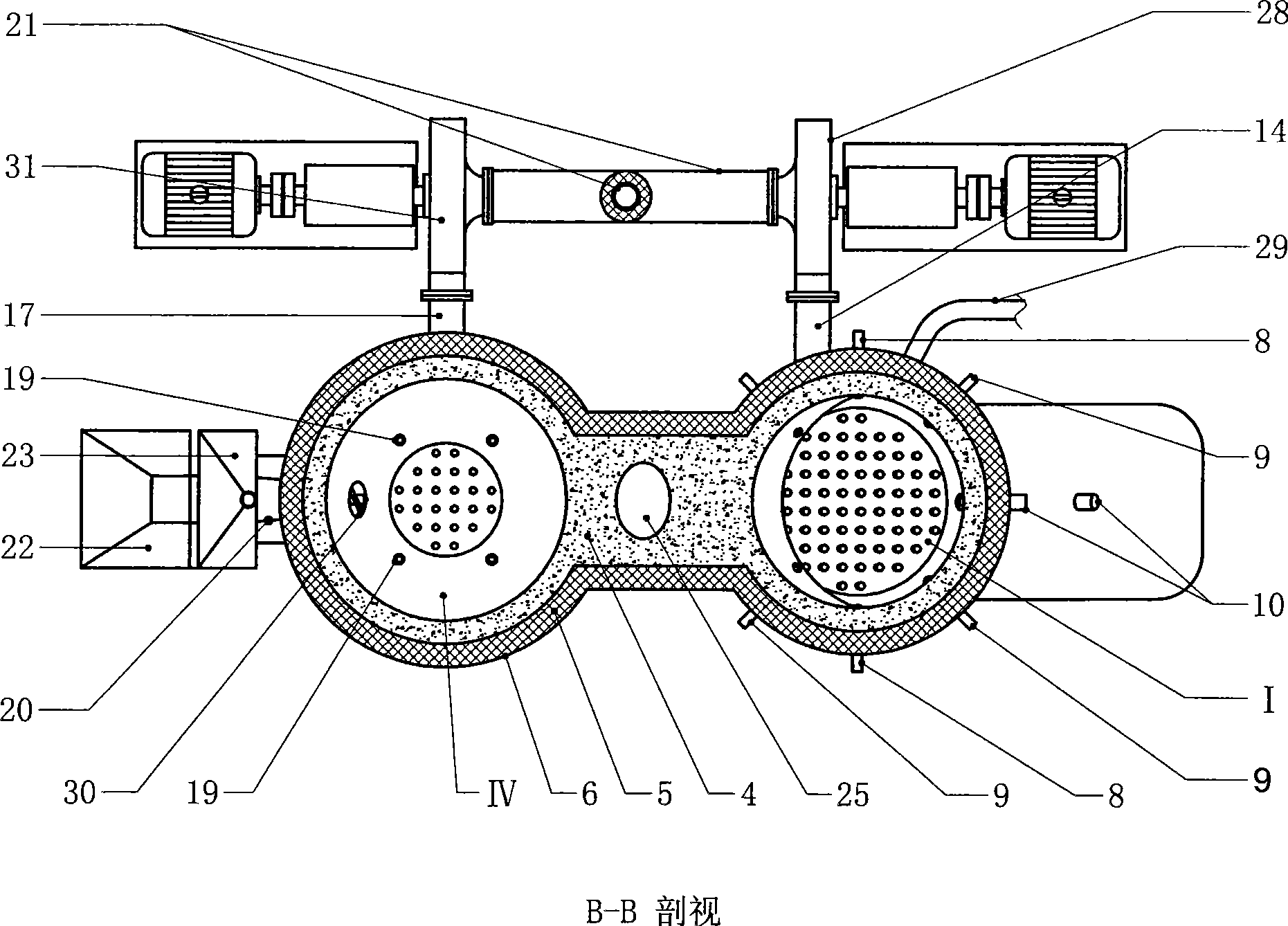

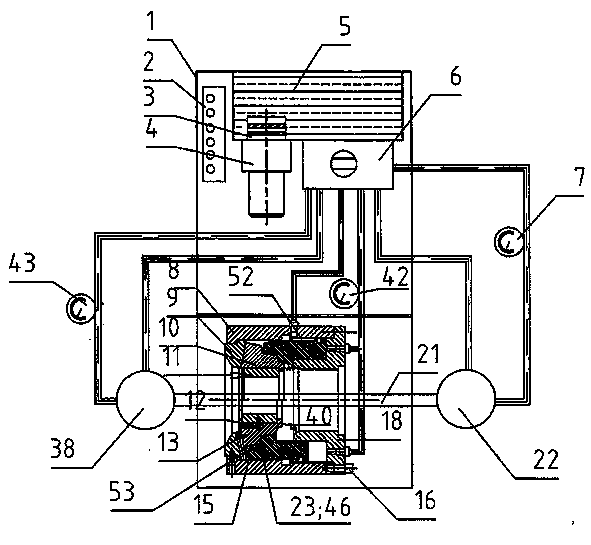

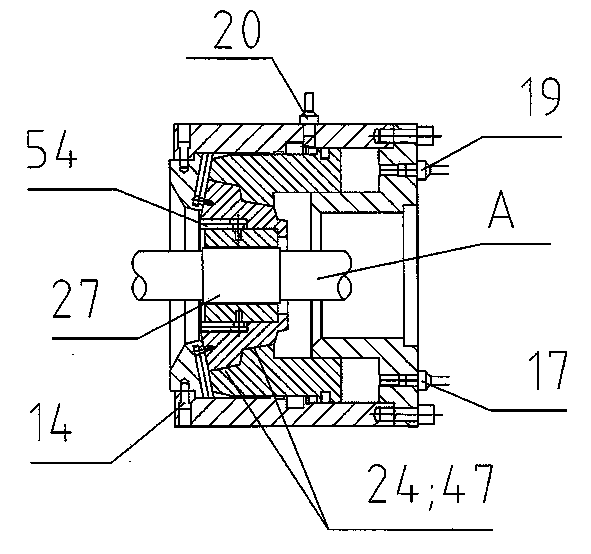

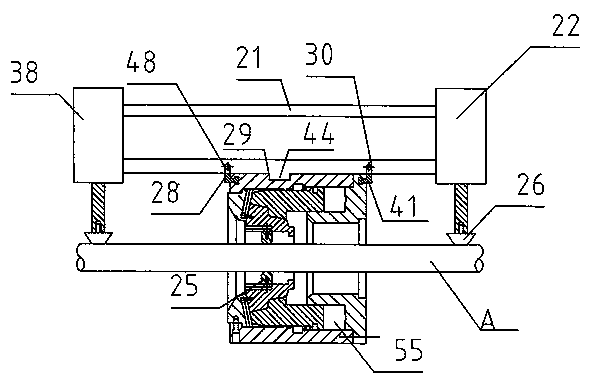

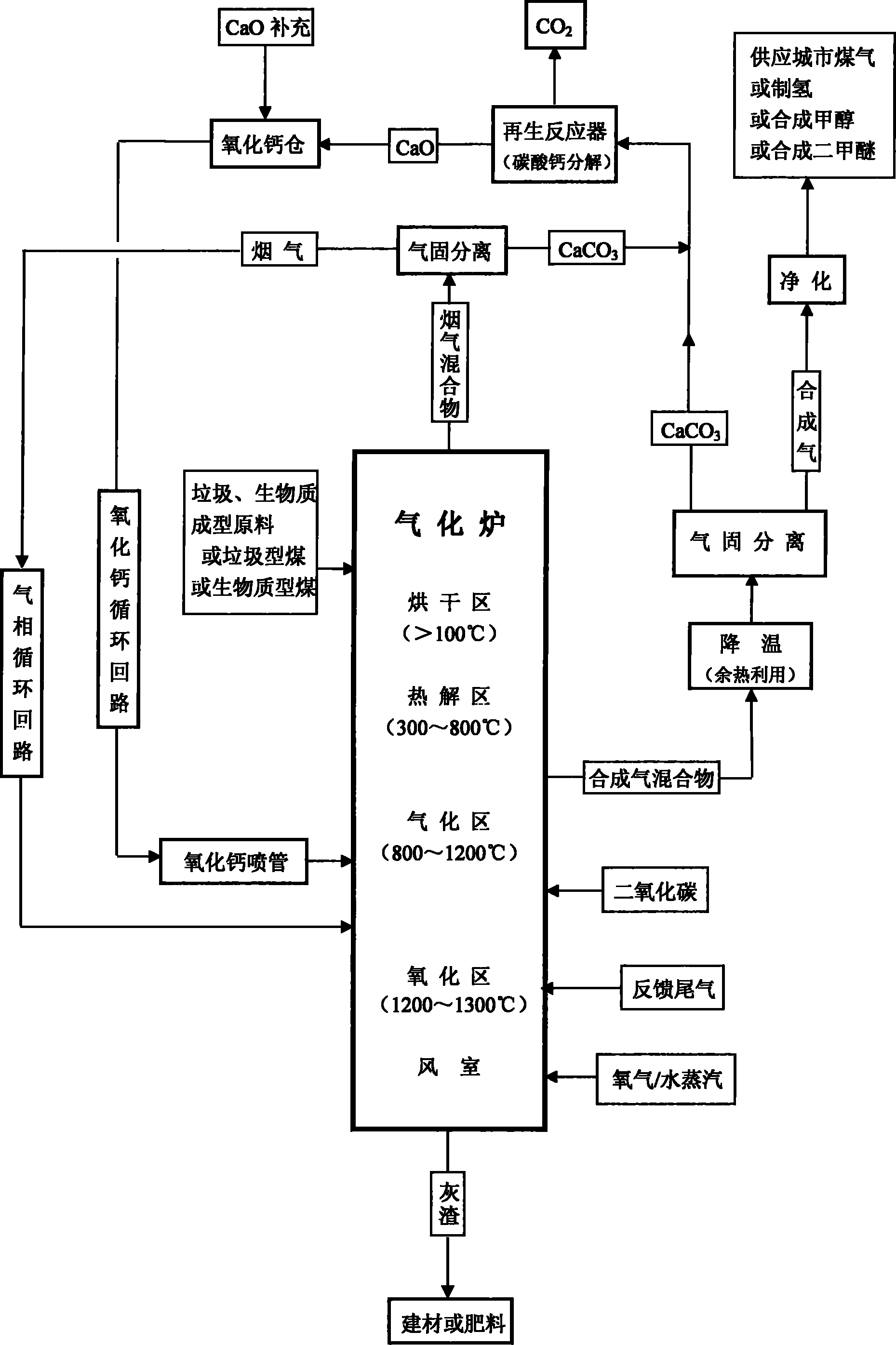

Process, system and device for waste biomass multi-production processing

ActiveCN101565629AEliminate pollutionHarmlessHydrogen separationCombustible gas catalytic treatmentEcological environmentGas phase

The invention relates to a process, a system and a device for waste biomass multi-production processing, in particular to a waste biomass gasification and liquefaction treatment system. The gasification treatment is performed to the waste biomass, the gas is used for producing clean energy and chemical raw materials, the furnace slag is used for producing building materials or fertilizer and the waste heat is used for electric power generation and heat supply so as to realize the environmental-friendly municipal solid waste treatment and the ecological environment protection. The system mainlycomprises a gas-phase circulation gasification furnace, a flue gas circulation air tube, a flue gas circulation fan, a dust-removal / purifying tower and a synthesis reactor and is characterized in that the gas-phase circular reaction is performed to the flue gas in the gasification furnace, the water vapor and the gaseous matter generated during the pyrolysis to obtain hydrogen-rich synthetic gas,and meanwhile, the dioxin (violent in toxicity) is broken up; and the post treatment is performed to the hydrogen-rich synthetic gas to generate city gas, methanol, dimethyl ether or hydrogen. The system has the advantages of full gasification of the solid raw material, no pollutant discharge, extremely low exhaust emission and easy purifying treatment, and the device is flexible in size and is feasible for popularization.

Owner:上海格灵迈环境科技有限公司

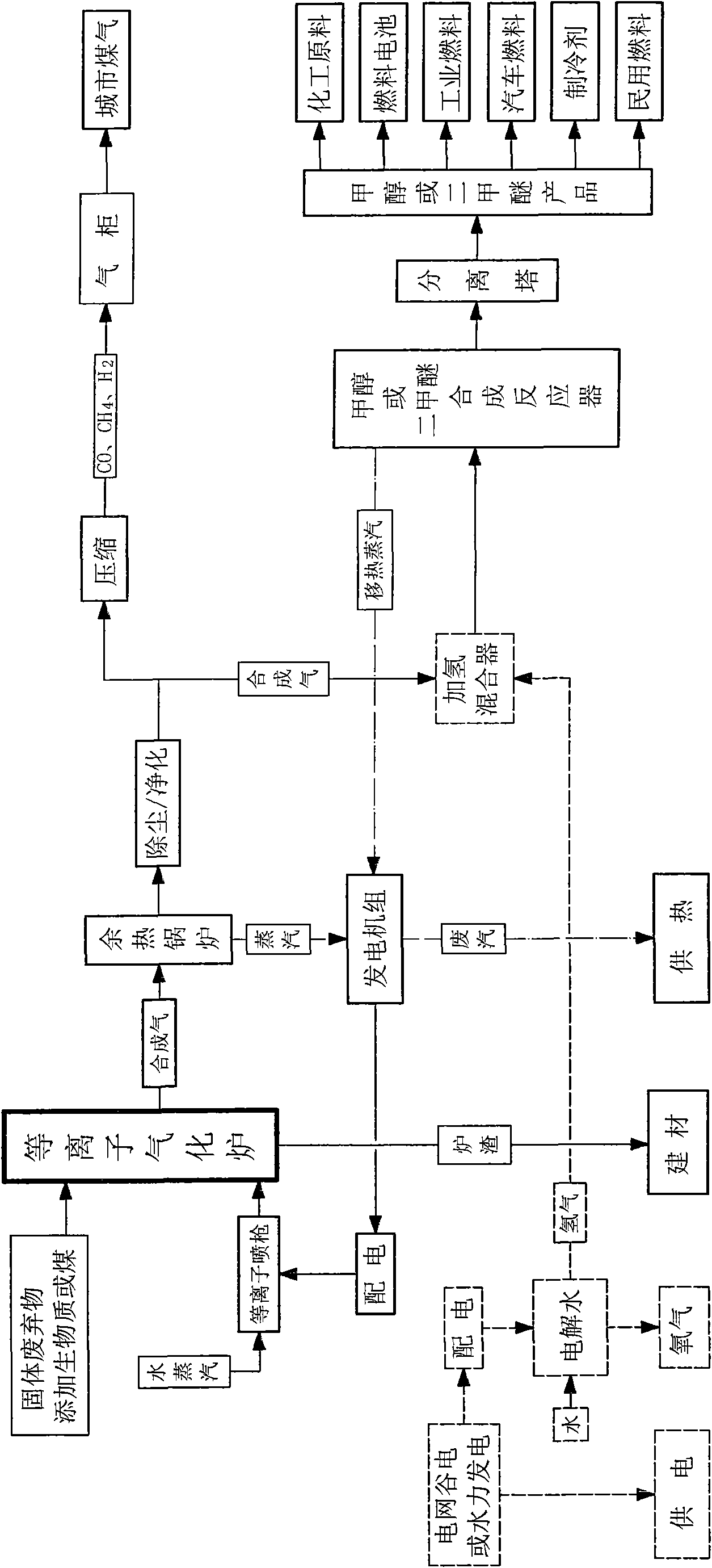

Plasma and calcium oxide cooperation-gasified rubbish biomass gasification method and equipment

InactiveCN101469865AReduce contentHigh calorific valueSpecial form destructive distillationIncinerator apparatusNew energyWater vapor

A method and apparatus for gasifying a plasma and calcium oxide cooperating with gasified rubbish biomass, relating to the rubbish processing and new energy resource field, characterized in that, the rubbish biomass is fed into a suspending fluidized bed thermal decomposition furnace, meanwhile, the heated fluidization material is circularly fed into the thermal decomposition furnace and is mixed with the raw materials to transfer heat, so that the rubbish biomass raw material is heated to decompose, and then the thermal decomposed gas and solid carbocoal is fed into a turbulent fluidized bed gasification furnace, the water vapor is heated over 3100 DEG C and is sprayed into the gasification furnace by a plasma spray gun, the water vapor is reacted with the solid carbocoal to generate carbon monoxide and hydrogen gas, the required heat of the gasification reaction in the gasification furnace can be provided by the plasma spray gun and an exothermal reaction of the calcium oxide absorbing the carbon dioxide. According to the invention, synthesis gas can be produced by rubbish and biomass raw materials under the condition without air or oxygen, the main ingredients of the synthesis gas are hydrogen gas and carbon monoxide which can be directly used for city gas or producing hydrogen gas, methanol and dimethyl ether and so on clean energies.

Owner:衢州市广源生活垃圾液化技术研究所

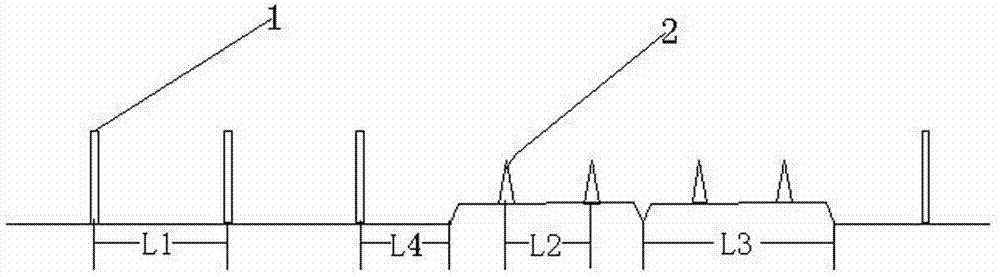

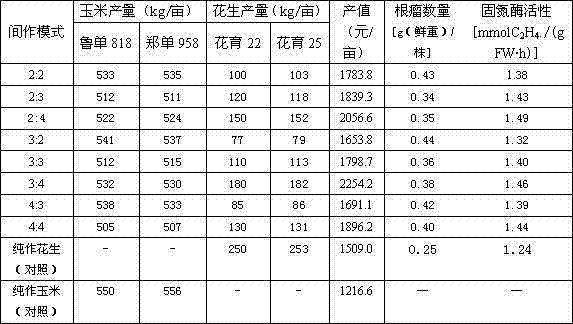

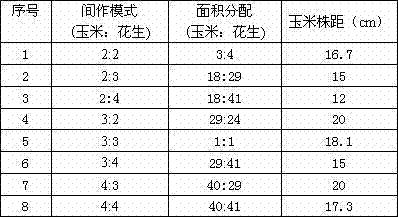

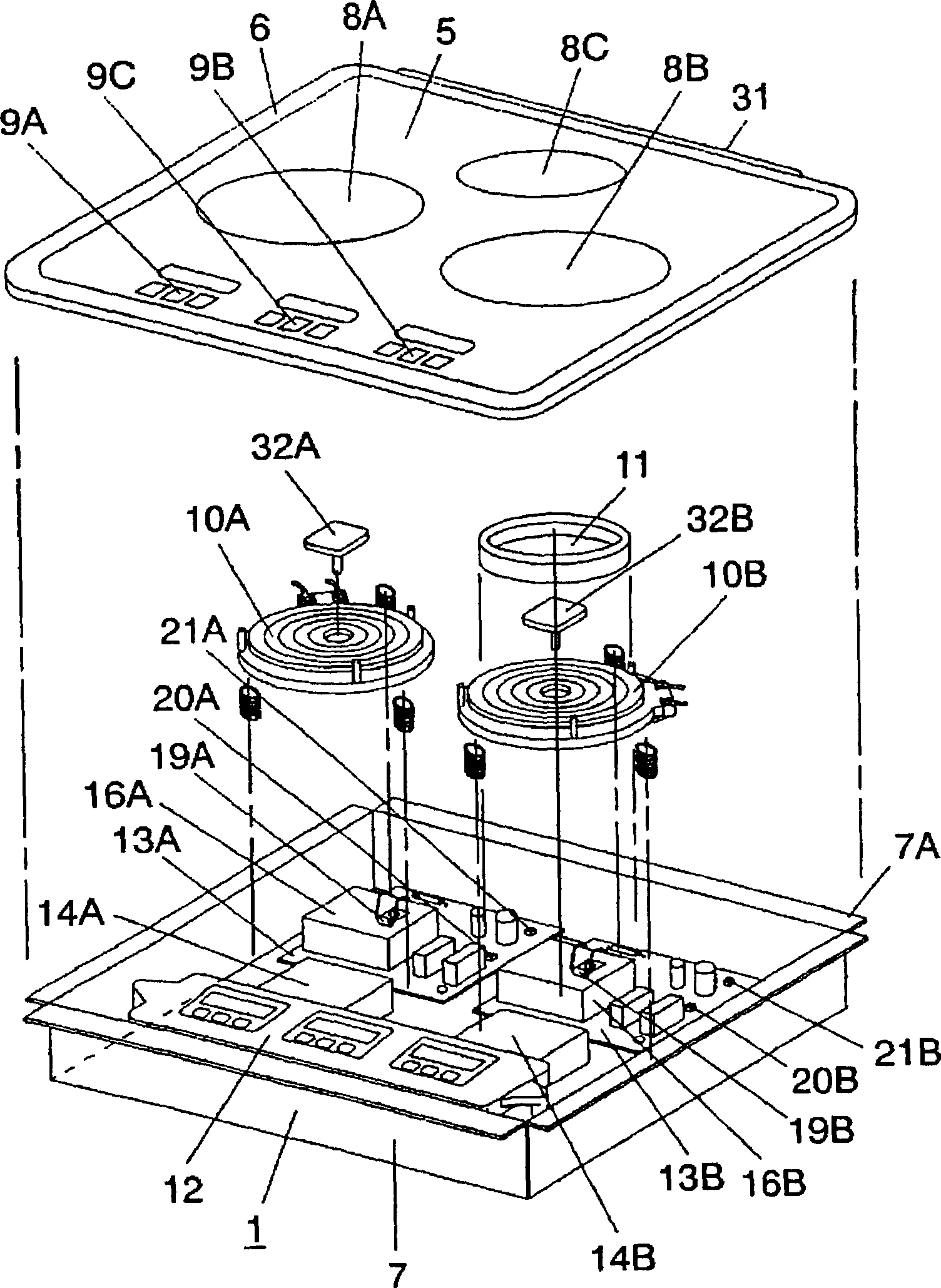

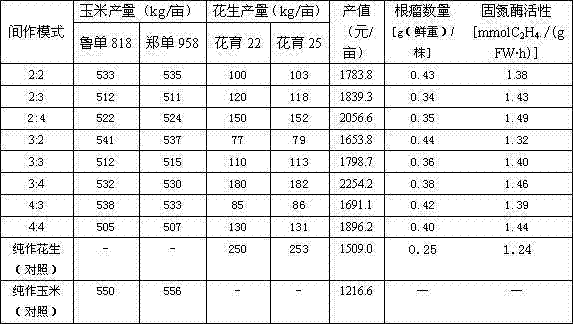

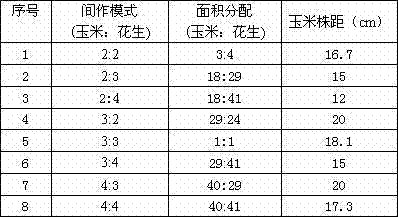

Summer corn and summer peanut intercropping planting method

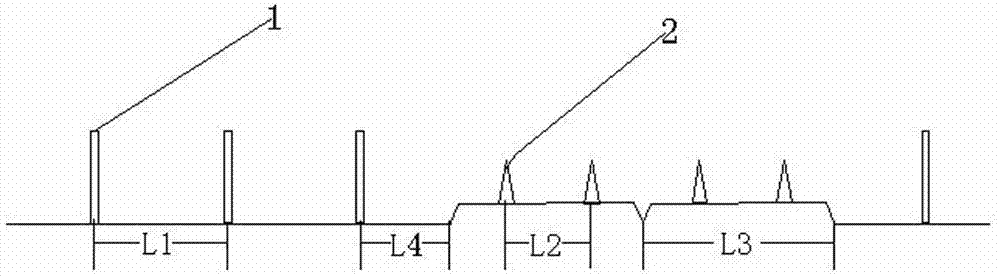

InactiveCN103650887AImprove nitrogen fixation capacityIncrease the number ofHorticultureAgricultural scienceArachis hypogaea

The invention relates to a summer corn and summer peanut intercropping planting method and belongs to the technical field of crop planting. According to the summer corn and summer peanut intercropping planting method, three lines of corn are intercropped with four lines of peanuts, the corn line width is 55cm, the corn planting distance is 15cm, the peanut line width is 33-35cm, the peanut hill spacing is 14cm, the peanuts are planted in a ridging mode, the ridge width is 85cm, two lines of the peanuts are sown in each ridge, and the distance between the corn lines and the peanut ridges is 35cm. Three lines of the corn and four lines of the peanuts are arranged in an alternating mode, intercropping is carried out in a wide width mode, the corn line width, the corn planting distance, the peanut line width, the peanut hill spacing, and the distance between the corn lines and the peanut ridges are strictly limited, and therefore the total output value is remarkably improved.

Owner:VEGETABLE RES INST OF SHANDONG ACADEMY OF AGRI SCI

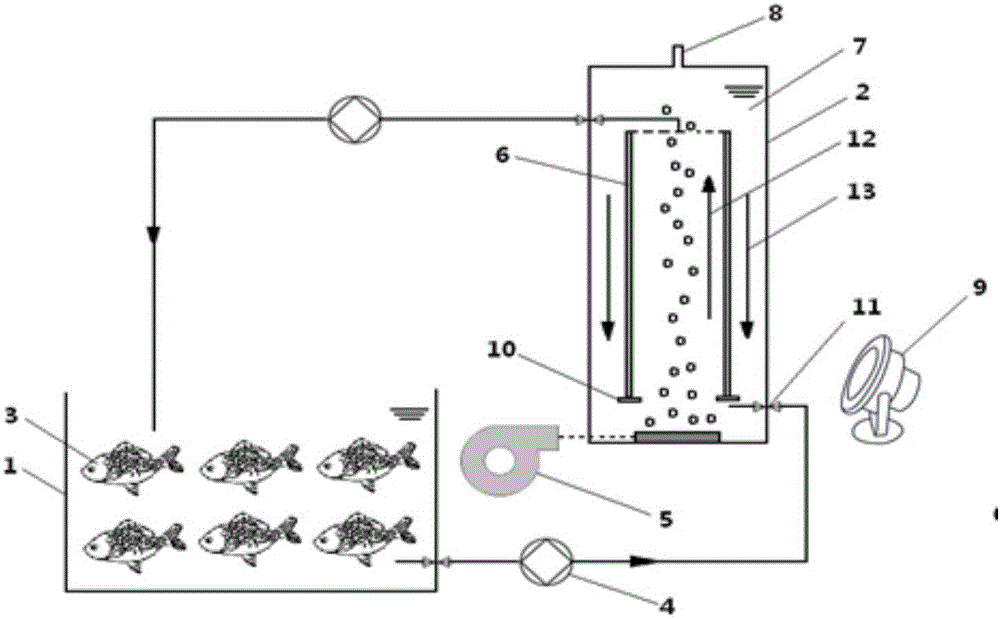

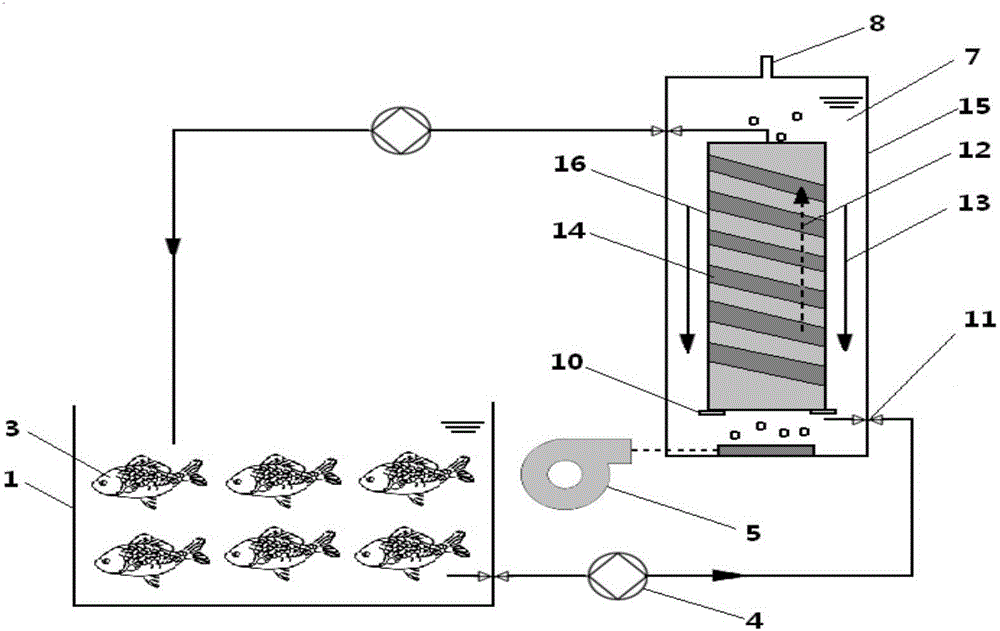

Fish-bacterium-algae-symbiotic ecological breeding system and running method thereof

ActiveCN105961303AImprove utilization efficiencyImprove purification effectClimate change adaptationPisciculture and aquariaOxygenWater processing

The invention discloses a fish-bacterium-algae-symbiotic ecological breeding system and a running method thereof. The fish-bacterium-algae-symbiotic ecological breeding system and the running method mainly aim at reducing aerating cost, improving the use efficiency of nitrogen and organisms and improving purification of breeding waste water. The system is composed of a fishpond, a photobioreactor, a membrane assembly, a light source and an aerating system, and is characterized in that aquaculture is combined with a bacterium-algae-symbiotic system and the membrane technology, the photosynthesis of microalgae continues, the dissolved oxygen concentration of processed waste water is high, healthy breeding of fishes is guaranteed, and aerating cost is reduced; due to excellent organism degradation and absorption of bacteria, the organism recycling capacity of the system is improved; due to the comprehensive synergistic effect of microalgae and microorganisms, waste water processing efficiency is improved; as microalgae absorb nitrogen substances, the nitrogen use efficiency of the system is improved; in addition, due to the adoption of the membrane technology, microalgae can be more easily harvested.

Owner:SHANDONG UNIV

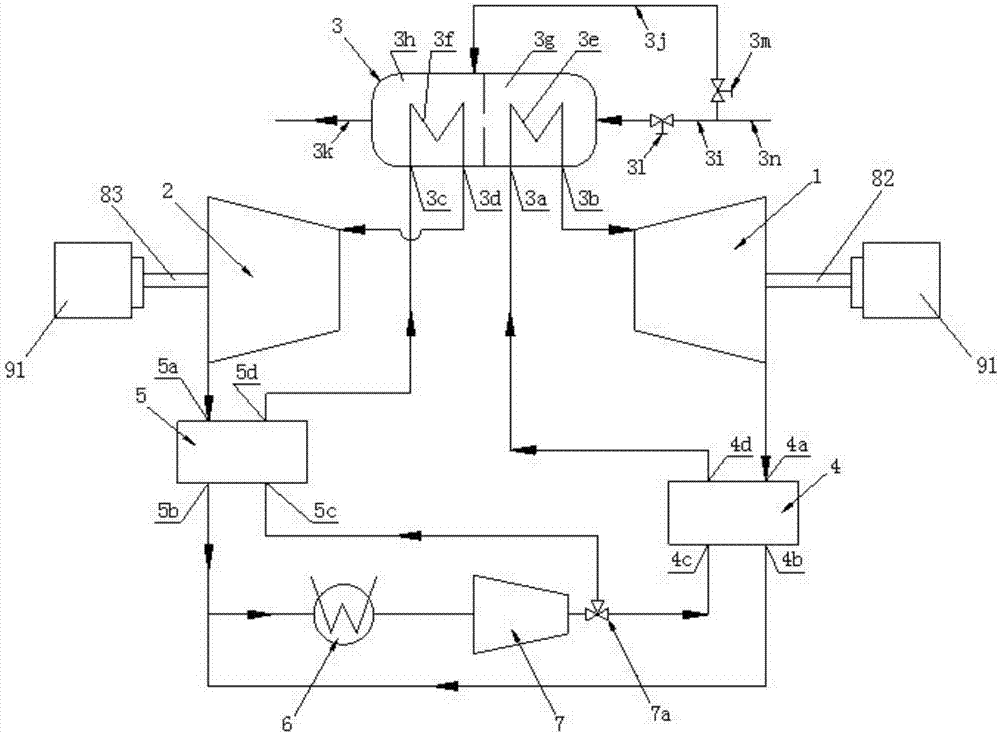

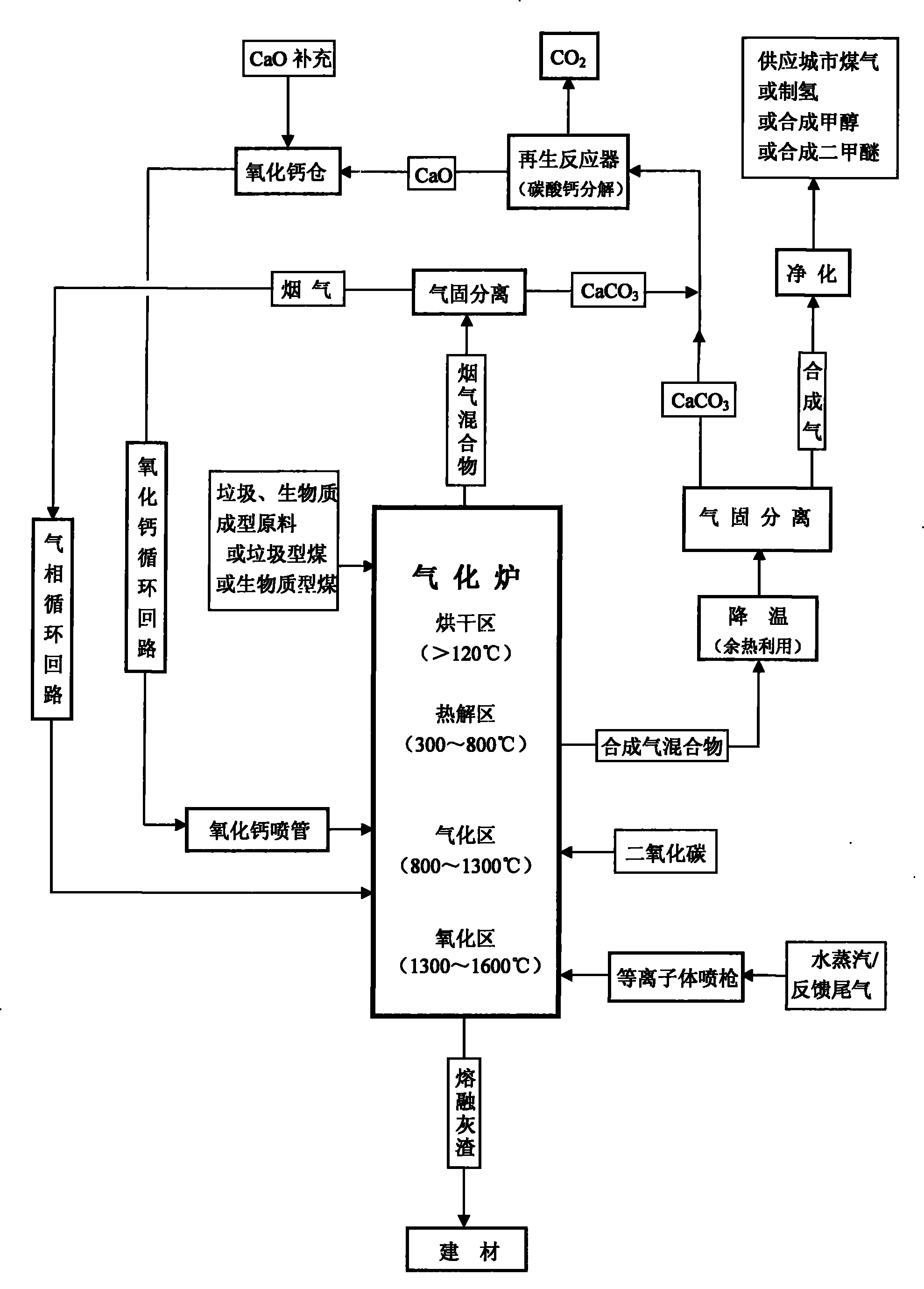

System and apparatus for producing synthesis gas from garbage and biomass raw material

The invention provides a system and equipment for producing synthesis gas by garbage and biomass raw materials, which relates to garbage and biomass gasification equipment. The system and the equipment are characterized in that a vapor circulation loop and a calcium oxide circulation loop are arranged in the system; the garbage and the biomass raw materials are vaporized by an exothermic reaction of absorbing CO2 of the calcium oxide in a gasification furnace to cooperate with thermal plasma, so that the garbage and the biomass raw materials are converted into high heating value synthesis gas for cleaning energy or chemical raw materials. The system mainly comprises a multiphase circulation gasification furnace, a plasma spray gun, the vapor circulation loop, the calcium oxide circulation loop, a wet purification tower and a gas holder, wherein a circulation output interface of the gasification furnace is connected to a gas-solid separator; a gas outlet of the gas-solid separator is connected to a circulating fan; an air outlet of the circulating fan is connected to the vapor circulation input interface of the gasification furnace; a dipleg of the gas-solid separator is connected to a feed delivery valve; the feed delivery valve is connected to a calcium oxide calcining furnace through a solid phase conveying pipe; and a calcium oxide outlet of the calcium oxide calcining furnace is connected to a calcium oxide jet tube of the gasification furnace through a refeed line.

Owner:衢州市广源生活垃圾液化技术研究所

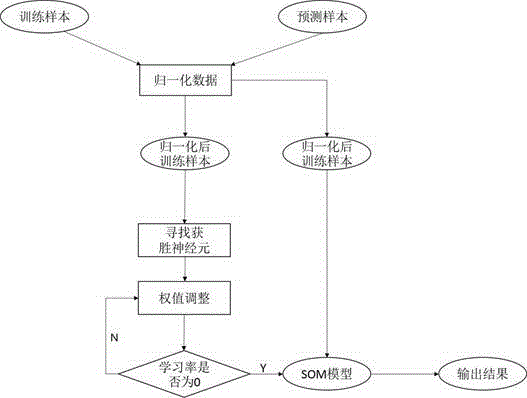

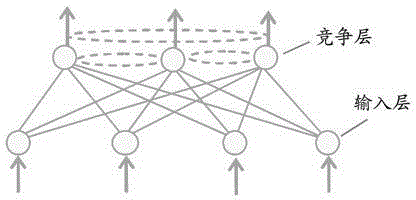

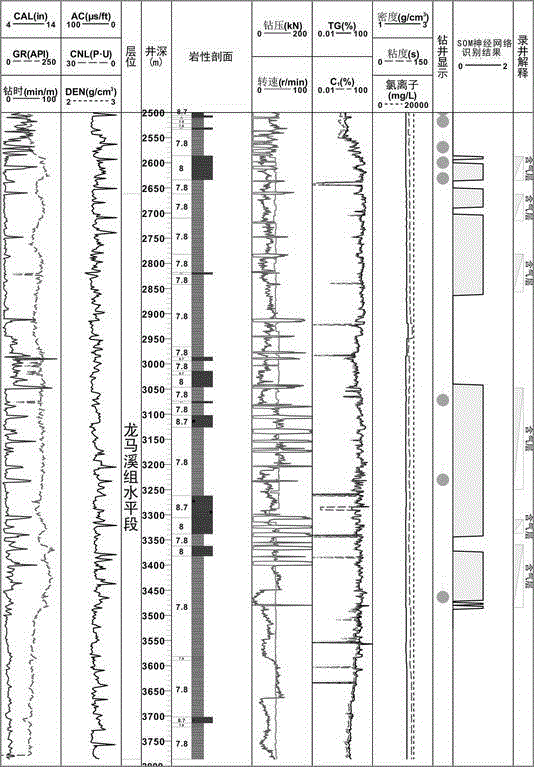

Shale gas reservoir recognition method based on self-organizing competitive neural network

ActiveCN104453875ARealization of Parameters While DrillingSolutionConstructionsSpecial data processing applicationsPattern recognitionNeural network analysis

The invention discloses a shale gas reservoir recognition method based on a self-organizing competitive neural network. The method comprises the following steps that a, data of drilled shale gas horizontal wells in the same block are synthesized and classified; b, regional data are used for conducting optimization with while-drilling parameters as training samples; c, the while-drilling parameters are subjected to normalization processing; d, a regional SOM neural network model is established; e, reservoir recognition is conducted on the forwards-drilled shale gas horizontal wells as forecast samples through the established model. According to the shale gas reservoir recognition method based on the self-organizing competitive neural network, the model capable of effectively recognizing shale gas reservoirs is established by means of SOM neural network analysis with the optimized while-drilling parameters as discrimination parameters according to known well logging interpretation and formation testing results, so that while-drilling interpretation of the shale gas reservoirs is realized, and the problems that shale gas reservoir logging interpretation methods are insufficient and multiple parameters are non-linear are solved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

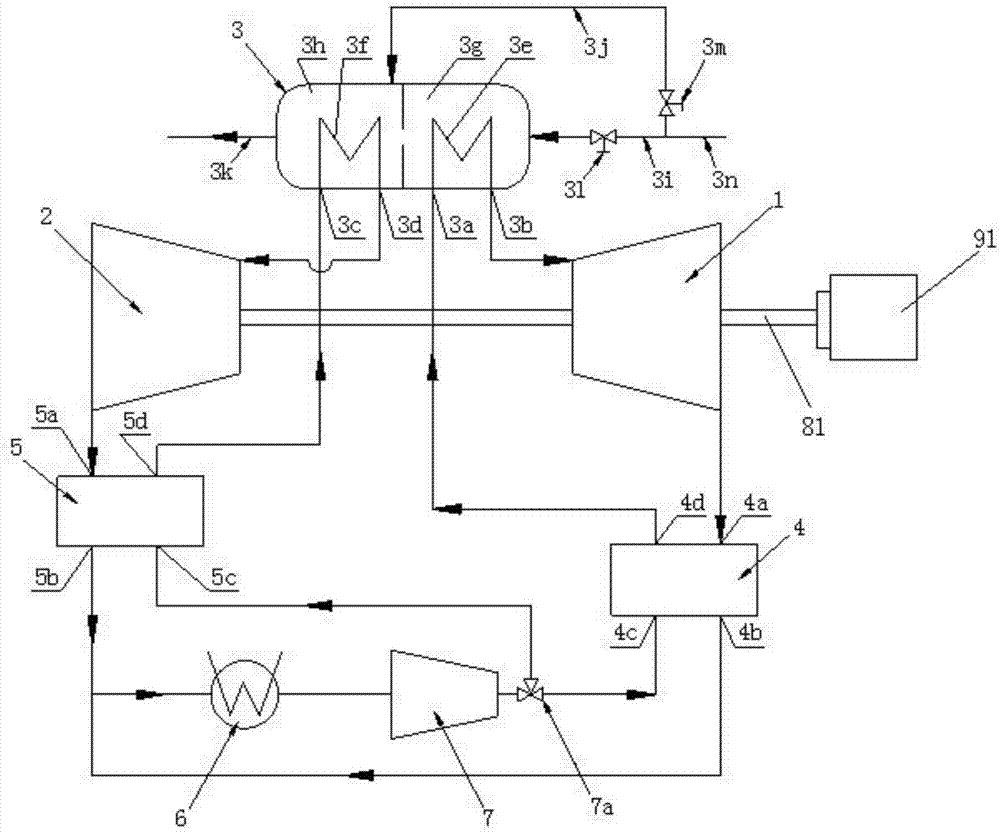

High-and-low-temperature supercritical carbon dioxide waste heat utilization system

ActiveCN105443170AEfficient use ofTake advantage ofSteam engine plantsGas compressorCycle efficiency

The invention provides a high-and-low-temperature supercritical carbon dioxide waste heat utilization system which comprises a high-temperature turbine, a low-temperature turbine, a waste heat recoverer, a high-temperature reheater, a low-temperature reheater, a condenser and a gas compressor. A gas inlet of the high-temperature turbine is sequentially connected with the waste heat recoverer, the high-temperature reheater, the gas compressor and the condenser. A gas inlet of the condenser is further sequentially connected with a gas outlet of the high-temperature reheater and a gas outlet of the high-temperature turbine, so that a high-temperature turbine circulation loop is formed. A gas inlet of the low-temperature turbine is sequentially connected with the waste heat recoverer, the low-temperature reheater, the gas compressor and the condenser. A gas inlet of the condenser is further sequentially connected with a gas outlet of the low-temperature reheater and a gas outlet of the low-temperature turbine, so that a low-temperature turbine circulation loop is formed. According to the high-and-low-temperature supercritical carbon dioxide waste heat utilization system, exhausted high-temperature gas of a gas turbine or industrial waste heat / lost heat serves as a heat source, high-grade heat energy is utilized efficiently, and low-grade heat energy is utilized, so that energy sources are utilized sufficiently, and the overall circulation efficiency is improved.

Owner:SHANGHAI TURBINE

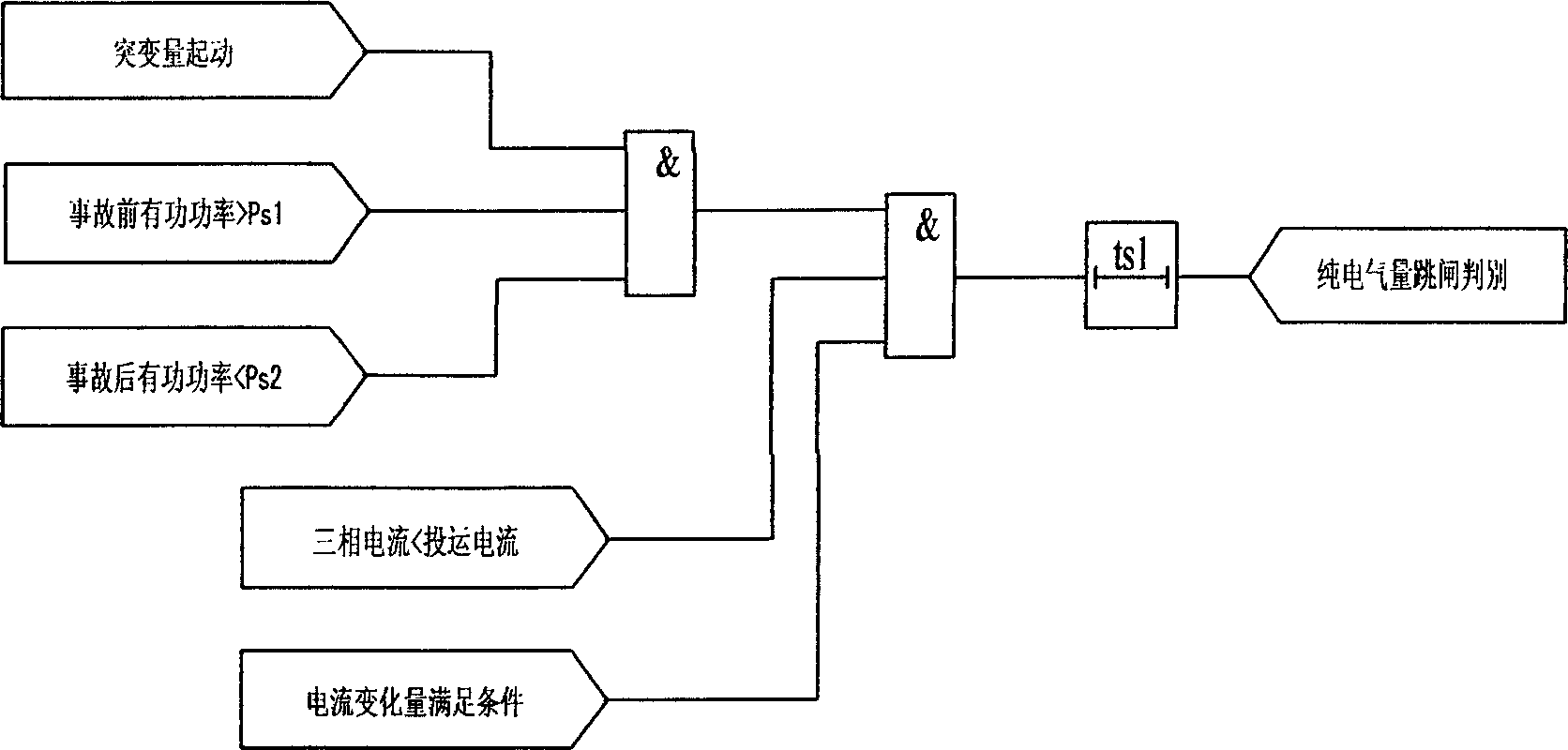

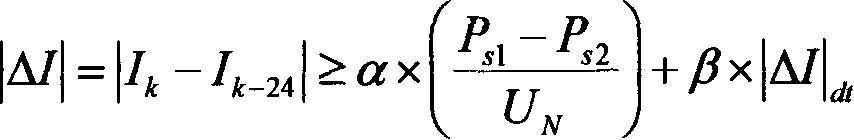

Trip discrimination method for pure electric power system

InactiveCN1808821AIncrease the total output valueTrip will notEmergency protective circuit arrangementsFault locationElectricityFloat Value

This invention relates to electricity power system jump judging method, which adopts the following bases: A, protruding variables starting; b, )P-0.2Sí¦PS1 means front power larger than set value PSI; c, PtíœPS2, fault power smaller than set value PS2; d, three-phase current IíœIS1, current smaller than operation current; e, current variable satisfies the base larger than current float gate; f, tí¦tS1, determining the above data time lag, wherein the PSI smaller than transmission power value; PS2 is larger than zero and the maximum floating value with operation current IS1 larger than open circuit current; the UN is ratio voltage.

Owner:NR ELECTRIC CO LTD

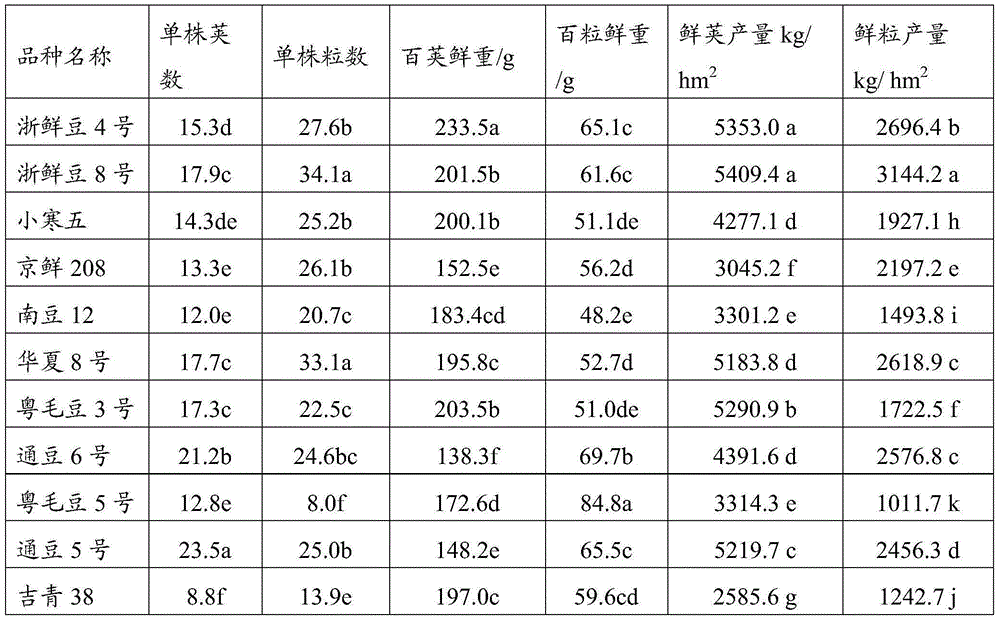

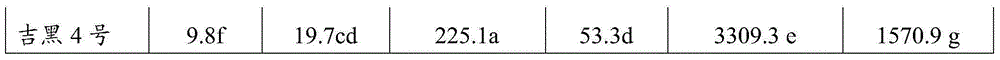

Cultivation method for corn and fresh edible soybean interplanting after rape harvesting

InactiveCN105052508AImprove land utilizationIncrease the total output valuePlant cultivationCultivating equipmentsNutrientAgriculture

The invention relates to the field of agricultural planting, in particular to a cultivation method for corn and fresh edible soybean interplanting after rape harvesting. The cultivation method for corn and fresh edible soybean interplanting after rape harvesting is mainly suitable for one-year-two-harvest cultivation areas of southwest dry land in Sichuan, Chongqing, Guizhou and the like. The planting area of fresh edible soybeans can be enlarged, and popularization and development of fresh edible soybeans are promoted. By the adoption of the planting method, land, nutrient and light and heat resources can be sufficiently utilized, the land equivalence ratio can be improved, land output is increased, the one-year-two-harvest effect is achieved, and the purposes of improving the land economic output and increasing incomes of farmers are achieved. In addition, the planting area of fresh edible soybeans can be enlarged, economic benefits are increased, and the living quality of people is improved.

Owner:SICHUAN AGRI UNIV

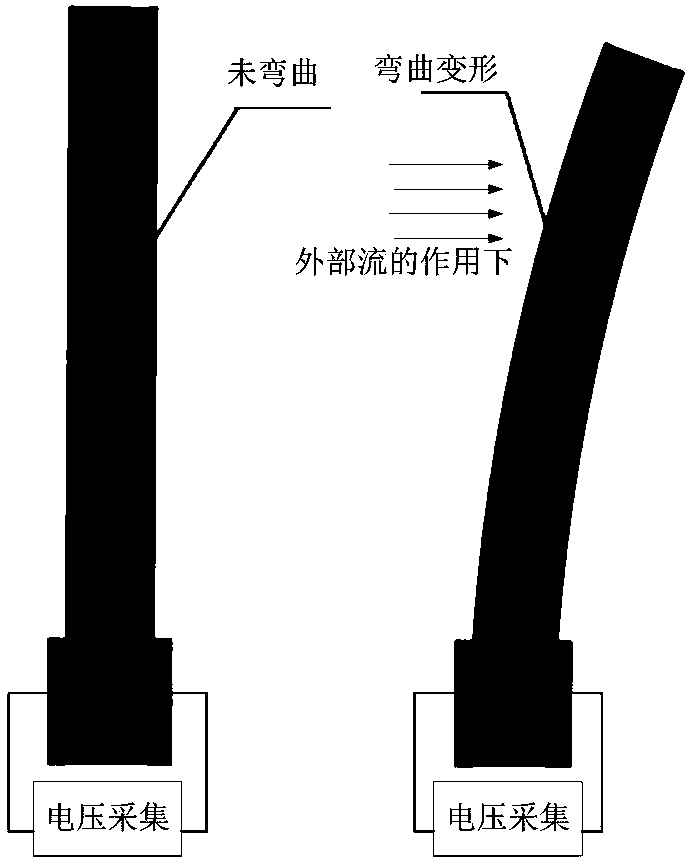

Novel bionic lateral line sensor

ActiveCN109238245ARealize integrated designSimple structureMeasurement apparatus componentsMeasuring open water movementLine sensorEngineering

The invention discloses a novel bionic lateral line sensor, which comprises a cilium housing, a cilium base rod, IPMC film sheets, extraction electrodes and a sensor housing. When an external flow acts on the free end of the cilium housing, the cilium housing generates mechanical deformation which can be transferred to the cilium base rod to cause deformation of the cilium base rod, deformation ofthe cilium base rod can lead to mechanical deformation of the IPMC film sheets, by using the IMC force electric effect, the IPMC film sheets can generate an induced voltage, and thus the magnitude ofthe external flow is calculated according to the collected induced voltage. The novel bionic lateral line sensor is adopted to be used for measuring the external flow, the cilium housing and cilium base rod are combined into one, the IPMC film sheets are used instead of strain gauges, and directly installed on the cilium base rod, the characteristics of integrated design, simple structure and convenient installation are achieved. Meanwhile, the novel bionic lateral line sensor can output the induced voltage accurately and obtain the flow velocity.

Owner:OCEAN UNIV OF CHINA

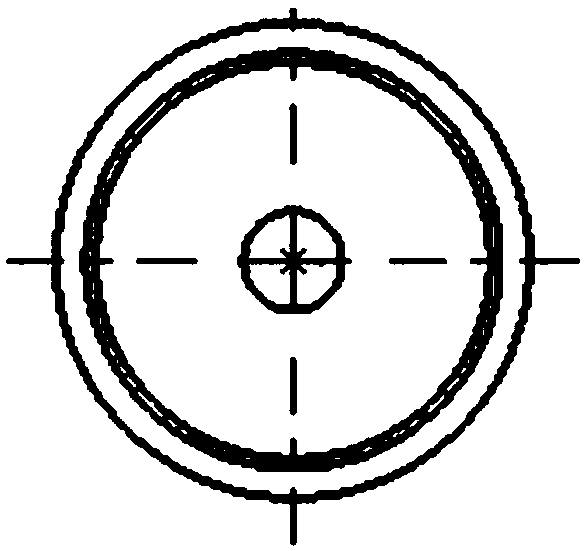

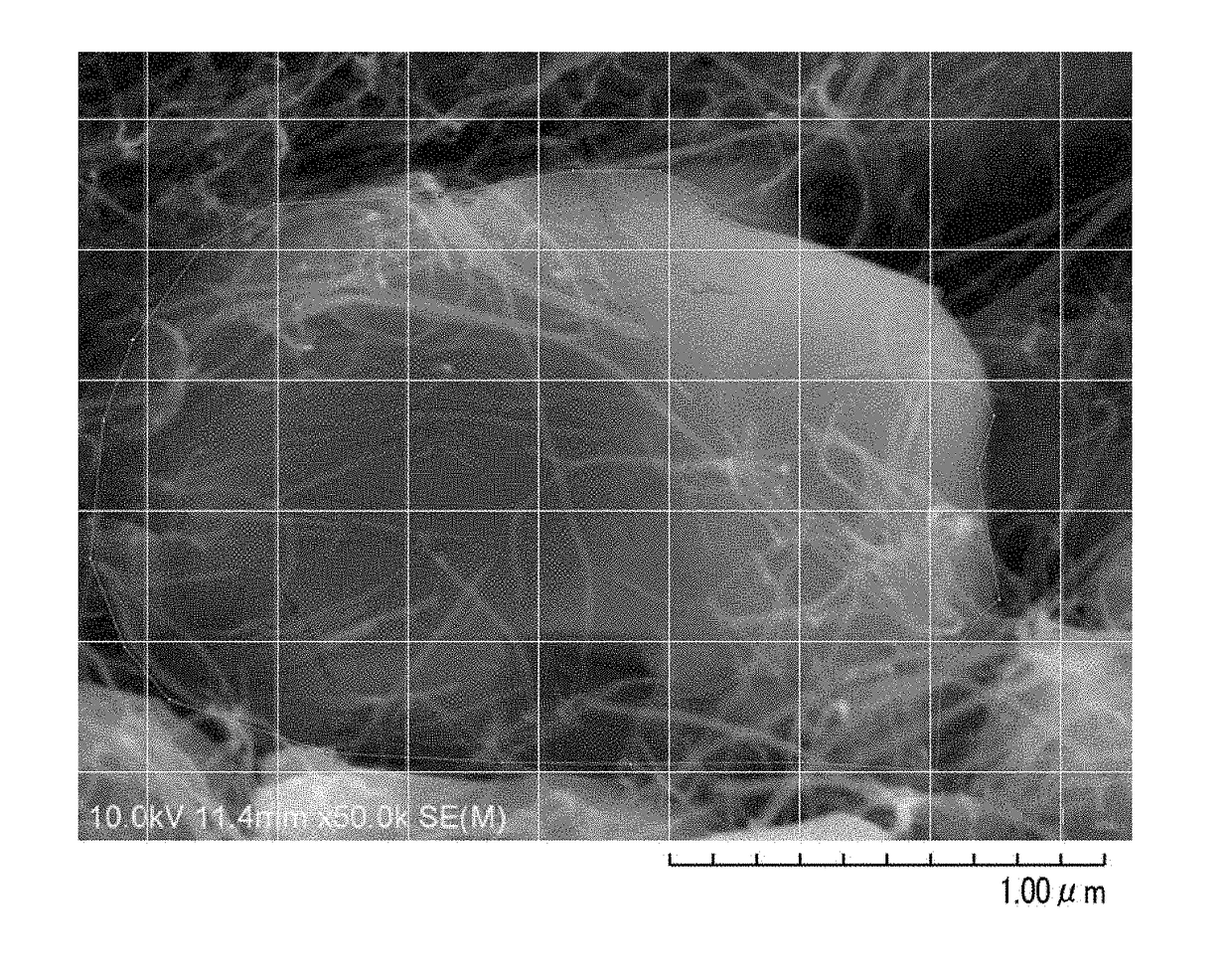

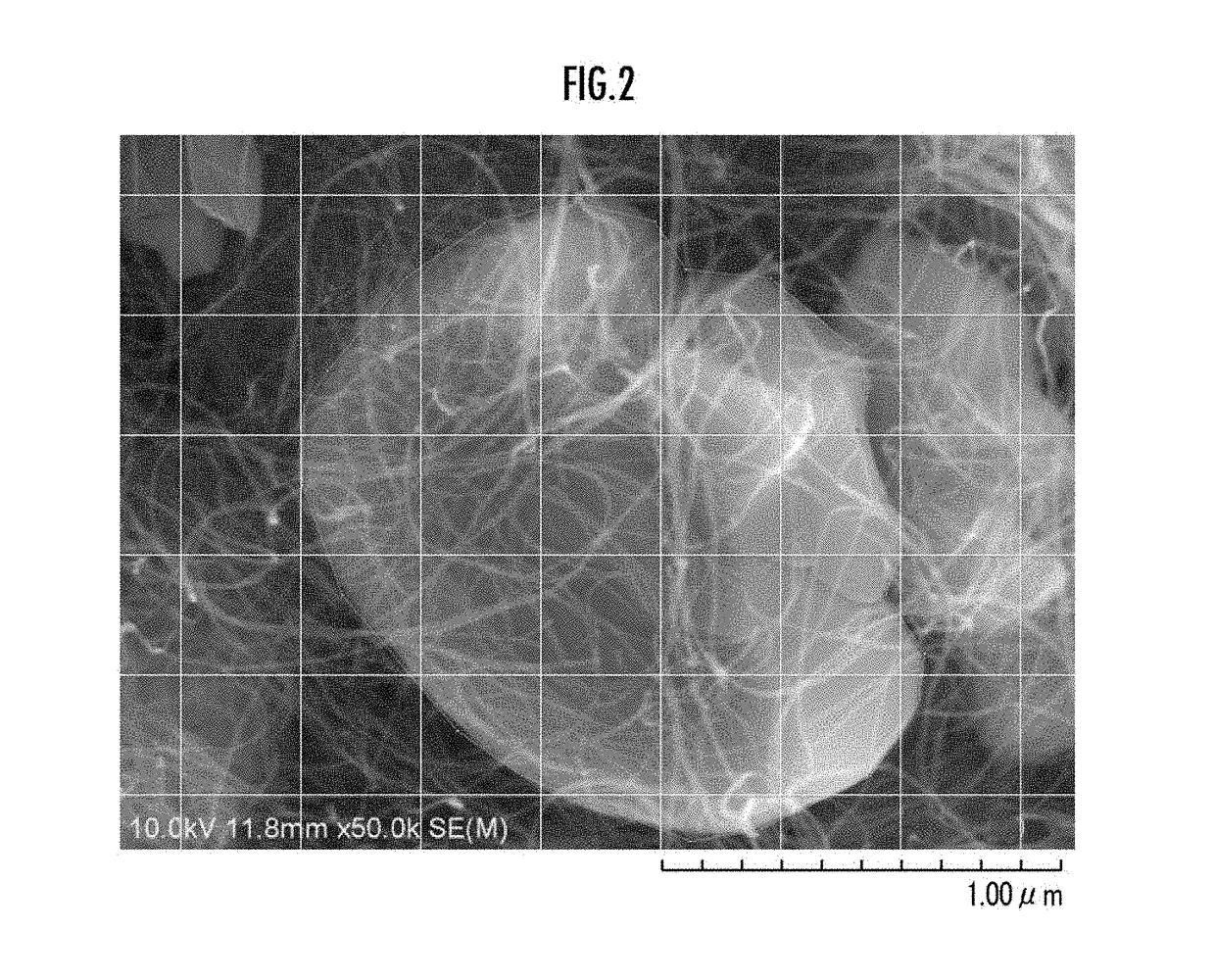

Electrode mixture layer

ActiveUS20180145333A1Lower internal resistanceIncrease value input valueMaterial nanotechnologyElectrode manufacturing processesElectrical resistance and conductanceElectrical conductor

Provided is an electrode mixture layer capable of reducing internal resistance by use of a carbon nanotube molding. The electrode mixture layer includes an active material and a conductor of carbon nanotubes in close contact with the surface of the active material, and the number density of the carbon nanotubes is 4 tubes / μm or more. The number density is defined as a value obtained by providing measurement lines on a scanning electron microscope image of a surface of the electrode mixture layer at 0.3 μm intervals both longitudinally and laterally, measuring the total number of the carbon nanotubes being in close contact with the surface of the active material and intersecting the measurement lines, and dividing the total number of the carbon nanotubes by the total length of the measurement lines on the active material surface.

Owner:HONDA MOTOR CO LTD

Solid bamboo charcoal stick and production method thereof

InactiveCN104293407AImprove combustion efficiencySolve the problem of burning too fastBiofuelsSolid fuelsCarbonizationPulp and paper industry

The invention discloses a solid bamboo charcoal stick and a production method thereof. The bamboo charcoal stick is prepared by the following steps: utilizing residues after bamboo processing as raw materials; crushing, screening and drying to press into a solid stick billet; and carbonizing in a high-temperature anaerobic charcoal kiln. The solid bamboo charcoal stick is characterized by being solid, wherein the diameter of a stick body is 4-6cm; and the length of the stick body is 40-50cm. Use of the solid bamboo charcoal stick prepared by the method as fuel is waste utilization, the combustion efficiency can be improved by 30%, the work efficiency of a bar making machine is 20%; the bamboo charcoal stick does not contain wood charcoal or wood flour, does not contain chemical glue and other adhesive, is slow in combustion speed, does not generate a fire head or smoke, is small in environmental pollution, and wide in use, and belongs to a high-quality bamboo charcoal stick; the market blank of the high-temperature exported solid bamboo charcoal stick is filled; economic income of a bamboo farmer can be increased; the ecological environment can also be improved; the solid bamboo charcoal stick can earn foreign exchange through exports, and is suitable for the areas with abundant bamboo resources and a plurality of bamboo processing factories; the bamboo processing industrial chain can be prolonged; the total value of the bamboo industry is increased; and the solid bamboo charcoal stick has obvious effects on promotion of income increase of a forest worker and improvement of economic benefits of bamboo processing enterprises.

Owner:HUNAN CHENGTOUSHAN AGRI & FORESTRY DEV

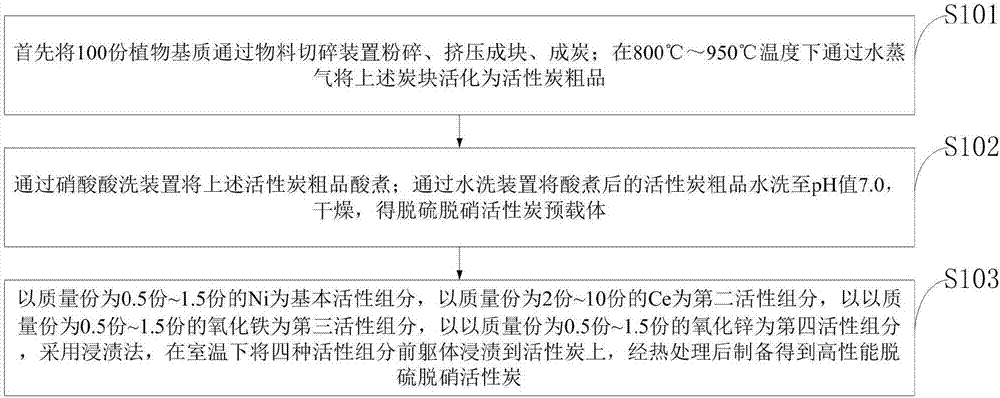

High-performance desulfurization and denitrification activated carbon and preparation method thereof

InactiveCN106955669AInhibition formationHigh yieldProgramme controlOther chemical processesFurfuralDenitrification

The invention belongs to the technical field of chemical materials and discloses a high-performance desulfurization and denitrification activated carbon and a preparation method thereof. The preparation method comprises the following steps: adopting a material crushing device for crushing plant substrates, extruding into blocks and forming carbon; activating; acid-cooking the crude product of the activated carbon by a nitric acid pickling device; taking 0.5-1.5 parts by mass of Ni as a basic active component, 2-10 parts by mass of Ce as a second active component, 0.5-1.5 parts by mass of ferric oxide as a third active component and 0.5-1.5 parts by mass of zinc oxide as a fourth active component; adopting an impregnation method and performing thermal treatment, thereby acquiring the high-performance desulfurization and denitrification activated carbon. The ferric oxide desulfurizing agent provided by the invention is a high-quality furfural extract, with higher desulfurizing efficiency and working sulfur capacity of 37-97mg SO2 / g catalyst. Denitrification is performed at different degrees while desulfurization is performed.

Owner:FUJIAN XINSEN CARBON

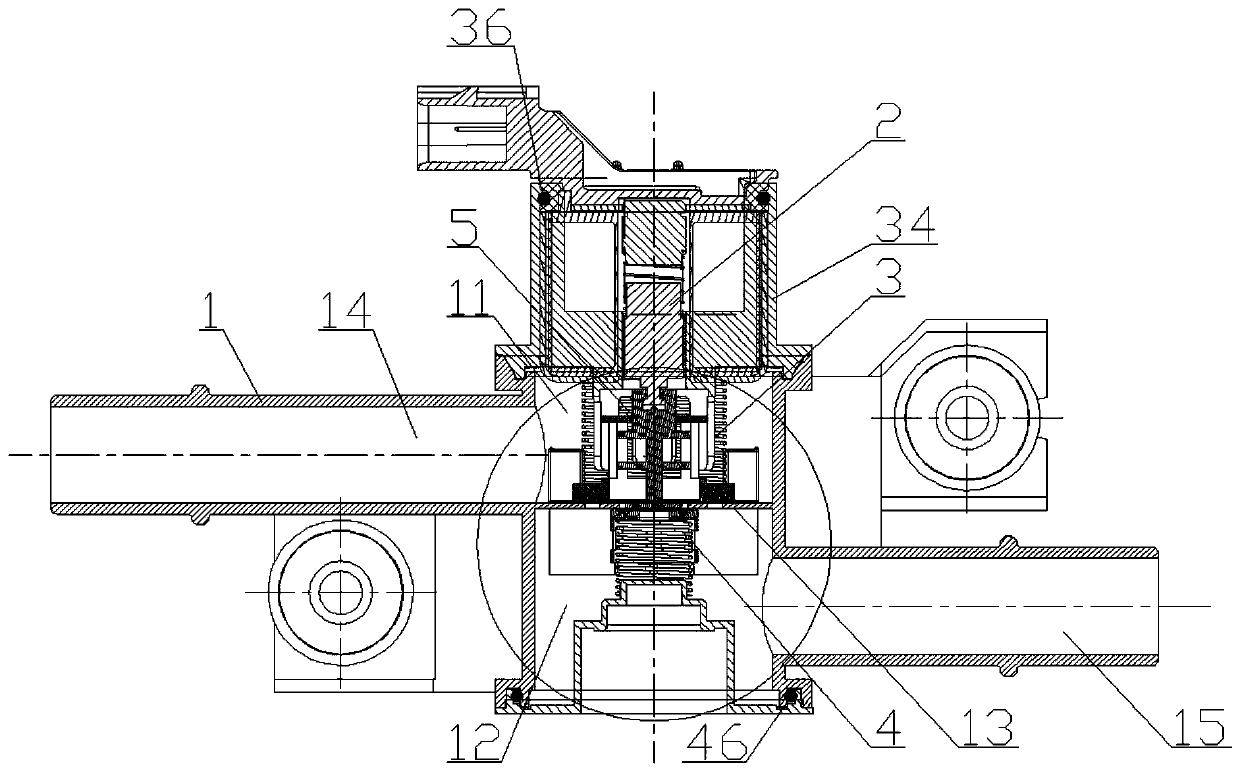

Device and method for testing mechanical property of water filter pipe

InactiveCN103969122AGet combined stressMake up for uneven spacingMaterial strength using tensile/compressive forcesMaterial strength using steady torsional forcesAutomatic controlWater filter

The invention discloses a device and a method for testing a mechanical property of a water filter pipe. The device comprises an automatic oil supply system pressure regulation control device and an expulsion device, wherein an oil supply system comprises an oil pump, an oil tank, reversing valves and the like; the extrusion device comprises a cylinder, an extrusion mold base, an extrusion mold, hydraulic cylinders, a tightening belt and the like; the oil supply can control hydraulic pipelines respectively, and can perform pressure maintaining on the hydraulic pipelines during working and perform fast unloading after working; and a replaceable conical extrusion mold base is mounted on the extrusion mold base of the extrusion device, so that the test for water filter pipes of different models is facilitated, simultaneously, a buckling device has high and low retraction and expansion speeds during working, and the work efficiency can be improved. The device and the method for testing the mechanical property of the water filter pipe has the advantages as follows: an integrated test for a confining pressure property, axial bending resistance and redial bending resistance of the water filter pipe can be realized, the applicable range is wide, the retraction and expansion pressure is large, the service life is long and the like.

Owner:JILIN UNIV

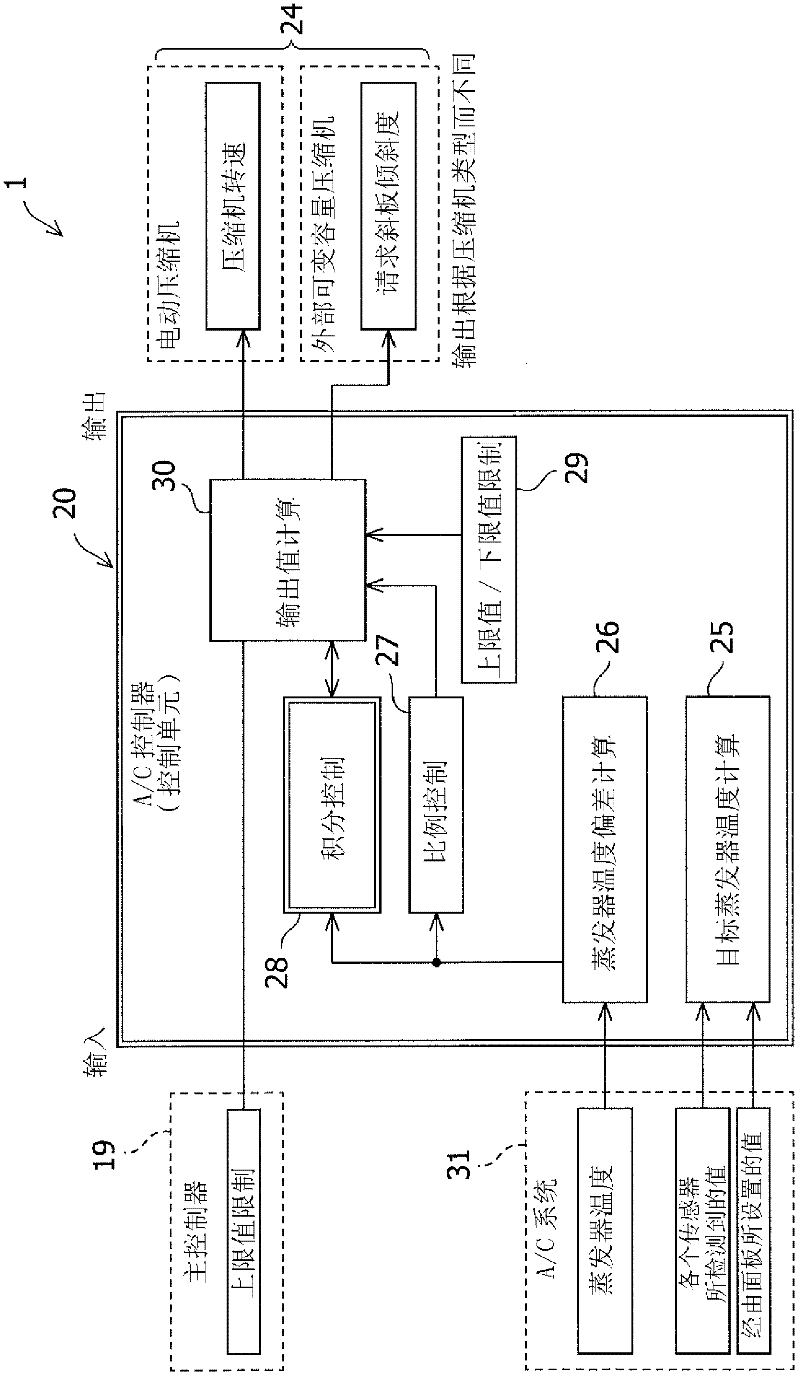

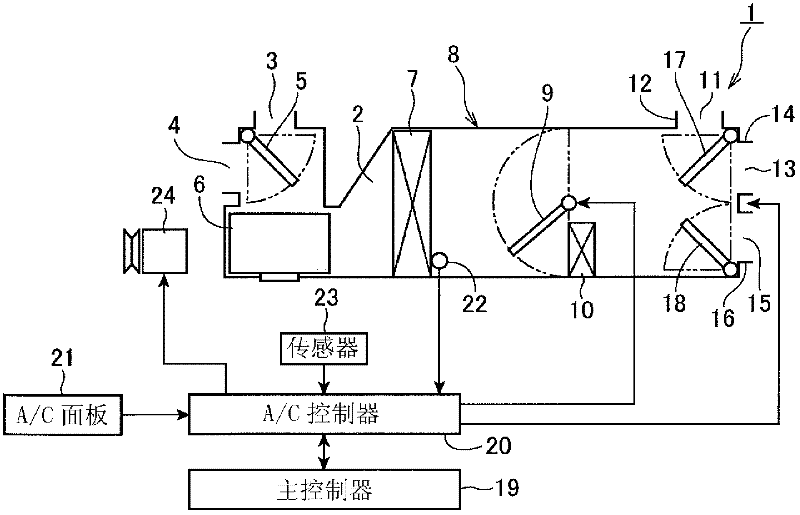

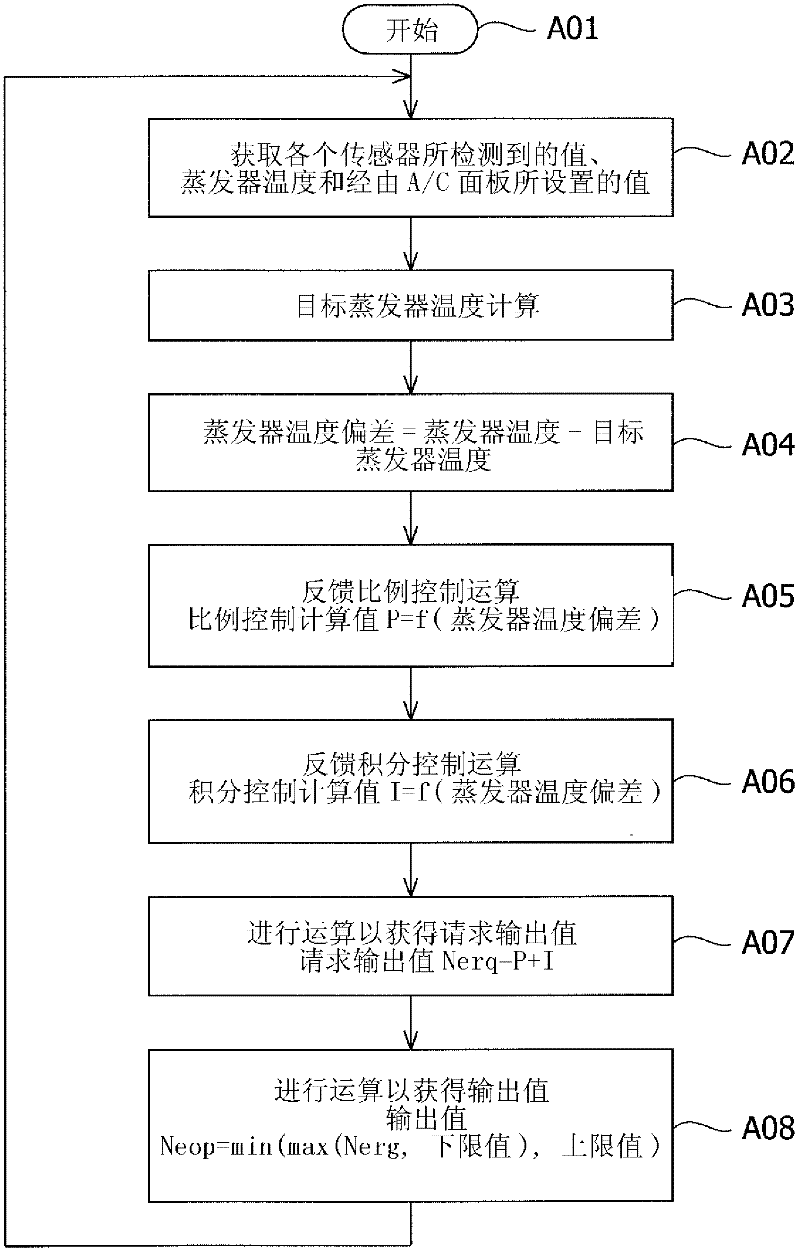

Vehicle air conditioning control system

InactiveCN102650461AAvoid divergenceIncrease the total output valueSpace heating and ventilation safety systemsLighting and heating apparatusLower limitControl system

Provided is a vehicle air conditioning control system, comprising an evaporimeter temperature deviation calculation unit, an integral control unit for calculating an integral value based on an evaporimeter temperature deviation and an output value calculation unit for calculating a request compressor output value based on the integral value and restraining the request compressor output value to calculate a compressor output value. When the request compressor output value is restrained, the integral control unit stop integral control; when the request compressor output value is restrained by a lower limit, the integral control unit does not stop integral control if the evaporimeter temperature deviation is smaller than zero; and when the request compressor output value is restrained by an upper limit, the integral control unit does not stop integral control if the evaporimeter temperature deviation is smaller than zero. Thereby to determine whether or not integral control is performed when a requested compressor output value is limited by an upper or lower limit, based on an evaporator temperature deviation, prevent divergence of an integral value, and make an evaporator temperature follow a target evaporator temperature during the integral control.

Owner:SUZUKI MOTOR CORP

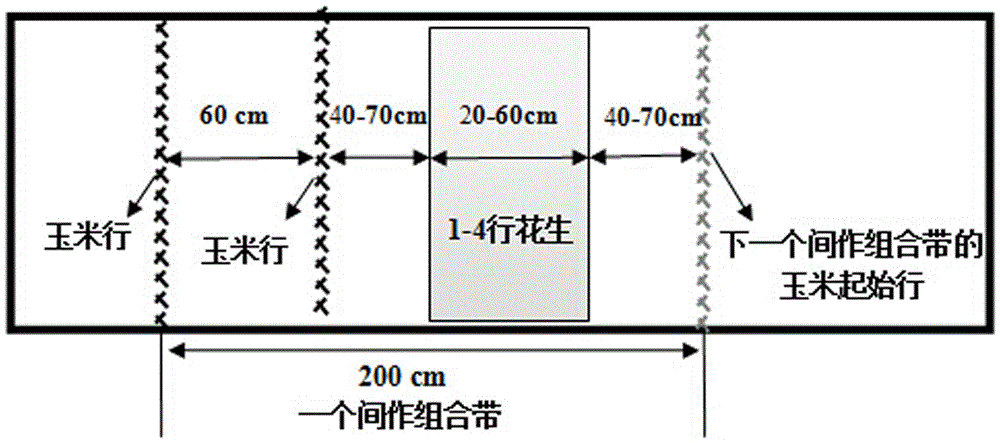

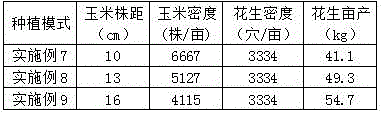

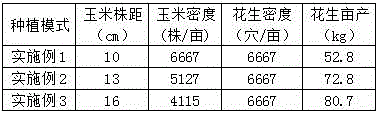

Corn and peanut intercropped planting mode for grain yield stabilizing and oil production increase

InactiveCN105532241AStable outputIncrease the total output valuePlant cultivationCultivating equipmentsOil productionBiology

The invention belongs to the technical field of crop cultivation and provides a corn and peanut intercropped planting mode for grain yield stabilizing and oil production increase. 1-4 rows of peanuts are intercropped at intervals of every two rows of corns in a strip-shaped mode, namely the row ratio of the corns to the peanuts is 2:(1-4); every two rows of corns and 1-4 rows of peanuts form an intercropping combined zone, the zone width of the intercropping combined zone is 200 cm; each intercropping combined zone starts from the corn rows, every two rows of corns and 1-4 rows of peanuts are sequentially arranged, the row spacing of every two rows of corns is 60 cm, the row spacing between each corn row and the adjacent peanut row is 40-70 cm, the row spacing of every two adjacent peanut rows is 20-60 cm, the plant spacing of the corns is 10-16 cm, and the hole spacing of the peanuts is 20-40 cm. In the corn and peanut intercropped planting mode, the corn yield is basically equal to the yield of singly-cultured corns, the amplitude of yield variation is within the range of + / - 3%, accordingly the purpose of peanut production increase while corn yield stabilizing is achieved under the condition that no additional land is input, namely groundnut kernels and peanut vines are 'obtained without effort', and the contradiction of contention for grain and oil land in our country can be effectively relieved.

Owner:CROP RES INST SHANDONG ACAD OF AGRI SCI

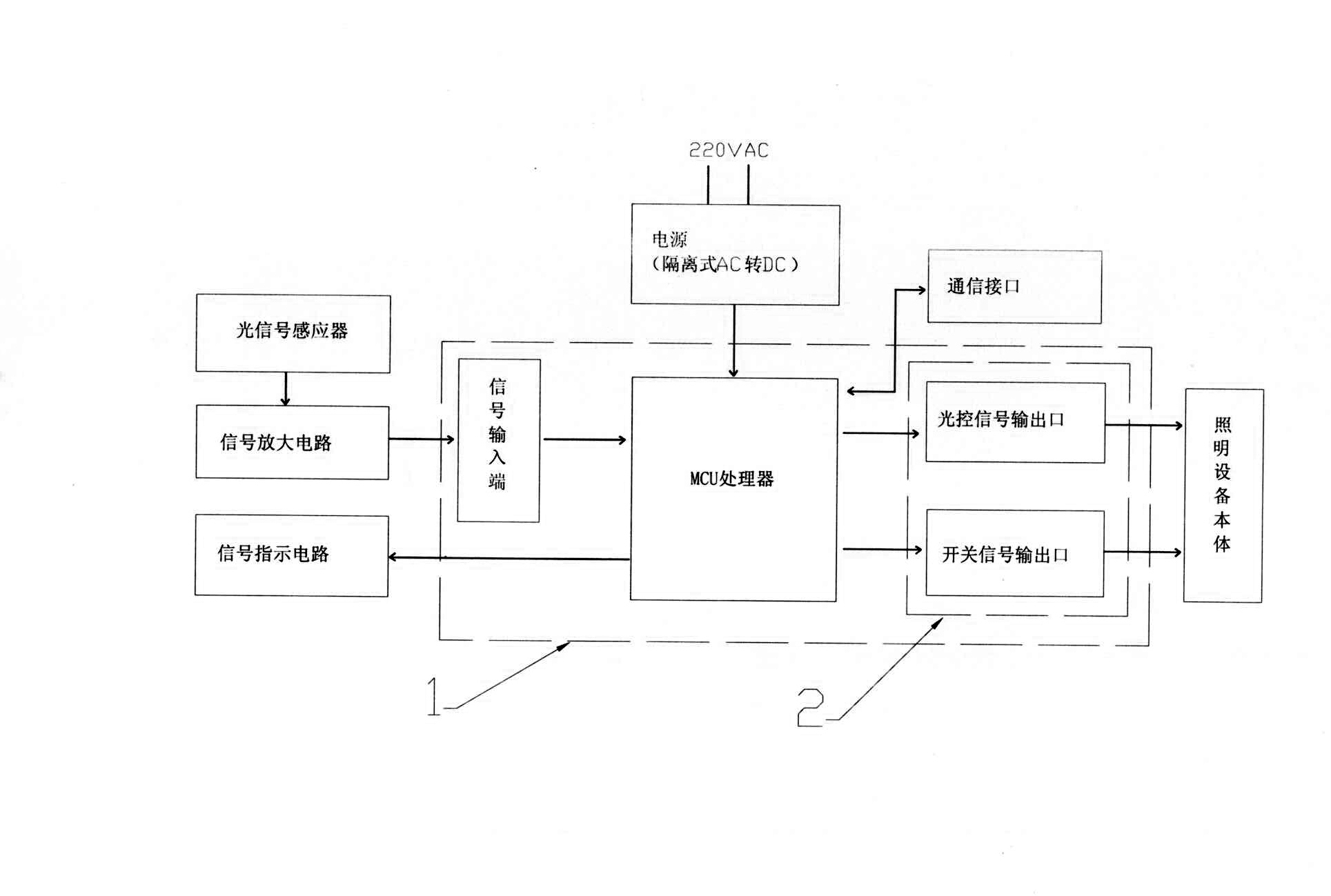

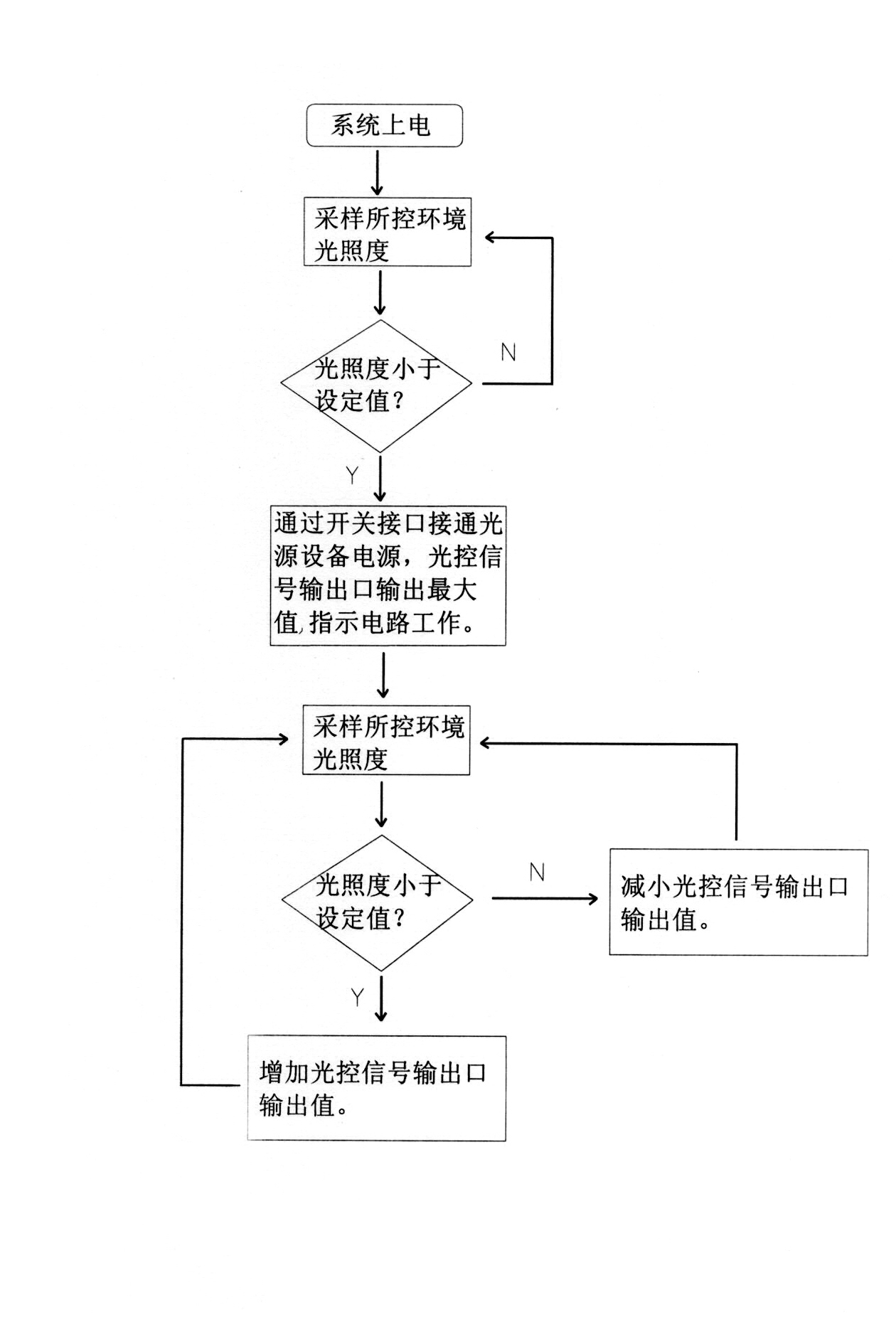

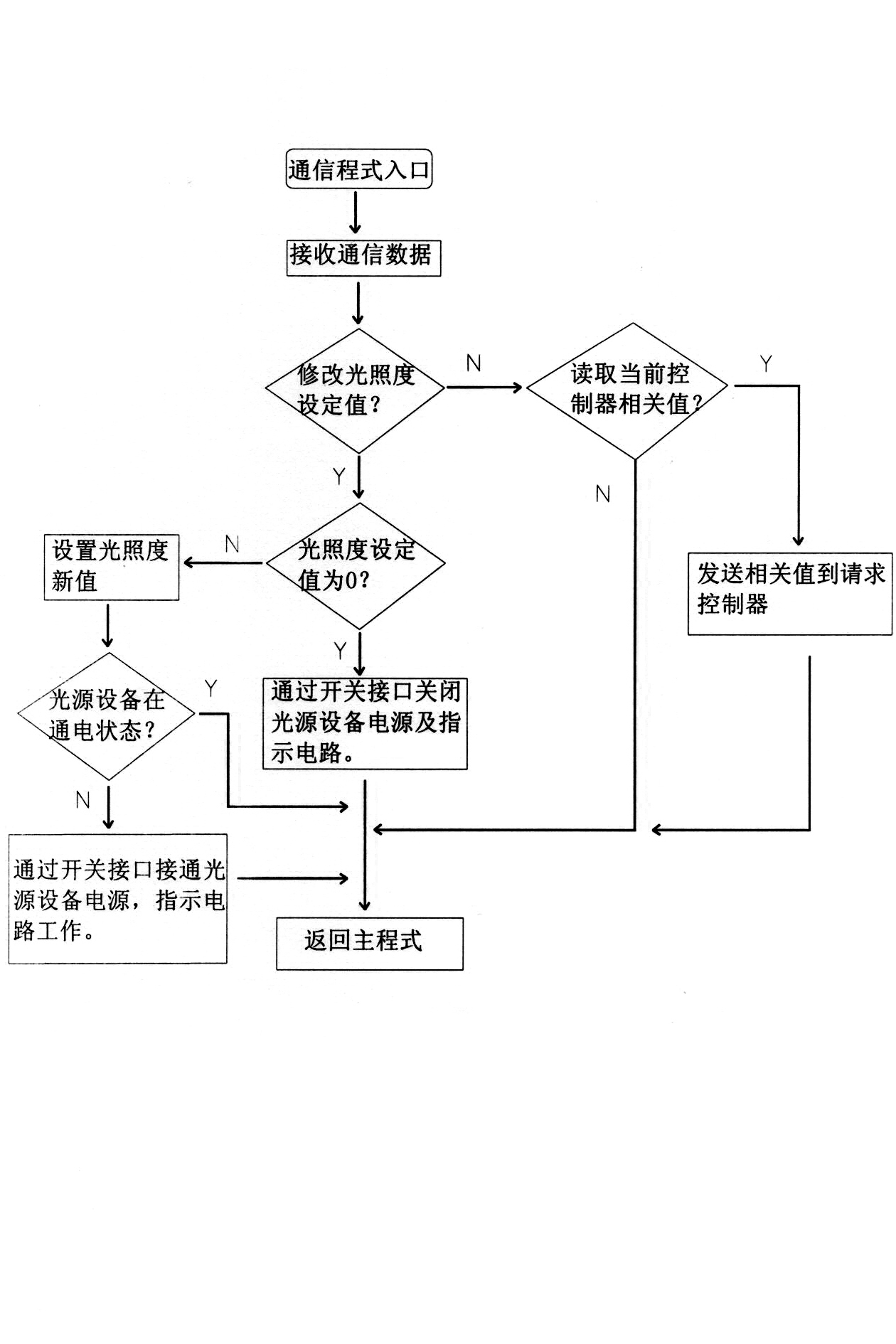

Control system and method of illumination equipment

InactiveCN102045917AIncrease the total output valueOutput value decreasesElectric light circuit arrangementEnergy saving control techniquesLight equipmentControl system

The invention discloses a control system of illumination equipment, comprising an illumination equipment body, a central processing unit and an inducing unit, wherein the inducing unit is an optical signal inducer; the central processing unit further comprises a signal input end, an MCU (Microprogrammed Control Unit) processor and an instruction output end, wherein the signal input end is unidirectionally communicated with the optical signal inducer and used for receiving signals from the optical signal inducer; the MCU processor is used for receiving data transmitted by the signal input end, calculating according to the preset program and sending an instruction to the instruction output end; and the instruction output end is used for receiving the instruction from the MCU processor and sending the instruction to the illumination equipment body to control the working state of the illumination equipment body. The control system can intelligently control the working states including on-off, luminance, colors and the like of the illumination equipment according to the strength of environmental light, thereby achieving the purposes of intelligence, energy saving and convenience for use.

Owner:ZHONGSHAN XINGHAN TECH

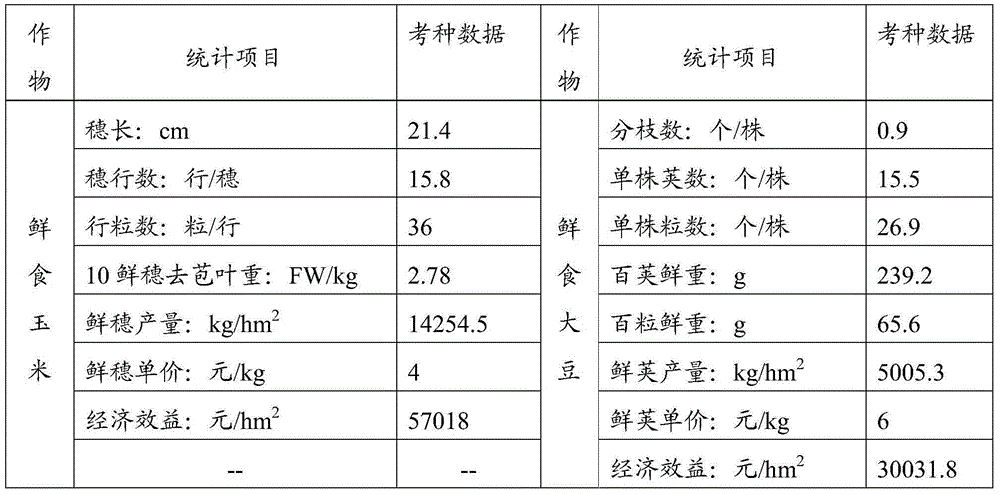

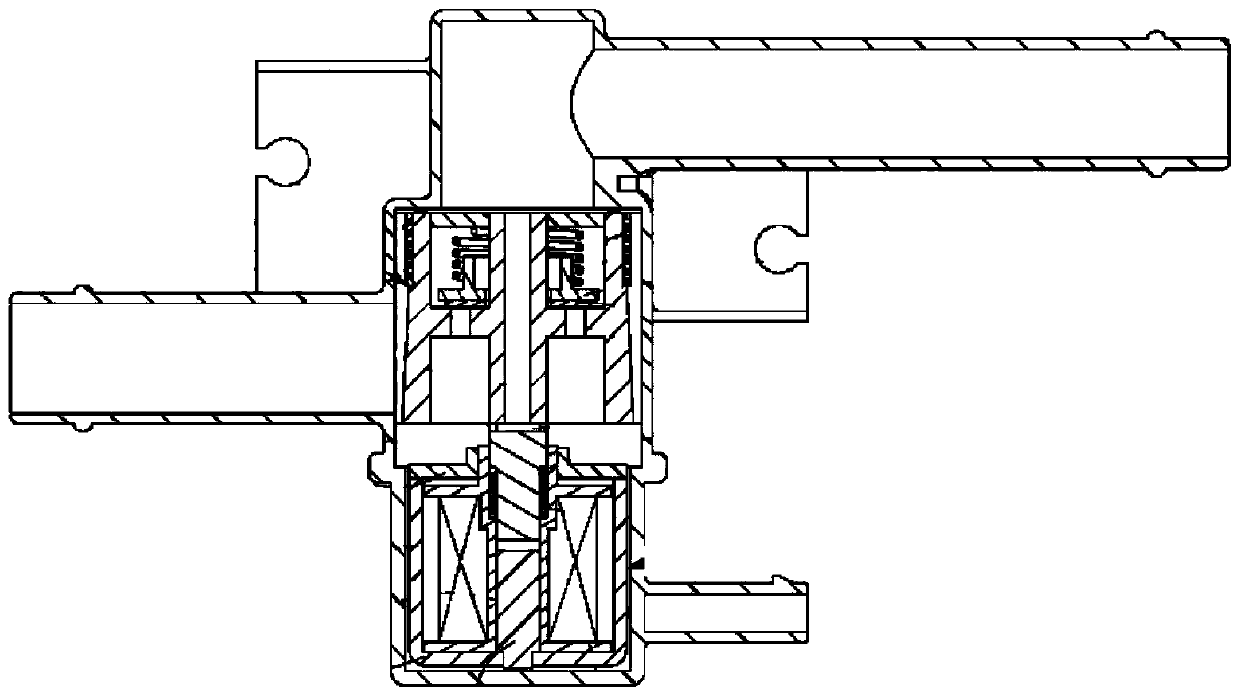

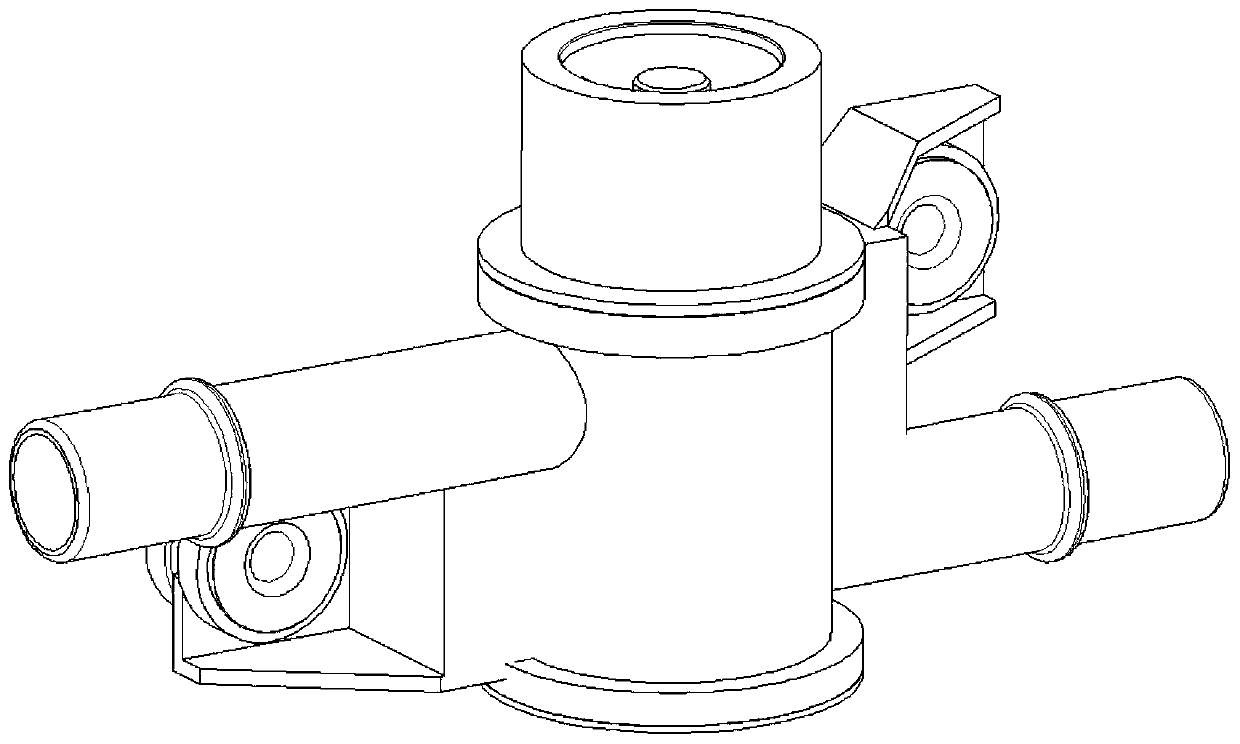

Integrated oil tank isolation valve

PendingCN110594459AEnsure safetyReduce the output force valueOperating means/releasing devices for valvesNon-fuel substance addition to fuelIsolation valveFuel tank

The invention relates to an integrated oil tank isolation valve. The integrated oil tank isolation valve comprises a shell body, an electromagnetic valve assembly, an air supply valve assembly, a deflation valve assembly and a sealing terminal. A first cavity body and a second cavity body are arranged in the shell body, the shell body is provided with a partition plate for partition. A first channel and a second channel are respectively extended along the first cavity body and the second cavity body. A central through hole and a circumferential through hole are formed in the partition plate. The air supply valve assembly is used for blocking the circumferential through hole and is arranged in the first cavity body, and the air supply valve assembly is provided with an air supply cavity connected with the first channel. The deflation valve assembly is arranged in the second cavity body, and the deflation valve assembly is provided with a deflation cavity connected with the second channel. The sealing terminal is arranged in the air supply cavity and can penetrate through the central through hole, and the sealing terminal is driven by the electromagnetic valve assembly to move to determine partition or communication of the air supply cavity and the deflation cavity. At the initial stage when the electromagnetic valve assembly is energized, the sealing terminal is subjected to small-distance displacement to relieve the partition of the deflation valve assembly, that is, the pressure difference between the air supply cavity and the deflation cavity is reduced when the air supply valve assembly is opened.

Owner:STANT AUTOMOTIVE SYST SUZHOU

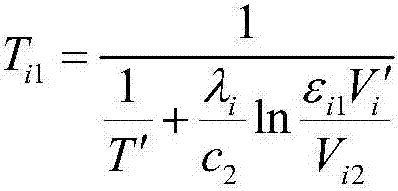

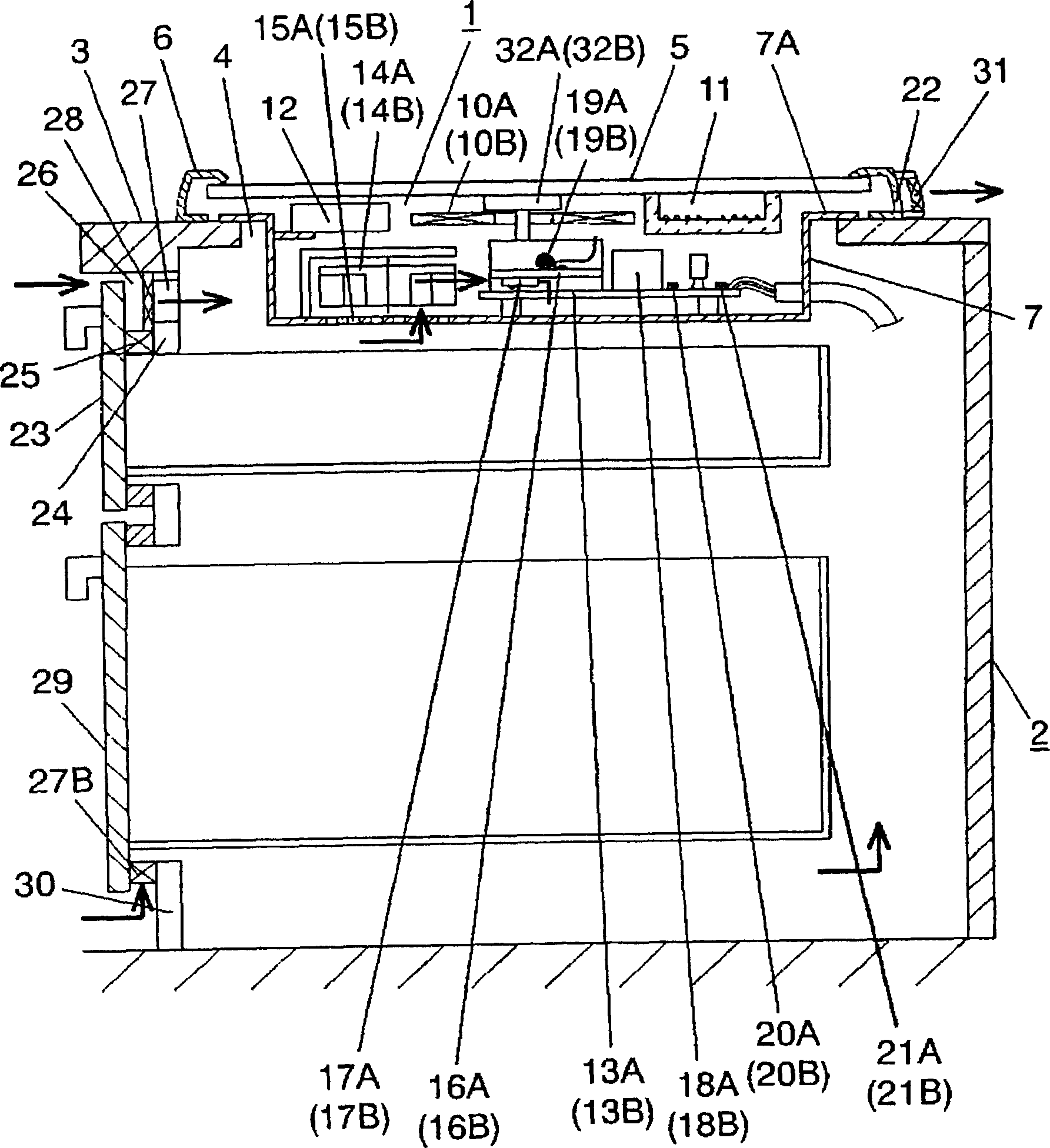

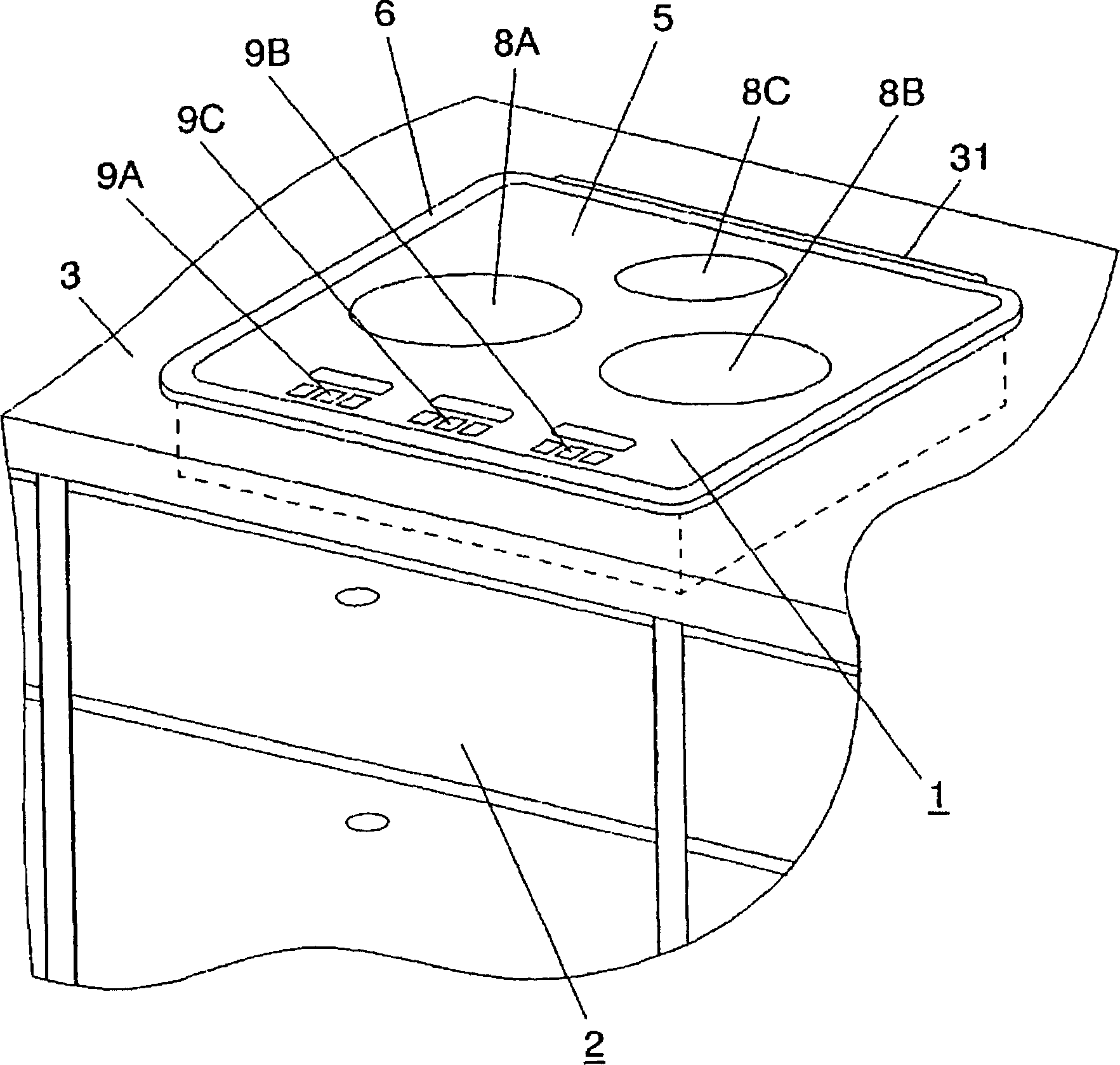

Induction heating cooker and cooking table using the same

InactiveCN1875661AIncrease the total output valueReduce outputInduction heating controlInduction heating apparatusEngineeringControl unit

An induction heating cooker includes: an external shell, a heating coil, a power source circuit, a plurality of temperature detection elements, and a control unit for controlling output of the heating coil. The heating coil is arranged in the external shell. The power source circuit has a plurality of heating elements and supplies a high-frequency current to the heating coil. The temperature detection elements respectively detect temperatures of the heating elements. When one of the temperatures detected by the temperature detection elements has reached a temperature predetermined for each of the temperature detection elements, the control unit lowers the output of the heating coil. When one of the temperatures detected by the temperature detection elements is higher than a first temperature and has reached a second temperature predetermined for each of the temperature detection elements, the output of the heating coil is further lowered.

Owner:PANASONIC CORP

Forage grass multiple cropping method by using potatoes

InactiveCN110447490AEliminate the effects of growthUniform growthSeed and root treatmentClimate change adaptationDiseaseDiseased plant

The invention discloses a forage grass multiple cropping method by using potatoes. Firstly, early-maturing potatoes are planted in a shed or a field to be harvested as early as possible, and forage grass multiple cropping is performed in time after the early-maturing potatoes are harvested; when the early-maturing potatoes are planted, a sandy loam or lam plot with a higher fertility level is chosen, deep ploughing is performed before winter, farmyard manure is spread before seeding, then deep ploughing and rotary tillage are performed, the shed is established in the shed planting plot at thesame time, fertilization and seeding are performed when the lowest temperature at the depth of 10-centimeter soil reaches 6-7 DEG C and the soil moisture content is reached no matter in the shed or inthe field, and after seedling emergence, ventilation, irrigation and artificial weeding are performed in time; first intertillage soil loosening combined with irrigation and weeding is performed whenthe seedling height is 5-10 centimeters; second intertillage soil loosening combined with weeding is performed when the seedling height is 15-20 centimeters, irrigation is combined, 5 kilograms of urea is dressed per mu, disease, insect and grass damage prevention and control are performed, and bad and diseased plants are removed; harvesting is performed in early June. The problems of land and light and heat resource waste and large artificial investment of only planting early-maturing potatoes are solved.

Owner:刘昭明

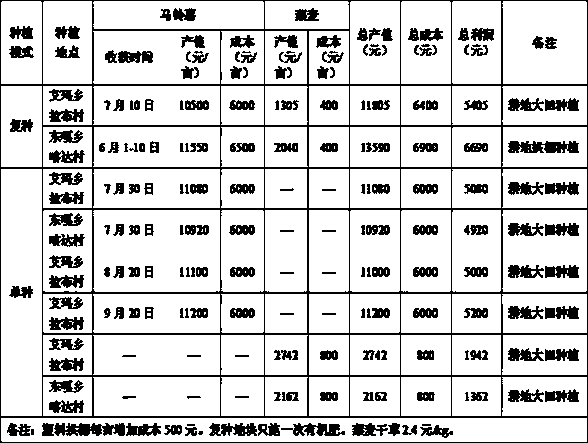

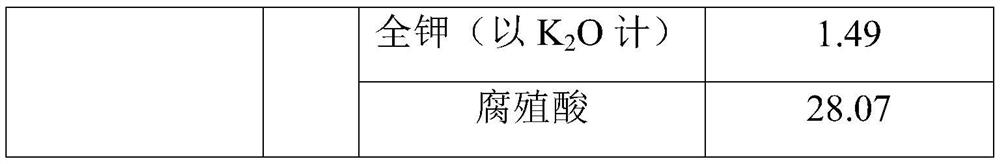

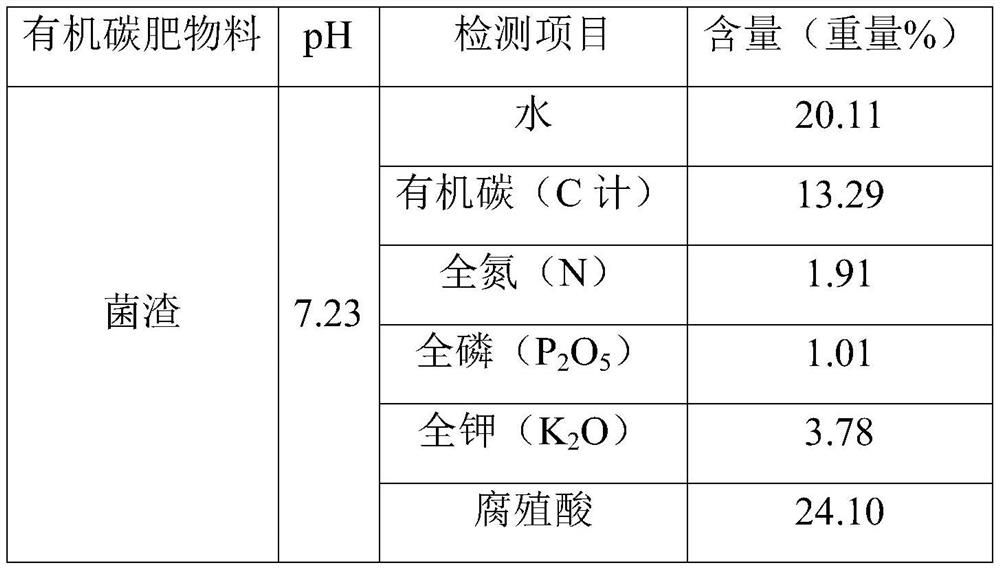

Organic carbon fertilizer, application thereof and method for preventing and treating tobacco rhizome diseases

ActiveCN112194532AWide variety of sourcesLow costBio-organic fraction processingBioloigcal waste fertilisersNicotiana tabacumPharmaceutical industry

The invention relates to the technical field of biological prevention and treatment of crop diseases, and discloses an organic carbon fertilizer, application thereof and a method for preventing and treating tobacco rhizome diseases. The organic carbon fertilizer provided by the invention has the characteristics of readily available raw materials, low cost, good prevention and treatment effect on tobacco rhizome diseases, environmental friendliness and the like. By utilizing the organic carbon fertilizer provided by the invention, continuous and effective prevention and treatment of tobacco rhizome diseases can be realized, meanwhile, the utilization rate of wastes in the mushroom breeding industry and the pharmaceutical industry is also improved, and mutual benefit and win-win between industries are realized, so that the production economy is improved, and the sustainable development of each industry is promoted.

Owner:云南省烟草公司保山市公司 +1

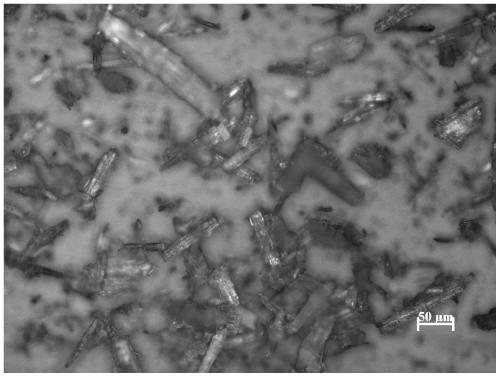

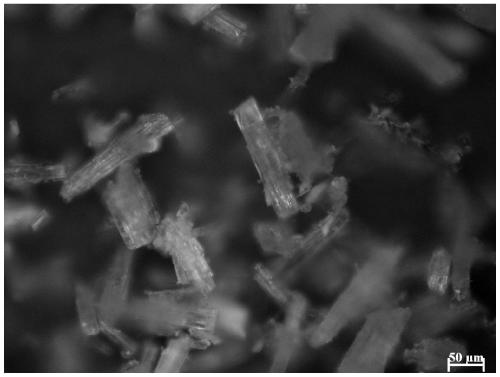

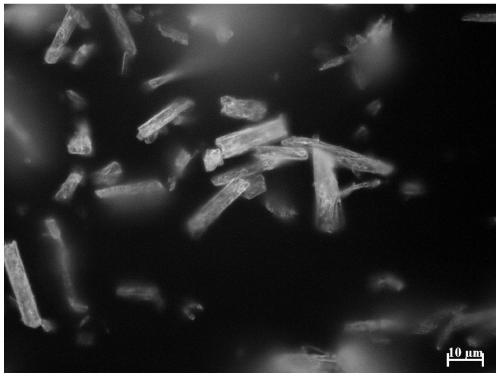

Method for preparing calcium sulfate whiskers from bone gelatin wastewater

ActiveCN111118606AEasy to handleHigh purityPolycrystalline material growthFrom normal temperature solutionsSulfatePulp and paper industry

The invention discloses a method for preparing calcium sulfate whiskers from bone gelatin wastewater. According to the method, waste water of a bone gelatin production line, namely waste water of a pickling workshop, is utilized as a raw material, wherein the calcium sulfate dihydrate whiskers grow in the aging process through the means of dilution, ammonium chloride addition for dissolution promotion, excessive sulfuric acid addition for acidification and the like, the recovery rate of calcium in the waste water of the pickling workshop can reach 80% or above, and the obtained whiskers are high in purity and whiteness and uniform in form. The method can effectively treat the problem of overhigh calcium content in the wastewater of the bone gelatin pickling workshop, reduce the discharge amount of three wastes and improve the output value of a bone gelatin production line.

Owner:ZHEJIANG HUANYAO ENVIRONMENTAL CONSTR

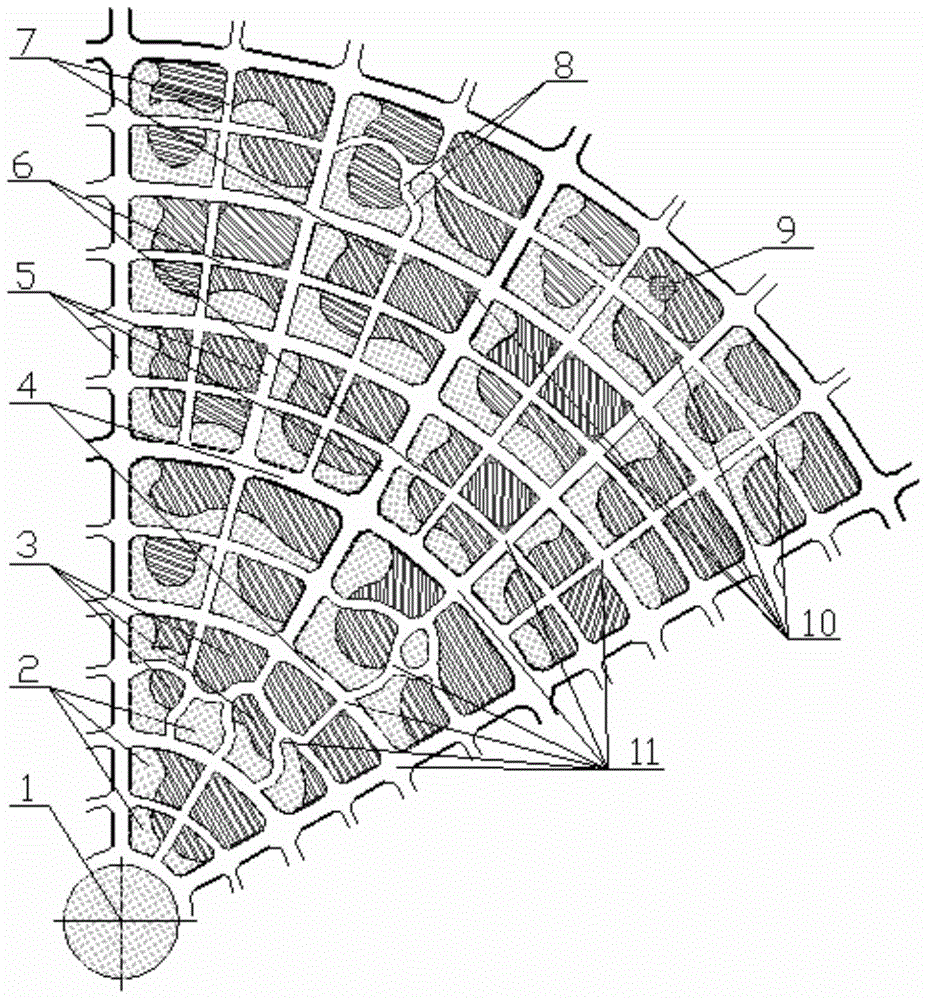

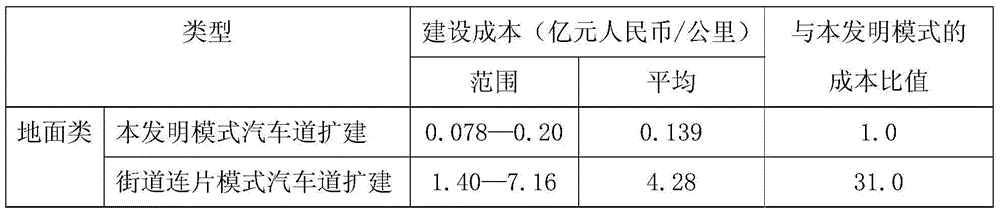

Town planning model adding natural features

ActiveCN104099840AIncrease the total output valueImprove the quality of lifeRoadwaysPublic buildingsWater sourceEngineering

The invention discloses a town planning model adding natural features. Natural features are added on the base of a street continuous planning model; each subarea of the town comprises natural features, town building areas and roads; the natural features comprise two parts of town function extending standby space and permanent natural features; comprehensive benefits of the town planning model is higher than the benefits of a street continuous model by one time. The town planning model adding natural features has the advantages as follows: 1, traffic advantage: the town planning model solves the problem that automobiles are blocked up in a town and parking is difficult; traffic investment is highly flexible; traffic investment price is low; population time density is improved by a plurality of times; 2, resource and environment advantages: renewable energy advantage is formed at first; at the same time, the advantages that secondary energy crisis is solved, atmosphere and water body pollution is basically controlled, and energy cost is reduced are formed; the town planning model adding the natural features has the advantages that town and city complement advantages mutually, and town water source and space required by public service extension are ensured.

Owner:池昭新

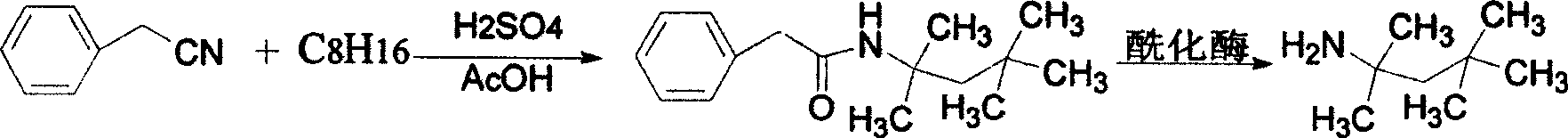

Process for preparing tert-octylamine

InactiveCN100503834CMild conditionsEasy to achieve industrial productionOrganic compound preparationFermentationBenzeneAcetic acid

The invention discloses a preparation method of tert-octylamine, which belongs to the technical field of chemical industry. The preparation process of the invention is as follows: (1) Using glacial acetic acid as a solvent, diisobutene and phenylacetonitrile are reacted under the action of concentrated sulfuric acid and water to generate N-tert-octyl phenylacetamide; (2) In a suitable solvent system, adding N-tert-octyl Phenylacetamide and acylase, make N-tert-octyl phenylacetamide fully hydrolyzed by acylase, and separate tert-octylamine and phenylacetic acid through distillation and recrystallization. Compared with the existing preparation method of tert-octylamine, the invention can not only improve the yield, but also co-produce phenylacetic acid at the same time, and can significantly improve the comprehensive economic benefit. And the hydrolysis conditions are mild and environmentally friendly.

Owner:SHANGHAI JIAO TONG UNIV

Gasification process for producing synthesis gas from garbage and biomass raw materials

InactiveCN101525118BEliminate pollutionHarmlessSolid waste disposalHydrogen productionWater vaporClean energy

The invention provides a gasification process for producing synthesis gas from garbage and biomass raw materials, which relates to a gasification processing technique of garbage and biomasses. The gasification process is characterized in that the technological process mainly comprises a raw material solid matter process, a gas phase circulation loop, a calcium oxide circulation loop and a synthesis gas drawing process; one or a mixture of more garbage, the biomasses and coal is sent into a gasification furnace to perform gasification so as to generate the synthesis gas; and simultaneously, calcium oxide is sent into the gasification furnace, an exothermic reaction of absorbing carbon dioxide by the calcium oxide provides the heat required by the gasification reaction in the furnace, and water vapor is sent into a plasma spraying gun and is heated to more than 3,100 DEG C to generate H2, O, O2 and H2O<*> which are sprayed into the gasification furnace to perform reactions with the garbage and the biomasses and supply heat into the furnace. The gasification process adopts a measure to spray the calcium oxide into the furnace to not only greatly reduce the electric energy consumptionof the plasma spraying gun, but also improve the quality and the yield of the synthesis gas, thus the aim of transforming the garbage and the biomasses into clean energy can be achieved easily.

Owner:周开根

Coated insecticide-fertilizer for preventing diseases and insect pests of strawberry and preparation method thereof

InactiveCN104177197AImprove permeabilityImprove physical propertiesFertilizer mixturesNutrientHydroxypropylmethyl cellulose

The invention discloses a coated insecticide-fertilizer for preventing diseases and insect pests of strawberry. The coated insecticide-fertilizer is characterized by being prepared from the following raw materials in parts by weight: 10-14 parts of peanut meal, 12-15 parts of seaweed meal, 13-16 parts of soybean meal, 9-11 parts of zeolite powder, 14-19 parts of urea, 14-18 parts of potassium double superphosphate, 1-2 parts of zinc sulfate, 15-18 parts of hydroxypropyl methylcellulose, 2-4 parts of fumaric acid, 1-2 parts of sodium tetraborate, 6-8 parts of BSFA, 5-7 parts of EM microbial inoculum, 10-15 parts of soil improvement agents and a right amount of water. By utilizing nutrient elements which meet the requirement for crop growth and the natural antibacterial and insecticidal effects of sweet potato seeds and thick-fruited millettia seeds, the coated insecticide-fertilizer disclosed by the invention not only can be used as an insecticide, but also can be used as a fertilizer and is capable of loosening the soil, enhancing the permeability of the soil and improving the physical property of the soil, thereby greatly increasing the additional value of products; and the added BSFA plays roles in loosening the soil, enhancing the fertilizer retaining capacity of the soil, strengthening the adhesive power and absorbing capacity of strawberry root systems. The coated insecticide-fertilizer disclosed by the invention has the advantages of easiness and convenience in processing, low cost and easiness in operation, is safe to the environment and can reduce the labor output and increase the output value.

Owner:HUAINAN YINONG MELON & FRUIT PRODION & MARKETING SERVICE

RGB to RGBW color decomposition method and system

ActiveCN101370148BImprove reflectivityDesaturationColor signal processing circuitsCathode-ray tube indicatorsPattern recognition

A Red Green Blue-to-Red Green Blue White (RGB-to-RGBW) color decomposition method and system. The RGB-to-RGBW color decomposition method includes: determining an output value of white based on inputted RGB values and a saturation; and outputting the output value when an input color is a pure color.

Owner:SAMSUNG ELECTRONICS CO LTD

Summer corn and summer peanut intercropping planting method

InactiveCN103650887BIncrease the total output valueNo reduction or slight reduction in outputHorticultureAgricultural scienceArachis hypogaea

The invention relates to a summer corn and summer peanut intercropping planting method and belongs to the technical field of crop planting. According to the summer corn and summer peanut intercropping planting method, three lines of corn are intercropped with four lines of peanuts, the corn line width is 55cm, the corn planting distance is 15cm, the peanut line width is 33-35cm, the peanut hill spacing is 14cm, the peanuts are planted in a ridging mode, the ridge width is 85cm, two lines of the peanuts are sown in each ridge, and the distance between the corn lines and the peanut ridges is 35cm. Three lines of the corn and four lines of the peanuts are arranged in an alternating mode, intercropping is carried out in a wide width mode, the corn line width, the corn planting distance, the peanut line width, the peanut hill spacing, and the distance between the corn lines and the peanut ridges are strictly limited, and therefore the total output value is remarkably improved.

Owner:VEGETABLE RES INST OF SHANDONG ACADEMY OF AGRI SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com