Transmission mechanism of full-automatic multi-impeller washing machine and washing machine and washing mode thereof

The technology of a pulsator washing machine and a transmission mechanism, which is applied in the field of washing machines, can solve the problems of single repetition of the throwing direction of clothes, affecting the service life of the washing machine, affecting the washing effect, etc., so as to improve the washing effect and work efficiency, improve the bad operating environment, and save the complex clutch. Effects of mechanisms and their operating systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

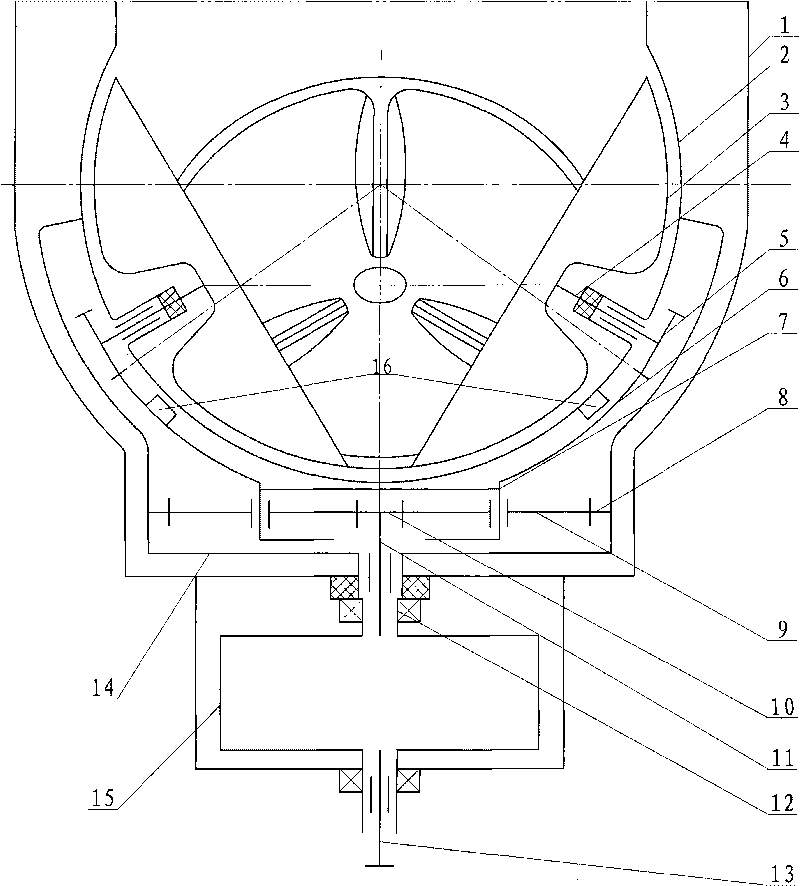

[0043] 1. combine figure 1 , is the first scheme of the transmission mechanism of the automatic multi-wave washing machine of the present invention and the structural schematic diagram of the washing machine thereof. A compound gear train composed of planetary gear reduction components. Its transmission route is:

[0044] The input shaft 13 rotates forward and backward → the output shaft 11 and the integrated sun gear 10 rotate negatively → the planetary carrier 7 and the driving bevel gear 6 integrated as a whole rotate reversely → the driven bevel gear 5 and the pulsator 3 rotate forward and backward;

[0045]The driving bevel gear 6 drives other driven bevel gears 5 and the pulsator 3 to rotate counterclockwise through the intermediate bevel gear (not shown in the drawings, at least one).

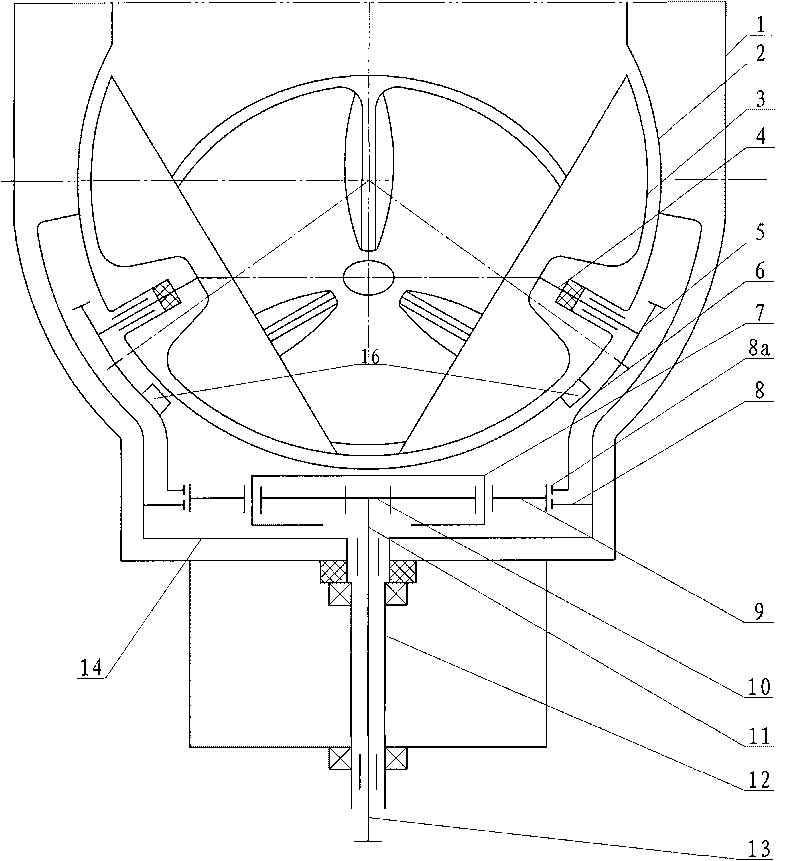

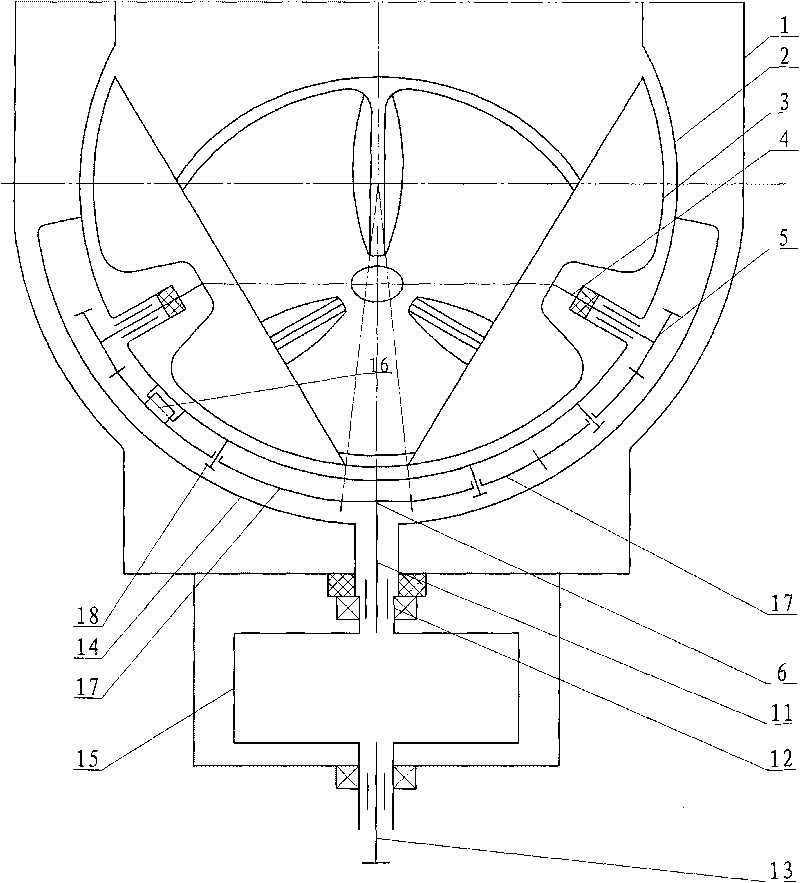

[0046] 2. combine figure 2 , is the second scheme of the transmission mechanism of the automatic multi-pulse washing machine of the present invention and the structural schematic dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com