Erbium-doped indium oxide gas-sensitive nano material, preparation method and application thereof

A technology of gas-sensing materials and nano-materials, applied in the field of erbium-doped indium oxide nano-gas-sensing materials and its preparation, to achieve the effects of easy industrial production, easy operation, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

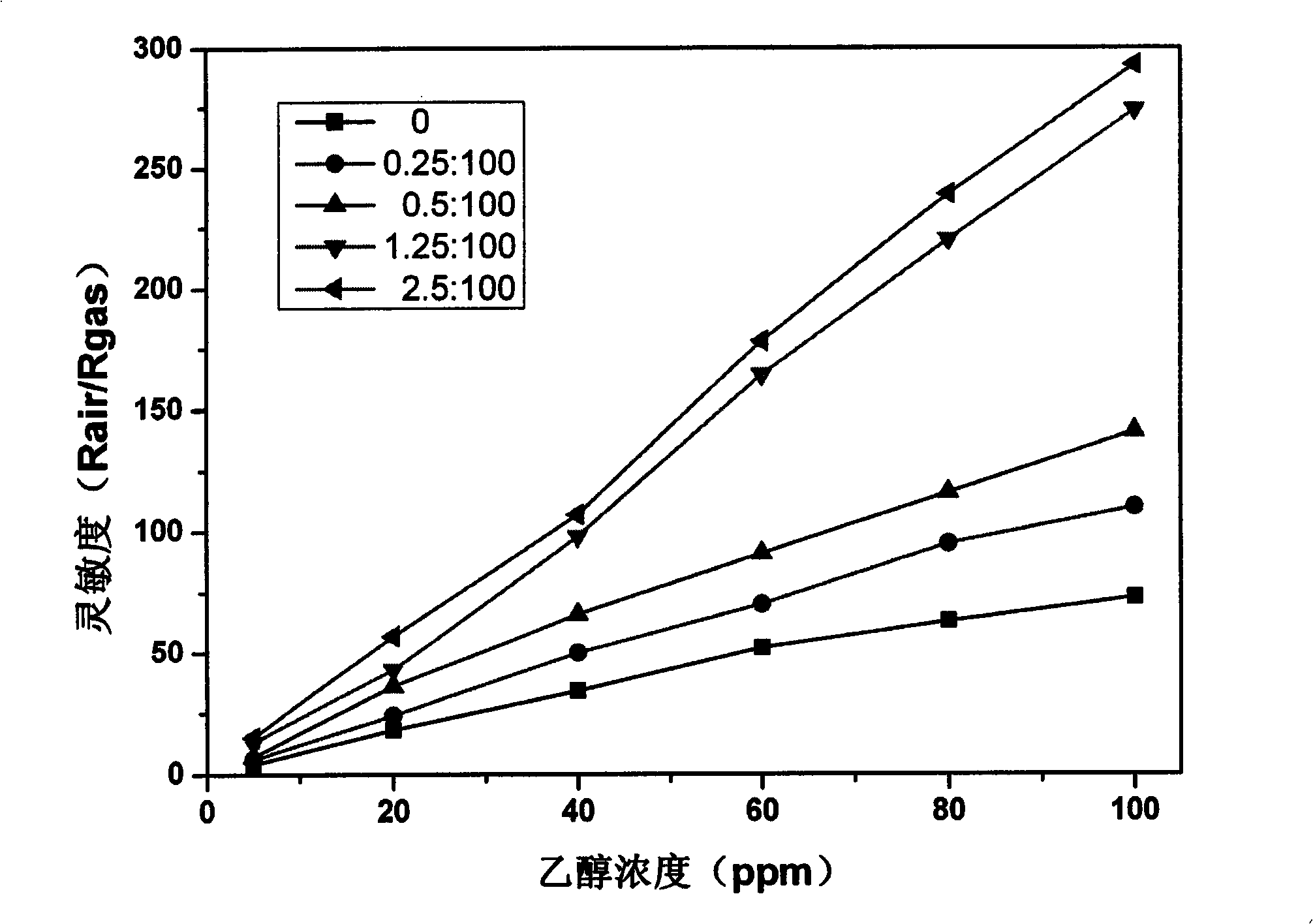

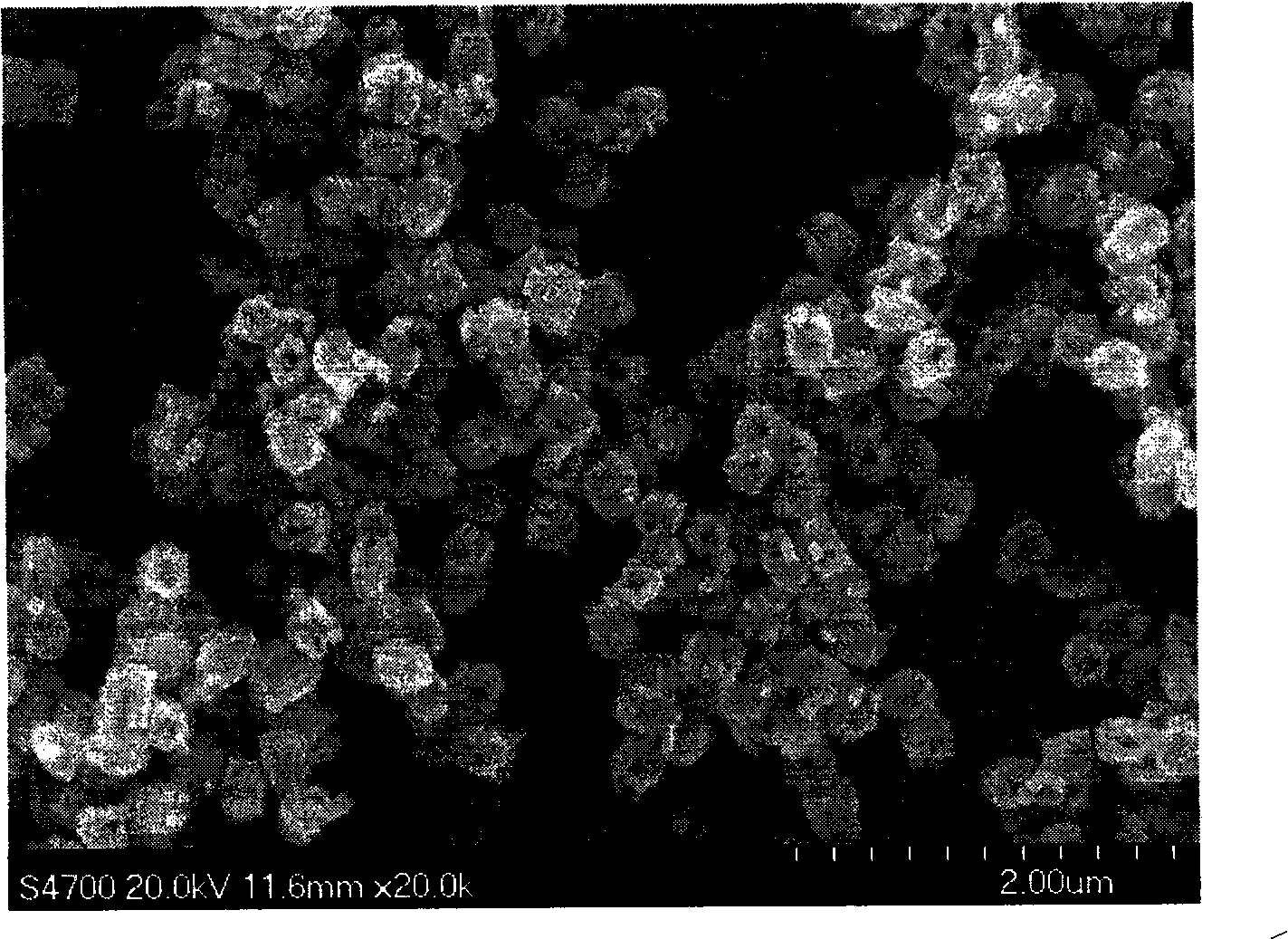

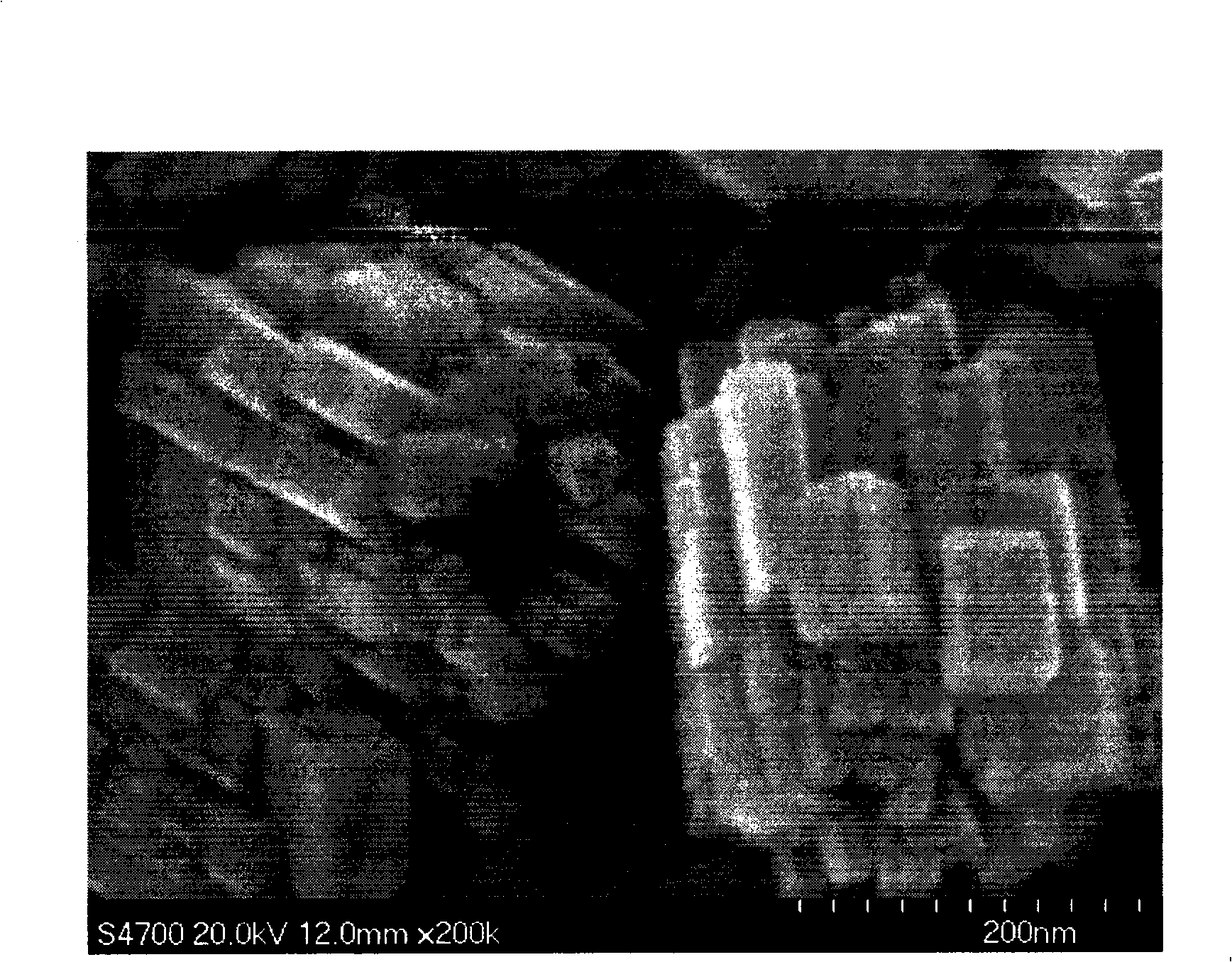

[0025] A. Take 1mmol of analytically pure indium salt, 5mmol of resorcinol, 5ml of formamide, and 10ml of deionized water, respectively, and add them into a 22ml polytetrafluoroethylene autoclave, and stir until the reactants are completely dissolved. The reaction kettle was directly put into an oven with a temperature of 160° C. for 12 hours. After the reaction was completed, it was cooled at room temperature to obtain a white precipitate. It was washed and centrifuged three times. The white precipitate was then dried at 60°C for 5 hours, and then calcined at 400°C for 3 hours to obtain light yellow indium oxide powder. The scanning electron microscope picture of the sample is shown in figure 2 with image 3 .

[0026] B. Take 0.03g of indium oxide and grind it in a mortar. Weigh 0.1036g Er(NO 3 ) 3 ·7H 2 O was dissolved in 100ml of deionized water to prepare a solution with a concentration of 0.00216mol / L, and 0.25ml of the solution was added dropwise into a mortar, ...

Embodiment 2

[0028] A. Same as Example 1

[0029] B. Take 0.03g of indium oxide and grind it in a mortar. Weigh 0.1036g Er(NO 3 ) 3 ·7H 2 O was dissolved in 100ml of deionized water to prepare a solution with a concentration of 0.00216mol / L, and 0.5ml of the solution was added dropwise into a mortar, and fully ground into a slurry. The slurry was then dried at 60°C for 3 hours and calcined at 400°C for 3 hours. That is, an erbium-doped indium oxide nanometer gas-sensing material with an Er / In molar ratio of 0.5:100 is obtained.

Embodiment 3

[0031] A. Same as Example 1

[0032] B. Take 0.03g of indium oxide and grind it in a mortar. Weigh 0.1036g Er(NO 3 ) 3 ·7H 2 O was dissolved in 10ml of deionized water to prepare a solution with a concentration of 0.0216mol / L, and 0.125ml of the solution was added dropwise into a mortar, and fully ground into a slurry. The slurry was then dried at 60°C for 3 hours and calcined at 400°C for 3 hours. That is, an erbium-doped indium oxide nanometer gas-sensing material with an Er / In molar ratio of 1.25:100 is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com