Preparation method of nanometer indium hydroxide

An indium hydroxide, nano-scale technology, applied in the field of ITO target materials, can solve the problems of increasing washing difficulty and washing water consumption, increasing preparation cost and operation steps, poor uniformity of indium hydroxide products, etc., so as to reduce washing difficulty. and washing water consumption, reducing the difficulty of wastewater treatment, and reducing the production of ammonium nitrate mother liquor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The invention provides a method for preparing nanoscale indium hydroxide, comprising the following steps:

[0032] a) passing ammonia gas into the indium nitrate aqueous solution to obtain a precursor slurry;

[0033] b) After washing the precursor slurry, it is spray-dried to obtain indium hydroxide powder.

[0034] According to the present invention, ammonia gas is introduced into the indium nitrate aqueous solution to obtain the precursor slurry.

[0035] In the present invention, the method of obtaining the indium nitrate aqueous solution is not particularly limited, and can be obtained in a manner well known to those skilled in the art; in some embodiments, the indium nitrate solid is mixed with water to obtain an indium nitrate aqueous solution; in other In the embodiment, the indium nitrate solution is diluted with water to obtain an indium nitrate aqueous solution. In the present invention, the molar concentration of indium in the indium nitrate aqueous soluti...

Embodiment 1

[0049] Dilute the indium nitrate solution with water until the molar concentration of indium is 2 mol / L, and feed ammonia gas at 60 mL / min while stirring at 40°C until the pH of the slurry is 10, stop the aeration, and age at 25°C for 8 hours. The slurry was transferred to a storage tank, washed with a filter press, and deionized water with a conductivity of 10 μs / cm was added for circular washing until the conductivity of the slurry was 19.0 μs / cm. Afterwards, a double-flow spray dryer is used for spray drying, with an inlet air temperature of 300°C and an outlet air temperature of 150°C to obtain indium hydroxide powder without sieving.

[0050] After testing, the purity of the obtained indium hydroxide product is 99.99%; the specific surface area is 47.2m 2 / g, D50 is 0.28μm; product moisture content is 0.1%.

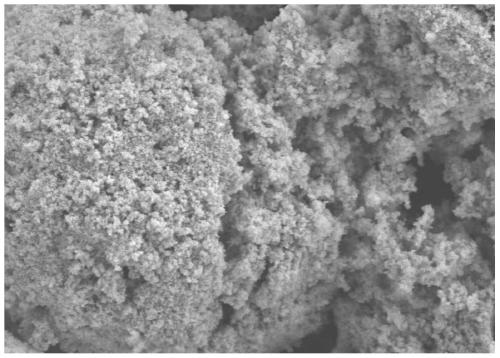

[0051] see figure 1 , figure 1 It is the SEM image (magnification is 3000 times) of the product obtained in Example 1 of the present invention; it can be seen tha...

Embodiment 2

[0054] Dilute the indium nitrate solution with water until the molar concentration of indium is 0.4 mol / L, feed ammonia gas at 20 mL / min with stirring at 25°C until the pH of the slurry is 7.5, stop the aeration, and age at 40°C for 8 hours. The slurry was transferred to a storage tank, washed with a filter press, and deionized water with a conductivity of 10 μs / cm was added for circular washing until the conductivity of the slurry was 17.6 μs / cm. Afterwards, a double-flow spray dryer was used for spray drying, with an inlet air temperature of 250° C. and an outlet air temperature of 120° C. to obtain indium hydroxide powder without sieving.

[0055] After testing, the purity of the obtained indium hydroxide product is 99.99%; the specific surface area is 50.02m 2 / g, D50 is 0.48μm; the water content of the product is 0.80%.

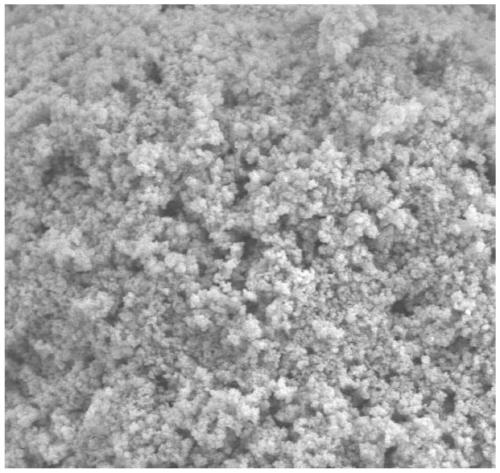

[0056] see image 3 , image 3 It is the SEM image (magnification is 3000 times) of the product obtained in Example 2 of the present invention; it ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com