Steam discharge pipeline structure for directly preventing freezing of air condenser in winter

A technology for air-cooled condensers and exhaust pipes, applied in steam/steam condensers, lighting and heating equipment, etc., can solve the problem of easy freezing of steam side channels, affecting the safe operation of air-cooled power plants, and affecting the economic benefits of power generation companies, etc. problems, to achieve the effect of preventing freezing phenomenon, preventing and suppressing large-scale freezing, and improving unit economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention provides an exhaust pipe structure for direct air-cooled condensers to prevent freezing in winter. The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

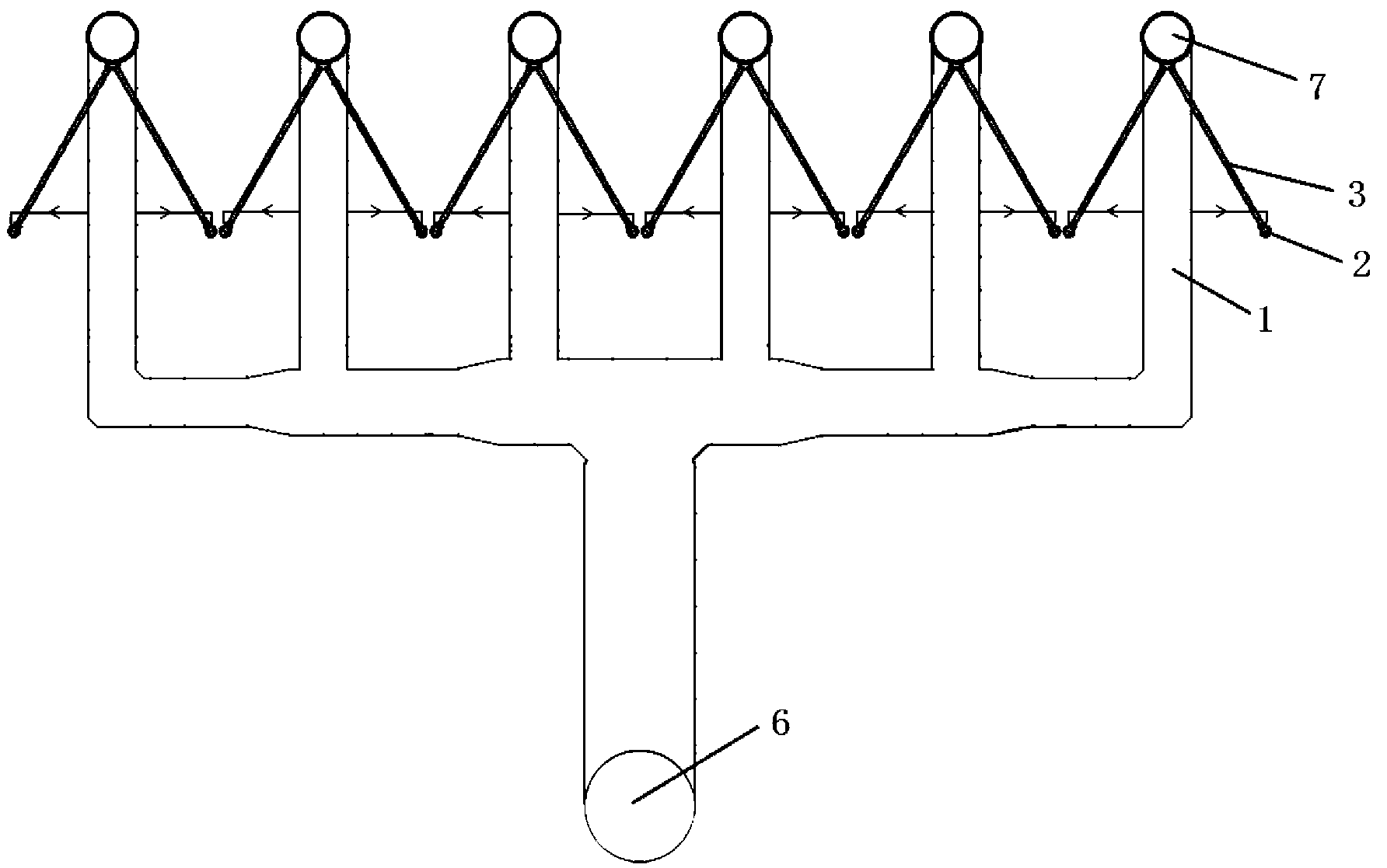

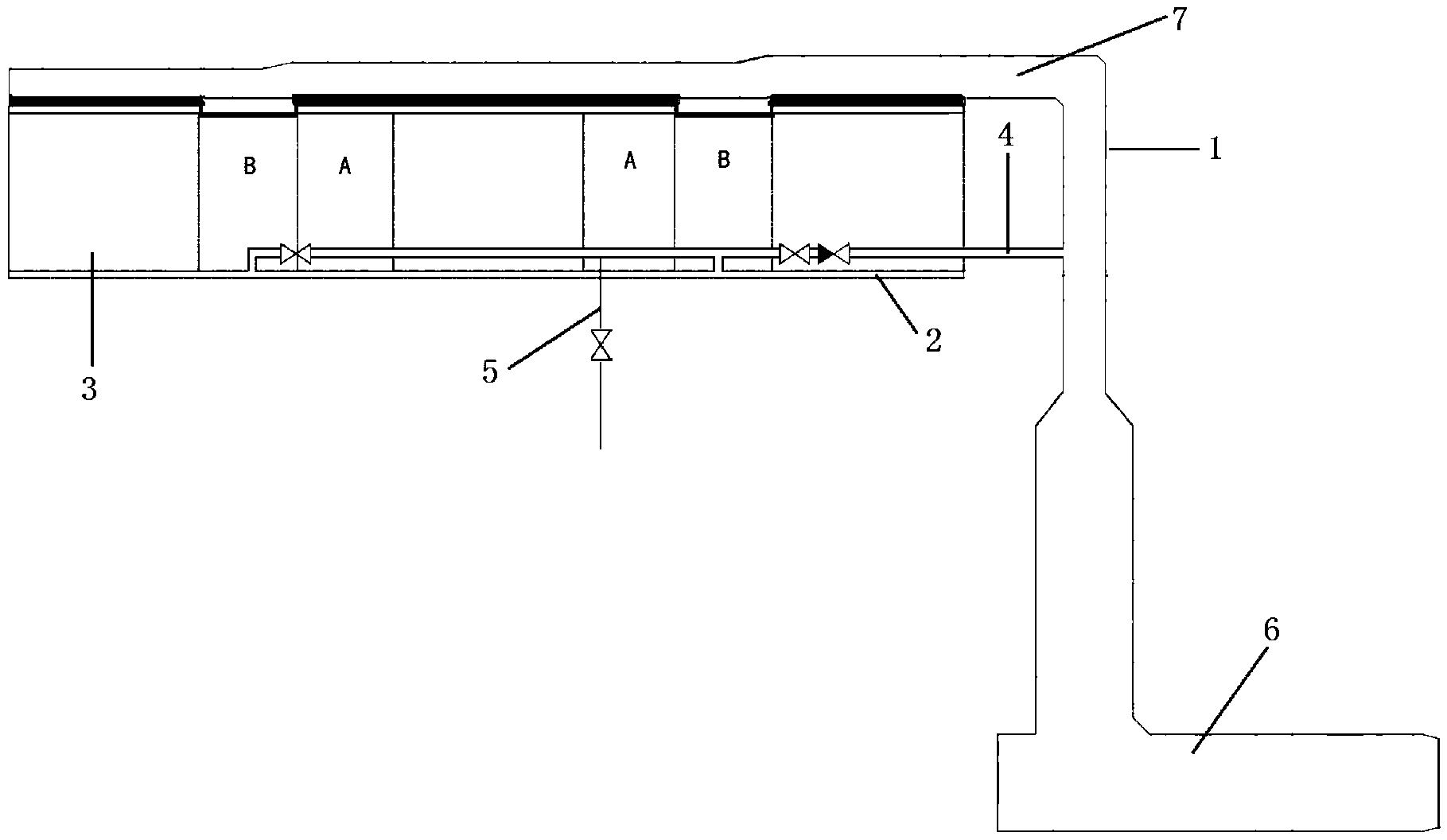

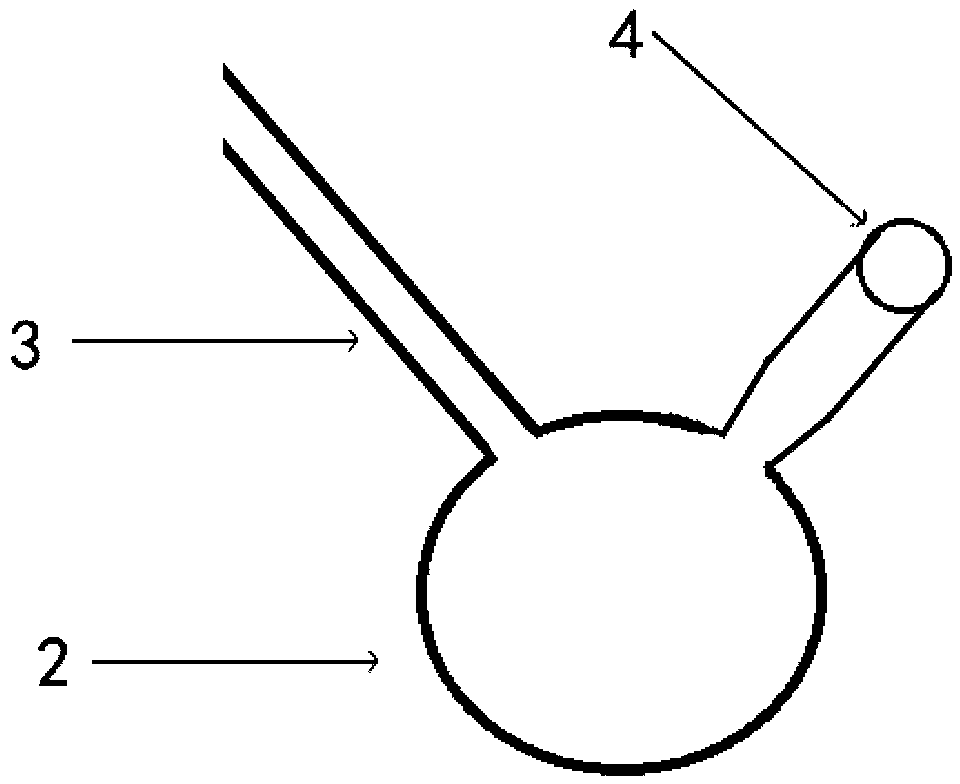

[0022] Such as figure 1 and figure 2 As shown, it is a schematic diagram of the steam turbine exhaust pipe of a 300MW direct air cooling unit. The steam turbine exhaust pipe 6 is connected to the steam distribution pipe 7 of each column of the air-cooled condenser through 6 parallel riser pipes 1, and each steam distribution pipe 7 is connected with 5 groups of condenser units 3 side by side, and each group of condenser units The lower end of 3 is connected through the condensate collection pipe 2; each group of condenser units 3 is divided into two pieces arranged obliquely on the left and right, forming an inverted "V" structure; among the five groups of condenser units 3, the downstream unit and the countercurrent The u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com