Process for accelerating core removal speed by utilizing liquid-electric effect and special high-temperature high-pressure core removal kettle

A technology of hydroelectric effect, high temperature and high pressure, applied in the field of investment precision casting ceramic core removal process and its device, to achieve the effects of simple equipment, simple process and high removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

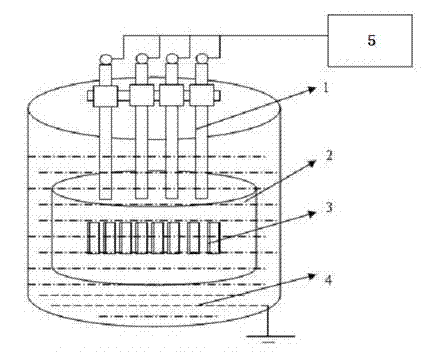

[0019] see figure 1 , in this embodiment, a corrosive liquid pool 4 is provided in the hydroelectric effect high temperature and high pressure core removal kettle, and the casting 3 to be removed from the core is loaded in the material frame 2, so that the casting 3 loaded in the material frame 2 is completely immersed in the corrosive liquid In the pool 4, an electrode 1 is arranged above the casting 3, and the bottom end of the electrode 1 is also immersed in the corrosion solution pool 4. The electrode 1 is not in contact with the casting 3 loaded in the material frame 2, and the top of the electrode 1 is connected to a high-voltage pulse power supply 5 , the corrosive liquid pool 4 is grounded, and the high-voltage pulse power supply 5 is controlled to continuously apply high-voltage pulse current to the corrosive liquid pool 4. Under the set temperature and pressure environment, the liquid corrosive medium in the corrosive liquid pool 4 is rapidly Vaporization, expansion,...

Embodiment 2

[0021] This embodiment is basically the same as Embodiment 1, especially in that:

[0022] In this embodiment, the casting containing the aluminum-based ceramic core is put into the material frame 2, and put together into the corrosion solution pool 4 of the high-temperature and high-pressure core removal kettle, and the alkaline solution is 25% NaOH aqueous solution. Also arrange the electrode 1 directly above the casting 3, cover the high-temperature and high-pressure core removal kettle, and heat it with electricity until the temperature rises to 200 degrees Celsius and the pressure reaches 0.7 MPa. After holding the heat for 1 hour, turn on the high-voltage pulse power supply 5, Apply a high-voltage pulse current for 10 minutes every half hour, three times in a row, to produce a hydroelectric effect, and use the shock wave and cavitation effects of the electrohydraulic effect to promote the corrosion products after corrosion to flow out of the inner cavity of the casting to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com