Patents

Literature

104results about How to "Easy to achieve industrial production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing high-purity cyclopentadiene

ActiveCN102060649AMild reaction conditionsControllableHydrocarbon by depolymerisationReboilerNitrogen gas

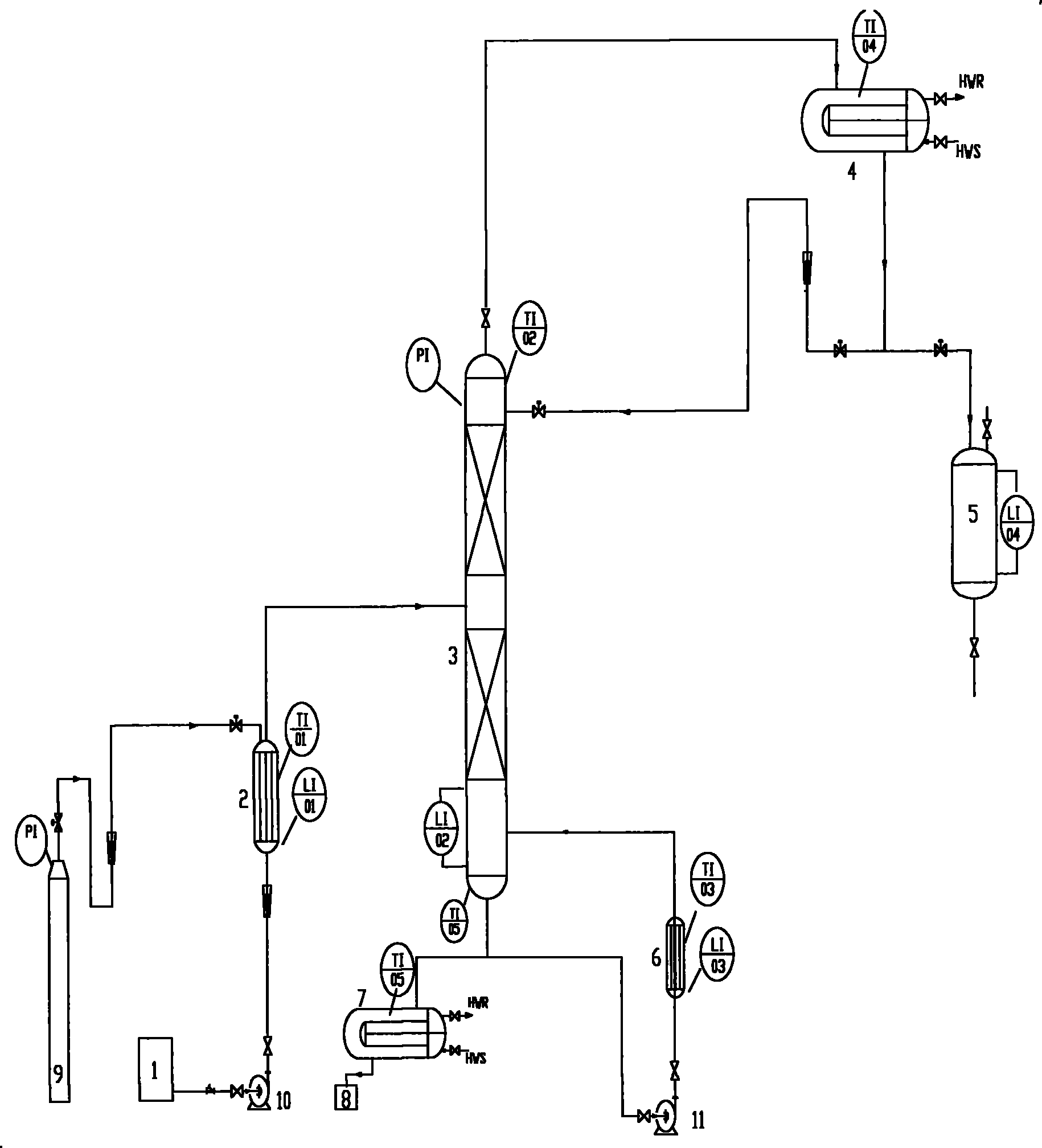

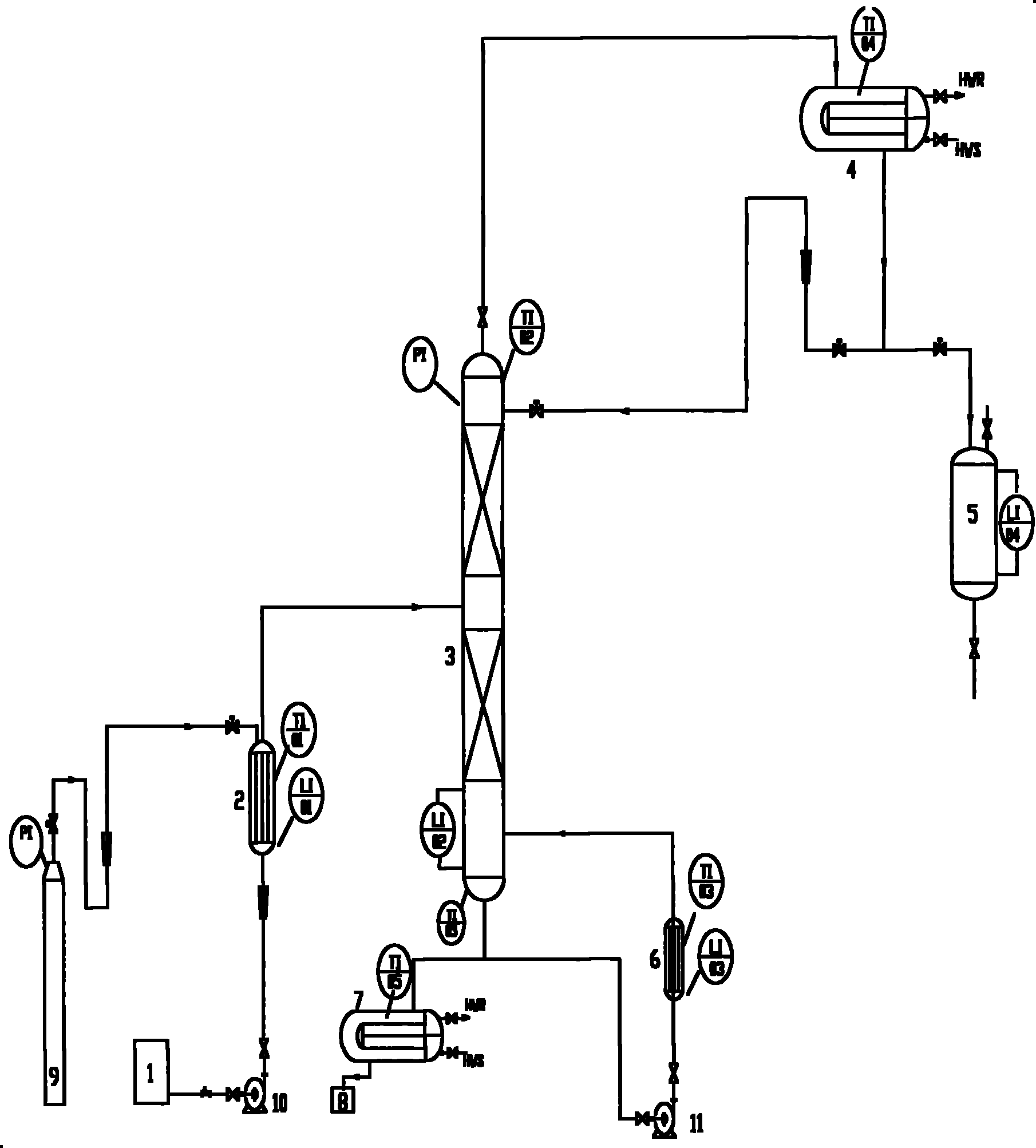

The invention relates to a method for preparing high-purity cyclopentadiene, which comprises the following steps of: heating a thermal decomposer containing purified conduction oil and a composite inhibitor and a rectifying reboiler to a specified temperature; adding dicyclopentadiene serving as a crude product into the thermal decomposer continuously and stably; allowing the depolymerized cyclopentadiene to enter a rectifying column; extracting high-purity cyclopentadiene from a tower top, heating a small amount of dicyclopentadiene and by-products by the reboiler at the tower bottom to rectify the small amount of dicyclopentadiene and by-products again, and recycling kettle liquid. The method has the advantages of simple equipment, high production capacity, little coking and long service life of the conduction oil serving as a raw material and the equipment.

Owner:PETROCHINA CO LTD

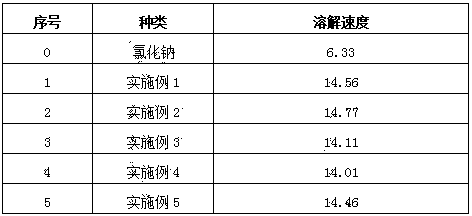

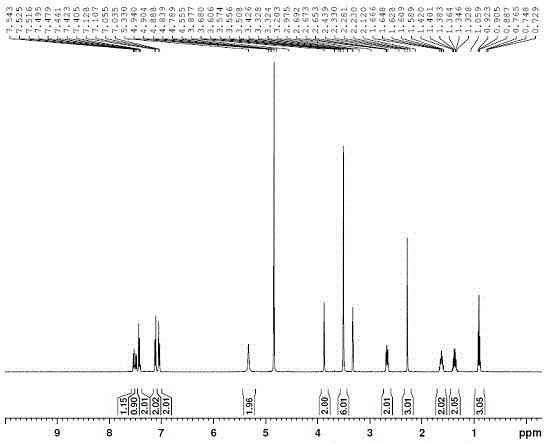

Ternary positive pole material precursor and method for adjusting and controlling crystal face growth of ternary positive pole material precursor

ActiveCN109742337AEasy to achieve industrial productionEasy to realize industrializationCell electrodesSecondary cellsManganeseSurface-active agents

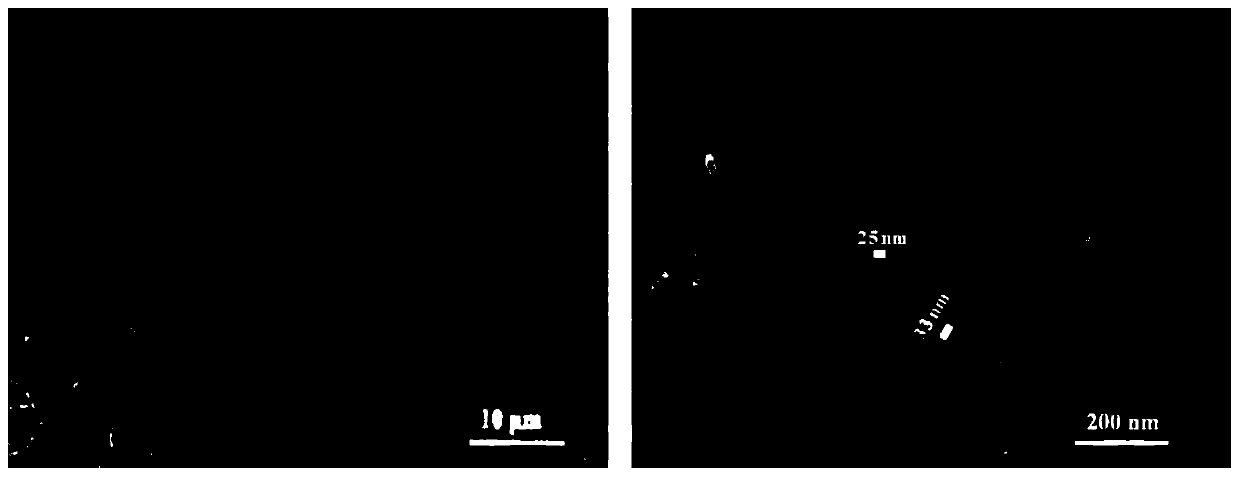

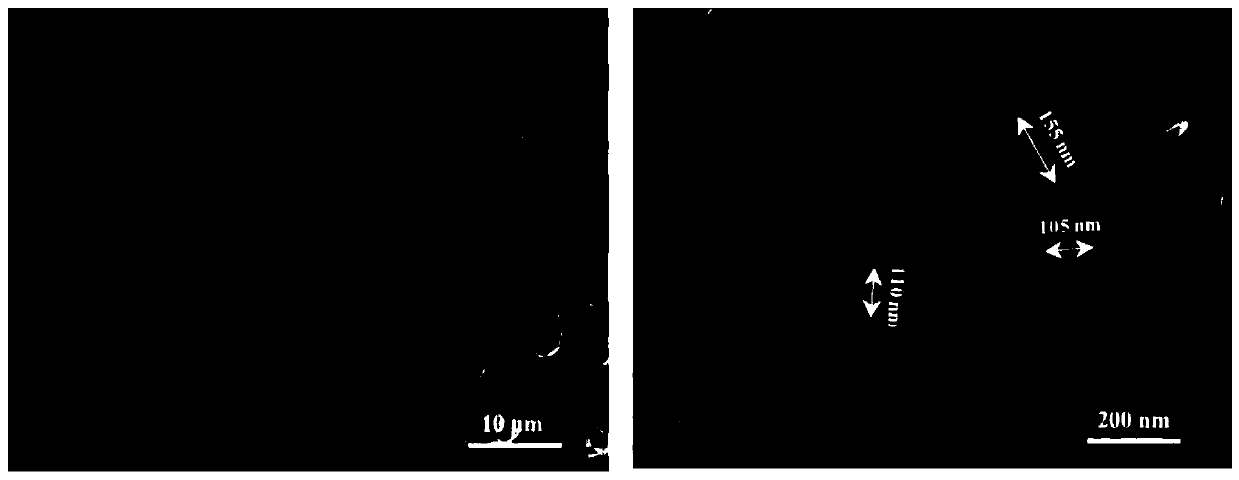

The invention discloses a ternary positive pole material precursor and a method for adjusting and controlling crystal face growth of the ternary positive pole material precursor, and belongs to the field of chemical energy storage batteries. The chemical formula of the ternary positive pole material precursor is Ni<x>Co<y>Mn<1-x-y>(OH)<2>, wherein 0<x<1, 0<y<1, and 0<(x+y)<1; primary particles ofthe precursor are nanosheets, and the thickness of the nanosheets is 20-250nm. The method for adjusting and controlling crystal face growth comprises the steps that the nickel-cobalt-manganese ternarypositive pole material precursor is prepared by a hydroxide co-precipitation method, a surface active agent is added in the synthesizing process to adjust and control growth of the preferential crystal face in the primary particles of the nickel-cobalt-manganese ternary positive pole material precursor, precursor materials of different preferential crystal face proportions are obtained, the positive pole material with different Li<+> diffusion speed is obtained through subsequent lithium-mixing calcination, and different electromechanical properties are shown.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

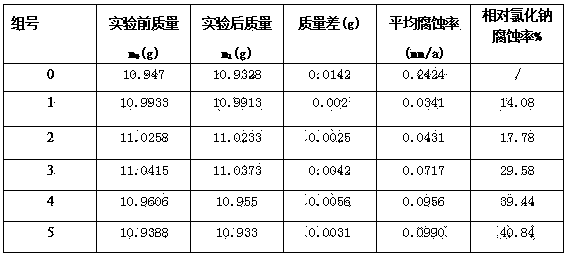

Low-corrosion and high-efficiency chlorine salt deicing agent and preparation method thereof

ActiveCN104293298ALow costWide variety of sourcesOther chemical processesChemical adsorptionTemperature and pressure

The invention discloses a low-corrosion and high-efficiency chlorine salt deicing agent, which is prepared from the following raw materials in percentage by mass: 85%-98% of sodium chloride, 1%-10% of a corrosion inhibitor and 1%-5% of an adjuvant, wherein the corrosion inhibitor is prepared from sodium silicate, disodium hydrogen phosphate, sodium tartrate and sodium citrate; and the adjuvant is prepared from sodium humate, urea and heteroauxin. Silicate in the corrosion inhibitor disclosed by the invention can form a protective film on the metal surface to avoid corrosion to metal caused by chlorine salt and synergistic effect of disodium hydrogen phosphate and sodium silicate; the corrosion inhibition effect is enhanced; a chemical adsorption layer is formed by coordinated complexation of polar radical of sodium citrate and sodium tartrate donor and a metal surface; a dual-electric layer structure is formed on the metal surface; a drainage layer is formed by nonpolar radical directional arrangement; chemical corrosion of metal is prevented; and the damages to soil and plants can be reduced by urea, sodium humate and heteroauxin. The preparation method disclosed by the invention is simple, mild in condition, available in raw materials, and easy to put into industrial application, and can be carried out under normal temperature and pressure.

Owner:黄山九星环保科技股份有限公司

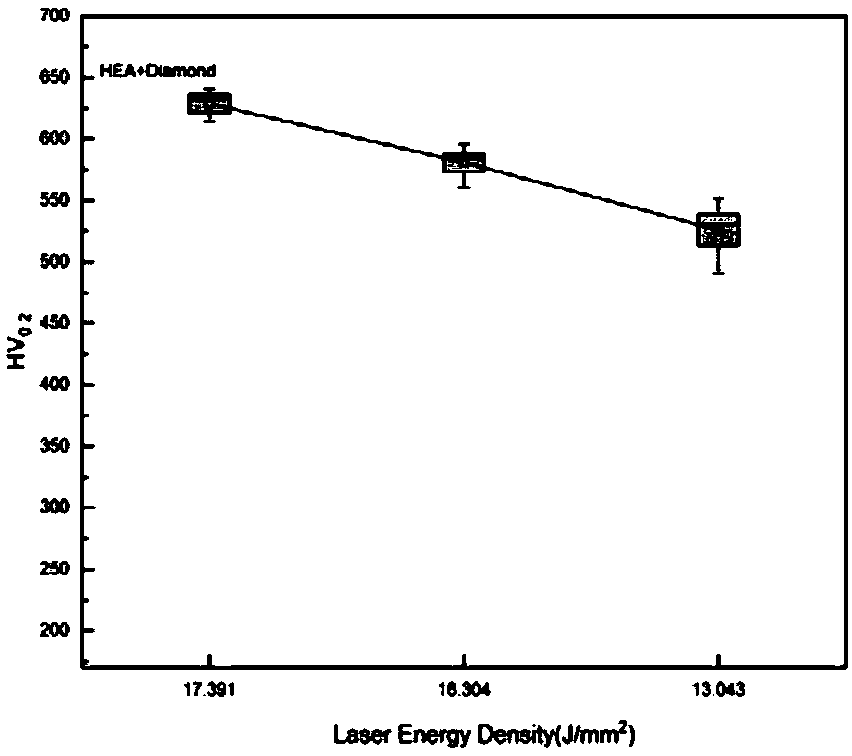

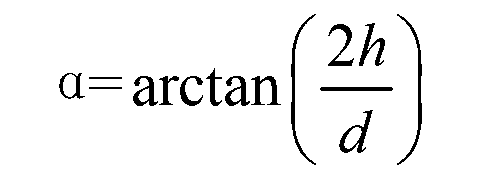

Method for preparing high-entropy alloy/diamond composite film or coating by fixed-point energy input and rapid cooling

ActiveCN108588704AImprove bindingImprove controllabilityMetallic material coating processesComposite filmHigh entropy alloys

The invention belongs to the field of preparation of composite materials, and relates to a method for preparing a high-entropy alloy / diamond composite film or coating by fixed-point energy input and rapid cooling. The preparation method comprises the steps that high-entropy alloy powder and diamond particles are prepared according to a set ratio; a high-entropy alloy / diamond composite is preparedby the methods of the fixed-point energy input and rapid cooling; the energy density range of the fixed-point energy input is 10-40J / mm<2>; the cooling rate is greater than or equal to 106 DEG C / min;and during fixed-point energy input, the diameter of an energy input point is 4.5-6.3mm, and the moving speed of the energy input point is 40-100mm / s. A carrier and diamonds are protected from being destroyed, and at the same time, the high-entropy alloy / diamond composite film or coating is rapidly prepared, so that uniform distribution of the diamond particles inside the carcass is realized, andthe process is suitable for the diamond particles with various qualities and various types of laser cladding equipment.

Owner:江西咏泰粉末冶金有限公司

Mobile starch and dry-process preparation method thereof

The invention discloses mobile starch and a dry-process preparation method thereof. The method comprises the following steps of: heating and drying the starch in a dry-process reactor, and cooling to room temperature; uniformly mixing the dried starch with the salt and alkali solution in the dry-process reactor respectively, heating and drying the starch, and cooling to room temperature; spraying alkenyl succinic anhydride into the dry-process reactor; closing the reactor; keeping stirring to react for 1-4 hours at 30-50 DEG C, and then continuing reacting for 30-100 minutes at 80-120 DEG C; spraying a hydrochloric acid solution into a reaction tank so that the starch is acid; adjusting and controlling the moisture content of the starch; spraying a high-valence ion salt solution to react, and heating to continue the reaction; and finally grinding and sieving to obtain the high-performance mobile starch. The obtained product has low production cost and good hydrophobicity and mobility, and is widely applied to the fields of chemicals for daily use, printing, oil exploitation, agriculture and the like.

Owner:SOUTH CHINA UNIV OF TECH

Method for preparing silk protein composite cellulose fibers

ActiveCN102505170AHigh recycling valueLow viscosityArtificial filaments from viscoseProtein solutionSulfonate

The invention discloses a method for preparing silk protein composite cellulose fibers, which includes steps: firstly, adding degummed waste silk into LiBr solution, dissolving the waste silk to prepare silk protein solution in which silk protein accounts for 3-15%, by weight; secondly, adding the silk protein solution into sodium hydroxide solution with cellulose sulfonate to obtain blended solution of silk protein and cellulose, wherein blended silk protein solution accounts for 5-50% of that of the sodium hydroxide with cellulose sulfonate by weight; and thirdly, spinning the blended solution by coagulating bath and obtaining the silk protein composite cellulose fibers by post-processing. By the method, recovery value of the waste silk is improved greatly, special effects of whitening and skin caring of the silk protein composite cellulose fibers can be realized, and the fibers are smooth and soft to touch as silk, and have the skin caring and whitening effects that the effects of protein powder fibers or blended fibers of protein powder and cellulose solution cannot match.

Owner:赛得利(盐城)纤维有限公司

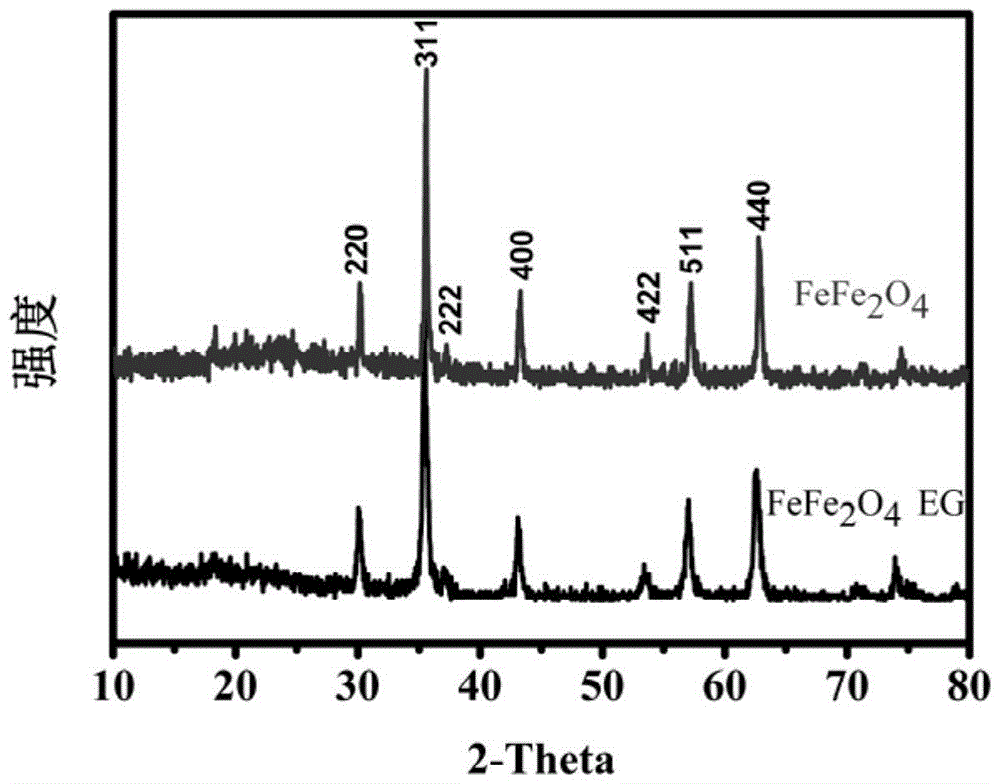

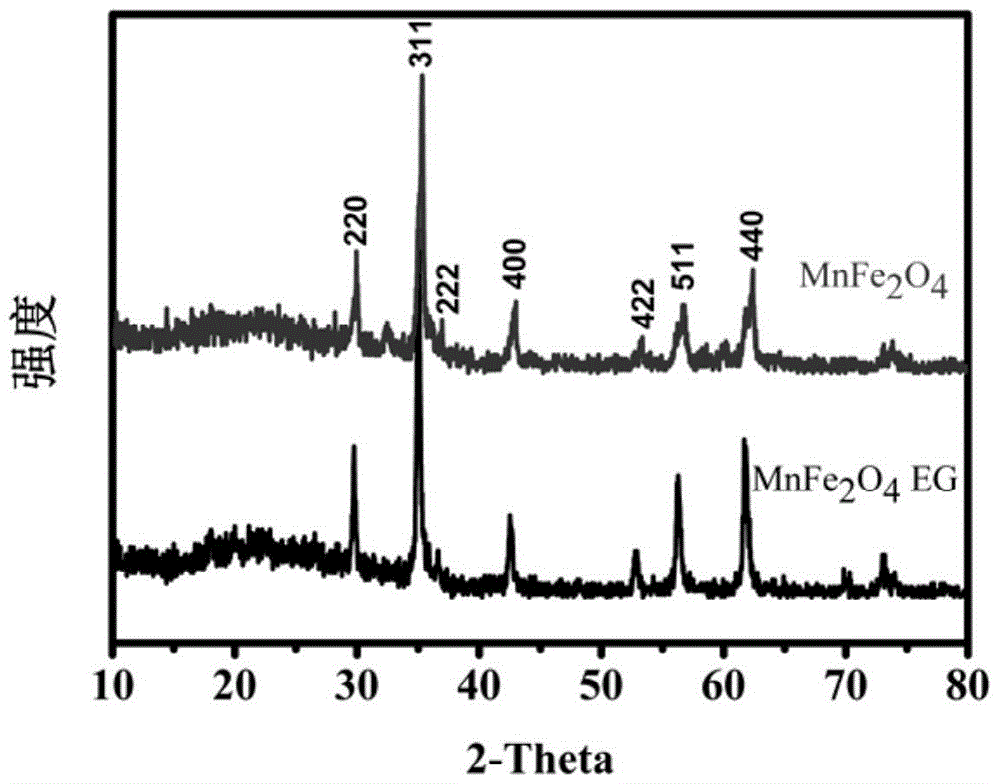

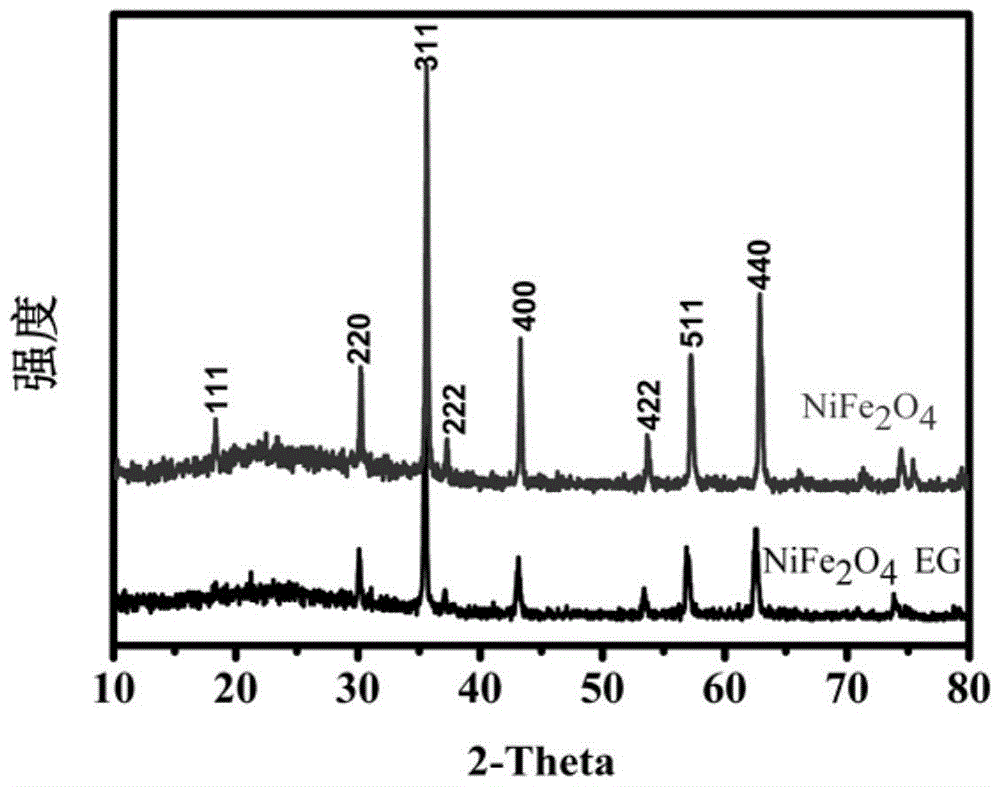

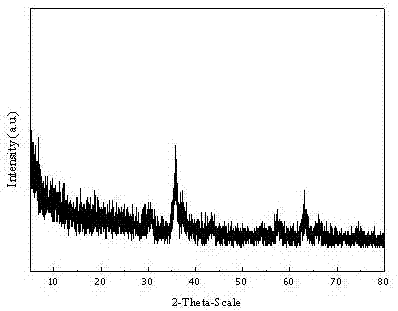

Hydrothermal synthesis method for iron-based spinel with high-density oxygen vacancies

InactiveCN105692714ASolve the problem of difficult restorationThe synthesis process is simpleMaterial nanotechnologyHydrocarbon from carbon oxidesHigh densityOxygen vacancy

The invention discloses a hydrothermal synthesis method for iron-based spinel with high-density oxygen vacancies. The method comprises the steps: firstly, dissolving MCl26H2O (M= Mn, Ni or Fe) and Fe(NO3)39H2O in ethylene glycol, carrying out intense stirring, and clarifying the solution; then, adding NaOH into the solution, and continuing to carry out stirring; then, subjecting the stirred solution to a hydrothermal reaction in a hydrothermal kettle, carrying out natural cooling, and carrying out washing and drying, thereby obtaining iron-based spinel nano-powder with high-density oxygen vacancies. The method has the beneficial effects that the preparation process is simple and convenient, the required equipment is simple, the method is environment-friendly, industrial production is easy to achieve, and the problem that the oxygen vacancies are difficult to reduce is solved fundamentally; the synthesized iron-based spinel has the high-density oxygen vacancies, so that the obtained product is of a pure phase. Under uniform conditions, the CO2 conversion ratio of the iron-based spinel with the high-density oxygen vacancies is increased by 80% or more relative to that of single corresponding iron-based spinel.

Owner:SHANGHAI INST OF TECH

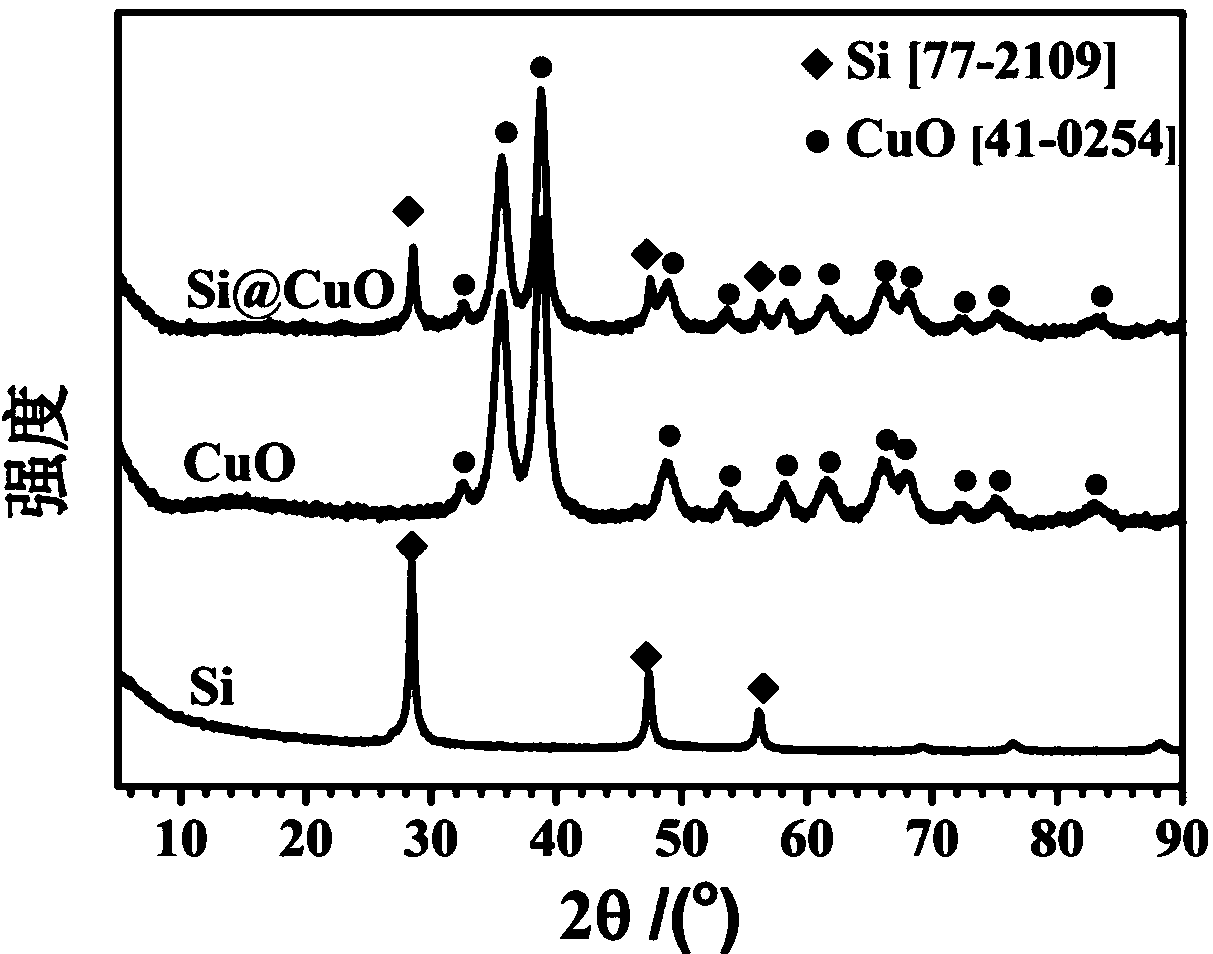

Core-shell structure thermite and preparation method thereof

ActiveCN109369312AShorten the mass transfer distanceLower activation energyExplosivesSilica fumeChemistry

The invention discloses a core-shell structure thermite and a preparation method thereof. The method includes the steps: dissolving poly- 4-vinylpyridine (P4VP) in isopropyl alcohol to form mixed liquid, placing nano-silicon powder into the mixed liquid to ultrasonically treat mixture, centrifugally separating the mixture, washing separated substances by isopropyl alcohol to remove the P4VP without being coated, and drying the separated substances to obtain silicon powder coated by the P4VP; placing the silicon powder into the isopropyl alcohol, adding metal oxide micro-powder with stoichiometric ratio, and ultrasonically treating mixture to form slurry; performing vacuum drying on the acquired slurry, and grinding and crushing the dried slurry to obtain the Si@MOx nano-scale core-shell structure thermite which takes nano-silicon powder as a core and a metal oxide as a shell. According to a core-shell structure, the mass transfer distance between the silicon powder and the metal oxideis shortened, reaction activation energy is reduced, and the external work doing capability of the compound thermite is improved. The preparation method is simple and easy, the prepared core-shell structure thermite has the advantages of good combustion performance, high heat release, accurate and adjustable shell layer thickness and the like.

Owner:CHONGQING UNIV

CN-MCN superhard self-lubricating nano-composite coating and preparation method thereof

InactiveCN102864411AHigh hardnessReduce internal stressVacuum evaporation coatingSputtering coatingHardnessIonization

The invention discloses a CN-MCN superhard self-lubricating nano-composite coating and a preparation method thereof. An electric arc discharge method and a hollow cathode electric arc discharge carbon source combination method are adopted to generate a combination layer, a transition layer, a supporting layer and a lubricating layer to sequentially form the nano-composite coating. The preparation method has the advantages of being high in ionization rate, simple in coating device structure, high in deposition rate and the like. The prepared CN-MCN superhard self-lubricating nano-composite coating is high coating hardness, strong in adhesive power, good in self-lubricating property, high in coating growing speed and production efficiency, low in production cost and friction coefficient and good in coating toughness and can remarkably improve the abrasion-resisting and lubricating performance of processing cutters, dies and mechanical parts. In addition, the preparation method is simple, industrial production is easily achieved, and the CN-MCN superhard self-lubricating nano-composite coating has good application prospect.

Owner:SHENZHEN YUANSIDACHENG TECH

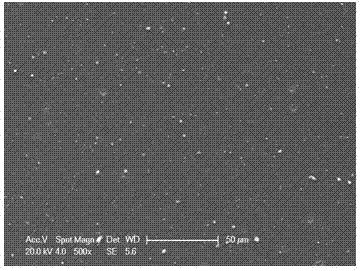

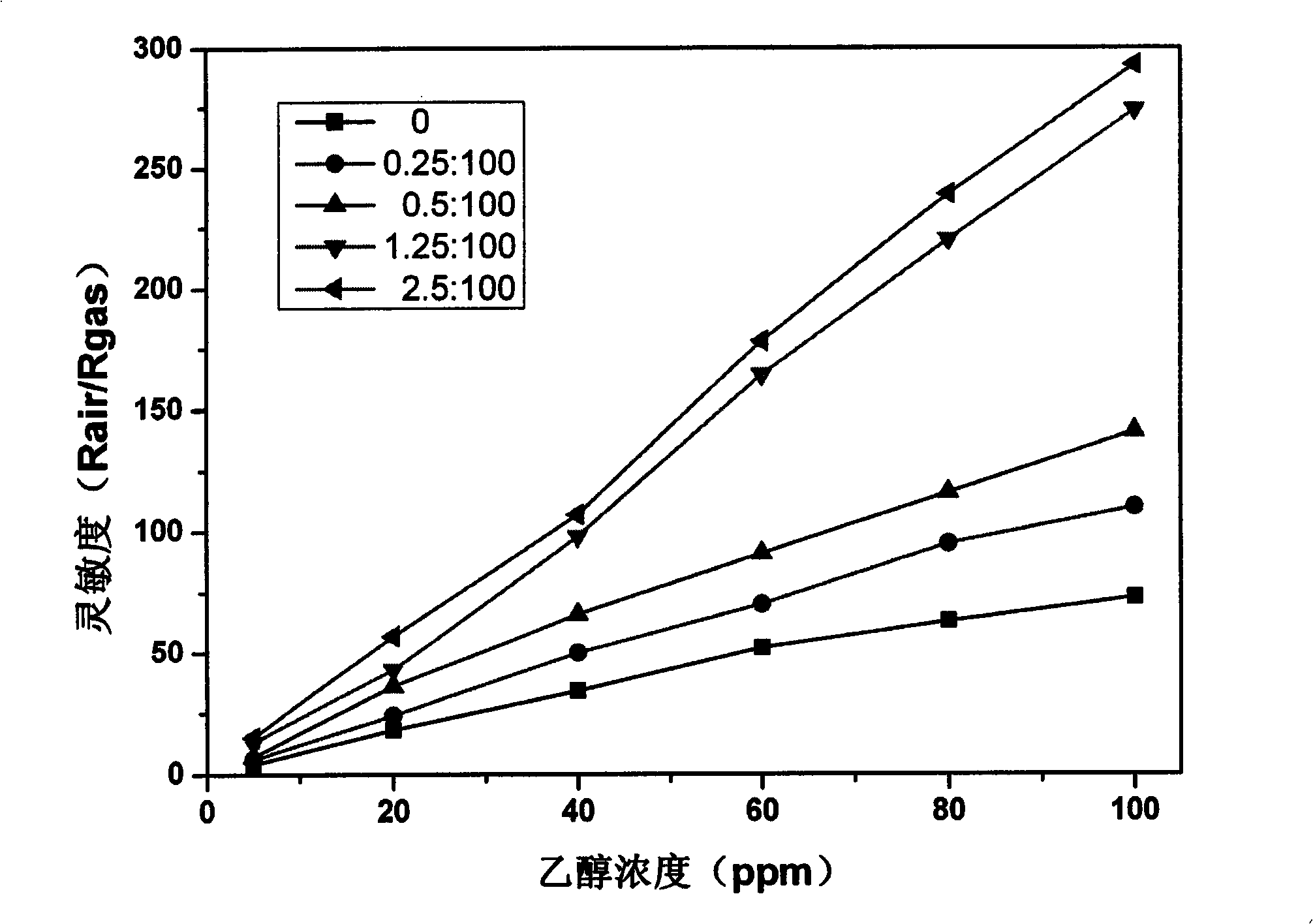

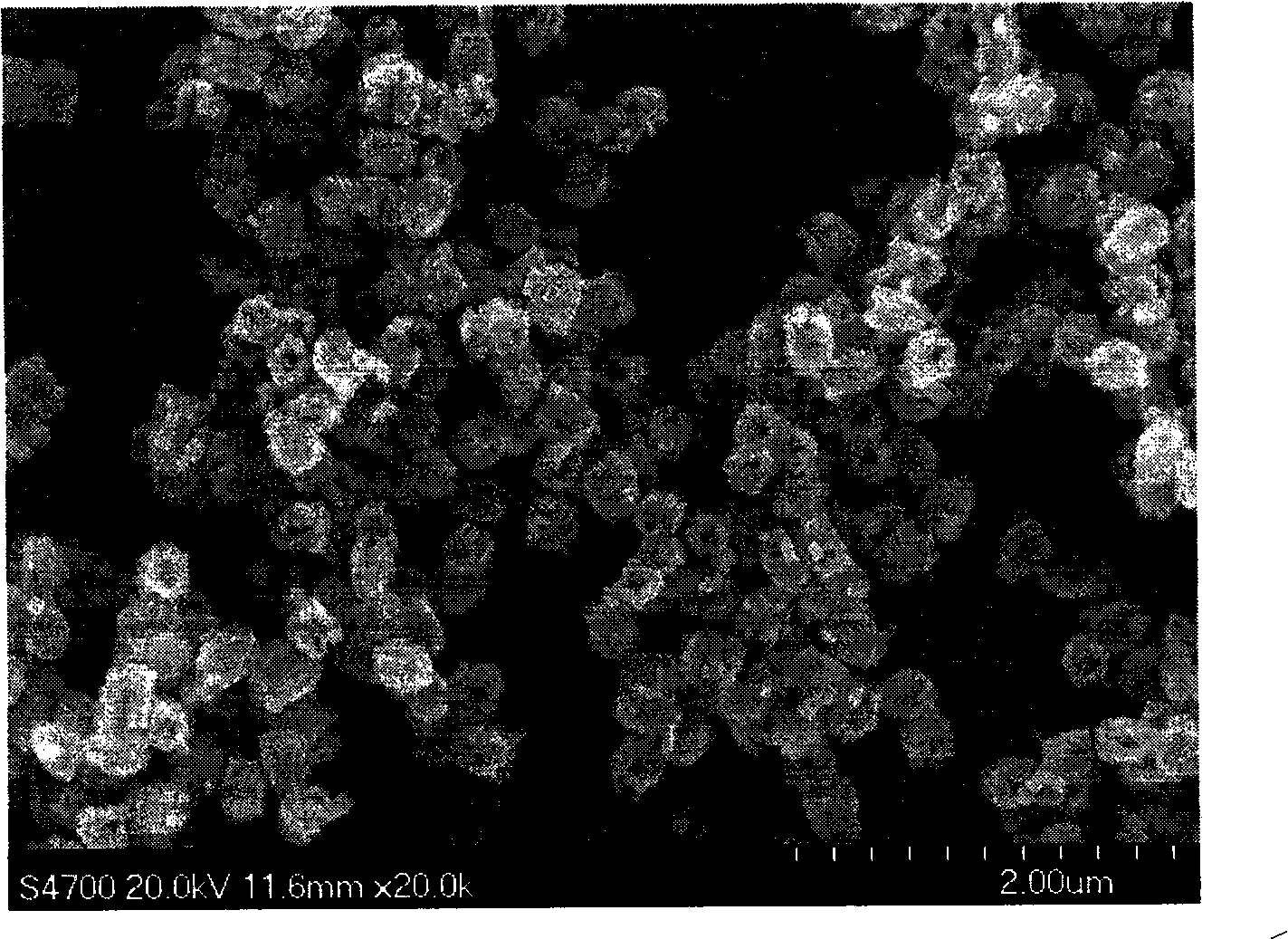

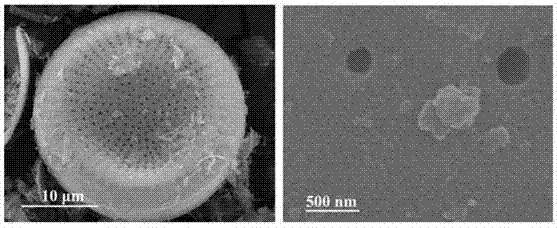

Erbium-doped indium oxide gas-sensitive nano material, preparation method and application thereof

InactiveCN101539537AThe process is simple and convenientEasy to operateGallium/indium/thallium compoundsMaterial resistanceIndium(III) hydroxideMicrosphere

The invention provides an erbium-doped indium oxide gas-sensitive nano material, a preparation method and application thereof. The erbium-doped indium oxide gas-sensitive nano material is an indium oxide nano material doped by erbium oxide and can be expressed as Er2O3-In2O3, wherein the molar ratio of Er to In is 0.25-2.5:100; the indium oxide is hollow spheres which consist of granules of 30 to 60 nanometers and of which diameters are 200 to 300 nanometers; and the erbium oxide is attached to the surface of the indium oxide granules. The preparation method comprises the following steps: using indium salt, methanamide and m-dihydroxybenzene as raw materials to synthesize hollow indium hydroxide microspheres by adopting a hydro-thermal method, and drying and calcining the hollow microspheres to form indium oxide carriers; and then adding indium salt solution into the indium oxide, and grinding, drying and calcining the precipitate to obtain the erbium-doped indium oxide nano material. The gas-sensitive material has high sensitivity for ethanol, and can be used for manufacturing an ethanol gas sensor.

Owner:BEIJING UNIV OF CHEM TECH

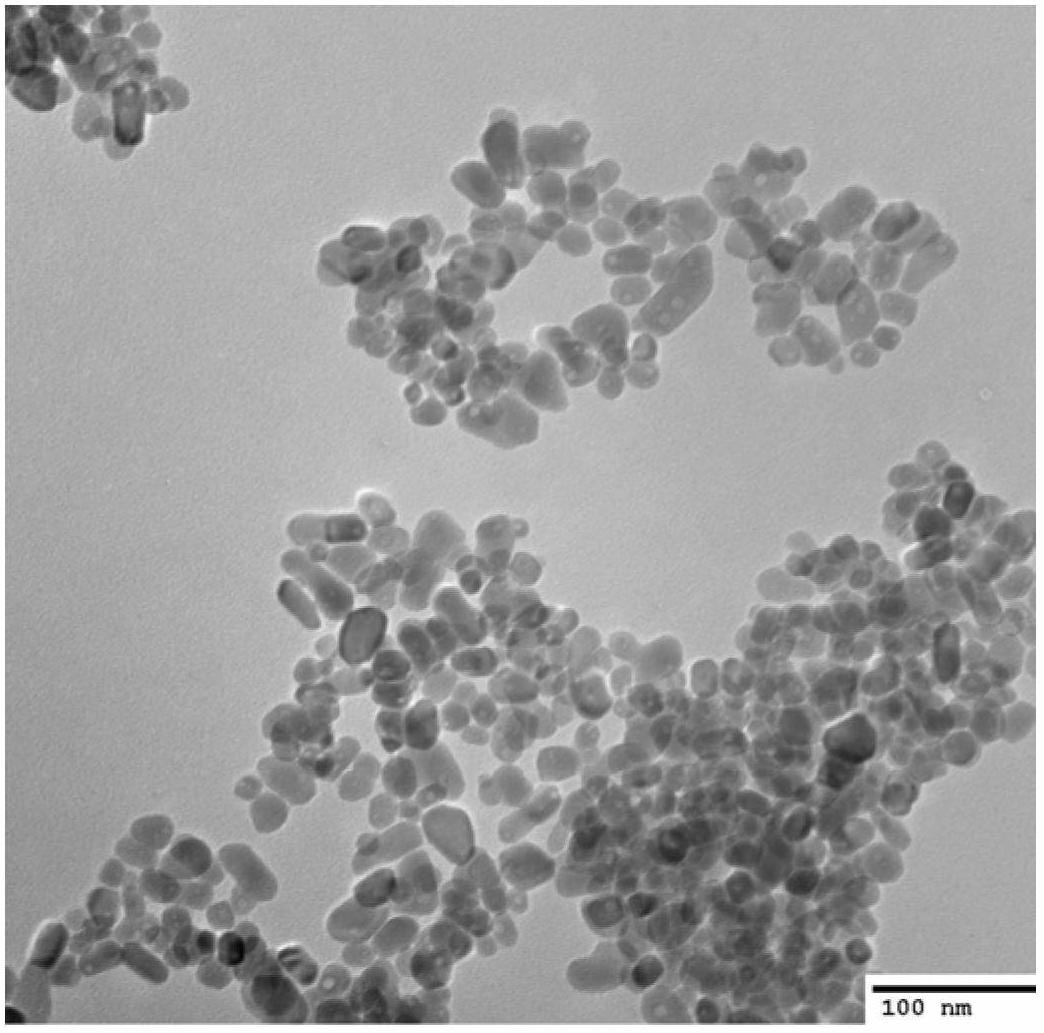

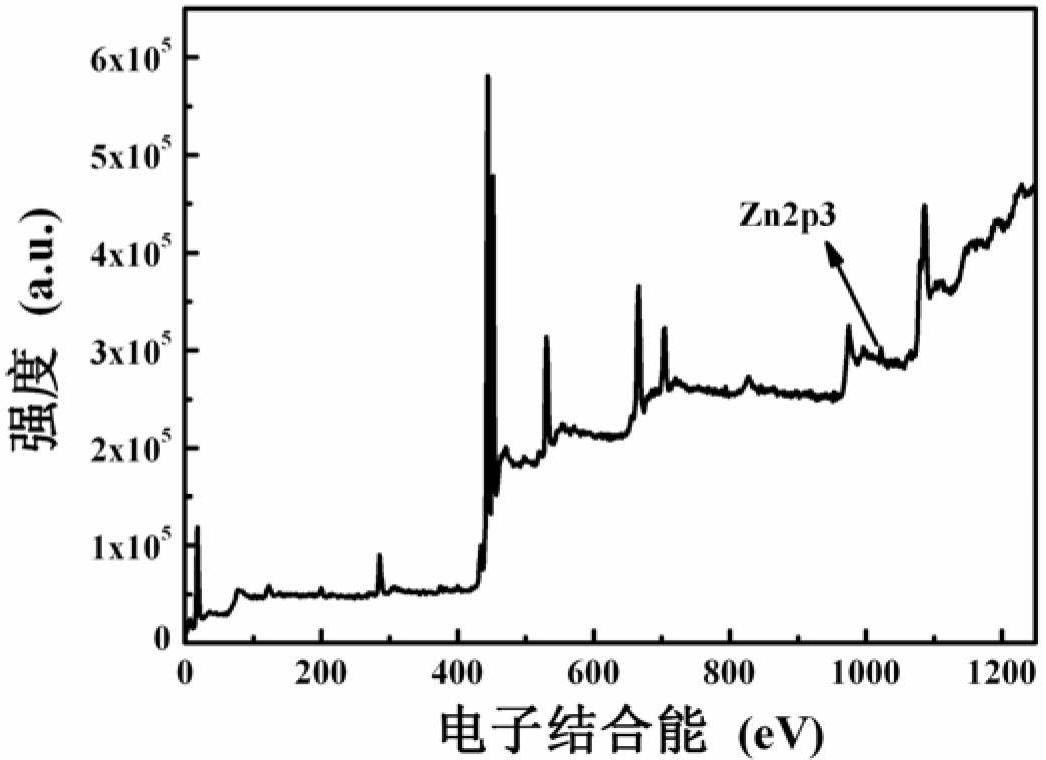

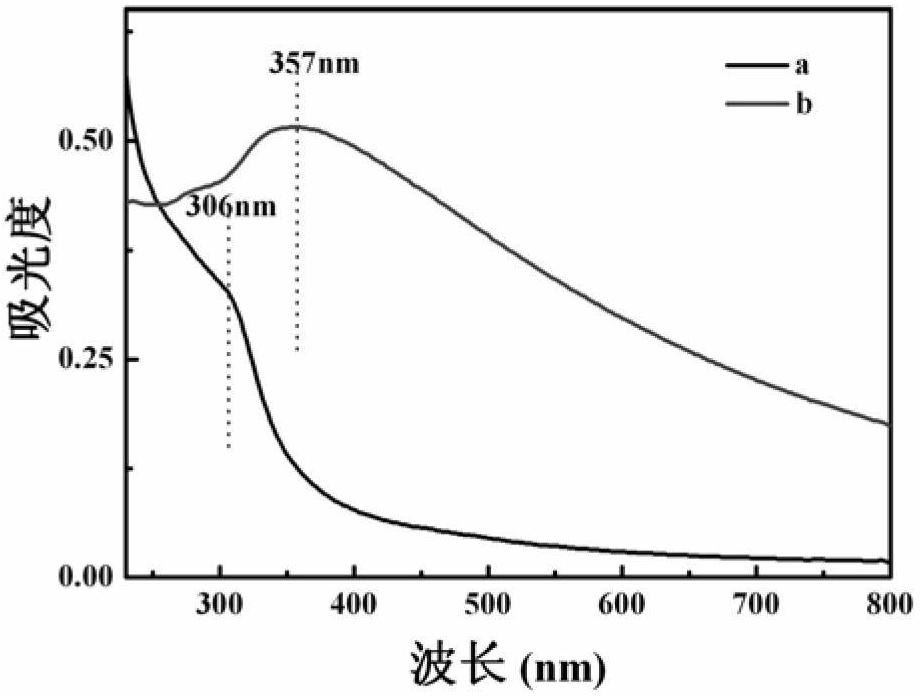

Zinc-doped indium oxide nano gas sensitive material and preparation method thereof

InactiveCN102653413ASimple processEasy to operateGallium/indium/thallium compoundsLuminescent compositionsUv absorbanceActive agent

The invention provides a zinc-doped indium oxide nano gas sensitive material and a preparation method thereof. The zinc-doped indium oxide nano gas sensitive material can be represented by ZnO-In2O3, wherein the mole ratio of Zn to In is (0.0042-1): 1; and the particle diameter is 10 to 30 nanometers. The zinc-doped indium oxide nano gas sensitive material is prepared by taking indium salt, zinc salt and a precipitant as raw materials by adopting a chemical solution method under the condition of no template, no surfactant and relatively low temperature; and the obtained zinc-doped indium oxide particles are uniformly scattered, and an agglomeration phenomenon is avoided. The zinc-doped indium oxide nano gas sensitive material is sensitive to ethanol and nitrogen dioxide, has the characteristics of low working temperature, high response recovery speed, high sensitivity, high selectivity and the like and can be used as a sensitive material of an ethanol and nitrogen dioxide sensor. The zinc-doped indium oxide nano gas sensitive material prepared by the method is relatively high in ultraviolet absorption performance and relatively high in fluorescence emission performance and can be used as a luminous material.

Owner:BEIJING UNIV OF CHEM TECH

Preparation method of forsterite refractory brick prepared from nickel-iron slag

The invention discloses a preparation method of a forsterite refractory brick prepared from nickel-iron slag. The nickel-iron slag is used as a raw material, and fine magnesite powder is added; the generation amount of a liquid phase in a firing process is controlled by regulating and controlling the mass ratios of all components, so that the volume density and the compression strength of the refractory brick are improved, and the sintering temperature is reduced; the mass ratios of all the components are controlled to meet the following conditions that the mass ratio of MgO to SiO2 is 0.98 to 1.67, the mass ratio of MgO to FeO is 5.87 to 7.71, the mass ratio of MgO to Al2O3 is 11.23 to 17.6, the mass ratio of Al2O3 to SiO2 is 0.087 to 0.095, and the sum of MgO and CaO to the sum of SiO2 and Al2O3 is 0.95 to 1.59; meanwhile, the preparation method comprises the following steps: additionally adding water and a binding agent, uniformly mixing, and carrying out compression moulding and drying treatment; after treatment, roasting at the temperature of 1200 to 1350 DEG C for 2 to 3.5 hours; adopting an oxidizing atmosphere in the firing process, thus obtaining the forsterite refractory brick. The preparation method disclosed by the invention has the advantages of high resource utilization rate, environment friendliness, simple process, low production cost and the like; the forsterite refractory brick prepared from the nickel-iron slag has the advantages of high compression strength, high volume density, low porosity and good thermal shock resistance.

Owner:CENT SOUTH UNIV

Preparation method of high temperature resistant forsterite type refractory material

The invention discloses a preparation method of a high temperature resistant forsterite type refractory material. The method comprises the following steps: using nickel-iron slag as raw materials and magnesia powder as additives, wherein the ratio of [w (MgO) + w (FeO)] to [w (Al2O3)+w (Cr2O3)] is 10.50 to 13.57, the ratio of w (MgO) to w (Cr2O3) is 34.90 to 48.12 and the ratio of w (MgO) to w (SiO2) is 1.19 to 1.61, adding binding agents and controlling calcination temperature to be 1360 DEG C to 1450 DEG C, inducing mineral phase reconstruction of the nickel-iron slag, optimizing transformation process of refractory crystal form (Mg2SiO4, MgO.Fe2O3, MgO.Al2O3, MgO.Cr2O3) to increase refractoriness of the refractory material. The refractoriness of the obtained refractory material is 1700 to 1800 DEG C, and the refractory material also has the advantages of high compressive strength, large bulk density, low apparent porosity, and can fully meet the industrial need of the refractory material. The preparation method of the high temperature resistant forsterite type refractory material has the advantages of high utilization rate of resources, high production efficiency, high added value, environment friendliness, easiness in process control, low production cost and the like.

Owner:CENT SOUTH UNIV

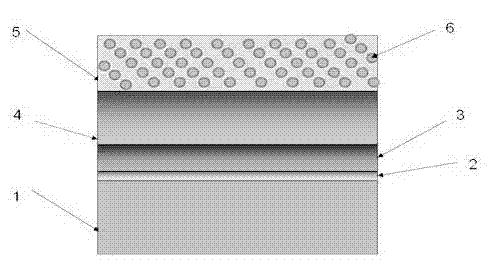

Transparent conductive metallic film and preparation method thereof

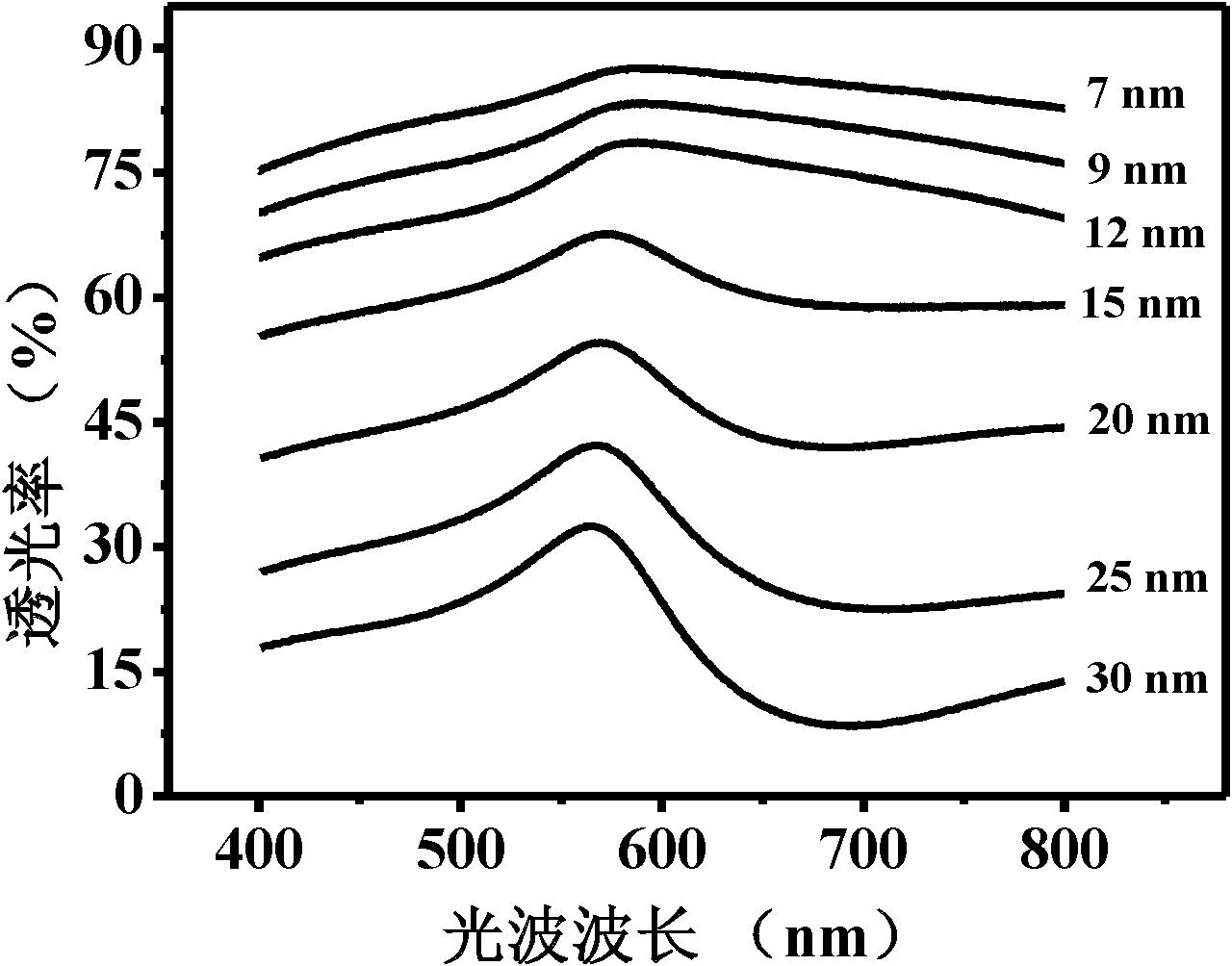

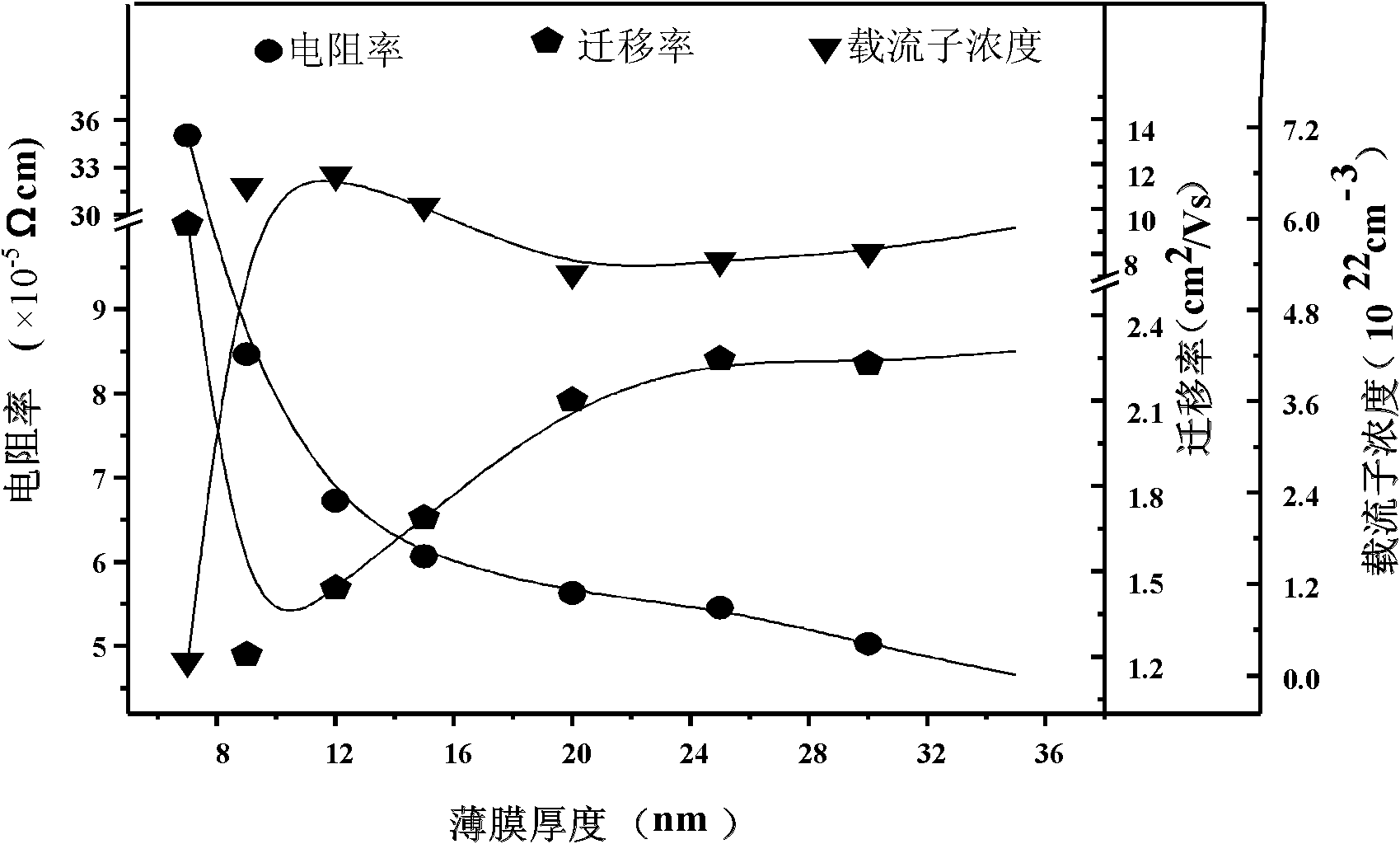

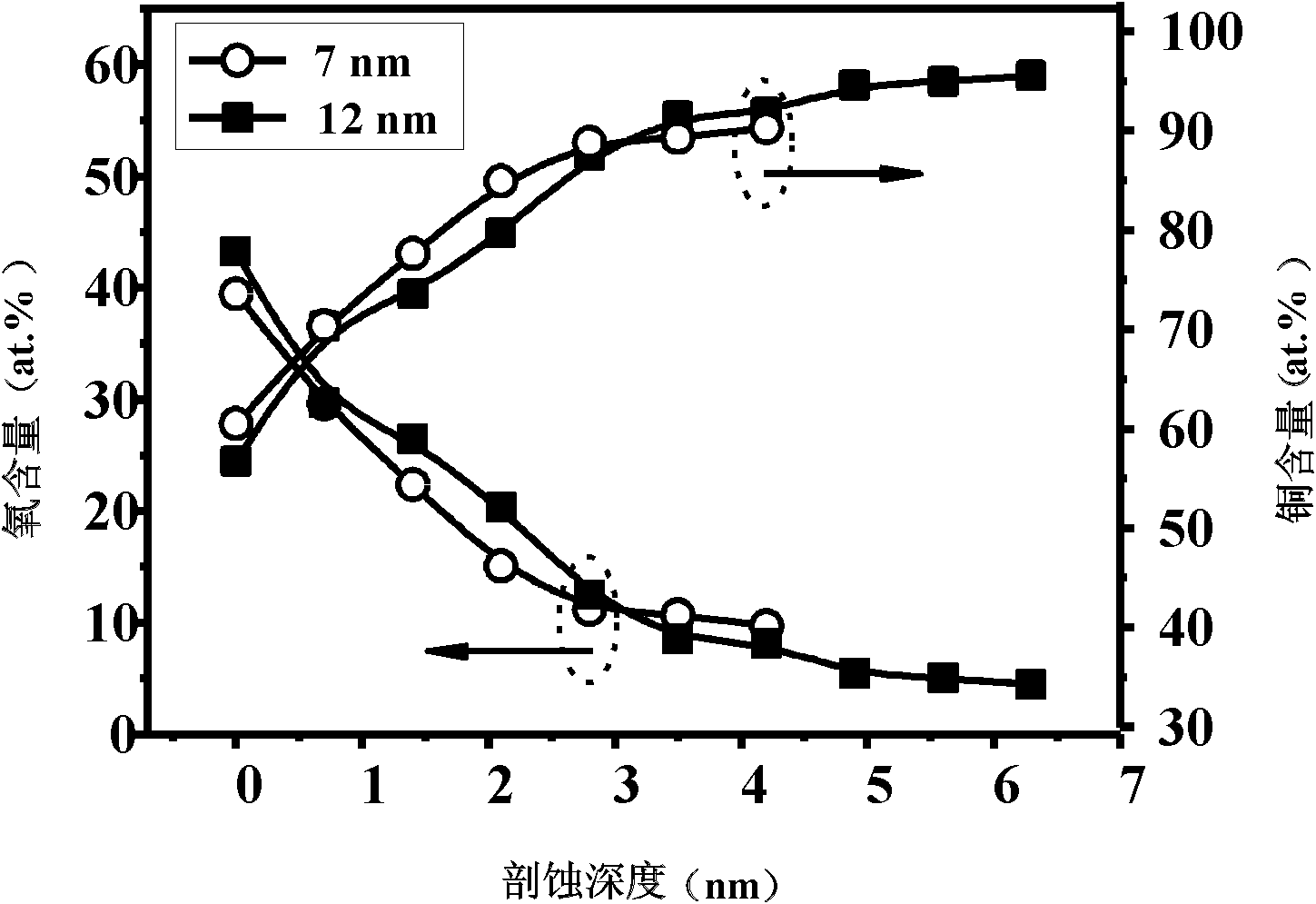

InactiveCN102051578ALow resistivitySimple preparation processVacuum evaporation coatingSputtering coatingLayered structureTransmittance

The invention provides a transparent conductive metallic film and a preparation method thereof. The film is prepared from amorphous metallic copper by using a magnetron sputtering method, wherein the transparent conductive metallic film has a thickness of 7-30nm and an electrical resistivity of 10-5 to 10-4 Ohm cm; when being preferably 7-12nm in thickness, the transparent conductive metallic film has the light transmittance of 78-85%; the transparent conductive metallic film has a double-layered structure, and the outermost layer is an oxygen absorbing layer with the thickness stabilized in the range of 3-5nm. The thickness of the oxygen absorbing layer is not increased following the increasing of the whole thickness of the transparent conductive metallic film, therefore, the transparent conductive metallic film has decreased reflectivity and increased light transmittance in the visible light range.

Owner:BEIHANG UNIV

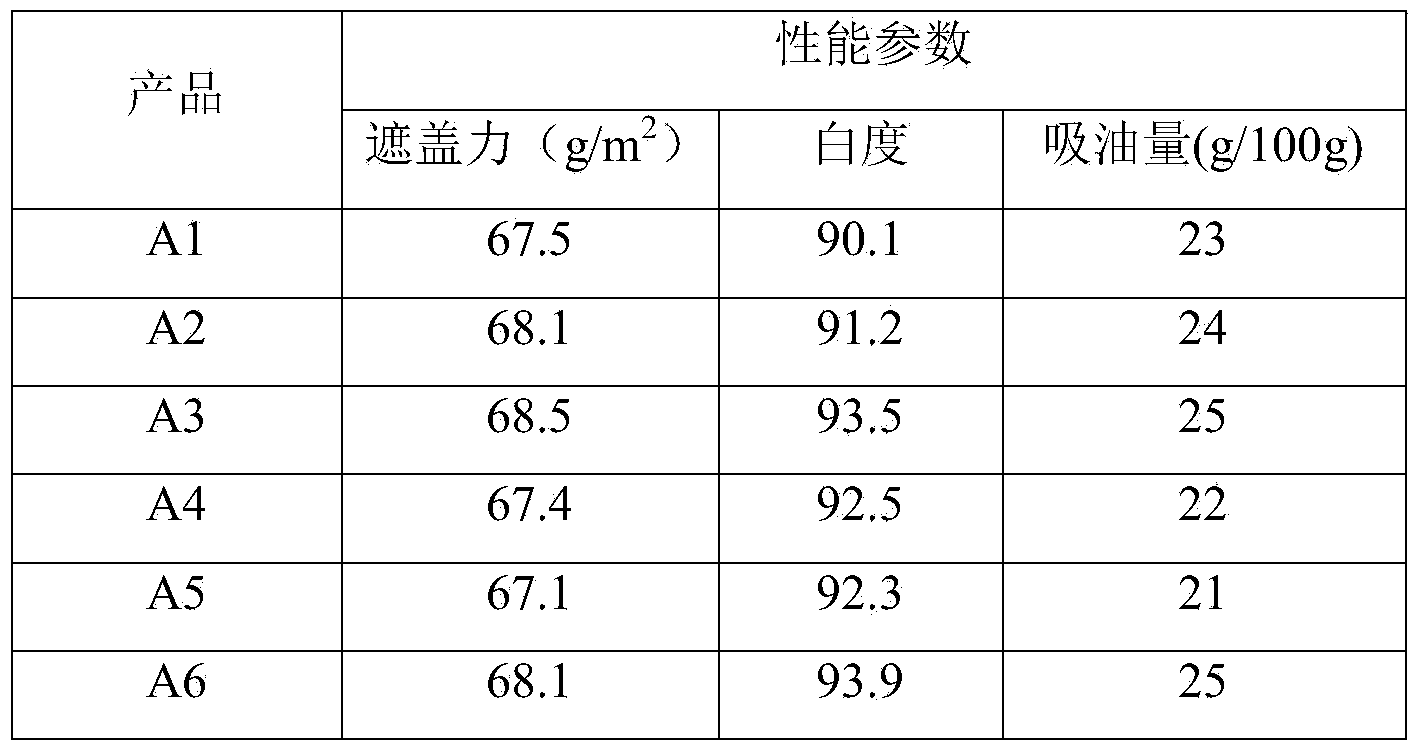

Preparation method of composite titanium dioxide

InactiveCN104387807AReduce manufacturing costEase of industrial productionInorganic pigment treatmentTitanium dioxideWeather resistanceTitanium dioxide

The invention provides a preparation method of composite titanium dioxide. According to the preparation method, rutile type titanium dioxide is firstly directly synthesized in a liquid phase system at normal pressure and room temperature without phase conversion at high temperature, the process is simple, the production cost is greatly reduced, and the method is easy to realize industrial production. Secondly, prepared rutile type TiO2 is coated with white inorganic mineral powder with low price, the inorganic mineral powder is taken as a core in the liquid phase system, titanium dioxide slurry is taken as a coating matter, and inorganic mineral powder / TiO2 composite titanium dioxide is synthesized by a particle-particle coating method, so that the white mineral powder has certain natures of TiO2, such as high covering power and excellent weather resistance. By adding the composite titanium dioxide into plastic and rubber, the whiteness and gloss of the plastic can be significantly improved; and the composite titanium dioxide has the advantages of low production cost, sufficient raw material sources, no environmental pollution, a wide range of applications, significant economic benefits and the like, and further has positive effects in fields of reducing consumption of resources, protecting the environment and expanding the range of applications of the titanium dioxide.

Owner:TIANJIN XINDETAI IRON POWDER

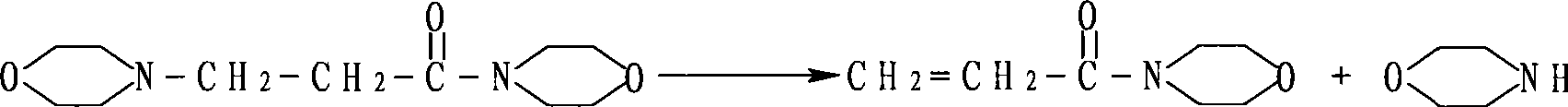

Synthesizing method for preparing N-acryloyl morpholine

ActiveCN101293880BRaw materials are easy to getMild reaction conditionsOrganic chemistryMorpholineSolvent

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Method for preparing pyrophillite-based antimony-doped tin oxide compound conductive powder

InactiveCN102249293AReduce manufacturing costImprove use valueCable/conductor manufactureTin oxidesAntimonateMaterials science

The invention discloses a method for preparing pyrophillite-based antimony-doped tin oxide compound conductive powder. The method is characterized in that a chemical precipitation process for respectively dropwise adding a tin salt and an antimony salt is adopted. The method is a preparation method for the compound conductive powder, the surface of which is covered with a layer of antimony-doped tin oxide. The method provided by the invention can be used for reducing the preparation cost of conductive powder. The acquired powder has light color and excellent conductivity.

Owner:HANGZHOU TENGSHI TECH

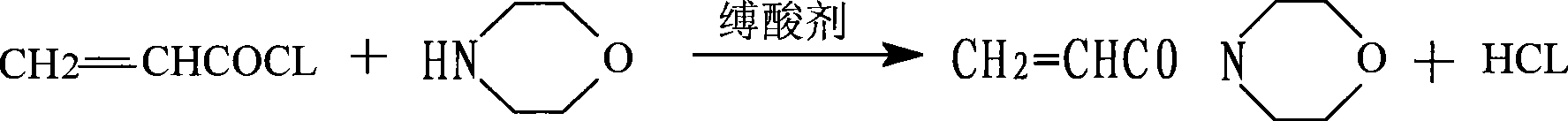

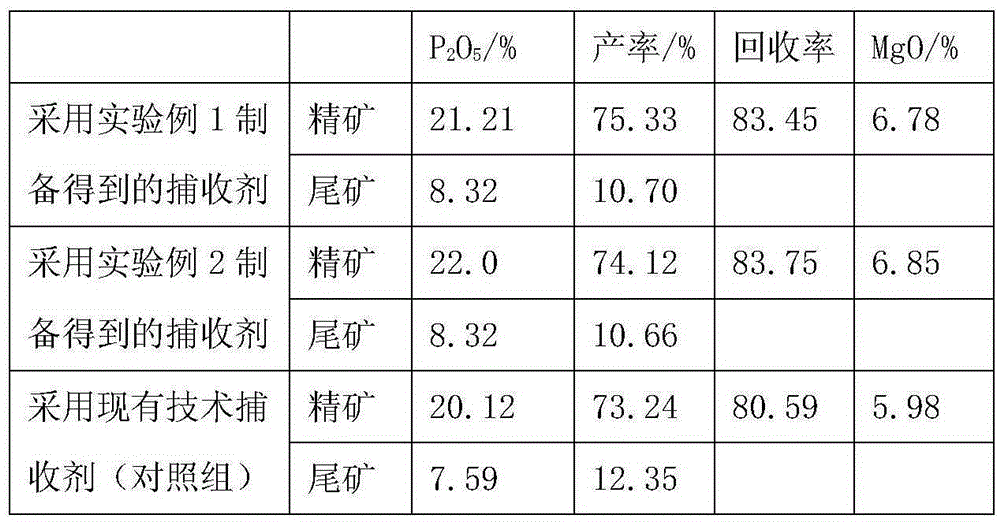

Collophanite direct-reverse flotation collecting agent and preparation method and application thereof

The invention belongs to the technical field of flotation collecting agents, and particularly relates to a collophanite direct-reverse flotation collecting agent and a preparation method and application thereof. The collophanite direct-reverse flotation collecting agent is prepared from vegetable oil residues, hydrogen peroxide, adsorbent, stearic acid, sodium hydroxide and diethyl phthalate. The mass ratio of the vegetable oil residues to sodium hydroxide to adsorbent to stearic acid to sodium hydroxide to diethyl phthalate is 10-15:0.5-2:1-2:4-7:2-5:0.4-1.3. The collophanite direct-reverse flotation collecting agent is high in selectivity and ore carrying capacity aiming at the characteristic of collophanite, can be used as a collecting agent of direct flotation desilicication and can also be used as a collecting agent of reverse flotation magnesium removal. Good selectivity and foamability are achieved, the comprehensive mineral separation efficiency is high, and raw material cost is low. Certain cost advantages are achieved, and wide industrial prospects are achieved.

Owner:WUHAN INSTITUTE OF TECHNOLOGY +1

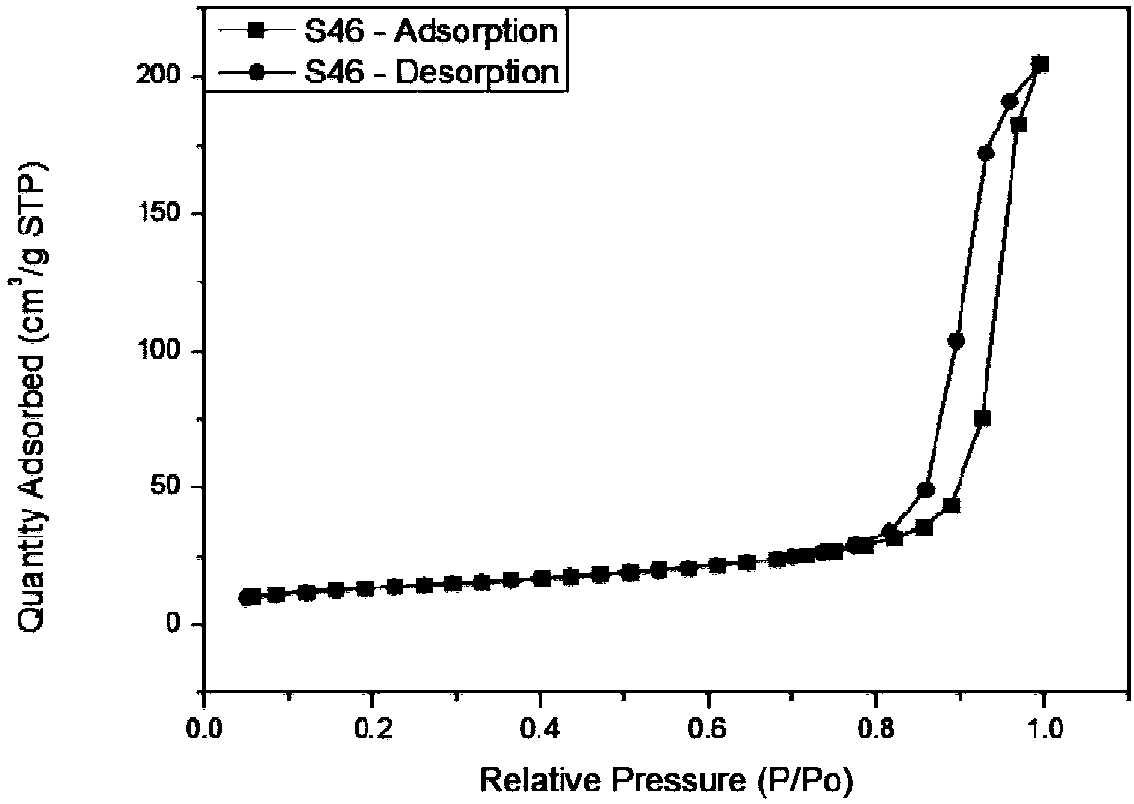

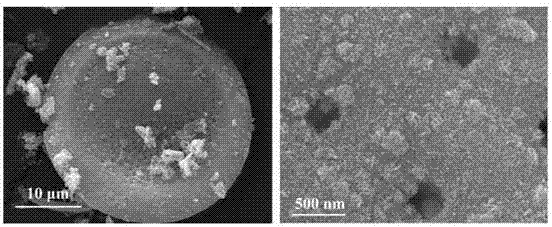

Preparation method of cobalt manganese spinel microspheres

ActiveCN108264093AHigh selectivitySolve the problem of low CO2 reduction activityHydrocarbon from carbon oxidesCatalystsHigh energyMicrosphere

The invention provides a preparation method of cobalt manganese spinel microspheres. The method comprises weighing manganese chloride and cobalt chloride, dissolving the manganese chloride and cobaltchloride in deionized water, weighing ammonium hydrogen carbonate as a pH adjuster, carrying out mixing through stirring, carrying out hydrothermal pretreatment at 100-150 DEG C, after the reaction product is naturally cooled, carrying out centrifugal filtration, orderly washing the precipitates through deionized water and ethanol, carrying out drying to obtain cobalt carbonate and manganese carbonate precursors, and calcining the cobalt carbonate and manganese carbonate precursors through a muffle furnace at a temperature of 500 to 700 DEG C for 1-3h to obtain the cobalt manganese spinel microspheres. The cobalt manganese spinel microspheres are used for research on thermal catalytic CO2 reduction and can produce synthetic organic fuel (methane). The cobalt manganese spinel obtained by the preparation method is a pure phase and spherical, has a high specific surface area, obvious exposes the high-energy crystal surface, reduces the temperature of thermal catalytic CO2 reduction and has high product selectivity.

Owner:SHANGHAI INST OF TECH

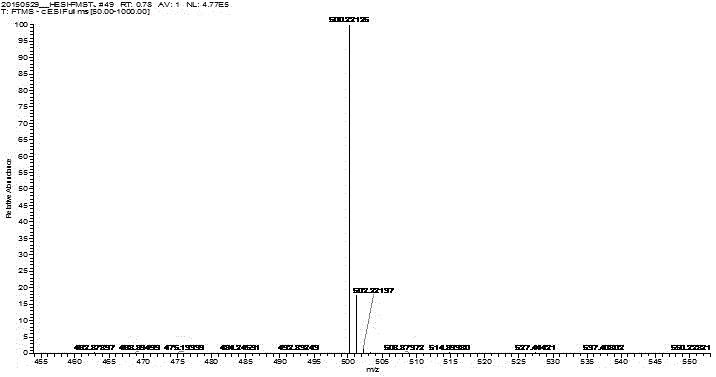

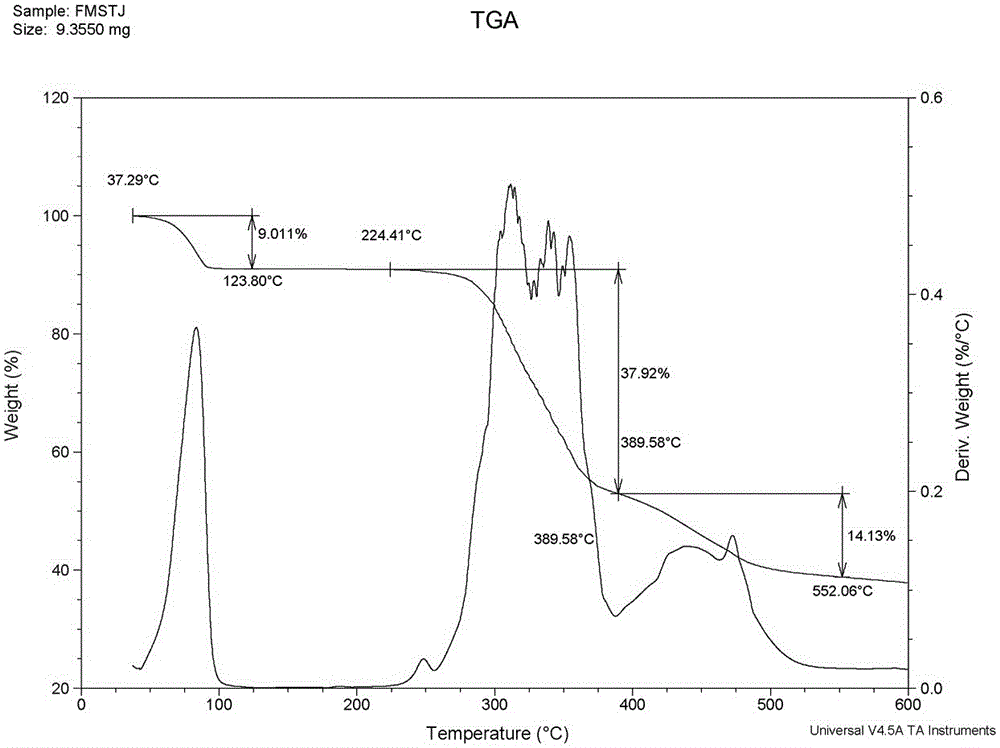

Preparation method of fimasartan potassium salt hydrate

InactiveCN105061405AReduce usageProcess raw materials are easy to getOrganic chemistryBulk chemical productionTetrazolePotassium

The present invention discloses a preparation method of a fimasartan potassium salt hydrate. The method is as below: reacting a starting material 1(2-(2-butyl-4-hydroxy-6-methylpyrimidine-5-yl)-N,N-dimethylacetamide) with a starting material 2 (N-(triphenylmethyl)-5-(4'-bromomethyl-biphenyl-2-yl) tetrazole) in the presence of an alkali metal hydride in a mixed solvent of ethyl acetate and DMF, so as to obtain a compound IV; hydrolyzing the compound IV under acidic conditions to remove the protective group to obtain a compound III; subjecting the compound II to a thioamidation reaction with a Lawesson's reagent to obtain a compound II; and subjecting the compound II and potassium hydroxide to a salt-forming reaction in a mixture of isopropyl alcohol and water to obtain a desired product. The present invention has the advantages of easily available process feedstock, mild reaction conditions at room temperature, economical performance, environment-friendliness and easiness to operation, reduces the process cost to a large extent, and is easy to realize industrial production.

Owner:合肥创新医药技术有限公司

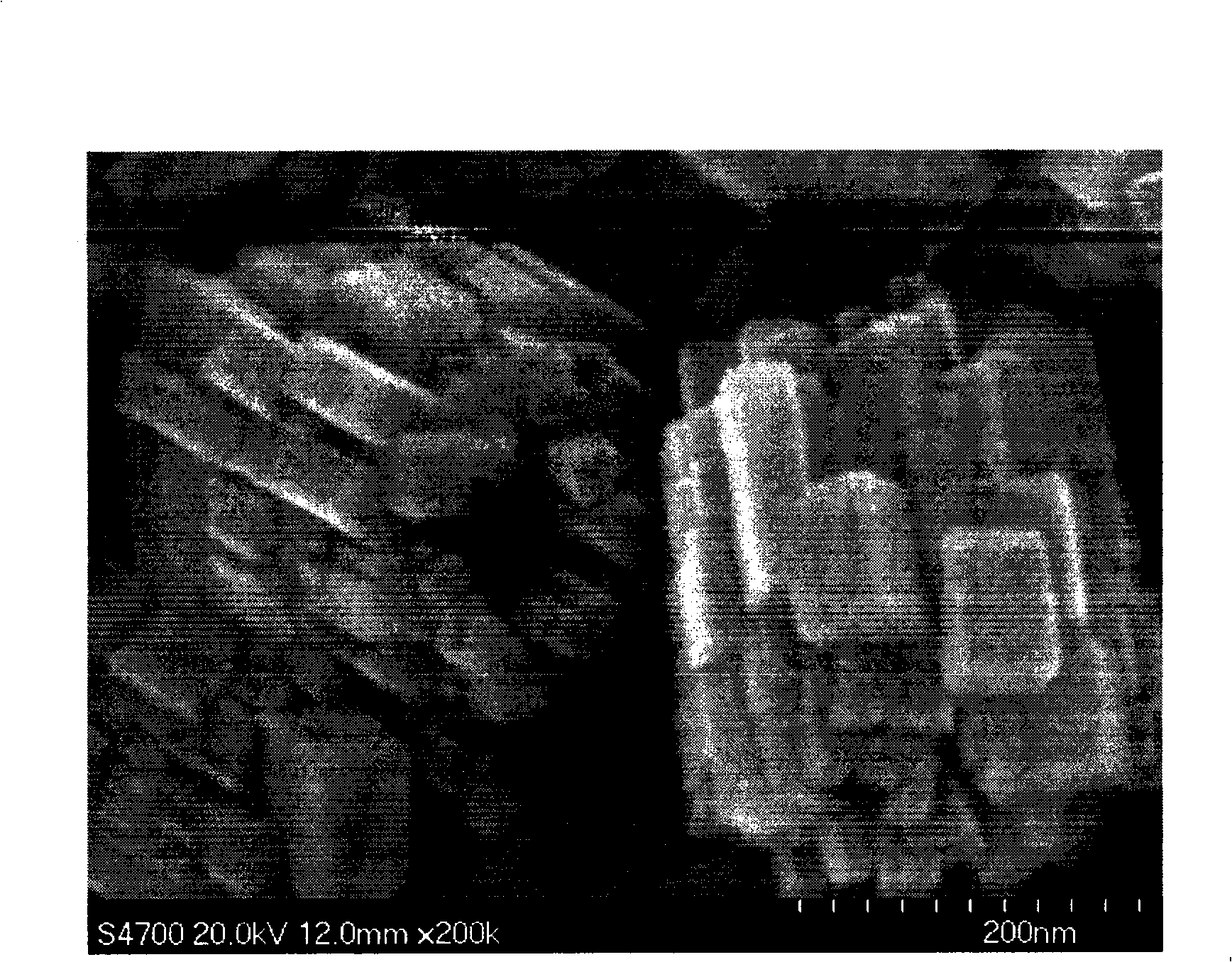

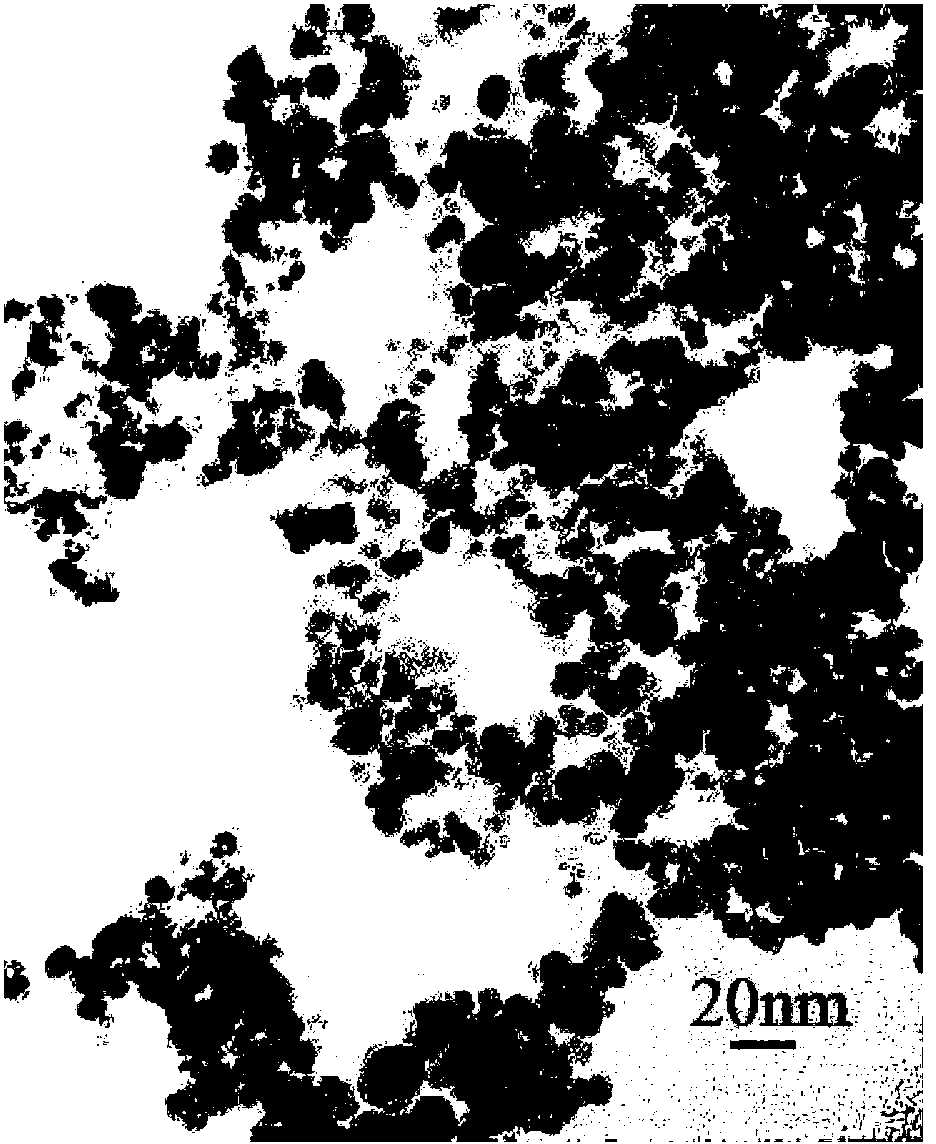

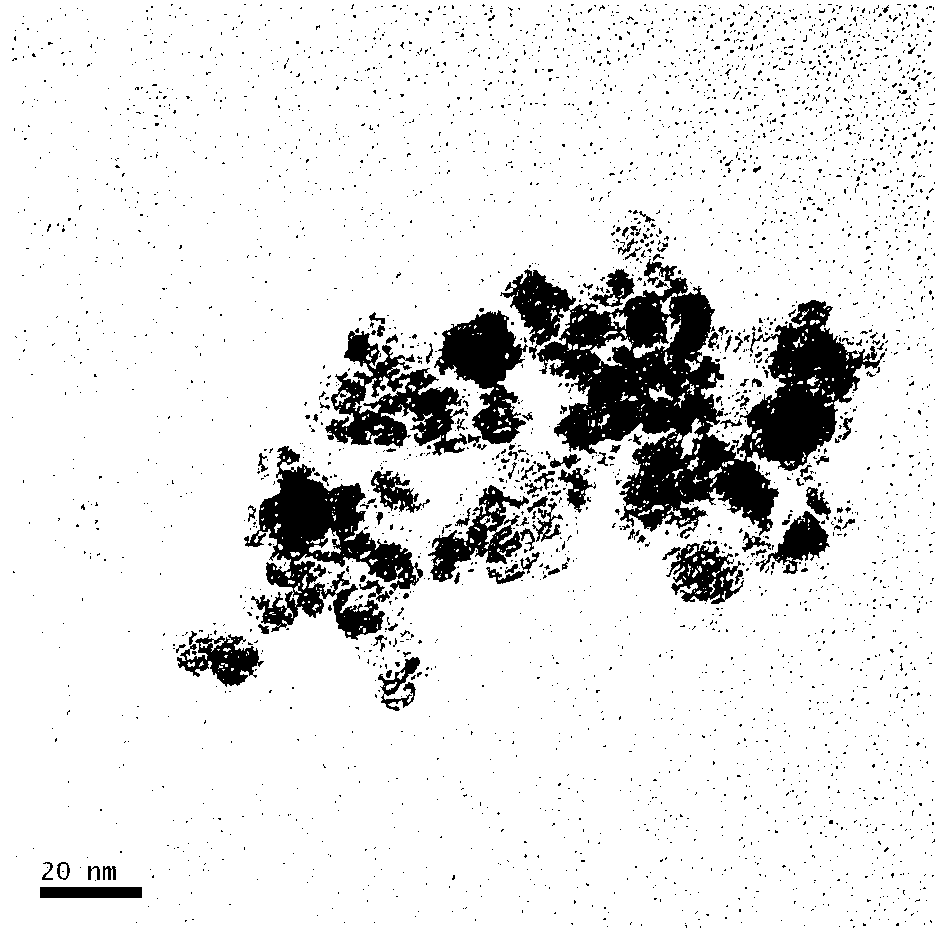

Method for simply regulating ferroferric oxide nanoparticle morphology

InactiveCN103288140AEasy to makeFast preparationMaterial nanotechnologyFerroso-ferric oxidesIron saltsIron(II,III) oxide

The invention relates to a method for simply regulating ferroferric oxide nanoparticle morphology. The method comprises: dissolving a ferrous iron salt and a ferric iron salt into water, adding NaOH, adjusting the pH value to 10-12, stirring to obtain ferroferric oxide, filtering, alternately washing with water and ethanol, and drying to obtain spherical ferroferric oxide nanoparticles; and dissolving a ferrous iron salt and a ferric iron salt into water, adding sodium dodecyl sulfate and NaOH, adjusting the pH value to 10-12, irradiating under a visible light source to obtain ferroferric oxide, filtering, alternately washing with water and ethanol, and drying to obtain cube-shaped ferroferric oxide nanoparticles or rod-like ferroferric oxide nanoparticles. The method has advantages of relative simpleness, low production cost, easy morphology control, and easy scalization achievement.

Owner:SHANXI DATONG UNIV

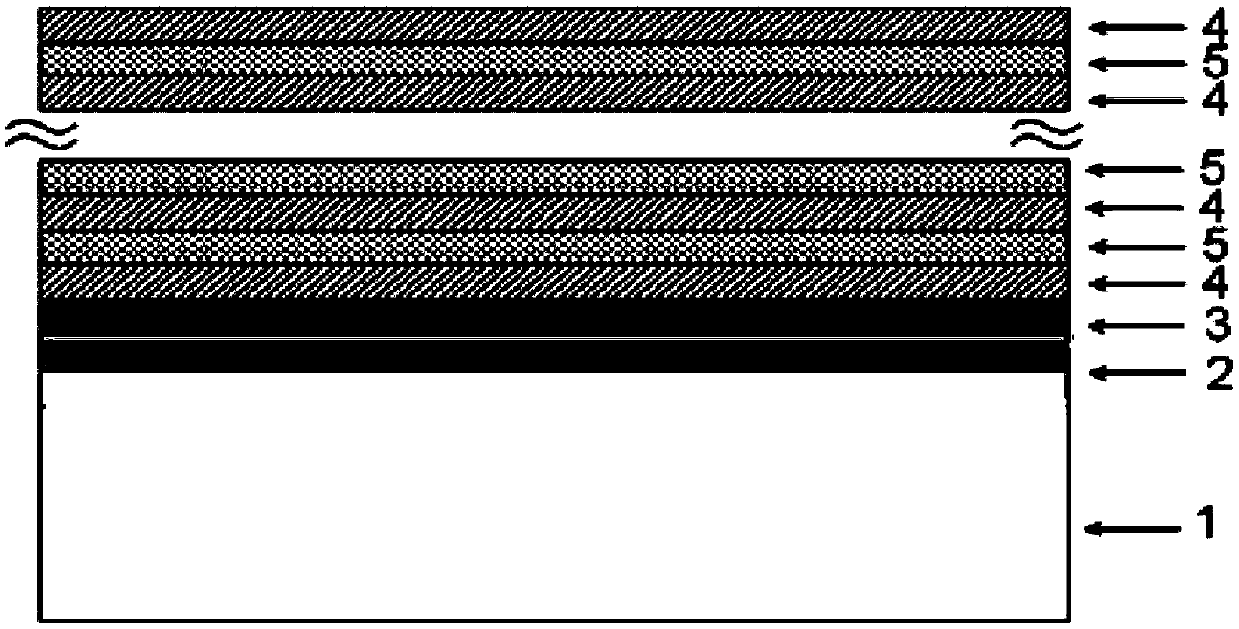

Space mechanism high-binding-force solid antibacterial lubricating film layer and preparation method thereof

ActiveCN109576641AAntimicrobial Lubricating Performance AchievedGood antibacterial and lubricating propertiesVacuum evaporation coatingSputtering coatingBinding forceTransition layer

The invention relates to the technical field of material surface vacuum coating, particularly relates to a high-binding-force solid antibacterial lubricating film layer of a space mechanism and a preparation method of the solid antibacterial lubricating film layer. The solid antibacterial lubricating film layer comprises a basal body, a Ti bonding layer, a TiN transition layer, a TiN functional layer and MoS2-Cu-Ag functional layer, a nanocrystalline composite coating formed in sequence, wherein the TiN functional layer is connected with the MoS2-Cu-Ag The Cu-Ag functional layers are alternately arranged, and the outermost layer is an MoS2-Cu-Ag functional layer. The prepared nanocrystalline composite film is high in adhesive force, low in friction coefficient and good in antibacterial effect, the service life of the space mechanism system component can be greatly prolonged, and the reliability of the space mechanism system component can be improved.

Owner:SHANGHAI AEROSPACE EQUIP MFG GENERAL FACTORY

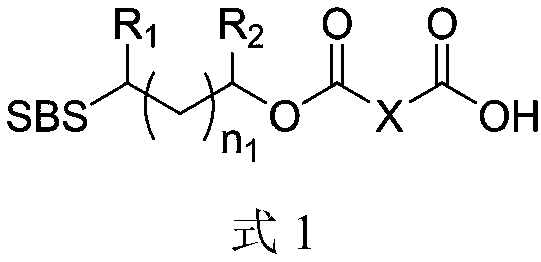

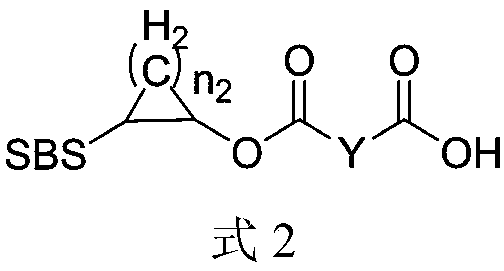

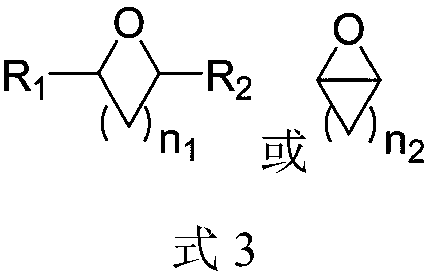

Terminal carboxyl group SBS, preparation and application thereof in asphalt modification

The invention discloses a terminal carboxyl group SBS, which has an epoxy ring opening flexible bond, an ester bond and a terminal carboxyl group and other structures. The preparation method of the terminal carboxyl group SBS is also disclosed, and active anionic SBS block polymer is prepared by using an anionic polymerization method; ring opening reaction is carried out on the anionic SBS block polymer and an epoxy hydrocarbon compound to obtain active oxygen anion SBS block polymer; terminal capping reaction is carried out on the active oxygen anion SBS block polymer and an acid anhydride compound; after the terminal capping reaction is finished, the terminal carboxyl group SBS is obtained after termination and post-treatment. Besides, the invention also discloses the application of theterminal carboxyl group SBS to asphalt modification. The terminal carboxyl group SBS can obviously improve the comprehensive performance of the asphalt and reduce a segregation value, thereby improving the transportation storage stability of modified asphalt. Besides, the preparation method of the terminal carboxyl group SBS is simple and is easy in industrialized implementation.

Owner:CHINA PETROLEUM & CHEM CORP +1

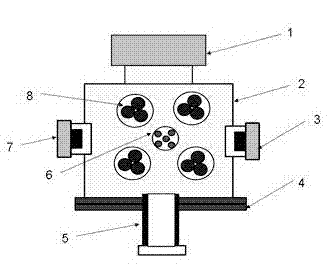

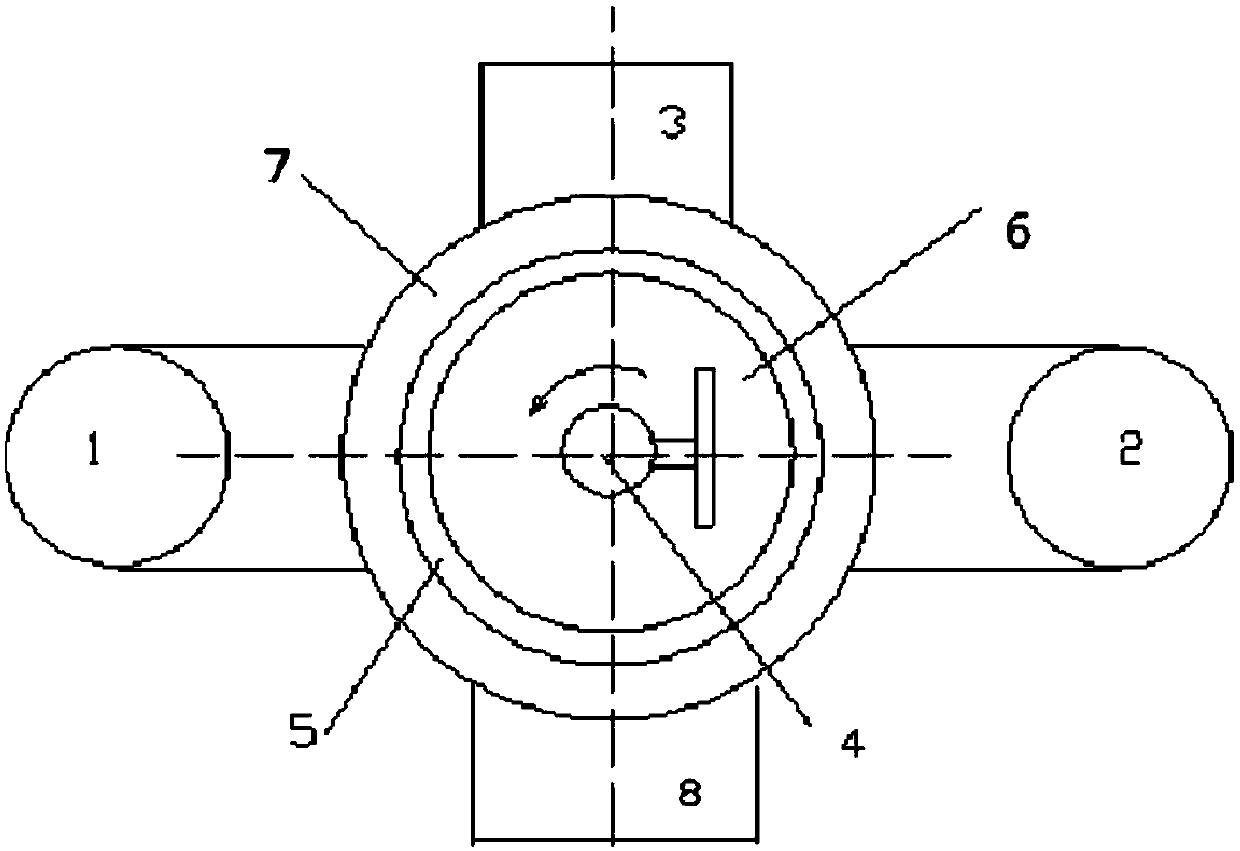

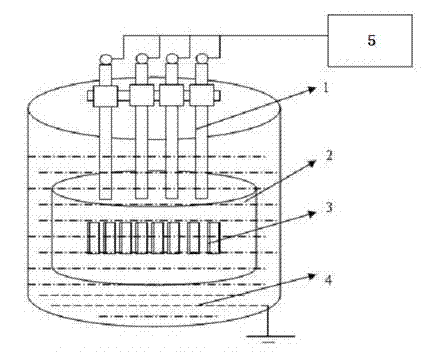

Process for accelerating core removal speed by utilizing liquid-electric effect and special high-temperature high-pressure core removal kettle

The invention discloses a process for accelerating a core removal speed by utilizing a liquid-electric effect. A corrosion removal process of a mold core of a cast part and a washing process of an inner cavity of the cast part are proceeded at the same time, namely, under a set temperature and pressure environment, a high-voltage pulse current is applied to a liquid corrosion medium without interruption at intervals, the liquid corrosion medium is quickly vaporized or expanded or generate a shock wave or a cavity by the liquid-electric effect, the mold core of the cast part is carried out chemical corrosion reaction and physical erosion, a corroded product flows out of a mold cavity of the cast part, and a new mold core corrosion interface of the cast part is formed in the mold cavity of the cast part without interruption so as to accelerate the removal speed of the mold core of the cast part. The invention further discloses a high-temperature high-pressure core removal kettle with the liquid-electric effect. An electrode is arranged above the cast part; a bottom end of the electrode is also soaked in a corrosion liquid pool; the electrode is not in contact with the cast part loaded in a material frame; a top end of the electrode is connected with a high-voltage pulse power supply; the corrosion liquid pool is grounded; and the high-voltage pulse power supply is controlled to apply the high-voltage pulse current to the corrosion liquid pool without interruption at intervals.

Owner:SHANGHAI UNIV

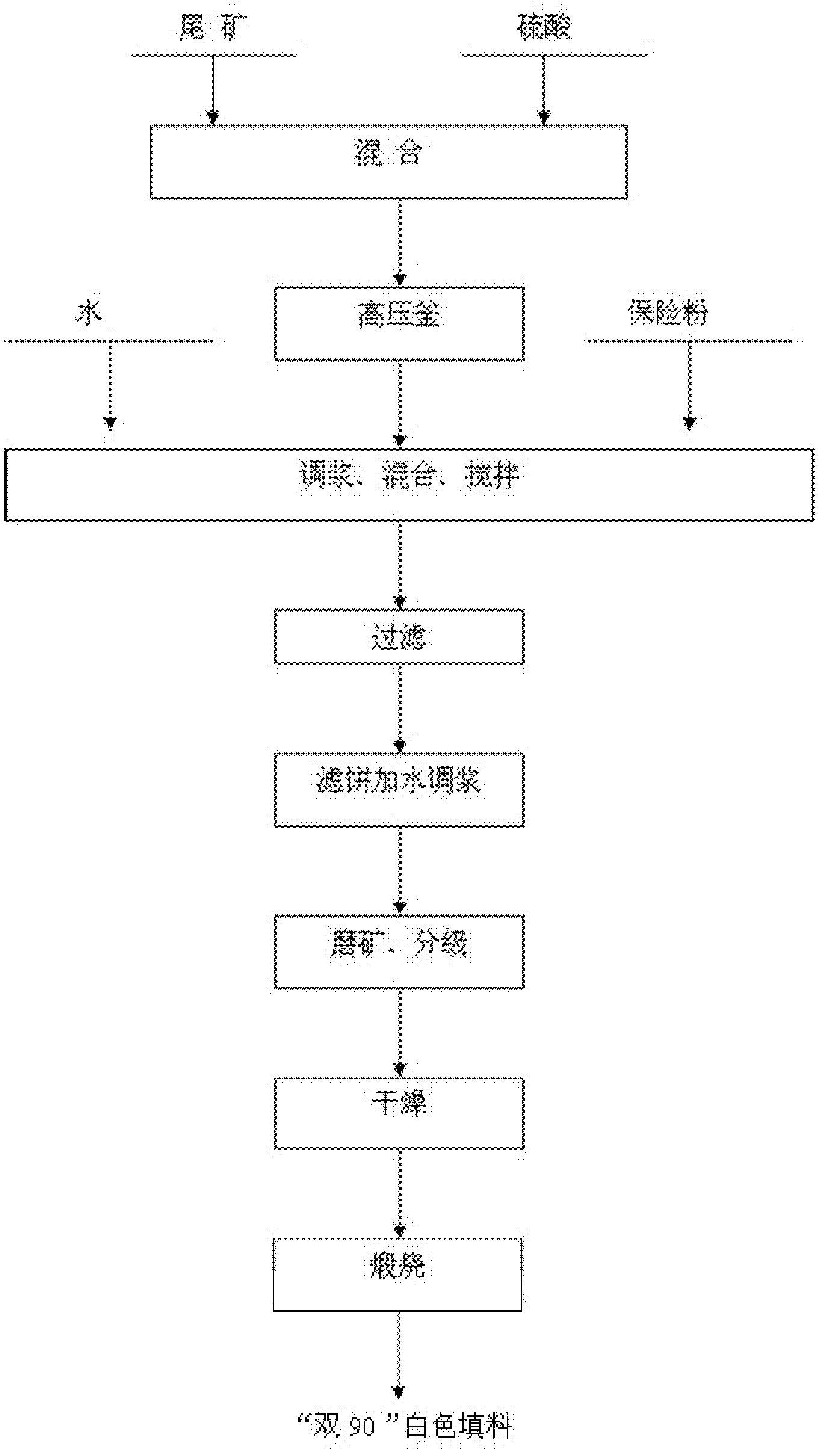

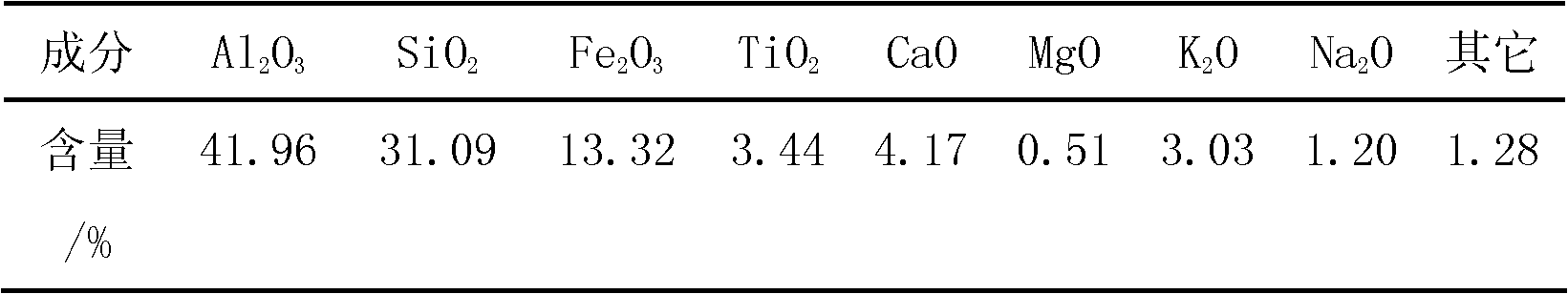

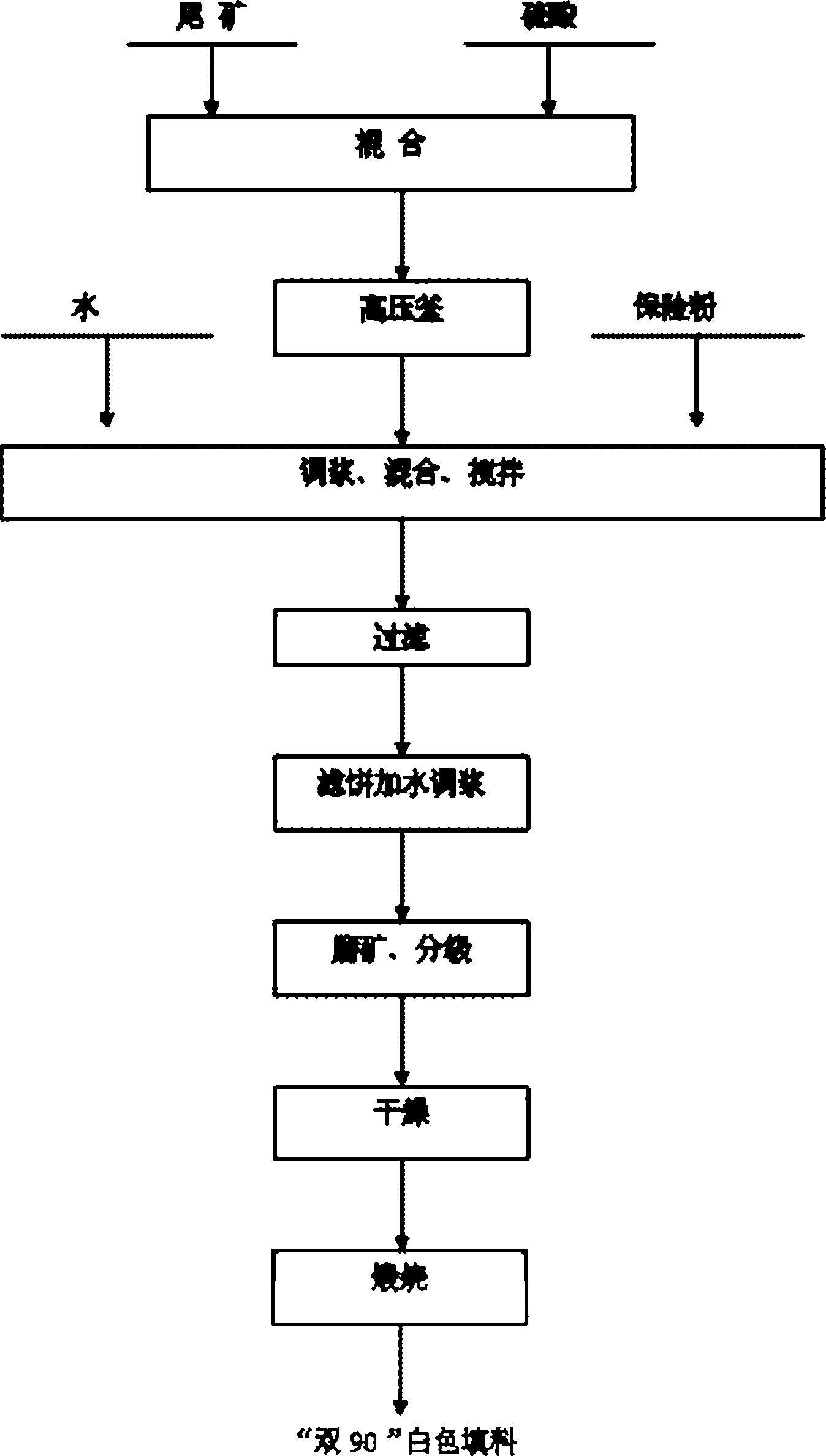

Method for preparing double-90 white filler from bauxite tailing

InactiveCN102675930AEffective iron removalEasy to removePigment physical treatmentSocial benefitsSodium dithionite

A method for preparing double-90 white filler from bauxite tailing comprises the following steps: firstly, heating the bauxite tailing and sulfuric acid at the temperature of 150-300 DEG C for 4-24 hours; secondly, adding water to adjust the pulp density and the pH value; adding sodium dithionite, performing reaction at the temperature of 25-90 DEG C and then filtering to obtain an ore sludge filter cake; adding water into the ore sludge filter cake and mixing to form ore pulp; grinding, grading and drying the ore pulp to obtain superfine powder with the grading content of 0.2 Mum and the whiteness of more than 90 percent; and finally, calcining the superfine powder at the temperature of 800-1000 DEG C to obtain the double-90 white filler. The double-90 white filler produced by the method disclosed by the invention has a high added value, can be applied to the fields of high-grade coating and paint, plastic, rubber and the like and has favorable economic benefits and social benefits. The method disclosed by the invention has the advantages of simple process, low cost, less investment and easiness in realization of industrial production. According to the method disclosed by the invention, the bauxite tailing can be treated in a large batch, the waste can be changed into valuables and a favorable technical path for treating and comprehensively utilizing the bauxite tailing is provided.

Owner:CENT SOUTH UNIV

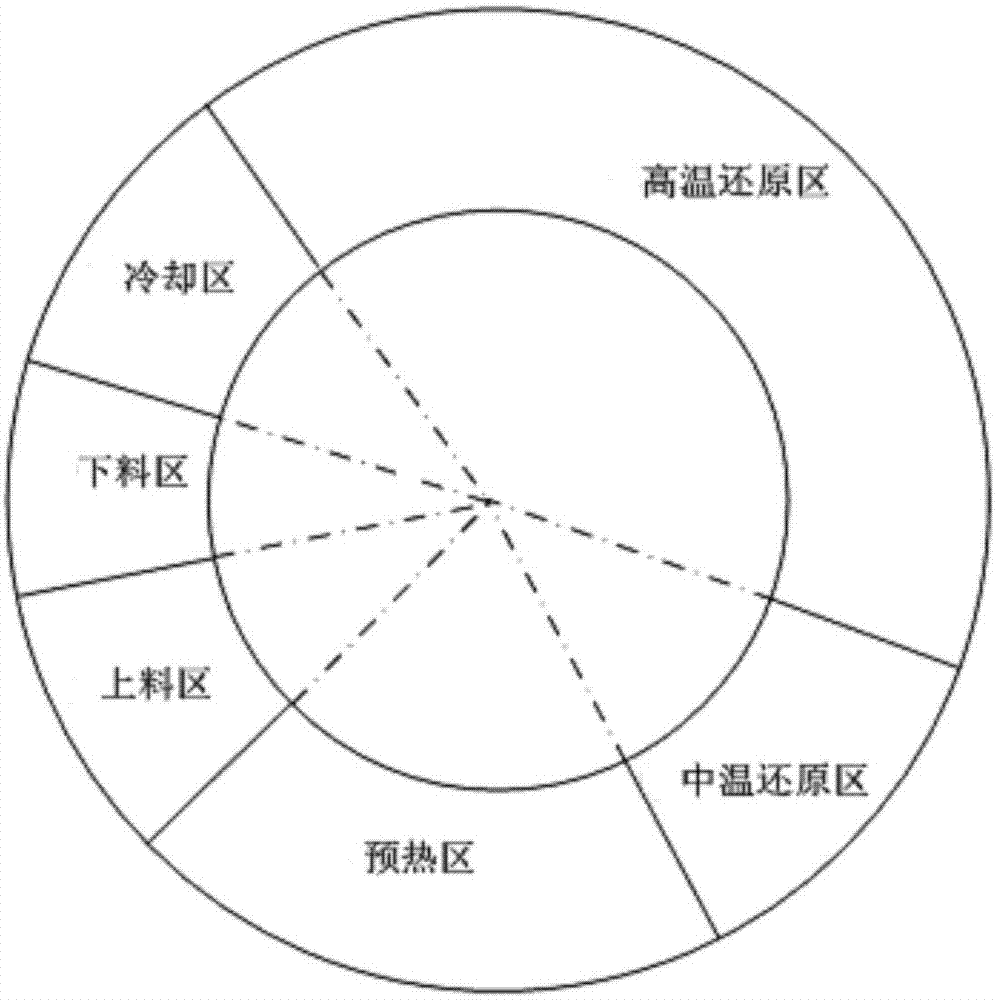

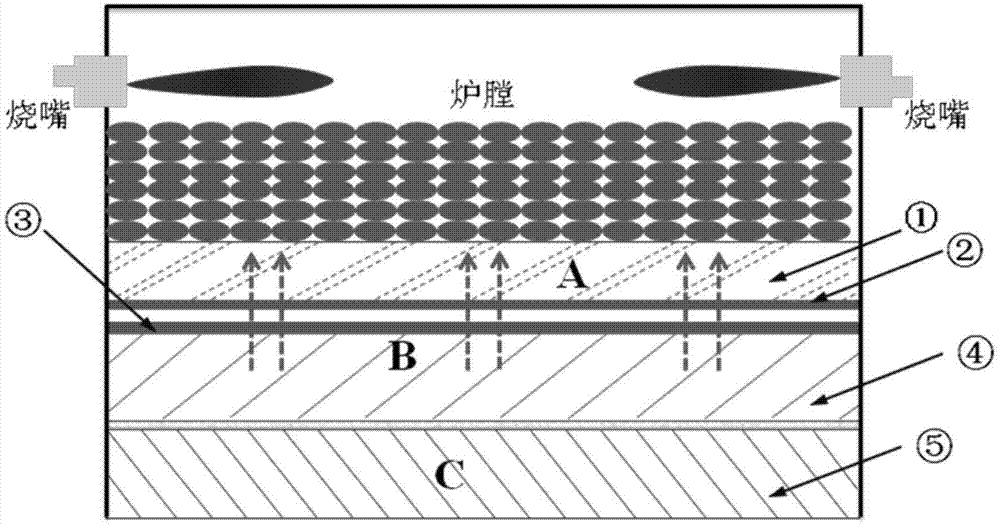

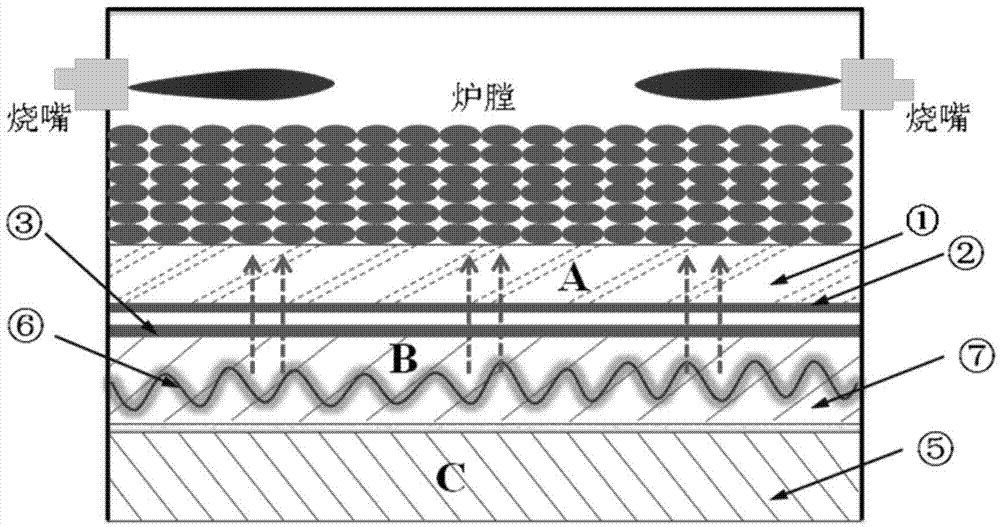

Furnace bottom structure capable of realizing reduction of deep bed for rotary hearth furnace

The invention provides a furnace bottom structure for a rotary hearth furnace. The furnace bottom structure comprises a heat preserving layer, a heating layer and an anti-slag-corrosion heat transfer layer in sequence from bottom to top, wherein the heat preserving layer and the heating layer are fixed; the anti-slag-corrosion heat transfer layer can rotate relative to the heat preserving layer and the heating layer; resistance wires are buried in the heating layer; the inside of the rotary hearth furnace is partitioned into a plurality of regions; the quantity of the resistance wires in the heating layer correspondsing to each region is set in advance; a layer of second steel plate is fixed on the upper part of the heating layer; a layer of first steel plate is fixed on the lower part of the anti-slag-corrosion heat transfer layer; a certain gap is kept between the first steel plate and the second steel plate, so that radiation heat transfer can be realized, and friction is prevented. By adopting the furnace bottom structure for the rotary hearth furnace provided by the invention, effective heat transfer and rapid reduction of a deep bed in a reduction process can be realized.

Owner:SHENWU TECH GRP CO LTD

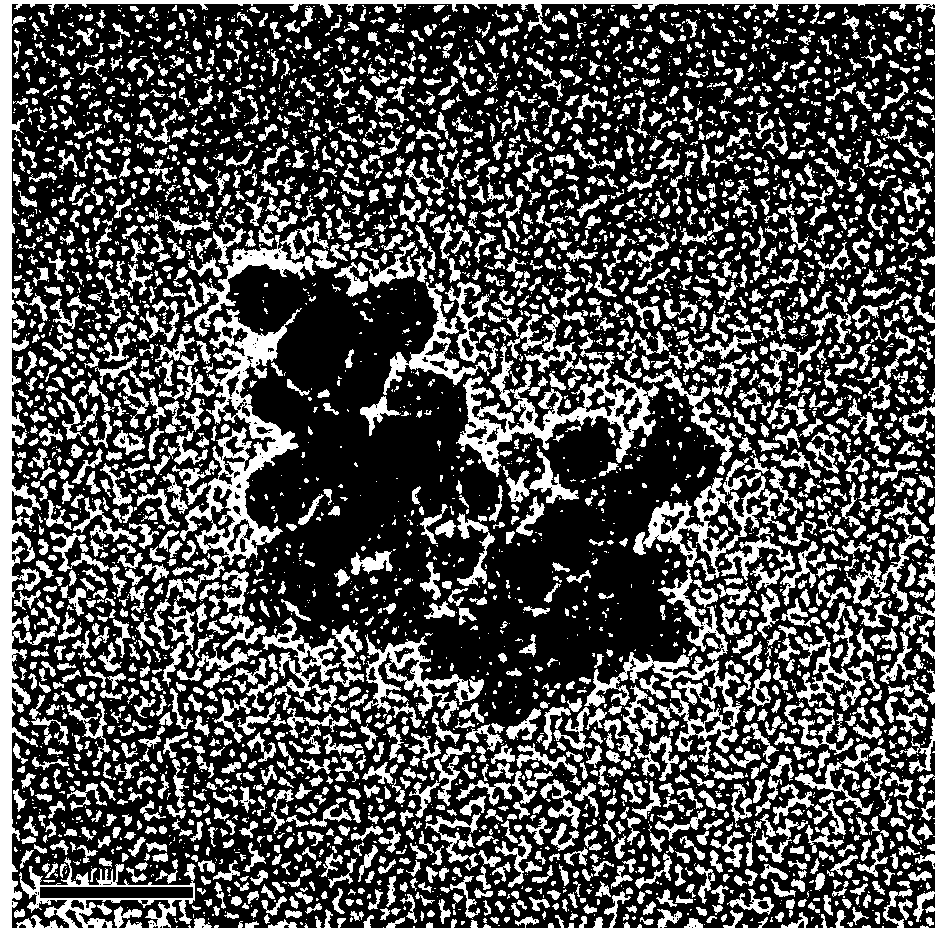

Composite ferroferric oxide and manganese dioxide Fenton catalyst and preparation method thereof

ActiveCN107570170AImprove securityGood dispersionOther chemical processesWater contaminantsDispersityOrganic solvent

The invention discloses a composite ferroferric oxide and manganese dioxide Fenton catalyst. The catalyst comprises diatomite, wherein the mass ratio of the diatomite to ferroferric oxide is (1:0.3) to (1:0.6); the mass ratio of the diatomite to manganese dioxide is (1:1) to (1:2). The preparation method comprises the following steps: taking natural diatomite as a carrier, sequentially supportinghighly dispersed ferroferric oxide nano-particles and manganese dioxide nanosheets onto the surface of the natural diatomite by virtue of a thermal decomposition reaction and a hydrothermal reaction in an organic solvent medium, thereby obtaining the natural diatomite supported composite ferroferric oxide and manganese dioxide Fenton catalyst. According to the catalyst disclosed by the invention,the manganese dioxide, ferroferric oxide and diatomite are mutually and tightly combined, and a special three-layer structure is formed. The catalyst has the outstanding advantages of being high in dispersity in water, high in adsorptivity, high in catalytic activity and easy to recycle and the like. The preparation process disclosed by the invention is simple in process, simple and convenient tooperate, low in equipment requirements and capable of easily realizing industrialized production.

Owner:CENT SOUTH UNIV

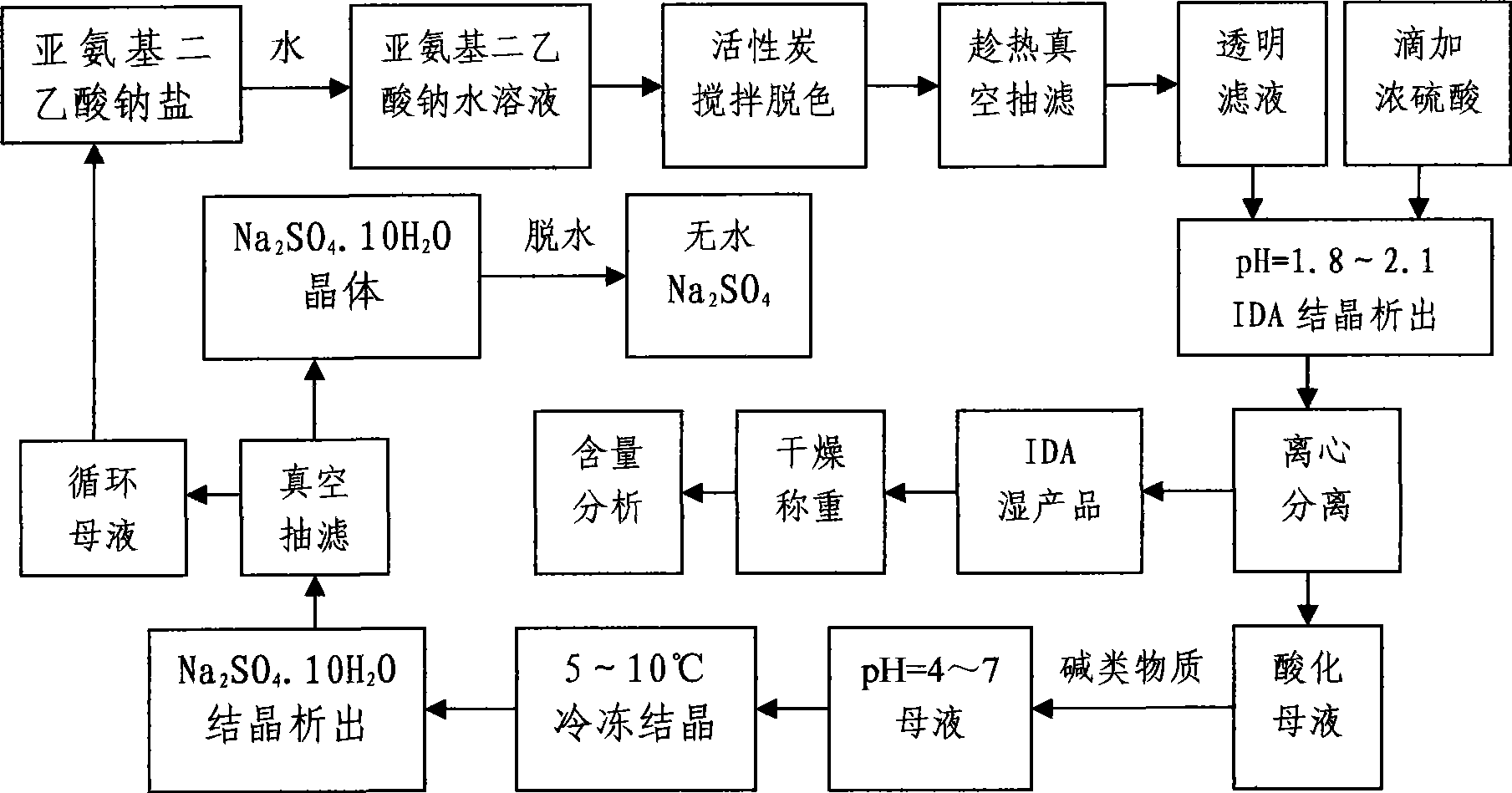

Cycling method for preparing iminodiacetic acid from iminodiacetic acid disodium salt

ActiveCN101445465AHigh purityCreate pollutionOrganic compound preparationAmino-carboxyl compound preparationIminodiacetic acidDesalination

The invention discloses a new cycling process for preparing iminodiacetic acid from iminodiacetic acid disodium salt by a freezing crystallization method. The method is characterized by comprising the following steps: taking the iminodiacetic acid disodium salt as a starting raw material; adding water and stirring to decolorize and dissolve the iminodiacetic acid disodium salt; adding concentrated sulfuric acid dropwise to control pH at 1.8-2.1; centrifuging to obtain the iminodiacetic acid; adding an alkaline matter to acid pregnant liquor until the pH equals 4-7; separating Na2SO4.10H2O out by crystallization at the temperature of 5-10 DEG C; performing vacuum filtration, and recycling the filtrate to continuously prepare the iminodiacetic acid (IDA), wherein, content and desalination rate of the IDA are above 98%, and the yield is about 97%. The pregnant liquor is not discarded in the production process and the whole process can have a plurality of cycles, thus improving production efficiency and utilization rate of the raw material, and avoiding environmental pollution.

Owner:GUANGXI RES INST OF CHEM IND CO LTD

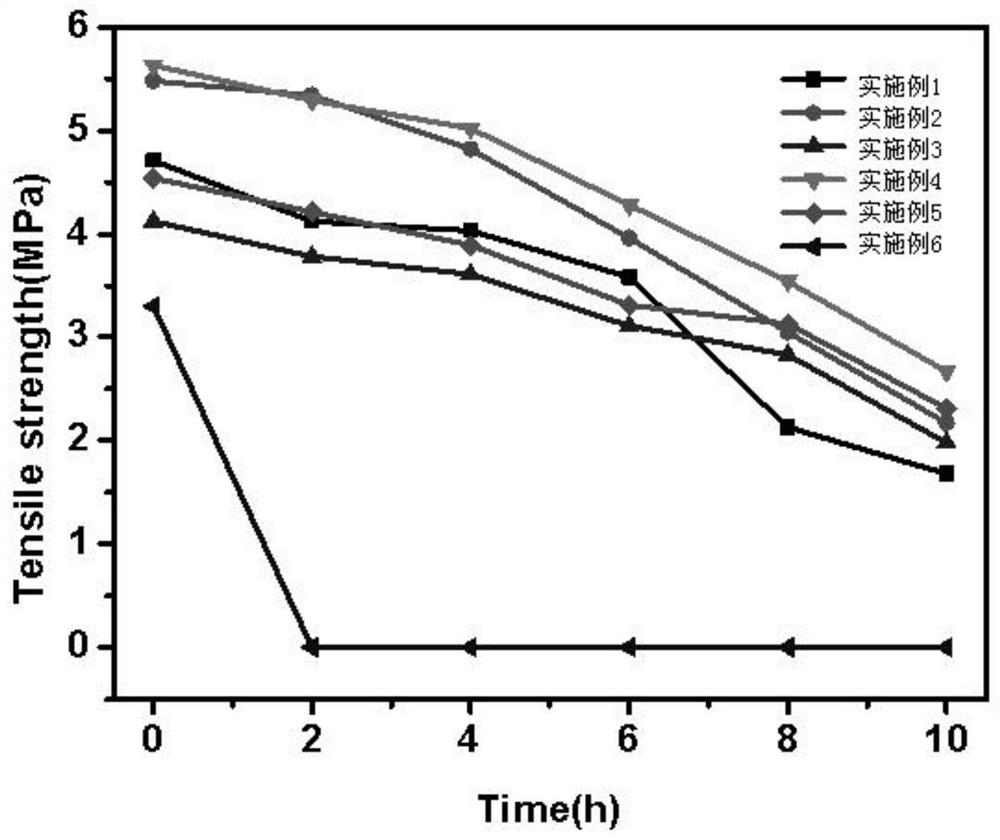

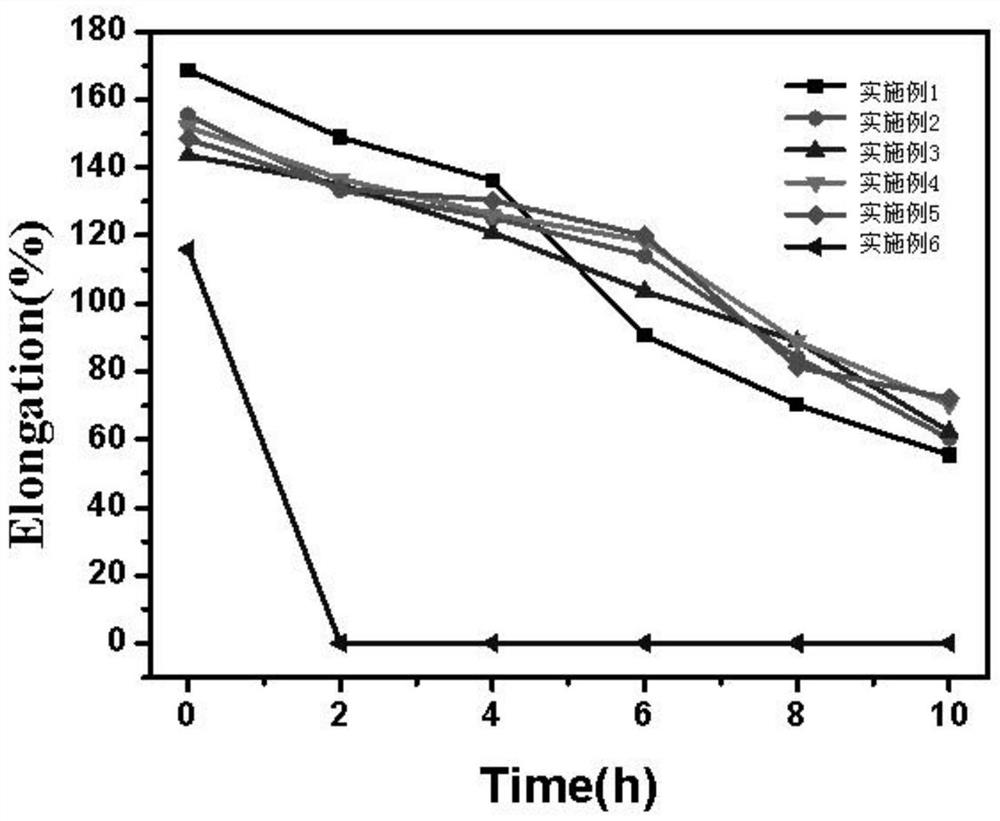

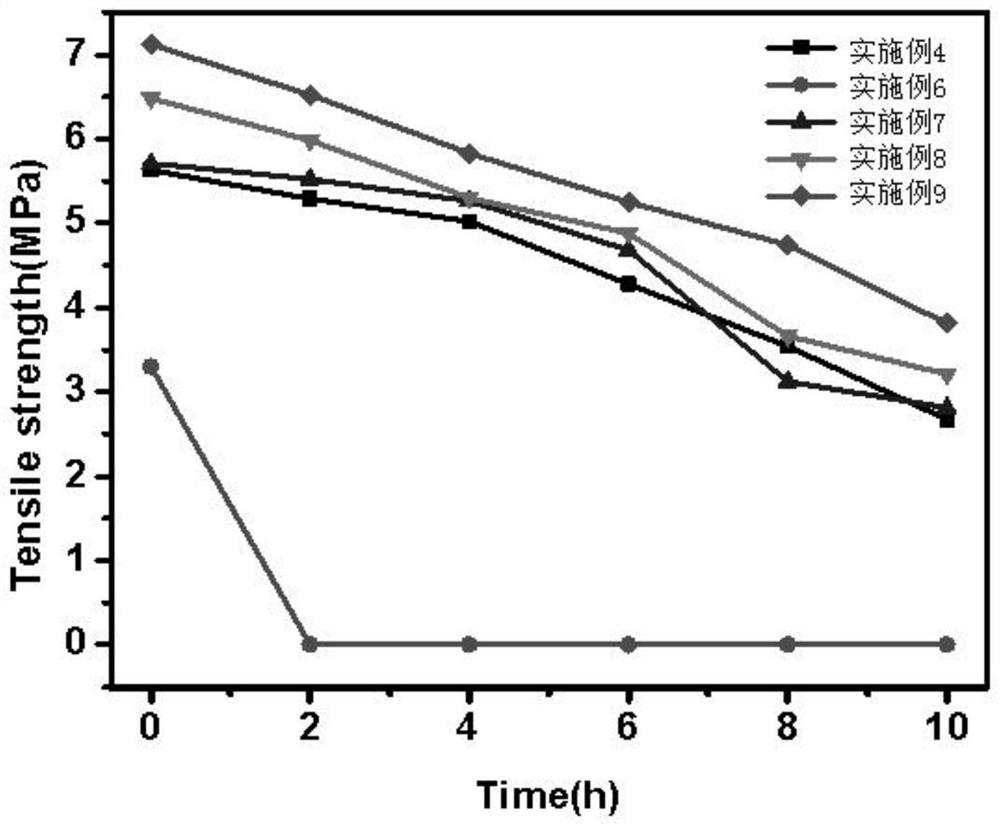

Waterproof starch film taking biodegradable polyurethane as coating and preparation method of waterproof starch film

InactiveCN111621046AImprove mechanical propertiesImprove waterproof performanceFlexible coversWrappersPolymer sciencePolyol

Owner:施塔希(绍兴)新材料有限公司

A kind of preparation method of 1-phenyl-5-mercaptotetrazolium

ActiveCN108947922BReduce pollutionThe azide reaction is fullyOrganic chemistryPtru catalystReaction temperature

The invention provides a preparation method for 1-phenyl-5-mercaptotetrazole. The preparation method takes sodium azide and phenyl isothiocyanate as a reaction raw material of preparing 1-phenyl-5-mercaptotetrazole by controlling a reaction temperature to 90-95 DEG C and reaction time to 110-130 min, so that full azido reaction of the sodium azide and phenyl isothiocyanate can be guaranteed undermilder conditions and without the use of a catalyst. The preparation method is simple in operation and small in environment pollution during production, and the use of complex production equipment isnot needed; and the preparation method is simple in post-treatment operation, low in production cost so that to realize large-scale industrial production is easy. Results of embodiments show that theyield of the target object (1-phenyl-5-mercaptotetrazole) can reach to 94.8% when the method is adopted to perform large-scale industrial production, so that actual production needs can be met.

Owner:ZHEJIANG BULK CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com