Non-vacuum preparation method of light absorption layer of copper indium gallium sulfur selenium (CIGSSe) thin film solar cell

A thin-film solar cell, copper indium gallium sulfide selenide technology, applied in coatings, circuits, electrical components, etc., can solve the problems of impurity residues, complex solution preparation, etc., to achieve uniform distribution, simple solution preparation process, and no residue of impurity ions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Preparation of organic precursor solution: according to Cu in the light absorbing layer 0.7 In 0.7 Ga 0.3 S 0.2 Se 1.8 In the stoichiometric ratio of copper, indium and gallium, 0.35mmol cuprous oxide (Cu 2 O), 0.7mmol indium hydroxide (In(OH) 3 ), 0.3mmol gallium hydroxide (Ga(OH) 3 ) was dissolved in 10mL of a mixed organic solvent of isopropanol, thioacetic acid, ethylene glycol, and ethanolamine, wherein the volume ratio of isopropanol, thioacetic acid, ethylene glycol, and ethanolamine was 5:2:2:1, at room temperature Stir to obtain a clear, transparent, stable organic precursor solution containing copper, indium, gallium, and sulfur;

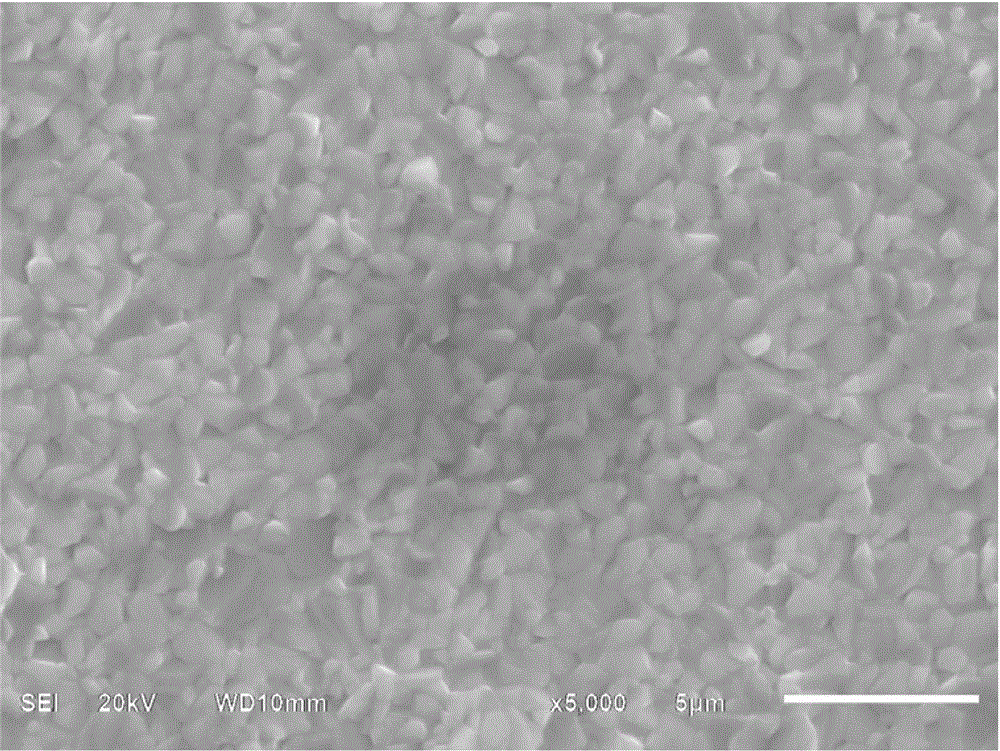

[0057] Preparation of CIGSSe precursor film: The organic precursor solution was spin-coated to prepare a CIGSSe precursor film on a molybdenum-coated glass substrate and dried on a heating plate at 300 °C;

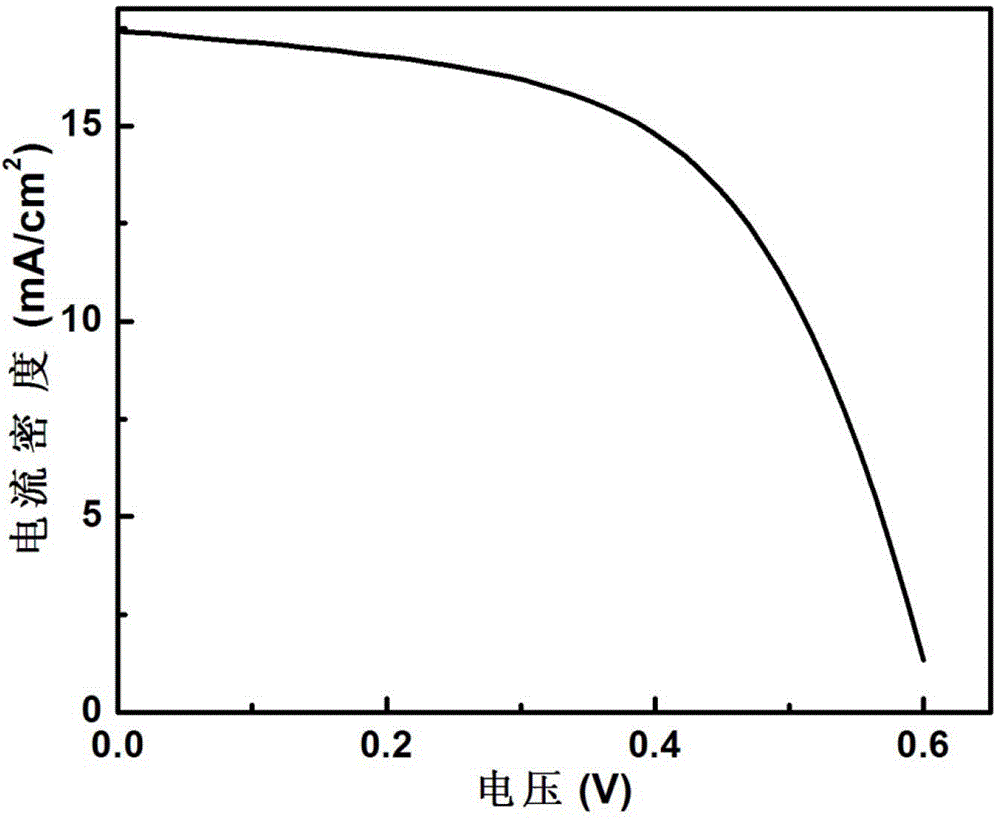

[0058] Annealing treatment of CIGSSe thin film: anneal the precursor thin film at 500°C for 30 minutes in a selenium at...

Embodiment 2

[0061] Preparation of organic precursor solution: according to Cu in the light absorbing layer 1.0 In 0.7 Ga 0.3 S 0.6 Se 1.4 In the stoichiometric ratio of copper, indium and gallium, 1.0mmol copper oxide (CuO), 0.7mmol indium hydroxide (In(OH) 3 ), 0.3mmol gallium acetylacetonate (Ga(C 5 h 7 o 2 ) 3 ) was dissolved in 10mL of methanol, thioacetic acid, and diethanolamine in a mixed organic solvent, wherein the volume ratio of methanol, thioacetic acid, and diethanolamine was 7:2:1, and stirred at room temperature to obtain clear, transparent, stable copper, indium, and Organic precursor solutions of gallium and sulfur;

[0062] Preparation of CIGSSe precursor film: The organic precursor solution was spin-coated to prepare a CIGSSe precursor film on a molybdenum-coated stainless steel substrate and dried on a heating plate at 300 °C;

[0063] Annealing treatment of CIGSSe thin film: anneal the precursor film at 500°C for 30 minutes in a sulfur and selenium atmosphere...

Embodiment 3

[0065] Preparation of organic precursor solution: according to Cu in the light absorbing layer 0.8 In 0.8 Ga 0.2 S 0.6 Se 1.4 In the stoichiometric ratio of copper, indium and gallium, 0.4mmol cuprous oxide (Cu 2 O), 0.8mmol indium hydroxide (In(OH) 3 ), 0.2mmol gallium acetylacetonate (Ga(C 5 h 7 o 2 ) 3 ) was dissolved in 10mL of a mixed organic solvent of ethanol, thioacetic acid, ethylenediamine, and glycerol, wherein the volume ratio of ethanol, thioacetic acid, ethylenediamine, and glycerol was 6.8:2:1:0.2, at room temperature Stir to obtain a clear, transparent, stable organic precursor solution containing copper, indium, gallium, and sulfur;

[0066] Preparation of CIGSSe precursor film: The organic precursor solution was pulled to prepare a CIGSSe precursor film on a molybdenum-coated glass substrate and dried on a heating plate at 300 °C;

[0067] Annealing treatment of CIGSSe film: anneal the precursor film at 500°C for 30 minutes in an atmosphere of hydro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com