Patents

Literature

99 results about "Indium(III) hydroxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Indium(III) hydroxide is the chemical compound with the formula In(OH)₃, its prime use is as a precursor to indium(III) oxide, In₂O₃. It is sometimes found as the rare mineral dzhalindite.

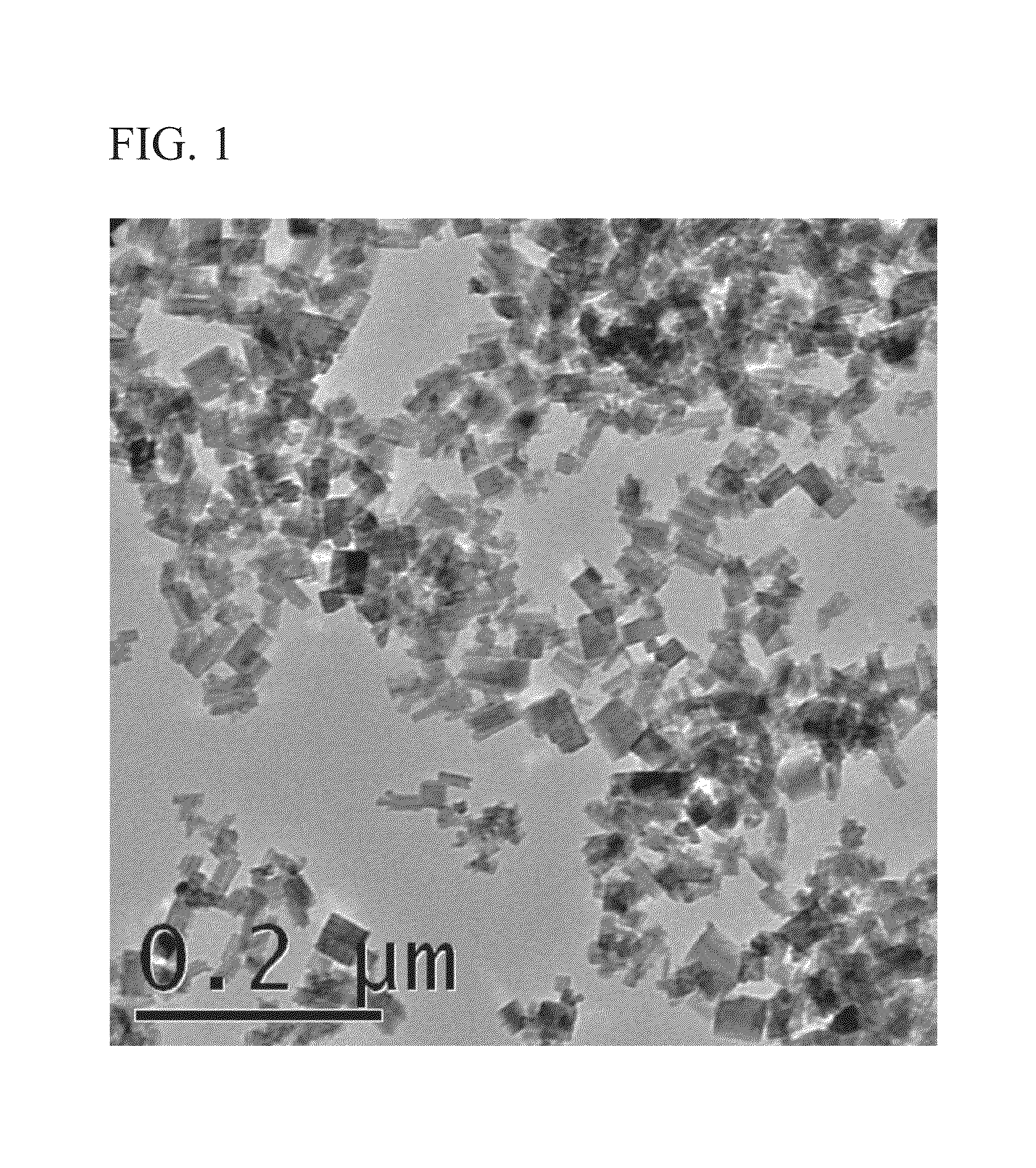

Preparation method for indium oxide nanometer material

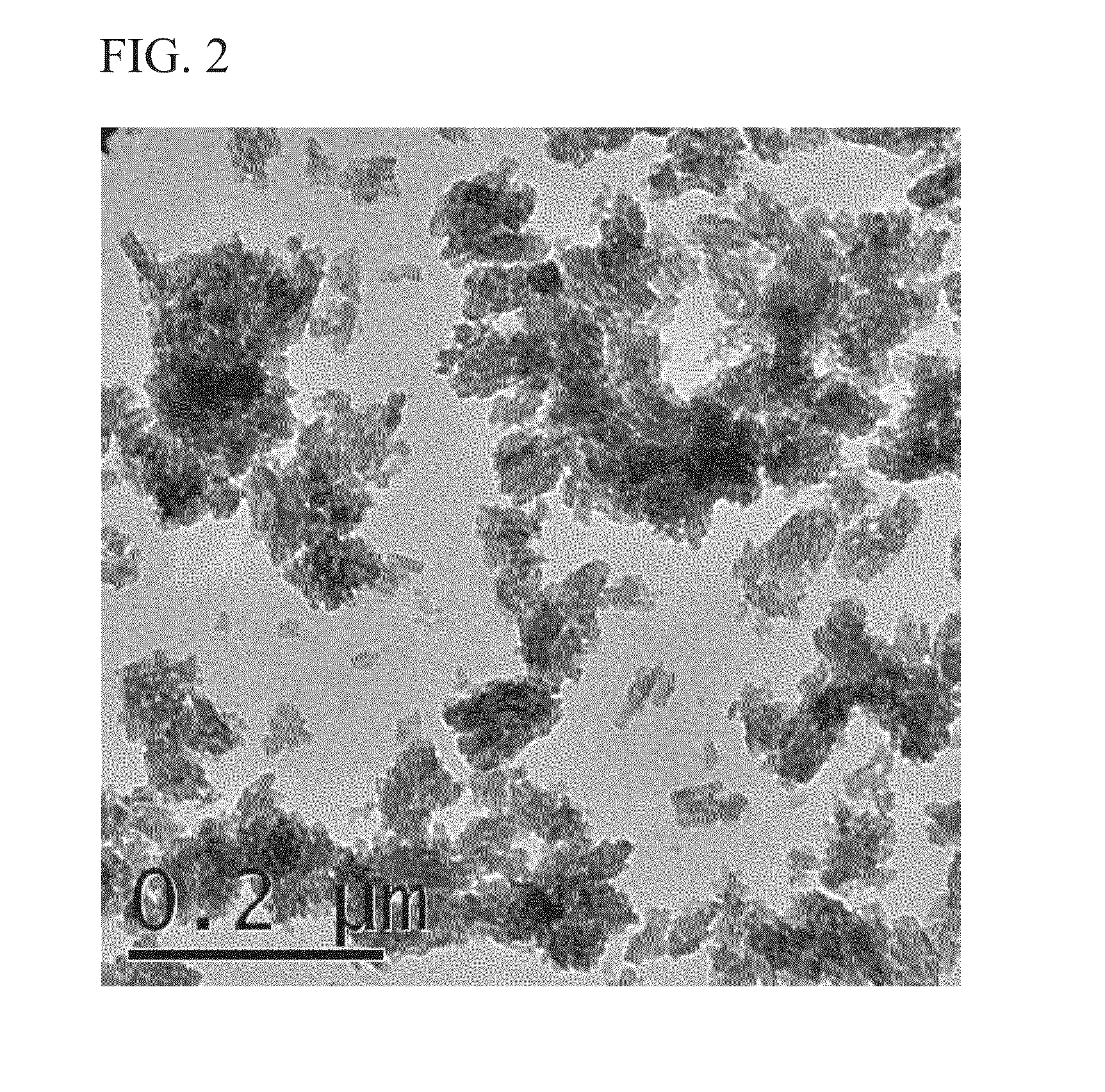

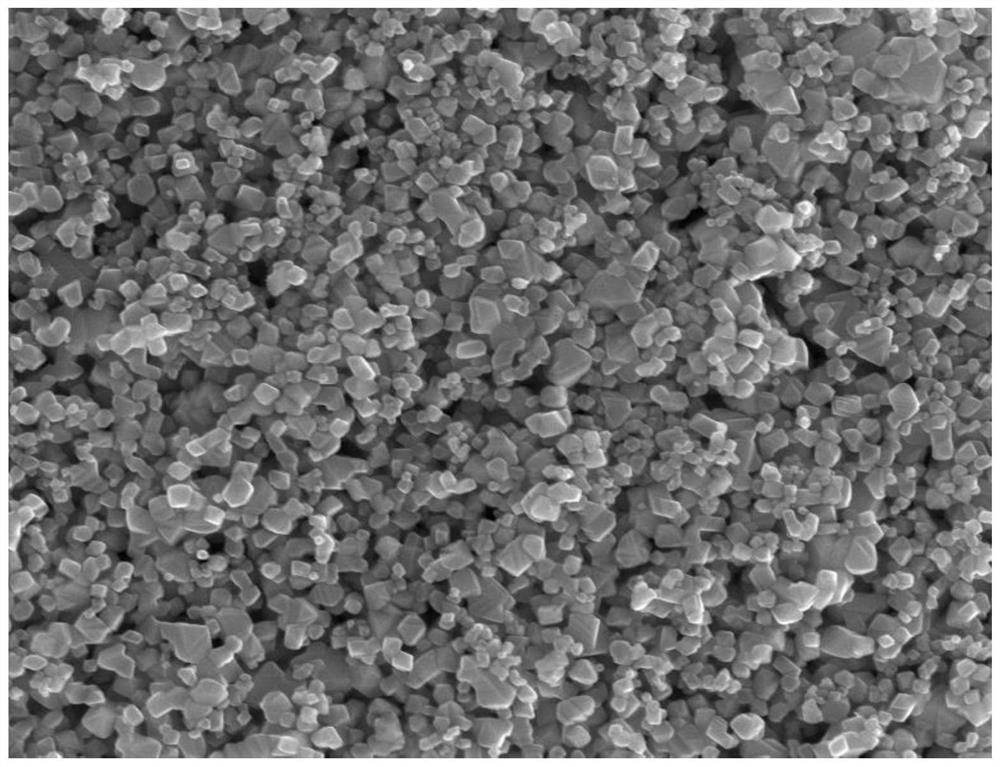

InactiveCN102826593AUniform particle size distributionHigh purityMaterial nanotechnologyGallium/indium/thallium compoundsDispersityFlat panel display

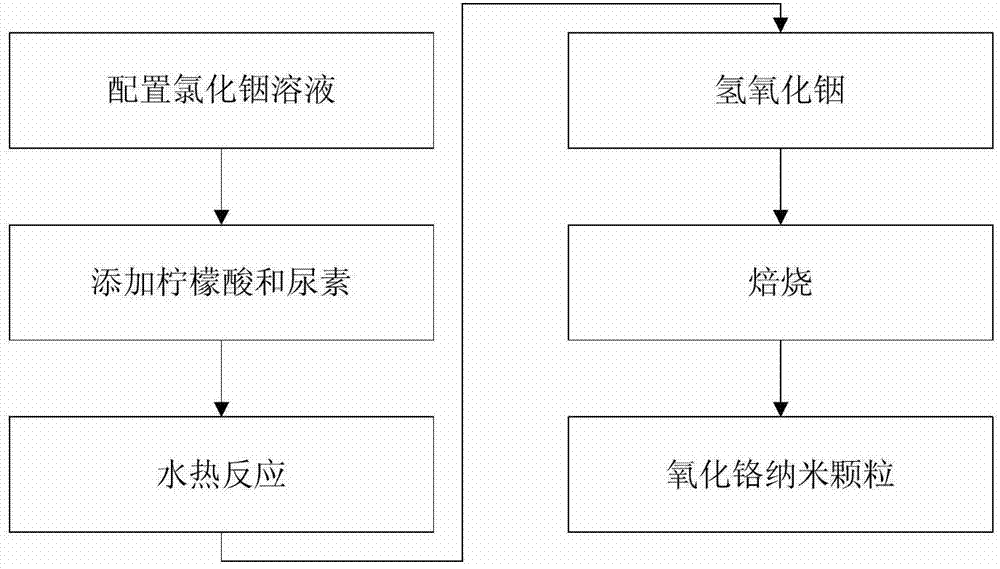

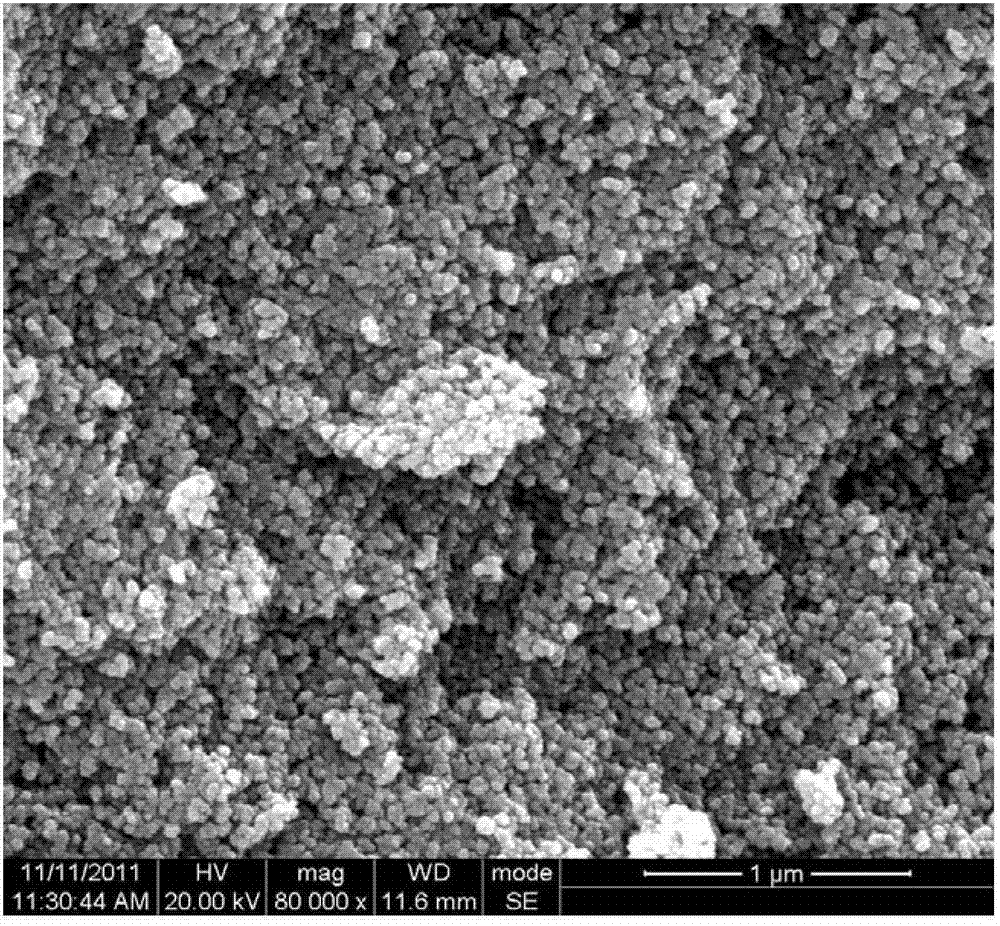

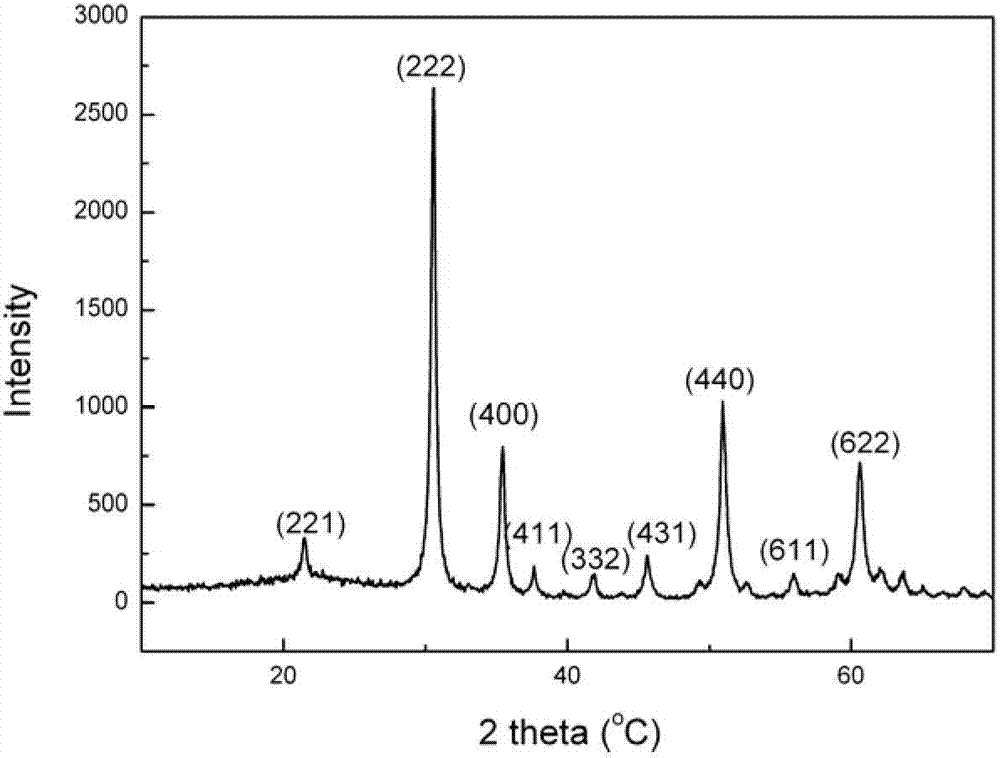

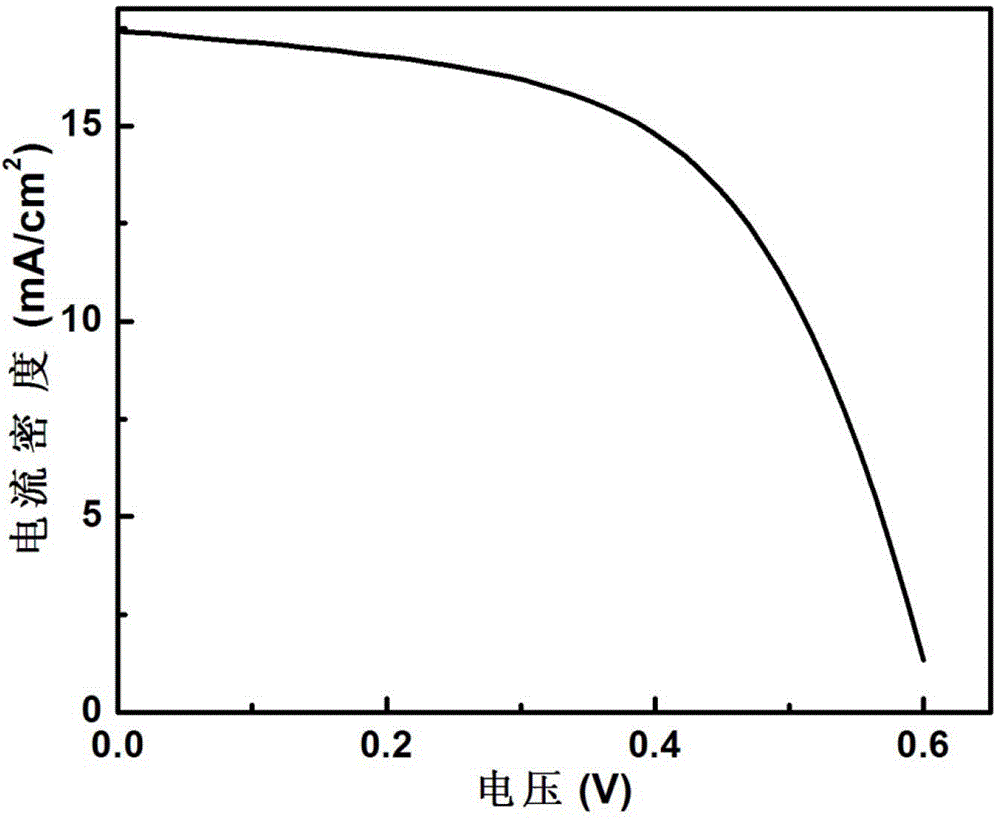

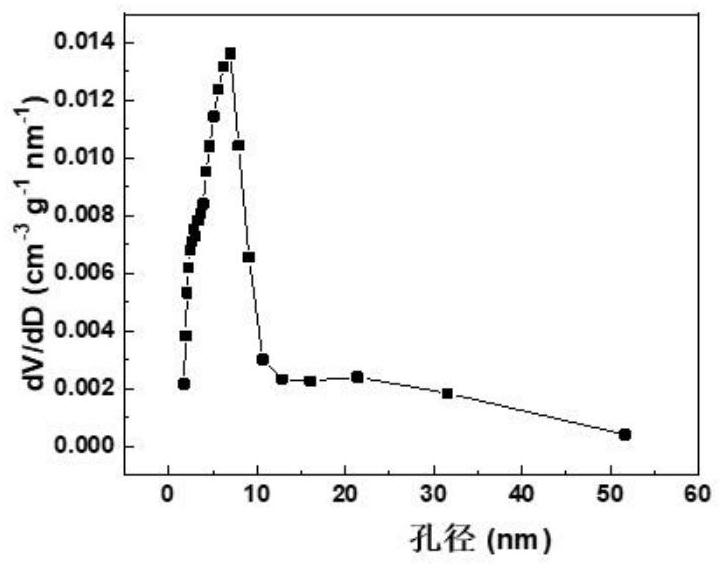

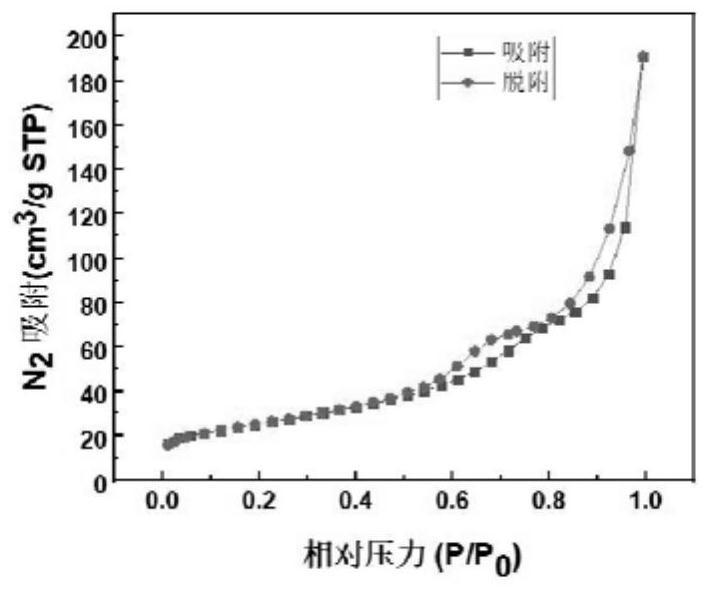

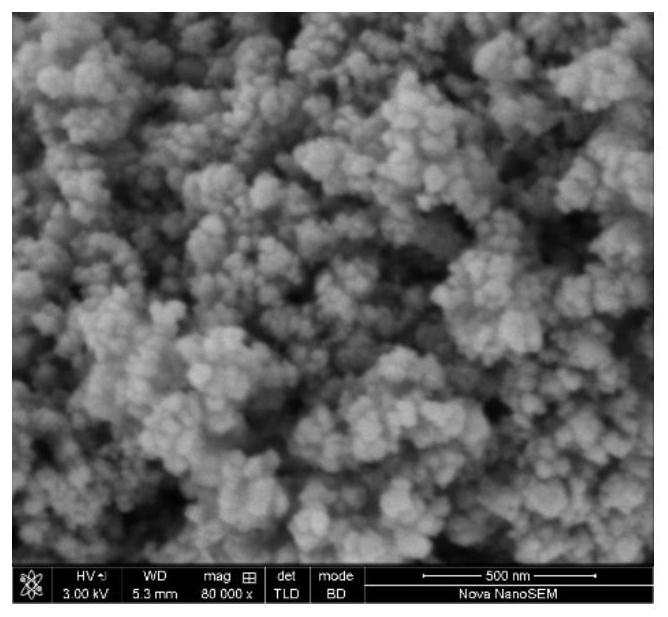

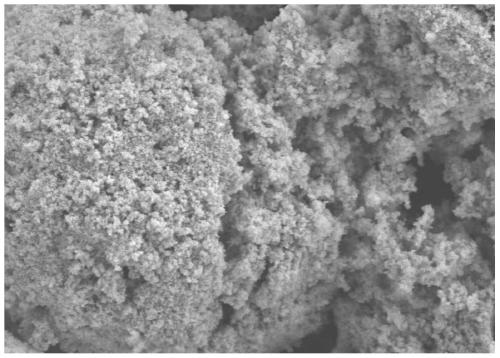

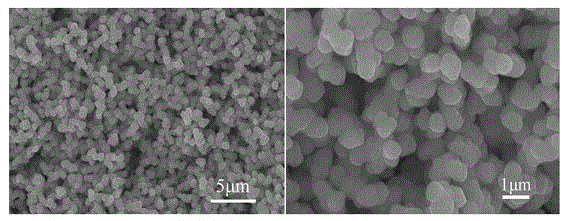

The invention relates to a preparation method for an indium oxide (In2O3) nanometer material, and belongs to the technical field of preparation of inorganic materials. The preparation method comprises the following steps: firstly, carrying out a hydrothermal reaction on indium chloride to prepare indium hydroxide (In(OH)3) nanometer particles under the condition of taking lemon acid and urea as additives; and then carrying out a thermal calcination treatment to obtain the spherical In2O3 nanometer material. The method has the advantages of low cost, simplicity in production process, and easiness in industrial large-scale production. The prepared nanometer chromium oxide is a spherical particle with the diameter of about 30nm, and has the advantages of uniform particle distribution, high purity, good dispersity and large specific surface area. Therefore, the prepared nanometer chromium oxide is suitable for the fields of solar batteries, gas sensitive elements, flat-panel displays, electric light regulators, sensors and the like.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA +1

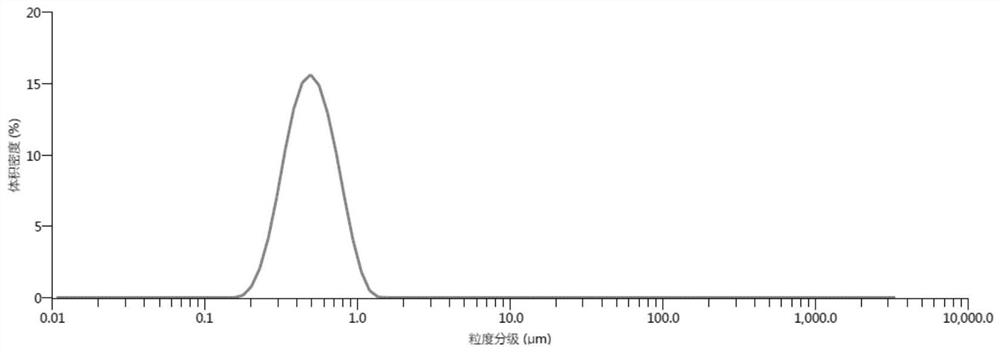

Liquid phase coprecipitation method for producing superfine tin indium oxide powder

InactiveCN1994894AGuaranteed complete simultaneous precipitationReduce clumpingGallium/indium/thallium compoundsIndium(III) hydroxideAlcohol

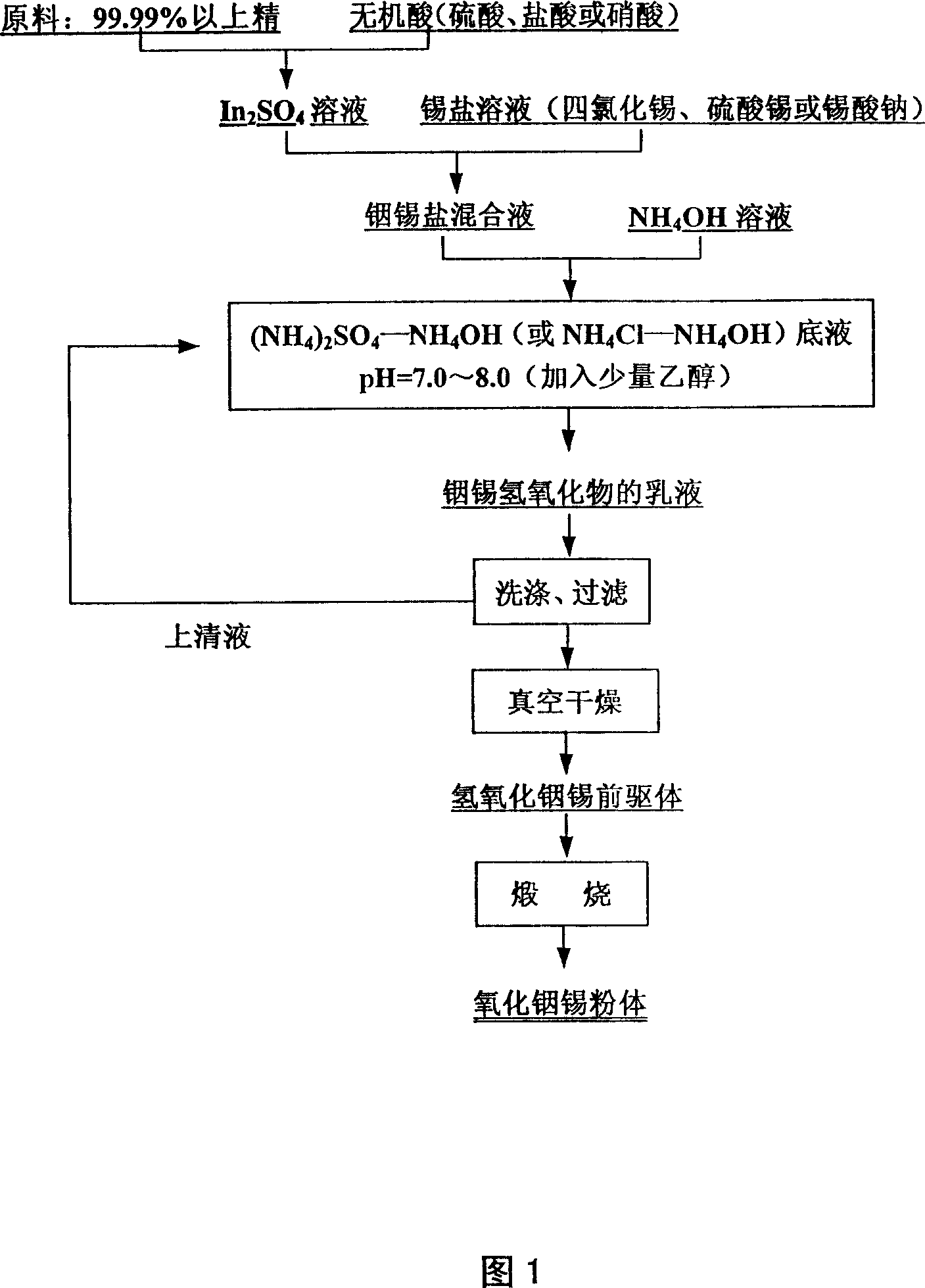

The invention discloses a making method of ultrafine indium tin oxide powder through liquid phase co-sedimenting method, which is characterized by the following: adopting metal indium with purity more than 99. 99%, SnCl4 .5H2O and ammonia as raw material; making (NH4)2SO4-NH3 .H2O or NH4Cl-NH3 .H2O with pH value at 7. 0-9. 0 as reacting substrate liquid; adding certain quantity of anhydrous alcohol; adopting liquid-phase co-sediment method to make white indium tin hydroxide predecessor; sintering to obtain light yellow green ball shaped ITO powder with even grain size at 20-60nm.

Owner:KUNMING UNIV OF SCI & TECH

Nb-doped nano indium tin oxide powder and method for preparing high density sputtering coating target thereof

InactiveCN101580379AHigh puritySmall granularityVacuum evaporation coatingSputtering coatingIndiumNiobium

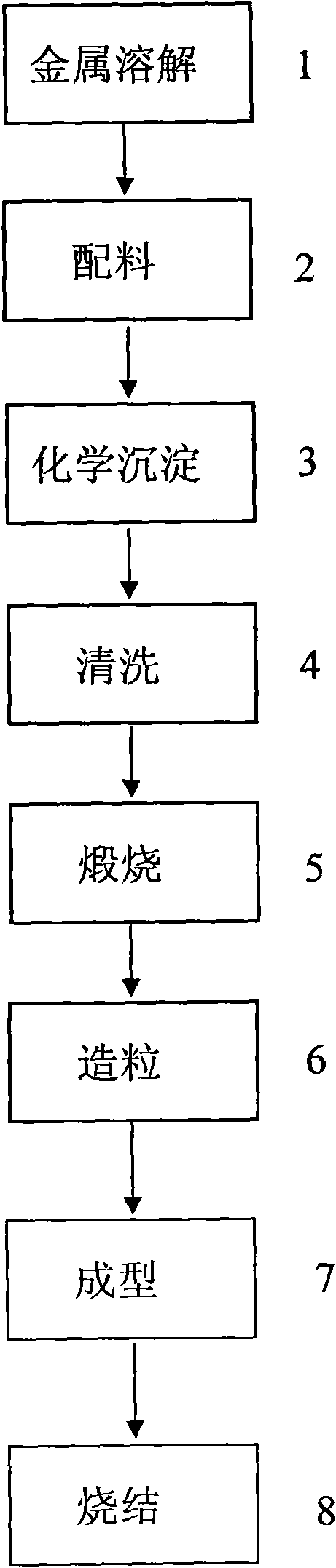

The invention relates to an Nb-doped nano indium tin oxide powder and a method for preparing high density sputtering coating target thereof. The method comprising the following steps: (1) dissolving high pure metals: high pure metal niobium, high pure metal indium and high pure metal tin are respectively dissolved into transparent solutions by inorganic acid; (2) mixing: the obtained transparent solutions are respectively filled into containers according to the proportion; (3) chemical precipitation: the three transparent solutions are made into Nb-doped and heavily tin-doped indium hydroxide nano-powder; (4) washing: the Nb-doped and heavily tin-doped tin indium hydroxide nano-powder is washed by de-ionized water and then precipitated; (5) calcinating: the nano-powder is calcined, and the Nb-doped nano indium tin oxide powder is prepared; (6) granulation: the Nb-doped nano indium tin oxide powder is added with a bonding agent and then dried, so that Nb-doped nano indium tin oxide powder before molding can be prepared; (7) molding: the Nb-doped nano indium tin oxide powder before molding is pressed into early embryo; (8) sintering: the early embryo is sintered under the normal pressure, and the high density sputtering coating target of the Nb-doped indium tin oxide can be prepared; in addition, pressure sintering can be adopted to further improve the density of the target.

Owner:BEIHANG UNIV +1

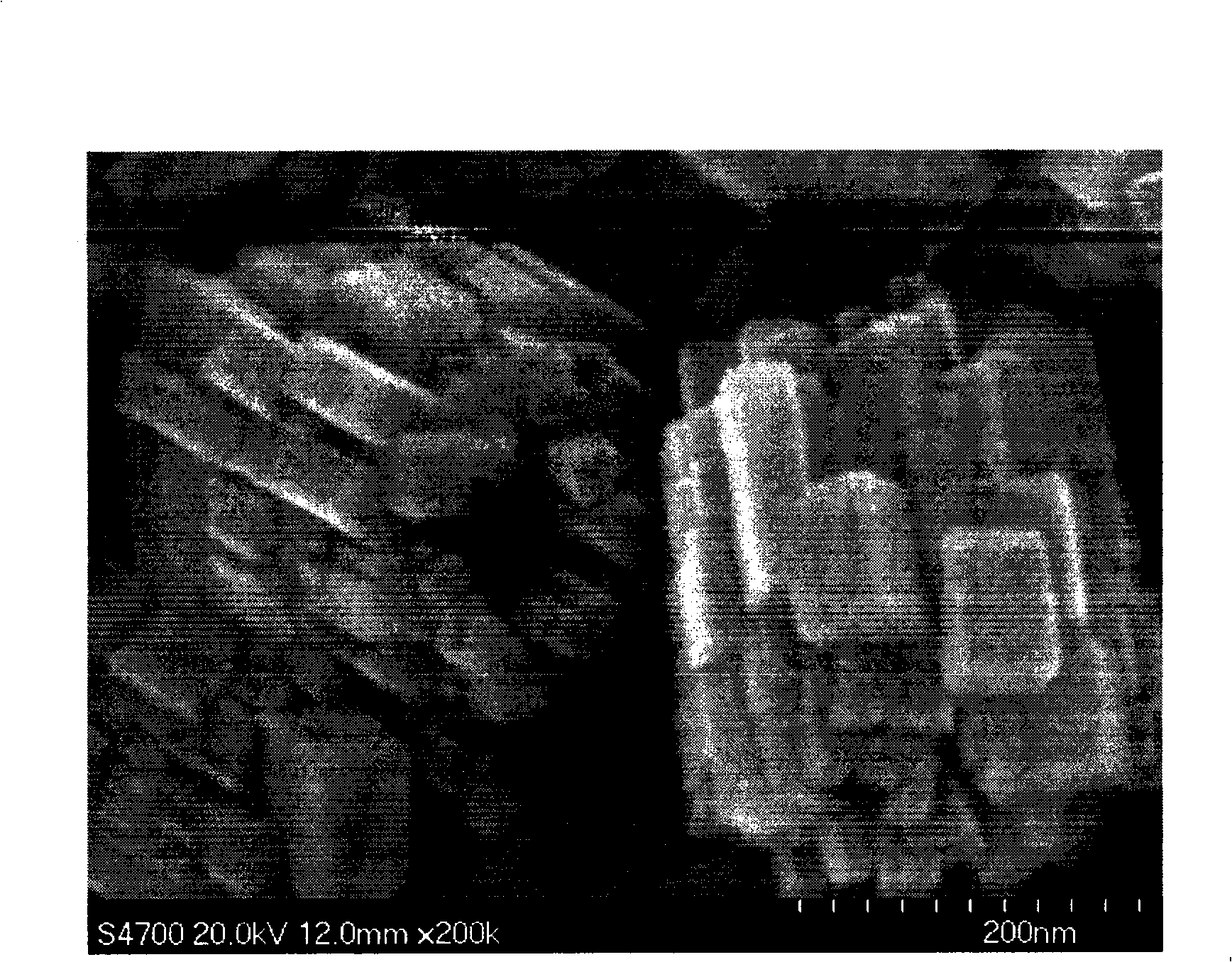

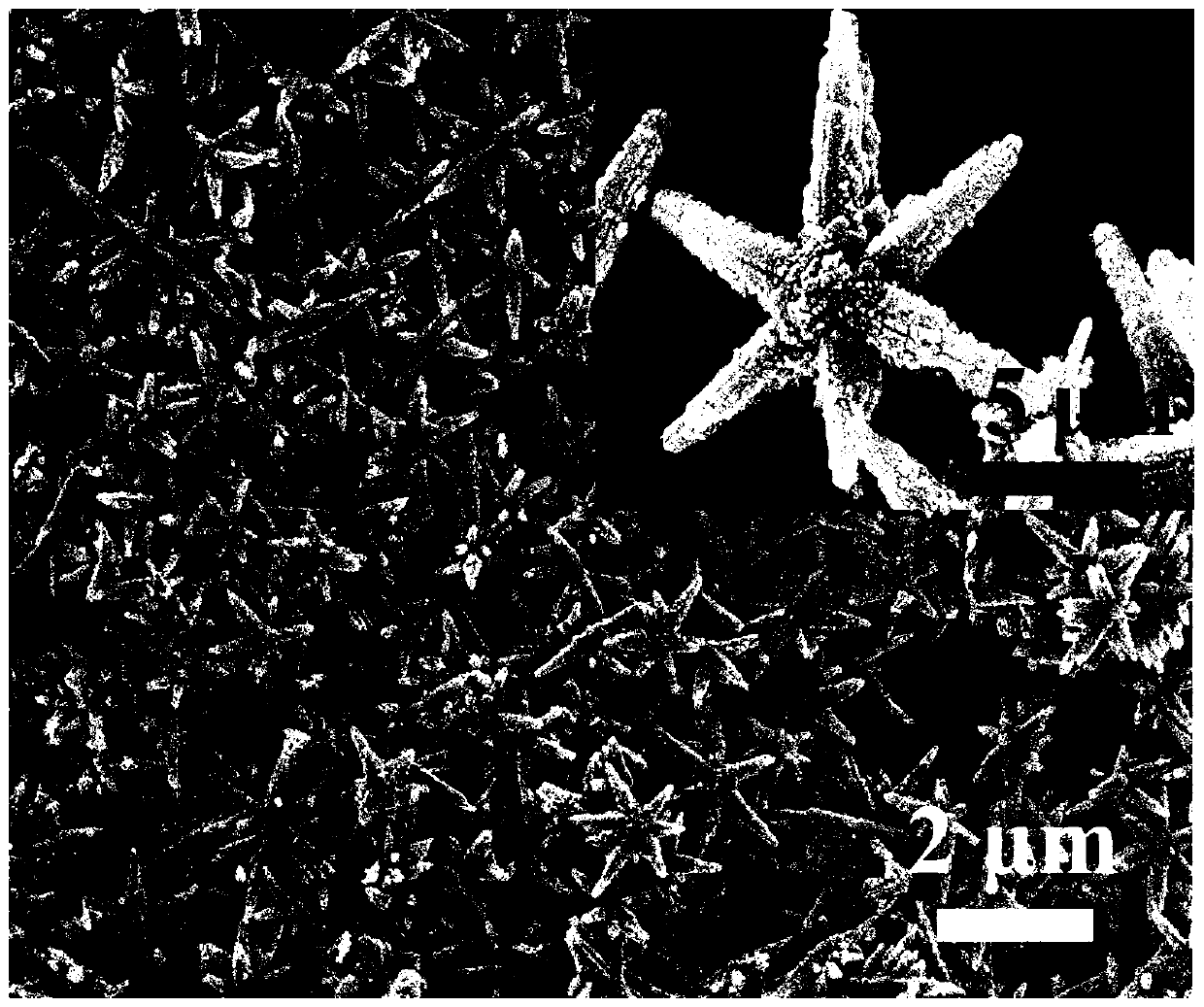

Preparing method of nano-rod-shaped indium oxide gas-sensitive material

ActiveCN108455659AGood sensor detection performanceLower working temperatureMaterial nanotechnologyGallium/indium/thallium compoundsIndium TrichlorideWorking temperature

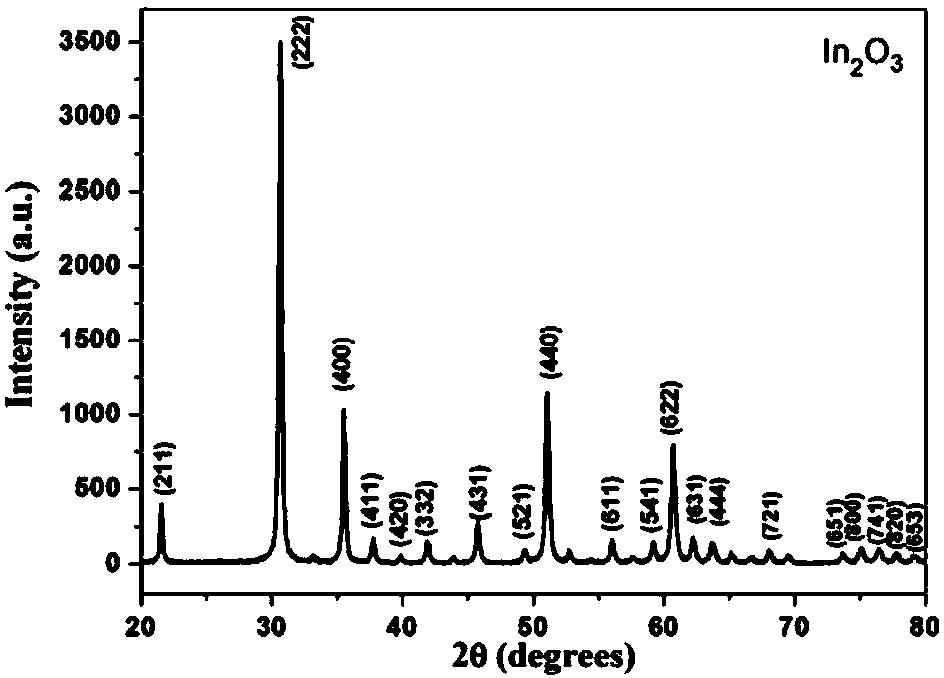

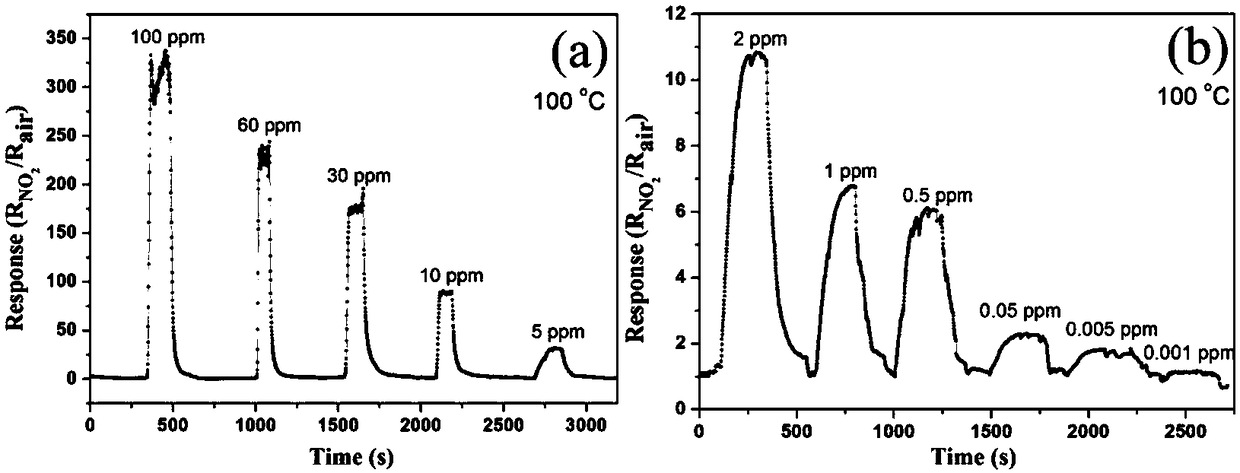

The invention relates to a preparing method of a nano-rod-shaped indium oxide (In2O3) gas-sensitive material, and belongs to the technical field of preparation of inorganic nanometer functional materials. The preparing method comprises the steps of with indium(III) chloride tetrahydrate being an indium source, by adopting hexadecyl trimethyl ammonium bromide as surface active agent, conducting a hydrothermal reaction under the alkaline condition of sodium hydroxide to prepare indium hydroxide and finally, conducting thermal roasting to obtain the indium oxide gas-sensitive material of a nano-rod-shaped structure. Finally prepared indium oxide is In2O3 with the cubic phase and of the nano-rod-shaped structure, has very good performance of sensing and detecting both nitrogen dioxide gas andhydrogen sulfide gas and is insensitive to other gases (carbon monoxide, ethyl alcohol, ammonia, hydrogen, formaldehyde and the like); the indium oxide also has low working temperature, a quick response and restoration, very high sensitivity, a low detection limit, high selectivity and high stability. Besides, the indium oxide gas-sensitive material can also be used in the fields of catalyst, battery materials, photoelectric materials and the like.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Zinc cathode electrolyte used for redox cells

The invention discloses a zinc cathode electrolyte used for redox cells. The electrolyte comprises divalent zinc ions as a main active component, and organic and inorganic additives. The additives comprise bromine-contained quaternary ammonium salts, boric acid borax, indium hydroxide and lead oxide. The additives are mainly used for pH adjustment, hydrogen suppression, and improvement of zinc depositing morphology. The zinc cathode electrolyte can be applied for zinc vanadium cells, zinc cerium cells, zinc iron cells and various redox cells taking zinc as the active component of the cathode.

Owner:周谨平

Indium tin oxide powder, method for producing same, dispersion, paint, and functional thin film

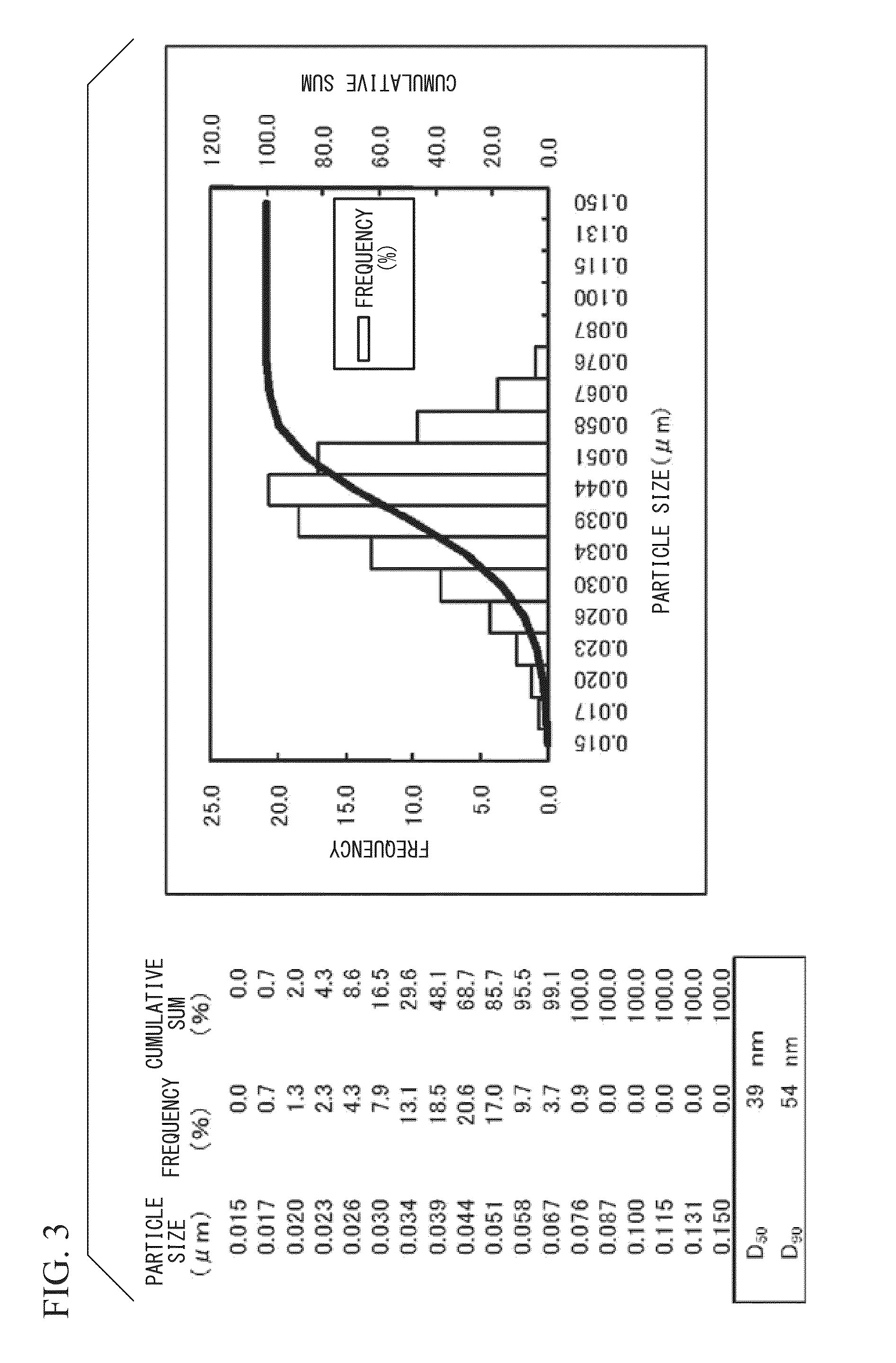

InactiveUS20130187104A1Small particle sizeSatisfactory dispersibilityMaterial nanotechnologyPigmenting treatmentIndium(III) hydroxideLiquid temperature

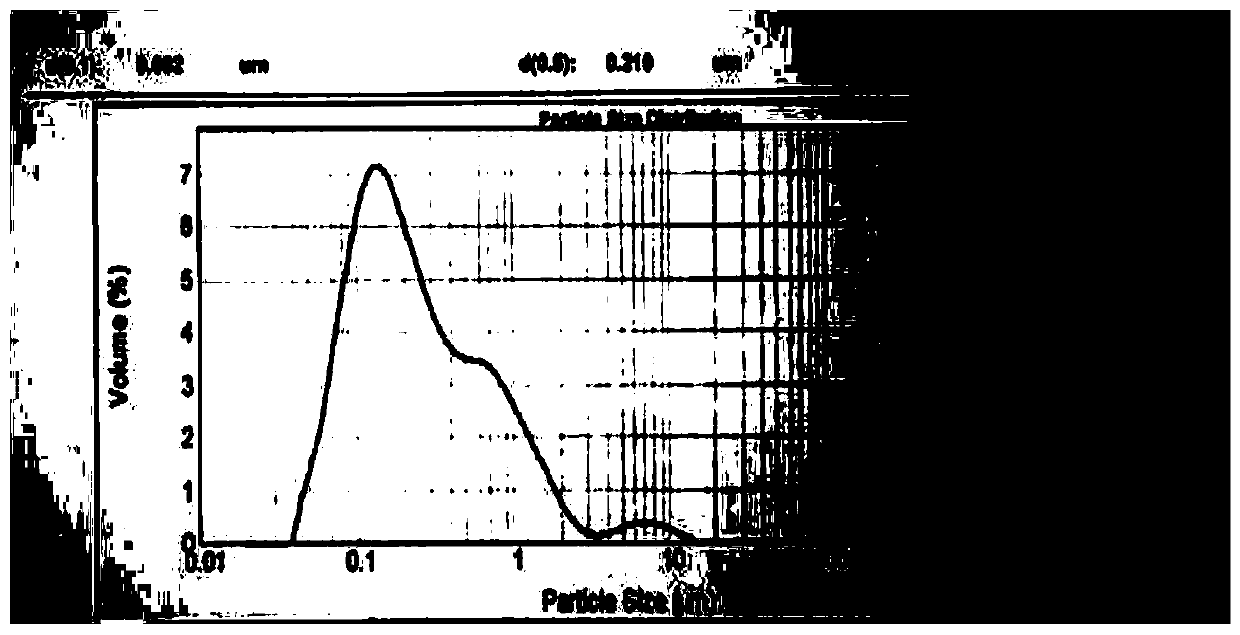

This indium tin oxide powder has a median diameter of 30 nm to 45 nm and a D90 value of 60 nm or less in a particle size distribution. This method for producing an indium tin oxide powder includes, in series: a step (A) of coprecipitating an indium tin hydroxide by using a tin (Sn2+) compound under conditions where a pH is in a range of 4.0 to 9.3 and a liquid temperature is in a range of 5° C. or higher, wherein the indium tin hydroxide has a color tone ranging from bright yellow to color of persimmon in a dried powder state; a step (B) of drying and calcining the indium tin hydroxide, and thereby, obtaining indium tin oxide; and a step (C) of dry pulverizing the obtained indium tin oxide in a nitrogen atmosphere.

Owner:MITSUBISHI MATERIALS CORP +1

Erbium-doped indium oxide gas-sensitive nano material, preparation method and application thereof

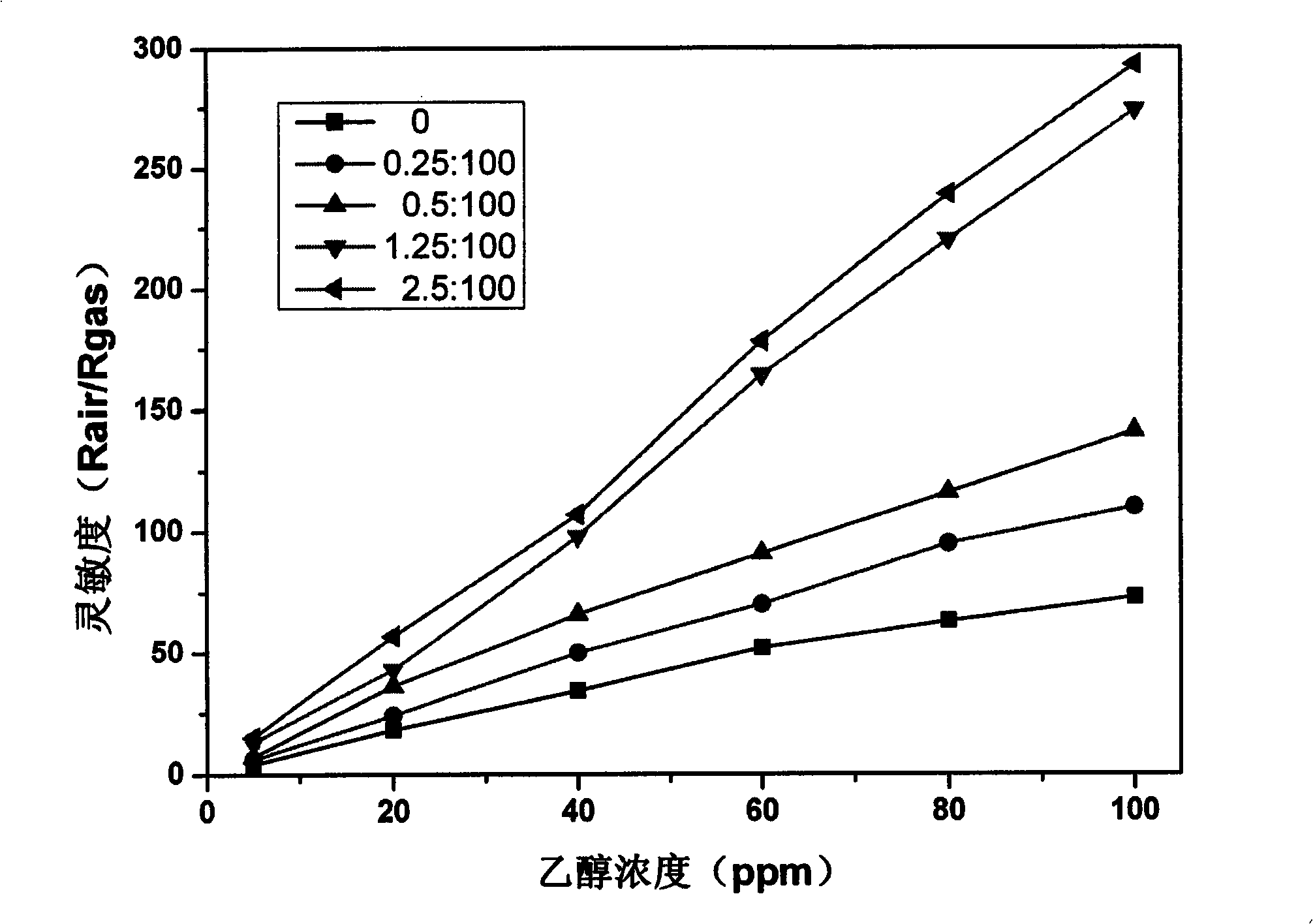

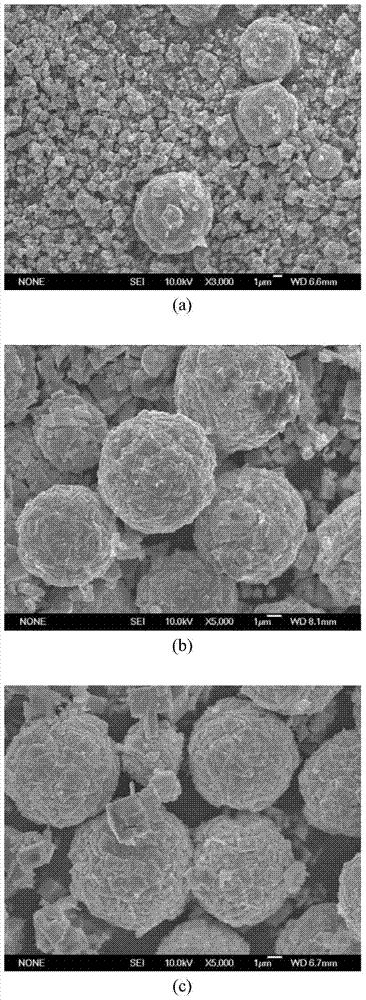

InactiveCN101539537AThe process is simple and convenientEasy to operateGallium/indium/thallium compoundsMaterial resistanceIndium(III) hydroxideMicrosphere

The invention provides an erbium-doped indium oxide gas-sensitive nano material, a preparation method and application thereof. The erbium-doped indium oxide gas-sensitive nano material is an indium oxide nano material doped by erbium oxide and can be expressed as Er2O3-In2O3, wherein the molar ratio of Er to In is 0.25-2.5:100; the indium oxide is hollow spheres which consist of granules of 30 to 60 nanometers and of which diameters are 200 to 300 nanometers; and the erbium oxide is attached to the surface of the indium oxide granules. The preparation method comprises the following steps: using indium salt, methanamide and m-dihydroxybenzene as raw materials to synthesize hollow indium hydroxide microspheres by adopting a hydro-thermal method, and drying and calcining the hollow microspheres to form indium oxide carriers; and then adding indium salt solution into the indium oxide, and grinding, drying and calcining the precipitate to obtain the erbium-doped indium oxide nano material. The gas-sensitive material has high sensitivity for ethanol, and can be used for manufacturing an ethanol gas sensor.

Owner:BEIJING UNIV OF CHEM TECH

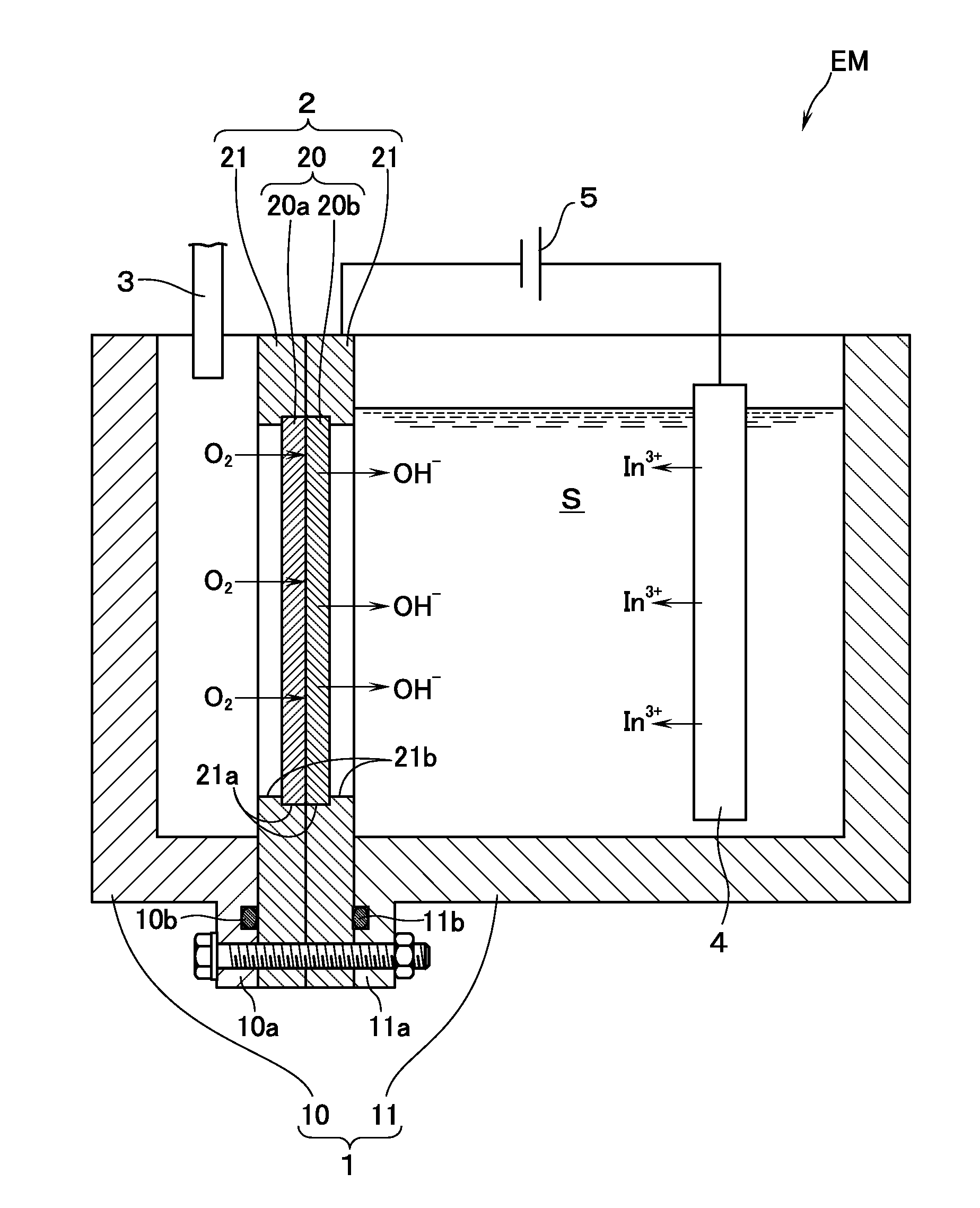

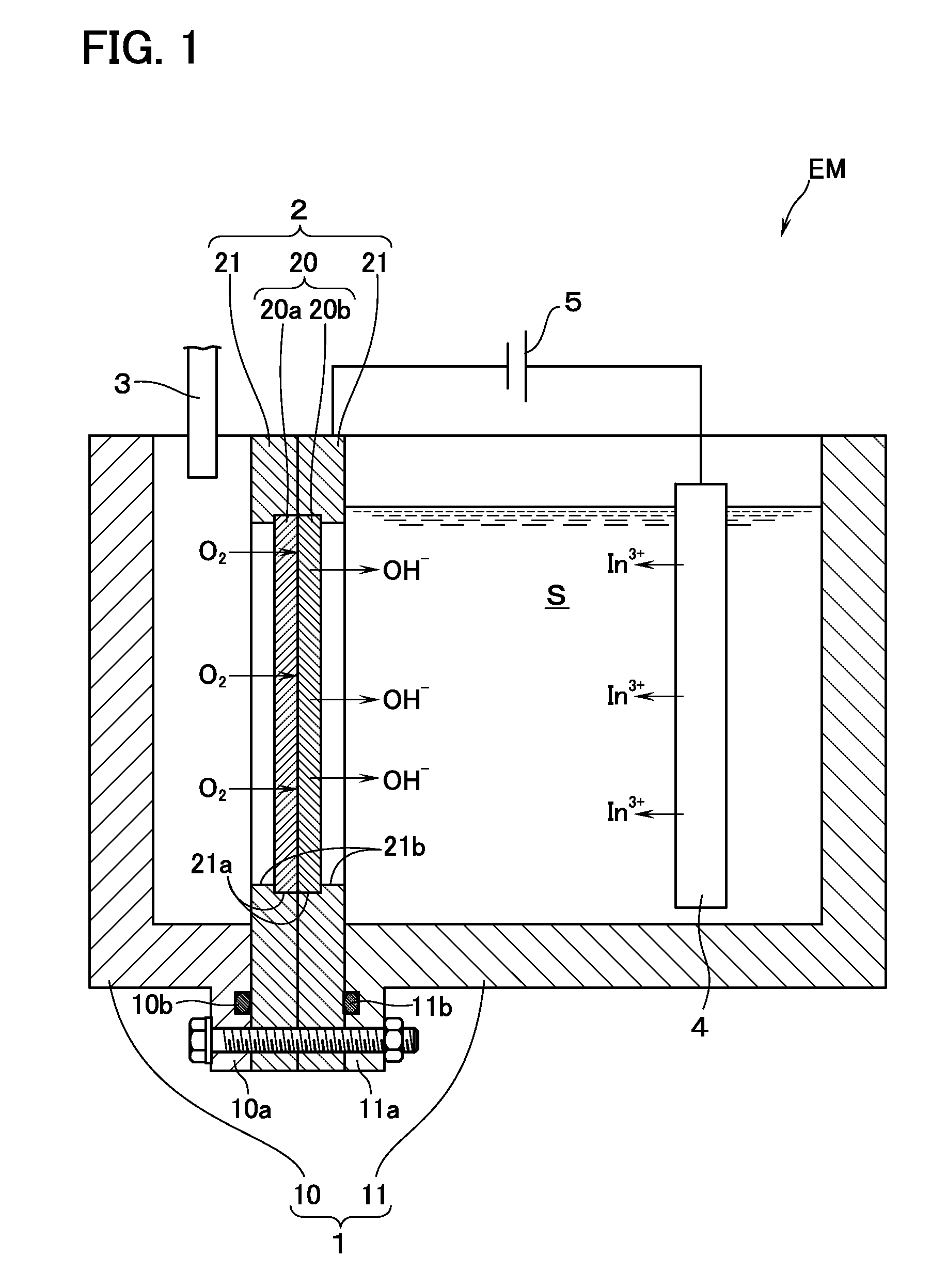

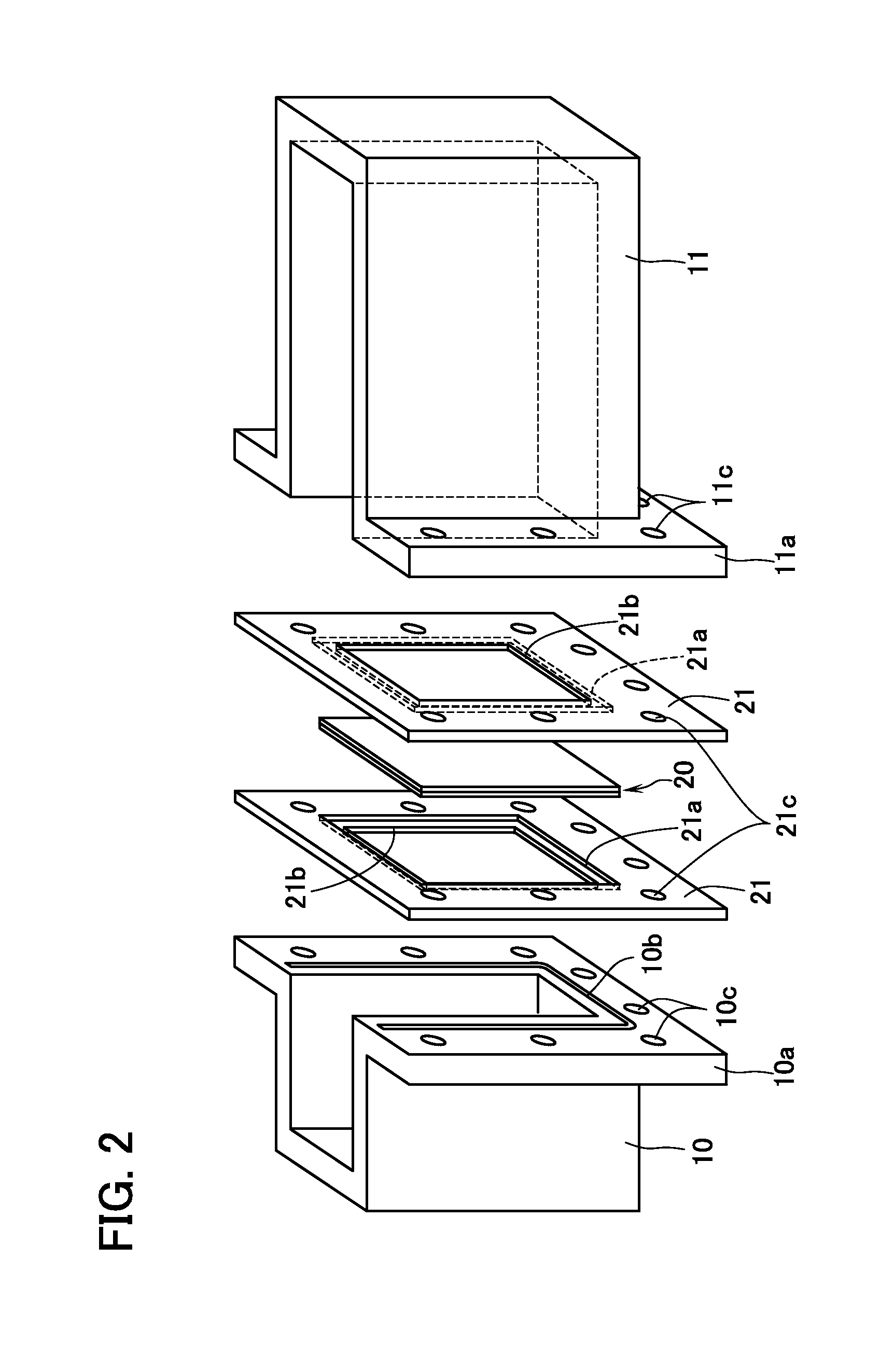

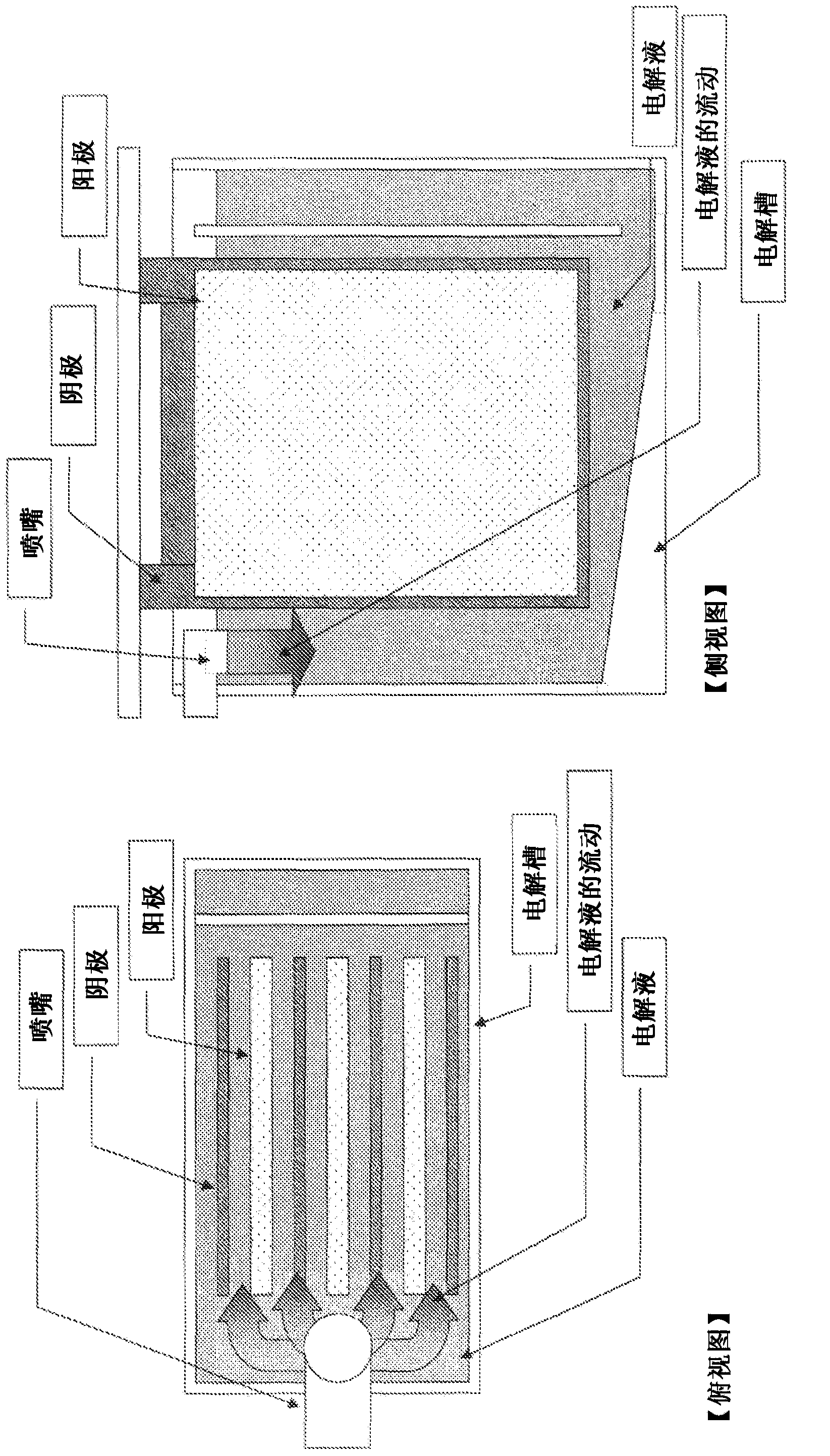

Method of manufacturing metal hydroxides and method of manufacturing ITO sputtering target

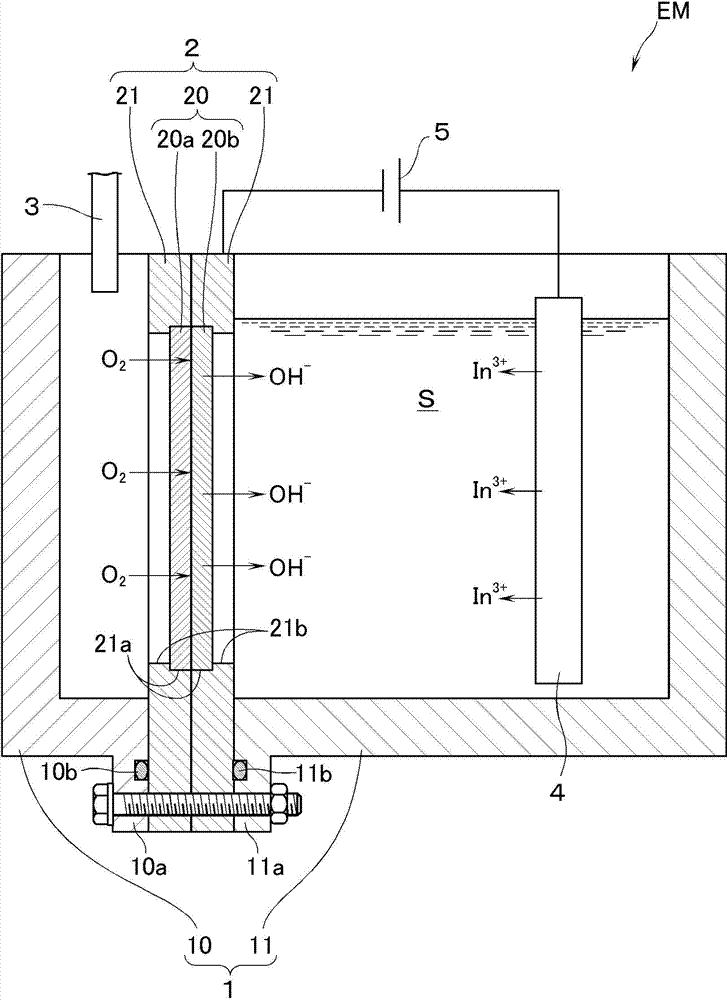

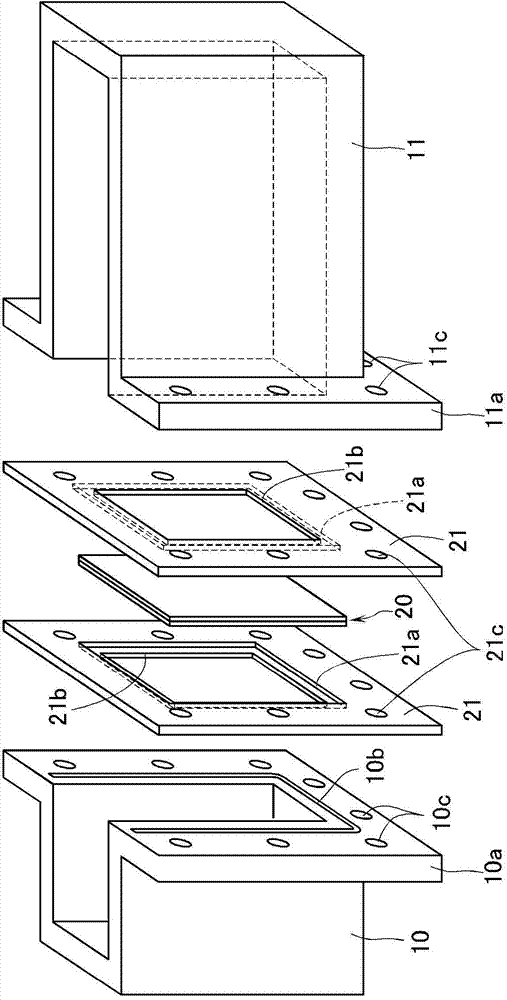

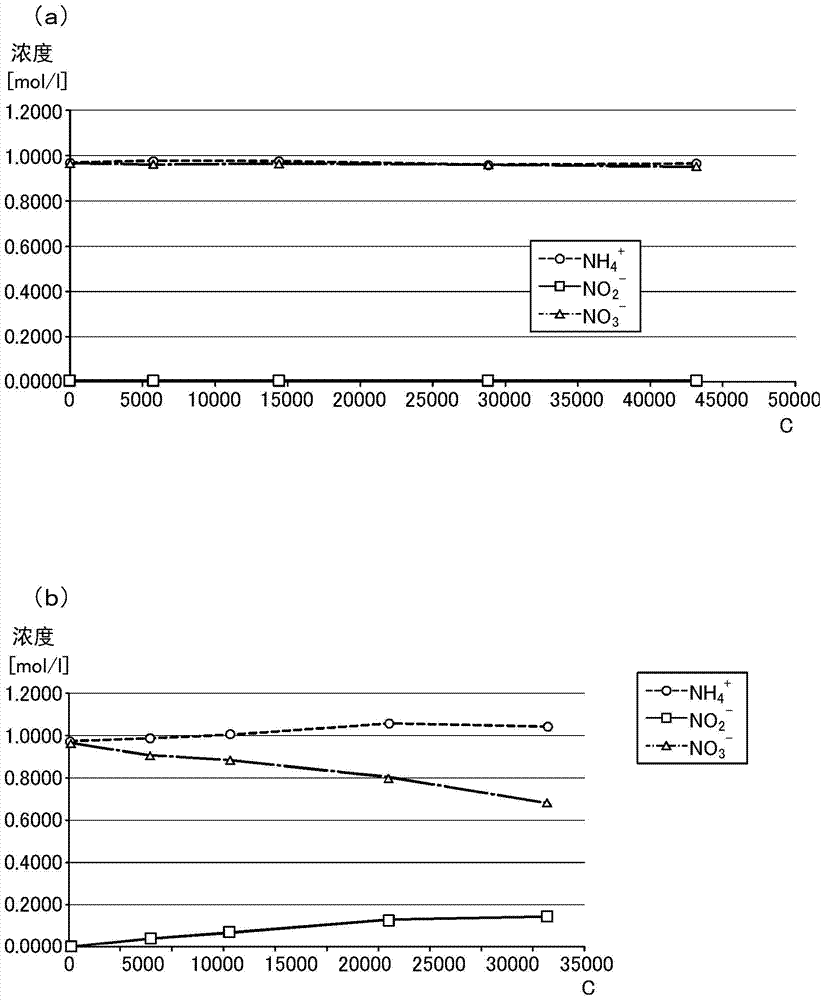

InactiveUS20150200082A1Improve batch productivityReduce manufacturing costCellsElectric discharge tubesReaction layerElectrolysis

A method of manufacturing metal hydroxides with high mass, and a method of manufacturing an ITO target are provided. A gas diffusion electrode 20 configured such that a hydrophobic gas diffusion layer 20a and a hydrophilic reaction layer 20b are laminated is installed in an electrolytic bath 1 to partition the electrolytic bath. An electrolytic solution S is stored in such a portion of a settling chamber 11 as to face the reaction layer of the partitioned electrolytic bath, and indium 4 is immersed in the electrolytic solution. A voltage is applied between a cathode defined by the gas diffusion electrode and an anode defined by indium. Oxygen is supplied into such a partitioned air chamber 10 as to face the gas diffusion layer to perform electrolysis. Indium hydroxides are thus deposited in the electrolytic solution.

Owner:ULVAC INC

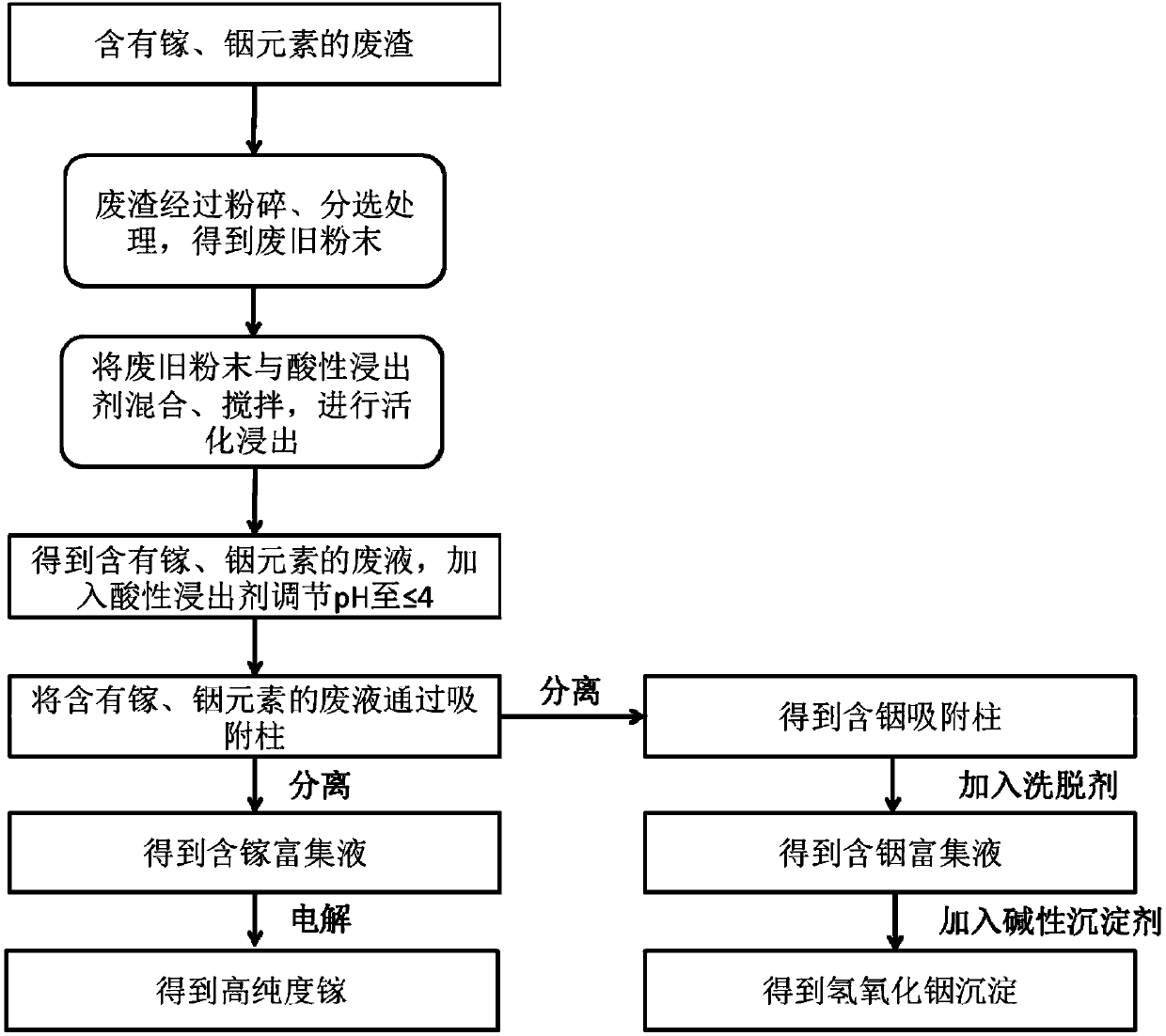

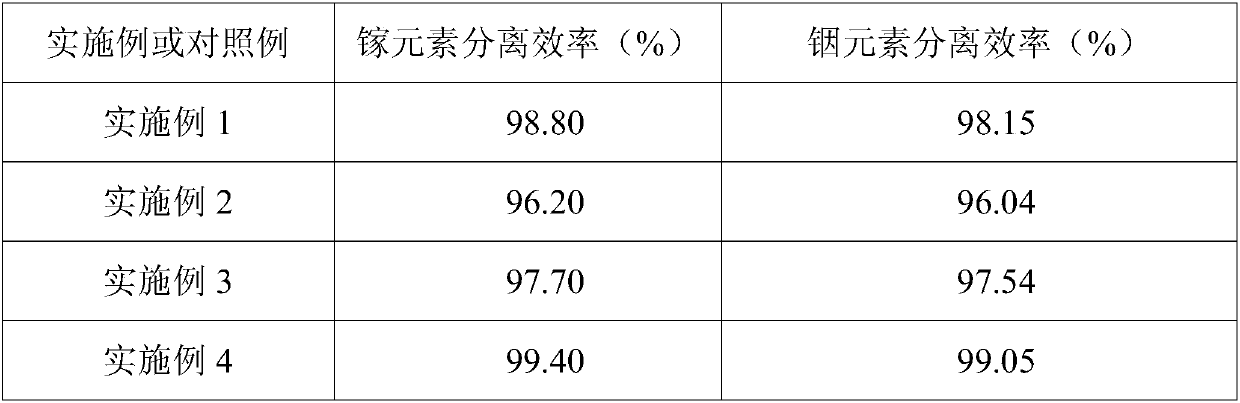

Method for recovering gallium and indium elements from waste residue containing gallium and indium elements

InactiveCN109897960AIncrease concentrationEfficient leachingPhotography auxillary processesProcess efficiency improvementIndium(III) hydroxideLixiviant

The invention relates to a method for recovering gallium and indium elements from waste residue containing the gallium and indium elements. The method includes the following steps that (1), the wasteresidue containing the gallium and indium elements and an acid lixiviant are mixed, activated leaching treatment is carried out, and waste liquor containing the gallium and indium elements is obtainedafter treatment; and (2) the acid lixiviant is added to the waste liquor containing the gallium and indium elements obtained in the step (1) to adjust the pH value to be less than or equal to 4, thenthe waste liquor containing the gallium and indium elements passes through an adsorption column, an indium-containing adsorption column and gallium-containing enrichment liquid are obtained, the indium-containing adsorption column is washed through an eluent to obtain indium-containing enrichment liquid, an alkaline precipitator is added into the indium-containing enrichment liquid to obtain indium hydroxide precipitates, and the gallium-containing enrichment liquid is electrolyzed to obtain elemental gallium. The method for recovering the gallium and indium elements from the waste residue containing the gallium and indium elements can adapt to a wider range of the pH change, the flow change and the temperature change, the separation efficiency and purity are high, and 96% or above of thegallium and indium elements can be separated from the waste residue.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

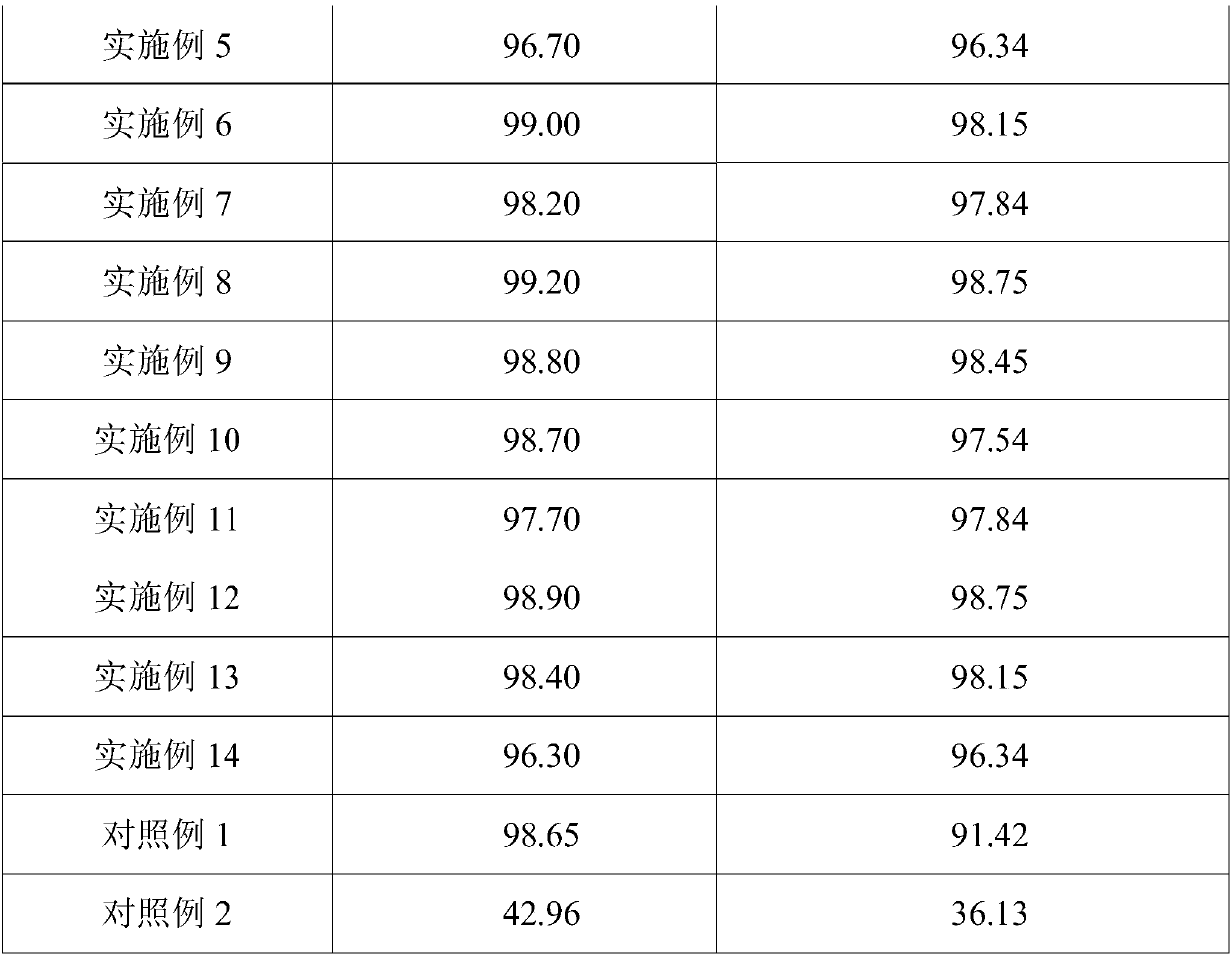

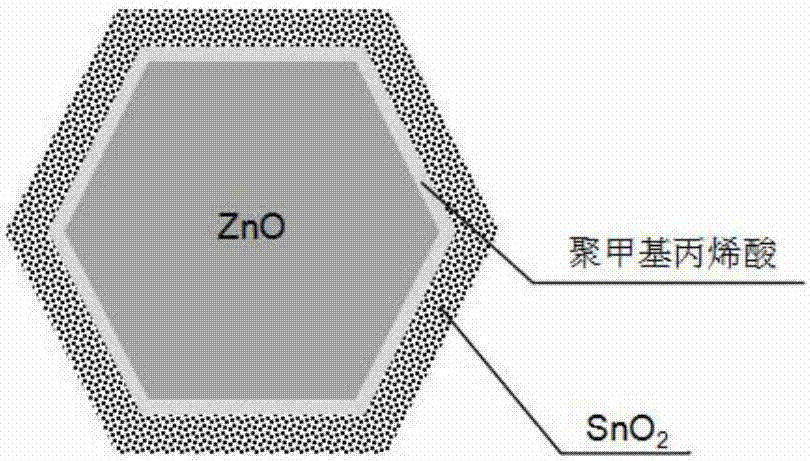

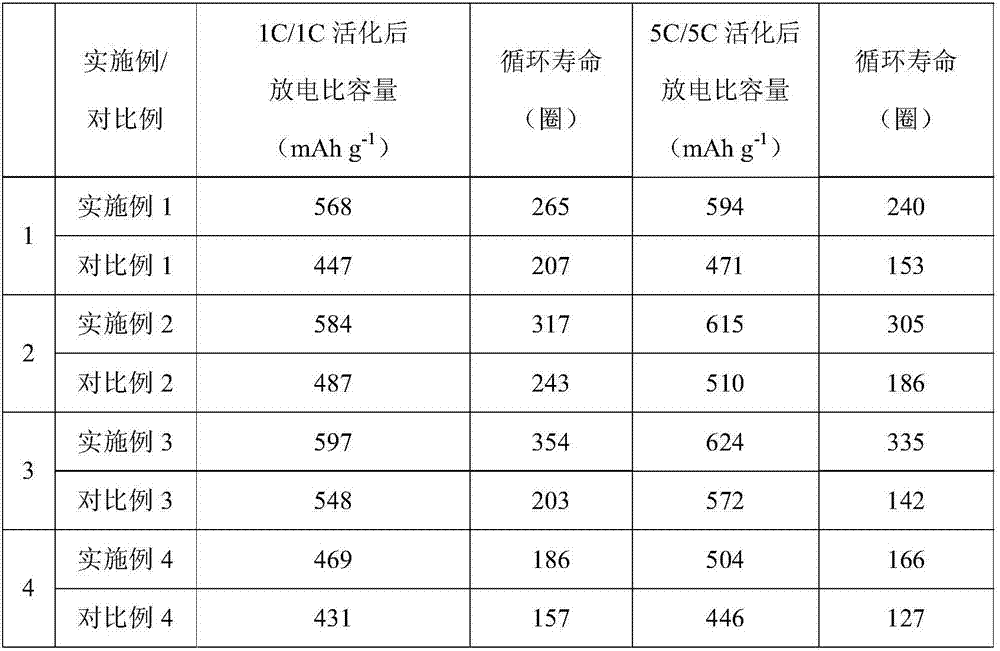

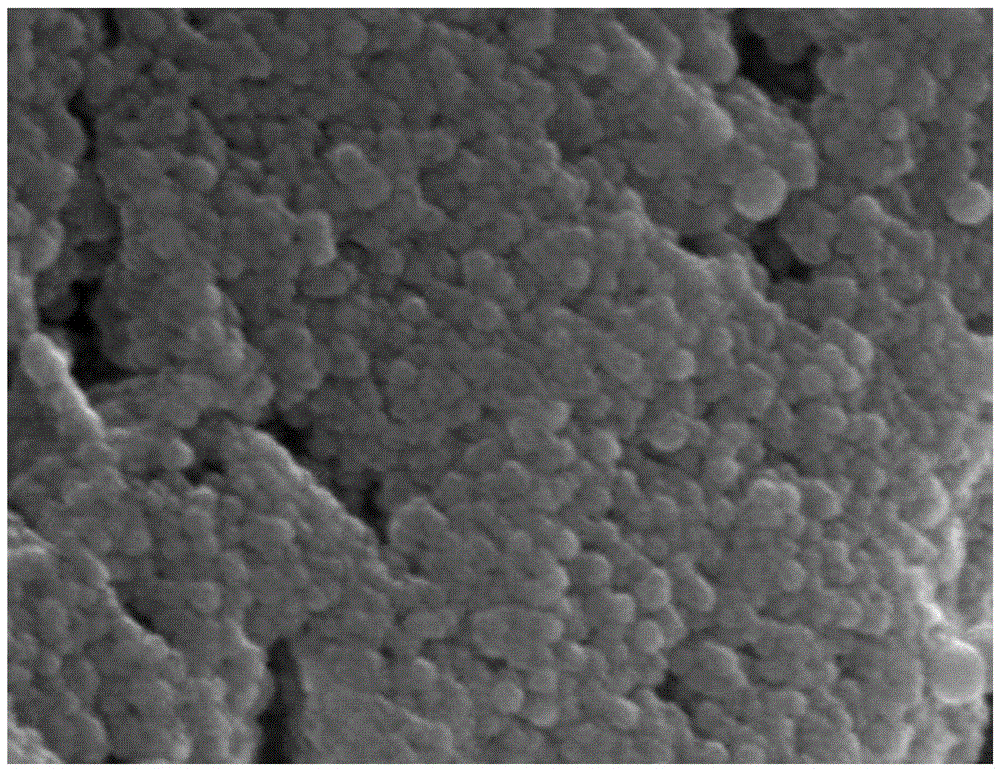

Zinc oxide negative electrode material of zinc air cell and preparation method thereof

InactiveCN107123804AImproved high current charging capabilityReduce resistanceFuel and secondary cellsNegative electrodesTin dioxideDouble coating

The invention relates to a zinc oxide negative electrode material of a zinc air cell and a preparation method thereof. The zinc oxide negative electrode material comprises a double-coating-layer structure, the double-coating-layer structure is that an inner coating layer is further evenly distributed between zinc oxide and an outer coating layer, the inner coating layer is a polymer coating layer, polymer used in the polymer coating layer is chosen from one of strong-base-resistant polyacrylic acid polymer, polymethylacrylic acid or acrylic acid polymer and methacrylic acid polymer, and the outer coating layer is an indium hydroxide and / or stannic oxide layer. According to the preparation method of the zinc oxide negative electrode material, a silane coupling agent is utilized to perform surface modification on the surface of zinc oxide, and then hexamine deposition metal oxide and / or hydroxide is utilized to achieve even coating of the outer coating layer. The zinc oxide negative electrode material disclosed by the invention effectively solves the problem of dendritic growth and deformation and the problem that the coating layers are prone to breaking and collapsing due to volume expansion generated by Zn / ZnO crystal transfer; thus, a finished product which has excellent rate capability and long cycle life can be obtained.

Owner:CENT SOUTH UNIV

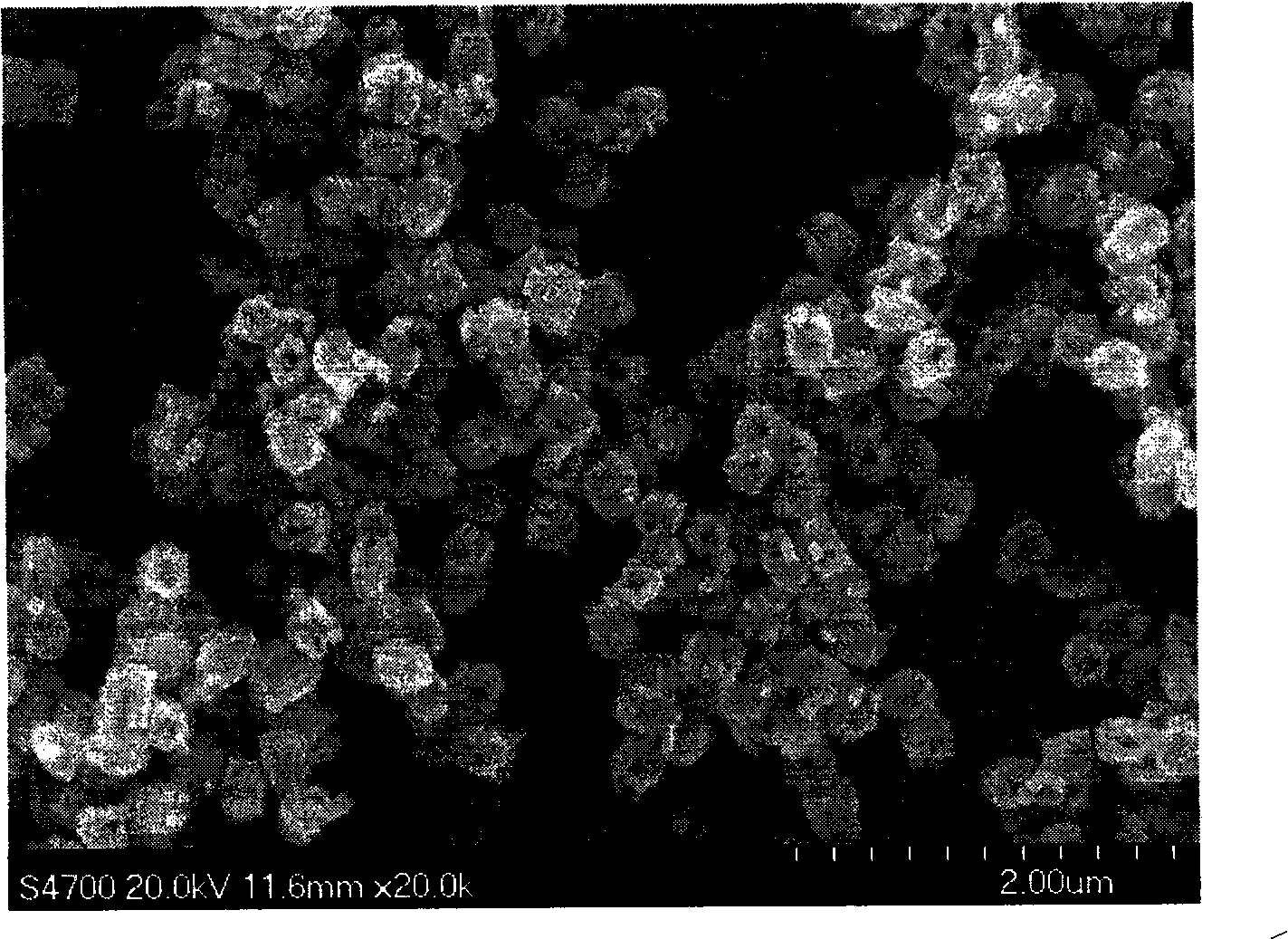

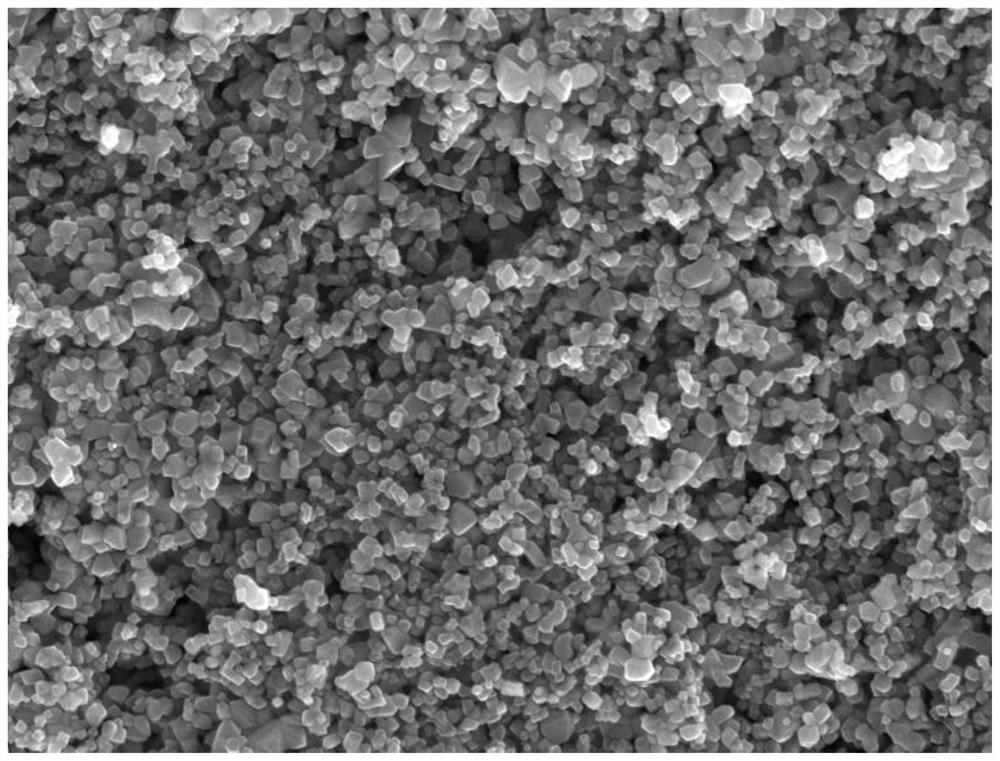

Production method for nanometer indium oxide

ActiveCN105836792ASuperiorSmall and round particlesGallium/indium/thallium compoundsNanotechnologyIndiumSolvent

The invention discloses a production method for nanometer indium oxide, and relates to the field of materials. According to the method, by a method of completely adopting an organic solvent, the problem of high water consumption and wastewater discharge caused by a method of dissolving metal indium by adopting an inorganic acid solvent is solved; a precursor indium hydroxide is obtained in a mixed solution environment of the organic solvent and water, so that indium oxide powder particles are fine, round, normal, uniform in particle size, narrow in granularity distribution range, unlikely to be agglomerate and high in dispersibility, and can be used for producing a high-density target. The method has the characteristics that a production process is high in environment friendliness and low in wastewater discharge and a product is uniform in granularity and high in dispersibility.

Owner:LUOYANG RUIDE MATERIAL TECH SERVICES CO LTD

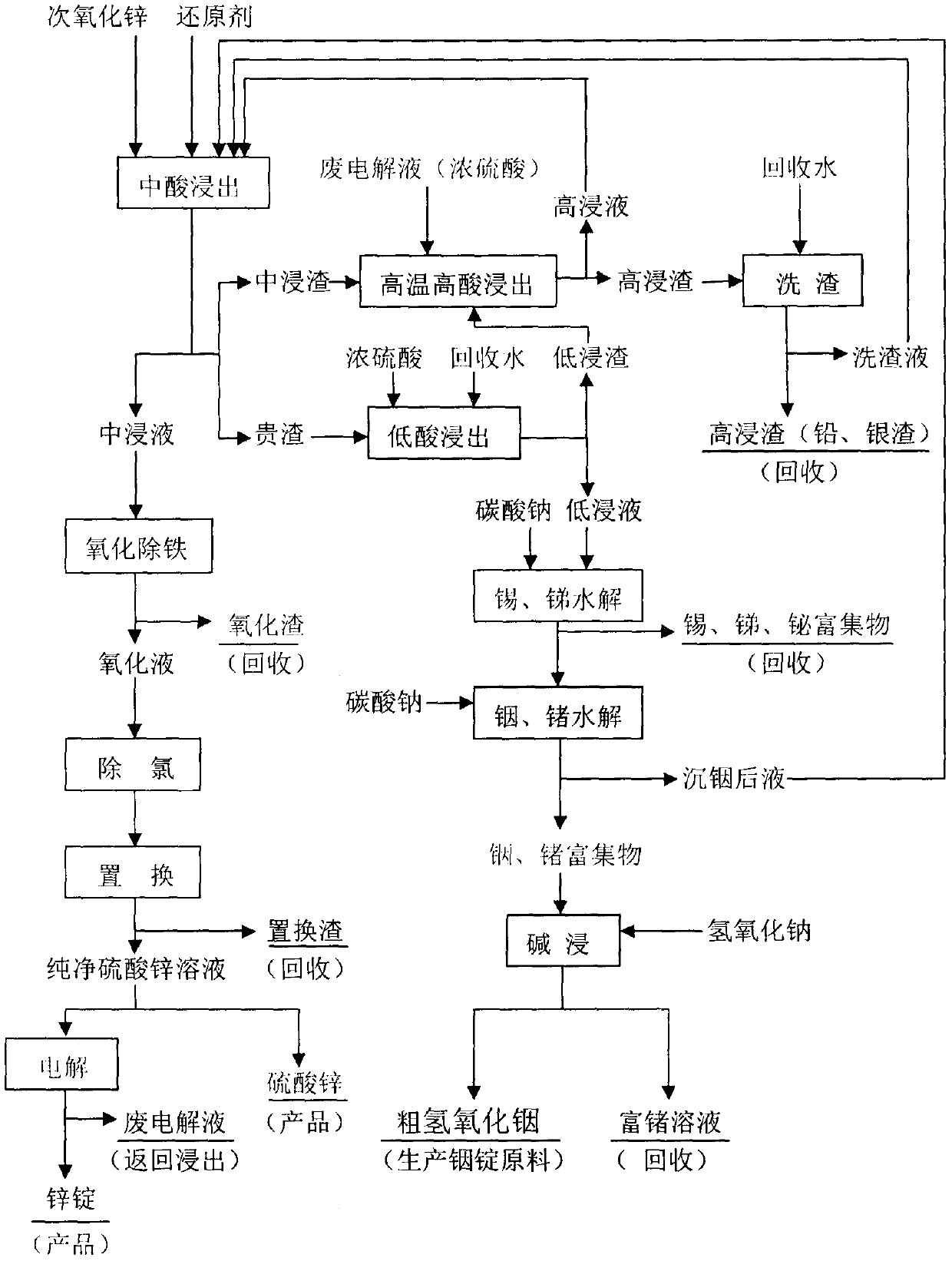

Efficient recycling method of crude zinc oxide raw material

ActiveCN109897966AHigh recovery rateEasy to separateProcess efficiency improvementIndiumStrong acids

The invention provides an efficient recycling method of a crude zinc oxide raw material, and belongs to the field of hydrometallurgy. The method is characterized in that the crude zinc oxide raw material is leached through intermediate acid and then is subjected to ferrum, arsenic, chlorine and heavy metal removing to obtain a solution for producing a zinc ingot; the intermediate leached residuesare leached by strong acid under high temperature and then is subjected to solid-liquid separation to obtain rich lead, silver residues and strong acid leaching liquid; the high leaching liquid is returned to leach through the intermediate acid; metals such as antimony, bismuth, tin, indium and germanium in the crude zinc oxide raw material are enriched in a plurality of times through the intermediate leaching residues; ferric iron is reduced through a reducing agent in the last leaching in the intermediate acid, and the solid-liquid separation is carried out to obtain heavy metal residues; the heavy metal residues are leached through weak acid and then are subjected to solid-liquid separation to obtain low-acid leached residues, and low-acid leaching liquid rich in antimony, bismuth, tin,indium and germanium; the low-acid leached residues are leached into strong acid under high temperature so as to recover valuable metal; the weak-acid leached liquid is subjected to step type precipitation and separation to obtain antimony, bismuth and tin enriched materials and indium and germanium enriched materials; and the indium and germanium enriched materials are leached in alkali to obtain coarse indium hydroxide and germanium-enriched solution. The method is simple in processes, and high in enriching degree and recovering rate of valuable metal, and achieves efficient recycling of the crude zinc oxide raw material.

Owner:何耀

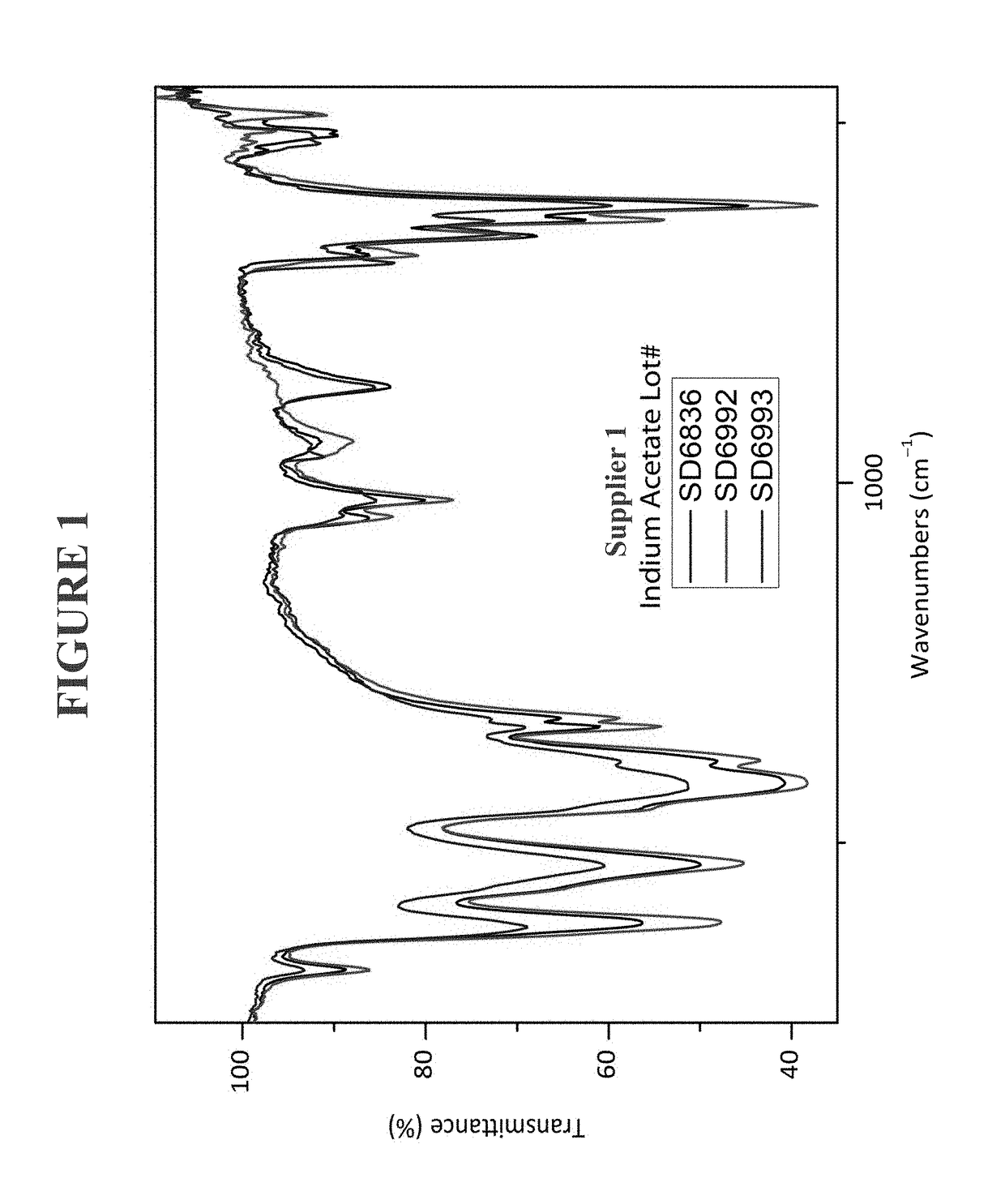

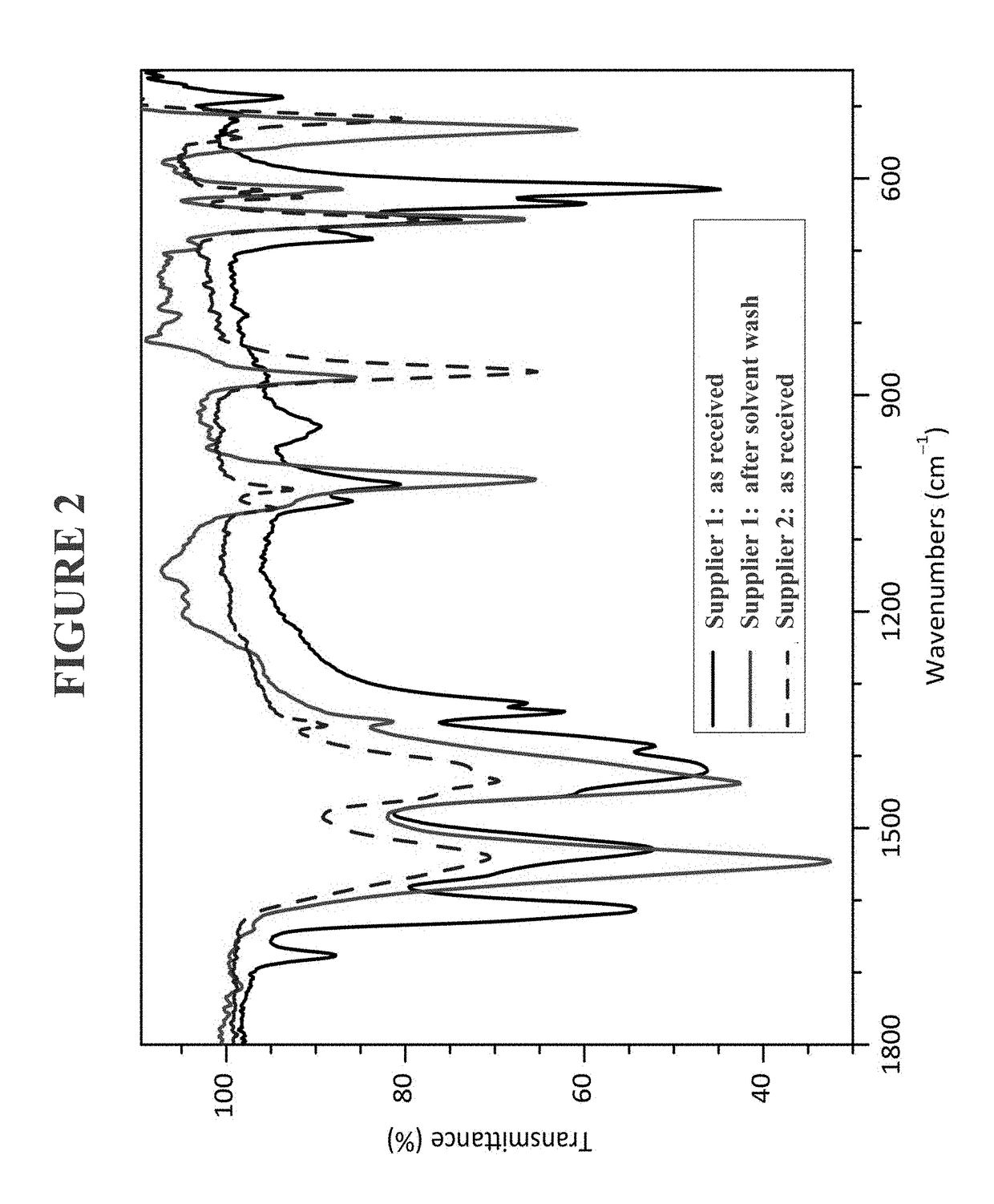

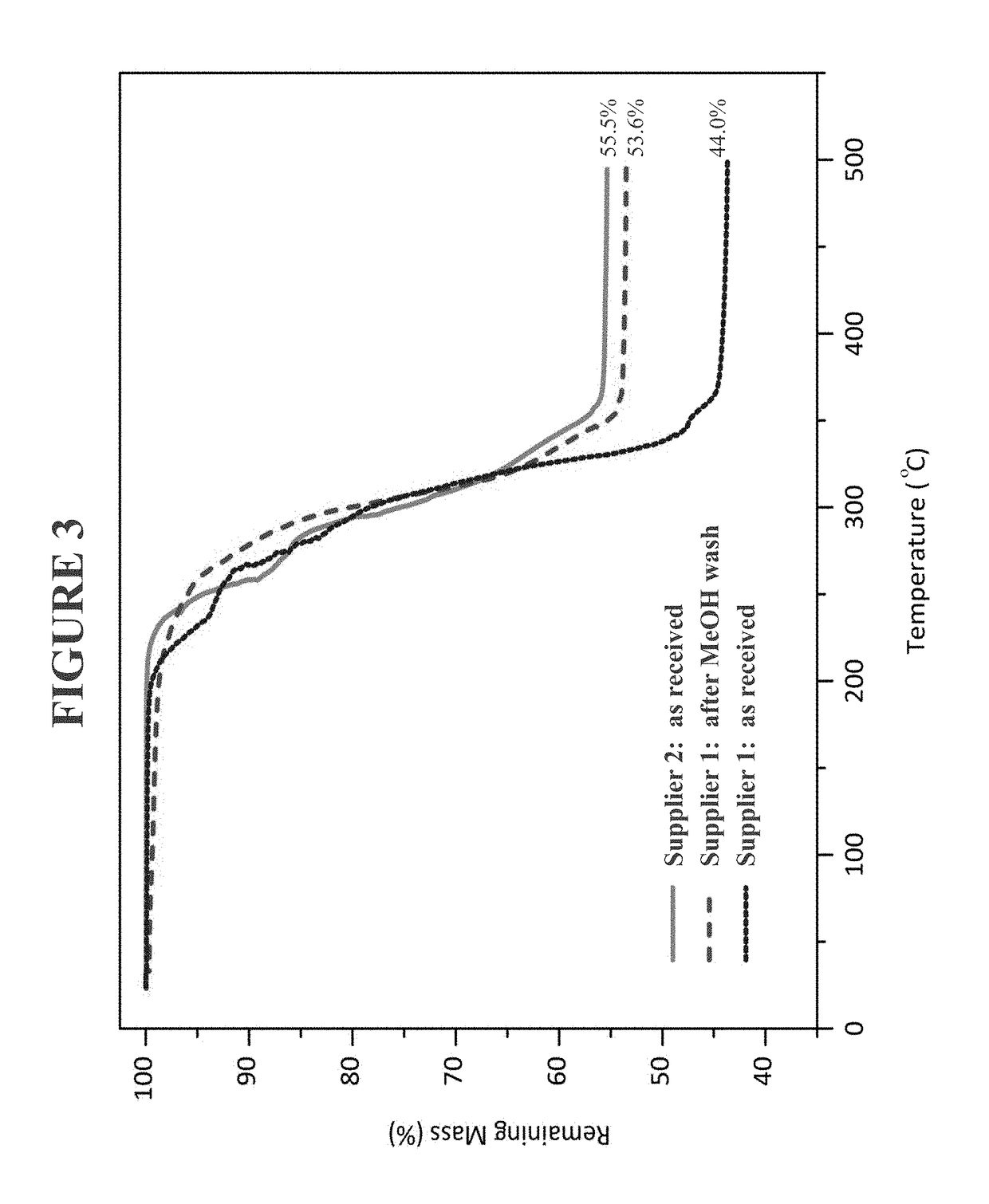

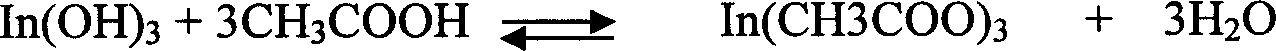

Use of heteroleptic indium hydroxides as precursors for inp nanocrystals

ActiveUS20170137360A1Preparation from carboxylic acid saltsGroup 3/13 organic compounds without C-metal linkagesIndium(III) hydroxideIndium

The present invention is in the field of nanostructure synthesis. The present invention is directed to methods for producing nanostructures, particularly Group III-V semiconductor nanostructures. The present invention is also directed to preparing Group III inorganic compounds that can be used as precursors for nanostructure synthesis.

Owner:NANOSYS INC

Non-vacuum preparation method of light absorption layer of copper indium gallium sulfur selenium (CIGSSe) thin film solar cell

InactiveCN103602982AEasy to prepareShort timeFinal product manufactureMetallic material coating processesCopper oxideIndium acetylacetonate

The invention relates to a non-vacuum preparation method of a light absorption layer of a copper indium gallium sulfur selenium (CIGSSe) thin film solar cell. The method comprises the following steps: according to the stoichiometric ratio of Cu to In to Ga in CuxInyGa(1-y)SzSe(2-z), dissolving a copper-containing compound, an indium-containing compound and a gallium-containing compound in an organic alcohol solution containing a complexing agent and a sulfur-containing micromolecule reagent, adding a certain viscosity modifier and solution modifier and forming a clear, transparent and stable organic precursor solution, wherein the x is greater than or equal to 0.6 and less than or equal to 1, the y is greater than or equal to 0 and less than or equal to 1, the z is greater than or equal to 0 and less than or equal to 2, the copper-containing compound is at least one of copper oxide, cuprous oxide, copper hydroxide and copper acetylacetonate, the indium-containing compound is at least one of indium oxide, indium hydroxide and indium acetylacetonate and the gallium-containing compound is at least one of gallium oxide, gallium hydroxide and gallium acetylacetonate; depositing a precursor thin film on a conducting layer of a substrate by using the organic precursor solution; and annealing the precursor thin film in the atmosphere of chalcogen to form the light absorption layer.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Use of heteroleptic indium hydroxides as precursors for INP nanocrystals

ActiveUS10029972B2Preparation from carboxylic acid saltsGroup 3/13 organic compounds without C-metal linkagesIndium(III) hydroxideIndium

The present invention is in the field of nanostructure synthesis. The present invention is directed to methods for producing nanostructures, particularly Group III-V semiconductor nanostructures. The present invention is also directed to preparing Group III inorganic compounds that can be used as precursors for nanostructure synthesis.

Owner:SHOEI CHEM IND CO LTD

Preparation method of low-density ITO target material

ActiveCN110483033AStable densityImprove qualityVacuum evaporation coatingSputtering coatingIndium(III) hydroxideIndium

The invention relates to a preparation method of a low-density ITO target material, which comprises the following steps: S1, recovering an ITO waste target, and pretreating the ITO waste target to obtain ITO waste target powder; S2, preparing indium hydroxide slurry, mixing a certain amount of indium hydroxide slurry and the ITO waste target powder according to the proportion, and obtaining ITO powder with a new proportion after drying; and S3, pressing and molding the ITO powder to obtain a green body, and sintering the green body to obtain the low-density target material. Compared with the prior art, according to the low-density ITO target material disclosed by the invention, the indium hydroxide slurry is added to change the ratio of indium to tin in the ITO waste target; the property,similar to colloid, of indium hydroxide slurry is utilized; the indium hydroxide powder can be fully mixed with original ITO powder and serves as an adhesive, so a green body cannot shrink in the process of forming indium oxide through indium hydroxide dehydration, the stability of the volume density of the formed green body is guaranteed, and the technical defect that when indium oxide is used asan additive for changing the proportion, the formed green body shrinks is overcome.

Owner:广东欧莱高新材料股份有限公司 +1

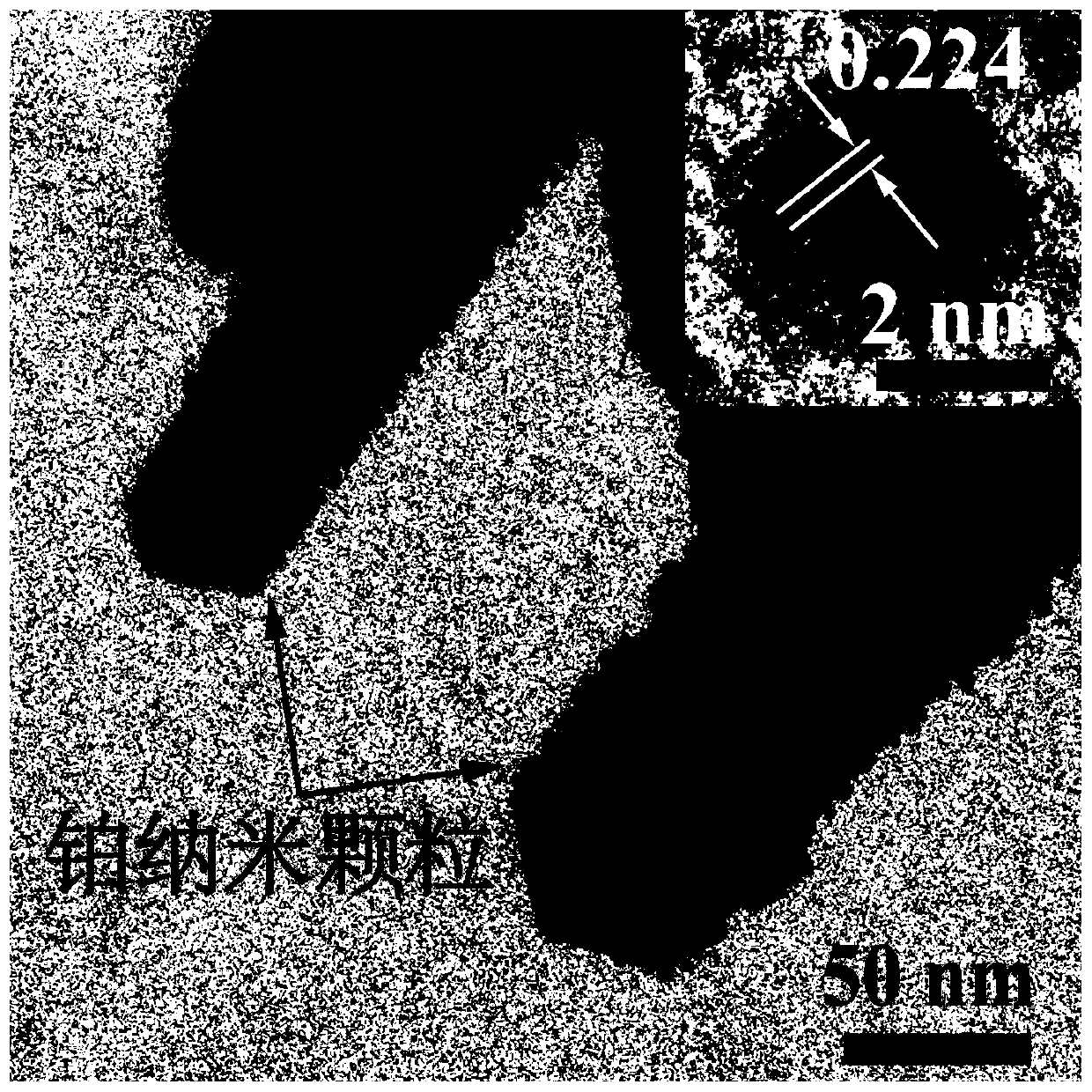

High-dispersion metal-oxide bifunctional catalyst and preparation method and application thereof

ActiveCN111632596AGood dispersionAtom utilization is highHydrocarbon by hydrogenationCatalystsIndium(III) hydroxidePtru catalyst

The invention discloses a high-dispersion metal-oxide bifunctional catalyst and a preparation method and application thereof. The preparation method comprises the following steps: (1) preparing an ethanol aqueous solution of an indium precursor, then adding a proper amount of an ammonia water-ethanol mixed solution under a stirring condition, controlling the reaction temperature to be 60-100 DEG Cin the adding process, after the addition is finished, continuously carrying out heat preservation and stirring for complete reaction to obtain a mixed solution containing indium hydroxide, cooling,carrying out suction filtration, washing, drying and calcining the mixed solution containing indium hydroxide to obtain a carrier In2O3, (2) uniformly dispersing the carrier In2O3 in a proper amount of absolute ethyl alcohol to obtain a dispersion liquid, and depositing metal atoms M on the carrier In2O3 by using an atomic layer deposition technology to obtain an M-In2O3 catalyst, and (3) carryingout thermal reduction on the M-In2O3 catalyst to obtain the high-dispersion metal-oxide bifunctional catalyst. The high-dispersion metal-oxide bifunctional catalyst has the characteristics of high catalytic activity, low reaction temperature, high ethylene selectivity and long service life.

Owner:EAST CHINA UNIV OF SCI & TECH

Preparation method of nanometer indium hydroxide

The invention provides a preparation method of nanometer indium hydroxide. The preparation method comprises the following steps: a) introducing ammonia gas into an aqueous indium nitrate solution to obtain a precursor slurry; and b) washing the precursor slurry, and performing spray drying to obtain an indium hydroxide powder. The preparation method provided by the invention can reduce the production of an ammonia nitrate mother liquor, reduce the washing difficulty and the consumption of washing water, reduce the generation of nitrogen-containing wastewater and reduce the wastewater treatmentdifficulty; the preparation method allows the nano-level product to be obtained without a dispersant, so the preparation cost is reduced, the operation steps are simplified, and impurities in the slurry are reduced, thereby the washing difficulty and the consumption of washing water are reduced; and the obtained product has small particle size and a good uniformity, and does not need to be sieved, so the preparation process is simplified.

Owner:先导薄膜材料(安徽)有限公司

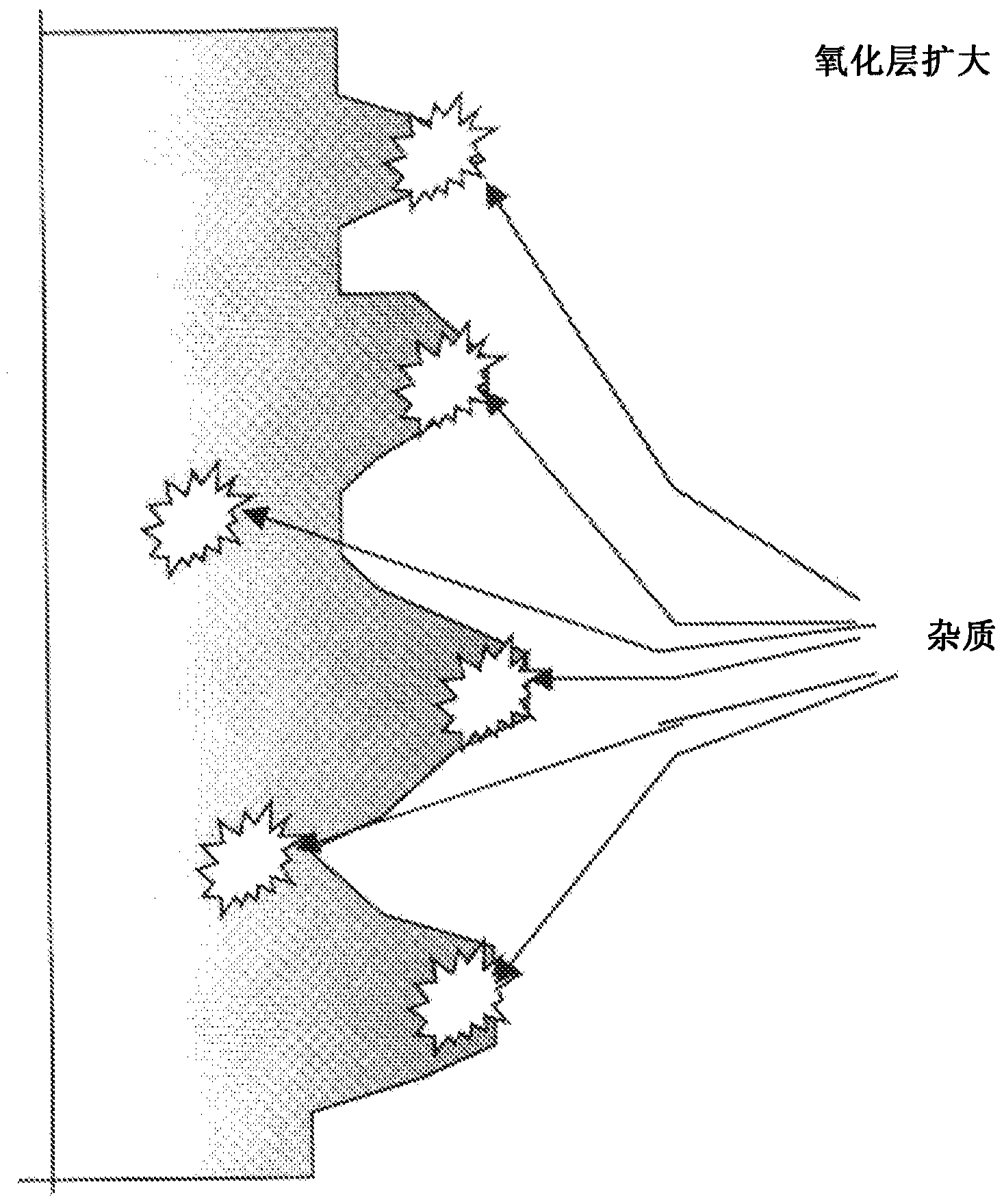

Preparation method of indium oxide and precursor thereof

ActiveCN110644013AAvoid it happening againSolve pollutionMaterial nanotechnologyElectrolysis componentsElectrolytic agentIndium

The invention provides a preparation method of indium oxide and a precursor thereof, belonging to the technical field of inorganic materials. According to the method, metal indium is used as a positive electrode, an inert electrode is used as a negative electrode, an aqueous ammonium salt solution is used as an electrolyte for electrolysis, and hydrogen peroxide is added during electrolysis to obtain indium hydroxide, so nitrate is prevented from being reduced to generate nitrite or nitric oxide, and the preparation process is environmentally friendlier; an anolyte circularly flows between a positive chamber and an anolyte storage tank, a catholyte flows through a negative chamber from a catholyte storage tank and then flows to the anolyte storage tank, and NH<4+> is diffused from the positive chamber to the negative chamber through a cation selective permeation membrane, so the stability of the anolyte and the catholyte is ensured, subsequent stable acquisition of nanometer indium oxide powder with uniform granularity is well guaranteed, and zero emission of waste gas and waste water is easy to achieve; meanwhile, the anolyte can still guarantee normal operation of a system underthe condition of a high solid content, so process efficiency is improved, productivity is increased, and production cost is reduced.

Owner:昆明先导新材料科技有限责任公司

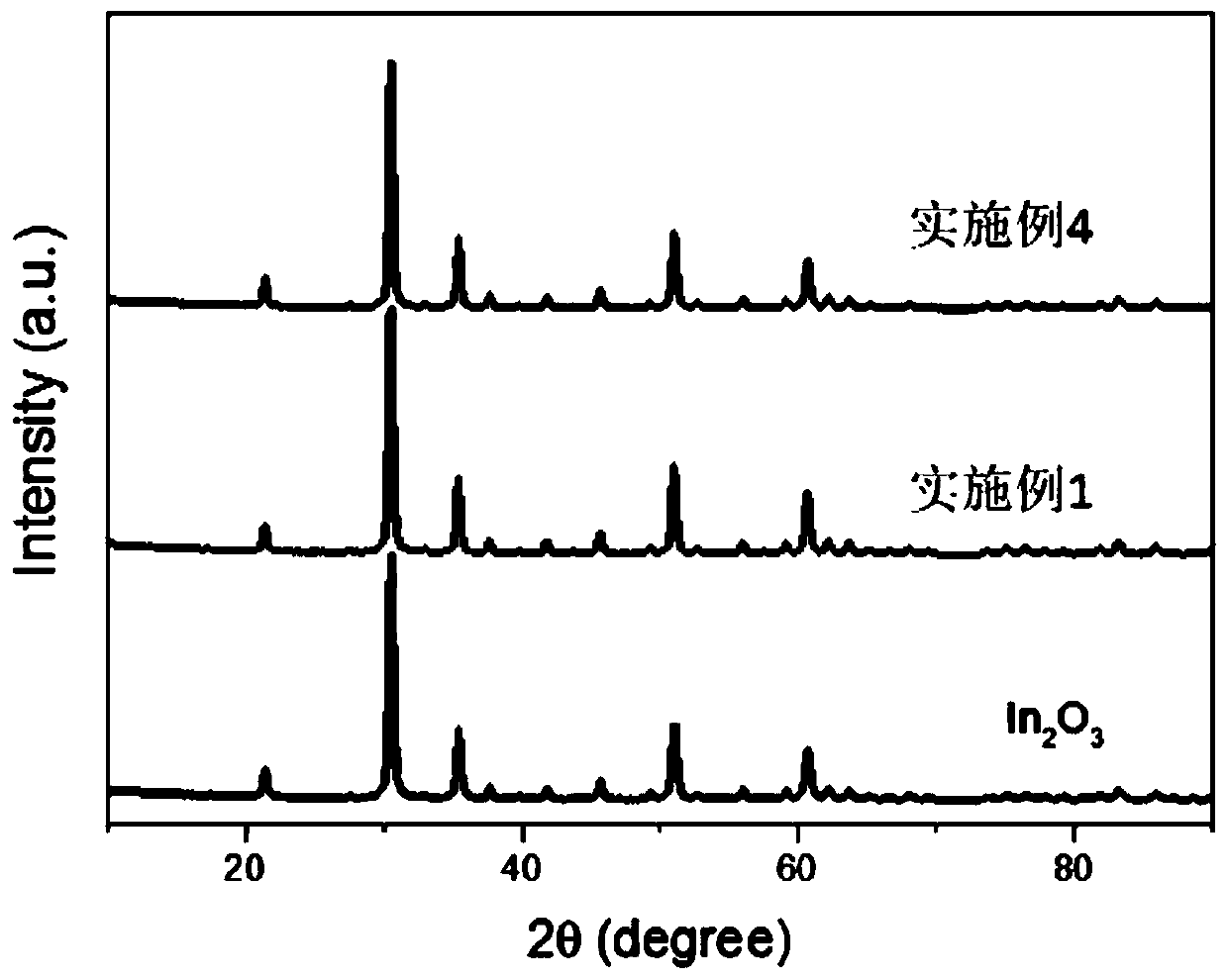

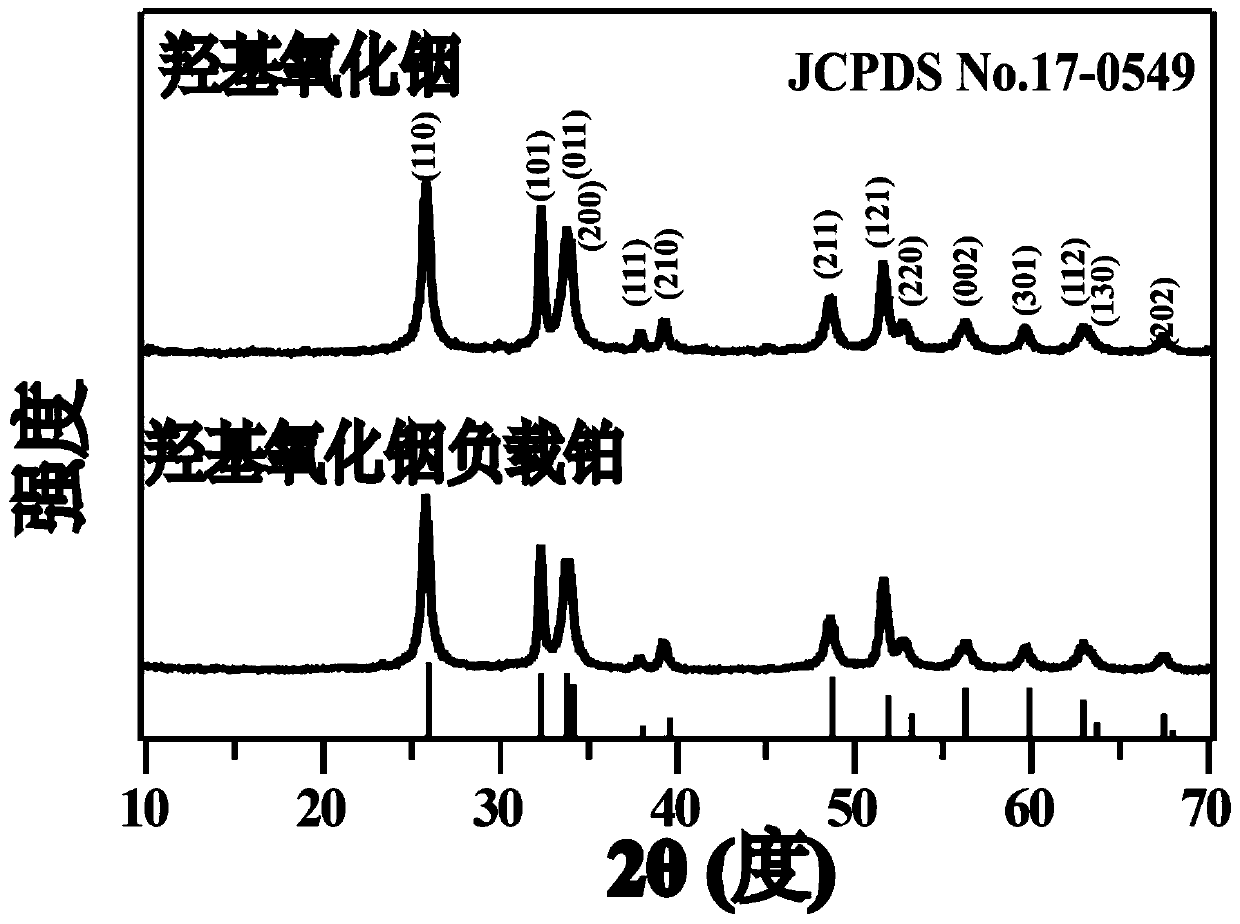

Method for preparing nanometer indium cadmium sulfide-indium hydroxide composite photocatalyst

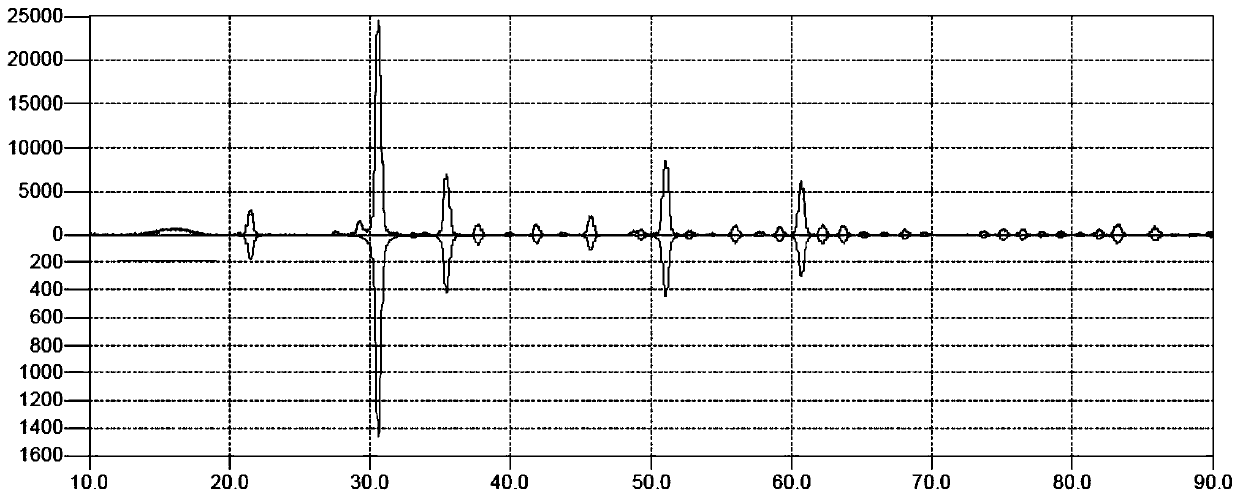

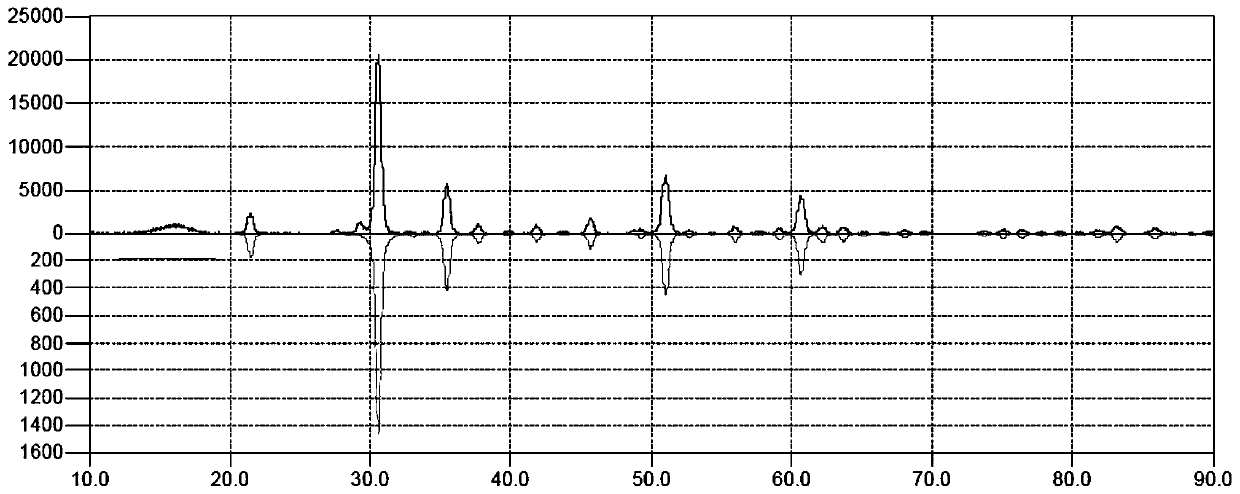

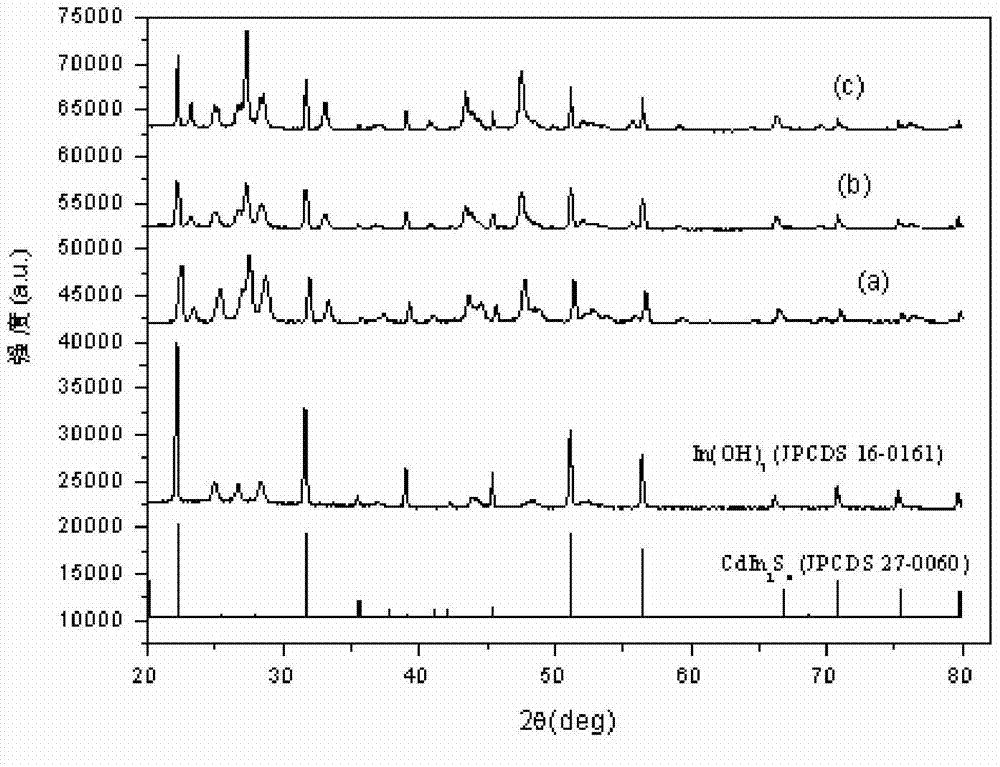

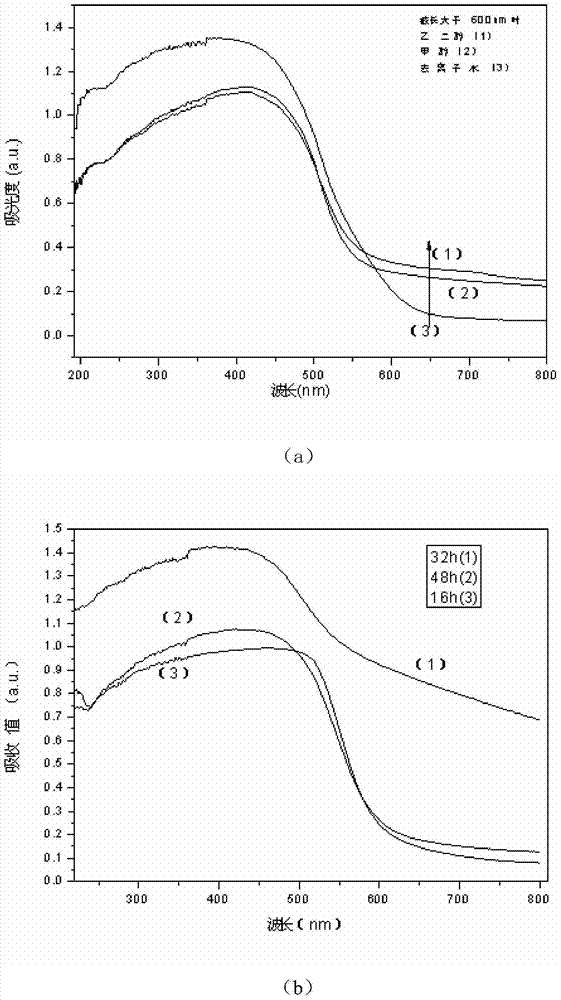

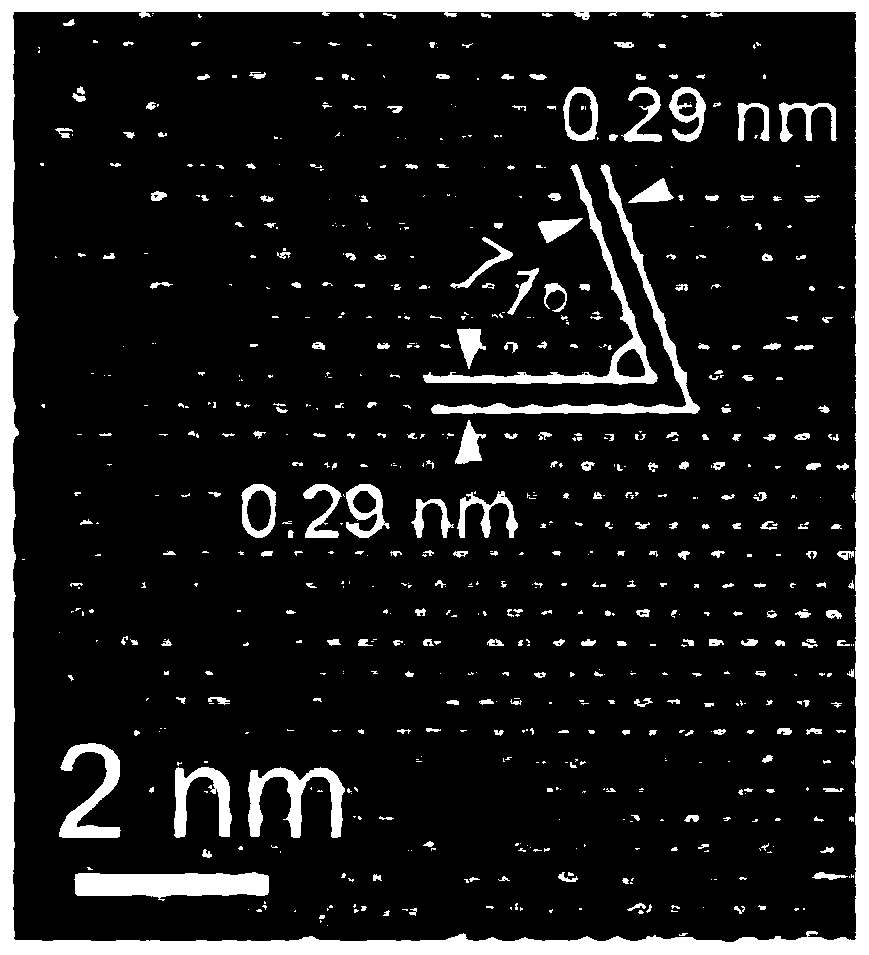

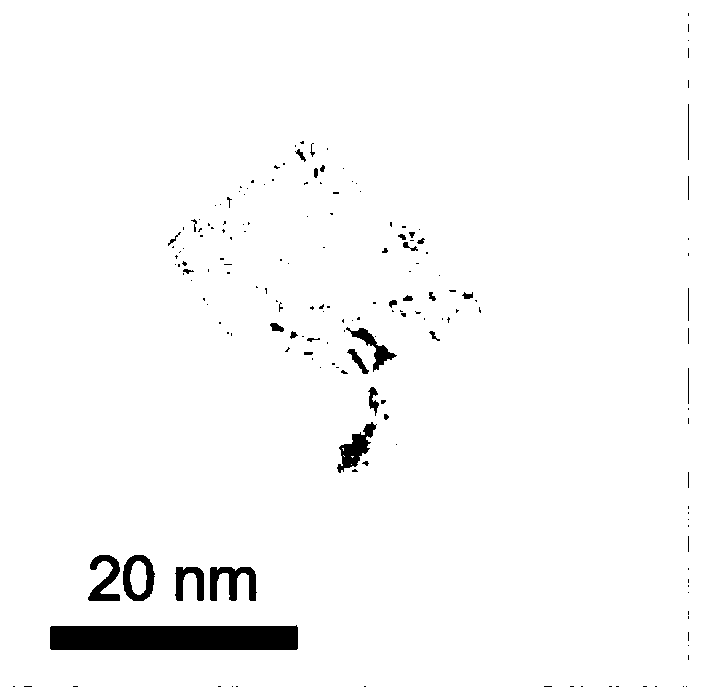

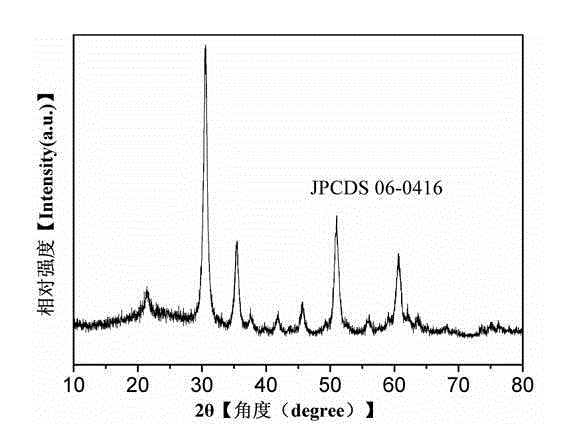

InactiveCN103934006AImprove photocatalytic activityEffective recoveryPhysical/chemical process catalystsThioureaX-ray

The invention relates to a method for preparing a nanometer indium cadmium sulfide-indium hydroxide composite photocatalyst. The chemical formula of the composite photocatalyst is CdIn2S4-In(OH)3. The catalyst is prepared from indium chloride, cadmium chloride, thiourea and deionized water by a hydrothermal method. According to the XRD (X-Ray Diffraction) spectrogram of the catalyst, along with the prolonging of hydrothermal time, the diffraction peak of In(OH)3 of a sample is gradually weakened and the diffraction peak of CdIn2S4 is gradually enhanced to form the CdIn2S4-In(OH)3 composite photocatalyst; no other impurity peak is found in the spectrogram. The method disclosed by the invention has the advantages that the method is simple in process and simple and convenient in operation; the obtained composite photocatalyst has very high photocatalytic activity and is used for performing catalytic reduction on CO2 to obtain methyl formate under the irradiation of ultraviolet light by taking methanol as a solvent, CO2 can be effectively reduced into organic ester and the green conversion is realized.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

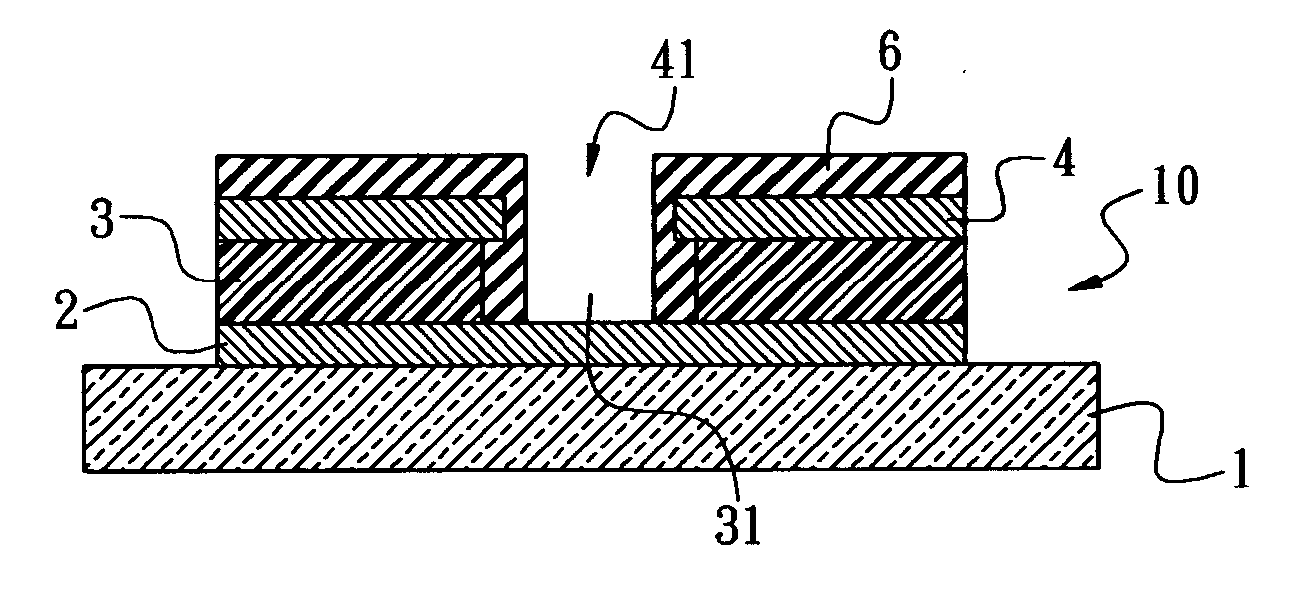

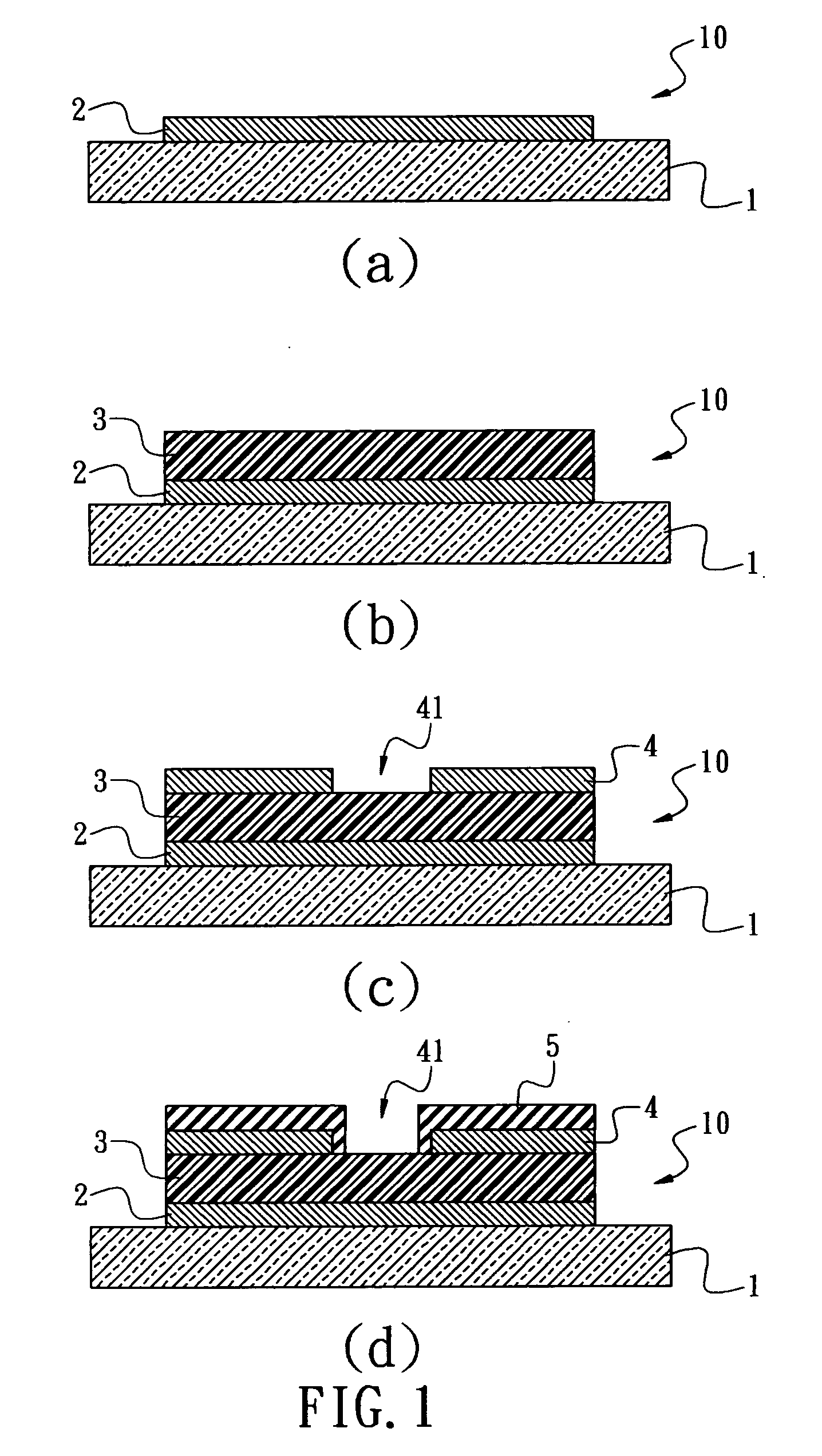

Method for enhancing homogeneity and effeciency of carbon nanotube electron emission source of field emission display

InactiveUS20060213774A1Improve distribution characteristicsIncrease productivityElectrolysis componentsVolume/mass flow measurementCarbon nanotubeElectron

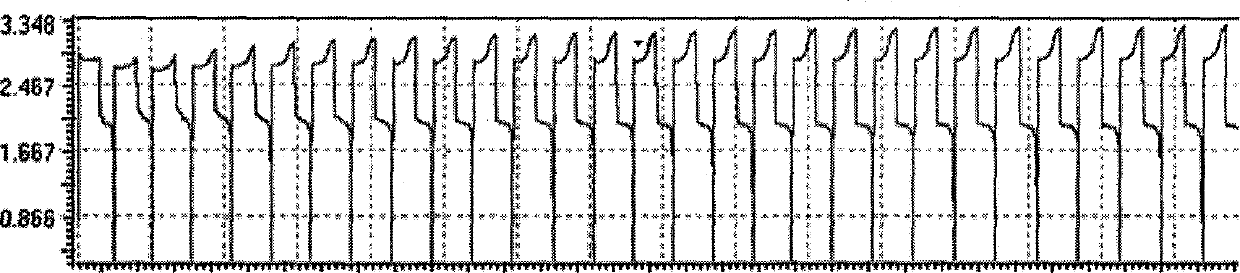

A method for enhancing the homogeneity and efficiency of carbon nanotube electron emission source. The method includes the following steps. First, a semi-manufactured cathode structure is prepared. Then, the cathode structure and the metallic plate are connected to the electrophoresis electrodes. After that, the side of the cathode structure to be electrophoresis deposited is kept a fixed distance in parallel with the metallic plate. Then, the electrophoresis deposition is performed to the semi-manufactured cathode structure by placing the combination into the solution of the electrophoresis tank. Later, an electric field is formed from a direct current voltage of a power supply. In this manner, the carbon nanotubes are deposited on the cathode electrode to form the electron emission source. After the deposition process of the cathode structure is completed, the combination is baked with a low temperature so as to remove the residual water solution on the cathode structure. Meanwhile, the indium chloride charger and the electrolyte hydroxide ions react to form indium hydroxide. Next, a sintering process is performed for re-oxidating the indium hydroxide on the cathode electrode layer back to indium oxide. Consequently, the electron conductivity of the carbon nanotubes and the cathode electron layer is enhanced.

Owner:TECO NANOTECH CO LTD

Method for electrochemically extracting uranium from seawater by using oxygen vacancy-containing metal oxide

ActiveCN110952107AImplement extractionAchieve recyclingGallium/indium/thallium compoundsUranium dioxideOxygen vacancyUranium

The invention discloses a method for electrochemically extracting uranium from seawater by using an oxygen vacancy-containing metal oxide, and the method comprises the following steps: adding glycerolinto an indium nitrate isopropanol solution, and transferring into a high-temperature high-pressure reaction kettle to react to obtain a spherical indium hydroxide solid; dissolving the spherical indium hydroxide solid in deionized water, and then transferring into the high-temperature high-pressure reaction kettle to react so as to obtain a flaky indium hydroxide solid; calcining the flaky indium hydroxide solid to obtain calcined In2O3-x with oxygen vacancies; adding the In2O3-x into ethanol, and then adding a membrane solution; uniformly coating carbon paper with the solution, naturally drying, clamping the dried carbon paper by using a gold electrode, and using the dried carbon paper as a working electrode in a three-electrode system, wherein a counter electrode in the three-electrodesystem is a platinum wire, and a reference electrode is a calomel electrode; adding simulated seawater into an electrolytic tank, placing the three-electrode system in the simulated seawater of the electrolytic tank, and stirring the simulated seawater for electrolysis to realize uranium extraction.

Owner:SOUTHWEAT UNIV OF SCI & TECH

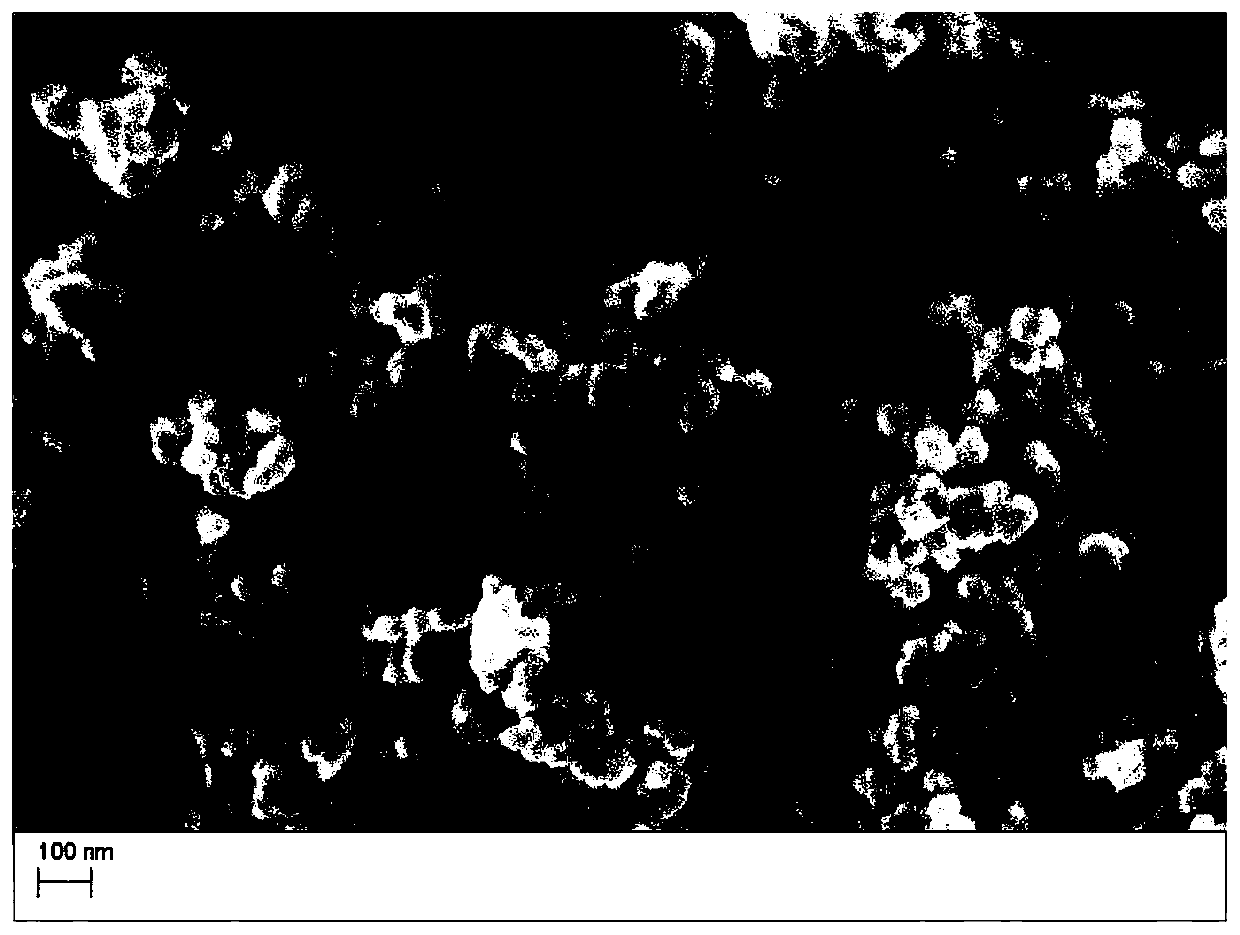

Indium oxide nanosphere and preparation method thereof

InactiveCN104591264ASimple processNo other substances requiredMaterial nanotechnologyGallium/indium/thallium compoundsIndium(III) hydroxideGlycol synthesis

The invention relates to the technical field of preparation of inorganic nanomaterials and particularly relates to an indium oxide nanosphere and a preparation method thereof. The invention aims at solving the problems of complex preparation process, high synthesis temperature and long reaction time of the existing preparation method of the indium oxide nanosphere and simultaneously providing a low-cost indium oxide nanosphere material. The preparation method of the indium oxide nanosphere comprises the following steps: firstly, preparing a mixed solution of indium nitrate and urea, adding ethanol and / or ethylene glycol, dissolving and magnetically stirring to obtain a homogeneous colorless transparent solution; secondly, reacting the colorless transparent solution by a solvothermal method and collecting a solvothermal product; thirdly, centrifuging and washing the solvothermal product to obtain an indium hydroxide precursor; and fourthly, carrying out high-temperature roasting to obtain the indium oxide nanosphere. The preparation method has the advantages of simple process, less reactants, low synthesis temperature, short reaction time and low obtained product cost, and can be widely applied.

Owner:XIAN TECHNOLOGICAL UNIV

Method for separating and extracting indium and gallium from indium-gallium solution

InactiveCN104928503AEasy to operateReduce manufacturing costProcess efficiency improvementOXALIC ACID DIHYDRATEIndium(III) hydroxide

The invention relates to a method for separating and extracting indium and gallium from an indium-gallium solution. The method comprises the steps that (1) extraction is carried out, i.e., organic phosphoric acid is adopted as an extraction agent, and diluents are added, so that an organic phase is obtained, and the organic phase is added to liquid to be extracted for extraction after pH value is adjusted; (2) reverse extraction of indium is carried out, i.e., reverse extraction is conducted on the extracted phase in the step (1) with concentrated hydrochloric acid, so that an indium-enriched aqueous phase is obtained; (3) reverse extraction of gallium is carried out, i.e., reverse extraction is conducted on the organic phase subjected to reverse extraction in the step (2) with an oxalic acid solution, so that a gallium-enriched aqueous phase is obtained; (4) zinc or aluminum is added into the indium-enriched aqueous phase obtained in the step (2) to obtain indium through replacement, or alkaline substances are added to obtain indium hydroxide sediment; (5) precipitants are added into the gallium-enriched water phase obtained in the step (3) to obtain calcium oxalate, filtration is carried out to remove calcium oxalate, and replacement is carried out on liquid obtained after filtration with zinc or aluminum to obtain the simple substance gallium, or alkaline substances are added to obtain gallium hydroxide sediment. According to the method, two elements are recovered by conducting extraction once and reverse extraction twice, separation is complete, the recovery rate is high, operation is easy, and production cost is reduced.

Owner:孙刚

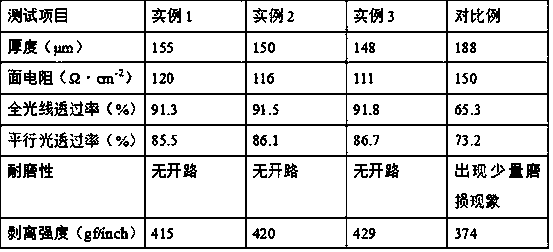

Preparation method for high-conductivity liquid crystal light-adjusting film

ActiveCN108107639AHigh light transmittanceImprove stabilityNon-linear opticsIndiumPotassium hydroxide

The invention relates to the technical field of the optical material preparation and in particular to a preparation method for a high-conductivity liquid crystal light-adjusting film. The method comprises the following steps: dissolving octan zinecnaty in isopropyl alcohol and adding diethanol amine and aluminum nitrate nonahydrate, to obtain transparent homogeneous sol; mixing stannous mono-sulphate, edetic acid and potassium hydroxide and dissolving in deionized water, to obtain complexing stannous mono-sulphate solution; adding polyvinylpyrrolidone powder and oxidation solution added with indium hydroxide to the complexing stannous mono-sulphate solution, to obtain reaction solution; adding indium tin oxide powder to the transparent homogeneous sol, to obtain transparent conductive solsolution, and to obtain a conductive liquid crystal film finally; bonding two sheets of the conductive liquid crystal films by coating with polyamide acid sol, to obtain transparent conductive film glass. In the method, the polyvinylpyrrolidone powder is dissolved in the complexing stannous mono-sulphate solution, the dissolving capacity of multiple types of organic molecules in the transparent homogeneous sol is enhanced, so the light transmission and the conductive performance of the transparent conductive film glass are improved, and the application prospect is extensive.

Owner:南京优写智能科技有限公司

Coating type ammonia sensor nano film and method for preparing same

InactiveCN1996004ALow detection limitLower working temperatureMaterial resistanceMaterial electrochemical variablesIndiumDecomposition

The coating type alkaline air sensor nanometer thin film forms with weight ratio of(100-90)(0-10) of indium trioxide, metatitanic acid, with the working process starting from adding alkaline water into the solution of InCl3 .4H2O stirring till the deposit of indium hydroxide, centrifugation, filtering, cleaning and drying to get dry gel by adding metatitanic acid after solution of the indium hydroxide with hydrolytic decomposition and glacial acetic acid volatilization, sintering, cooling to get the titan mixed indium oxide particle and grinding, getting the clear liquid after ultrasonic settlement, centrifugation, getting indium trioxide powder. It is simple, with good response and optional feature, high sensitivity, low monitoring limit, quick recovery of response, good stability and low working temperature.

Owner:GUANGZHOU UNIVERSITY

Supported catalyst and preparation method thereof

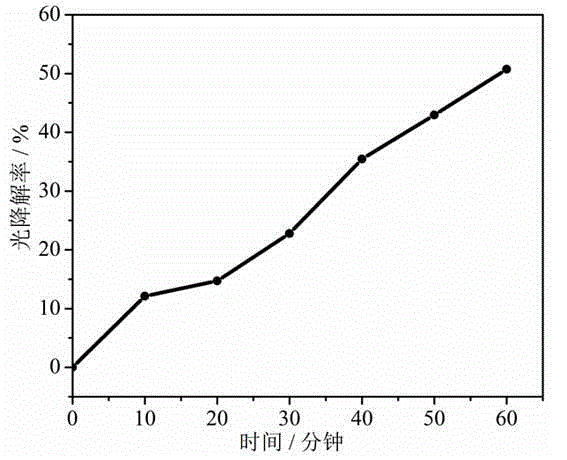

The invention relates to a supported catalyst and a preparation method thereof. The supported catalyst comprises a carrier and an active component loaded on the carrier. The carrier is hydroxyl indiumoxide, and the active component is precious metals. Hydroxyl indium oxide is taken as the carrier and is rich in hydroxyl groups, which can be used as growth anchorage points for precious metal nanoparticles that have a small particle size, are highly dispersed, and are tightly adhered on the carrier. Moreover, more adsorption sites are provided for formaldehyde molecules; and through the synergistic effect between hydroxyl indium oxide and precious metals, the degradation of formaldehyde molecules is promoted. The speed constant of formaldehyde mineralization, which is catalyzed by the supported catalyst and generates carbon dioxide and water, is 0.19*10<-2> ppm<-1>.min<-1> and is 3.8 times and 19 times greater than the speed constants of formaldehyde mineralization catalyzed by an indium trioxide supported precious metal catalyst and an indium hydroxide supported precious metal catalyst respectively.

Owner:CHANGSHA UNIVERSITY

Preparation method of nano indium oxide

InactiveCN112323084AImprove stabilityUniform sizeMaterial nanotechnologyElectrolysis componentsElectrolytic agentIndium(III) hydroxide

The invention discloses a preparation method of nano indium oxide, which comprises the following steps: carrying out electrolysis by using metal indium as an anode, an inert electrode as a cathode andan ammonium salt aqueous solution as an electrolyte, heating the electrolyzed solution to a preset temperature after electrolysis for a first preset time, continuously adding an ammonia water solution into the electrolyzed solution, stirring for a second preset time to obtain indium hydroxide, carrying out solid-liquid separation on indium hydroxide in the electrolyte, and carrying out high-temperature calcination to obtain the nano indium oxide powder. According to the preparation method of the nano indium oxide, provided by the invention, a solution after electrolysis is subjected to heating neutralization stirring, solid-liquid separation and calcination, so that the nano indium oxide with good stability, uniform particle size and uniform particle distribution can be obtained, the method solves the technical problems that the nano indium oxide powder prepared in the prior art is unstable in property due to the fact that the particle size is too small, then particle distribution isuneven, and agglomeration is likely to happen.

Owner:XIANDAO THIN FILM MATERIALS GUANGDONG CO LTD

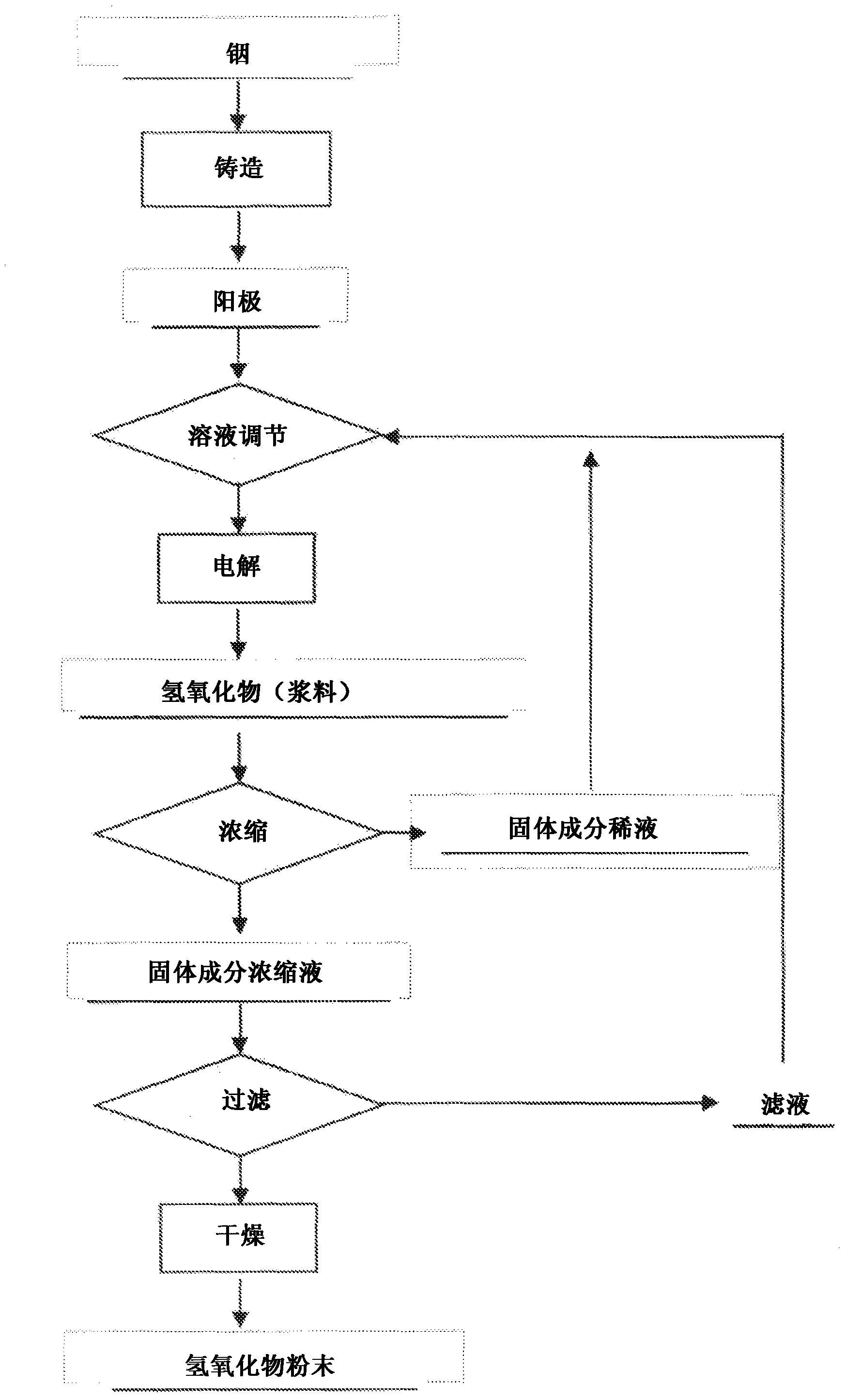

Method for producing indium hydroxide or compound containing indium hydroxide

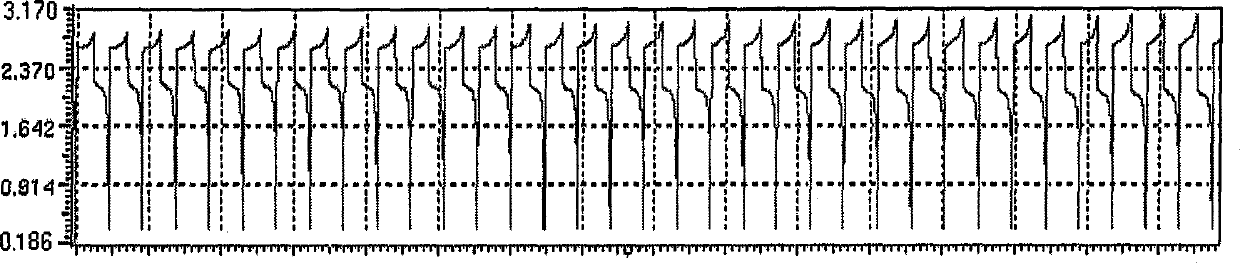

ActiveCN103857830AEfficient preparationImprove sintering performanceAnodisationElectrodesIndium(III) hydroxideProduction rate

A method for producing indium hydroxide or a compound containing indium hydroxide by electrolysis. The purpose of this method is to suppress deterioration of the productivity and deterioration of the quality by performing electrolysis, while setting the electrical conductivity of the electrolyte solution at 10 mS / cm or more, so that indium hydroxide or a compound containing indium hydroxide is precipitated in the electrolyte solution, and then cleaning the thus-precipitated indium hydroxide or compound containing indium hydroxide until the electrical conductivity of the cleaning liquid becomes 1 mS / cm or less.

Owner:JX NIPPON MINING & METALS CO LTD

Method for production of metal hydroxide and method for production of ITO sputtering target

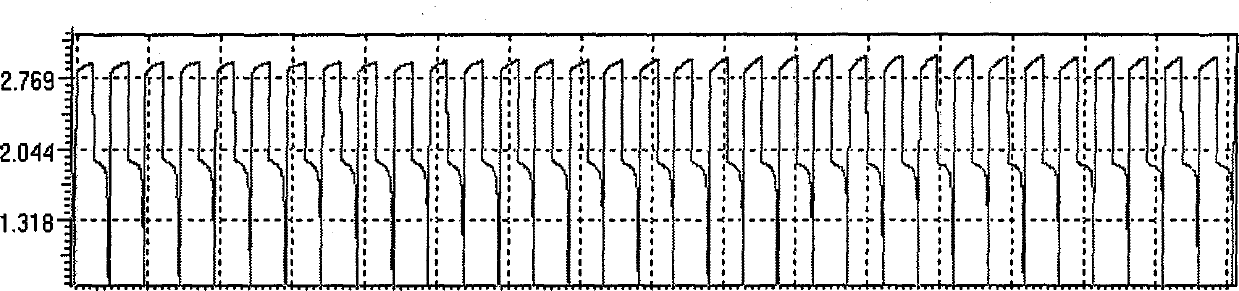

InactiveCN104334771AEfficient mass productionComposition unchangedCellsElectric discharge tubesIndiumElectrolysis

Provided are a method for production of metal hydroxide highly suited to volume production, whereby it is possible to obtain a metal hydroxide having a uniform desired particle size, without the need for wastewater treatment of the electrolysis solution; and a method for production of ITO sputtering target. A gas diffusion electrode (20) constituted by stacking of a hydrophobic gas diffusion layer (20a) and a hydrophilic reaction layer (20b) is arranged within an electrolysis tank (1), partitioning the electrolysis tank interior. A deposition tank (11) facing the reaction layer of the partitioned electrolysis tank holds an electrolysis solution (S) inside, and indium (4) is immersed into the electrolysis solution. With the gas diffusion electrode as the cathode and the indium as the anode, voltage is applied across the two electrodes, and oxygen is supplied into an air tank (10) facing the gas diffusion layer of the partitioned electrolysis tank to carry out electrolysis, causing indium hydroxide to precipitate into the electrolysis solution.

Owner:ULVAC INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com