Preparation method for reducing sulfur content of NCM ternary precursor

A technology of precursor and sulfur content, applied in chemical instruments and methods, electrical components, inorganic chemistry, etc., can solve the problems of high environmental protection pressure and high sulfur content, and achieve the effect of less water, low washing water consumption, and low washing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

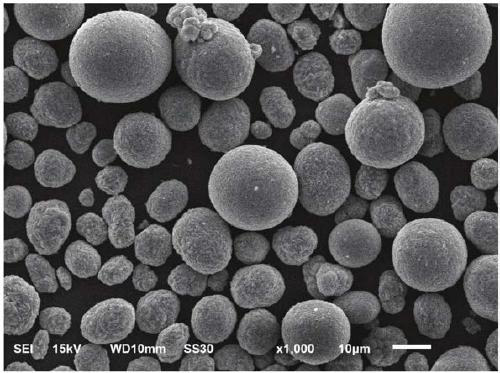

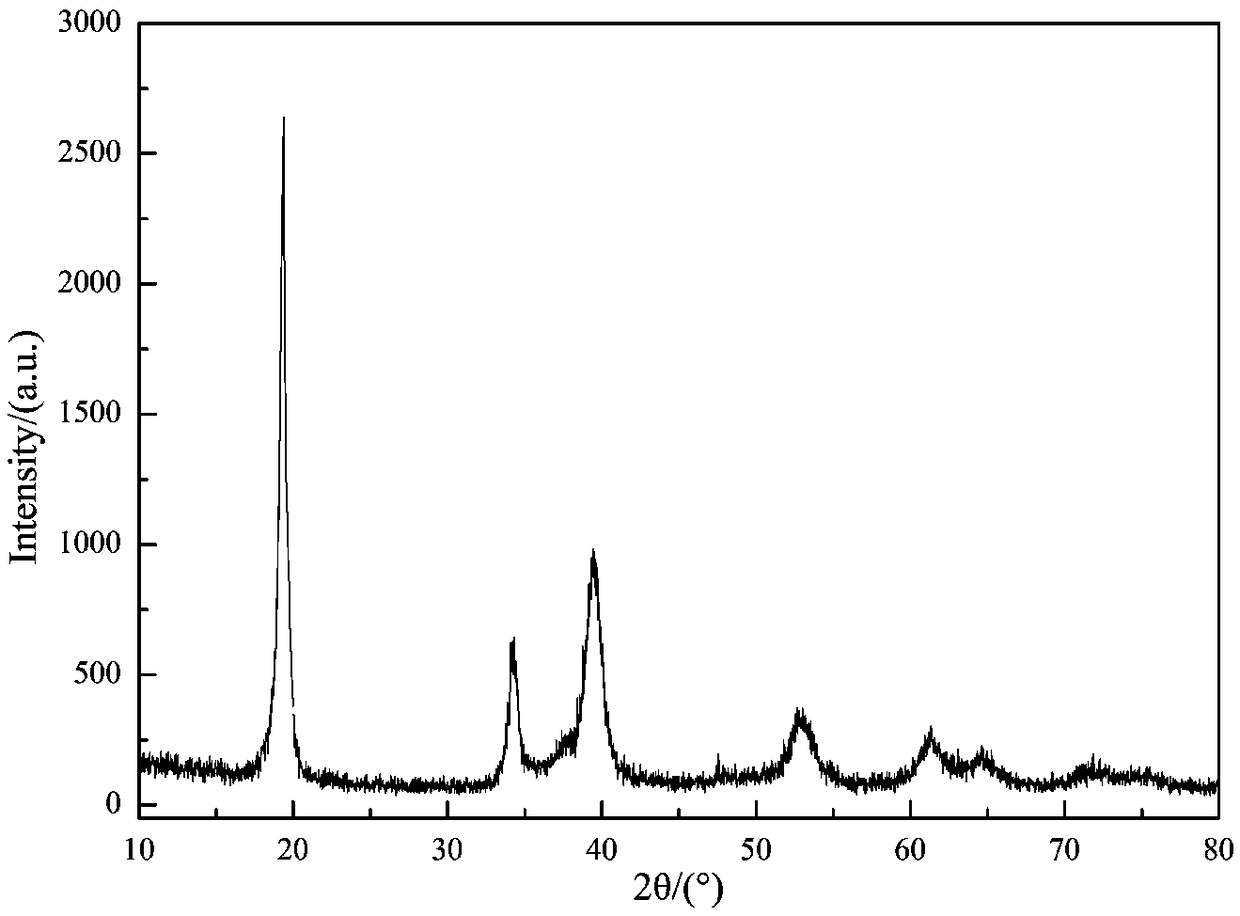

Image

Examples

Embodiment 1

[0044] Weigh a certain amount of nickel sulfate, cobalt sulfate and manganese sulfate in proportion, dissolve them in 4L deionized water, configure a 523 type (NiCoMn molar ratio) salt solution with a concentration of 2mol / L, add 0.9ml ethanolamine and 1g ascorbic acid. The solution after stirring evenly passes through the iron remover and microporous filter in turn to obtain the solution as ternary solution a; measure a certain amount of 32% liquid caustic soda, dilute it with pure water to 4L, and use a NaOH solution with a concentration of 5mol / L as a precipitate Agent b; Weigh 444ml of 25% ammonia water, add 156ml of water to dilute to obtain 600ml of 18% ammonia solution as precipitant c.

[0045] in N 2 Bottom water was added to the protected 2L reactor, the temperature was raised to 55° C. and stirring was started at 700 rpm. Add solutions b and c, so that the pH value in the kettle is 10.4, and the ammonia content is 9g / L. Use a peristaltic pump to pump solution a i...

Embodiment 2

[0047] Take a certain amount of nickel sulfate, cobalt sulfate and manganese sulfate in proportion, be dissolved in 4L deionized water, be configured into a 622 type (NiCoMn molar ratio) salt solution with a concentration of 1.8mol / L, add 0.9ml ethanolamine, 0.8ml diethanolamine and 1g ascorbic acid. The solution after stirring evenly passes through the iron remover and microporous filter in turn to obtain the solution as ternary solution a; measure a certain amount of 32% liquid caustic soda, dilute it with pure water to 3L, and use a NaOH solution with a concentration of 5mol / L as a precipitate Agent b; Weigh 444ml of 25% ammonia water and add 156ml of water to dilute to obtain 600ml of 18% ammonia solution as precipitant c.

[0048] in N 2 Bottom water was added to the protected 2L reactor, the temperature was raised to 60° C., and stirring was started at a speed of 750 rpm. Add solutions b and c, so that the pH value in the kettle is 10.6, and the ammonia content is 9.5g...

Embodiment 3

[0050] Weigh a certain amount of nickel sulfate, cobalt sulfate and manganese sulfate in proportion, dissolve them in 4L of deionized water, and configure the 811 type (NiCoMn molar ratio) salt solution with a concentration of 1.8mol / L, and add 0.9ml of diethanolamine to the solution , 1 g of ascorbic acid and 1 g of glucose. The solution after stirring evenly passes through the iron remover and microporous filter in turn to obtain the solution as ternary liquid a; measure a certain amount of 32% liquid caustic soda, dilute it into 2L with pure water, and use NaOH solution with a concentration of 8mol / L as the precipitate Agent b; weigh 369ml of 25% ammonia water, add 131ml of water to dilute, and obtain 500ml of 18% ammonia solution as precipitant c.

[0051] in N 2 Bottom water was added to the protected 2L reactor, the temperature was raised to 65° C., and stirring was started at a speed of 800 rpm. Add solutions b and c, so that the pH value in the kettle is 10.8, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com