Method for enhancing homogeneity and effeciency of carbon nanotube electron emission source of field emission display

a carbon nanotube and electron emission source technology, applied in the manufacture of electrode systems, liquid/fluent solid measurements, electric discharge tubes/lamps, etc., can solve the problems of reducing the efficiency of carbon nanotubes, limiting the manufacturing cost and cubic structure, and unable to achieve homogeneity of large-scale electron emission sources. , to achieve the effect of enhancing the electron conductivity of carbon nanotubes and the cathode electron layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to better understanding the features and technical contents of the present invention, the present invention is hereinafter described in detail by incorporating with the accompanying drawings. However, the accompanying drawings are only for the convenience of illustration and description, no limitation is intended thereto.

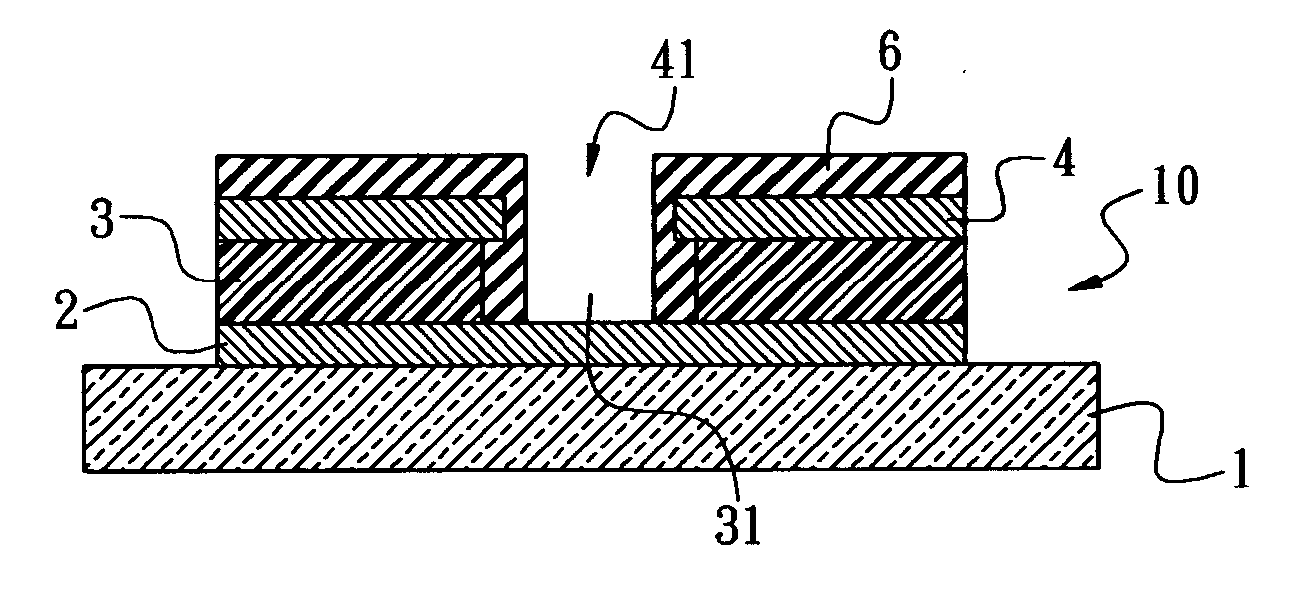

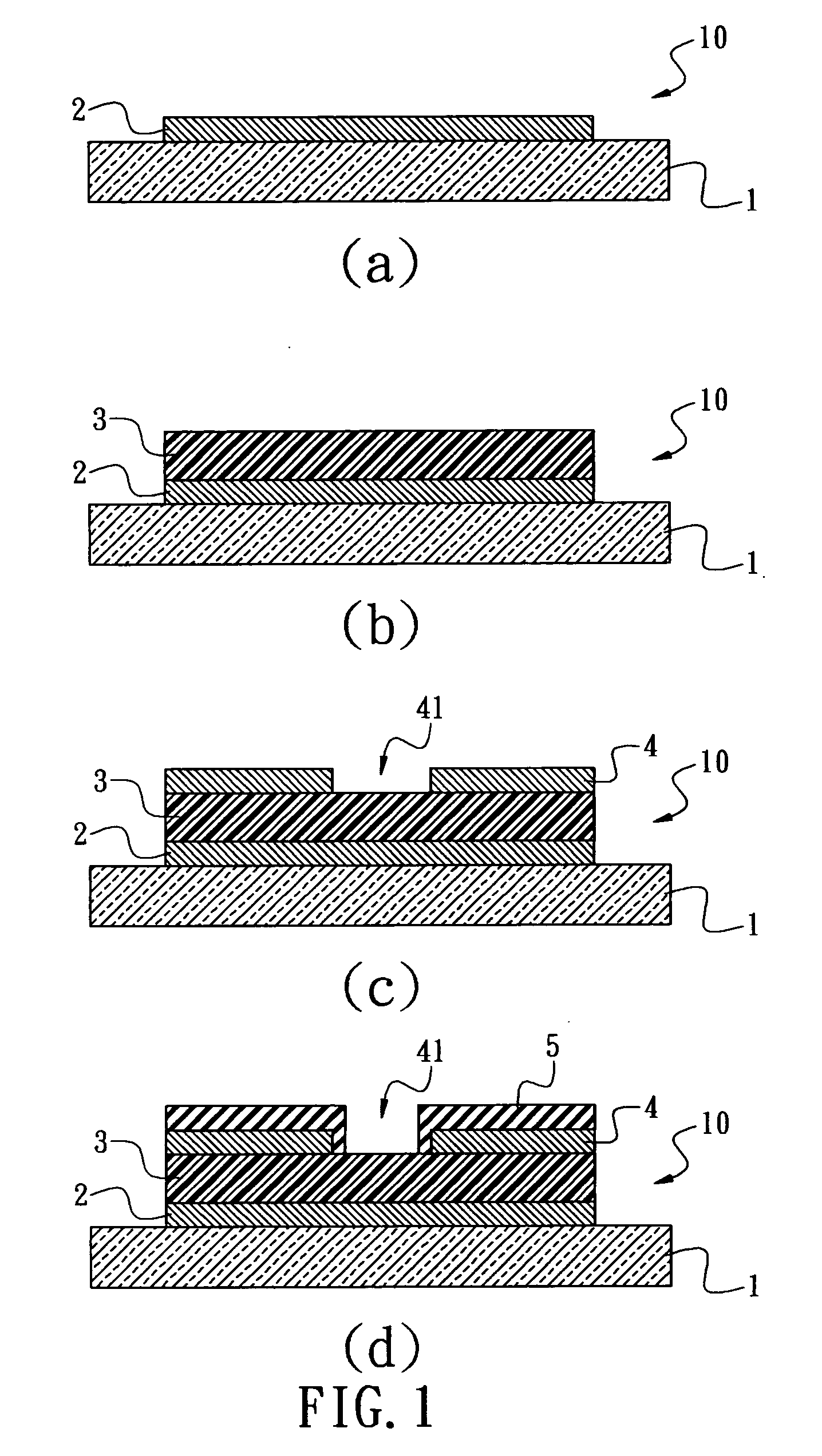

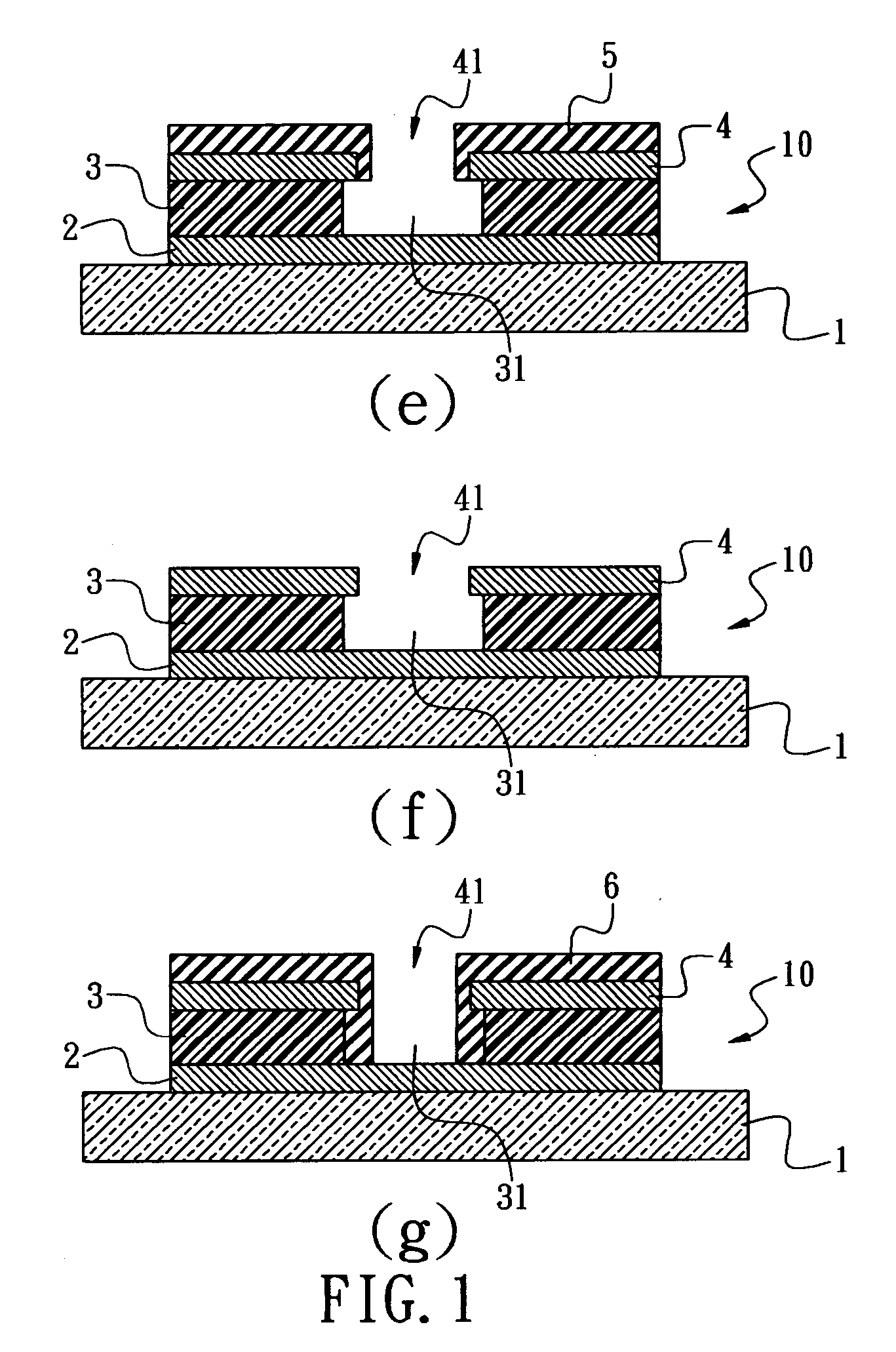

[0018] Referring to FIG. 1(a) to FIG. 1(g), a process for manufacturing a semi-manufactured cathode structure, in accordance with the present invention, is illustrated. As shown, the method of the present invention for enhancing the efficiency and the homogeneity of carbon nanotube electron emission source manufactured by means of electrophoresis deposition employs some proper charger to manufacture the carbon nanotube electron emission source, thereby improving the homogeneity of carbon nanotubes deposited on the surface of the cathode structure 10.

[0019] In the beginning, a cathode electrode layer 2 is formed on the surface of a glass substrate 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electric field | aaaaa | aaaaa |

| electric field | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com