Hydrothermal synthesis method for iron-based spinel with high-density oxygen vacancies

A hydrothermal synthesis, oxygen vacancy technology, applied in the direction of iron compounds, chemical instruments and methods, iron oxide/iron hydroxide, etc., to achieve the effect of simple synthesis process, high selectivity, and short synthesis cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) 2mmolFeCl 2 4H 2 O and 4mmolFe(NO 3 ) 3 9H 2 After O is mixed, dissolve in a certain volume of ethylene glycol, and stir vigorously for 30 minutes at a speed of 800 r / min to make the solution clear. Then add 2.4gNaOH, continue to stir until the solution is clear again; the FeCl 2 6H 2 O, Fe(NO 3 ) 3 9H 2 Both O and NaOH are analytically pure;

[0031] (2) Place the mixed solution obtained after mixing in step (1) in a hydrothermal kettle, and control the temperature to 200° C. to react for 10 hours to obtain a reaction product;

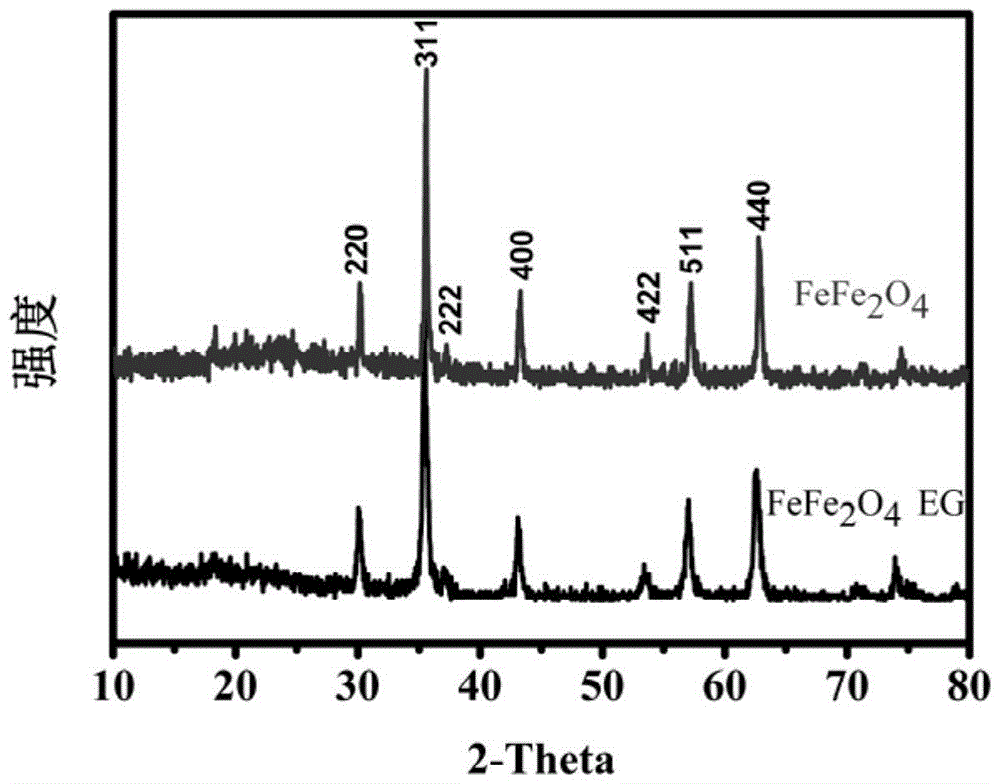

[0032] (3) After the reaction product is naturally cooled, it is centrifugally filtered, and the obtained product is washed 3-5 times with deionized water, and then washed 2 times with absolute ethanol, and then the product is dried in an oven at a temperature of 60° C. for 6 hours to obtain Ferrous spinel with a high density of oxygen vacancies (FeFe 2 o 4 ) Black nanopowder of nanopowder. figure 1 It is the X-ray diffraction ...

Embodiment 2

[0034] (1) 2mmolMnCl 2 4H 2 O and 4mmolFe(NO 3 ) 3 9H 2 After O is mixed, dissolve in a certain volume of ethylene glycol, and stir vigorously for 30 minutes at a speed of 800 r / min to make the solution clear. Then add 2.4gNaOH, continue to stir until the solution is clear again; the MnCl 2 6H 2 O, Fe(NO 3 ) 3 9H 2 Both O and NaOH are analytically pure;

[0035] (2) Place the mixed solution obtained after mixing in step (1) in a hydrothermal kettle, and control the temperature to 200° C. to react for 10 hours to obtain a reaction product;

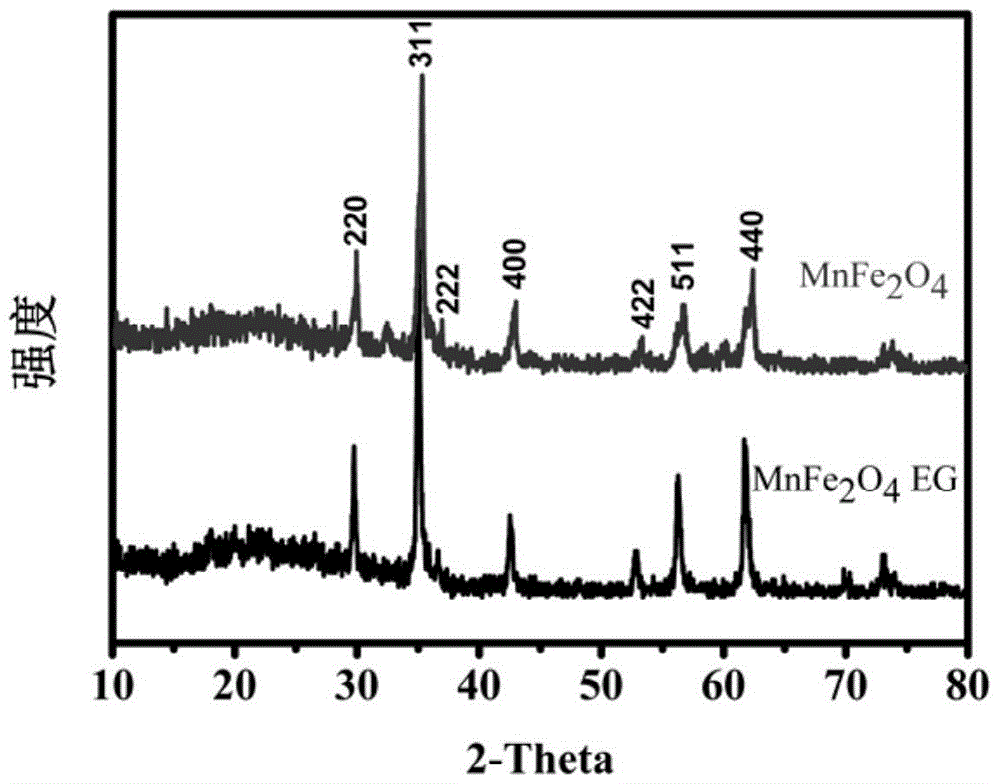

[0036](3) After the reaction product is naturally cooled, it is centrifugally filtered, and the obtained product is washed 3-5 times with deionized water, and then washed 2 times with absolute ethanol, and then the product is dried in an oven at a temperature of 60° C. for 6 hours to obtain Manganese ferrite spinel with a high density of oxygen vacancies (MnFe 2 o 4 ) Black nanopowder of nanopowder. figure 2 It is the X-ray di...

Embodiment 3

[0038] (1) 2mmolNiCl 2 6H 2 O and 4mmolFe(NO 3 ) 3 9H 2 After O is mixed, dissolve in a certain volume of ethylene glycol, and stir vigorously for 30 minutes at a speed of 800 r / min to make the solution clear. Then add 2.4gNaOH, continue to stir until the solution is clear again; the NiCl 2 6H 2 O, Fe(NO 3 ) 3 9H 2 Both O and NaOH are analytically pure;

[0039] (2) Place the mixed solution obtained after mixing in step (1) in a hydrothermal kettle, and control the temperature to 200° C. to react for 10 hours to obtain a reaction product;

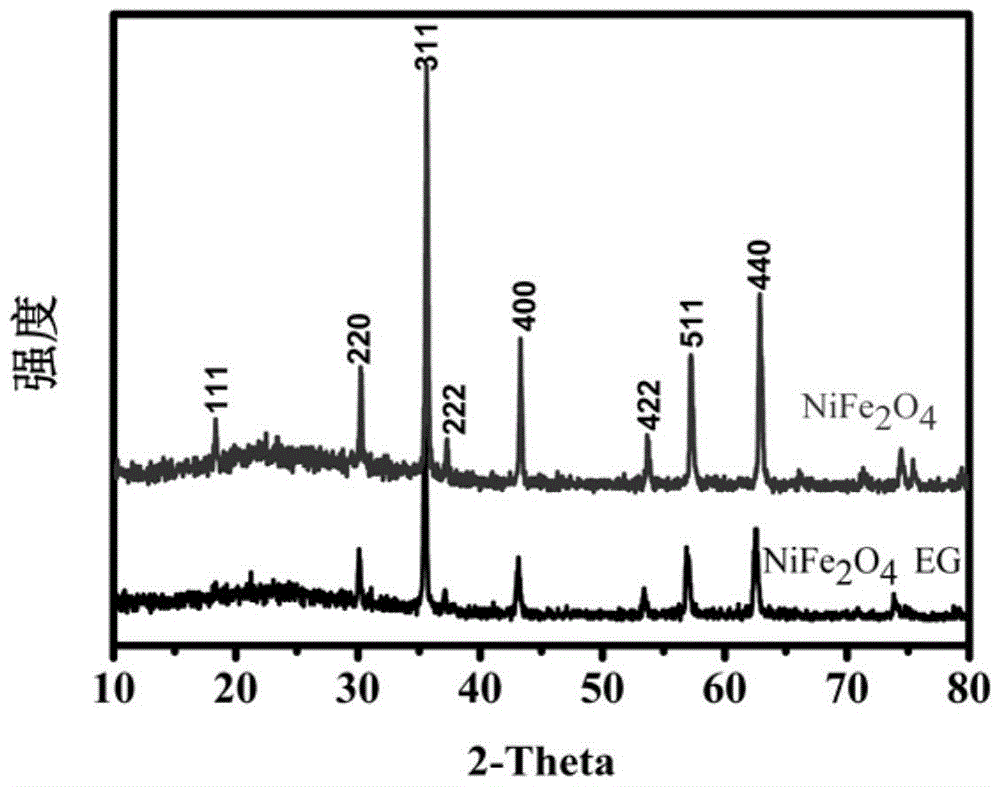

[0040] (3) After the reaction product is naturally cooled, it is centrifugally filtered, and the obtained product is washed 3-5 times with deionized water, and then washed 2 times with absolute ethanol, and then the product is dried in an oven at a temperature of 60° C. for 6 hours to obtain Nickel ferrite spinel (NiFe 2 o 4 ) Black nanopowder of nanopowder.

[0041] image 3 It is the XRD of the iron-based spinel prepared in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com