Patents

Literature

176results about How to "Reduce washing water consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

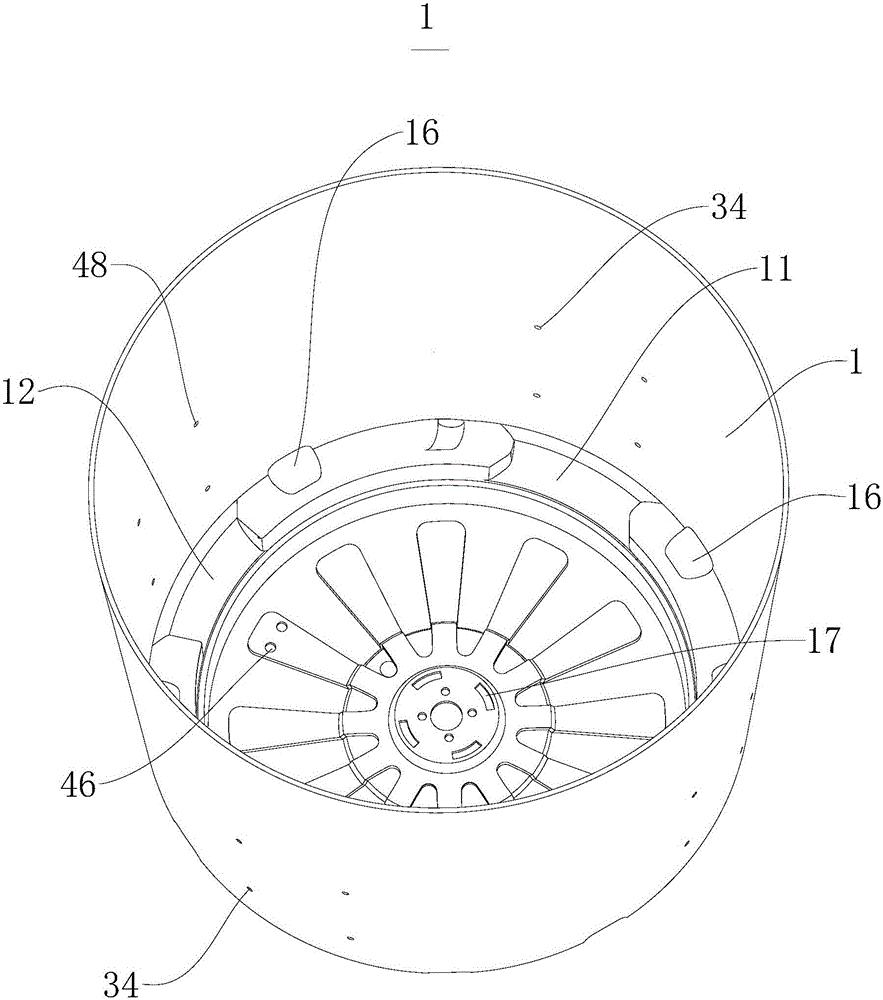

Roller washing machine

ActiveCN104005201AAvoid waterReduce washing water consumptionOther washing machinesWashing machine with receptaclesWater dischargeWash water

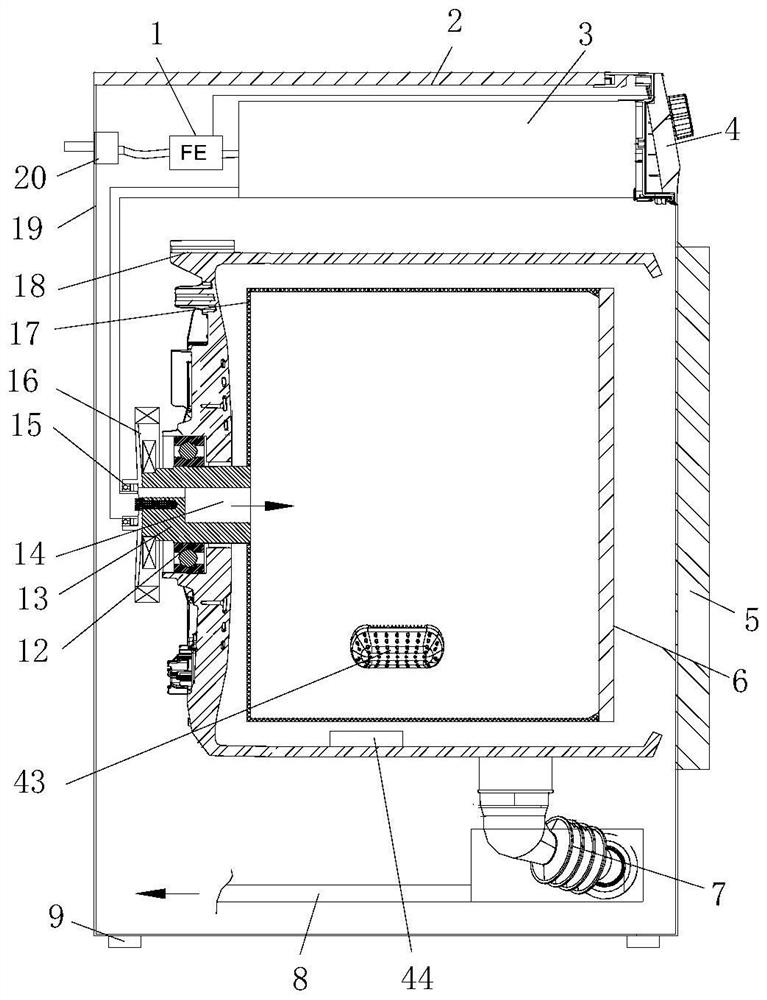

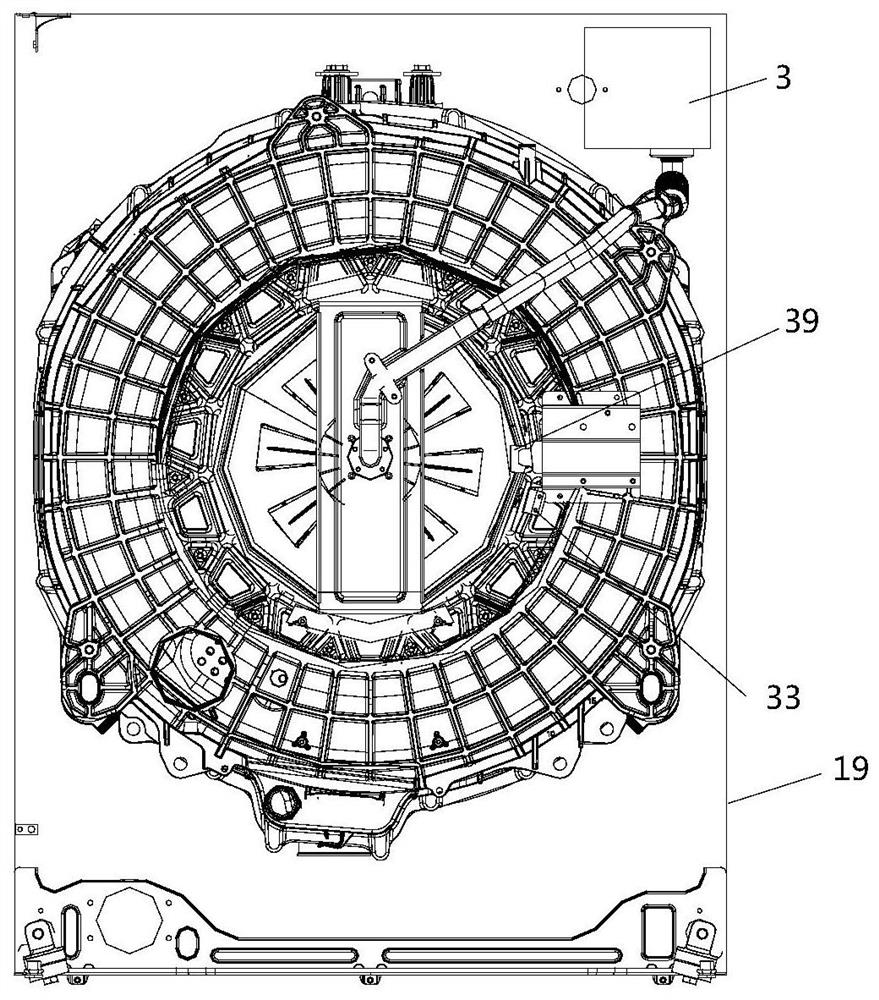

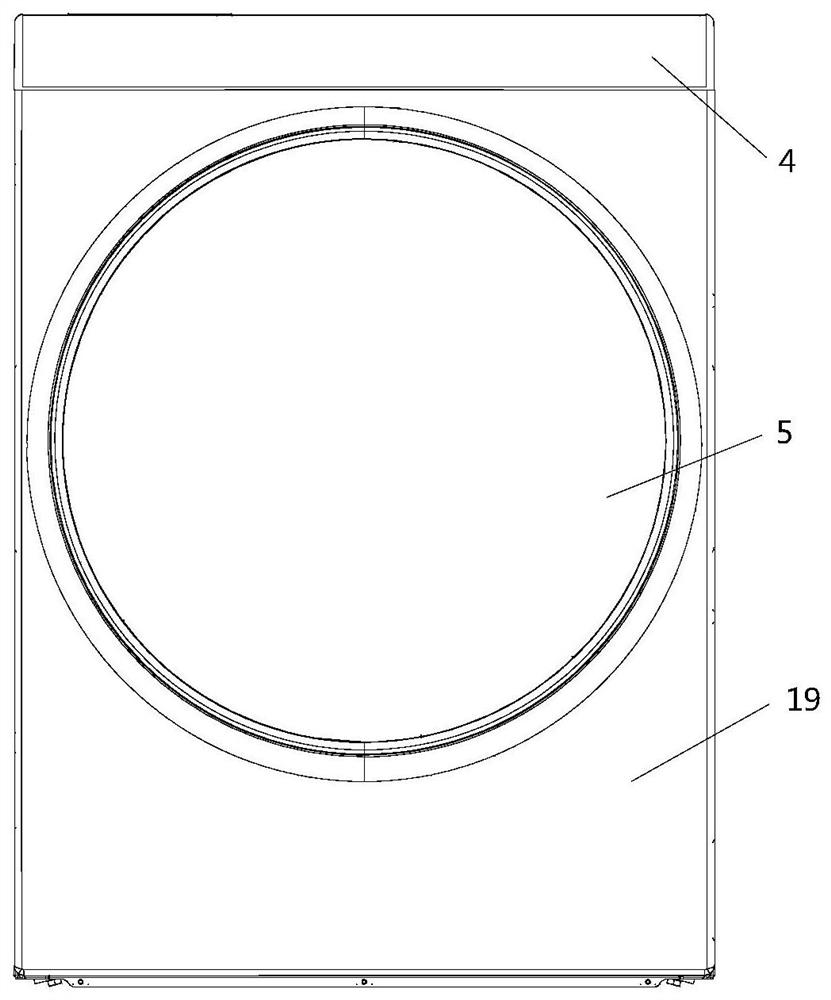

The invention relates to a roller washing machine. The roller washing machine comprises a box body, wherein an inner barrel and an outer barrel are arranged in the box body, a door seal is arranged between the outer barrel and the box body, the inner barrel is connected with a driving device, the inner barrel is a hole-free inner barrel and is a conical barrel of which the diameter at the bottom is small and the diameter at the opening is large, the opening of the inner barrel is contracted inwards in an arc shape, a water inlet guide pipe is arranged on the door seal, one end of the water inlet guide pipe is connected with a wash water rapid heating device, the other end of the water inlet guide pipe penetrates through the door seal and extends into the inner barrel, and a water discharging opening and a water pressure detection device are arranged on the outer barrel. According to the technical scheme, the inner barrel is the hole-free inner barrel, water enters the inner barrel through the water inlet guide pipe arranged on the door seal and is discharged through the shape of the inner barrel in the water discharging process, so that water is prevented from being accumulated between the inner barrel and the outer barrel, and the amount of washing water is largely saved.

Owner:WHIRLPOOL CHINA

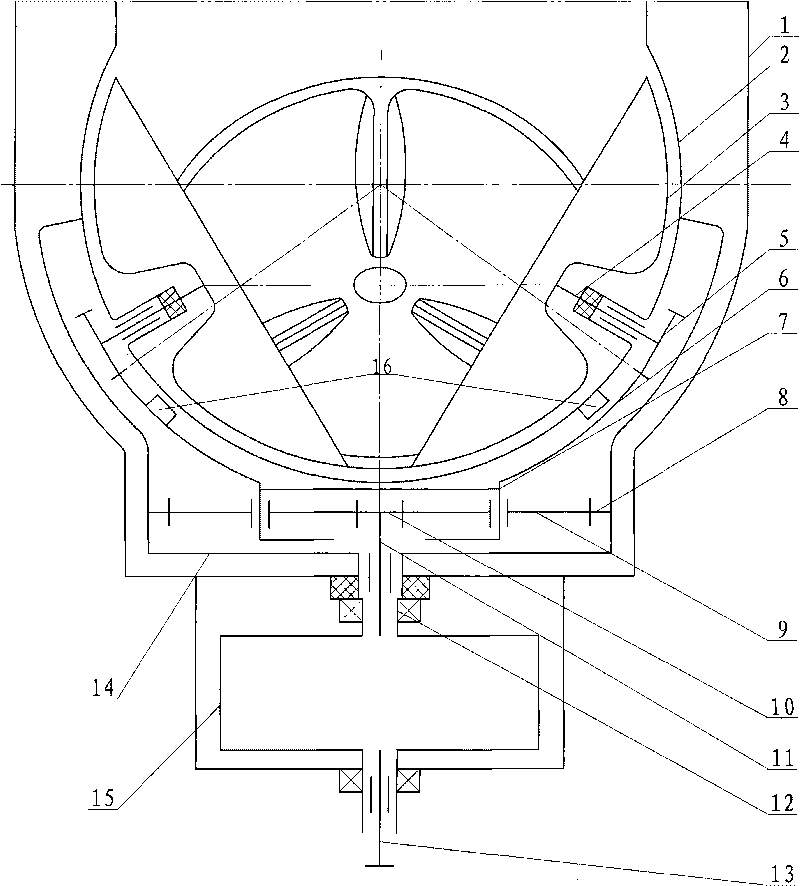

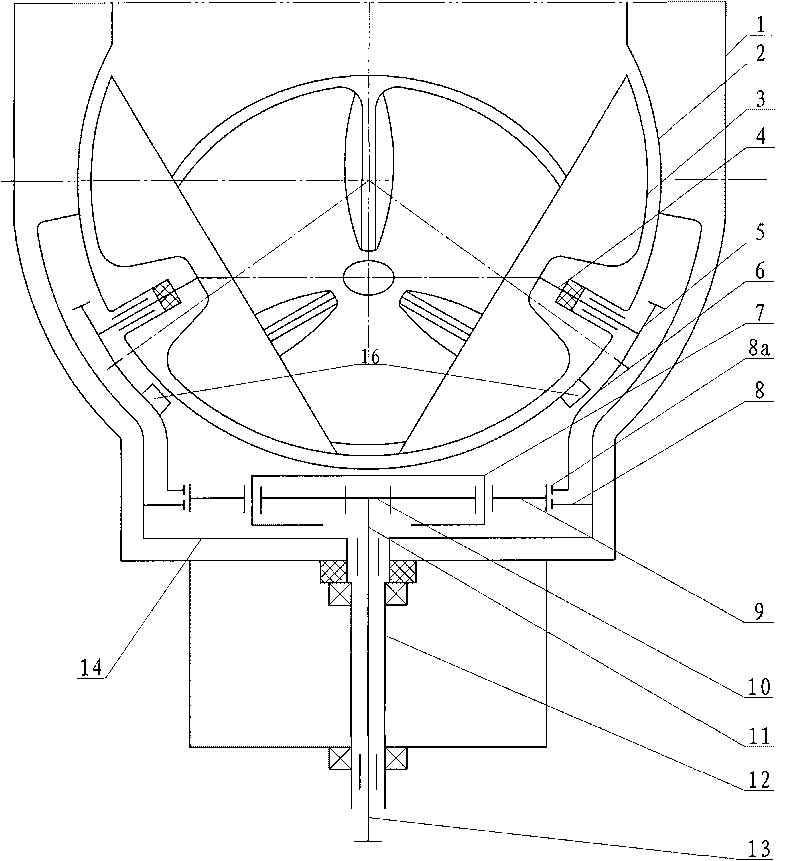

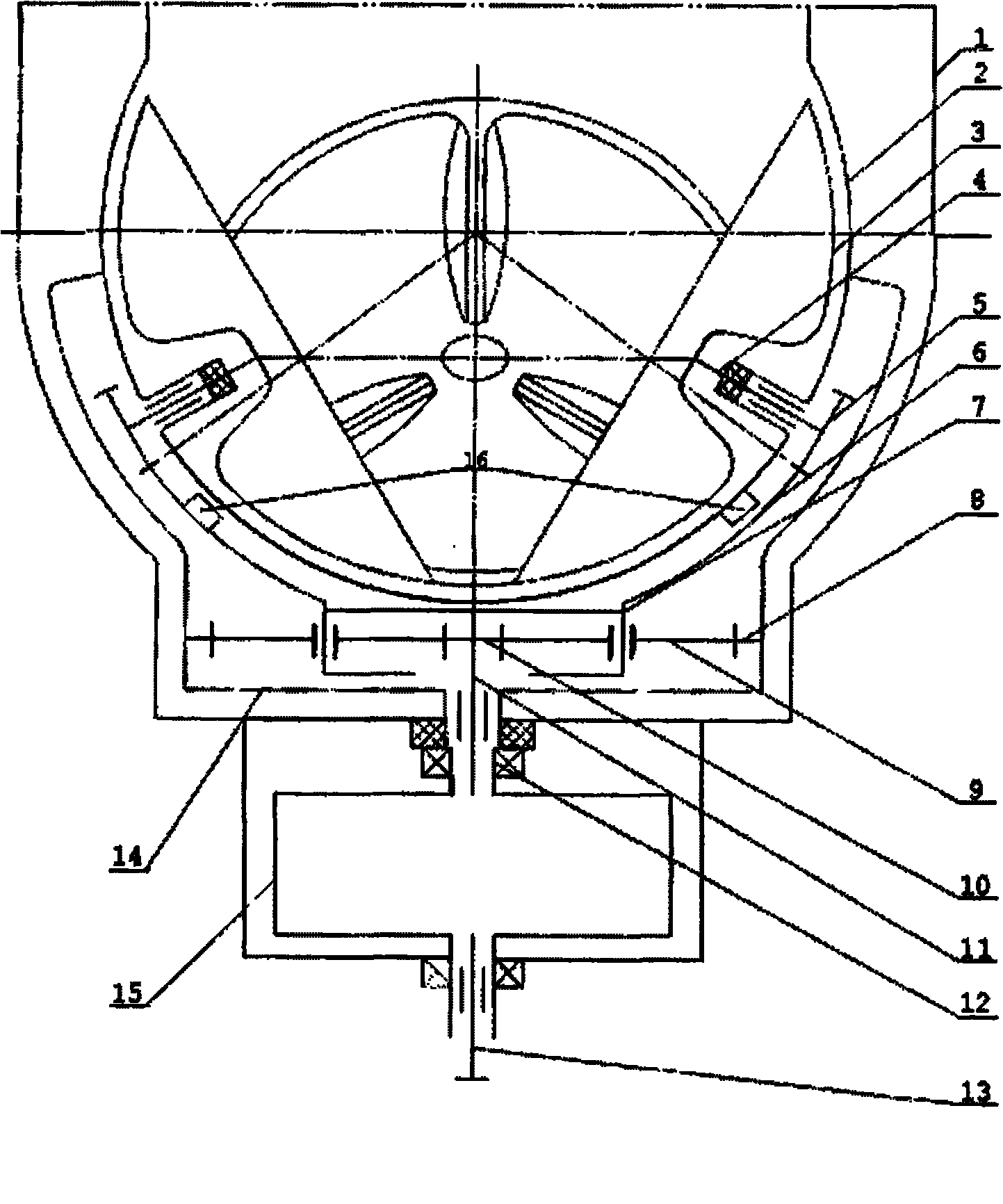

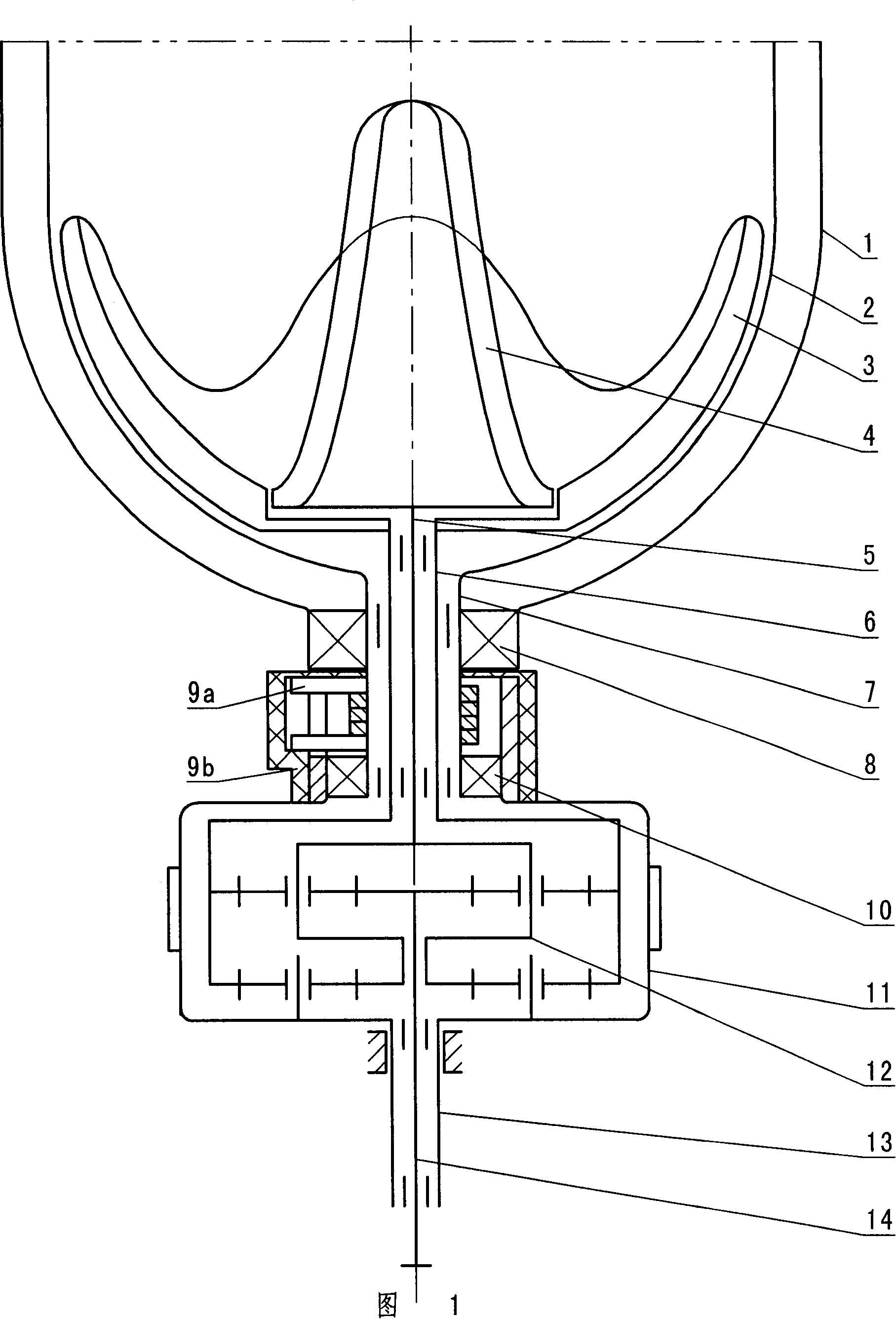

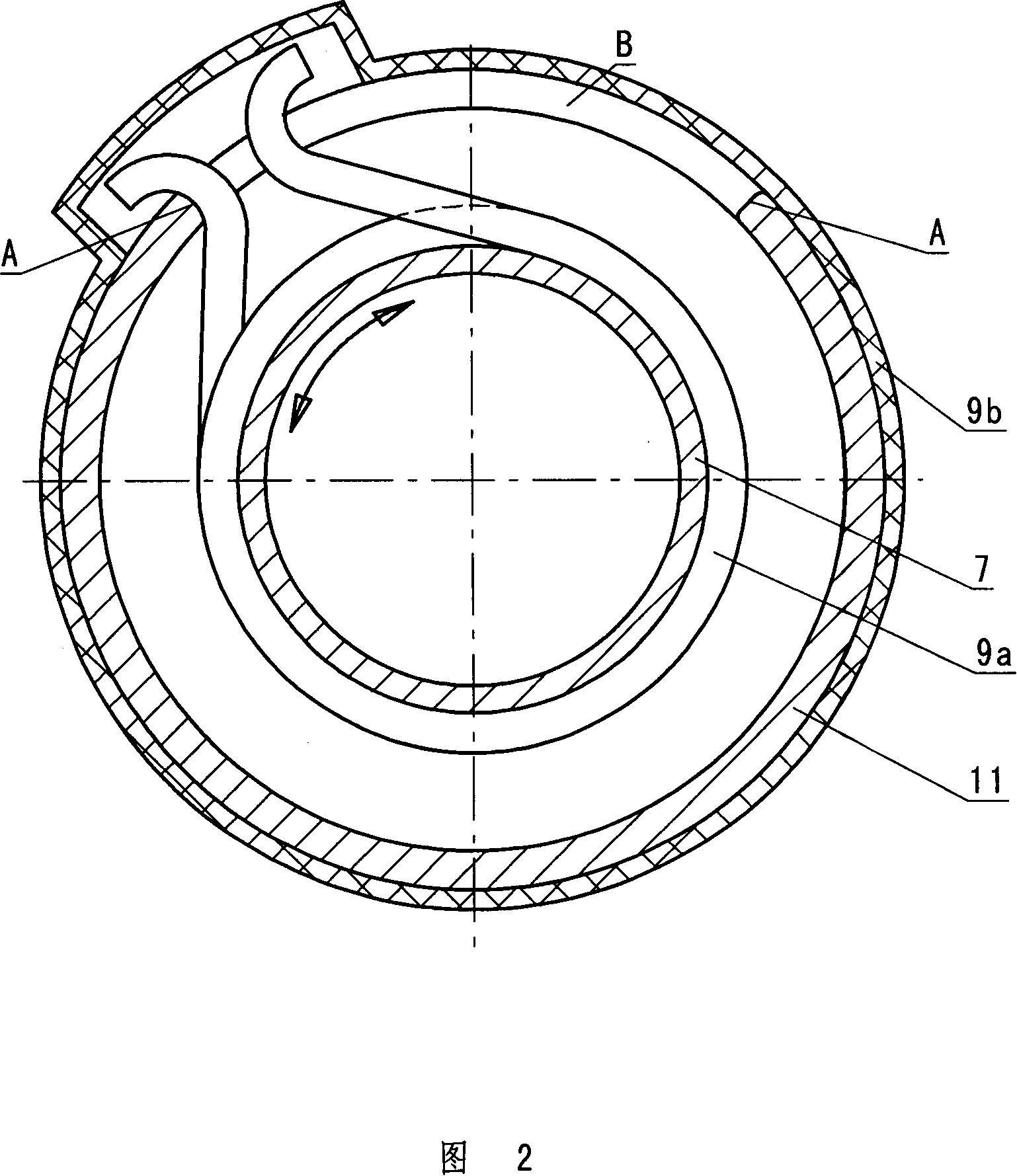

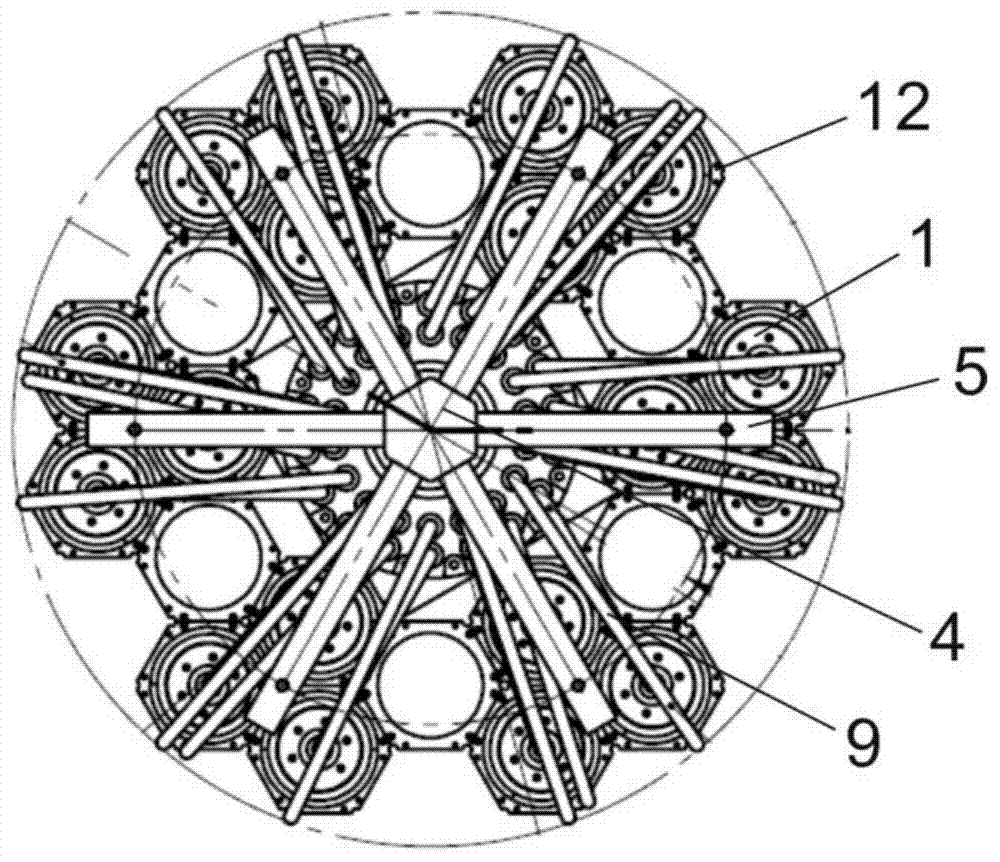

Transmission mechanism of full-automatic multi-impeller washing machine and washing machine and washing mode thereof

InactiveCN101718030ASolution to short lifeImprove poor operating environmentOther washing machinesWashing machine with receptaclesImpellerVertical plane

The invention provides a transmission mechanism of a full-automatic multi-impeller washing machine and a washing machine and a washing mode thereof, relating to the technical field of washing machines, in particular to an full-automatic multi-impeller washing machine; the transmission mechanism of the full-automatic multi-impeller washing machine is mainly composed of a bevel gear part, all bevel gears of the bevel gear part run in the same spherical surface and are all arranged in a closed transmission box, so as to be separated from washing liquid; when in washing, only the impeller rotate, the shell of the transmission box does not rotate, and when in dehydration, the transmission box and an inner barrel rotate together; the rotating directions of the impellers, including forward rotation and reversal rotation, are different when being looked down from the center of the upper opening of the inner barrel, wherein at least one impeller rotate along the opposite direction with the other impellers; when in washing working condition, the clothes is thrown upwards to the great extent, and is rolled in a vertical plane, and the clothes rotate in a horizontal plane simultaneously; in addition, the different throwing phase positions are changed, so as not to lead the clothes to be twined, greatly improve the washing effect of the washing machine and the working efficiency and save the time and the water consumption.

Owner:NINGGUO JULONG IND

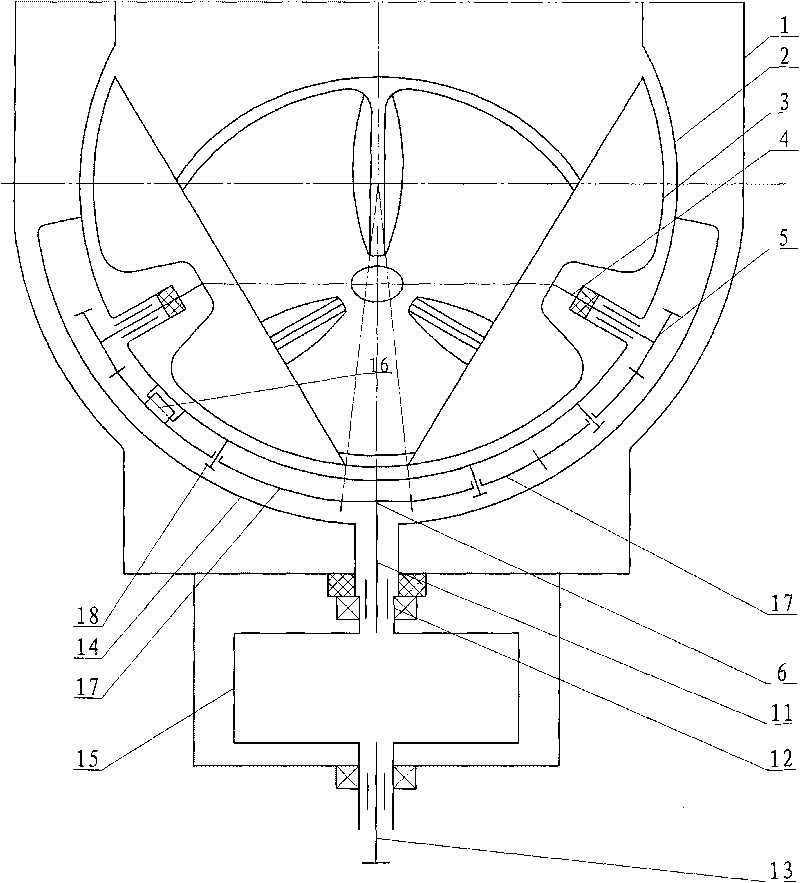

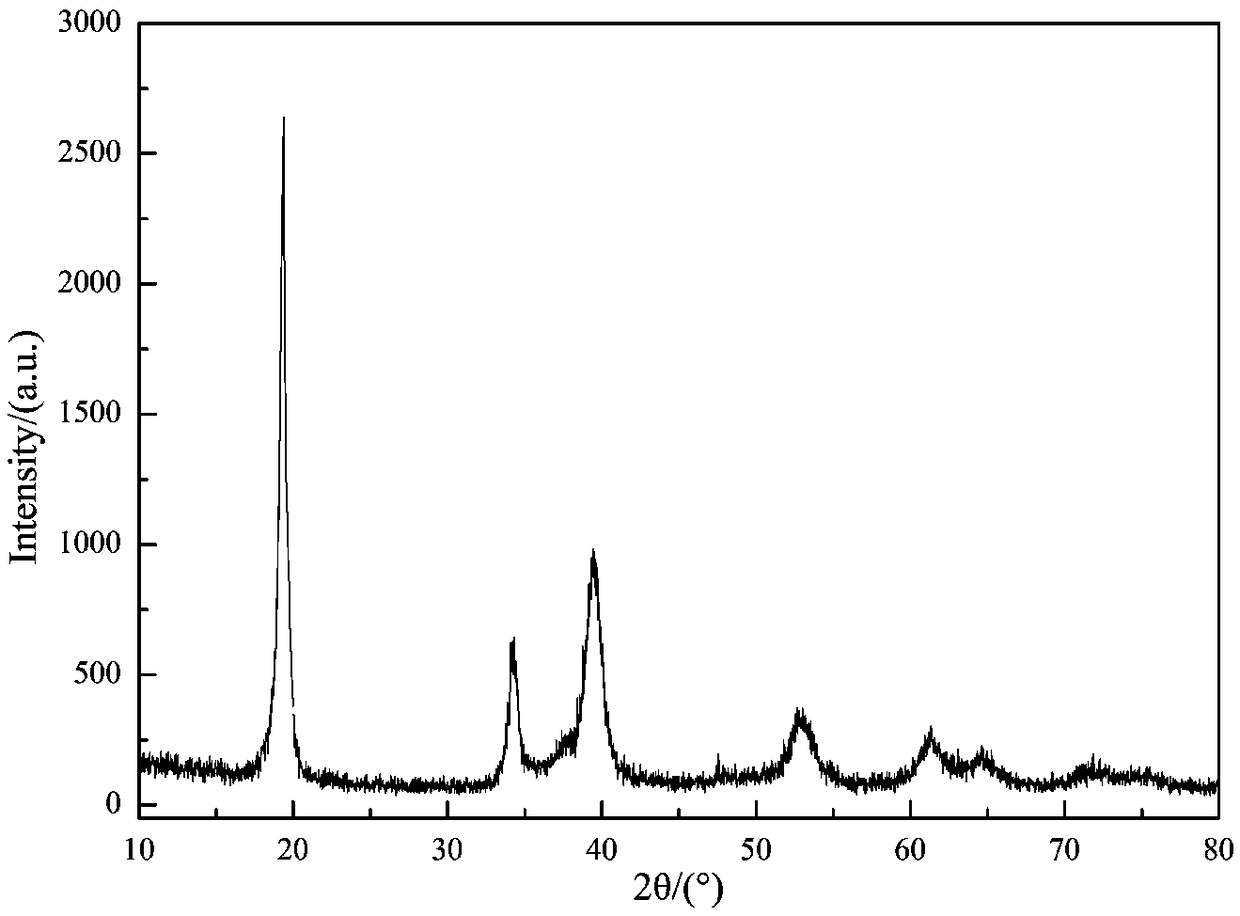

Method of producing pseudo boehmite

ActiveCN101172631AGood effectAchieving low alkali agingAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAluminium oxides/hydroxidesSlurryCarbonation

The invention relates to a preparative method of pseudo-boehmite, belonging to the field of the preparative technology of alumina exclusive of metallurgical usage. The method comprises the steps as follows: sodium metaaluminate solution is carbonated into mucus, aging, separating, washing and drying. The invention is characterized in that after the sodium metaaluminate solution becomes mucus, pulp-liquid separation is carried out primarily; filter cake is added; heating and aging are performed after water washing and mixed pulping. The invention has the advantages of low washing water consumption, low production cost, easy control of product quality and good practicality.

Owner:中铝山东新材料有限公司

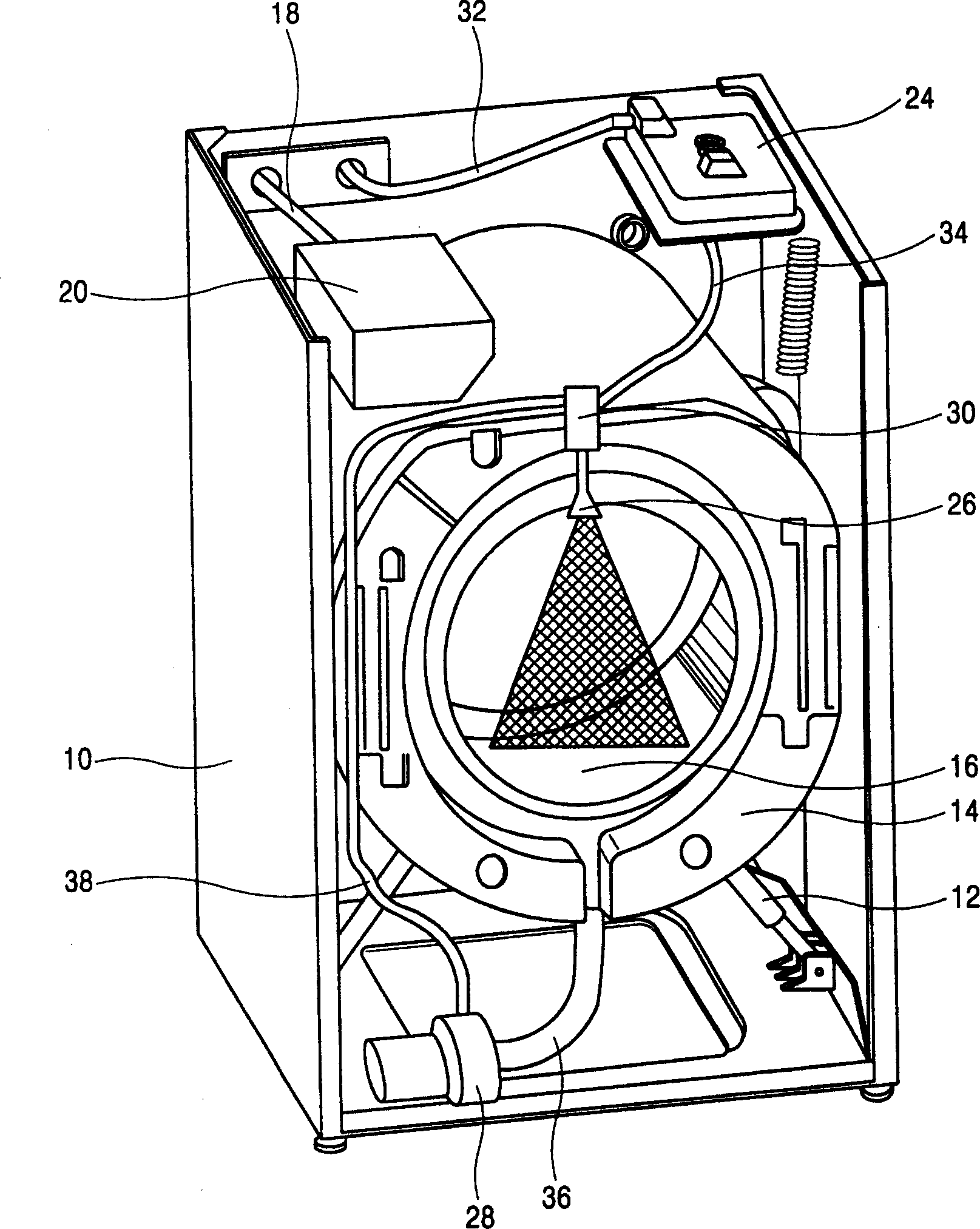

Washing machine provided with ultra-fine bubble generating device

InactiveCN105986400AImprove dissolution rateReduce usageOther washing machinesTextiles and paperPollutant emissionsUltra fine

The invention relates to the field of household appliances, in particular to a washing machine provided with an ultra-fine bubble generating device. The washing machine comprises a case body and an outer tub installed in the case body, wherein an inner tub is rotatably arranged in the outer tub, at least one ultra-fine bubble generating device is arranged between the case body and the outer tub, a gas-liquid mixing outlet of each ultra-fine bubble generating device is communicated with the outer tub, ultra-fine bubbles produced by the ultra-fine bubble generating device enter washing body through the gas-liquid mixing outlet to make a washing agent fully dissolved. The washing ratio of clothes is improved, meanwhile pollutant discharge is reduced, and environmental pollution is reduced.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

Preparation method of white carbon black, as well as white carbon black

Owner:ZHUZHOU XINGLONG CHEM IND

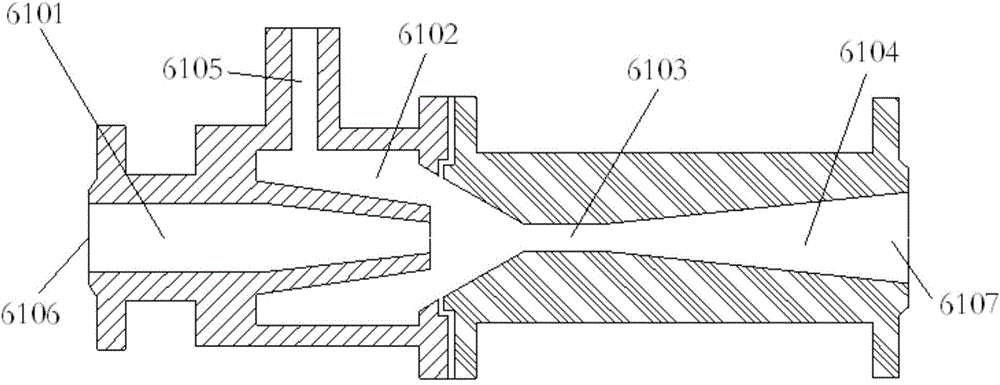

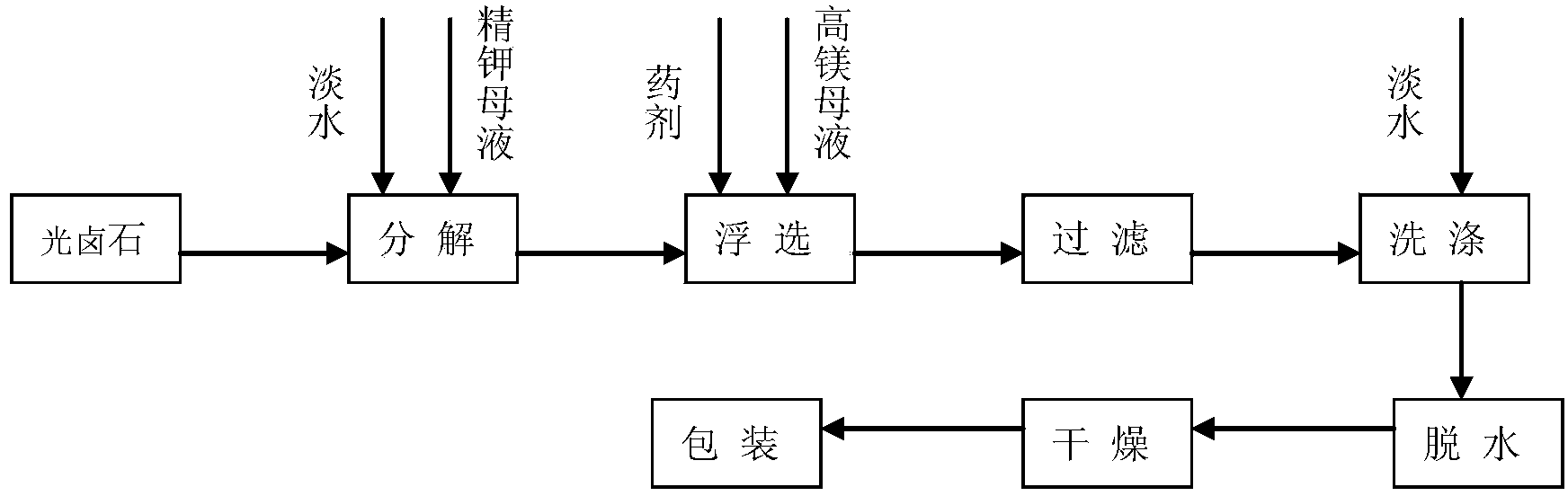

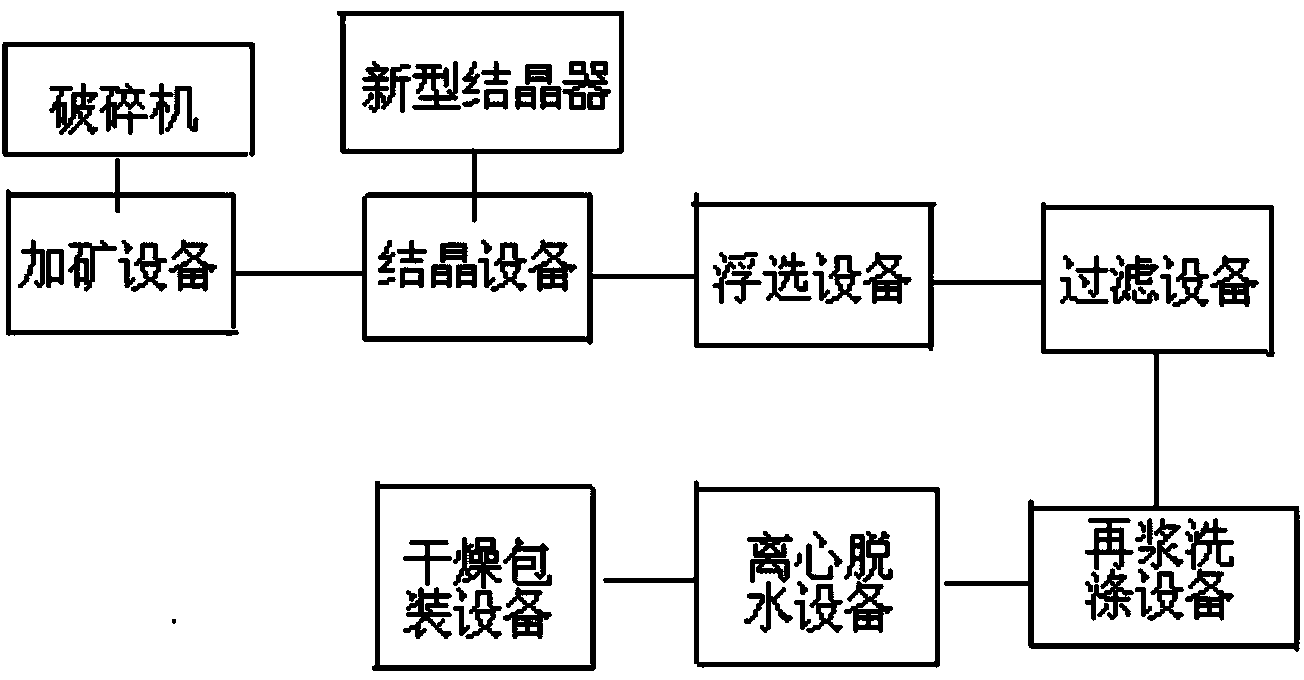

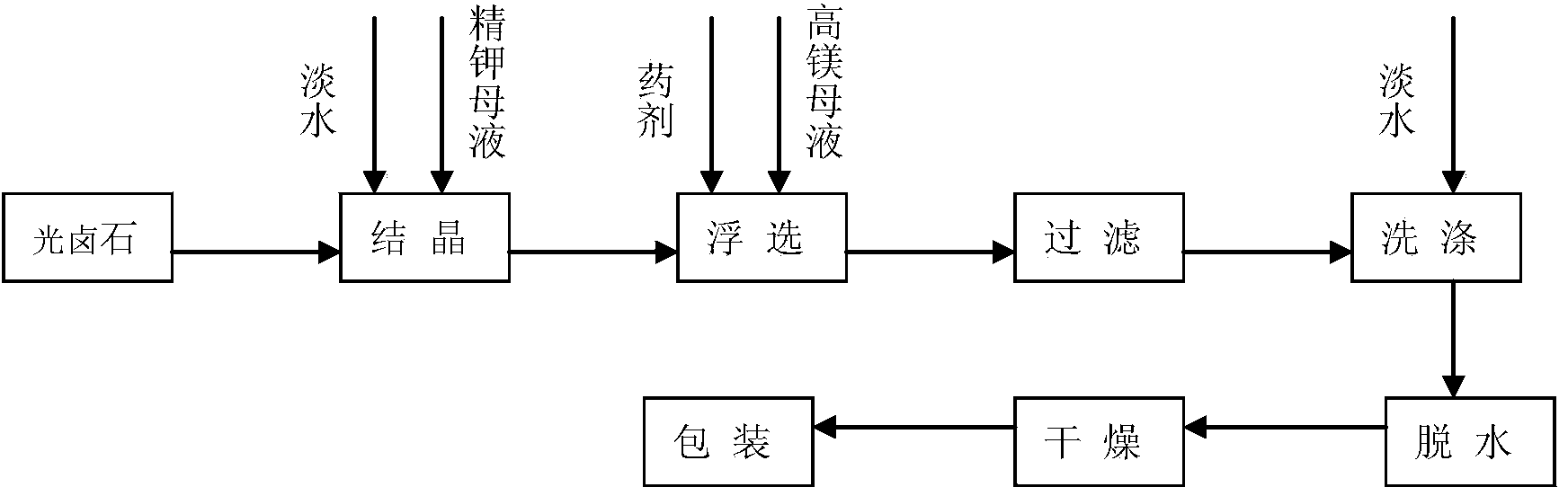

Novel system and method for producing potassium chloride by utilizing carnallite

ActiveCN104058428AHigh recovery rateRealize learning from each otherAlkali metal chloridesDecompositionFiltration

The invention discloses a novel system and method for producing potassium chloride by utilizing carnallite. The novel system for producing the potassium chloride by utilizing the carnallite comprises ore adding equipment, crystallization equipment, floatation equipment, filtration equipment, repulping and washing equipment, centrifuging and dehydrating equipment and drying and packaging equipment which are sequentially connected; a crushing machine is added on the ore adding equipment, so that a crystallization system can conveniently decompose crystals; meanwhile, in the crystallization equipment, a novel crystallizer invented by the company (described in the specification) is used for replacing carnallite decomposition equipment in the conventional cold decomposition-direct floatation technology. The novel system and method for producing the potassium chloride by utilizing the carnallite have the advantages that production technological conditions of the conventional direct floatation technology are improved, the recovery rate of potassium chloride is increased to 60%, a potassium chloride product with the purity of 90% is eliminated, the purity of the potassium chloride product is increased to 93-95%, product granularity is increased, and energy consumption is reduced.

Owner:QINGHAI SALT LAKE IND

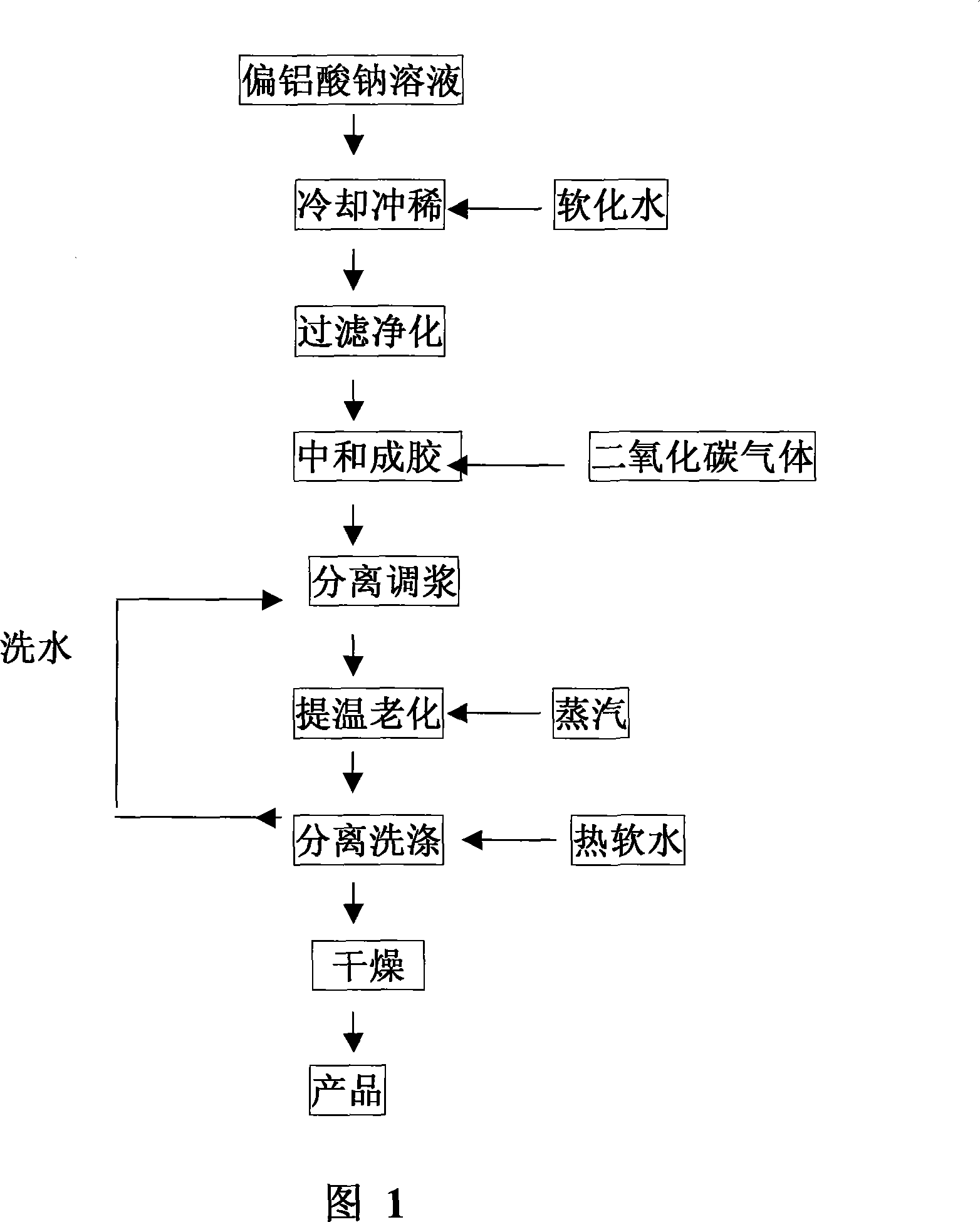

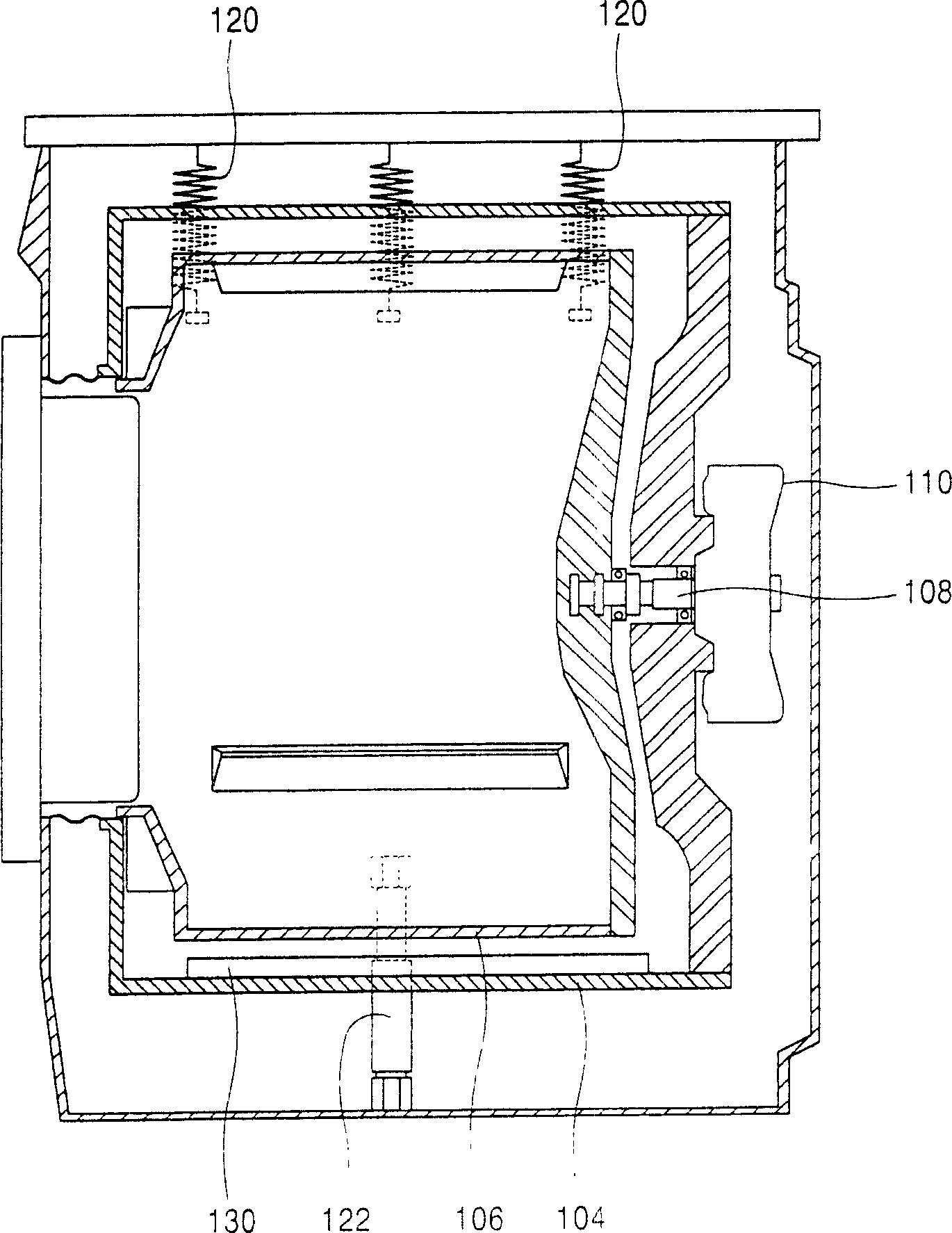

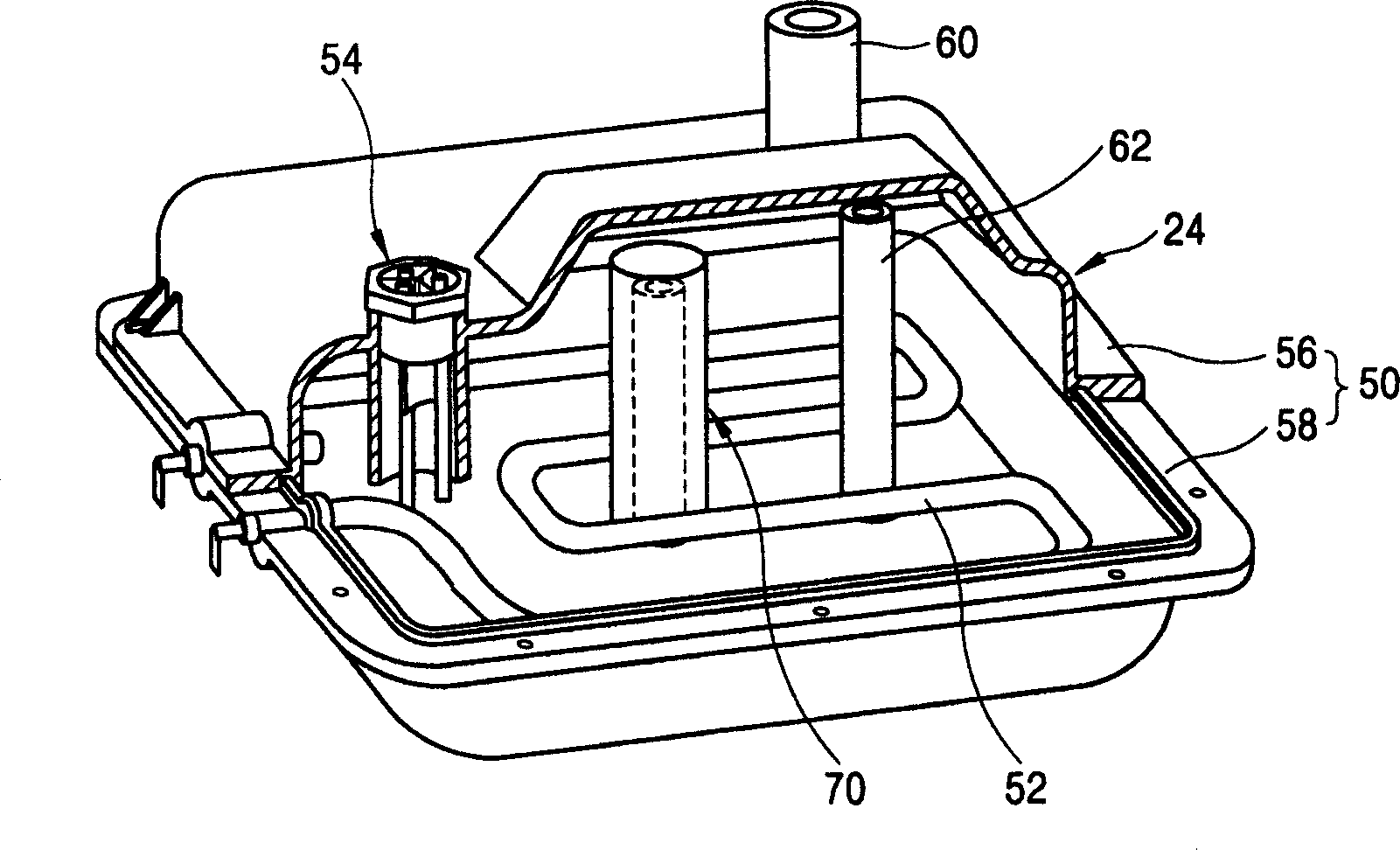

Heating apparatus of washing machine and control method thereof

ActiveCN1580369ASmall sizeReduce washing water consumptionOther washing machinesControl devices for washing apparatusProcess engineeringWater supply

A heating apparatus of a washing machine comprises: a steam generator for generating steam; and a spray nozzle for spraying steam generated from the steam generator into a tub, in which a water level sensor for detecting a level of water supplied for steam generation step by step is mounted at the steam generator. According to this, an entire size of the washing machine is reduced, an amount of washing water is reduced, and a water level inside the steam generator is detected more accurately, thereby enhancing a performance of the heating apparatus.

Owner:LG ELECTRONICS INC

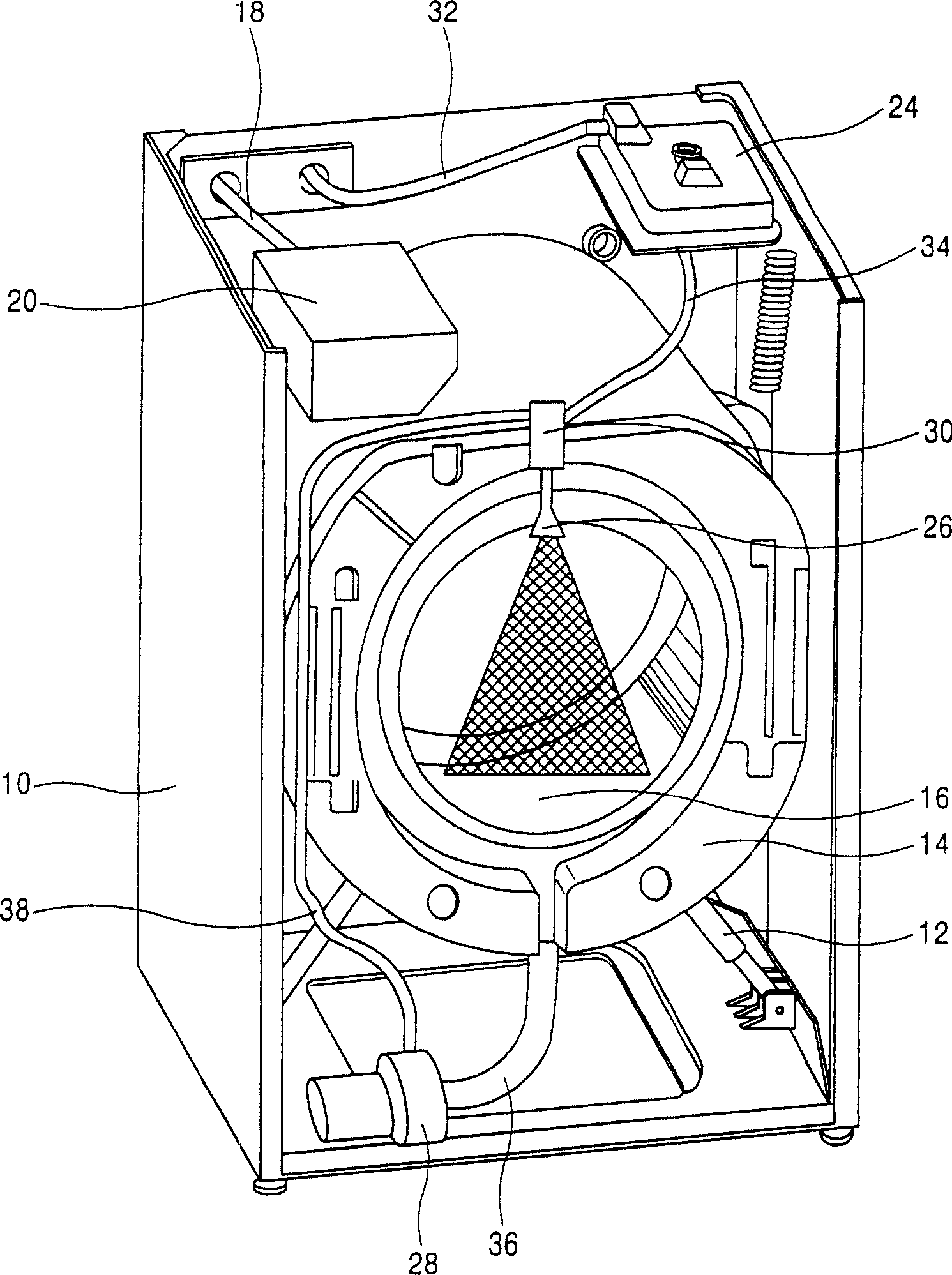

Steam generator for washing machine

InactiveCN1580371AReduce volumeReduce washing water consumptionSteam generation heating methodsOther washing machinesProcess engineeringWater supply

A steam generator for a washing machine comprises: a hermetic container provided with a water supply port for supplying water and a steam exhaustion port for exhausting steam; a heater arranged in the hermetic container for heating water supplied into the hermetic container; and a drain unit for draining residual water inside of the hermetic container outwardly. According to this, residual water inside of the steam generator is outwardly exhausted thus to maintain cleanness of the steam generator. Also, the drain unit using a siphon principle is installed thus to naturally exhaust residual water inside of the steam generator without an additional valve device, thereby reducing a fabrication cost.

Owner:LG ELECTRONICS INC

Agglomeration washing method of fluorinated ethylene propylene

This invention discloses a method for condensing and washing perfluoroethylene-perfluoropropylene copolymer prepared by emulsion polymerization. The method comprises: (1) adding 1-10 deg.C deionized water to perfluoroethylene-perfluoropropylene copolymer emulsion, stirring, demulsifying, and washing the precipitate with 40-80 deg.C deionized water for 2-6 times (1-5 min for each time). The method can largely increase the equipment productivity, lower the consumption of pure water, save the raw materials, and shorten the treatment period.

Owner:SHANDONG HUAXIA SHENZHOU NEW MATERIAL

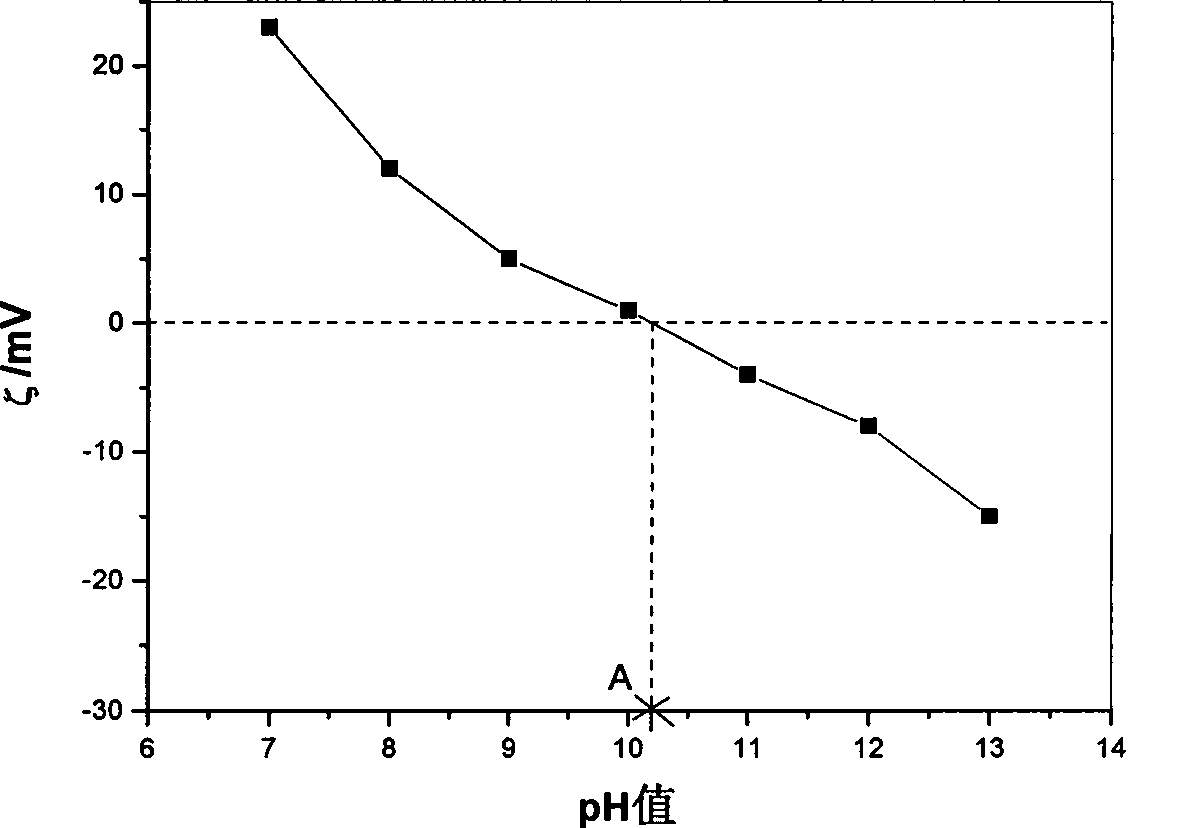

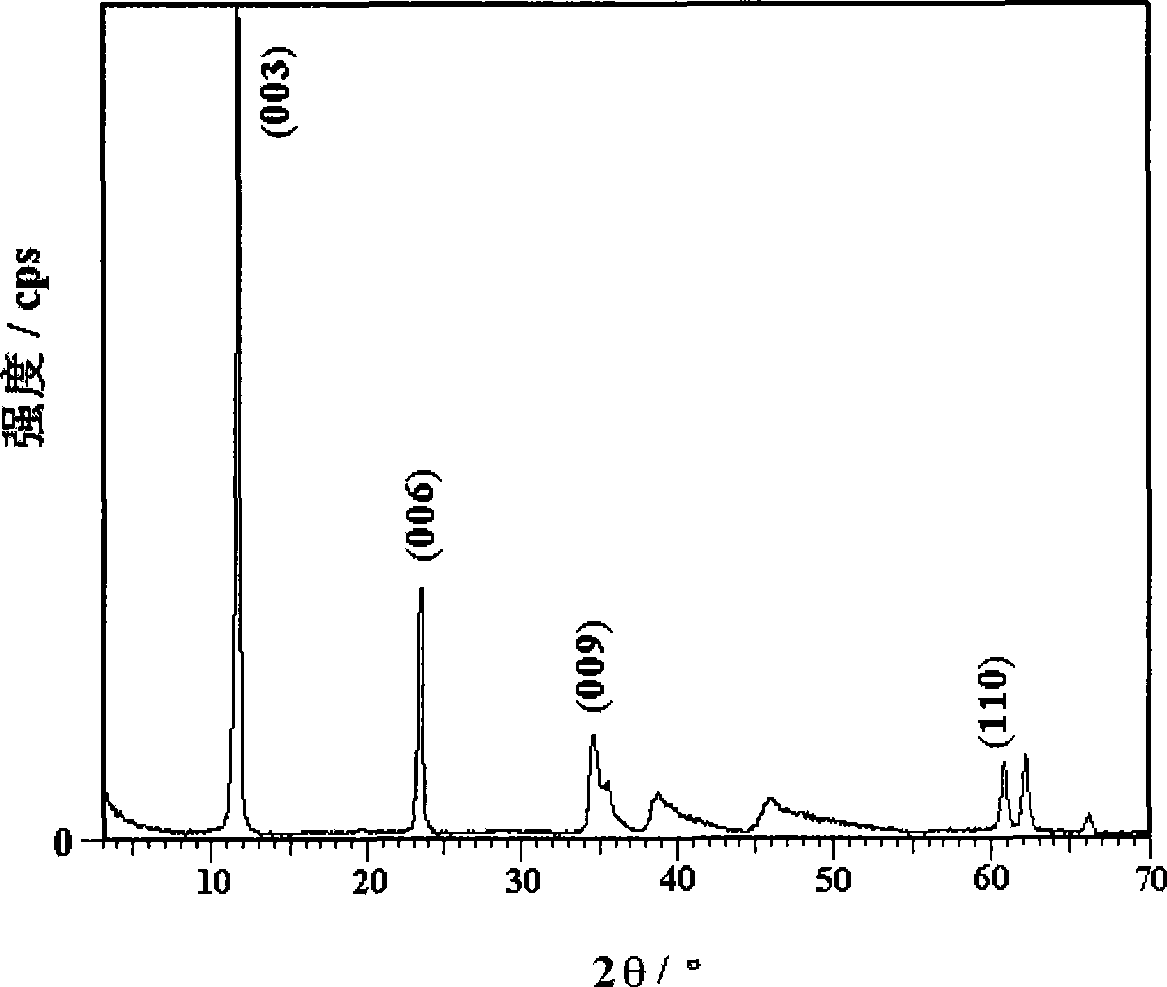

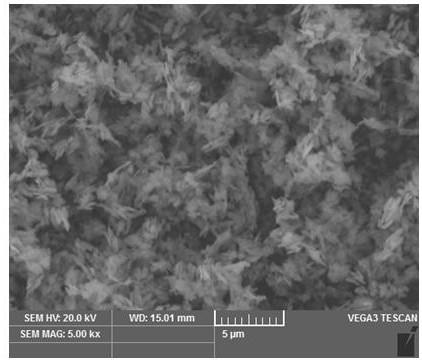

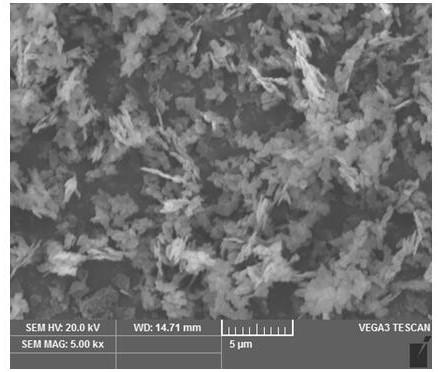

Method for in situ modification by isoelectric point layered composite metal hydroxides

InactiveCN101503182AAvoid reunionEasy to modifyOxide/hydroxide preparationAluminium oxides/hydroxidesInorganic particleFiltration

The invention provides a technology for carrying out surface in situ modification on clad composite metal hydroxid by using isoelectric points. After the clad composite metal hydroxid is prepared for reaction, the system PH value is adjusted to be lower than the isoelectric points of particles before washing, and then modifying agent is directly added for in situ modification so as to lead modifying agent molecules and surface groups of inorganic particles to have physico chemical adsorption and cover on the surface, thus achieving good modification effect. After modification, products can quickly float on the water, so that the process of separation and filtration can be simplified. The method not only effectively avoids ion glomeration, but also greatly simplifies the washing process, thus reducing water consumption when in washing.

Owner:BEIJING UNIV OF CHEM TECH +1

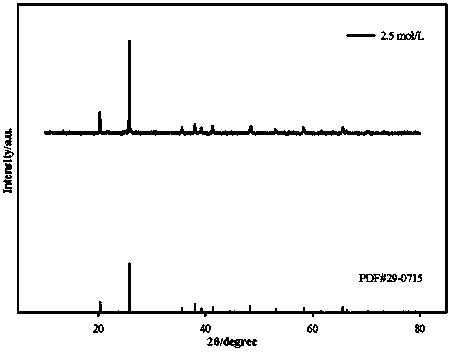

Preparation method for iron phosphate nanosheets

ActiveCN110294466AHigh purityAvoid interferenceMaterial nanotechnologyPhosphorus compoundsFiltrationPhosphate

The invention discloses a preparation method for iron phosphate nanosheets. The preparation method comprises the steps that iron black is slowly added to phosphoric acid with the concentration of 1.5-3.0 mol / L, stirring and heating are conducted for reacting, and after the reaction, the iron phosphate nanosheets are obtained through suction filtration, washing, drying, dewatering and other steps.The iron phosphate prepared by using the method has a nanosheet-shaped morphology, the thickness of the nanosheets is 70-80 nanometers, and the specific surface area is high. By optimizing the reaction conditions, in the reaction procsess, the pH value does not need to be adjusted, and no oxidizing agents are added; the interference with anionic and cationic impurities is effectively avoided, theiron phosphate obtained by using the method is free of impurity phases and high in purity. Besides, less water is used for washing iron phosphate precipitation, the iron phosphate synthesizing cost isreduced, and the pollution to the environment is reduced. The technology is simple, operation is convenient, industrial production is facilitated, and the preparation method is wide in application prospect.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

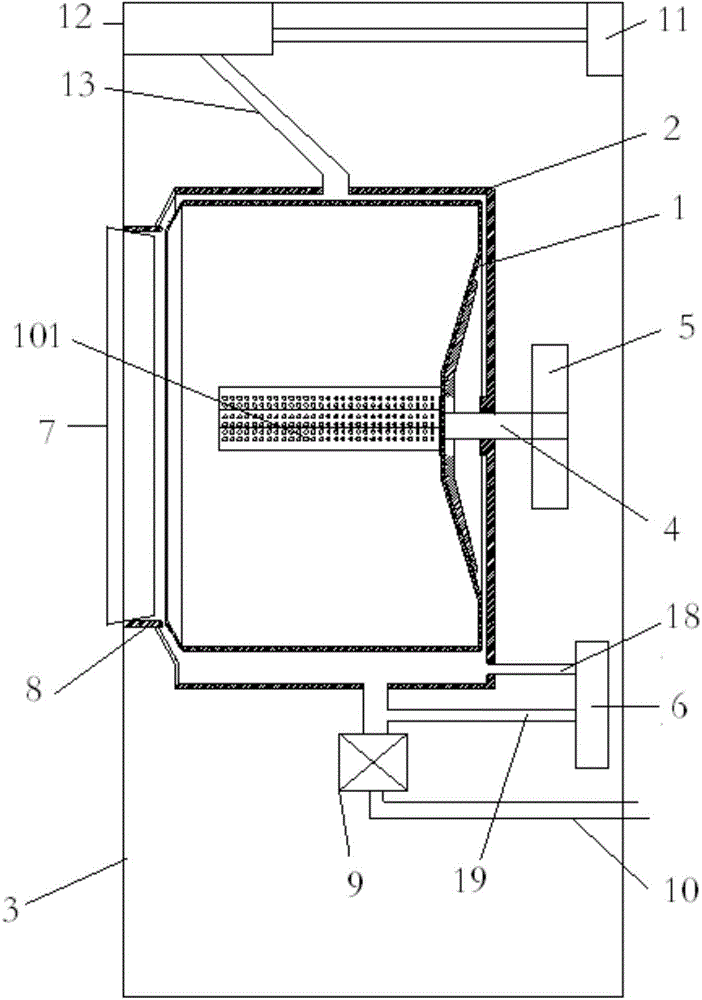

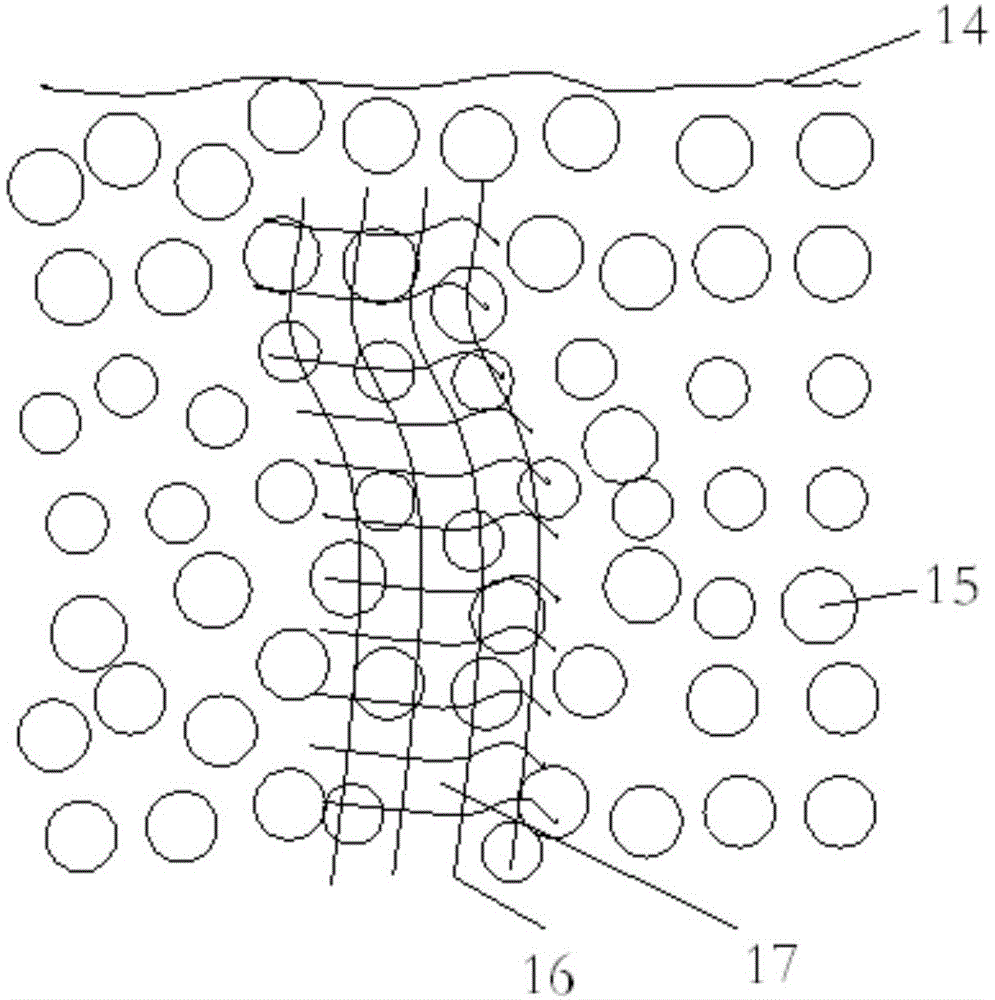

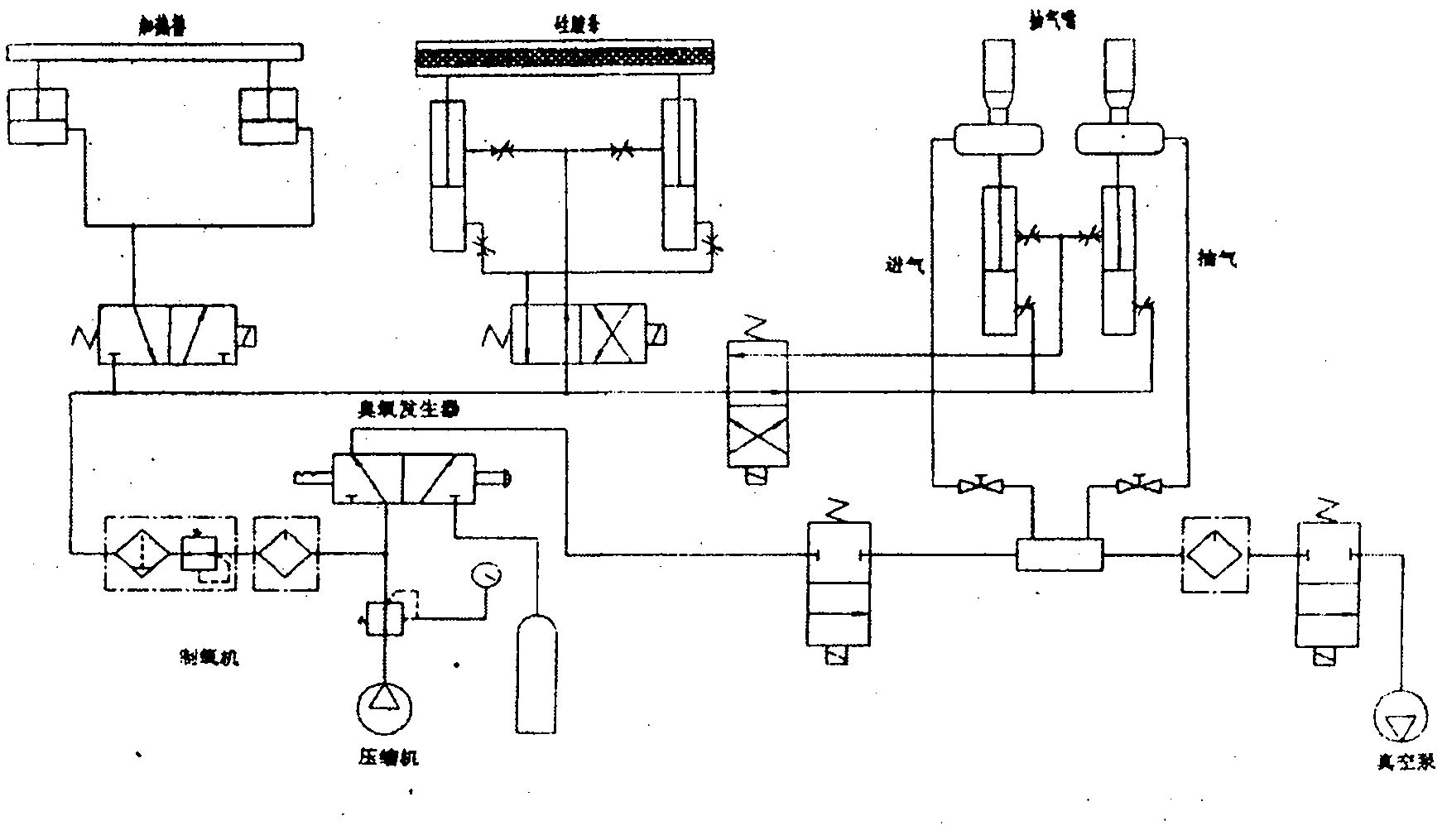

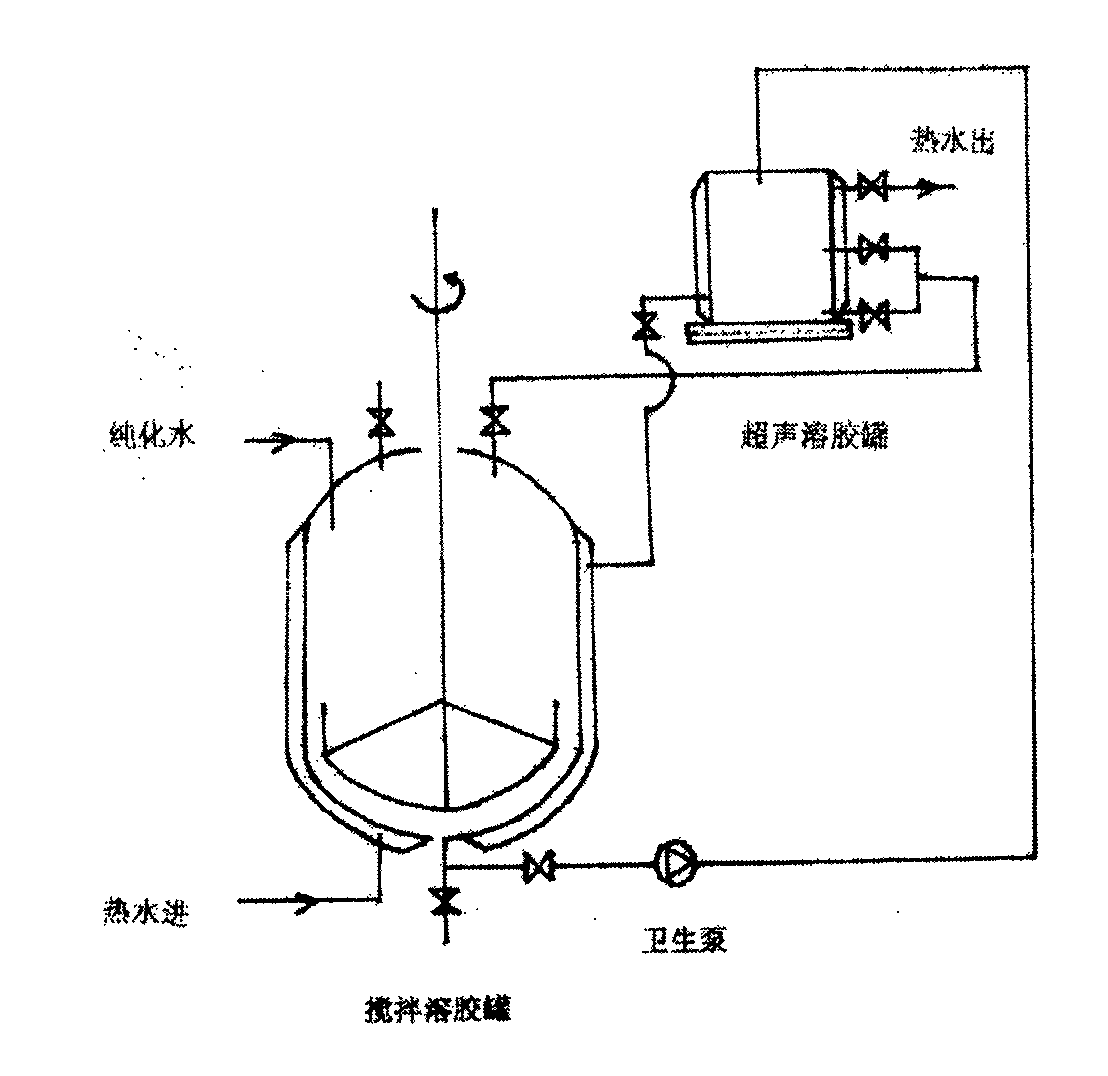

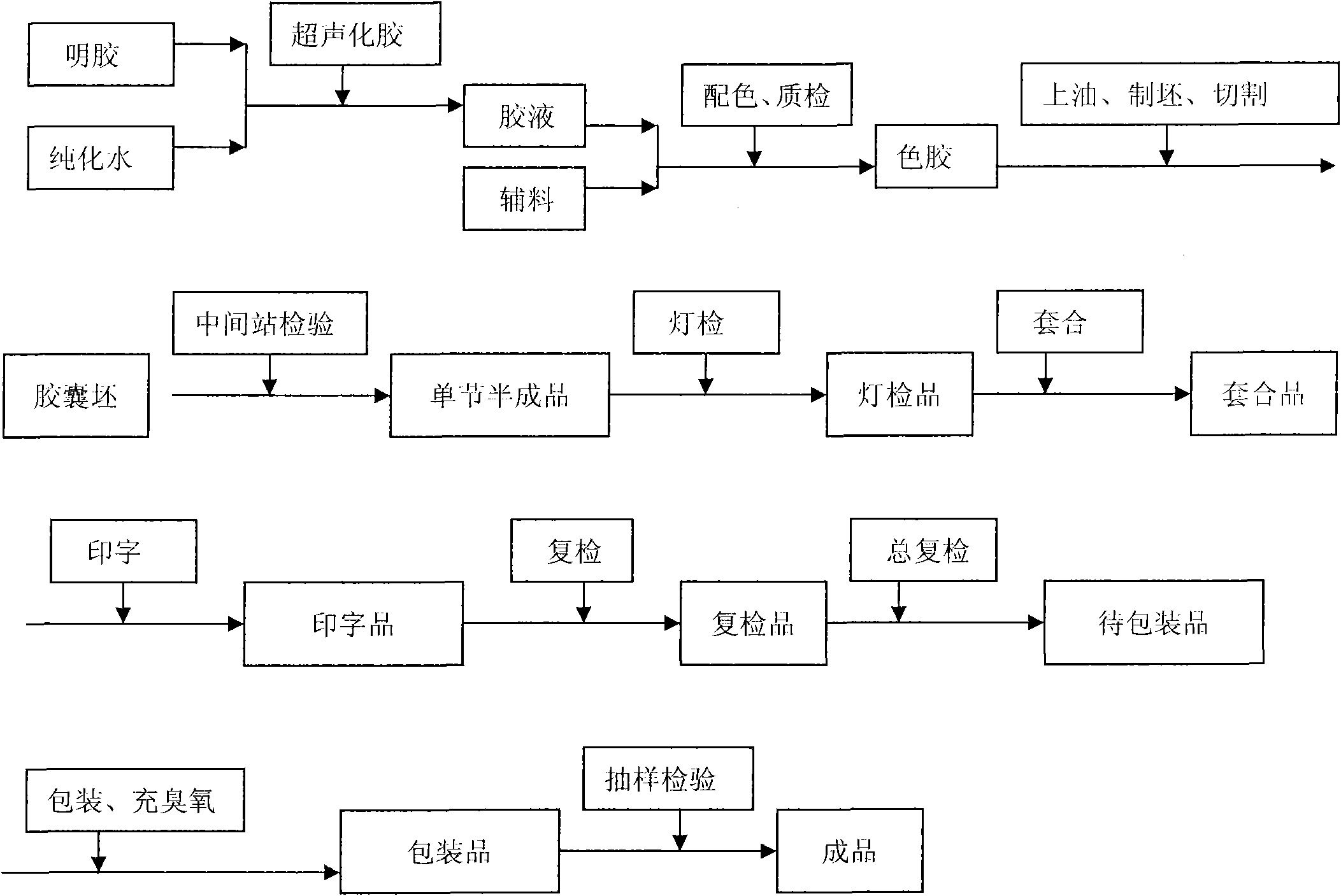

Medicinal hollow capsules and preparation method and manufacturing equipment thereof

ActiveCN101953816AMedication safetyViolent impactCapsule deliveryMacromolecular non-active ingredientsPreservative freeActive agent

The invention relates to the technical fields of medicinal auxiliary materials and preparation methods and equipment thereof in the biopharmaceutical industry, in particular to medicinal hollow capsules and preparation method and manufacturing equipment thereof. The medicinal hollow capsules consist of gelatin, water, a surfactant, a coloring agent and / or an opacifier. The preparation method comprises the following steps of gelatin dissolution; color blending; and sterilization, wherein in the step of gelatin dissolution, ultrasonic gelatin dissolution or a mode of combining ultrasound and stirring is adopted; and the ozone sterilization is adopted in the step of sterilization. The manufacturing equipment comprises gelatin dissolution equipment and sterilization equipment, wherein the gelatin dissolution equipment is fully made of stainless steel; and the ozone sterilization device is a semi-automatic or full-automatic sterilization device. The capsules do not contain any preservative and are safe to medicate; the production process is favorable for environmental protection due to less wastewater discharge; and the ozone sterilization is thorough without residue.

Owner:ZHEJIANG ANGLIKANG CAPSULE

Poly-p-phenylene terephthamide (PPTA) polymer washing and solvent recovery method

The invention provides a poly-p-phenylene terephthamide (PPTA) polymer washing and solvent recovery method. The method comprises the steps of washing a PPTA polymerization product by aliphatic halogen alkane, separating NMP (N-methyl-2-pyrrolidone) and part calcium chloride from the PPTA polymer in a washing way, and washing the PPTA polymer by water to obtain PPTA resin with high purity. The method has the advantages that the energy consumption is low, the water consumption is reduced, the wastewater treatment pressure is reduced, the purification efficiency is high, the halogen alkane washing solution can be directly circulated into a polymerization process for use, and the like.

Owner:AFCHINA CORP CO LTD +1

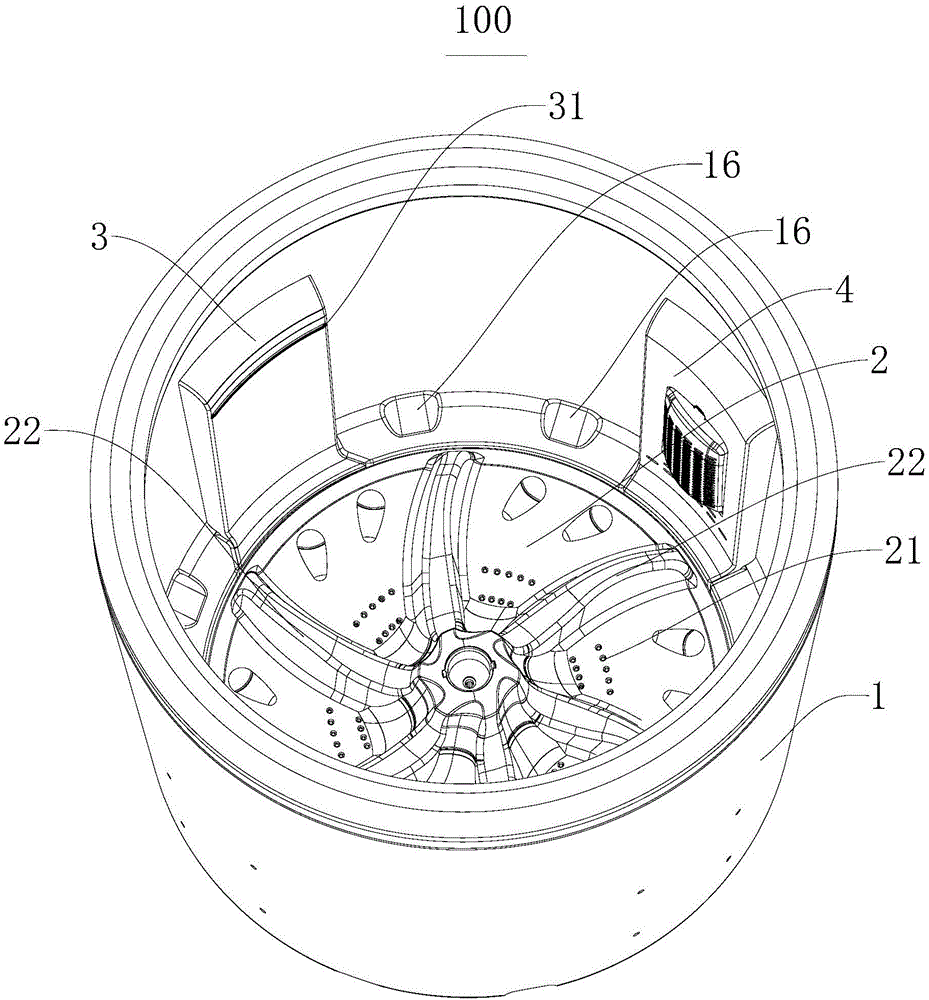

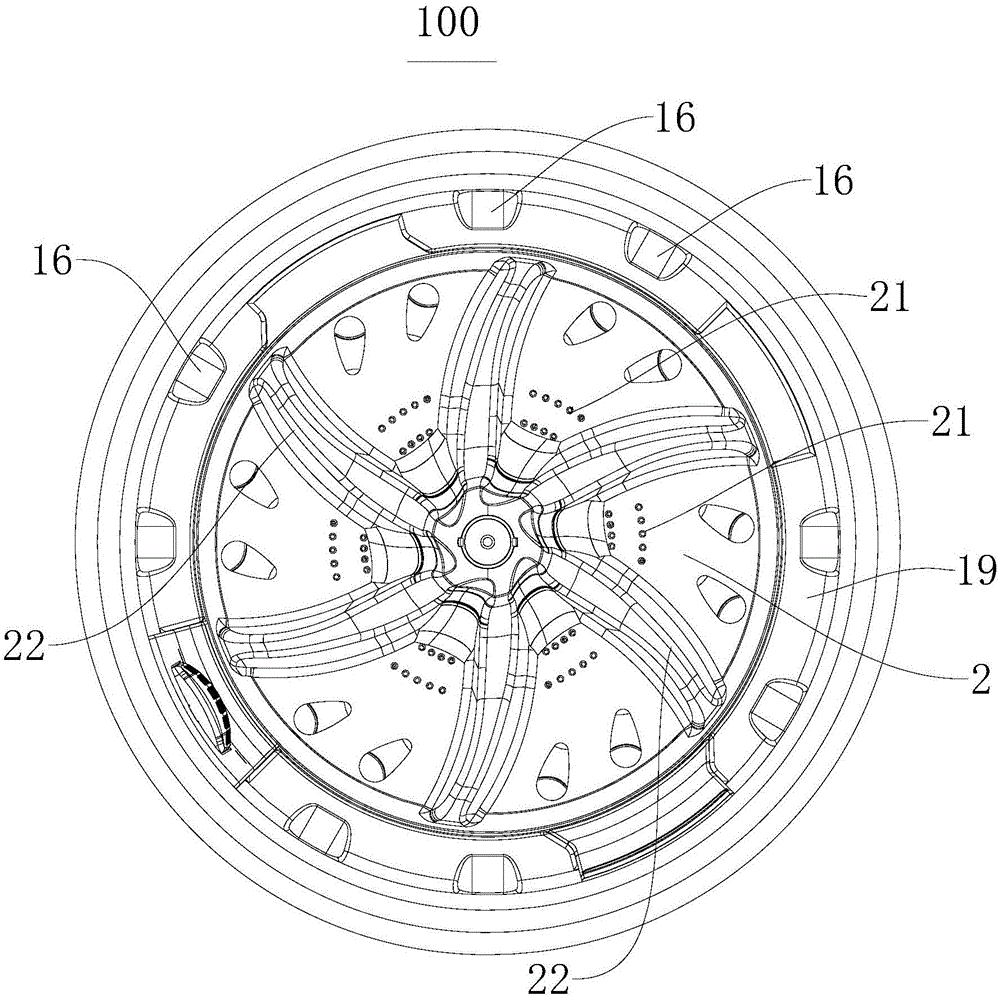

Impeller-type washing machine

ActiveCN106757960AReduce water consumptionAvoid the problem of easy dirtOther washing machinesWashing machine with receptaclesImpellerWater flow

The invention discloses an impeller-type washing machine. The impeller-type washing machine comprises a washing drum, an impeller, at least one water jetting plates and at least one water supplementing plate; the impeller is rotatably arranged in the washing drum; the water jetting plates are arranged in the washing drum, and the water jetting plates and the inner side wall of the washing drum are arranged in a spaced mode, so that water jetting channels are defined out, water jetting openings are formed in the water jetting plates, and the water jetting openings and the water jetting channels are used for jetting water into the washing drum; the water supplementing plates are arranged in the washing drum, and the water supplementing plates and the inner side wall of the washing drum are arranged in a spaced mode, so that water supplementing channels communicated with the water jetting channels are defined out, water supplementing openings are formed in the water supplementing plates, and the water supplementing openings are communicated with the water supplementing channels to guide water in the washing drum into the water supplementing channels and guide the water into the water jetting channels. According to the impeller-type washing machine, massive water flow jetting circulation can be kept, and a good washing effect can be guaranteed.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

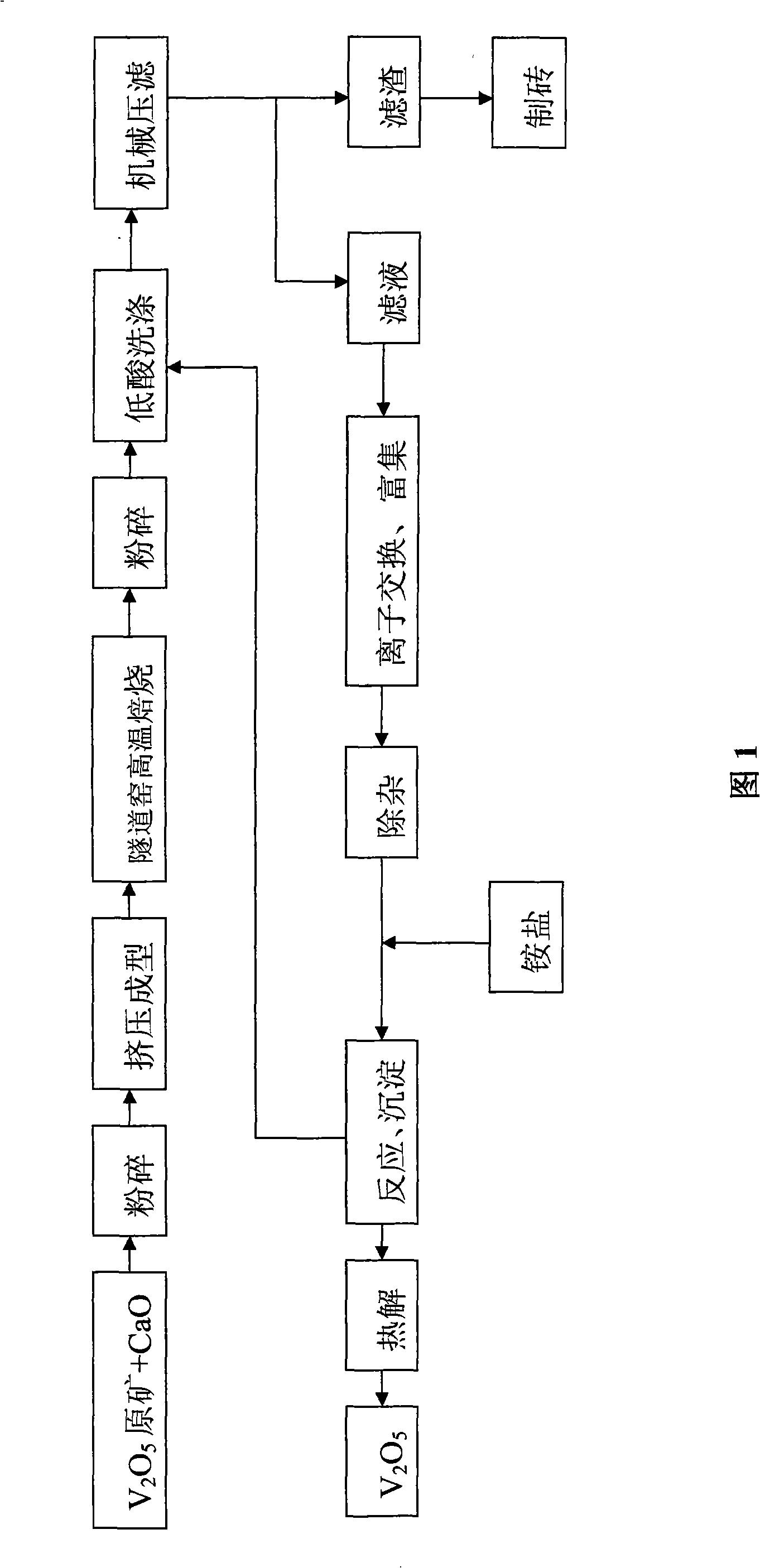

Technique for extracting vanadium pentoxide by tunnel kiln calcification roasting

InactiveCN101265522AEasy to stackReduce sulfur dioxide contentProcess efficiency improvementTunnel kilnBrick

The invention relates to a method for extracting vanadium pentoxide by calcification and calcination of tunnel kiln coal gas, which comprises the steps of: mixing mineral soil and calcium oxide at a proper proportion, crushing, squeezing to obtain bricks, stacking on a kiln cart, placing into a coal gas tunnel kiln, calcinating at a certain temperature, pulverizing the calcinated bricks with a ball mill, placing the obtained powder into a large stirring tank, leaching with low concentration sulphuric acid solution under stirring to obtain slurry, press filtering with a press filter, washing, separating, transferring the filtrate to a ion-exchange column for exchange and enrichment, purifying to obtain ammonium metavanadate, and performing thermal decomposition with an electrothermal burning furnace to obtain vanadium pentoxide. The inventive method has the advantages of low production equipment investment, convenient and accurate process condition control, low production operating cost, high product extraction yield (mean value about 75%), and high product purity (over 99%). The exhaust gas emission meets the standards, the waste water is recycled and reused without external discharge, and the waste residues are integrally utilized to produce bricks, so as to realize clean and environmentally friendly production.

Owner:闫国正

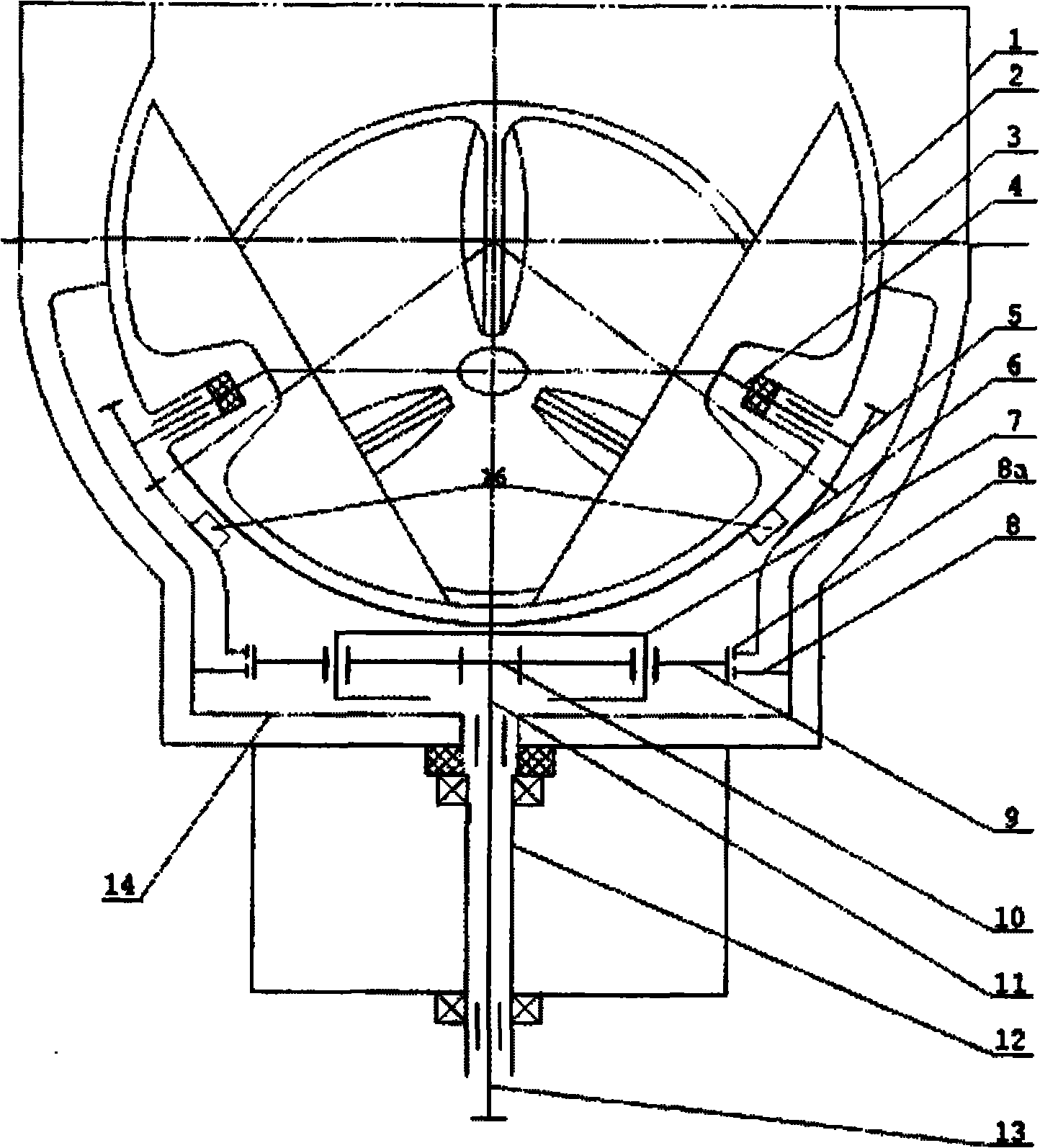

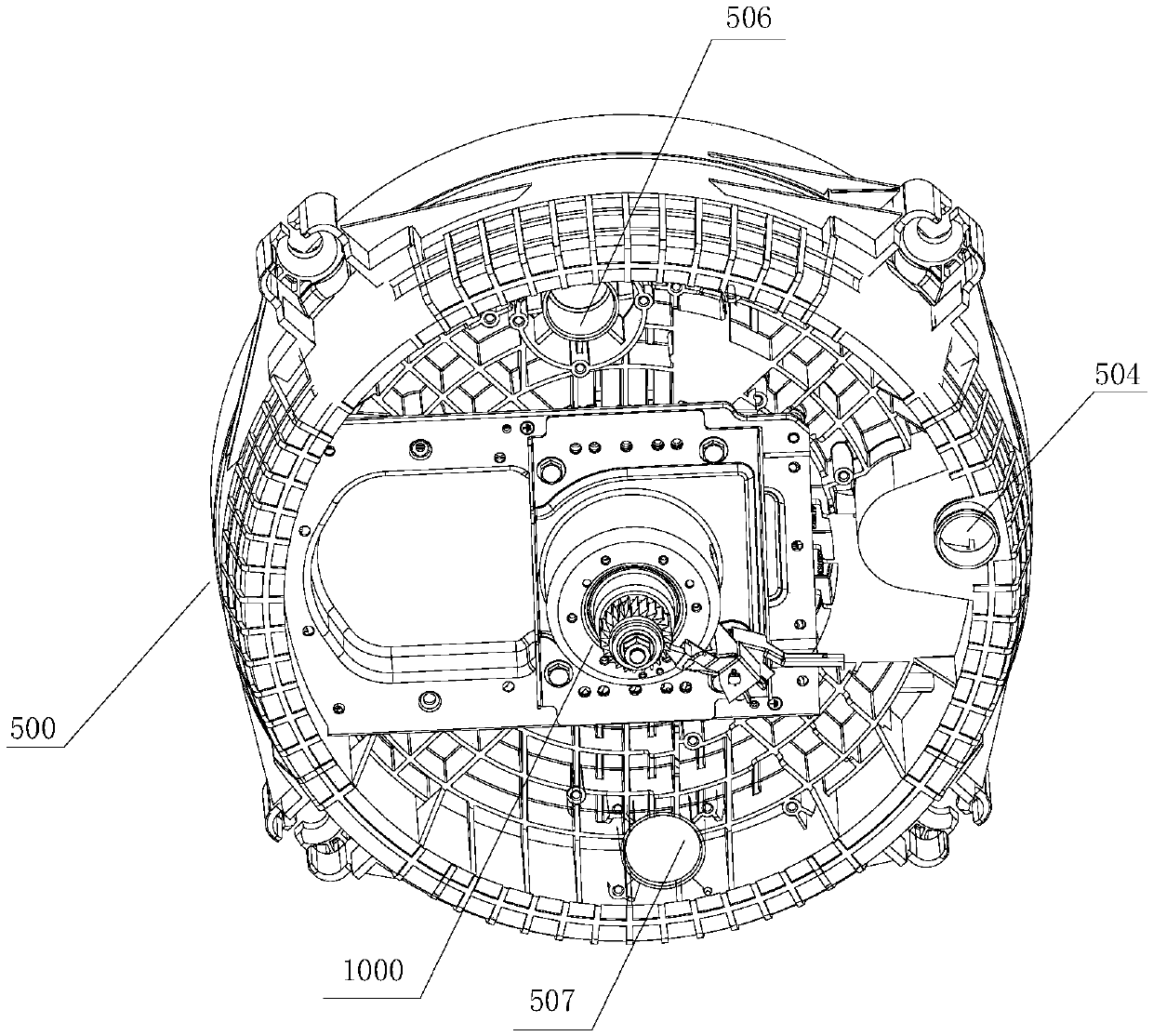

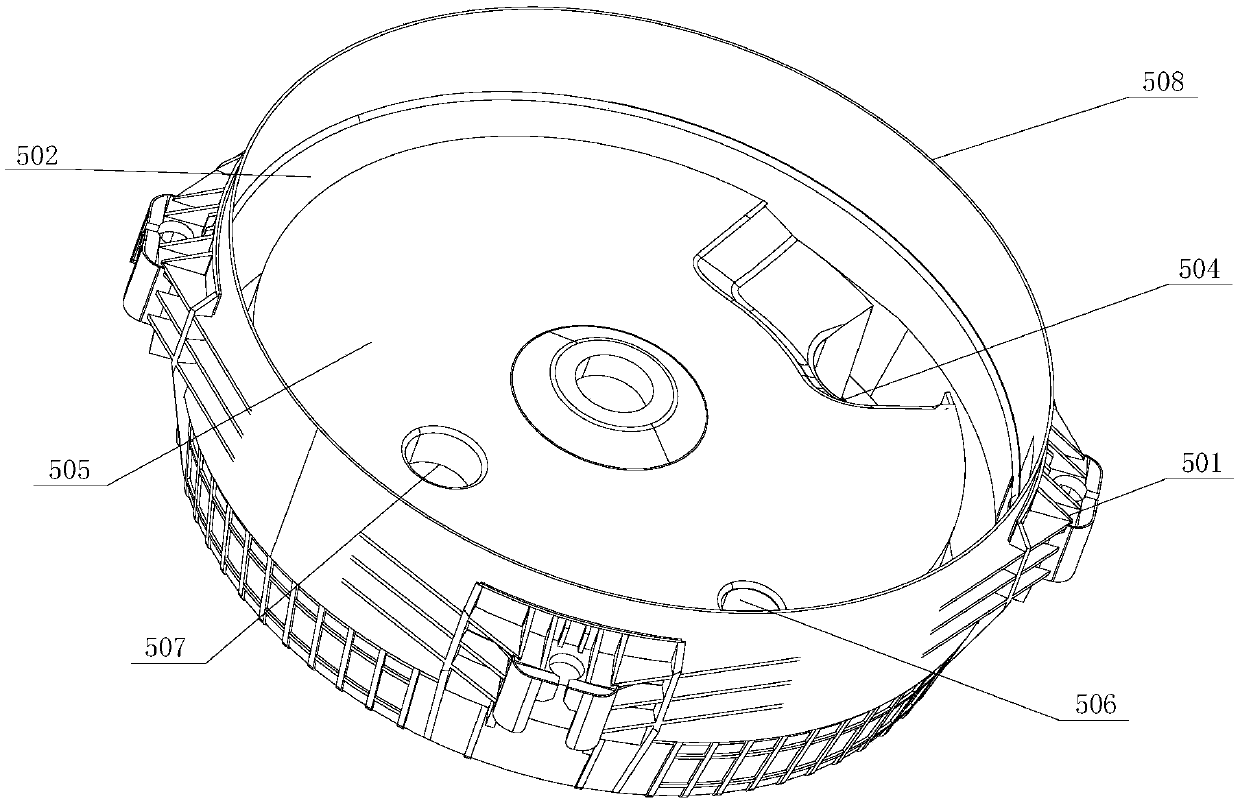

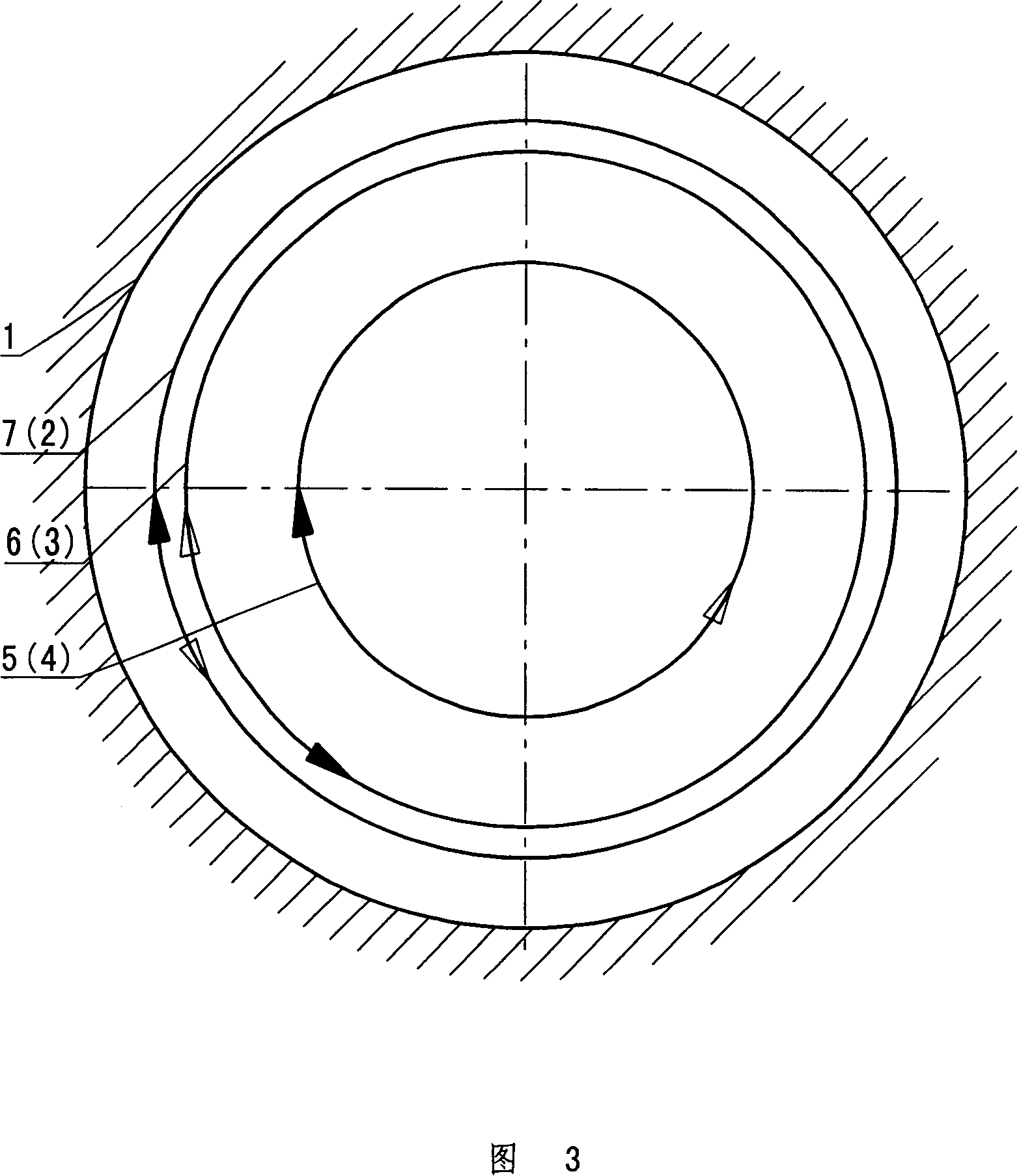

Impeller type washing machine transmission mechanism integrated with inner drum

InactiveCN101906708ASolution to short lifeImprove poor operating environmentOther washing machinesTextiles and paperImpellerGear wheel

The invention discloses an impeller type washing machine transmission mechanism integrated with an inner drum. The transmission mechanism is mainly composed of bevel gear components which are all arranged in a sealed transmission case and are insulated from washing liquid; during washing, only an impeller rotates and the shell of the transmission case does not rotate; and during dehydration, the transmission case and the inner drum rotate together.

Owner:NINGGUO JULONG IND

Preparation method for reducing sulfur content of NCM ternary precursor

ActiveCN109279661AReduce the introductionImprove removal effectCell electrodesSecondary cellsLyonium ionSynthesis Phase

The invention belongs to the field of lithium ion battery materials, and particularly discloses a preparation method for reducing the sulfur content of an NCM ternary precursor. The preparation methodcomprises the following steps: obtaining a nickel-cobalt-manganese ternary solution containing Ni<2+>, Co<2+>, Mn<2+>, SO4<2->, a surfactant and a reducing agent; and then carrying out co-precipitation to prepare the NCM ternary precursor. According to the preparation method provided by the invention, a processing idea of carrying out washing after a precursor is synthesized in the prior art is changed, and a processing idea of controlling sulfur introduction from a synthesis stage is provided. The surfactant and the reducing agent are creatively added into a NCM raw material solution, and co-precipitation is carried out under the solution system, so that the sulfur content of the obtained precursor can be remarkably reduced.

Owner:湖南鸿捷新材料有限公司

Washing machine

PendingCN106757959AImprove work performanceImprove cleaning ratioOther washing machinesWashing machine with receptaclesImpellerWater flow

The invention discloses a washing machine which comprises an outer cylinder, an inner cylinder, a plurality of water flow passage plates, an impeller disk and a plurality of floating blocks. The inner cylinder is arranged in the outer cylinder and spaced apart from the outer cylinder. The water flow passage plates are spaced apart along the circumference of the inner cylinder. Each of the water flow passage plates and an inner wall of the inner cylinder limit a water flow passage. Each of the water flow passage plates is provided with a plurality of sprays arranged along its length. The impeller disk is rotatably provided at the bottom of the inner cylinder. A water exclusive chamber is defined between the impeller disk and the bottom of the inner cylinder. One side of the impeller disk facing the water exclusive chamber is provided with a water drainage rib. A plurality of floating blocks is movably provided on one side of the water flow passage plates facing away from the water flow passage to open and close the corresponding water sprinklers according to the water level of the inner cylinder. The washing machine improves the strength and the amount of the jet spray water flow, improves the washing ratio of the washing machine, and reduces the washing water amount.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

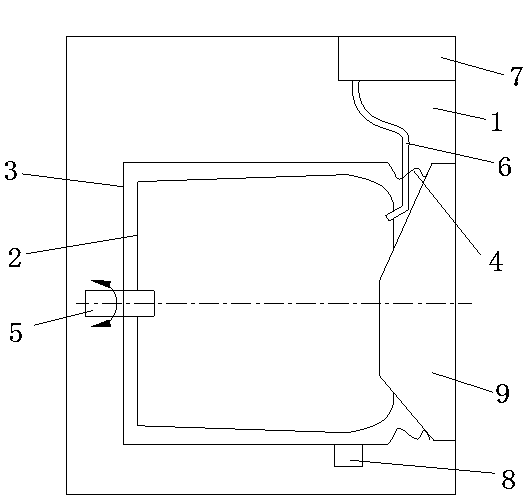

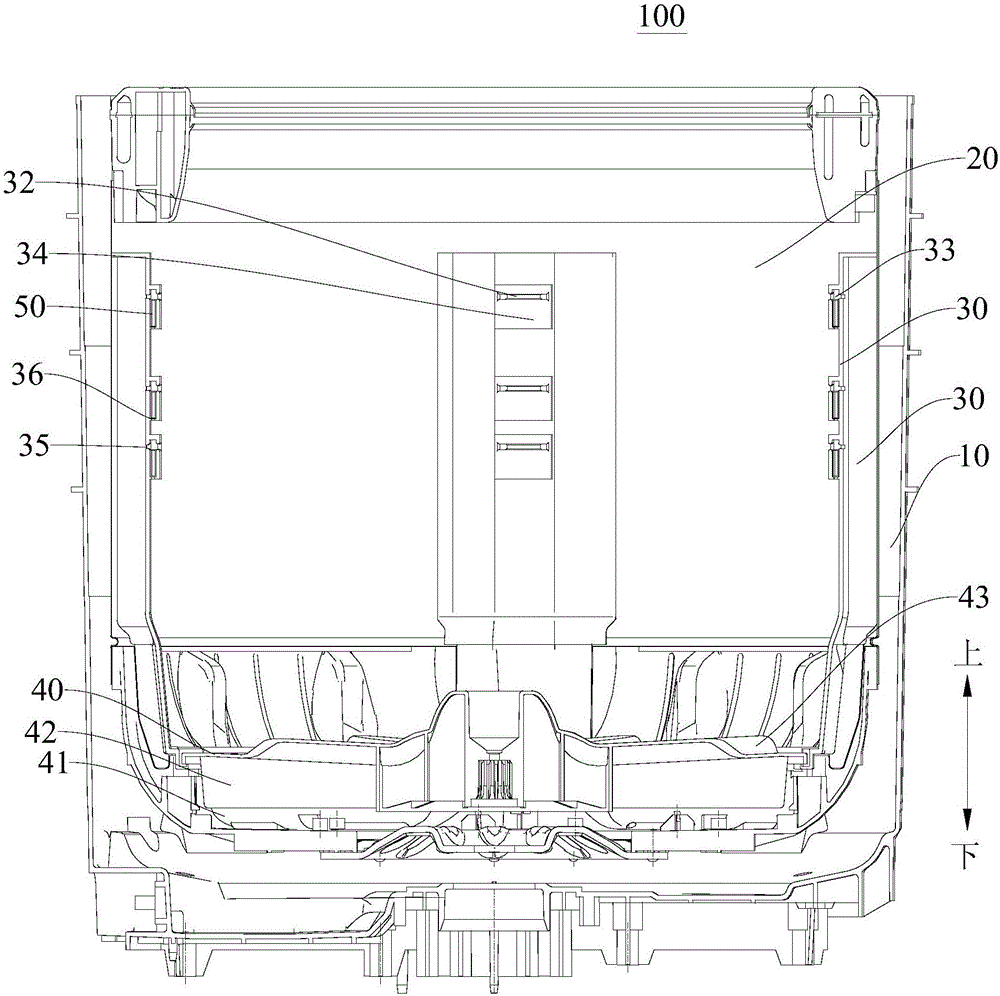

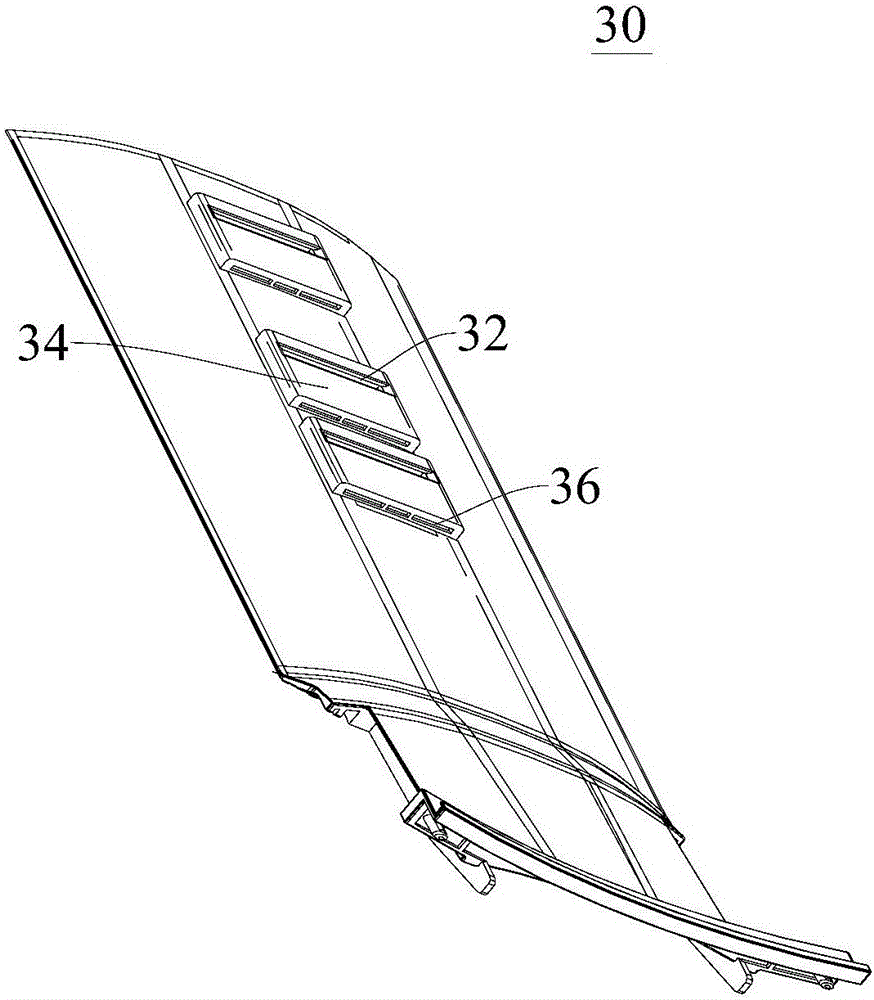

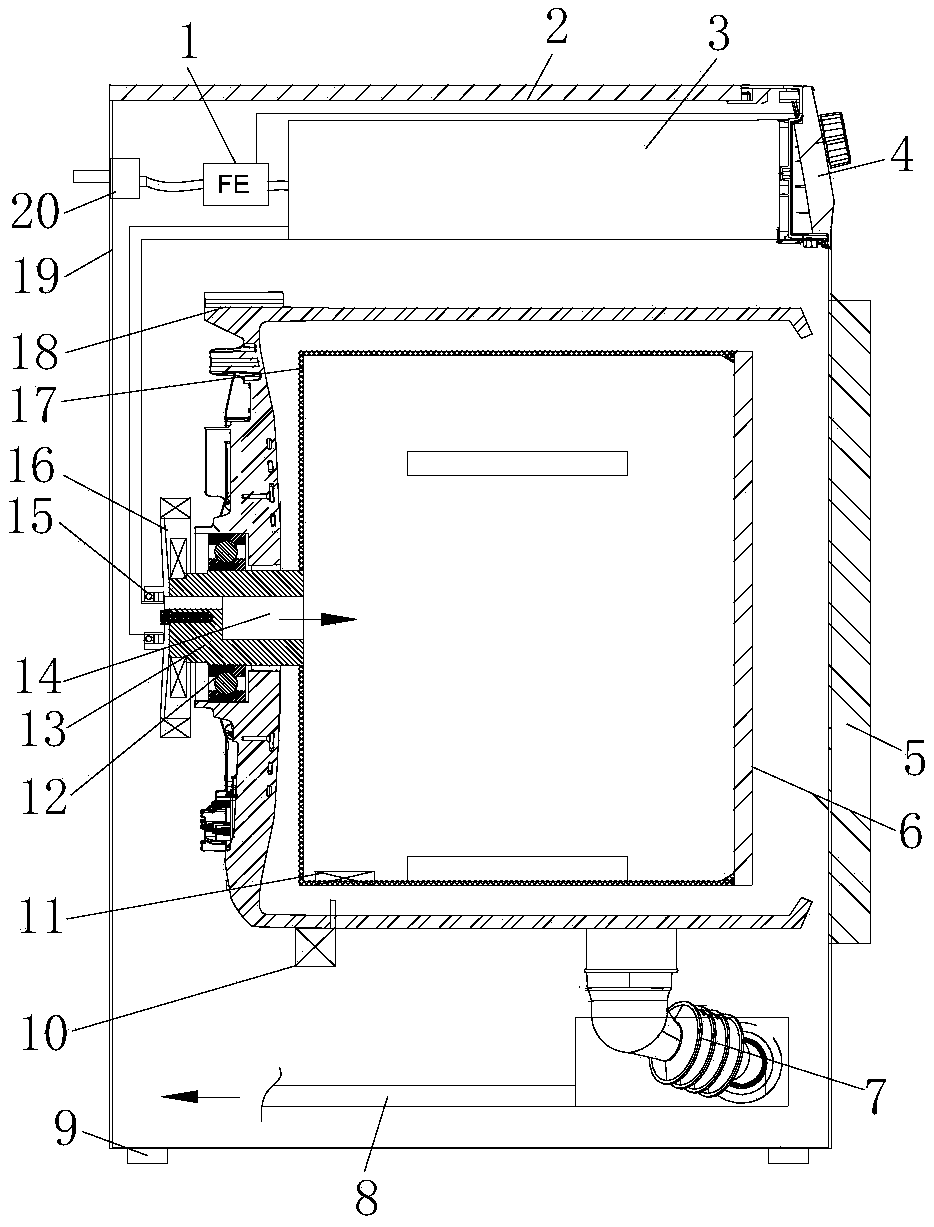

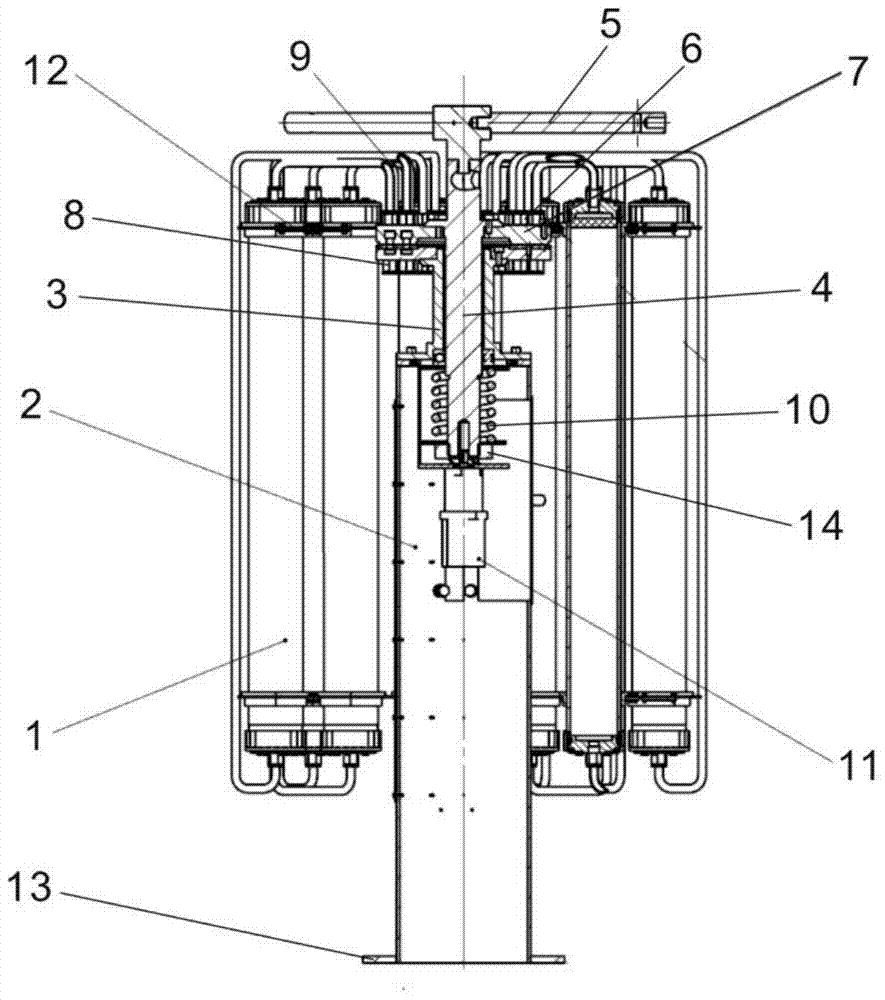

Roller washing machine

ActiveCN111691129ASimple structureReduce washing water consumptionOther washing machinesWashing machine with receptaclesWater savingWater storage

The invention discloses a roller washing machine. The roller washing machine comprises an inner barrel, an outer barrel, a pneumatic balancing mechanism and a water inlet device, wherein the inner barrel is rotatably arranged in the outer barrel by virtue of an inner barrel shaft, the inner barrel is used as a water storage container when clothes are washed, a water outlet and a sealing valve fornormally closing the water outlet are formed in and arranged on the circumferential wall of the inner barrel, the water outlet can be opened by the sealing valve under the centrifugal action when theinner barrel rotates at the speed above the set rotating speed, the pneumatic balancing mechanism is used for communicating the inner barrel with the external environment so as to balance the internalpressure of the inner barrel, a hollow channel is formed in the inner barrel shaft, the water inlet device communicates with the interior of the inner barrel through the hollow channel of the inner barrel shaft, the pneumatic balancing mechanism is arranged on the inner barrel shaft, and a non-contact heating module is arranged on the outer barrel and does not make contact with the inner barrel so as to heat the washing water stored in the inner barrel. The roller washing machine has the characteristics of water conservation and cleanness.

Owner:QINGDAO HAIER WASHING ELECTRIC APPLIANCES CO LTD +1

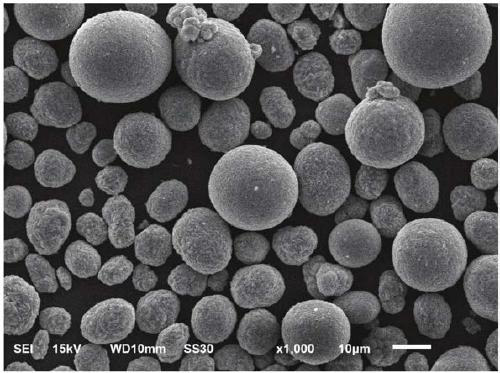

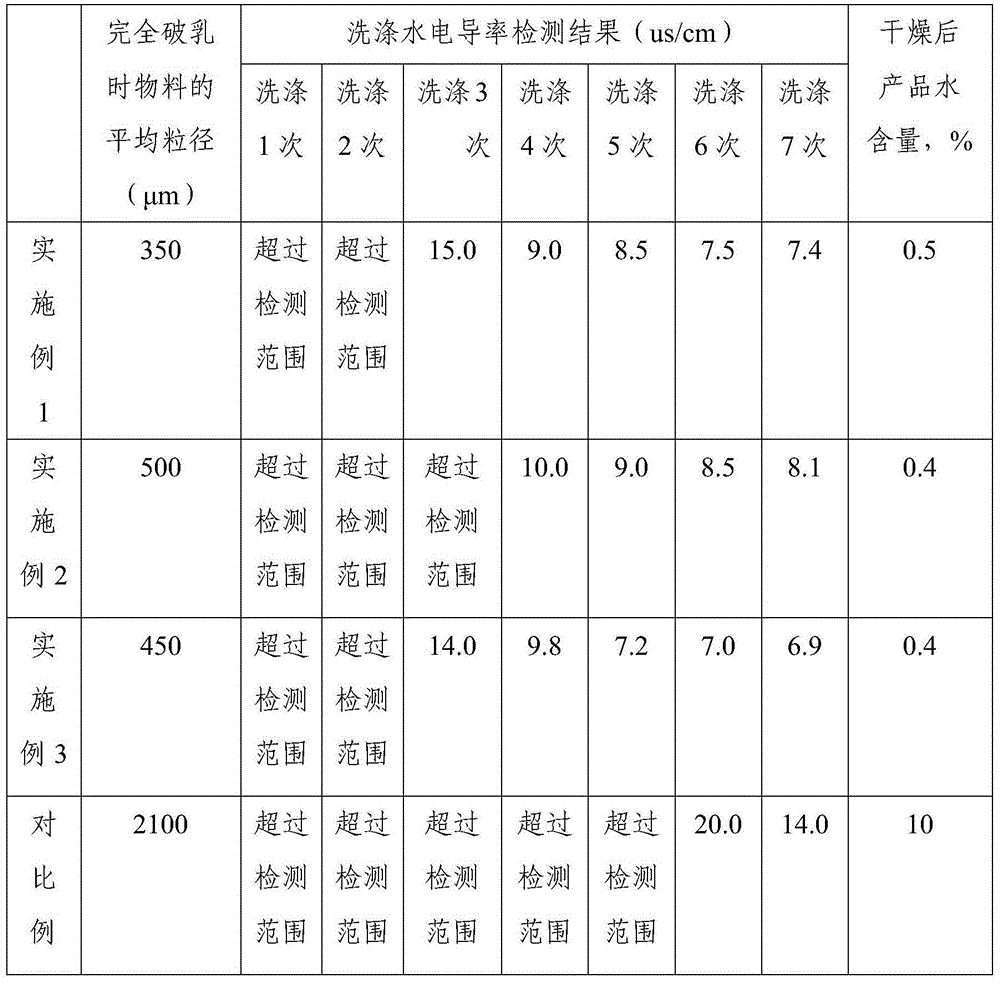

Fluorine-containing polymer powder and preparation method thereof

The invention discloses fluorine-containing polymer powder and a preparation method thereof. The method comprises the following steps: 1) adding deionized water at 1-15 DEG C into fluorine-containing emulsion, and adjusting the specific gravity of the emulsion to 1.05-1.15; 2) stirring the fluorine-containing emulsion at a speed of 1,000-3,000rpm while adding a flocculant, stirring for 5-30min to obtain a demulsified fluorine-containing polymer; and 3) washing the demulsified fluorine-containing polymer with deionized water at 1-30 DEG C until the electrical conductivity of the washing water is lower than or equal to 10us / cm, and drying to obtain the fluorine-containing polymer powder. By adopting the technical scheme provided by the invention, the average particle size of the demulsified fluorine-containing polymer is 350-700mu m, the moisture content after washing and drying is low, and the fluorine-containing polymer is in a powder form which facilitates the washing and drying in the after-treatment process; and moreover, the use of washing water can be reduced, the drying time is shortened, the productivity of the equipment is improved, and industrial production is facilitated.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

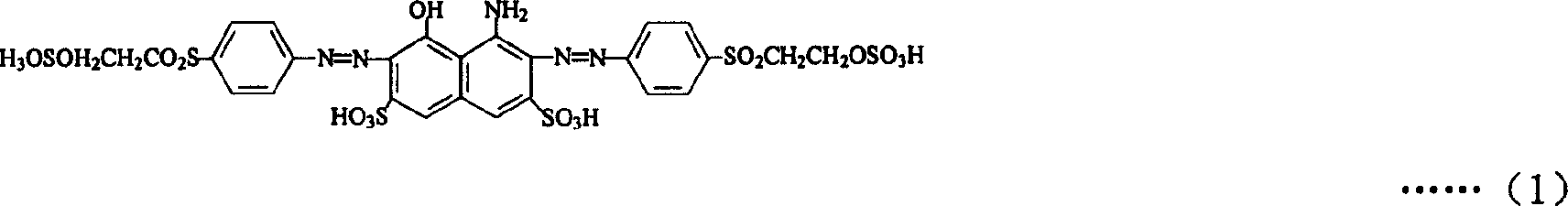

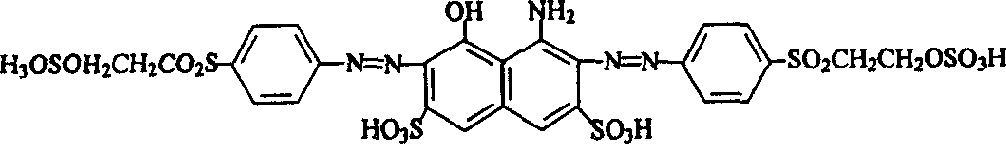

Water soluble crude dye refining method based on membrane separation and integration technology

This invention relates to fine water solvent saw dye process method based on membrane isolation integration technique, which processes desalinization on the saw dye and condensation to isolate the inorganic salts like sodium chloride and sodium sulfate in the raw dye to get the purified dye and also makes the membrane process finishing rate more than 99.9 úÑ and to get the further liquid dye for process.

Owner:SHANGHAI HUAYI GRP CO

Preparation method of nanometer indium hydroxide

The invention provides a preparation method of nanometer indium hydroxide. The preparation method comprises the following steps: a) introducing ammonia gas into an aqueous indium nitrate solution to obtain a precursor slurry; and b) washing the precursor slurry, and performing spray drying to obtain an indium hydroxide powder. The preparation method provided by the invention can reduce the production of an ammonia nitrate mother liquor, reduce the washing difficulty and the consumption of washing water, reduce the generation of nitrogen-containing wastewater and reduce the wastewater treatmentdifficulty; the preparation method allows the nano-level product to be obtained without a dispersant, so the preparation cost is reduced, the operation steps are simplified, and impurities in the slurry are reduced, thereby the washing difficulty and the consumption of washing water are reduced; and the obtained product has small particle size and a good uniformity, and does not need to be sieved, so the preparation process is simplified.

Owner:先导薄膜材料(安徽)有限公司

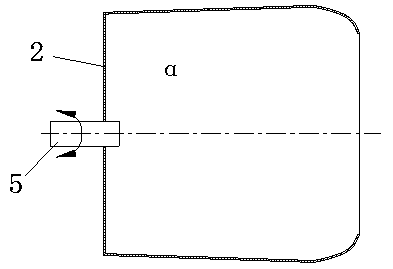

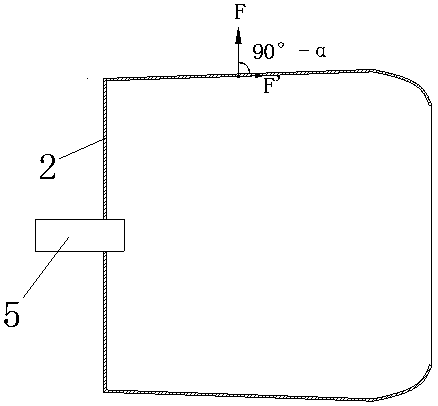

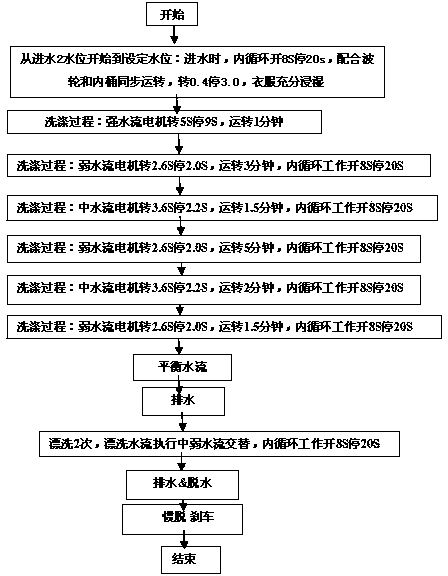

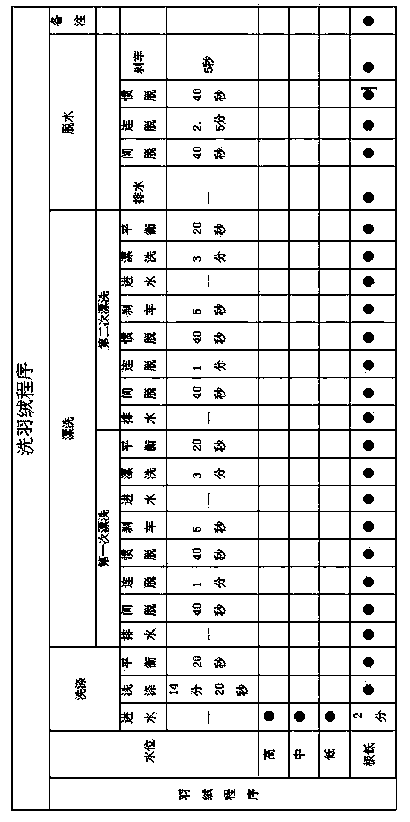

Laundering procedure suitable for washing easy-to-float clothes and washing machine

ActiveCN104250908AReduce washing water consumptionIncreased wash concentrationOther washing machinesControl devices for washing apparatusWater flowEnvironmental engineering

The invention provides a laundering procedure suitable for washing easy-to-float clothes and a washing machine. The technical solution is as follows: the laundering procedure suitable for washing easy-to-float clothes includes a washing procedure, a rinsing procedure and a spinning procedure; in the washing procedure, strong water flow is first adopted to operate, medium water flow and weak water flow then operate alternately, and at the same time, as the medium water flow and the weak water flow operate alternately, internal circulation operates; in the rinsing procedure, the medium water flow and the weak water flow are adopted to operate in turn, and at the same time, internal circulation operates. The invention also provides the full-automatic washing machine adopting the laundering procedure suitable for washing easy-to-float clothes. By selecting the procedures, fitting a gland-check ring structure over the low-water level space in an internal tub and combining the strong water flow and the weak water flow in alternation in cooperation with internal circulation, the dissolution of detergent is accelerated, medium and low water levels are adopted to increase the concentration of the detergent, consequently, the cleaning rate of easy-to-float clothes is effectively increased, and water consumption is reduced.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

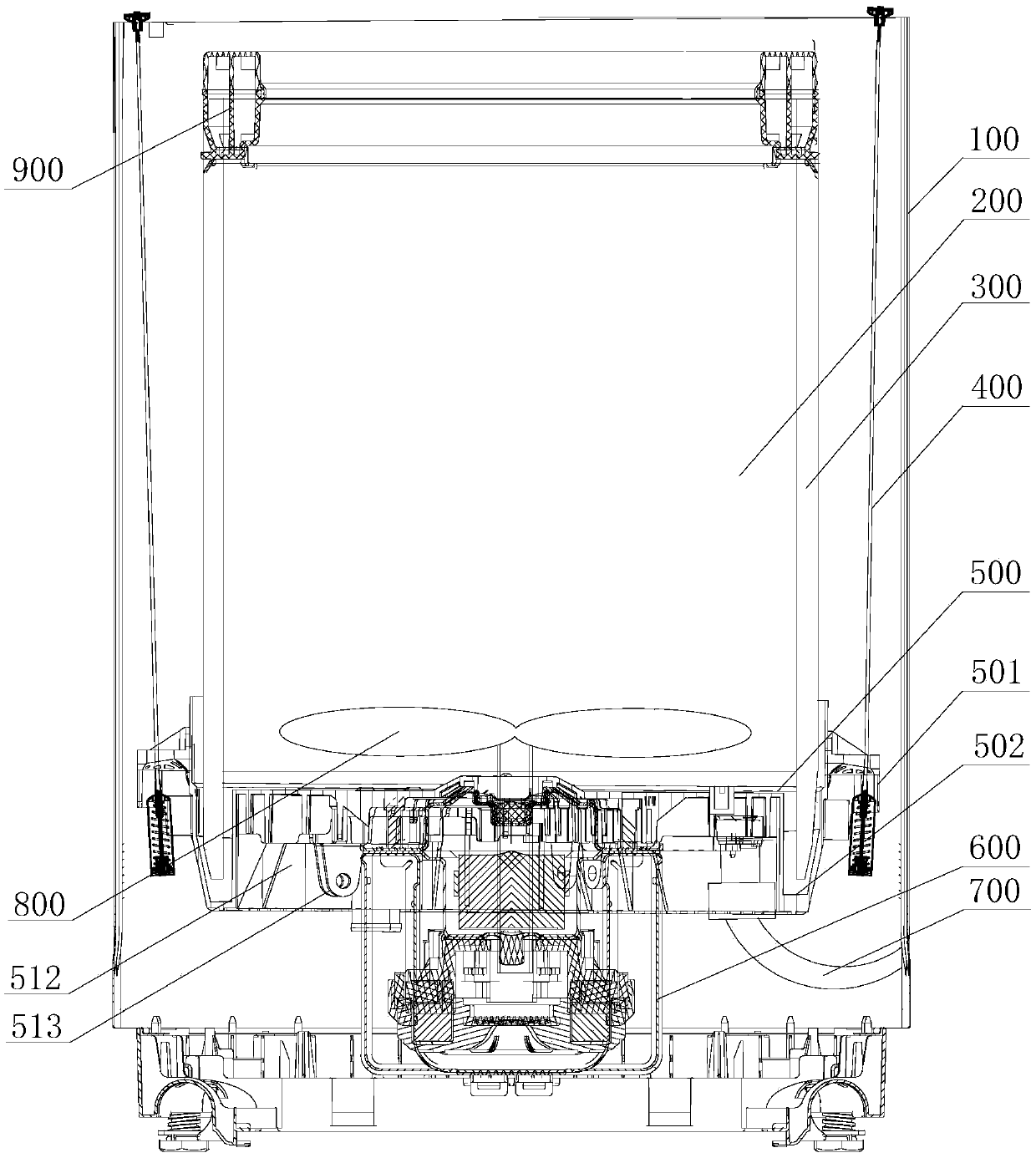

Washing machine

ActiveCN110409104ALarge capacityAchieve expansion effectOther washing machinesWashing machine with receptaclesWater dischargePulp and paper industry

The invention provides a washing machine. The washing machine comprises a washing cylinder capable of being used for containing water in the washing process, a water collection device used for collecting water discharged by the washing cylinder, and a driving assembly and / or water discharging assembly installed at the bottom of the water collection device, and an installation cavity used for installation of the driving assembly and / or the water discharging assembly is formed in the bottom of the water collection device. According to the washing machine, due to the fact that an outer cylinder of a traditional washing machine is saved, a driving assembly and a water discharging assembly are installed at the bottom of the outer cylinder of the traditional washing machine, and the installationcavity used for installation of the driving assembly and / or the water discharging assembly is formed in the bottom of the water collection device of the washing machine, the installation problem of the driving assembly and / or water discharging assembly of the washing machine without the outer cylinder is solved, and the waterproof purpose of the driving assembly and / or the water discharging assembly is achieved.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

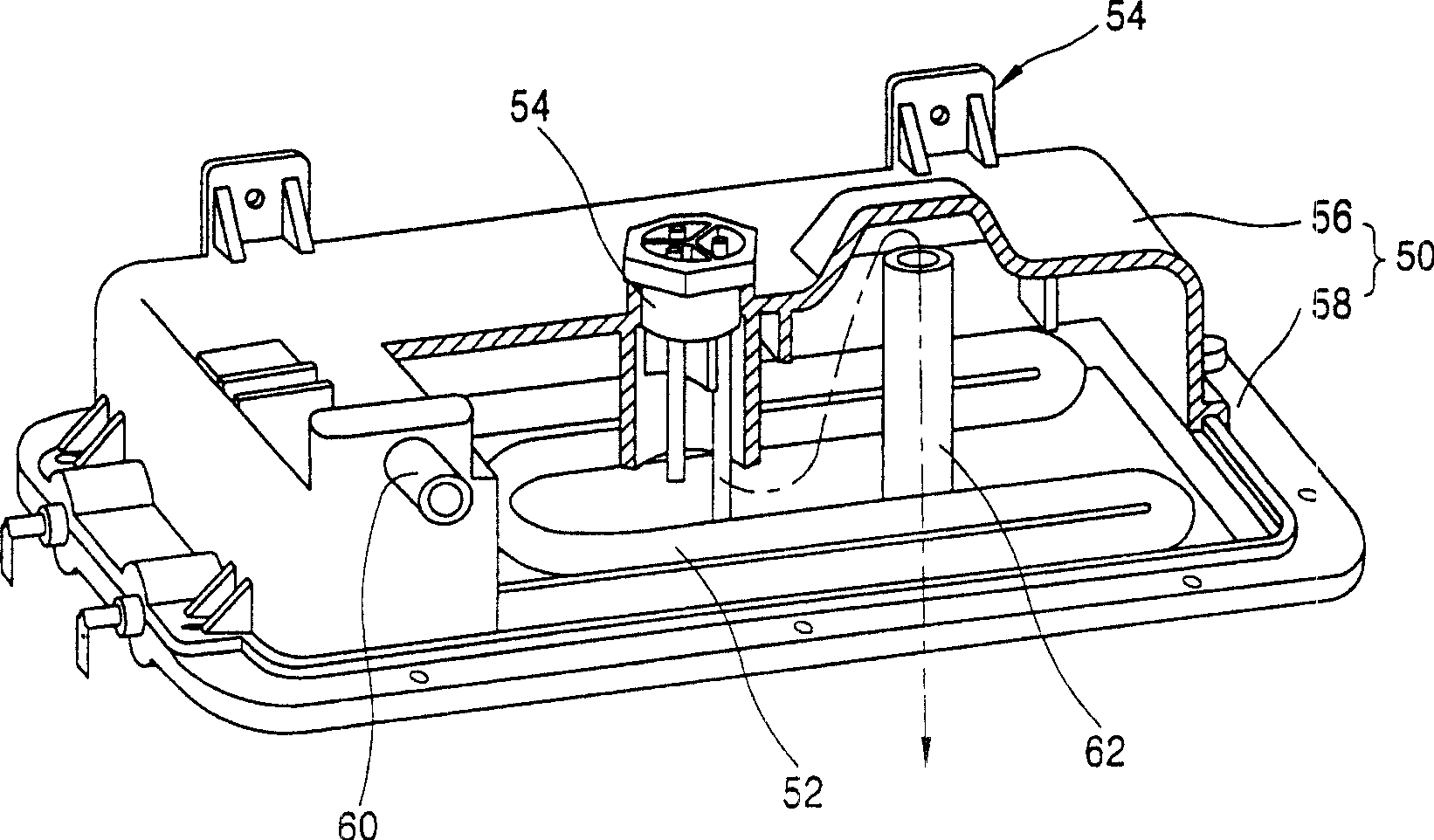

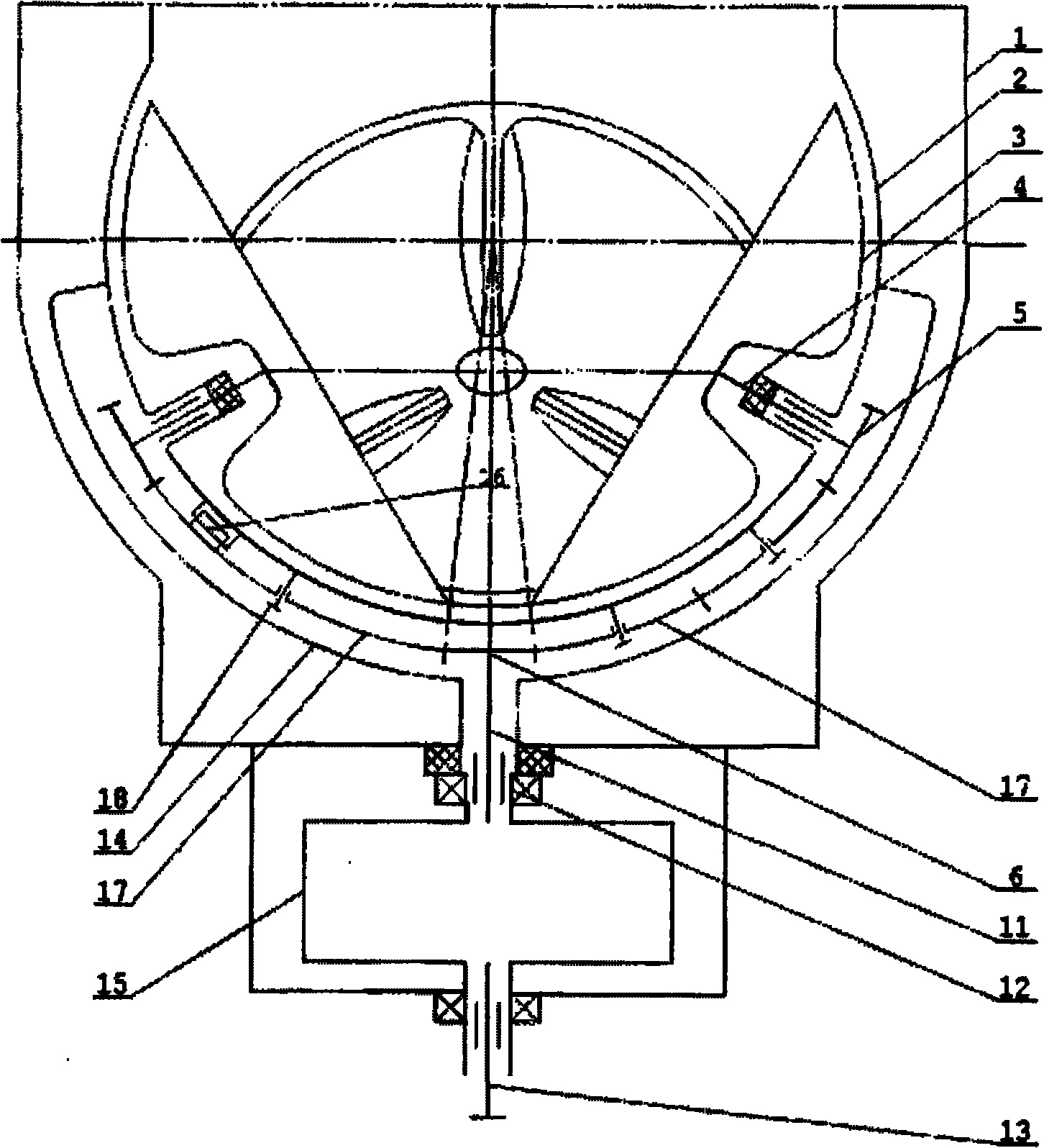

Full-automatic deceleration clutch and washing machine thereof

ActiveCN101113558ASave raw materialsLow costOther washing machinesWashing machine with receptaclesWater flowEngineering

A wholly automatic decelerating clutch and a washing machine thereof pertain to washing machine technical field; an output shaft of the wholly automatic decelerating clutch consists of a small whirlpool agitator shaft, a large whirlpool agitator shaft and a dewatering shaft that are sleeved concentrically; the whirlpool agitator of the washing machine adopting the wholly automatic decelerating clutch is a small whirlpool agitator and a large whirlpool agitator, wherein the small whirlpool agitator is fixedly arranged on the small whirlpool agitator shaft and in the center part of the large whirlpool agitator, and the large whirlpool agitator is fixedly arranged on the large whirlpool agitator shaft, and an inner bucket is fixedly arranged on the dewatering shaft. The washing manner of the washing machine adopting the wholly automatic decelerating clutch is that: the small whirlpool agitator, the large whirlpool agitator and the inner bucket are mutually, reversely and bidirectionally rotated to and fro at a certain ratio, different speeds and different rotating angles, to produce complicated, vertically and horizontally crossed impacting water flow, to strike and rinse clothes, and fully roll, strongly rub and sway the clothes, thus improving the cleanness rate of clothes and not twisting the clothes; when the clothes are dewatered, a torsional spring automatically integrates the decelerating clutch into a whole, and decenters and dewater the clothes in high speed, without needing a whole set of clutch parts and operating mechanisms of the normal decelerating clutch.

Owner:NINGGUO JULONG IND

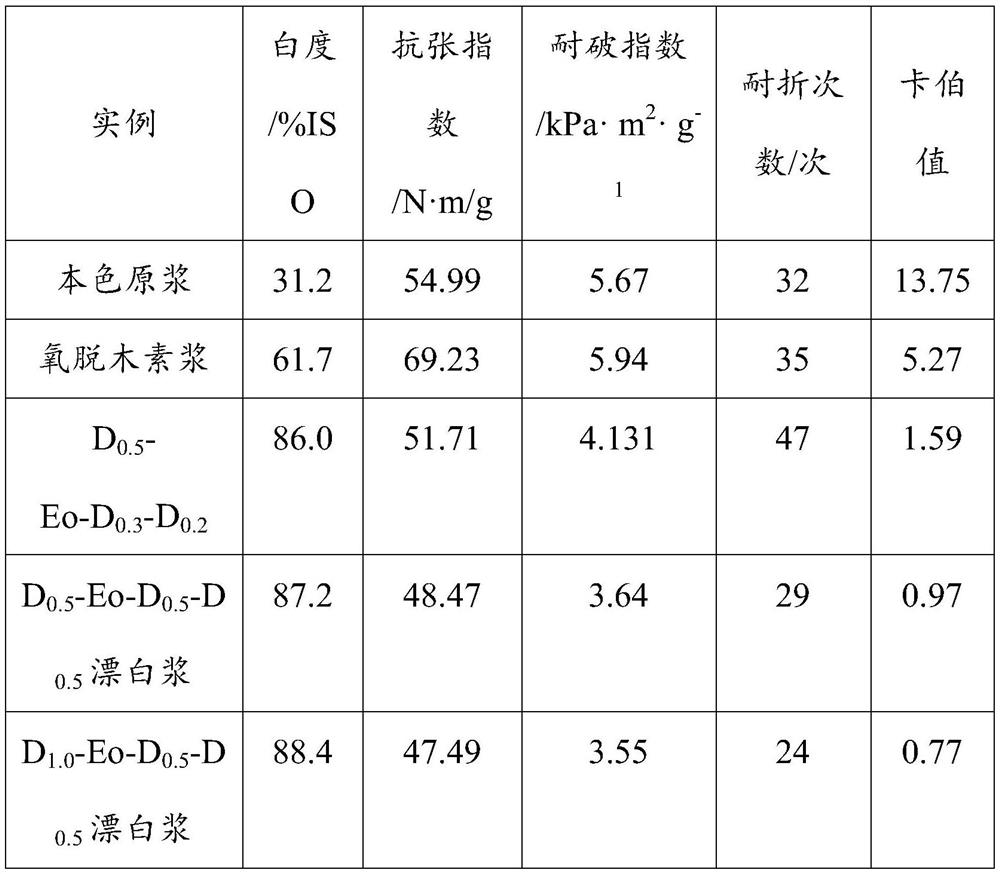

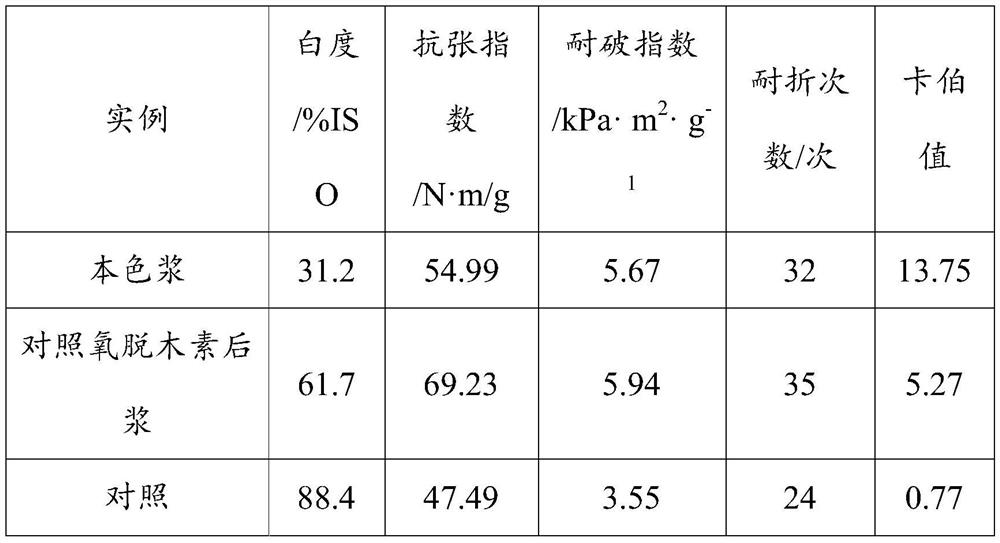

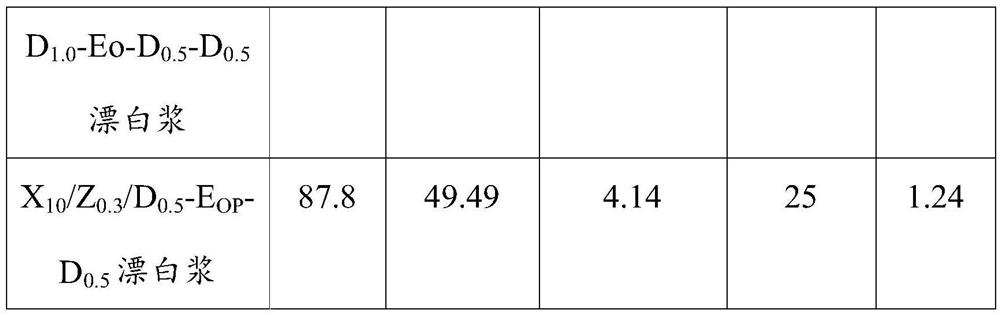

Sulfate wood pulp short-sequence ECF bleaching process X/Z/D-EOP-D or X/D/Z-EOP-D

PendingCN111979818AHigh whitenessHigh strengthPulp bleachingPulping with inorganic basesChlorine dioxidePapermaking

The invention belongs to the technical field of papermaking, and relates to a sulfate wood pulp short-sequence ECF bleaching process X / Z / D-EOP-D or X / D / Z-EOP-D. The process comprises the following steps: (1) sequential bleaching (X / Z / D or X / D / Z): carrying out X / Z / D or X / D / Z sequential bleaching on sulfate wood pulp subjected to oxygen delignification to obtain semi-bleached paper pulp; (2) enhanced alkali extraction (EOP): carrying out hydrogen peroxide and oxygen enhanced alkali extraction treatment on the sequentially bleached paper pulp to further dissolve out residual lignin in the pulp; and (3) supplementary bleaching (D): carrying out chlorine dioxide supplementary bleaching on the paper pulp to obtain fully bleached paper pulp (88% ISO). Through the above bleaching treatment, the paper pulp with high whiteness and strength index is obtained. Compared with a traditional D-EO-D-D bleaching sequence, X / Z / D-EOP-D or X / D / Z-EOP-D bleaching sequence reduces one chlorine dioxide bleaching section, and under the condition that the final whiteness is the same, the chlorine dioxide consumption is reduced by 30% or above, and the water consumption is reduced by 20% or above.

Owner:QILU UNIV OF TECH

Method for reducing acid content of dimethyldichlorosilane hydrolysate

ActiveCN106397474AProportionally largeRealize green and clean productionSilicon organic compoundsHydrolysateChloride

Belonging to the field of chemical engineering, the invention relates to a method for reducing the acid content of a dimethyldichlorosilane hydrolysate. The method includes the steps of: (a) subjecting the dimethyldichlorosilane hydrolysate and a calcium chloride aqueous solution to countercurrent mixing and washing; (b) then continuously contacting the hydrolysate with a hydrochloric acid mass fraction gradually reduced aqueous phase, and performing full washing. On the basis of washing, the method provided by the invention introduces calcium chloride to increase the proportion of the hydrolysate and water, realizes rapid layering of the two, avoids emulsification phenomenon during washing, and improves the washing and acid removing effects. In addition, the method provided by the invention significantly reduces the consumption of washing water and lowers the production load, and the calcium chloride can be recycled, thus achieving green and clean production.

Owner:SHANDONG DONGYUE ORGANIC SILICON MATERIAL

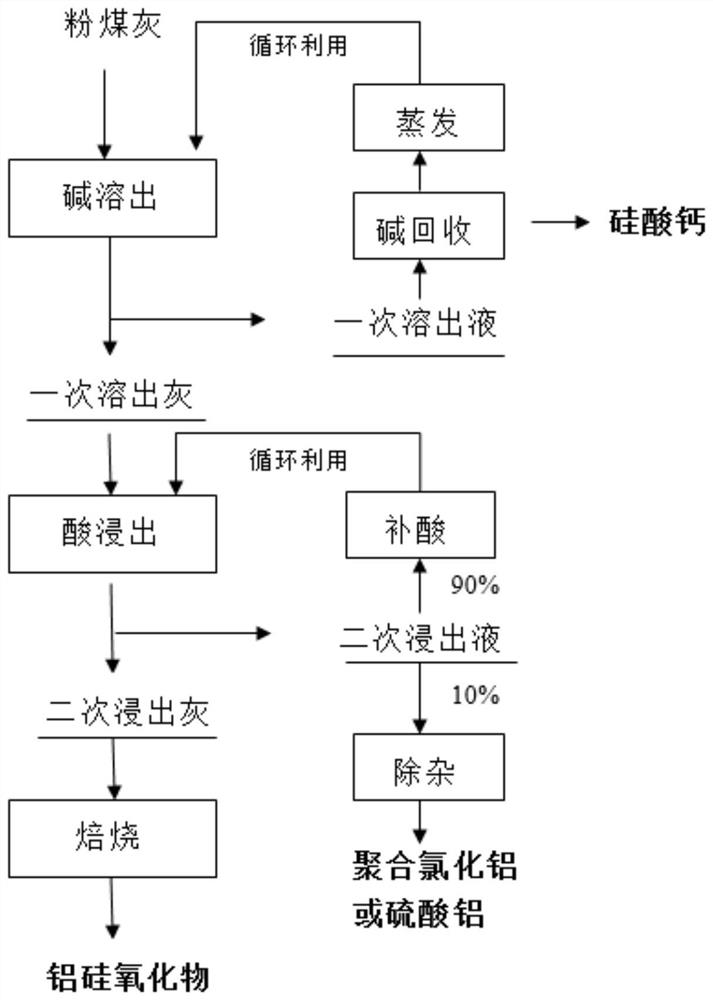

Method for preparing aluminum-silicon oxide from fly ash

ActiveCN111606339ASimple processHigh silica contentSilicaAlkaline-earth metal silicatesPhysical chemistrySilicon oxide

The invention provides a method for preparing aluminum-silicon oxide from fly ash. The method comprises the following steps: sequentially carrying out alkali dissolution treatment, acid leaching treatment and roasting treatment on the fly ash. According to the preparation method for extracting the aluminum-silicon oxide from the coal ash, the coal ash is used as a raw material, and undergoes two-stage atmospheric pressure leaching, so the reaction pressure is reduced, the equipment investment is reduced, the preparation process is simple and easy to operate, and the preparation cost is low.

Owner:内蒙古蒙泰集团有限公司

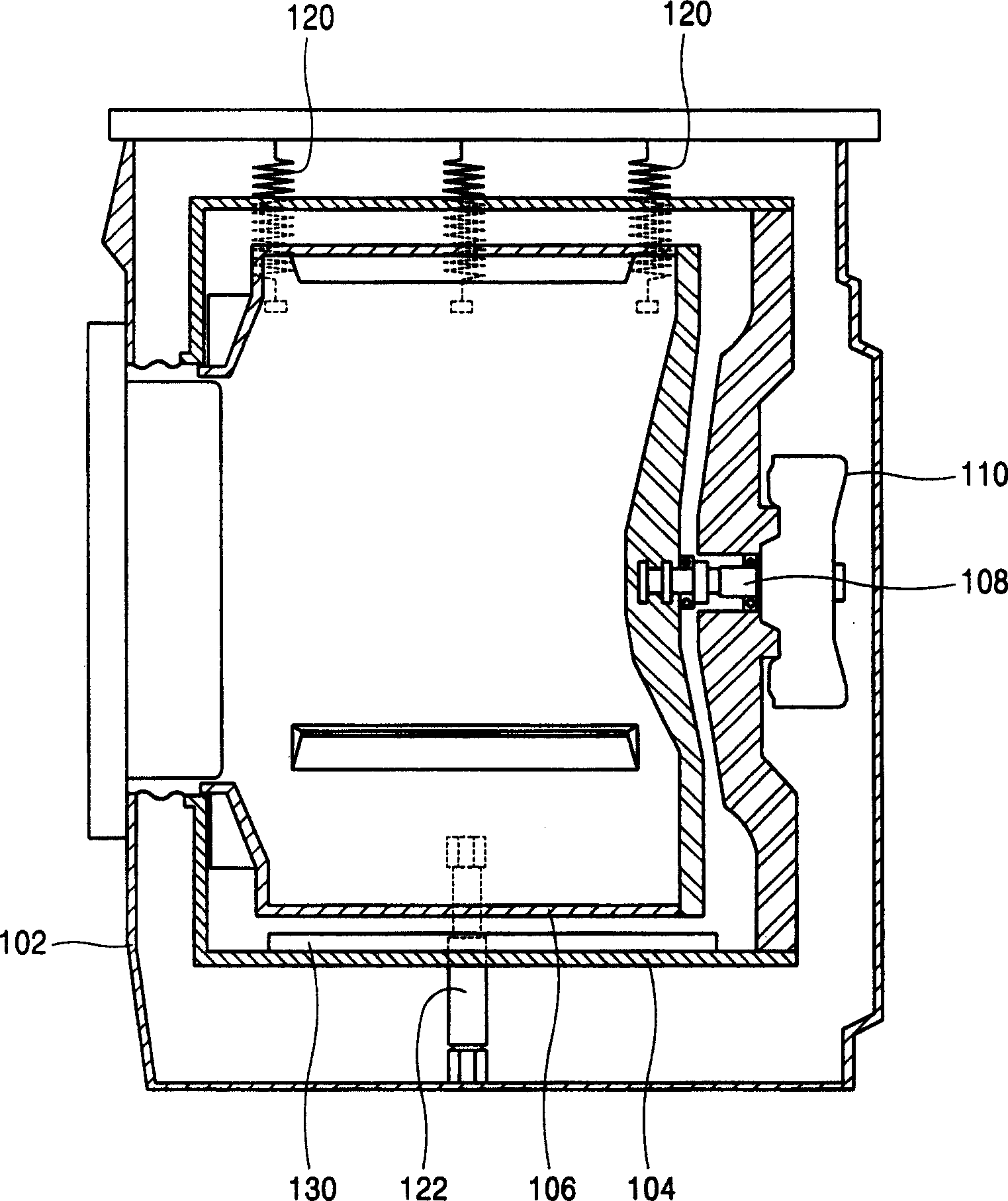

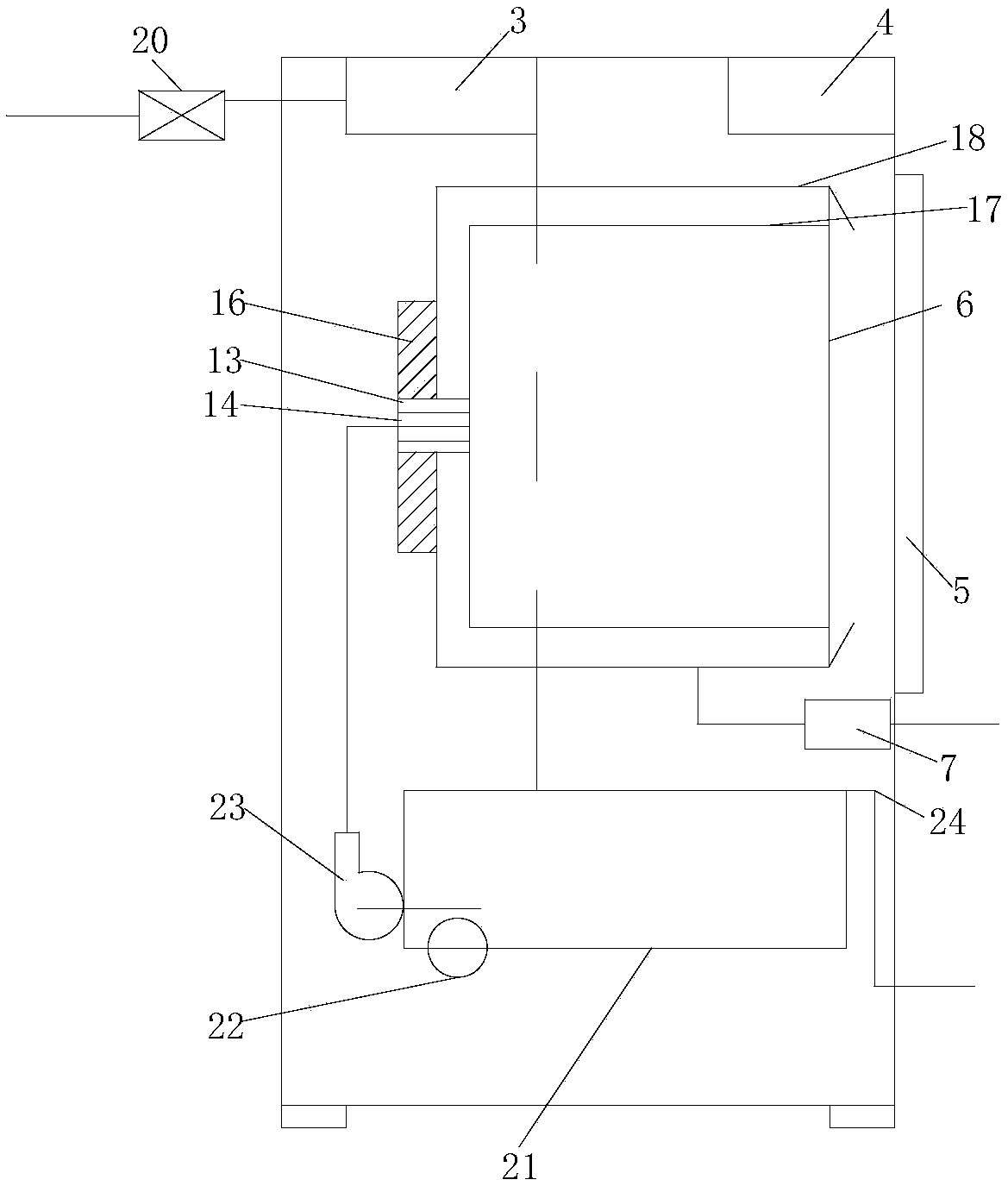

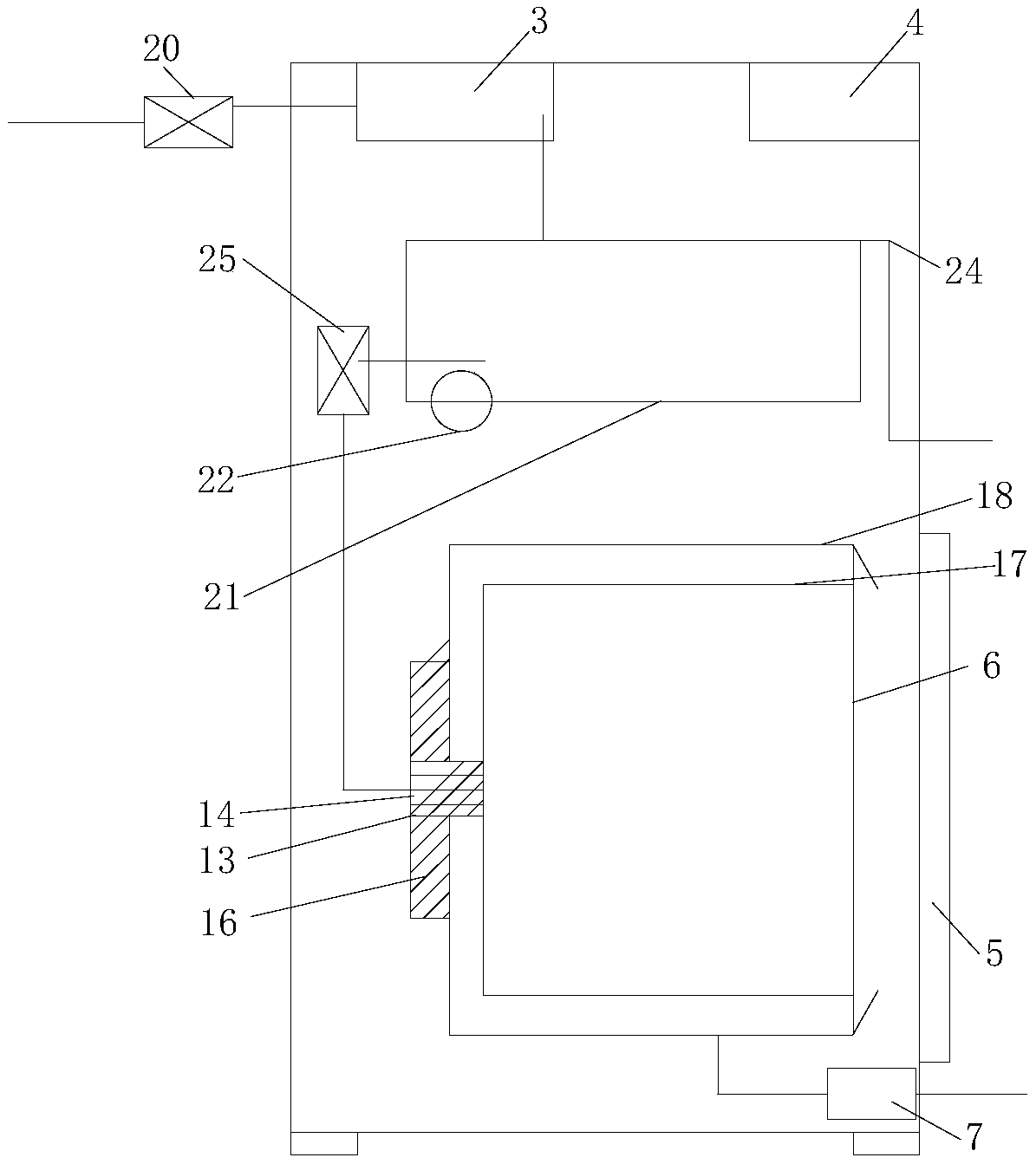

Roller washing machine

ActiveCN111088636ASimple structureReduce washing water consumptionOther washing machinesWashing machine with receptaclesLaundry washing machineWater discharge

The invention provides a roller washing machine comprising an inner cylinder and an outer cylinder. The inner cylinder is a non-porous inner cylinder and used for containing washing water during washing clothes; the outer cylinder is coaxially arranged outside the inner cylinder and is used for collecting water discharged from the inner cylinder and discharging the water through a drainage pipeline; and the roller washing machine further comprises a position detection device arranged on the outer cylinder and used for detecting the position of the inner cylinder. The roller washing machine ina non-porous inner cylinder front open type structure in the invention is simple in structure, and washing / rinsing water does not need to be filled between the inner cylinder and the outer cylinder so that the washing water consumption of the washing machine can be greatly reduced. The possibility of dirt attachment between the inner cylinder and the outer cylinder is avoided. User health and user experience are greatly improved, and water resources are greatly saved.

Owner:QINGDAO HAIER WASHING ELECTRIC APPLIANCES CO LTD +1

Method for continuously treating heavy metal liquid

ActiveCN104843819AReduce loadReduce washing water consumptionWater contaminantsWater/sewage treatment by sorptionDesorptionFixed bed

The invention discloses a method for continuously treating heavy metal liquid. The method comprises the following steps: firstly, pre-treating the heavy metal liquid to enable the heavy metal liquid to meet the water inlet requirements of equipment; secondly, processing the heavy metal liquid by using a continuous adsorption process, namely continuously operating a plurality of process areas in sequence through the rotation of adsorption columns; finally, after-treating the wastewater of each process area, and separating and recycling heavy metal. According to the method, multi-adsorption column and multi-process continuous operation is carried out, and fully-automatic control, simple operation and stable running are realized; the treatment process flow can be flexibly changed, and the method is applied to process change caused by external fluctuation; the operation flow speed is high, the regeneration cycle period is short, and metal ions in a water body are efficiently adsorbed, separated, enriched and recycled; in addition, compared with a conventional fixed bed process, the method has the advantages that the filling quantity of adsorption materials, the consumption of washing water, the consumption of a desorption agent and the consumption of a regeneration agent are reduced, and the operation cost is reduced.

Owner:陕西厚亿节能环保新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com