Fluorine-containing polymer powder and preparation method thereof

A polymer and powder technology, applied in the field of fluorine-containing polymer powder and its preparation, can solve the problems of unfavorable follow-up washing and easy caking, and achieve the effects of shortening drying time, not easy to agglomerate, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

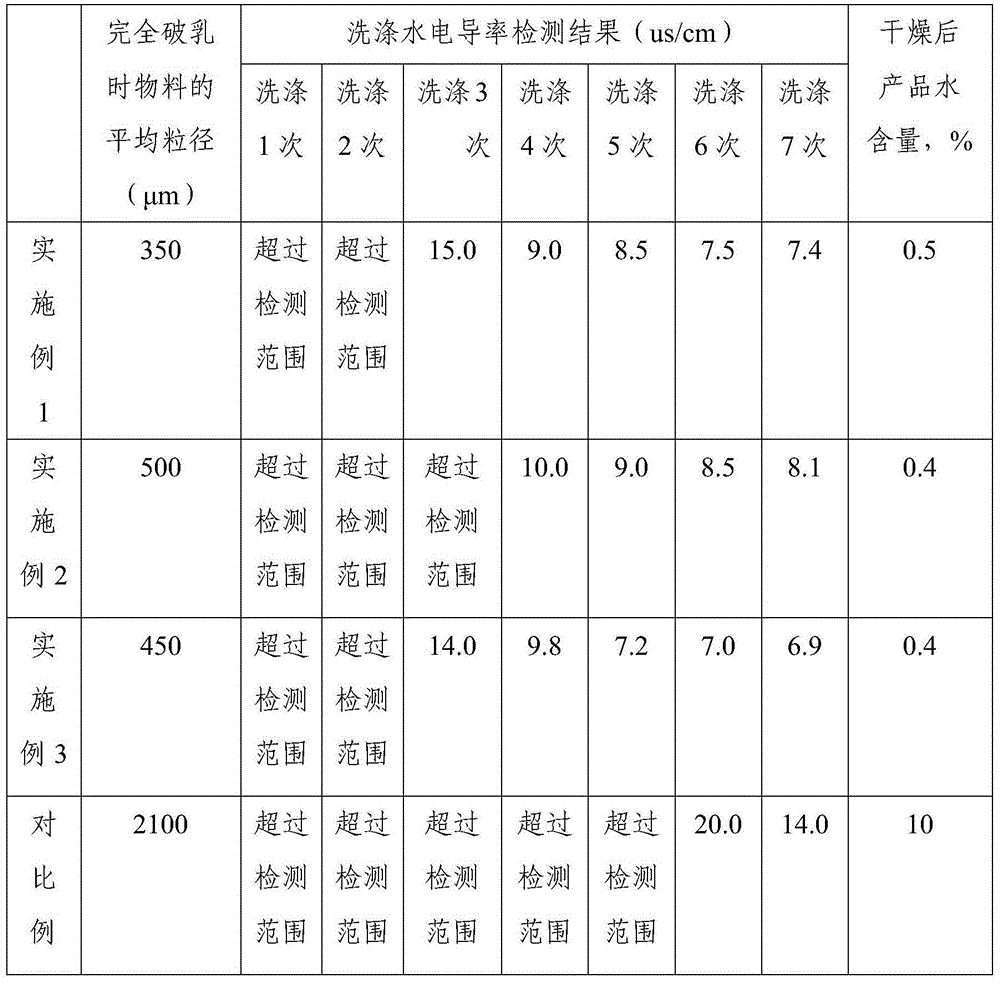

Embodiment 1

[0028] The preparation method of embodiment 1 fluoropolymer powder

[0029] 1. Add 10°C deionized water to the fluorine-containing emulsion to adjust the specific gravity of the emulsion to 1.1. The fluorine-containing emulsion is obtained by emulsion polymerization of vinylidene fluoride and chlorotrifluoroethylene at a molar ratio of 1:1, and the solid content is 30%;

[0030] 2. Stir the fluorine-containing emulsion after adjusting the specific gravity under the condition of 2000 rpm, add 200g of magnesium chloride during the stirring process, stir for 20min, and obtain the fluorine-containing polymer precipitated by demulsification after the stirring is stopped;

[0031] 3. Wash the fluorine-containing polymer separated out by demulsification with 10°C deionized water (the average particle diameter of the fluorine-containing coating separated out by demulsification is 350 μm), wash repeatedly 4 times, and the amount of deionized water used for each wash It is twice the vo...

Embodiment 2

[0032] The preparation method of embodiment 2 fluoropolymer powders

[0033] 1. Add 1°C deionized water to the fluorine-containing emulsion to adjust the specific gravity of the emulsion to 1.05. The fluorine-containing emulsion is obtained by emulsion polymerization of vinylidene fluoride and hexafluoropropylene at a ratio of 1:4 (molar ratio), and the solid content is 27%;

[0034] 2. Stir the fluorine-containing emulsion after adjusting the specific gravity under the condition of 1000 rpm, add 300g of magnesium chloride during the stirring process, stir for 5 minutes, stop stirring to obtain the fluorine-containing polymer precipitated by demulsification;

[0035] 3. Wash the fluorine-containing polymer separated out by demulsification with 1° C. of deionized water (the average particle diameter of the fluorine-containing polymer separated out by demulsification is 700 μm), and wash repeatedly 8 times, and the amount of deionized water used for each washing is The amount i...

Embodiment 3

[0036] The preparation method of embodiment 3 fluoropolymer powders

[0037] 1. Add 15°C deionized water to the fluorine-containing emulsion to adjust the specific gravity of the emulsion to 1.15. The fluorine-containing emulsion is obtained by emulsion polymerization of vinylidene fluoride and tetrafluoroethylene at a ratio of 3:1 (molar ratio), and the solid content is 30%,;

[0038] 2. Stir the fluorine-containing emulsion after adjusting the specific gravity under the condition of 3000 rpm, add 900g coagulant magnesium chloride during the stirring process, stir for 30min, stop stirring to obtain the fluorine-containing polymer precipitated by demulsification;

[0039] 3. Wash the fluorine-containing polymer separated out by demulsification with 30° C. deionized water (the average particle diameter of the fluorine-containing polymer separated out by demulsification is 600 μm), and wash repeatedly 6 times. The amount of deionized water used for each wash is 1.5 times the vo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com