Method for improving particle acceleration performance of air jet mill

An acceleration performance and jet milling technology, which is applied in the field of powder processing, can solve the problems of acceleration of a large number of material particles, and achieve the effects of increasing the collision speed, improving the distribution characteristics, improving the collision probability and crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

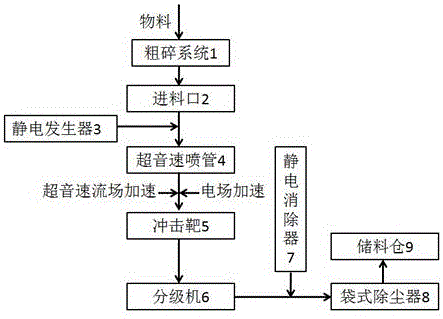

[0018] see figure 1 , a method for improving the acceleration performance of jet mill particles, specifically comprising the following steps: the dried industrial solid waste (such as fly ash, sulfur-fixed ash, etc.) is crushed to within 3mm by a coarse crushing system 1, and the coarse The particles are used as the inlet material of the jet mill feed port 2. During the feeding process, the industrial solid waste particles are positively charged by the electrostatic generator 3, and the industrial solid waste particles are directly sent into the supersonic nozzle 4 by mixed flow acceleration. Acceleration, when the material particles enter the acceleration area between the annular iron block at the exit of the nozzle and the impact target 5, they are accelerated under the coupling effect of the drag force of the supersonic flow field and the electric field force until the material collides with the impact target 5 and is crushed , the pulverized material is classified by the c...

Embodiment 2

[0020] see figure 1 , a method for improving the acceleration performance of jet mill particles, which can also be applied to the processing of non-metallic ore, specifically includes the following steps: non-metallic ore (such as mica, gypsum, etc.) The crushed particles are used as the inlet material of the jet mill inlet 2. During the feeding process, the non-metallic ore particles are positively charged by the electrostatic generator 3, and the non-metallic ore particles are directly sent into the supersonic nozzle by mixed flow acceleration. 4, when the material particles enter the acceleration area between the annular iron block at the outlet of the nozzle and the impact target 5, they are accelerated under the coupling effect of the drag force of the supersonic flow field and the electric field force until the material and the impact target 5 Collision crushing is carried out, and the crushed materials are classified by the classifier 6, and the non-metallic mineral pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com