Linked insulating rod bank used for solid insulating ring main unit

A solid insulation and insulating rod technology, which is applied in the setting of switchgear, switchgear, electrical components, etc., can solve the problems of unreasonable rigidity speed, deformation of tie rod, falling off and breaking, etc., to avoid large deformation or even breaking and falling off, improve The distribution characteristics of the force, the effect of reducing the concentrated force point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

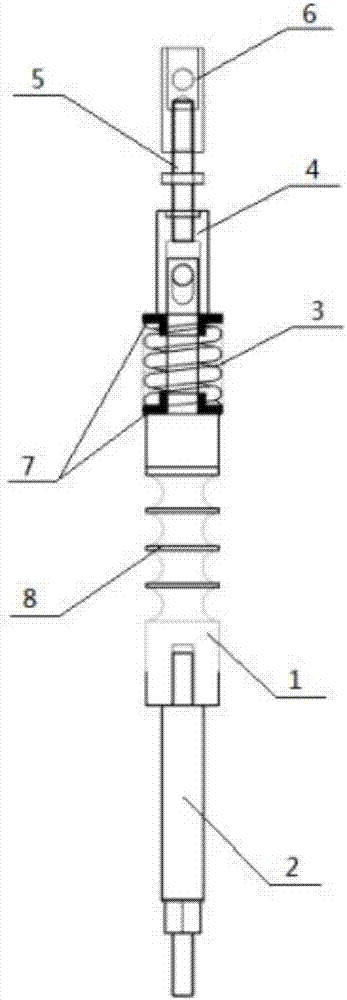

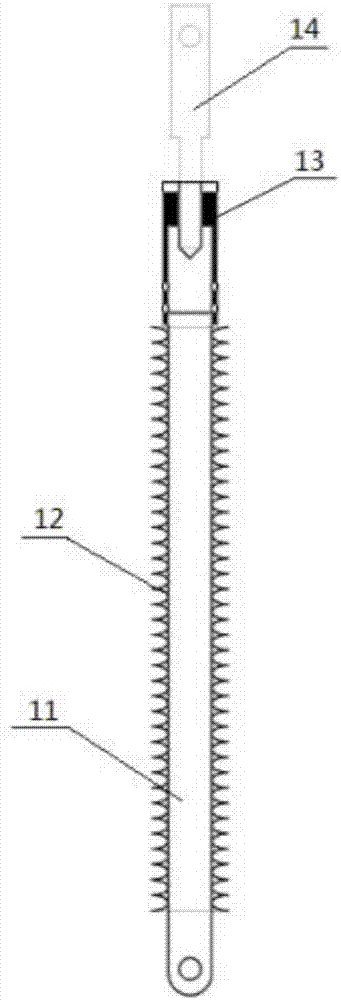

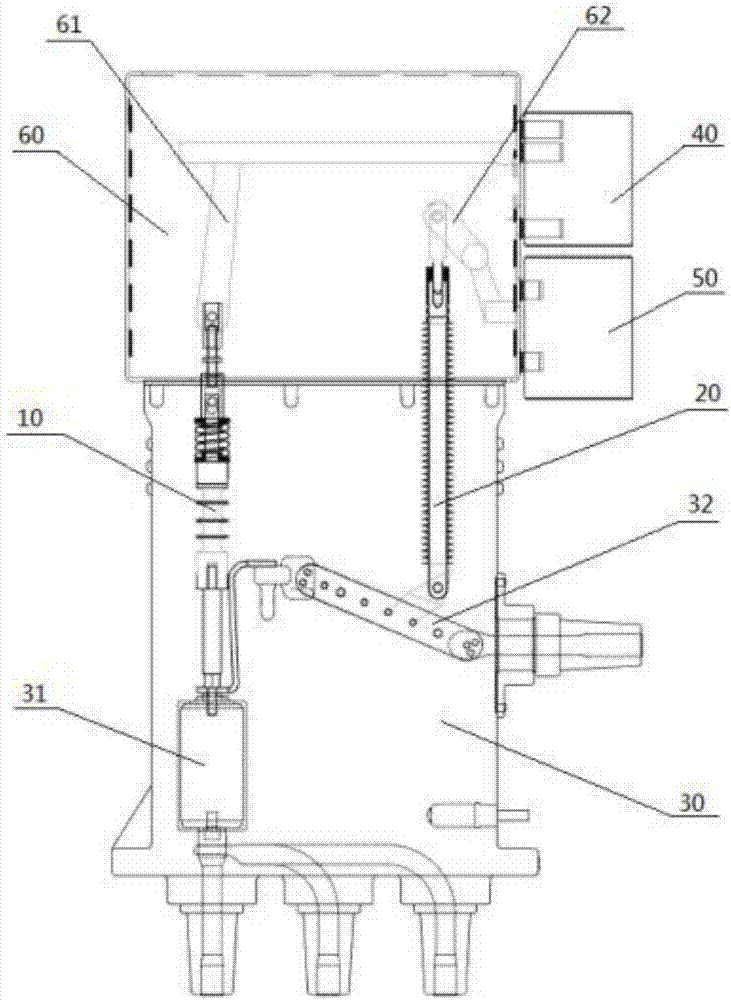

[0029] like image 3 As shown, a linkage insulating rod group for a solid insulating ring network cabinet includes a circuit breaker insulating rod 10 and an isolation insulating rod 20; it can effectively connect the switch and the operating mechanism of the insulating module 30 of the solid insulating ring network cabinet ( That is, the circuit breaker operating mechanism 40, the isolation operating mechanism 50) and the transmission mechanism 60 are connected to form a complete control system. When the operation mechanism is reached, the vacuum interrupter 31 and the three can be driven by the transmission mechanism 60 and the linkage insulating rod group The contact of the station isolating switch 32 is closed or separated to complete the on-off control of the main circuit. In addition to achieving reasonable insulation performance, the insulating rod group can also achieve the tensile strength of the insulating tie rod to effectively prevent deformation and ensure good mec...

Embodiment 2

[0046] The difference from Embodiment 1 is that there are various spring specifications for the compression spring 3 to have an elastic deformation force of 1950-2050 N, wherein the compression spring 3 has a free height of 45 mm, a spring wire diameter of 7 mm, and a spring outer diameter of 37 mm. The compression amount of the compression spring 3 is 8-10mm, which can meet the design size requirements of the insulating rod 10 of the circuit breaker. And buffer spring 3 used material is 60Si 2 Mn, the buffer spring is designed with silicon-manganese spring steel material, which has good mechanical properties such as tensile strength and yield strength, elongation, and reduction of area, and can withstand large loads.

Embodiment 3

[0048] The difference from Embodiment 1 is that the first insulating core body of the first insulating rod main body 1 is a high-strength flame-retardant nylon rod, and its internal insulation strength is affected by the sharp change of the temperature of the heating element parts, and the insulating rod is slightly deformed when the operating mechanism operates. The impact of the external environment such as impact force is very small, and the material has high electrical properties, high impact strength, high rigidity, high heat resistance, good dimensional stability, and the environment has little effect on the deterioration of the insulating material, and the internal insulation performance can be be guaranteed. More importantly, it is suitable for molding and pouring, and is suitable for pouring steel column inserts. The first insulating jacket of the first insulating rod main body 1 is made of silicone rubber, which has excellent insulation performance, high and low temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com