Patents

Literature

419results about "Spin-dryers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Washing machine and rinsing control method thereof

InactiveUS20090183319A1Improve rinsing efficiencyReduce rinse timeOther washing machinesControl devices for washing apparatusMechanical engineeringEngineering

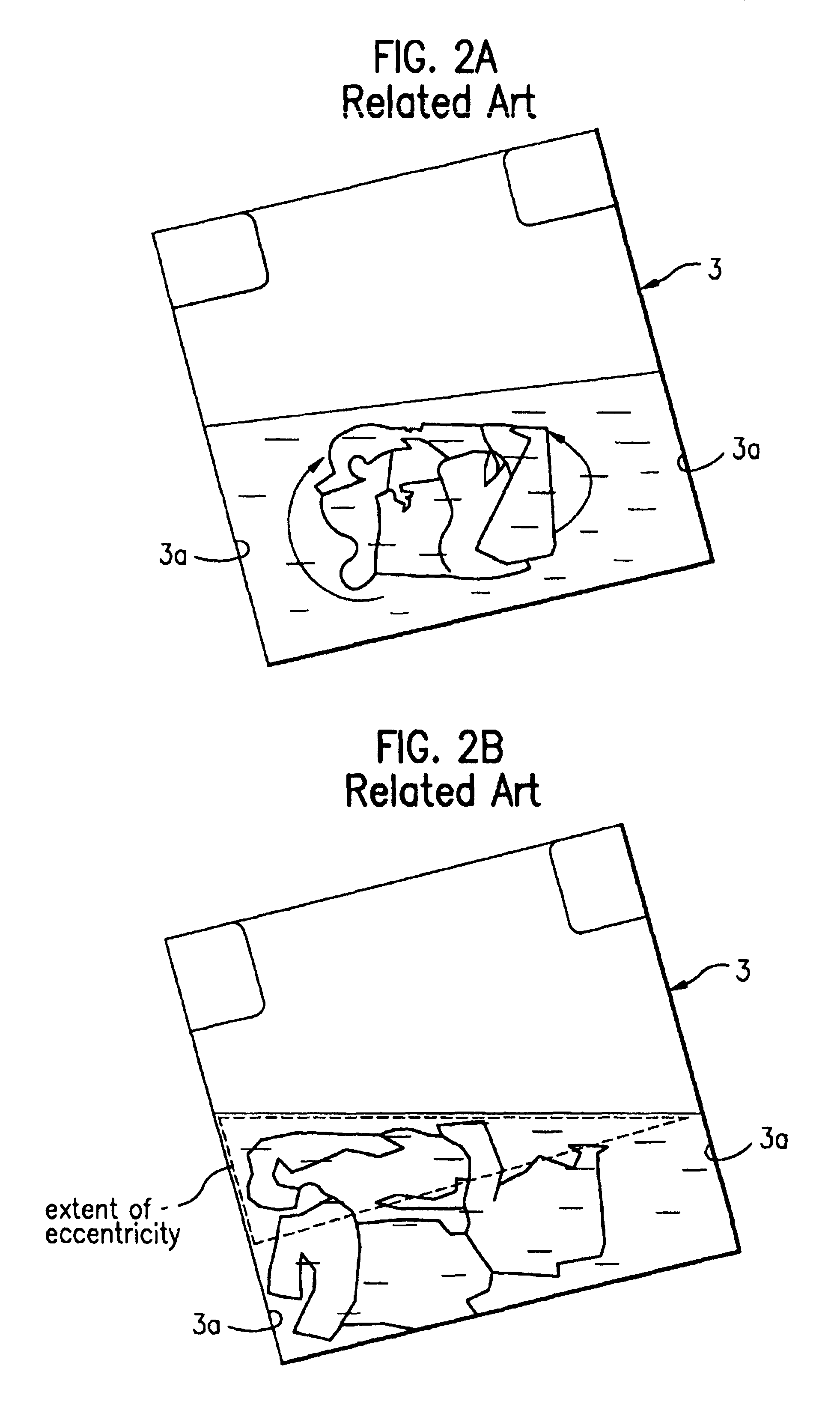

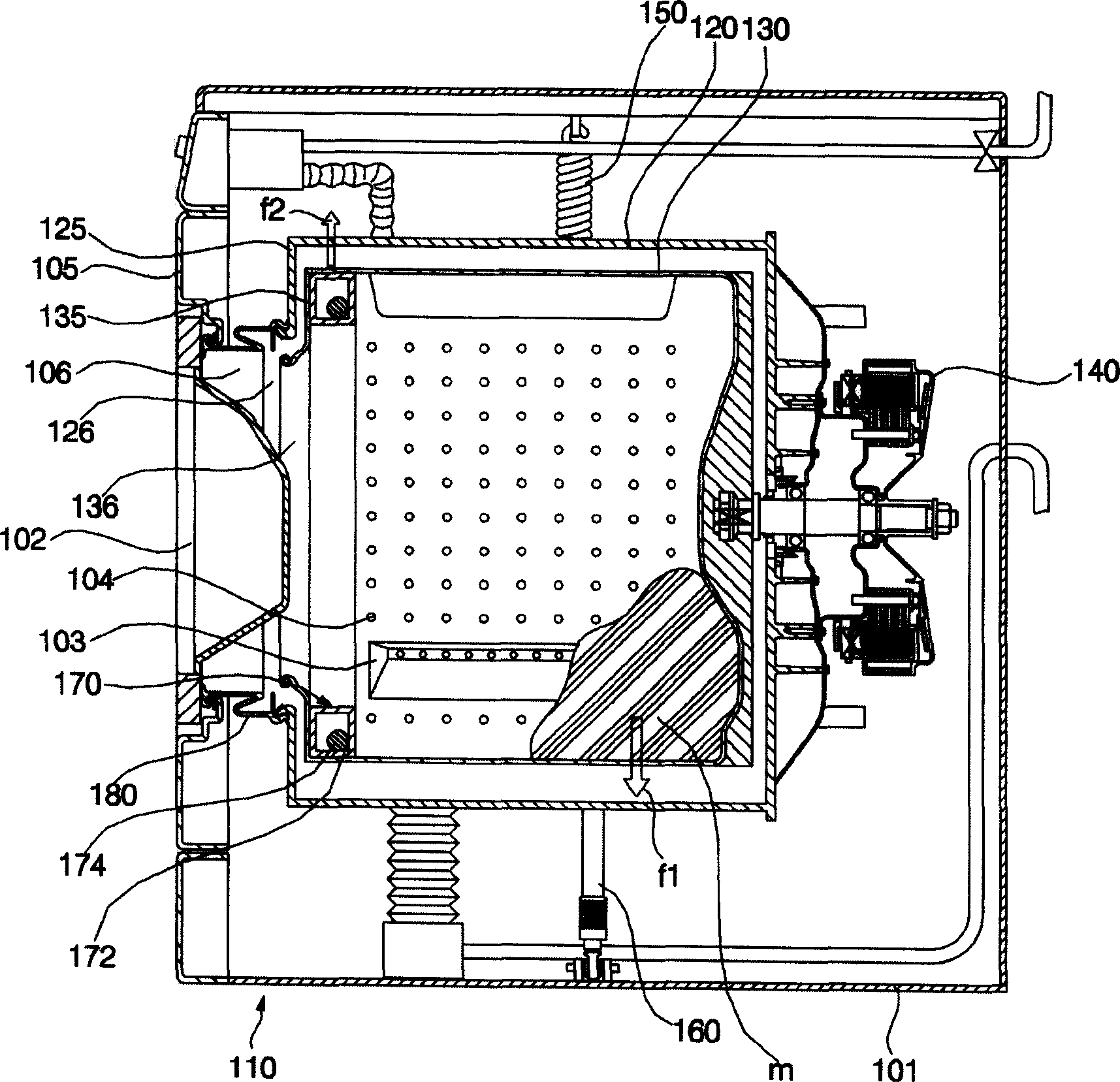

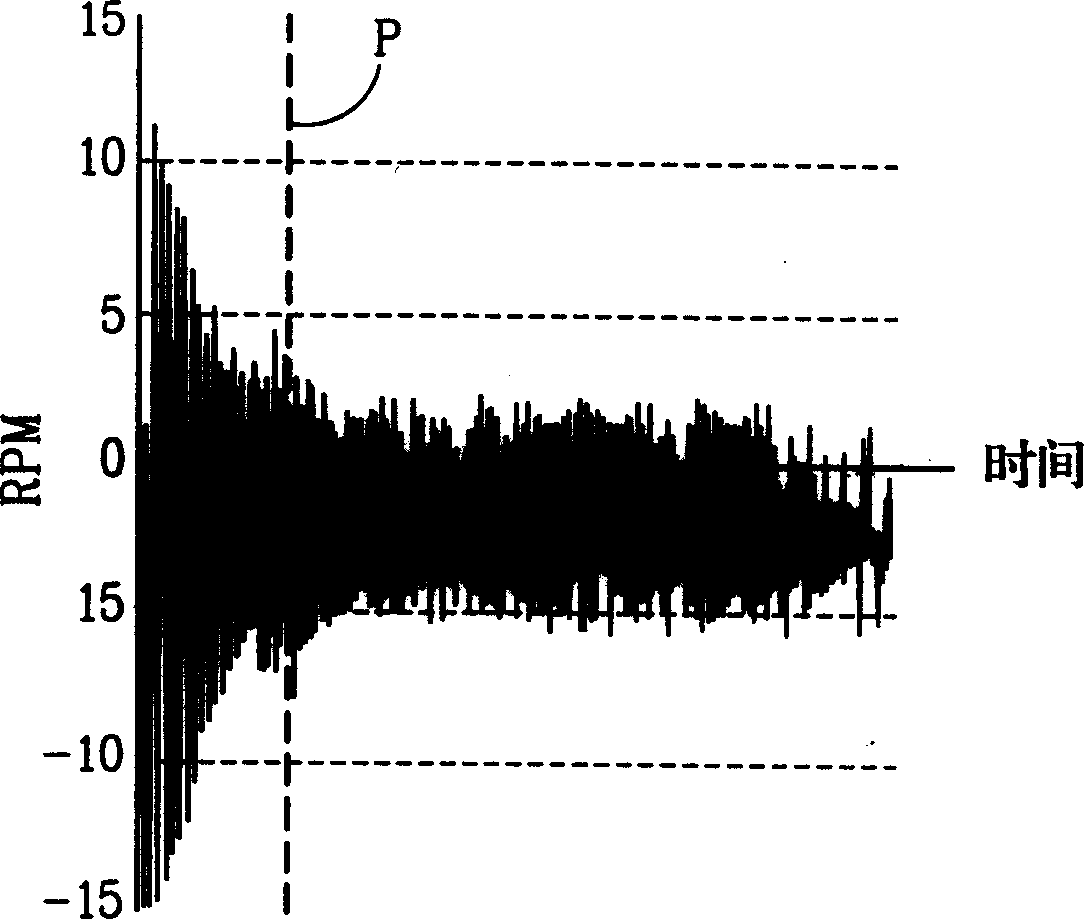

Disclosed herein are a washing machine that performs a rinsing operation while rotating a drum at a predetermined RPM without stopping the drum after spin-drying and a rinsing control method thereof The washing machine includes a drum to receive laundry and a motor to rotate the drum. The rinsing control method includes rotating the drum to perform spin-drying and decelerating the drum to a predetermined velocity to perform rinsing. Consequently, it is possible to improve rinsing efficiency even using a small amount of water. Also, it is possible to uniformly distribute the laundry in the drum without eccentricity, although a laundry untangling process for spin-drying is performed only once during the rinsing, which is performed several times, thereby reducing the total rinsing time.

Owner:SAMSUNG ELECTRONICS CO LTD

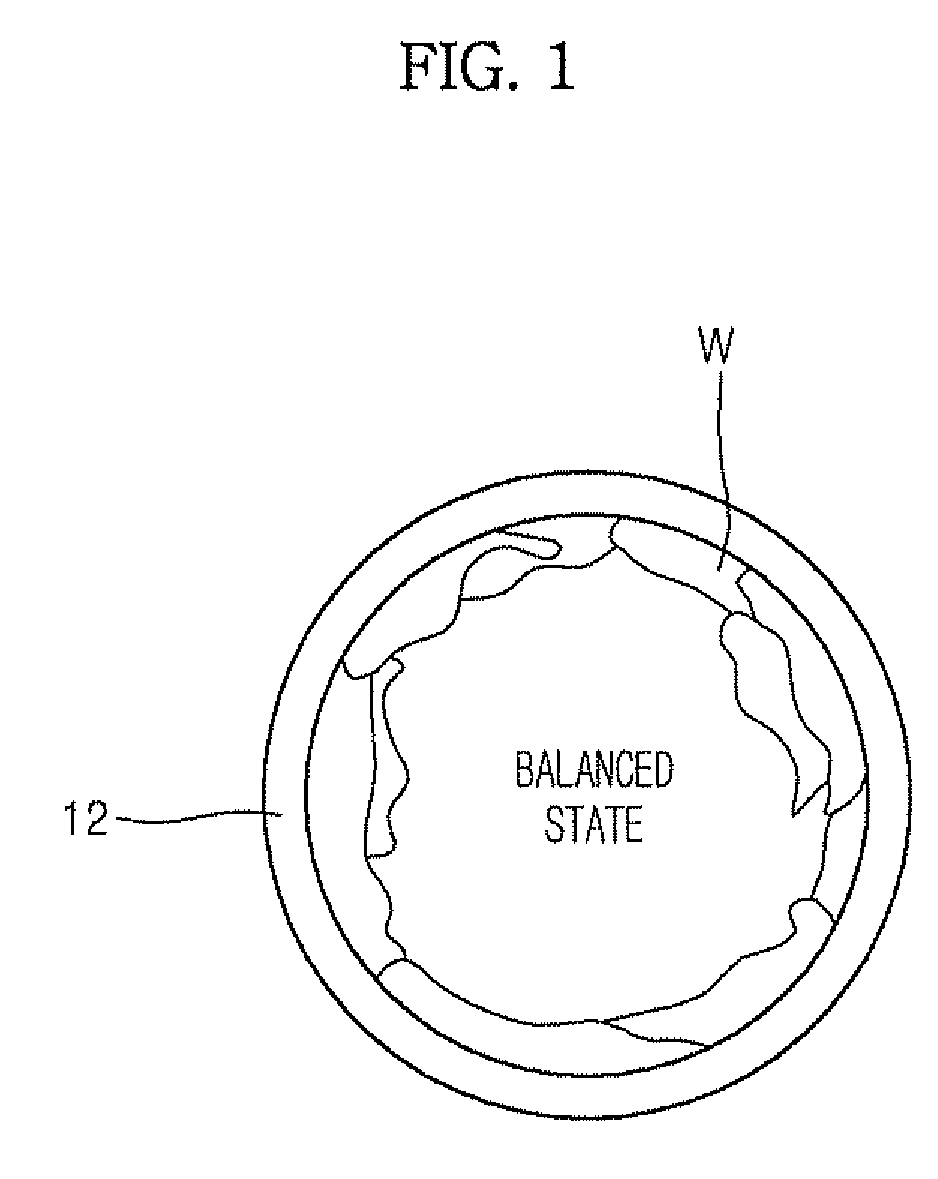

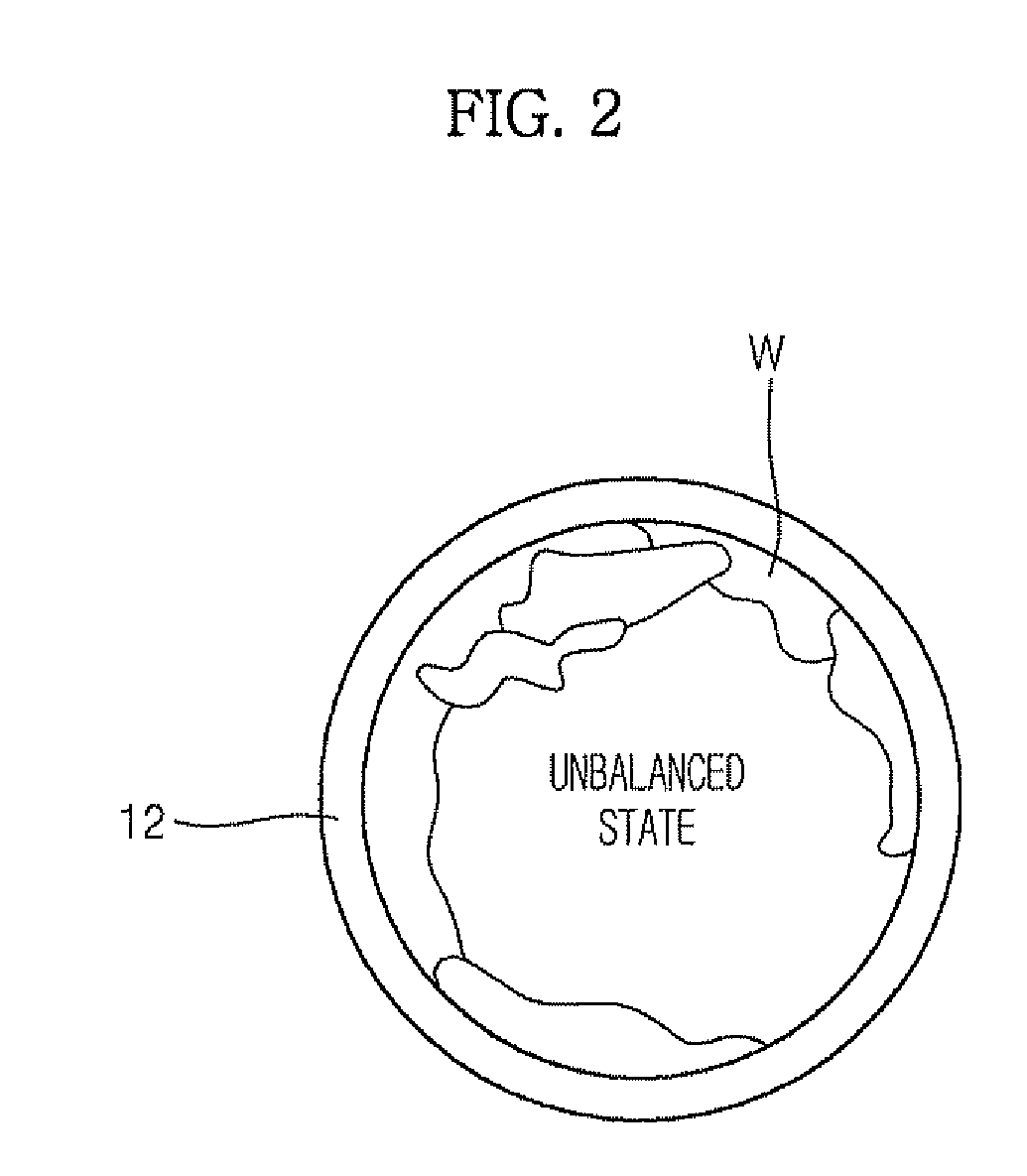

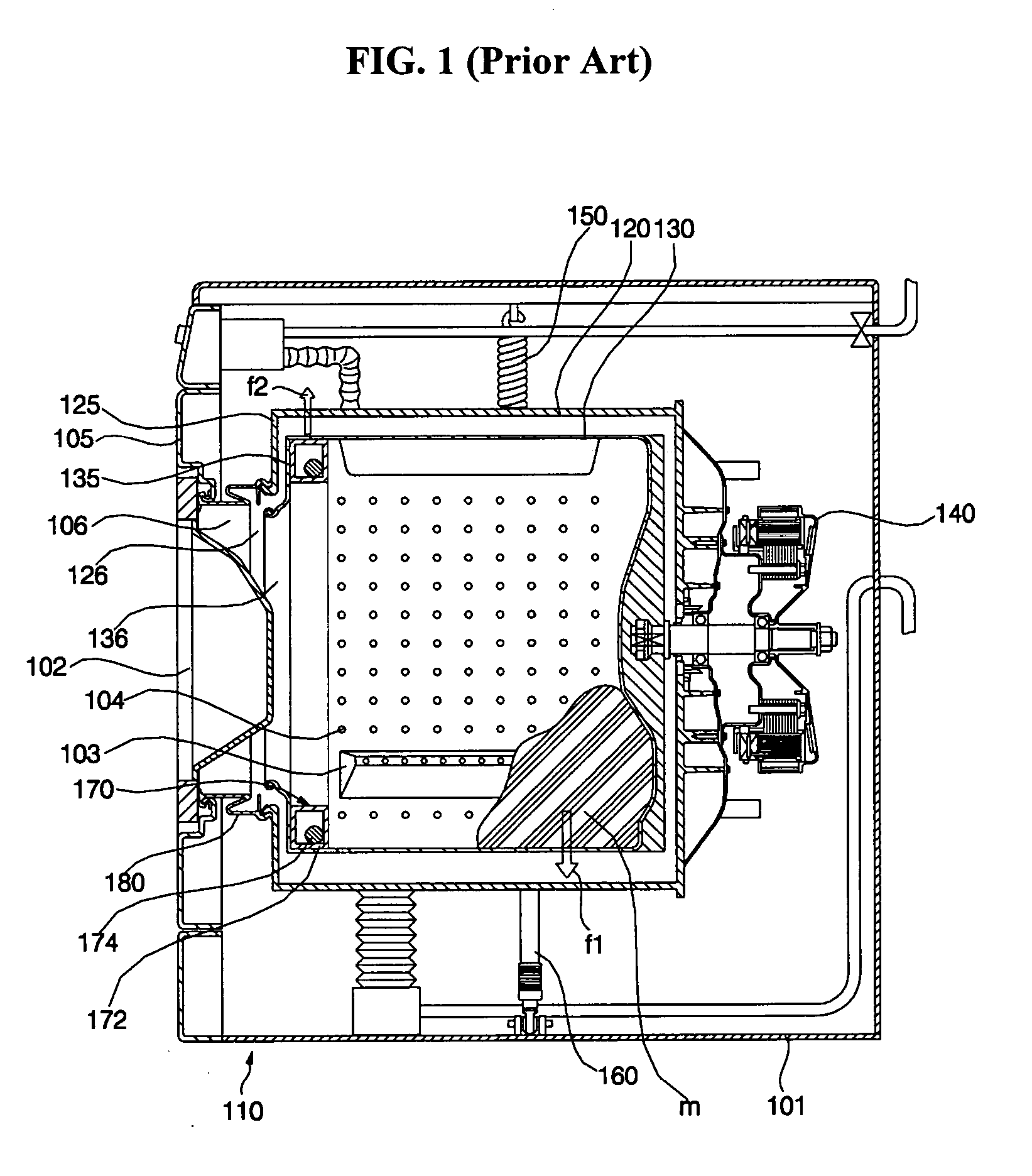

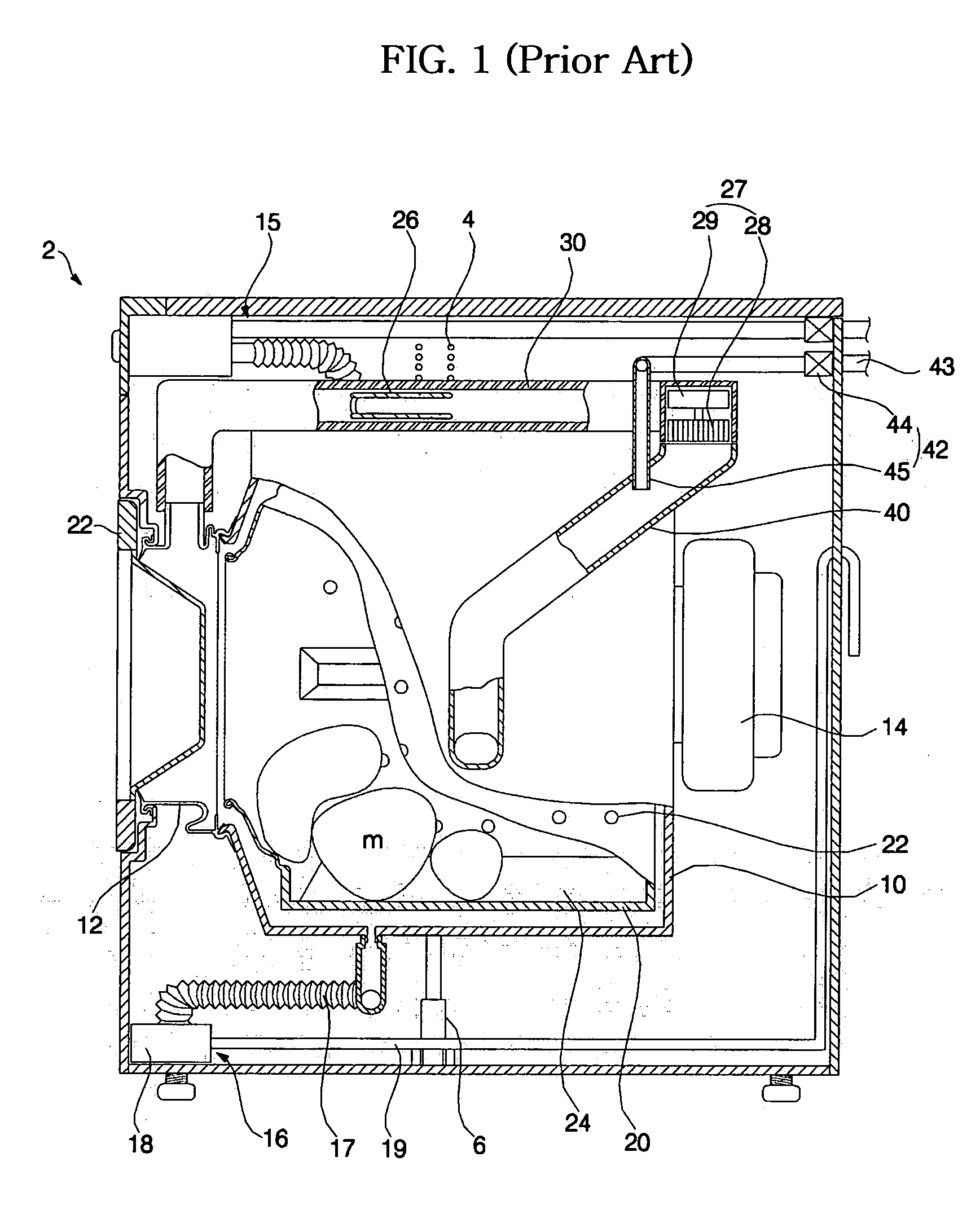

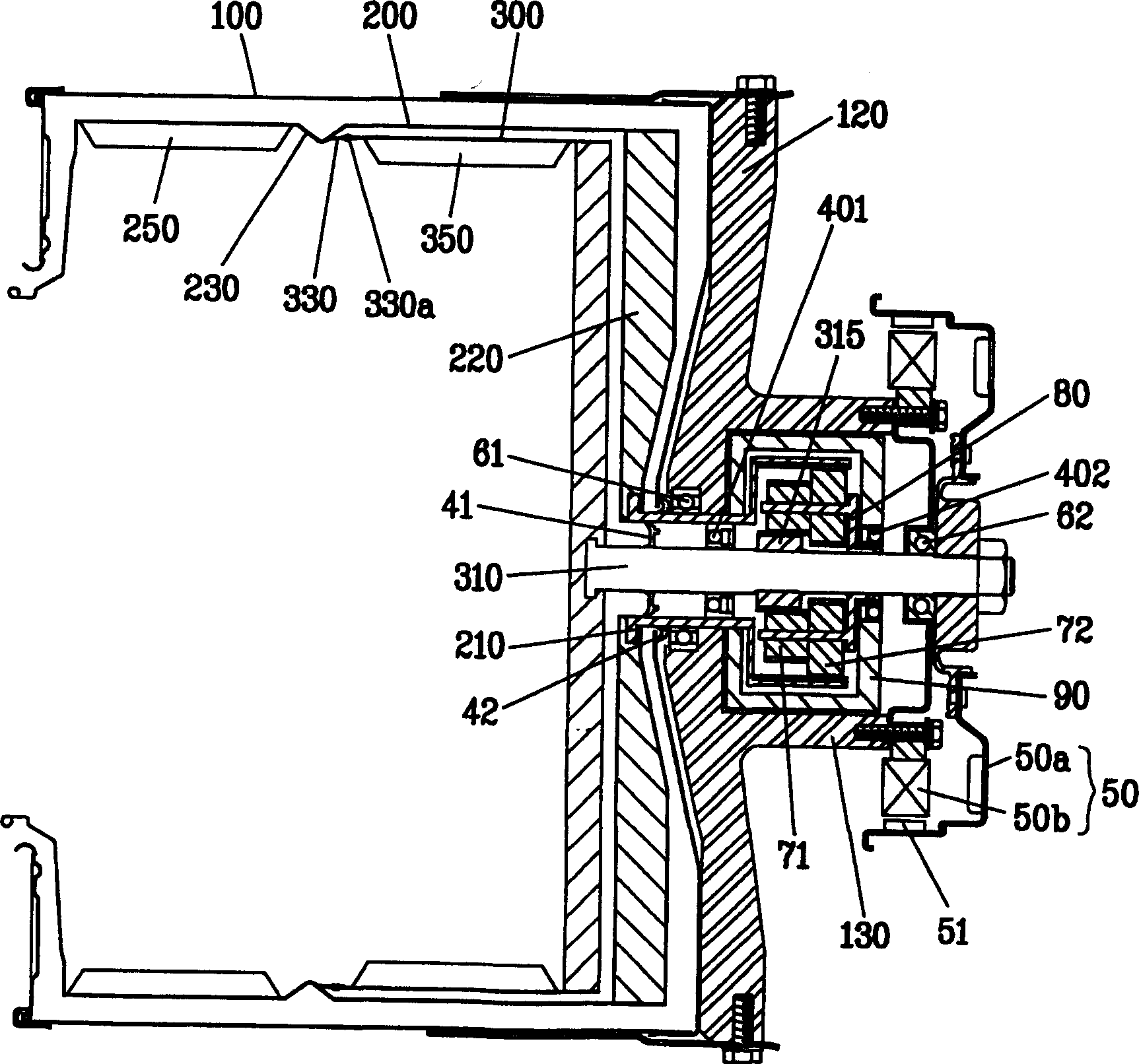

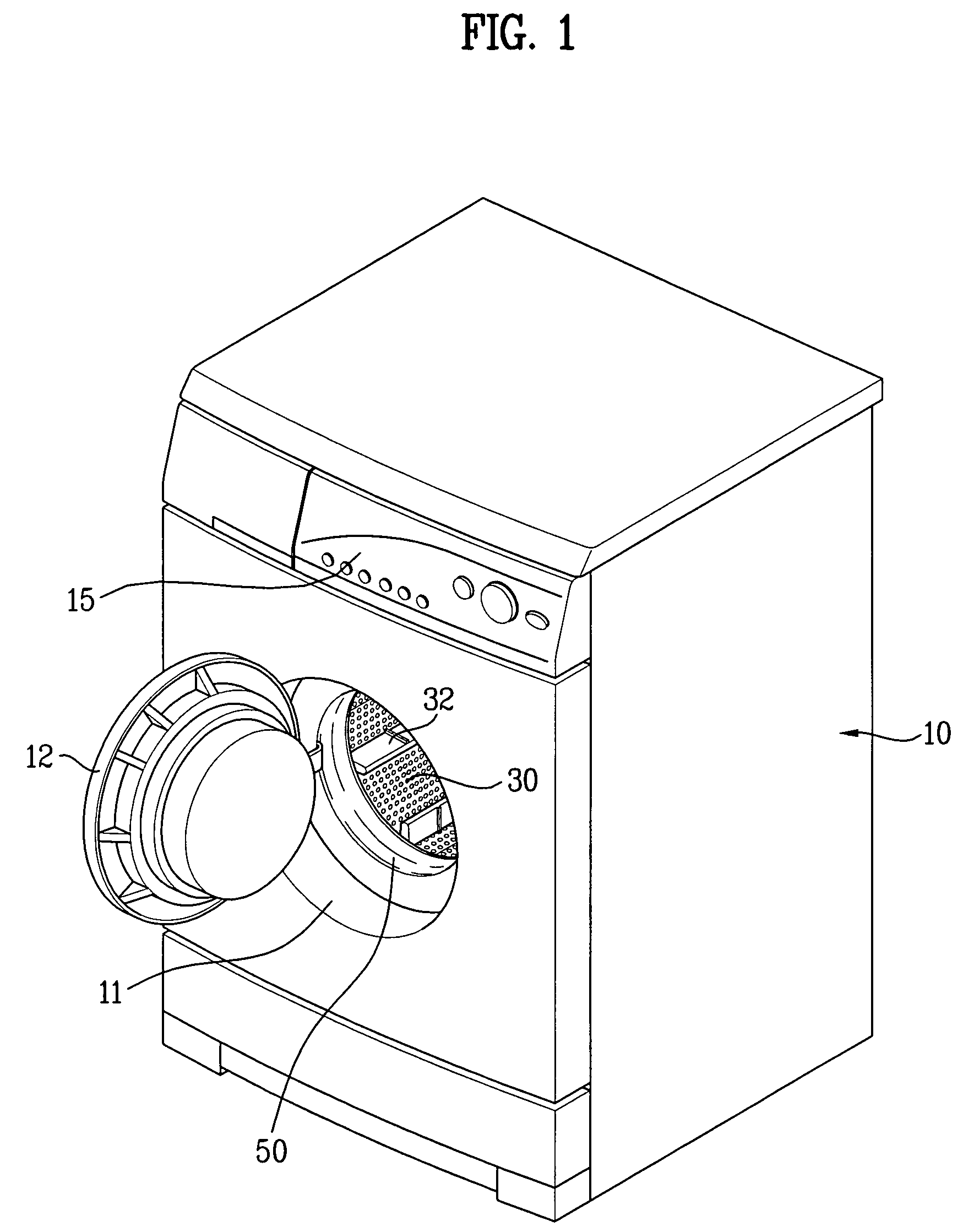

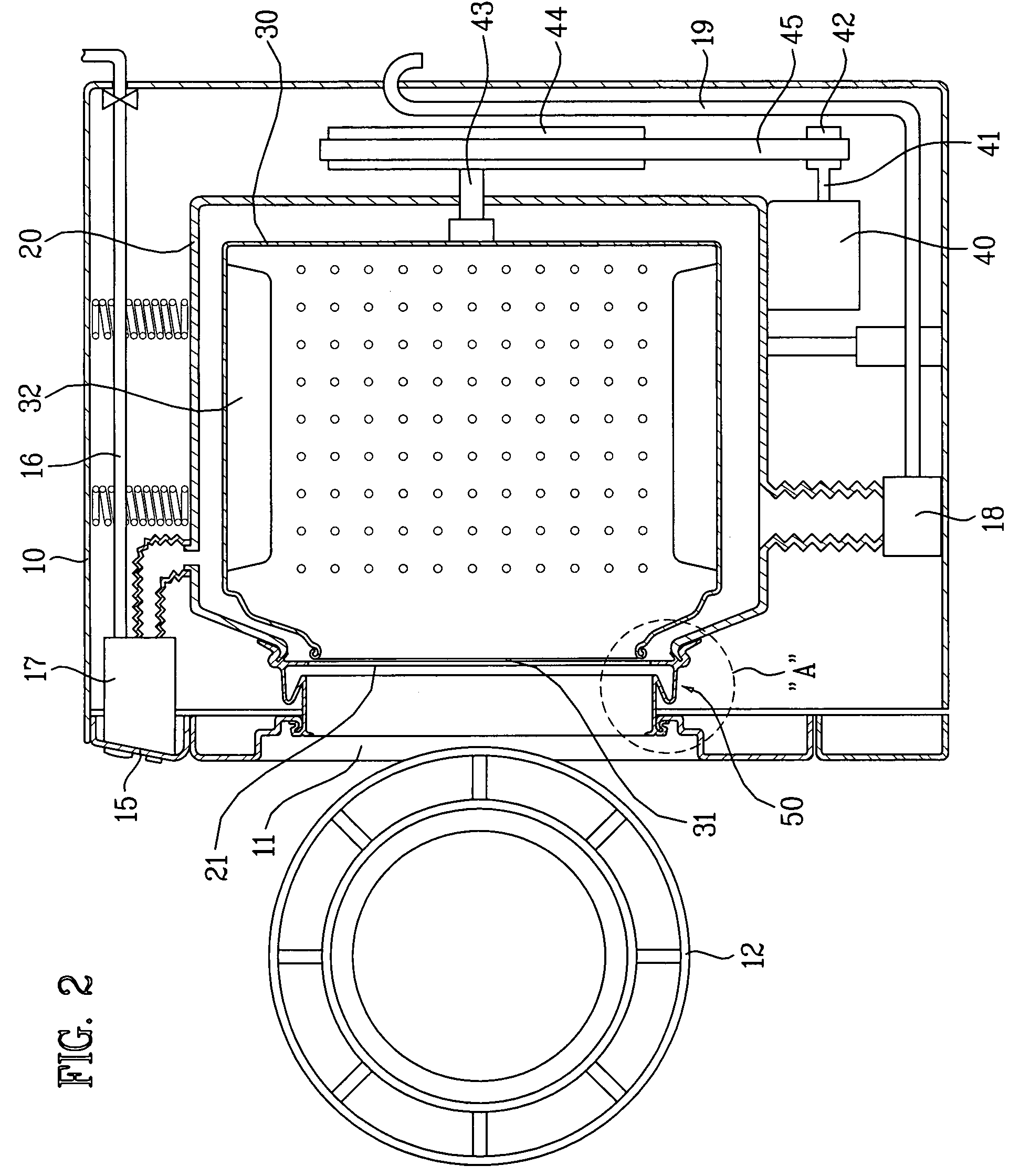

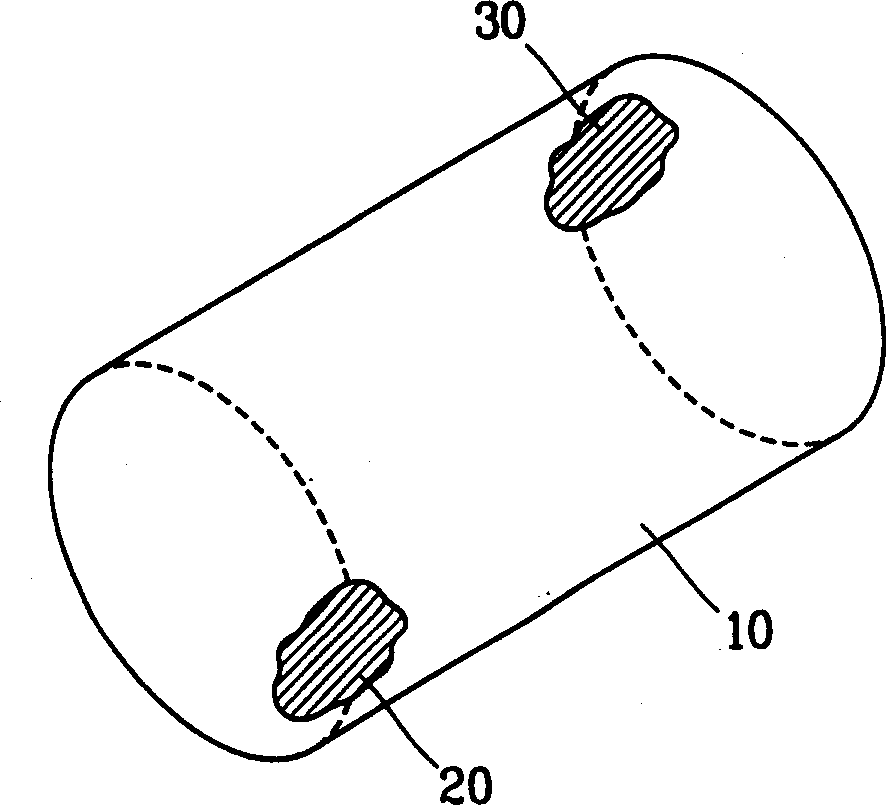

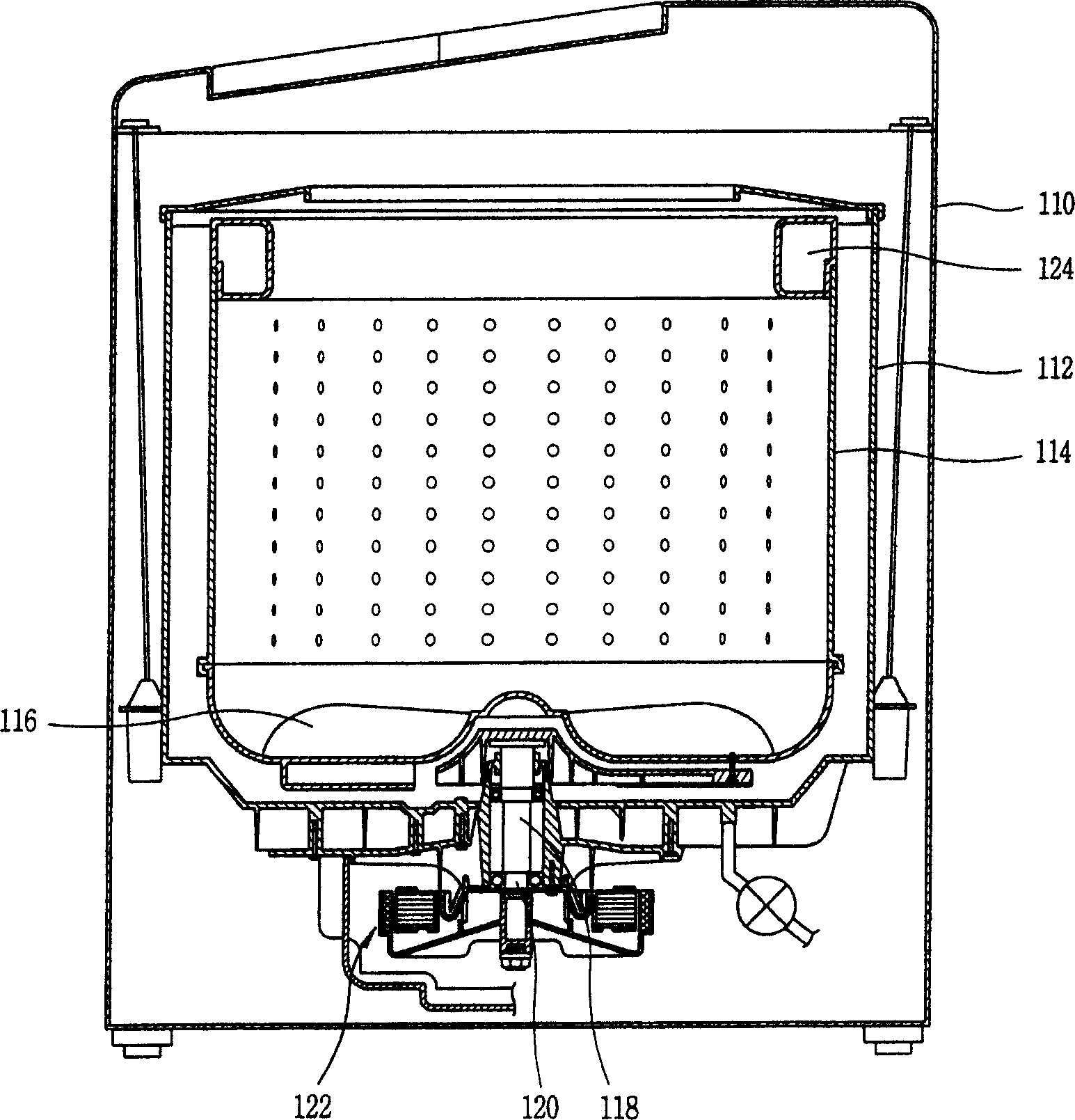

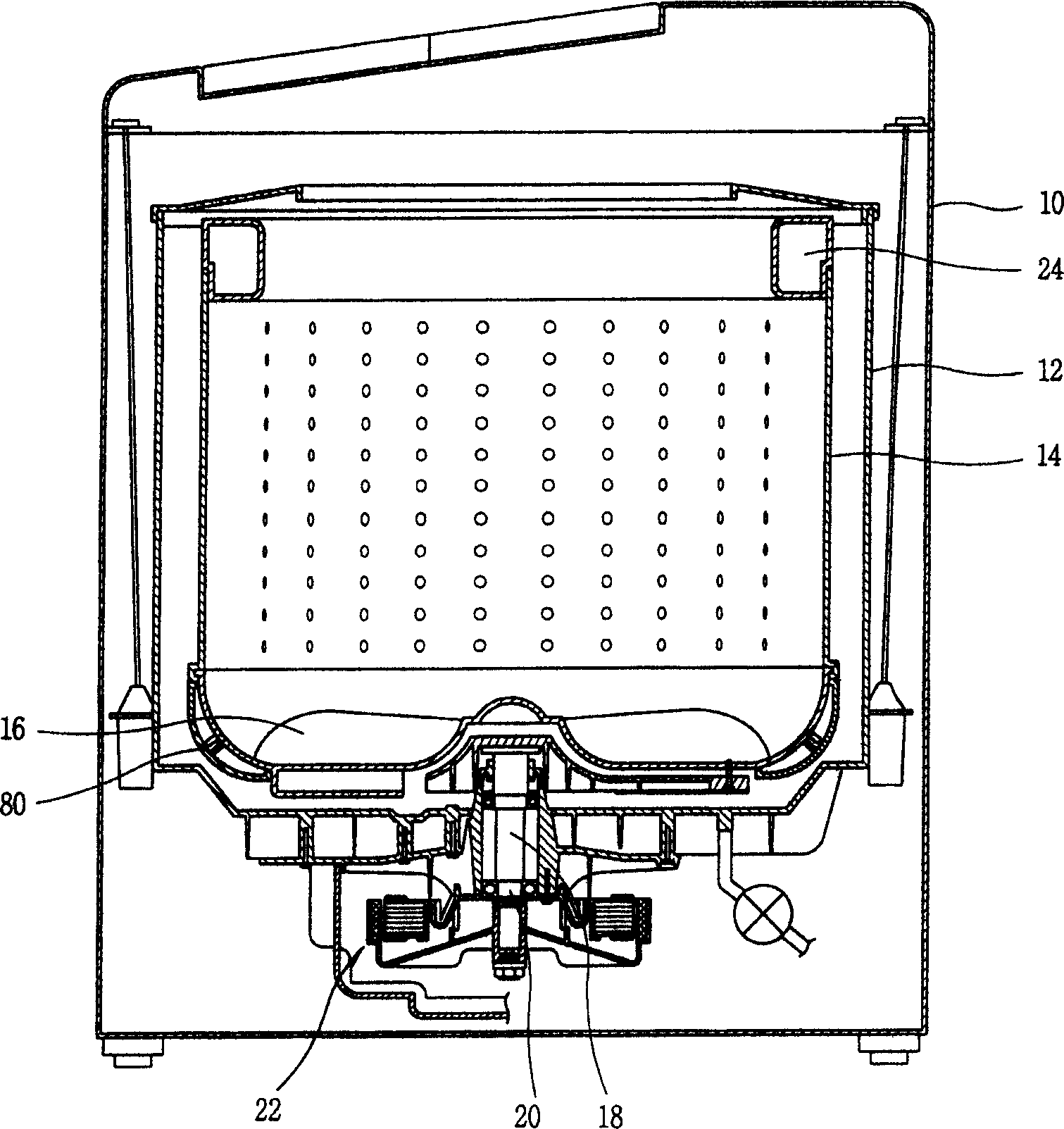

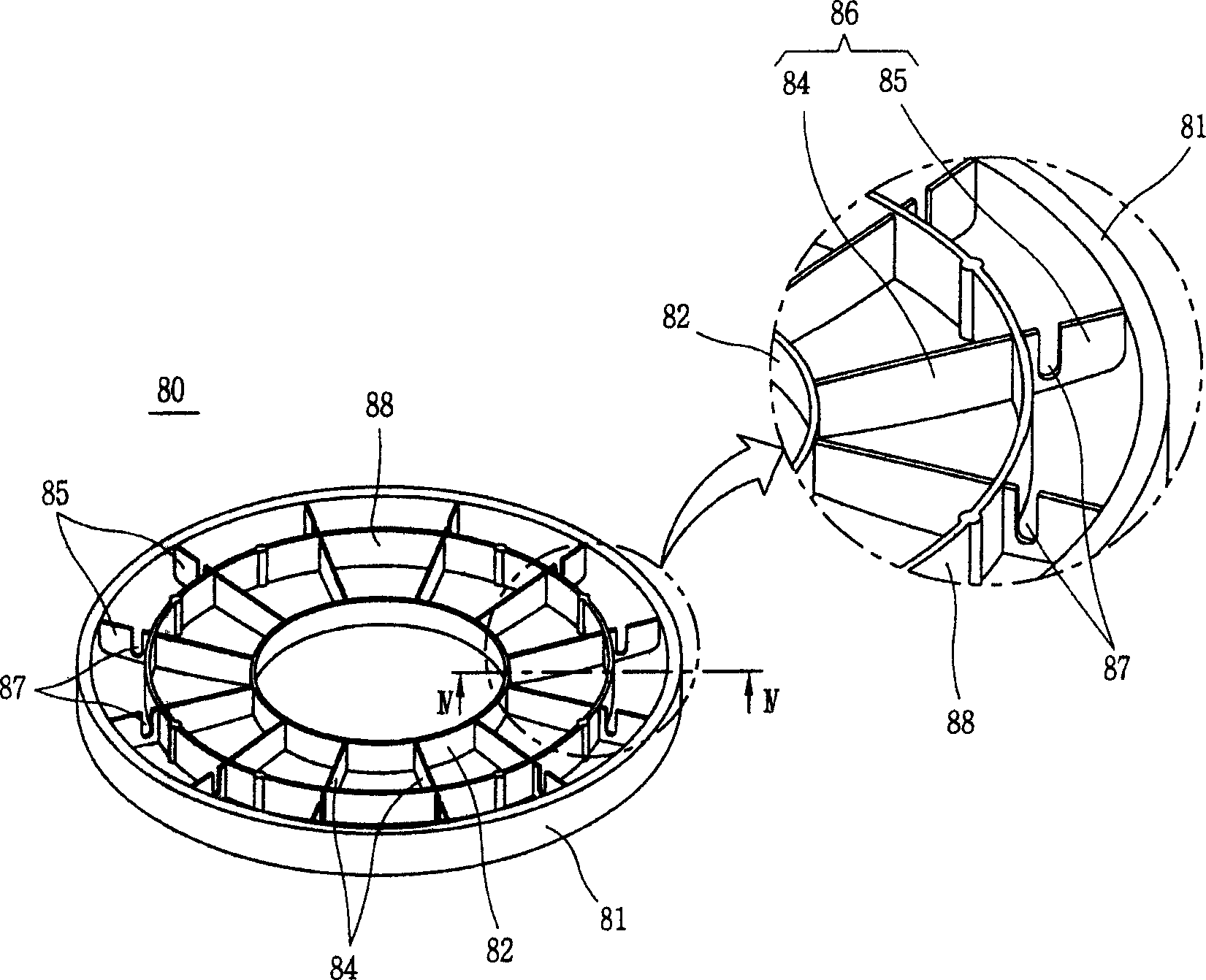

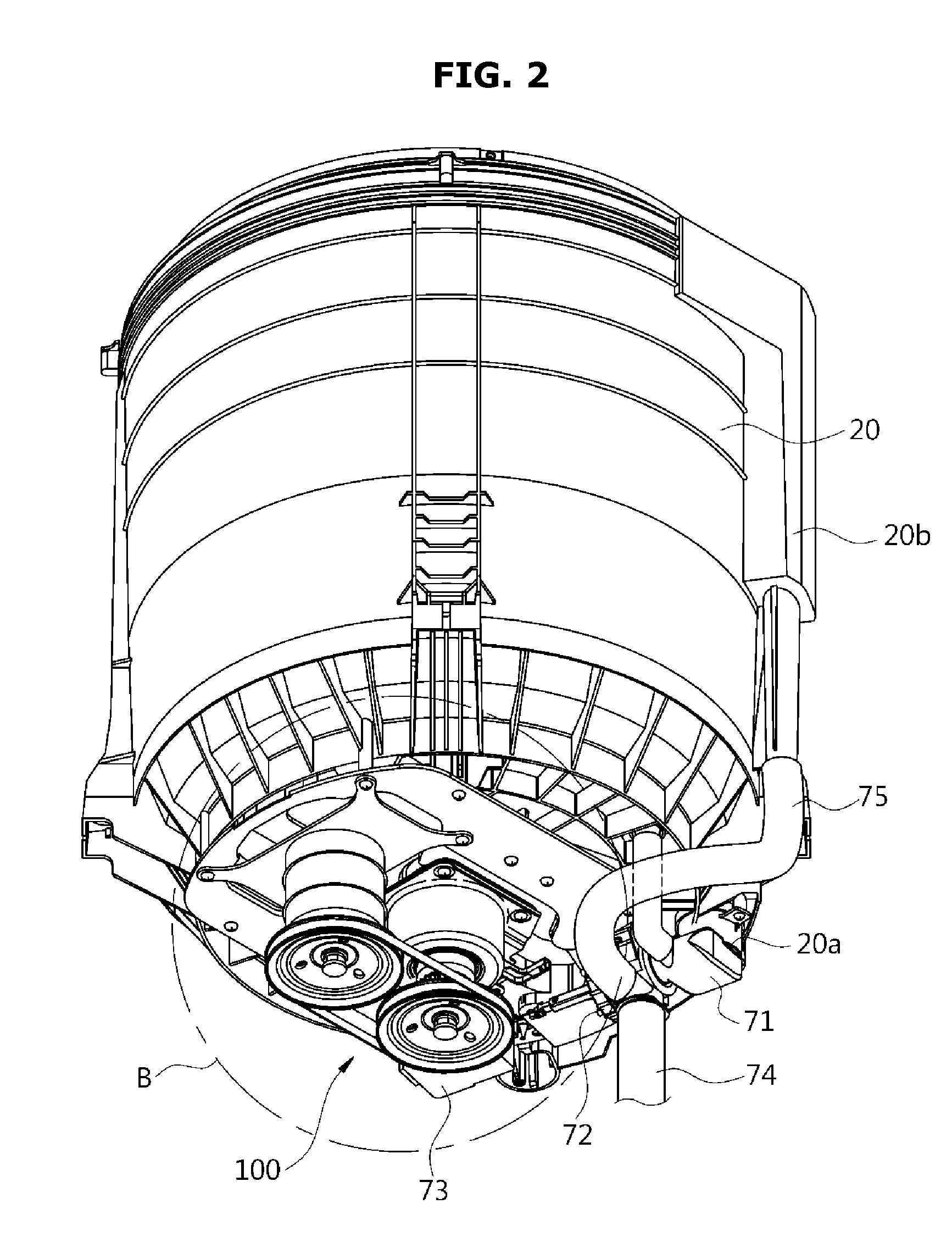

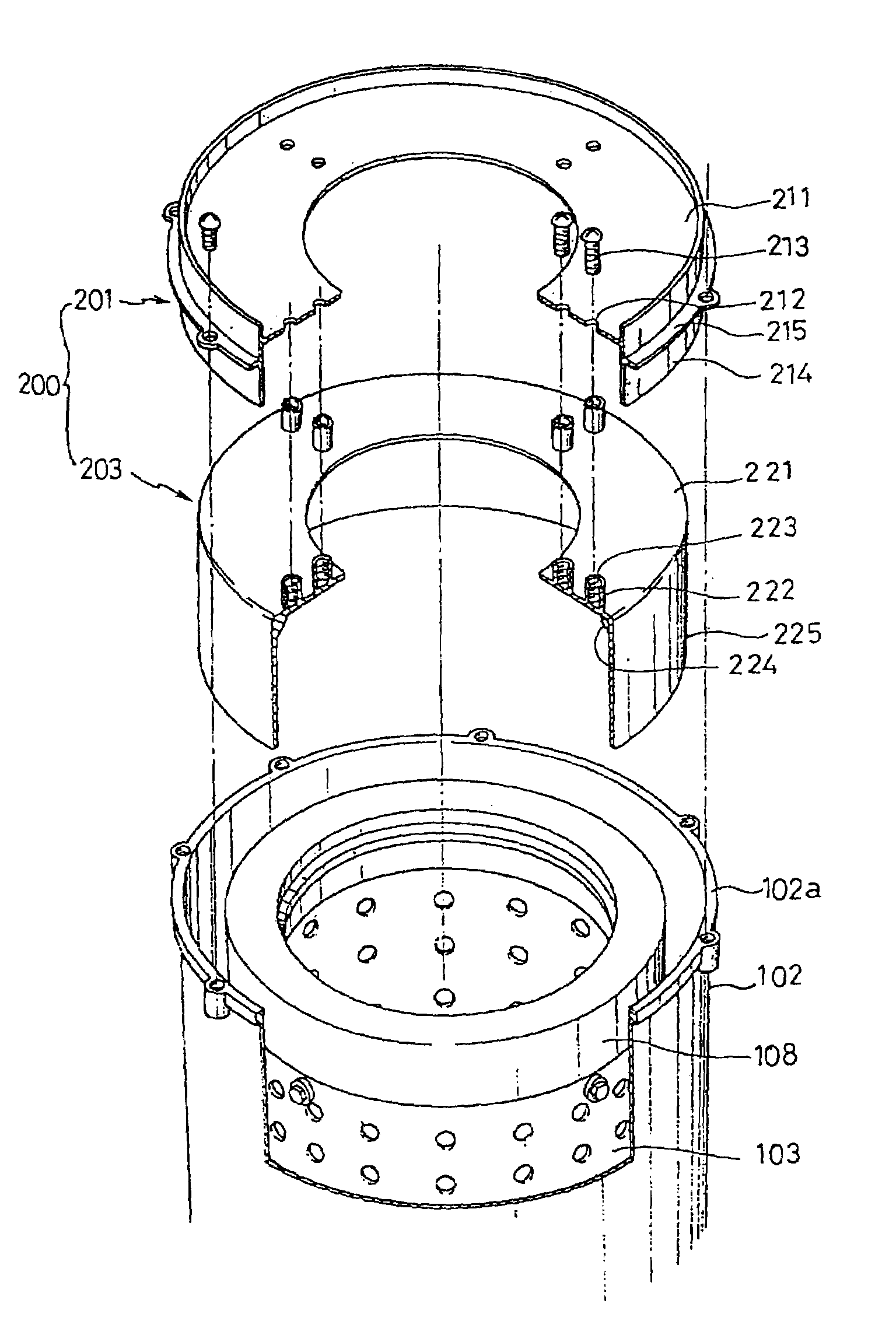

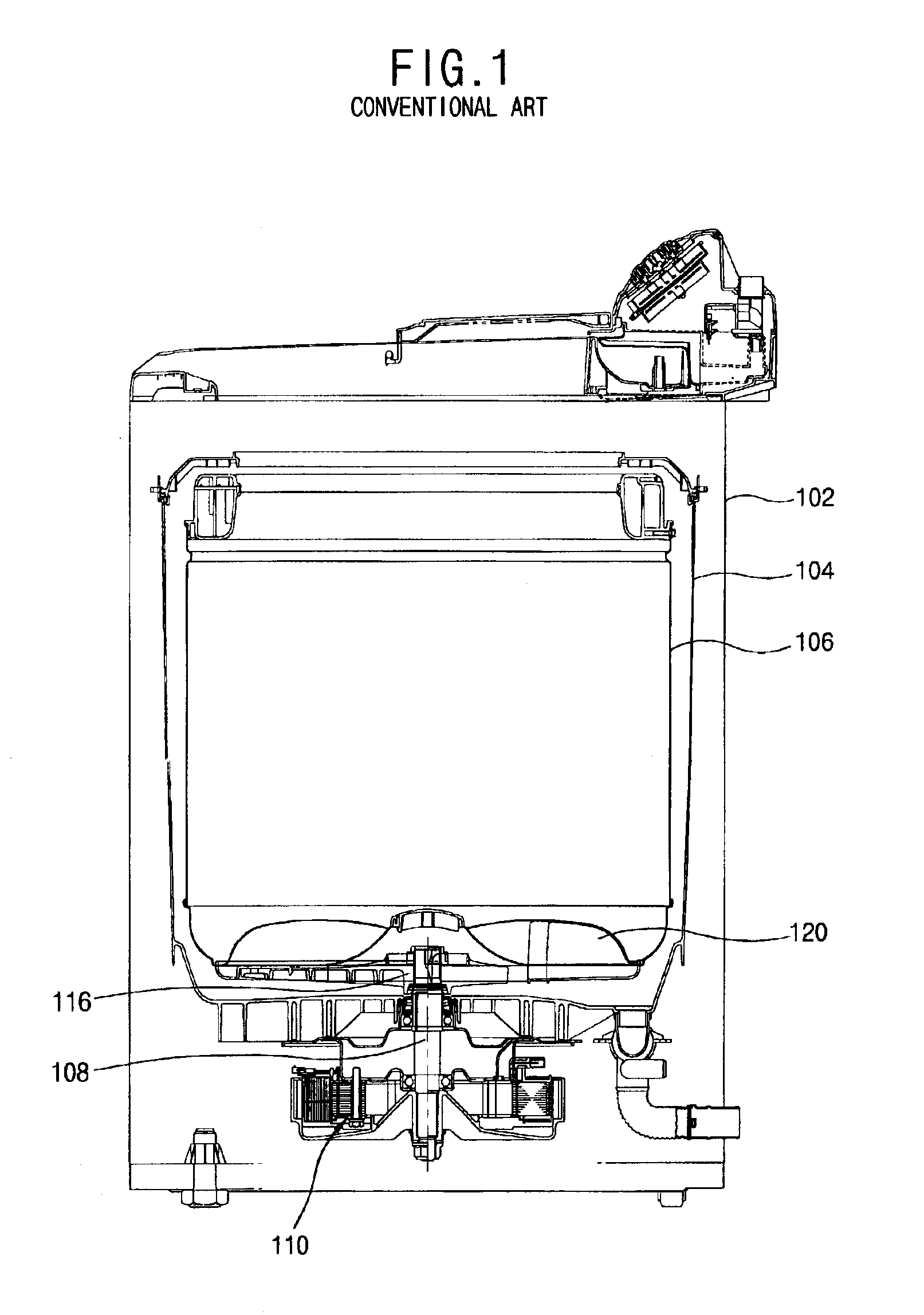

Drum type washing machine and drum therefor

InactiveUS20050274159A1Eliminate eccentric forceOther washing machinesWashing machine with receptaclesEngineeringMechanical engineering

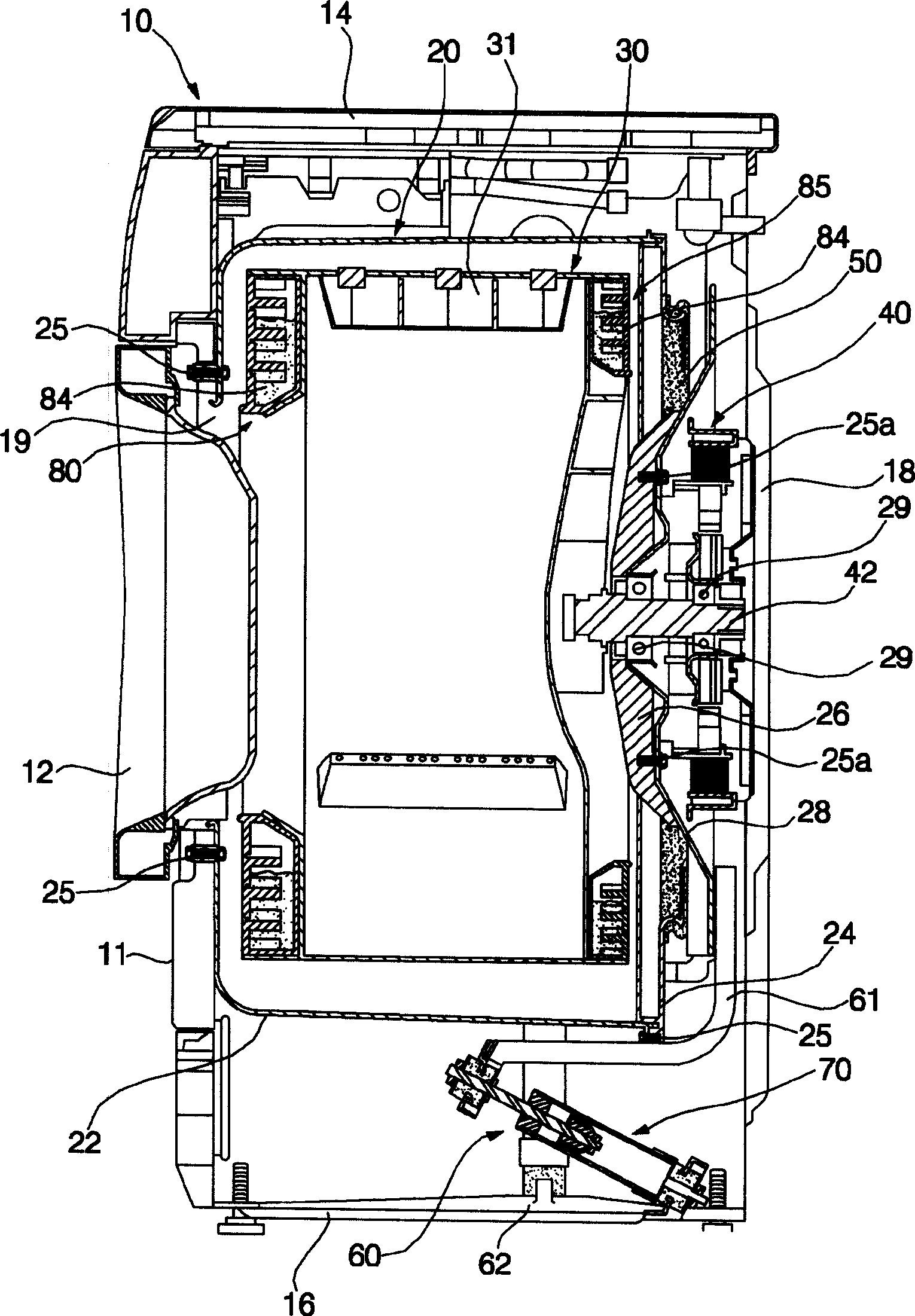

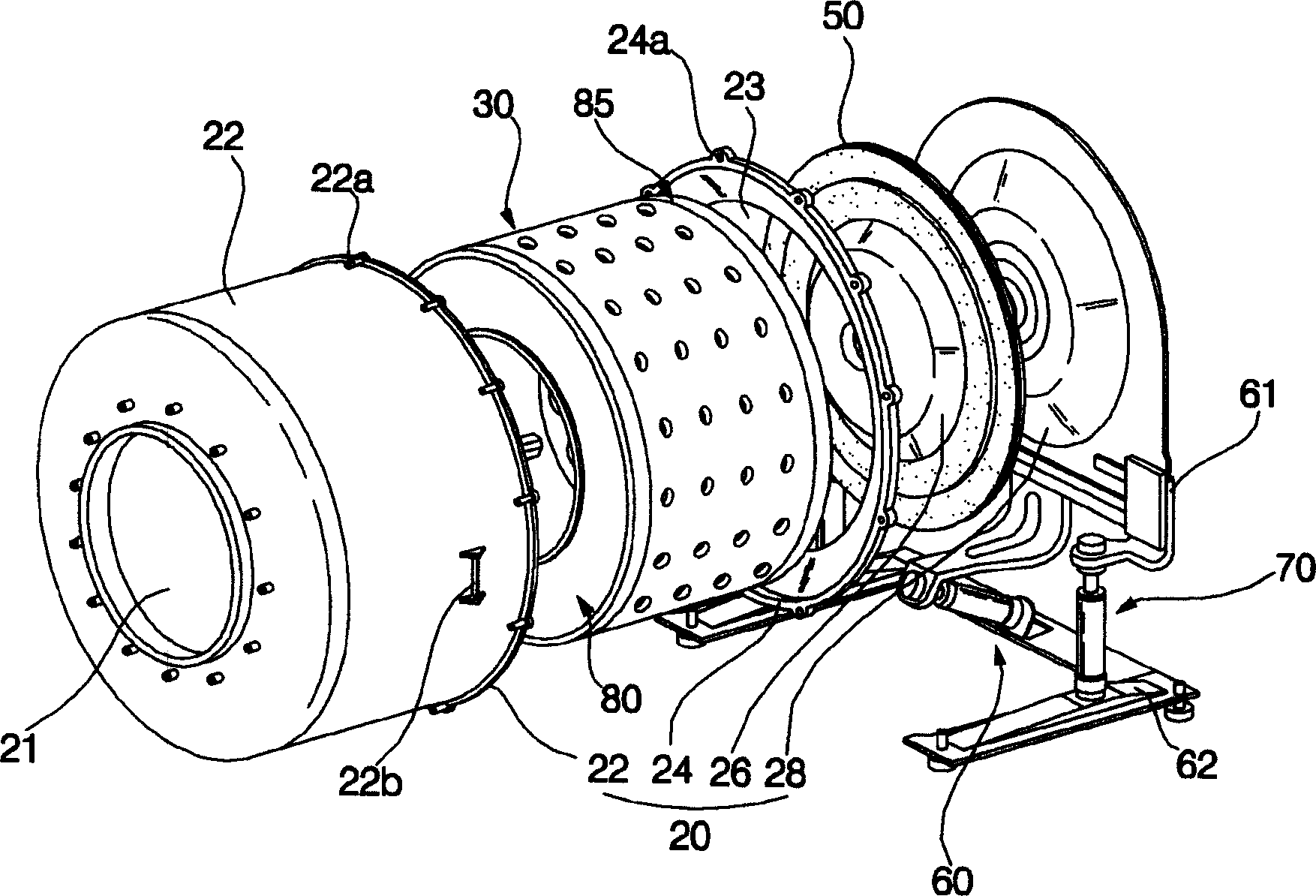

Disclosed herein is a drum type washing machine. The drum type washing machine comprises front and rear balancers mounted at the front and rear sides of a drum, respectively. Consequently, an eccentric force generated by laundry is complementarily eliminated by the front and rear balancers even when the laundry is eccentrically placed at one side of the drum.

Owner:LG ELECTRONICS INC

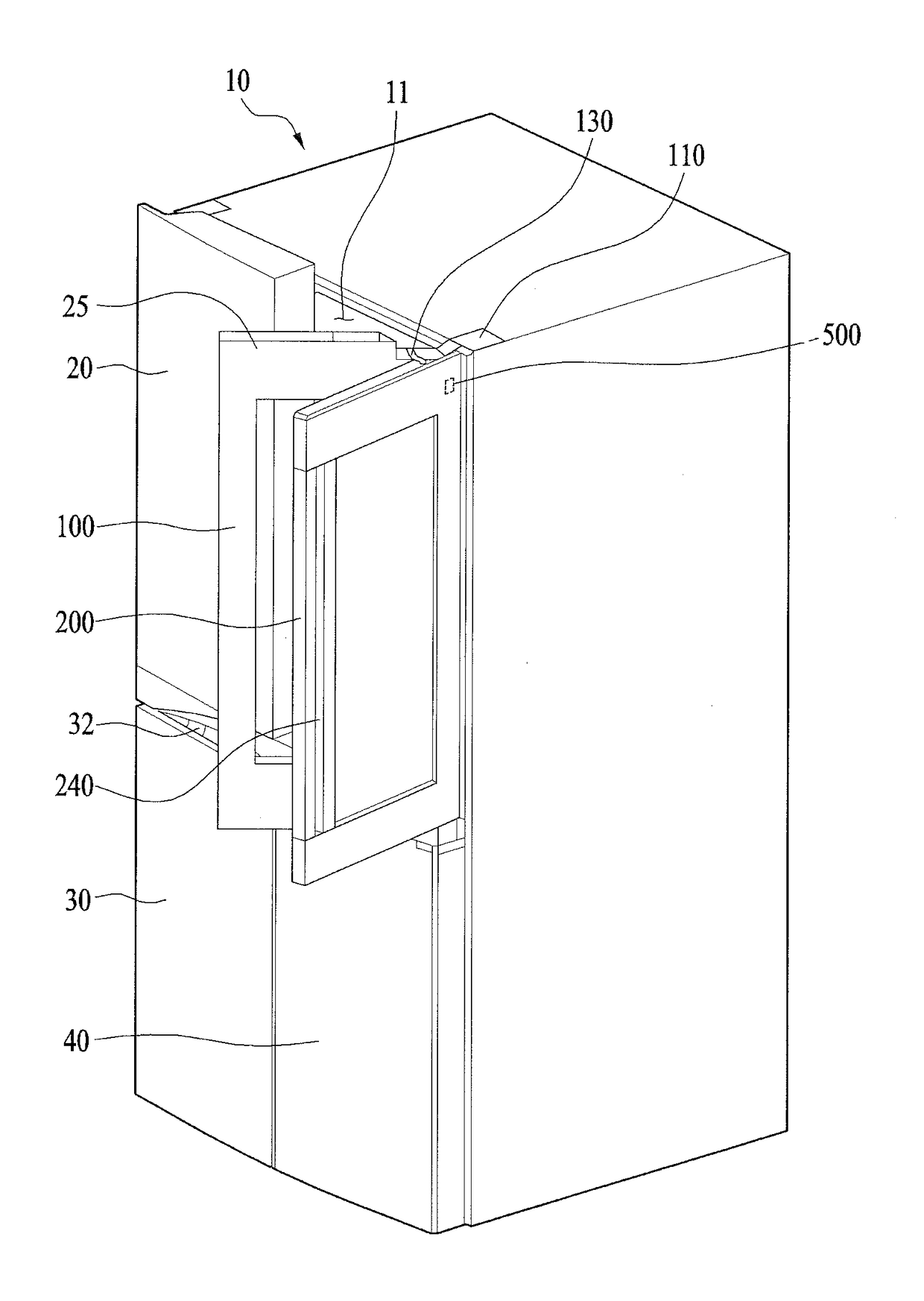

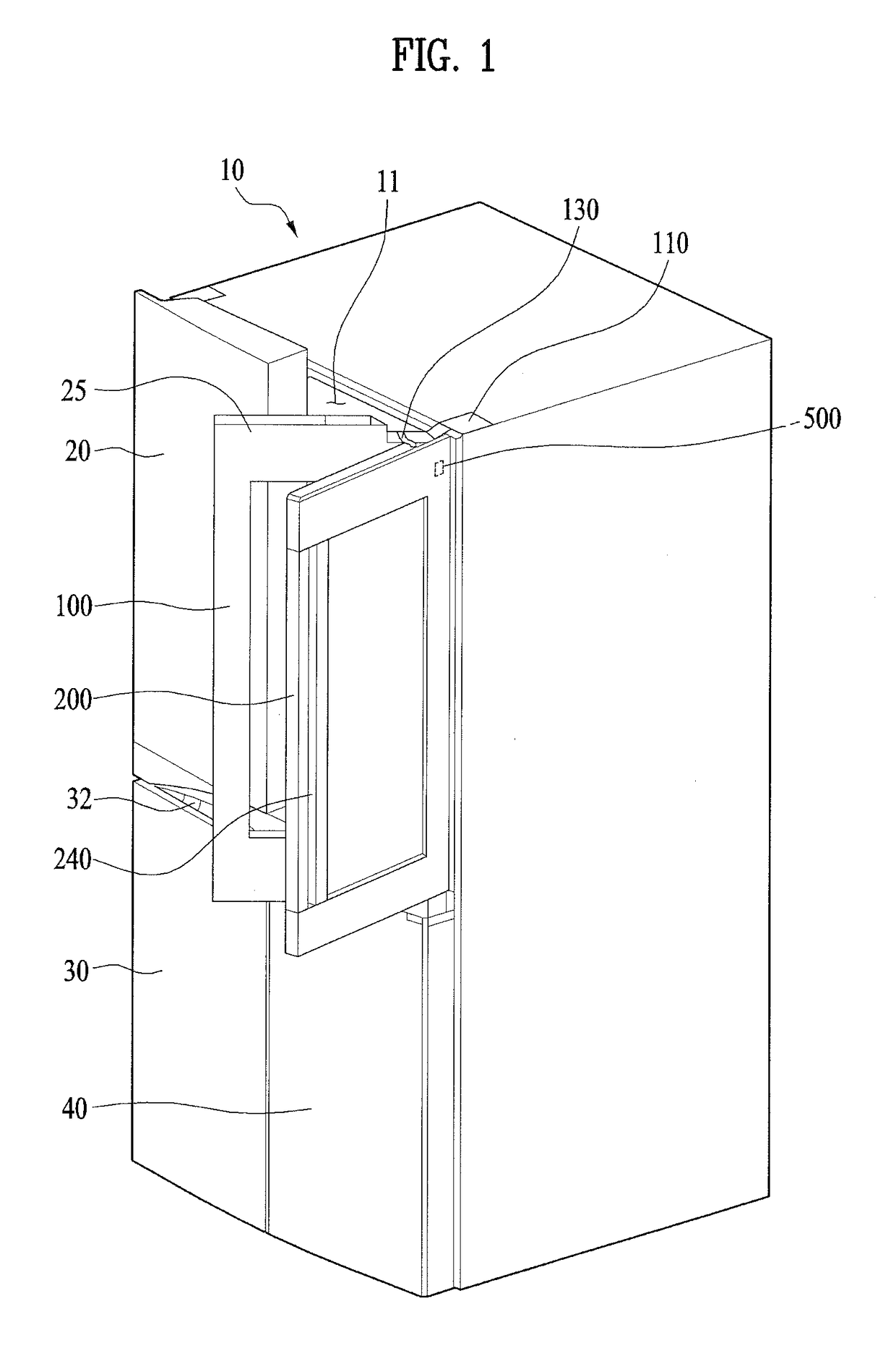

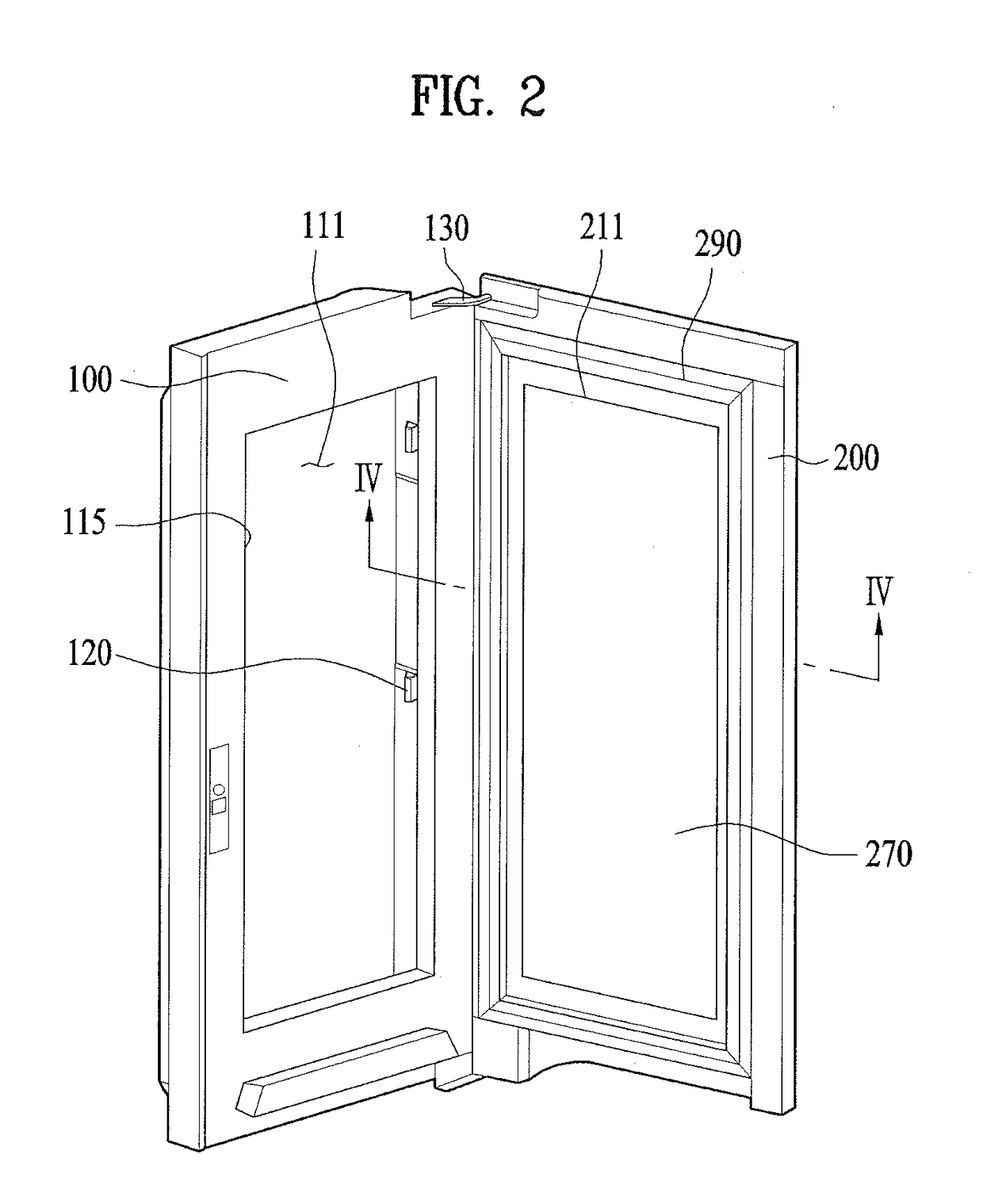

Refrigerator

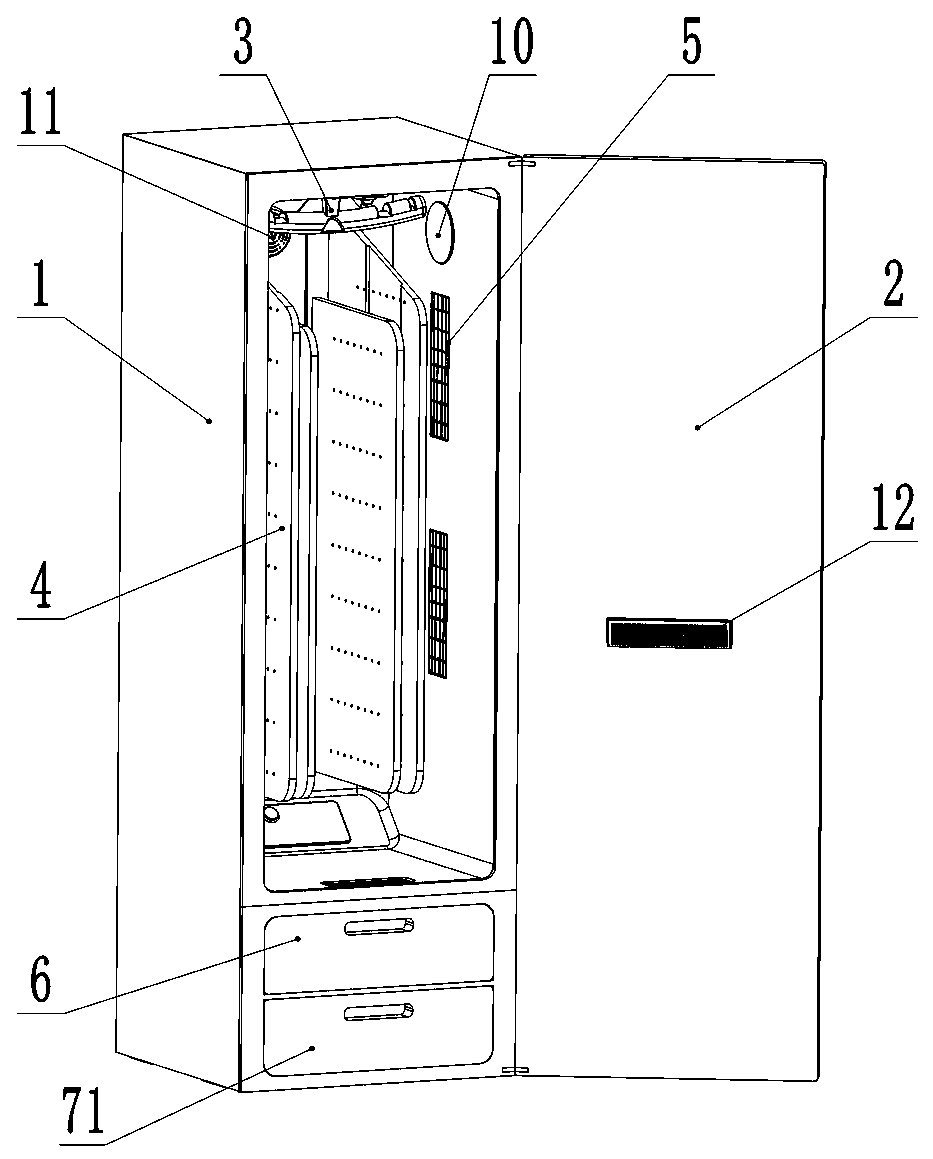

ActiveUS20170211874A1Efficient use ofReduce input errorVibration measurement in solidsVibration measurement in fluidEngineeringAcoustic wave

A refrigerator equipped with a door that becomes transparent as necessary to make the interior thereof visible is disclosed. The refrigerator includes a cabinet having a storage compartment defined therein, a lighting device for illuminating the interior of the storage compartment, a door, which is hingedly coupled to the cabinet to open and close the storage compartment, and has an opening and a panel assembly including a front panel disposed on the front surface thereof, a sensor for detecting sound waves, which are generated by a knock input applied to the door and are transmitted through the front panel, and a controller for controlling the lighting device to allow light to be transmitted through the panel assembly, thus making the storage compartment visible from outside the door through the opening when a predetermined knock input is detected.

Owner:LG ELECTRONICS INC

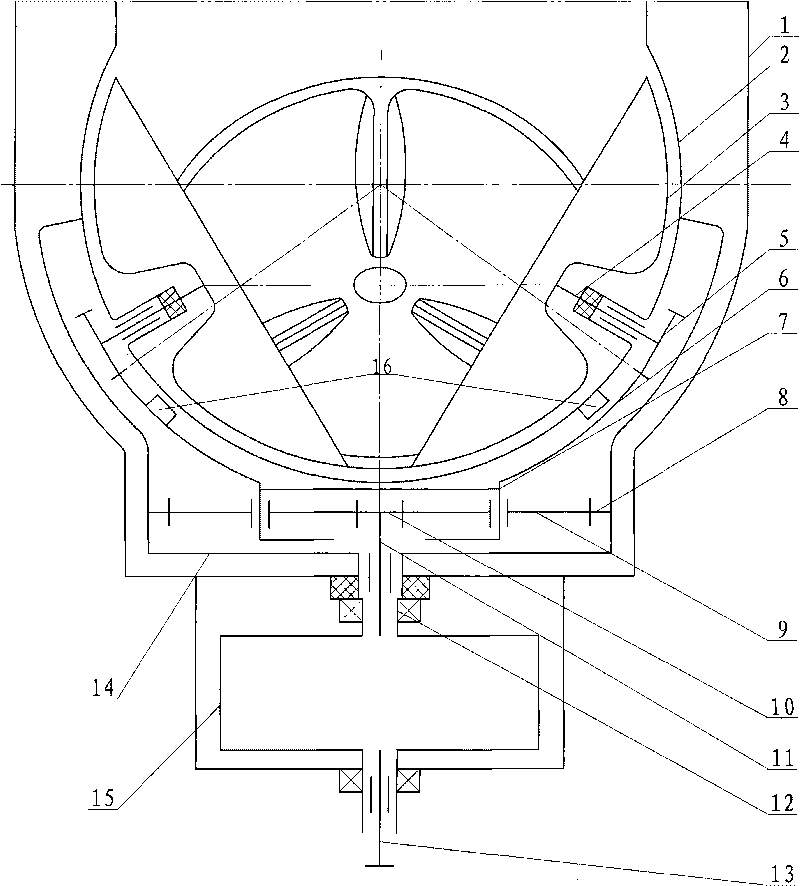

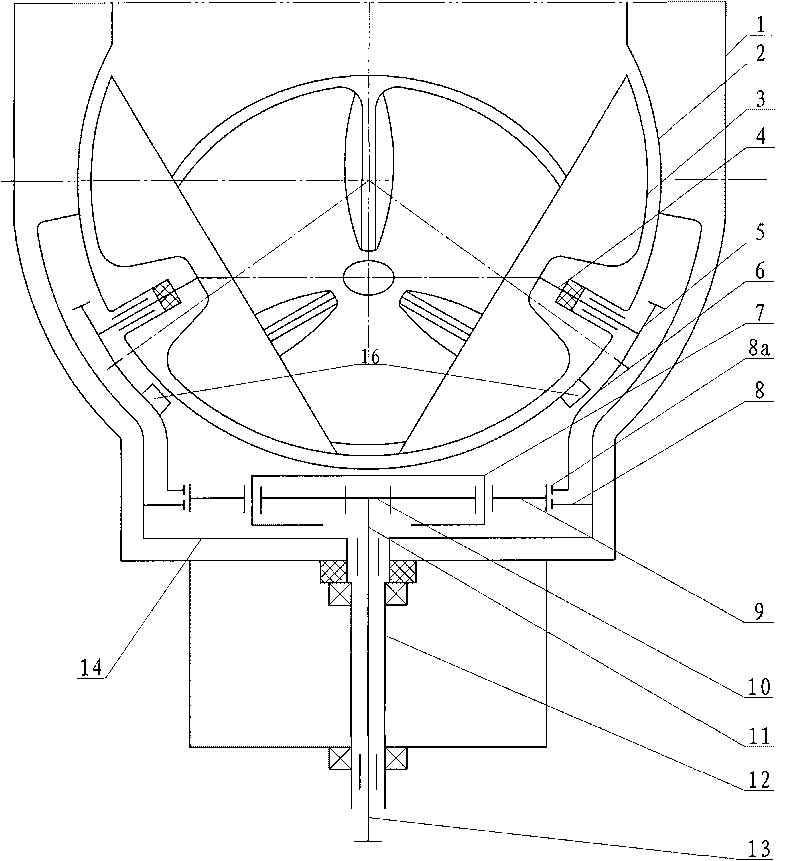

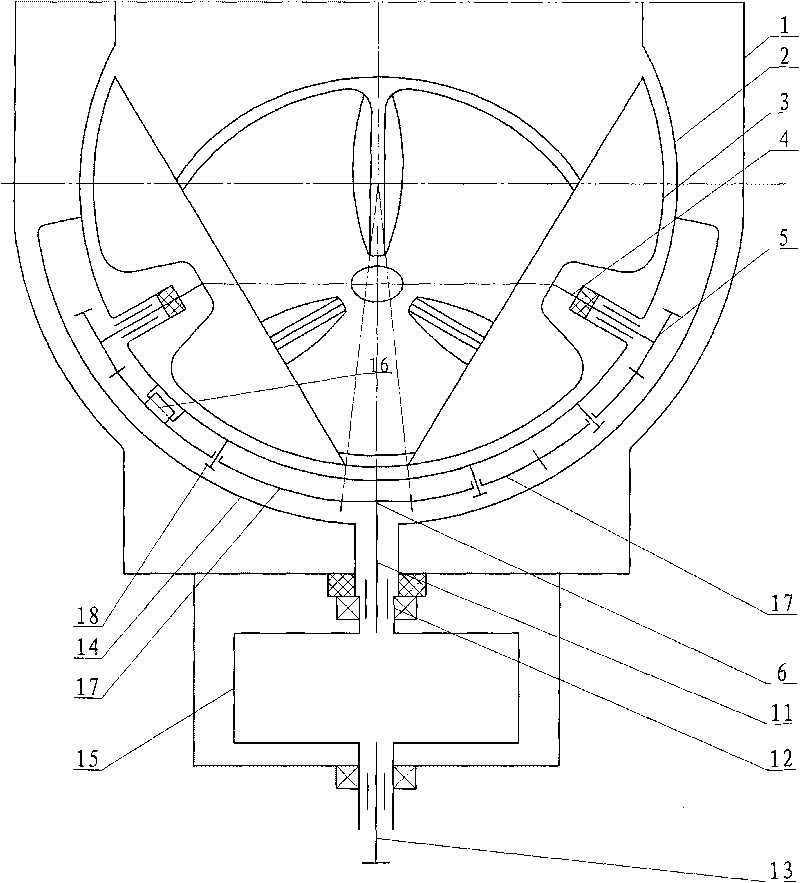

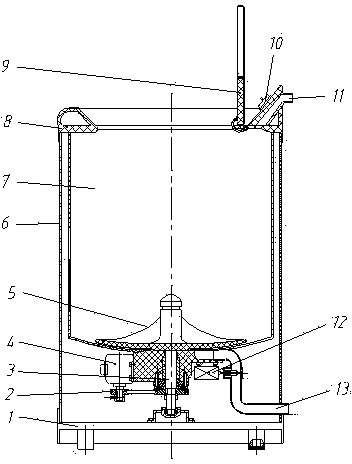

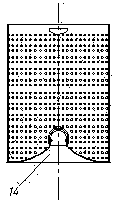

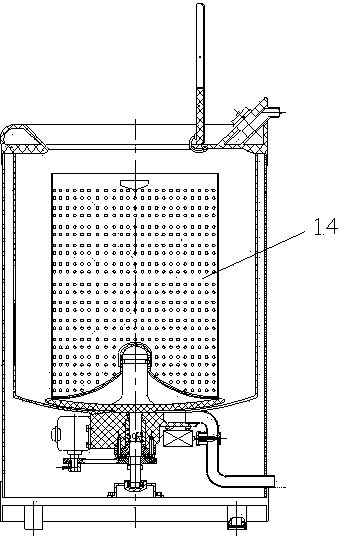

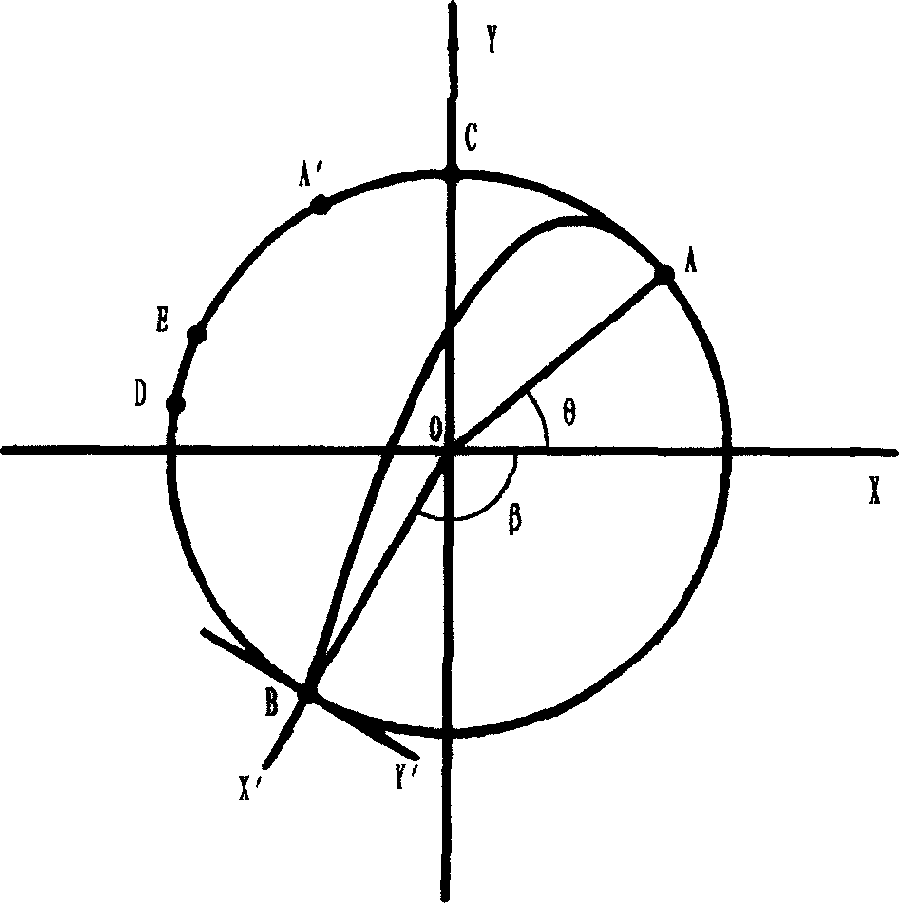

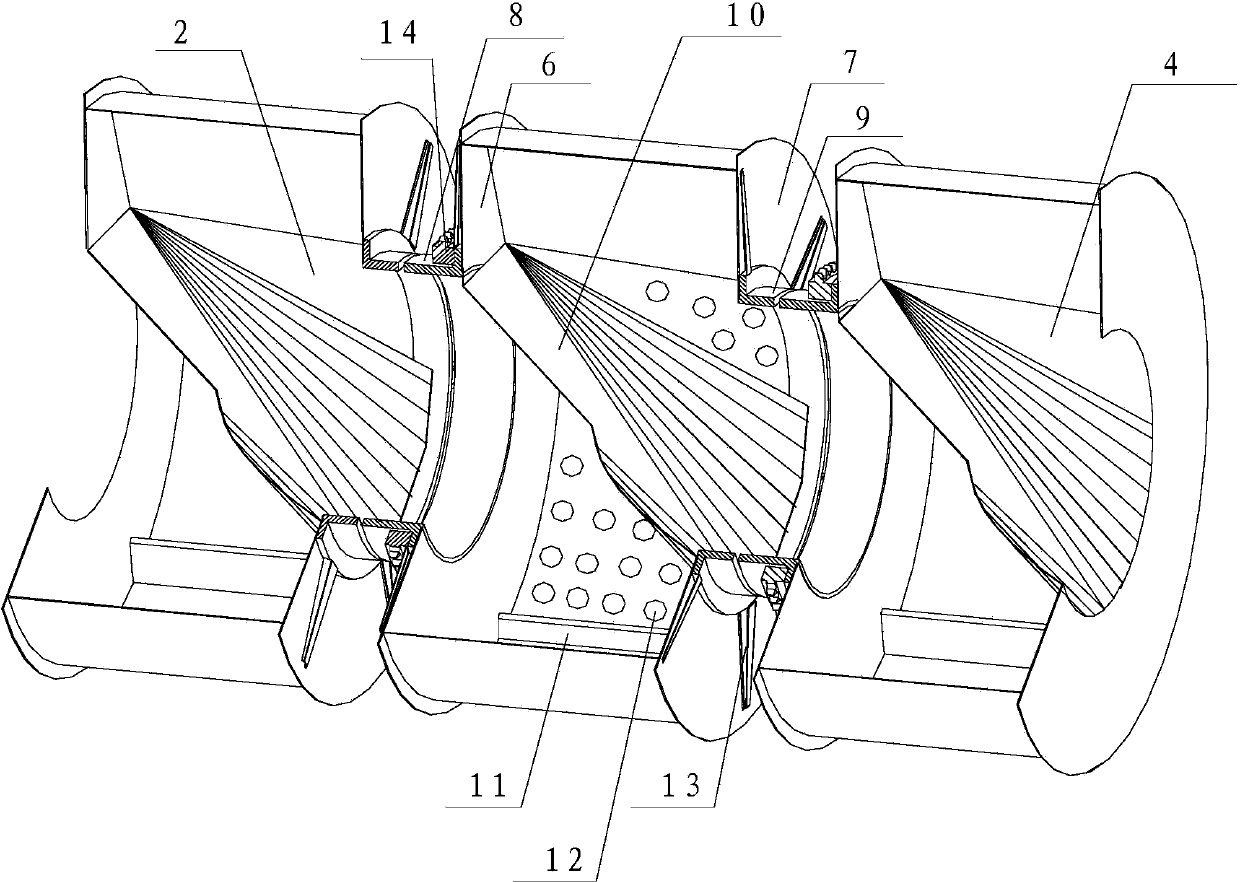

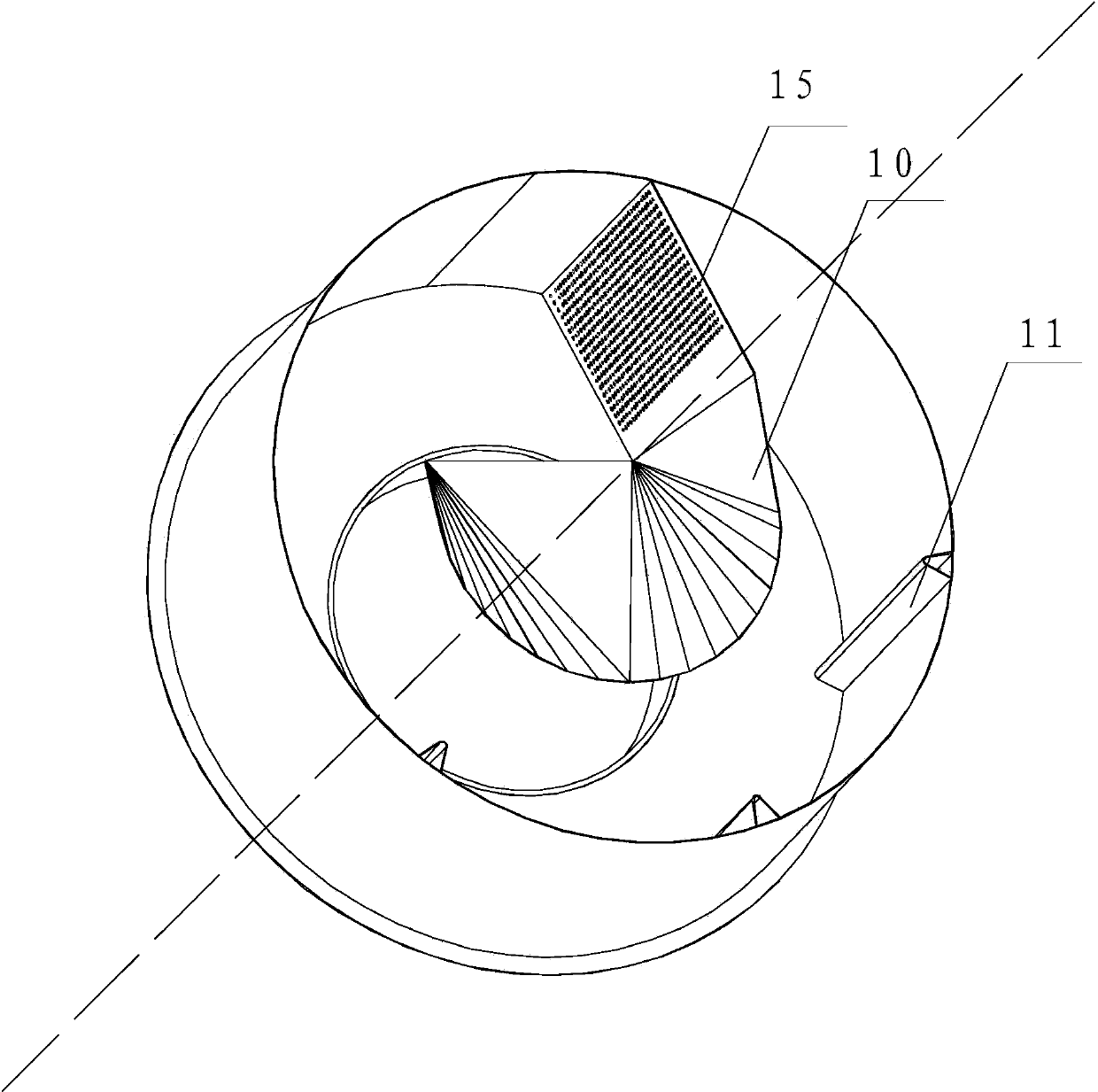

Transmission mechanism of full-automatic multi-impeller washing machine and washing machine and washing mode thereof

InactiveCN101718030ASolution to short lifeImprove poor operating environmentOther washing machinesWashing machine with receptaclesImpellerVertical plane

The invention provides a transmission mechanism of a full-automatic multi-impeller washing machine and a washing machine and a washing mode thereof, relating to the technical field of washing machines, in particular to an full-automatic multi-impeller washing machine; the transmission mechanism of the full-automatic multi-impeller washing machine is mainly composed of a bevel gear part, all bevel gears of the bevel gear part run in the same spherical surface and are all arranged in a closed transmission box, so as to be separated from washing liquid; when in washing, only the impeller rotate, the shell of the transmission box does not rotate, and when in dehydration, the transmission box and an inner barrel rotate together; the rotating directions of the impellers, including forward rotation and reversal rotation, are different when being looked down from the center of the upper opening of the inner barrel, wherein at least one impeller rotate along the opposite direction with the other impellers; when in washing working condition, the clothes is thrown upwards to the great extent, and is rolled in a vertical plane, and the clothes rotate in a horizontal plane simultaneously; in addition, the different throwing phase positions are changed, so as not to lead the clothes to be twined, greatly improve the washing effect of the washing machine and the working efficiency and save the time and the water consumption.

Owner:NINGGUO JULONG IND

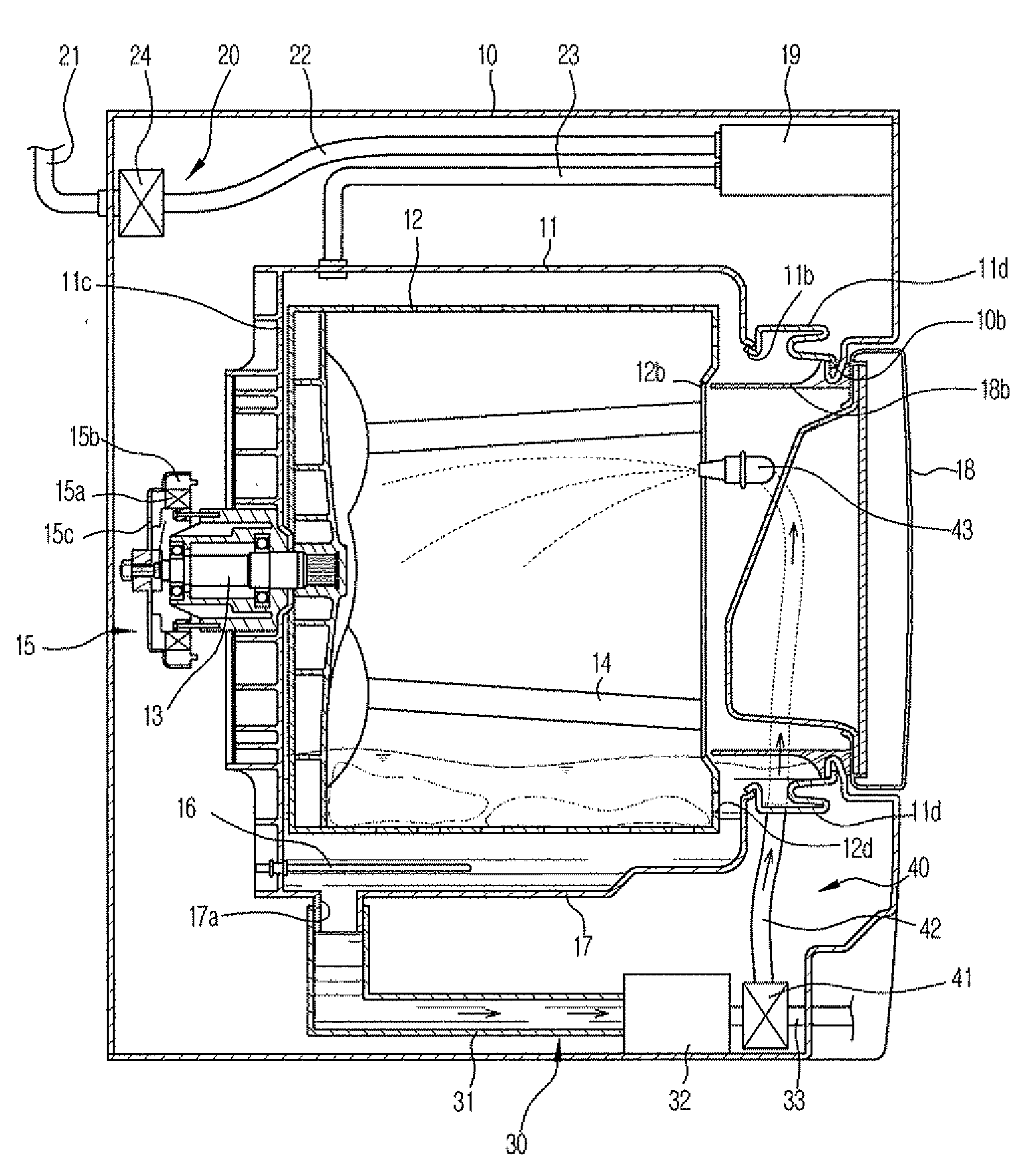

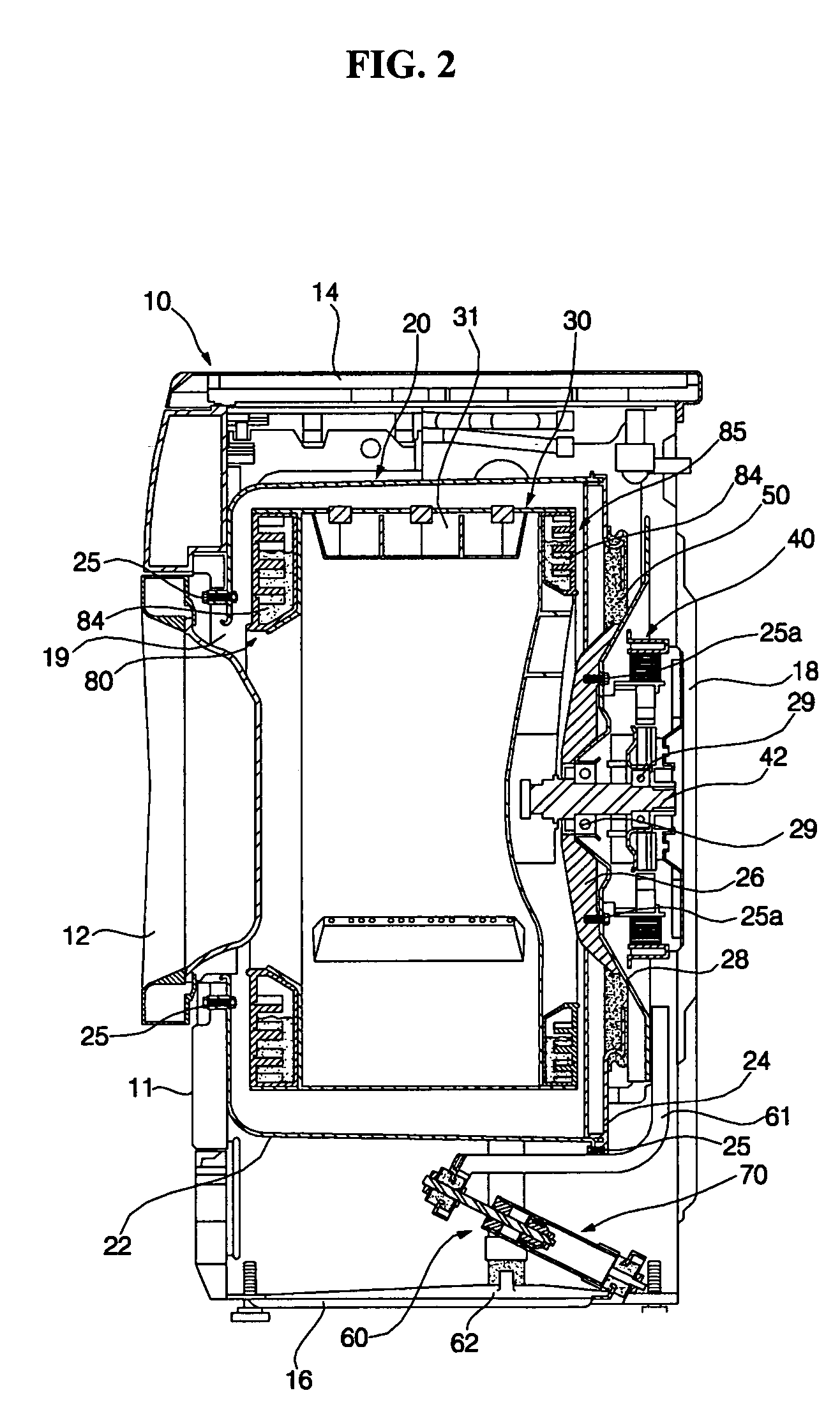

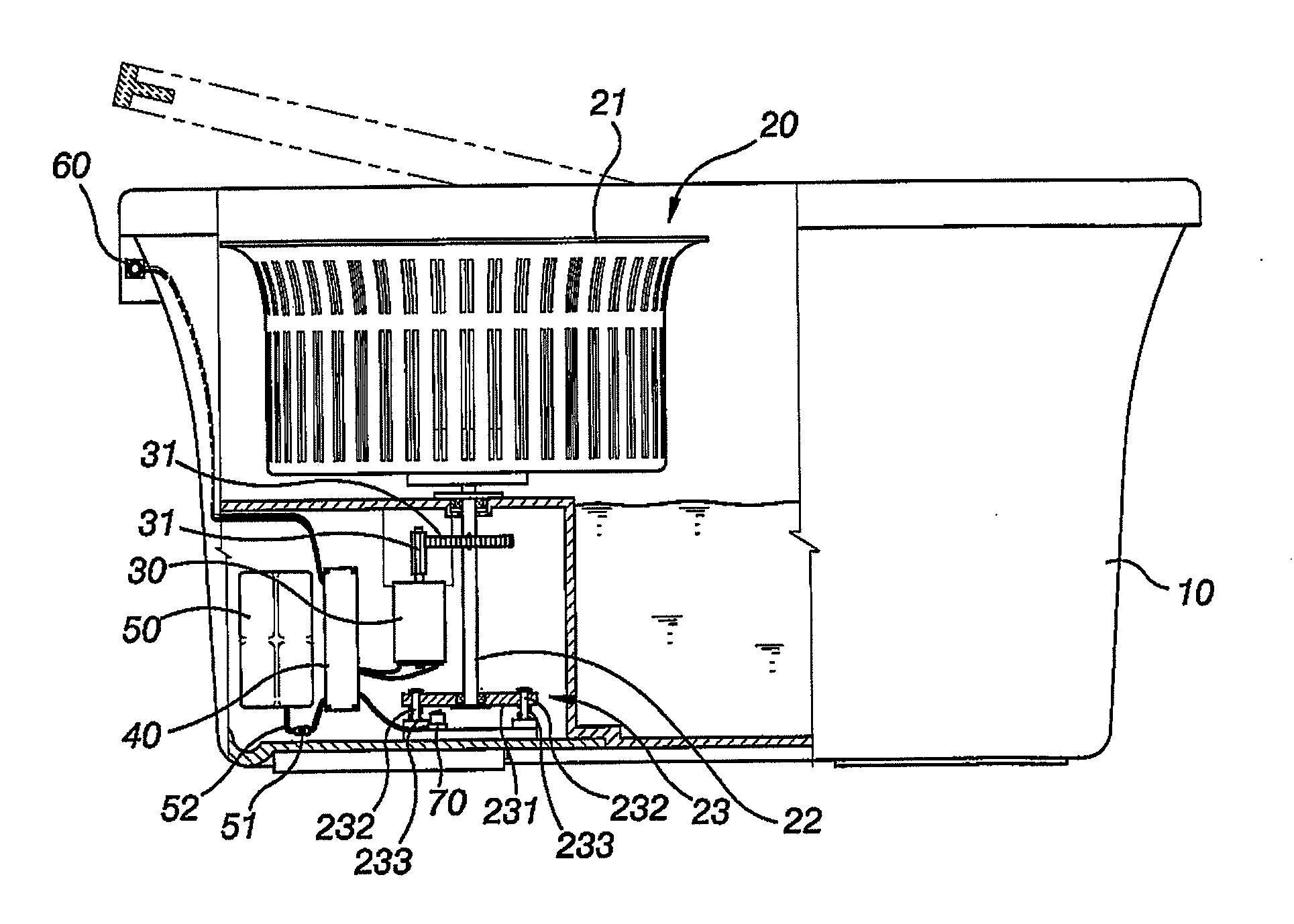

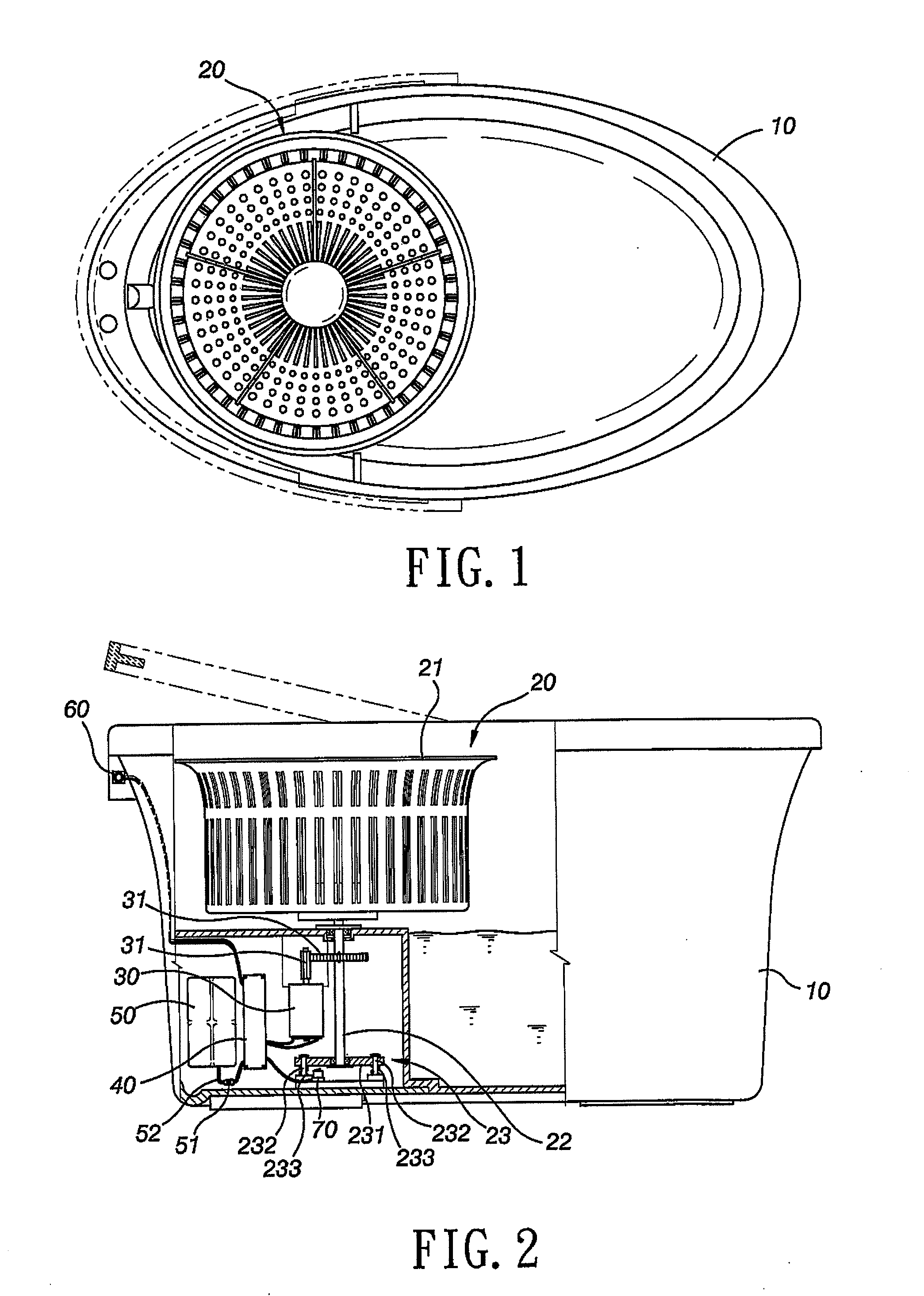

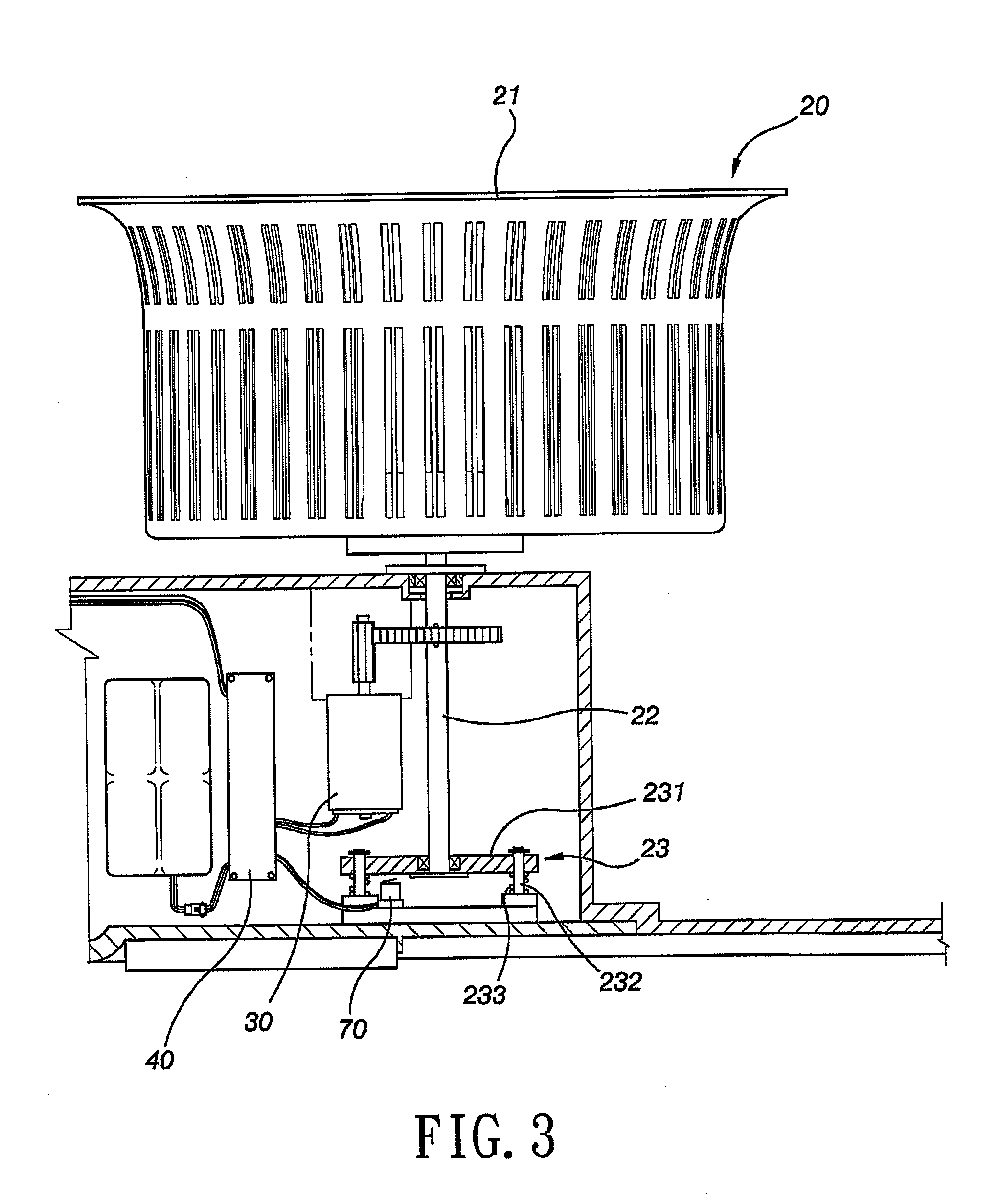

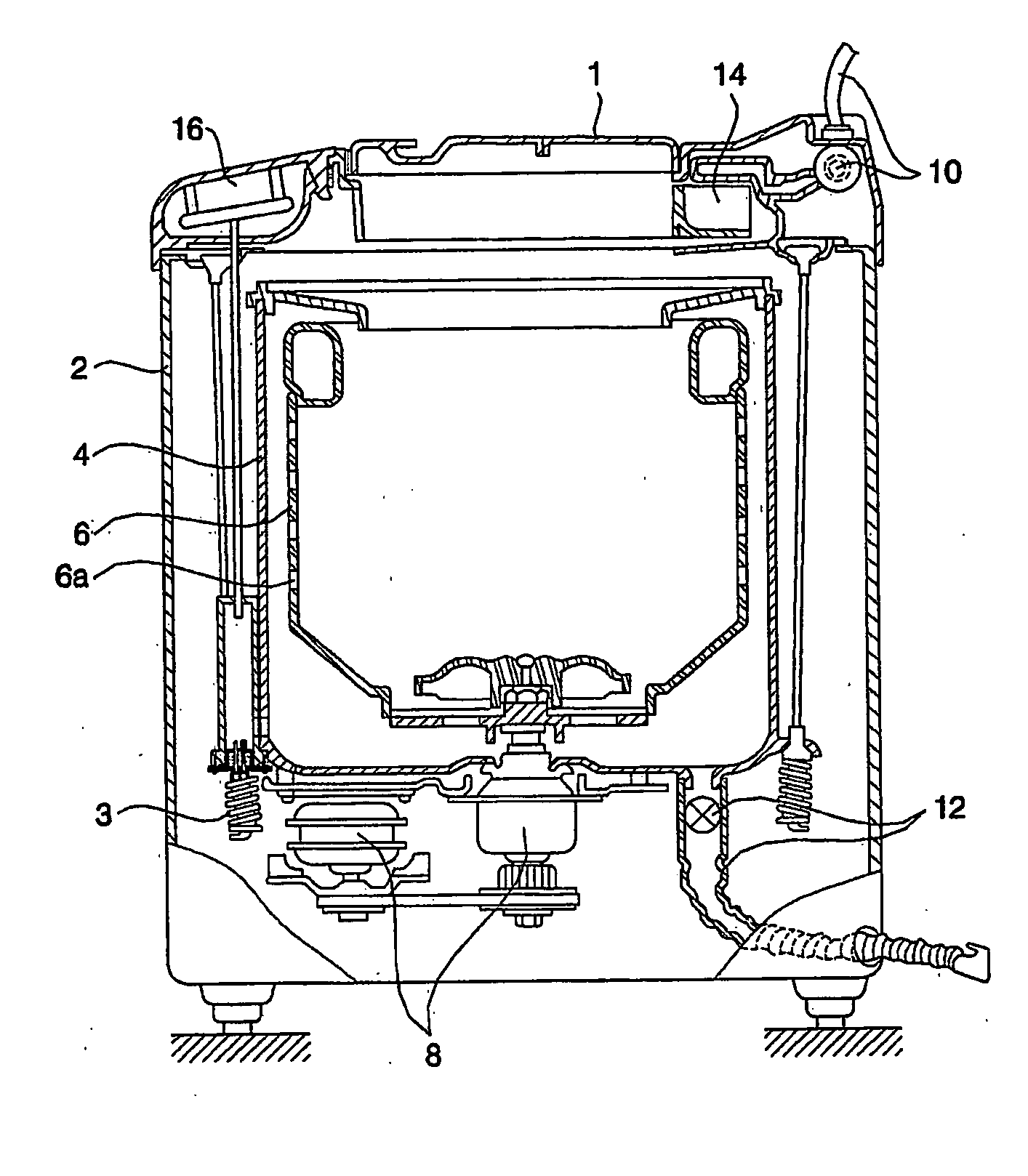

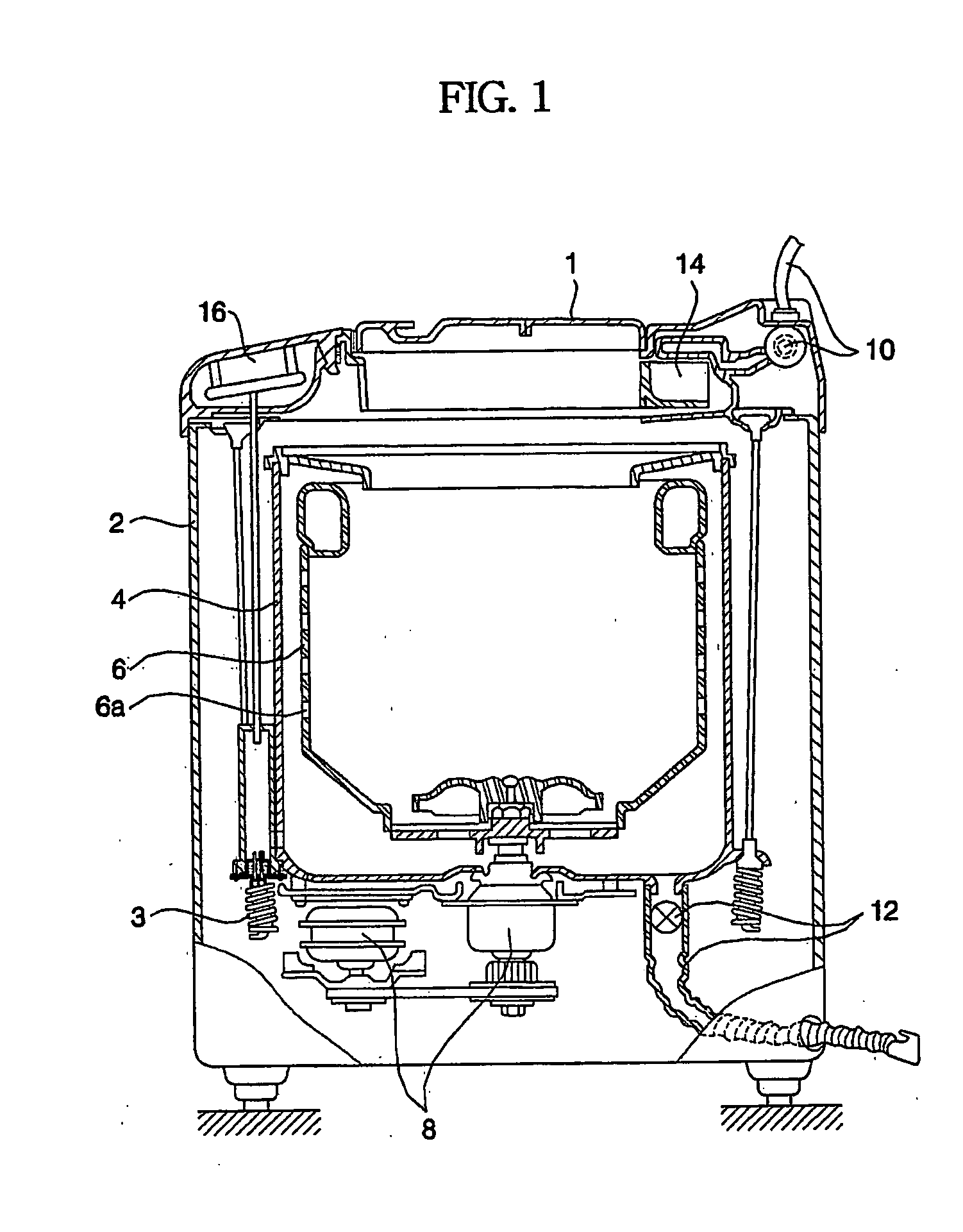

Drum washing machine

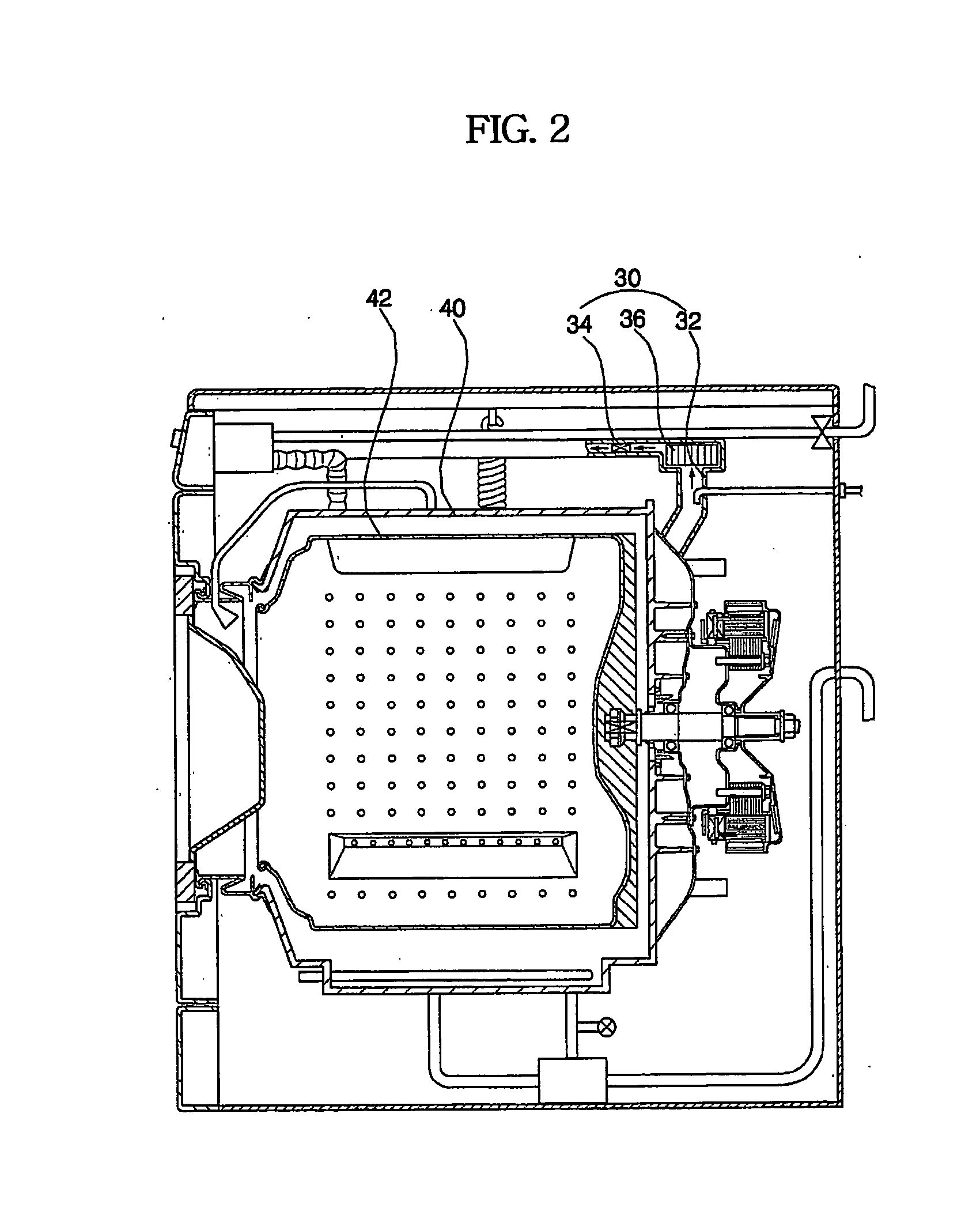

InactiveUS6782722B2Easy to useQuiet operating soundRotating bodies balancingOther washing machinesWater storageMechanical engineering

Owner:SANYO ELECTRIC CO LTD

Drying control method for washing machines with drying functions/drying machines

InactiveUS20060101587A1Easy to operateEffective controlOther washing machinesControl devices for washing apparatusProcess engineeringMoisture

A drying control method for washing machines with drying functions / drying machines includes measuring an air temperature of heated air passing through a heater duct by a heater during a drying operation of the washing machine with drying function or the drying machine, and measuring at least one of the temperature of air before being heated and the temperature of air after being heated about the heater. The method further includes calculating a load, calculating a moisture content and controlling a drying operation.

Owner:LG ELECTRONICS INC

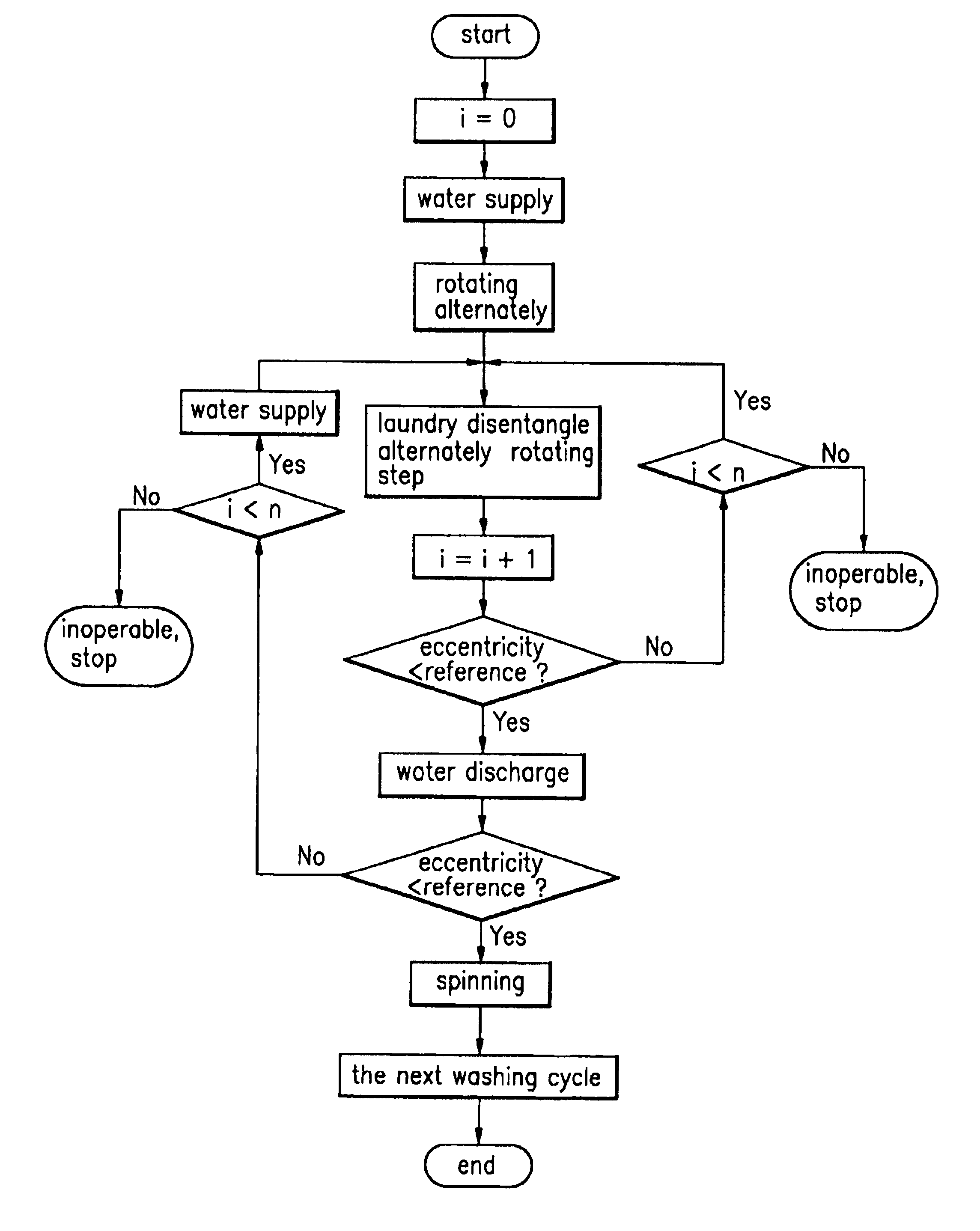

Method for controlling washing during spinning in tilt-type washing machine for attenuation of vibration

InactiveUSRE40732E1Reduce vibrationVibration minimizationOther washing machinesControl devices for washing apparatusUltrasound attenuationWater discharge

Method for controlling washing during spinning in a tilt-type washing machine for attenuation of vibration, including (a) a main rotation step for exerting a centrifugal force to the laundry gathered to a center of the inner tub for spreading the laundry to an inside wall of the inner tub before the water discharging step, (b) a laundry disentangle alternately rotating step for alternately rotating the inner tub for a preset times to disentangle the laundry spread to the inside wall of the inner tub, and (c) a supplementary rotating step for rotating the inner tub at a preset RPM to keep the laundry in the tilted inner tub spread evenly during the water discharge step, or alternatively (a) a laundry disentangle alternately rotating step for alternately rotating the inner tub to eliminate the eccentricity of the laundry in the inner tub before the water discharge step, and (b) a determining step either for carrying out a control pattern to eliminate the eccentricity of the laundry if the eccentricity of the laundry after the step (a) is greater than a preset value, or for proceeding to the water discharging step if the eccentricity of the laundry after the step (a) is smaller than the preset value, whereby attenuating the vibration to the minimum.

Owner:LG ELECTRONICS INC

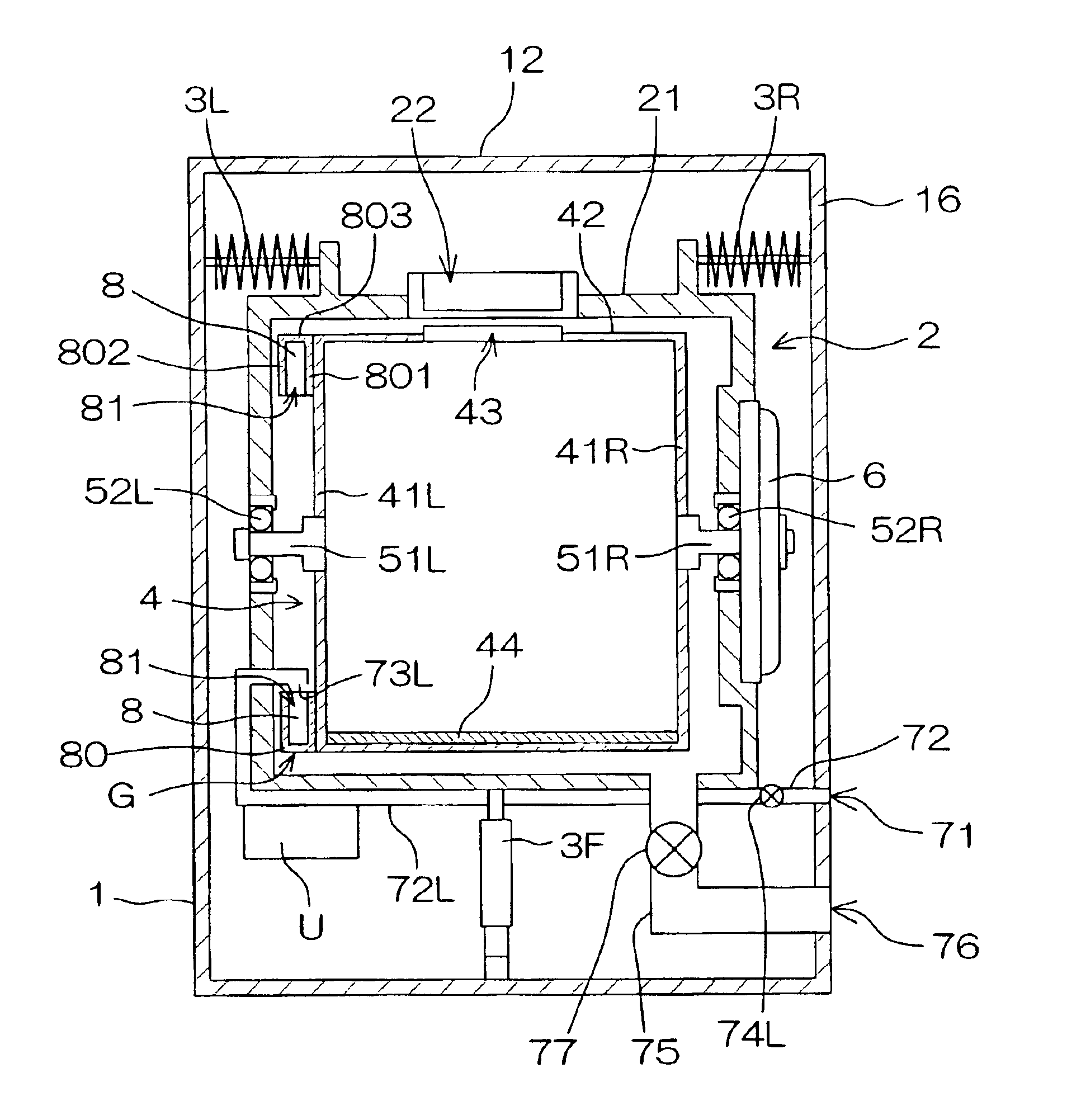

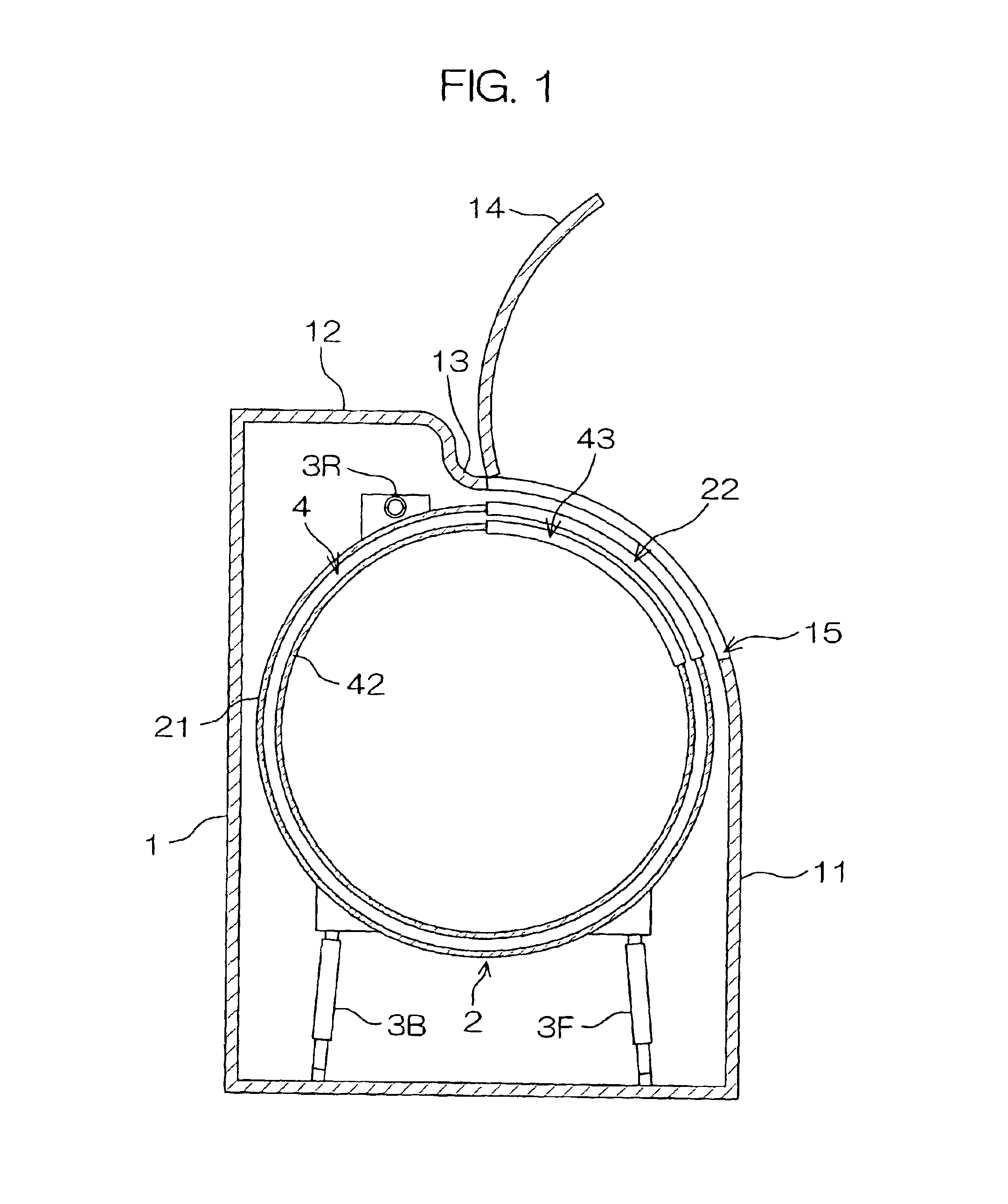

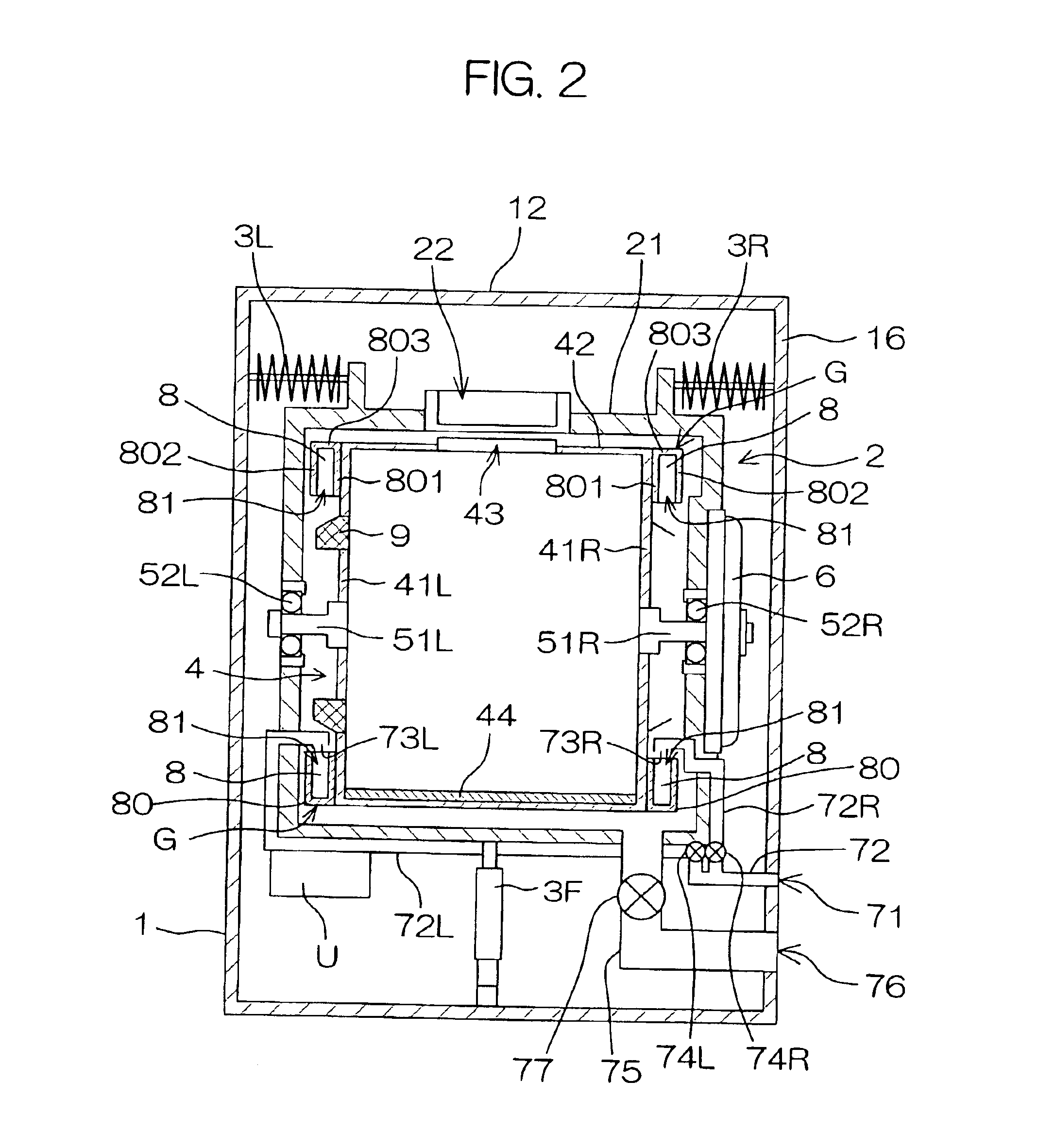

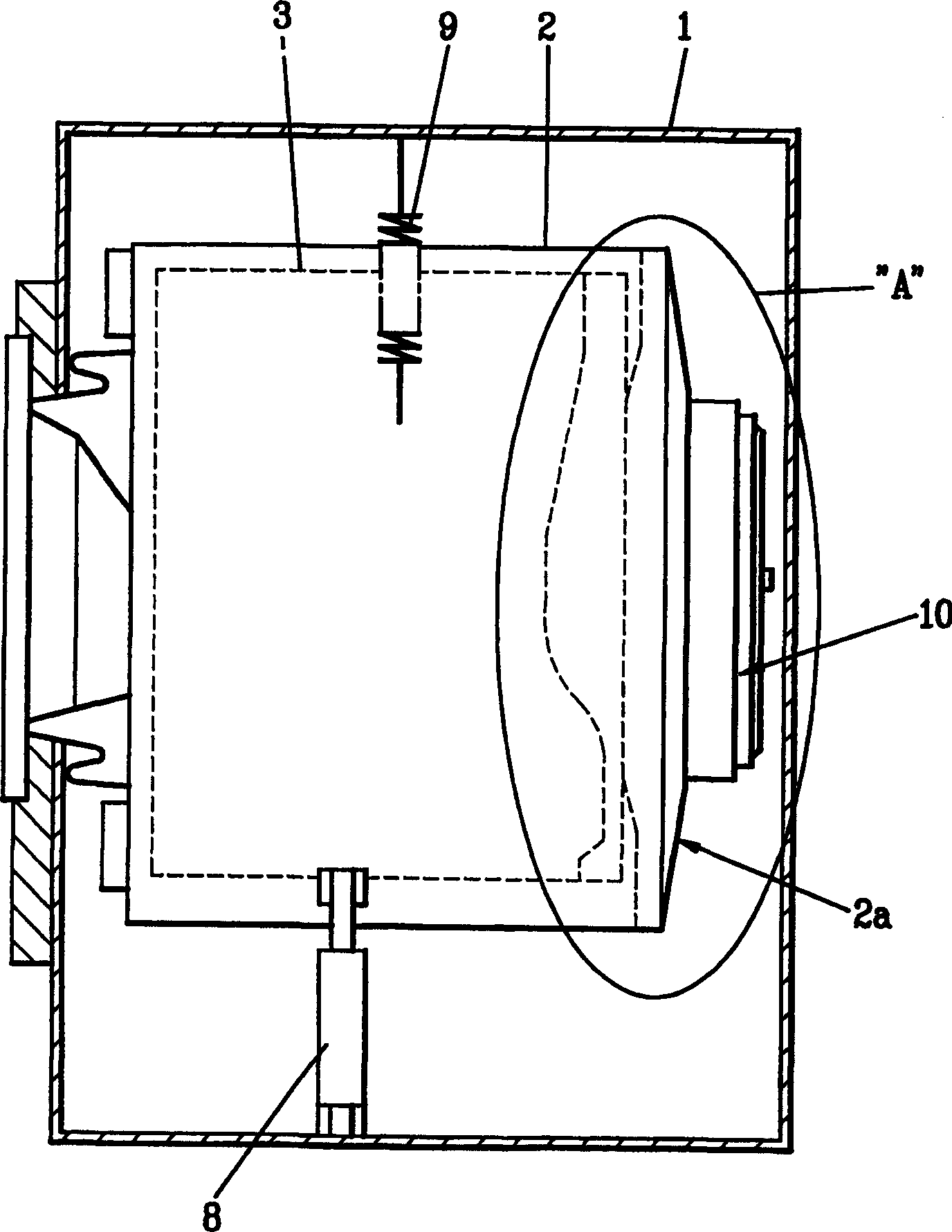

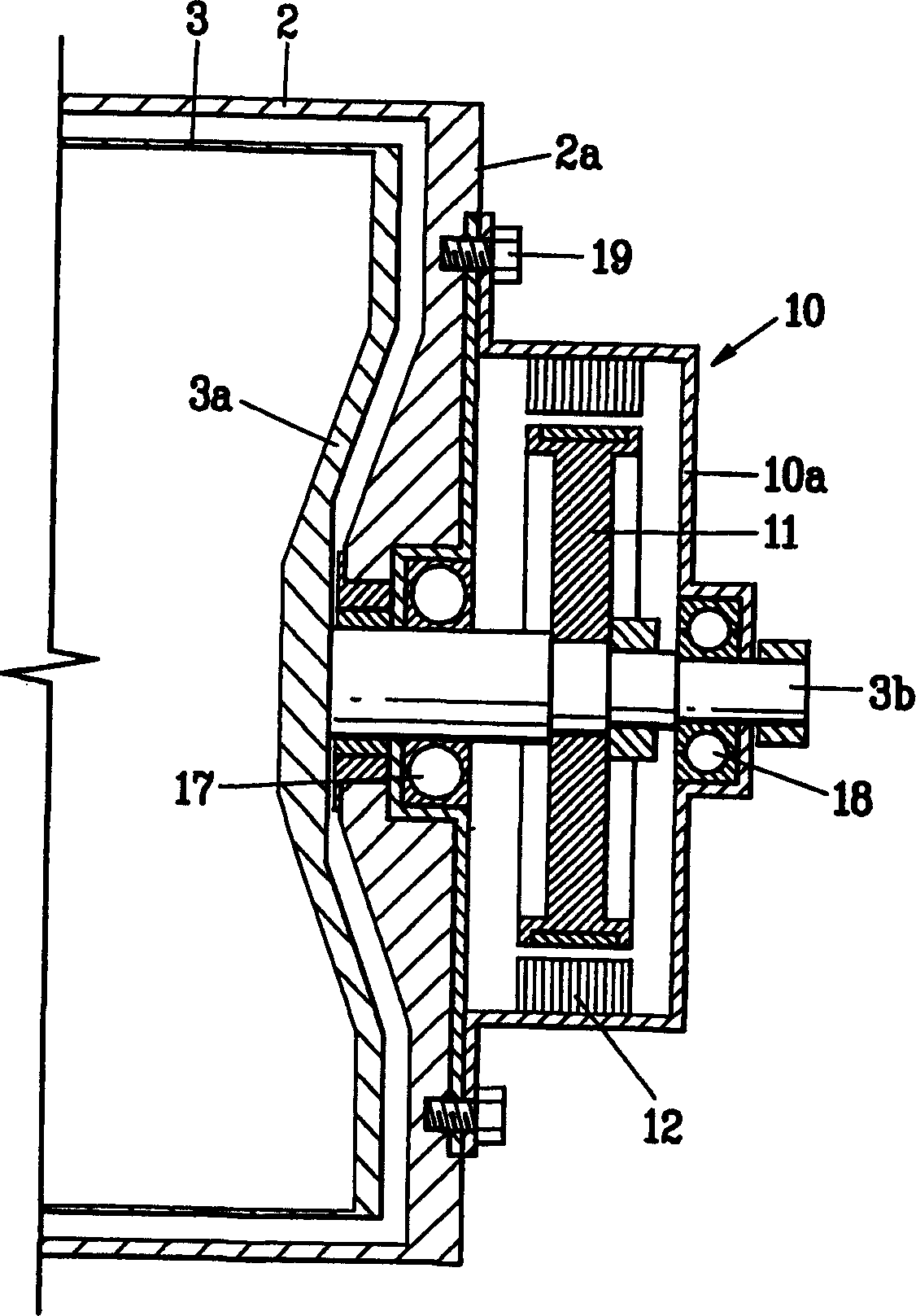

Rolling drum type washing machine

InactiveCN1408932AReduce vibrationSuppress noiseMechanical apparatusOther washing machinesMechanical engineering

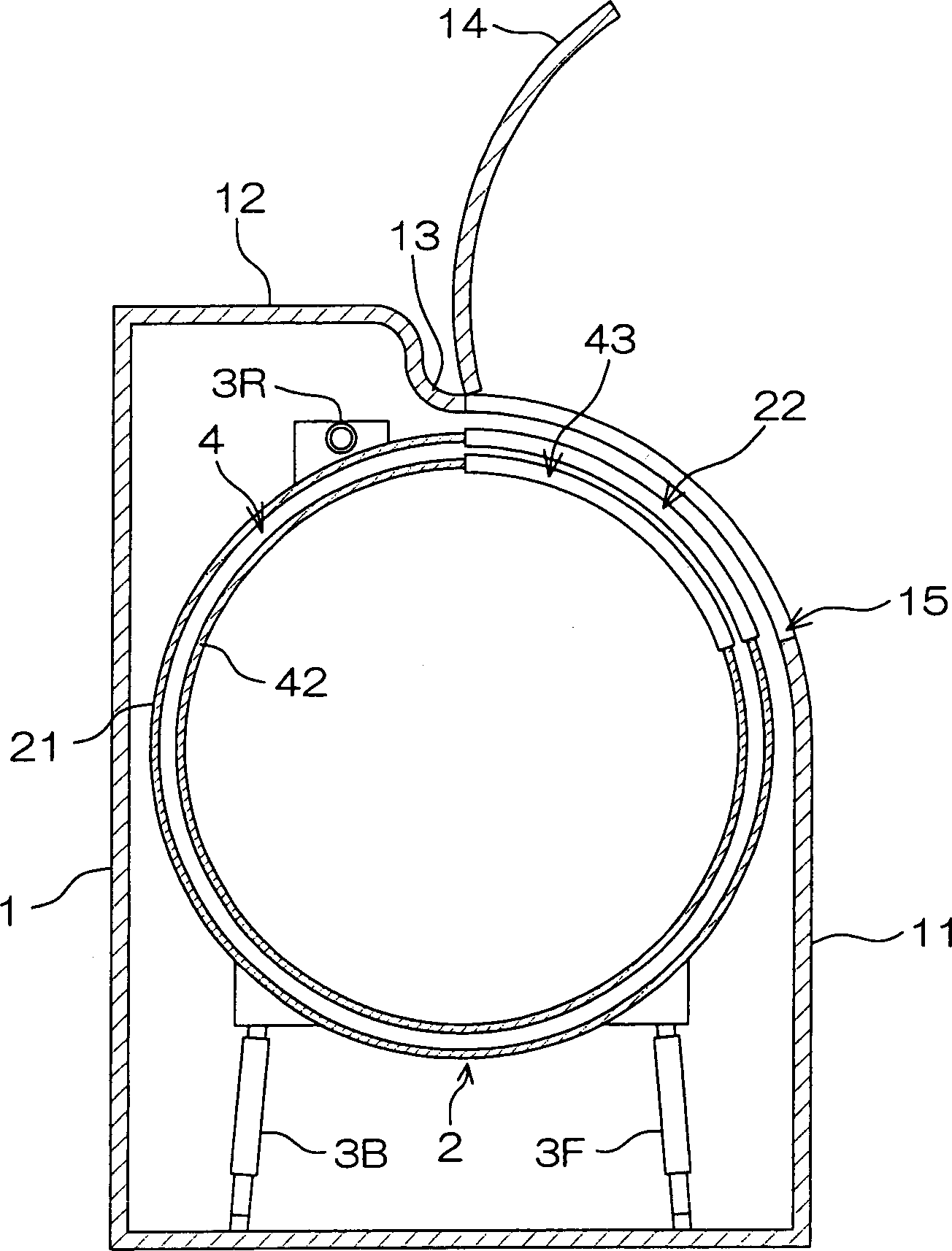

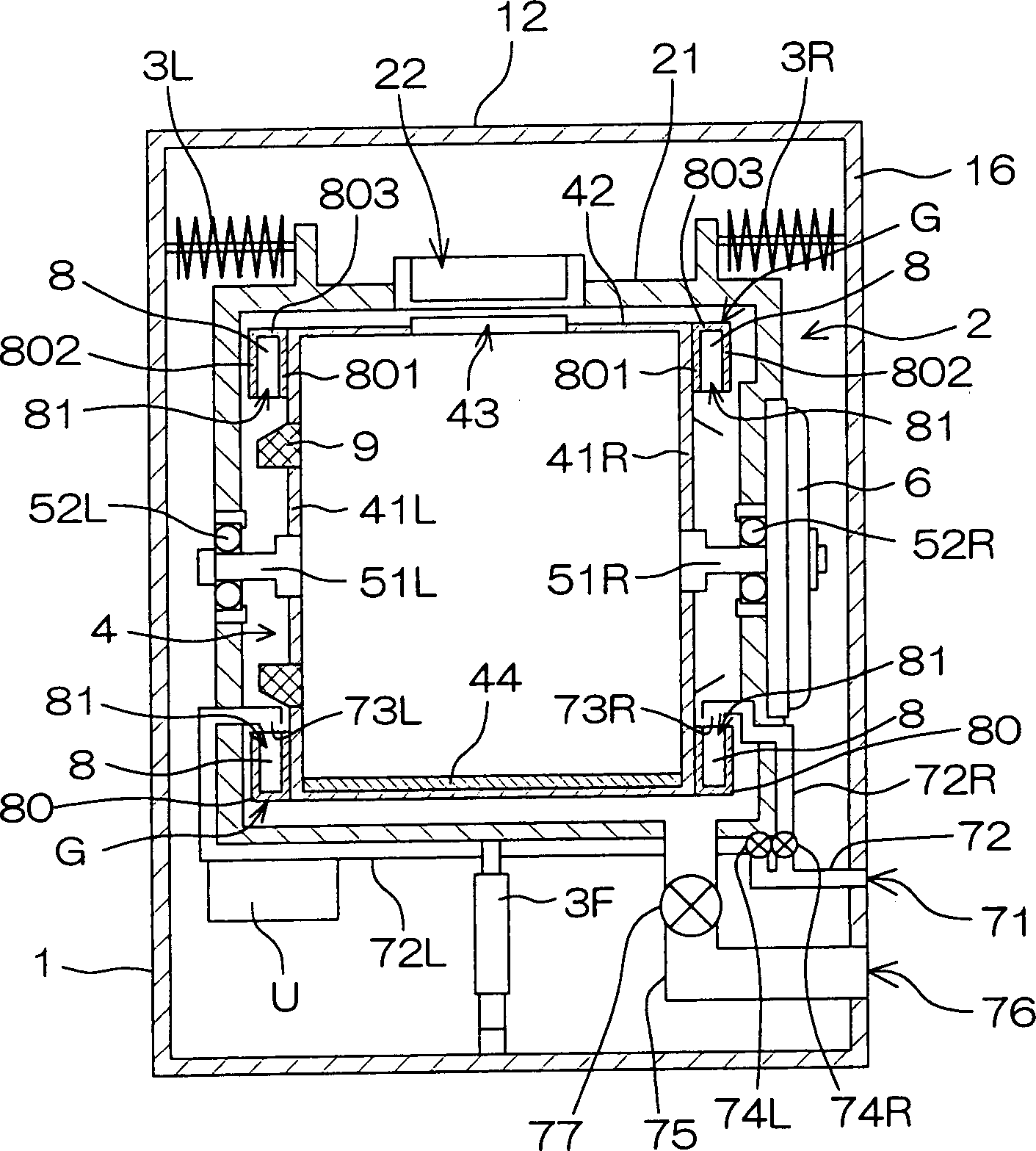

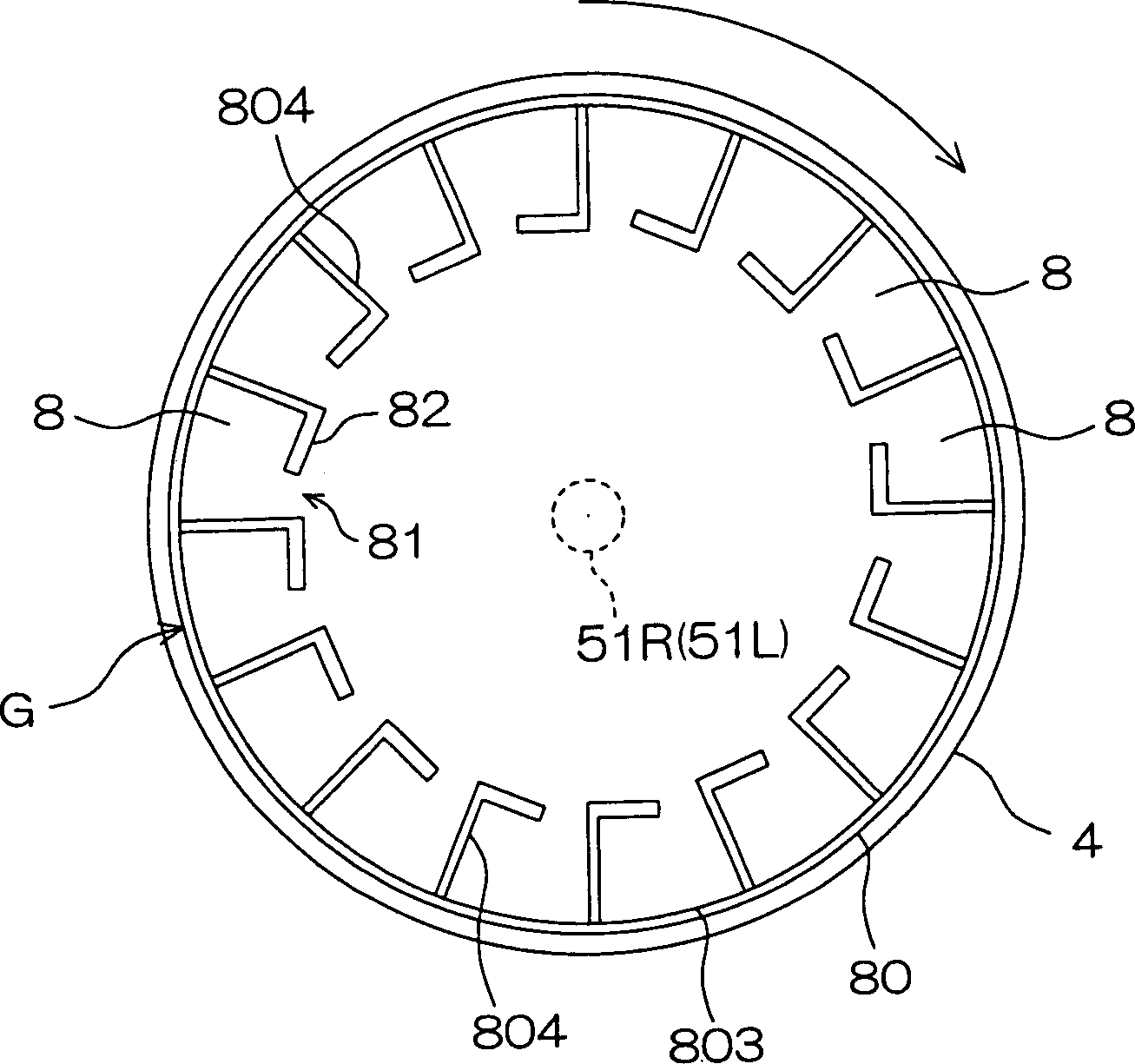

A drum washing machine according to the present invention restrains vibration and noise at the time of spin-drying. For this purpose, a drum 4 is supported so as to be rotatable by rotating shafts 51L and 51R respectively extending in an approximately horizontal direction outward from its end surface walls 41L and 41R. Water storage balancers G are respectively attached to the end surface walls 41L and 41R of the drum 4, and a fluid balancer 9 is further attached to the end surface wall 41L.

Owner:SANYO ELECTRIC CO LTD

Drum type washing machine and drum therefor

The invention discloses a drum type washing machine. The drum type washing machine includes a front balancer and a rear balancer respectively installed on the front side and the rear side of the drum. Therefore, even when the laundry is eccentrically placed on one side of the drum, the eccentric force generated by the laundry can be complementarily eliminated by the front and rear balancers.

Owner:LG ELECTRONICS INC

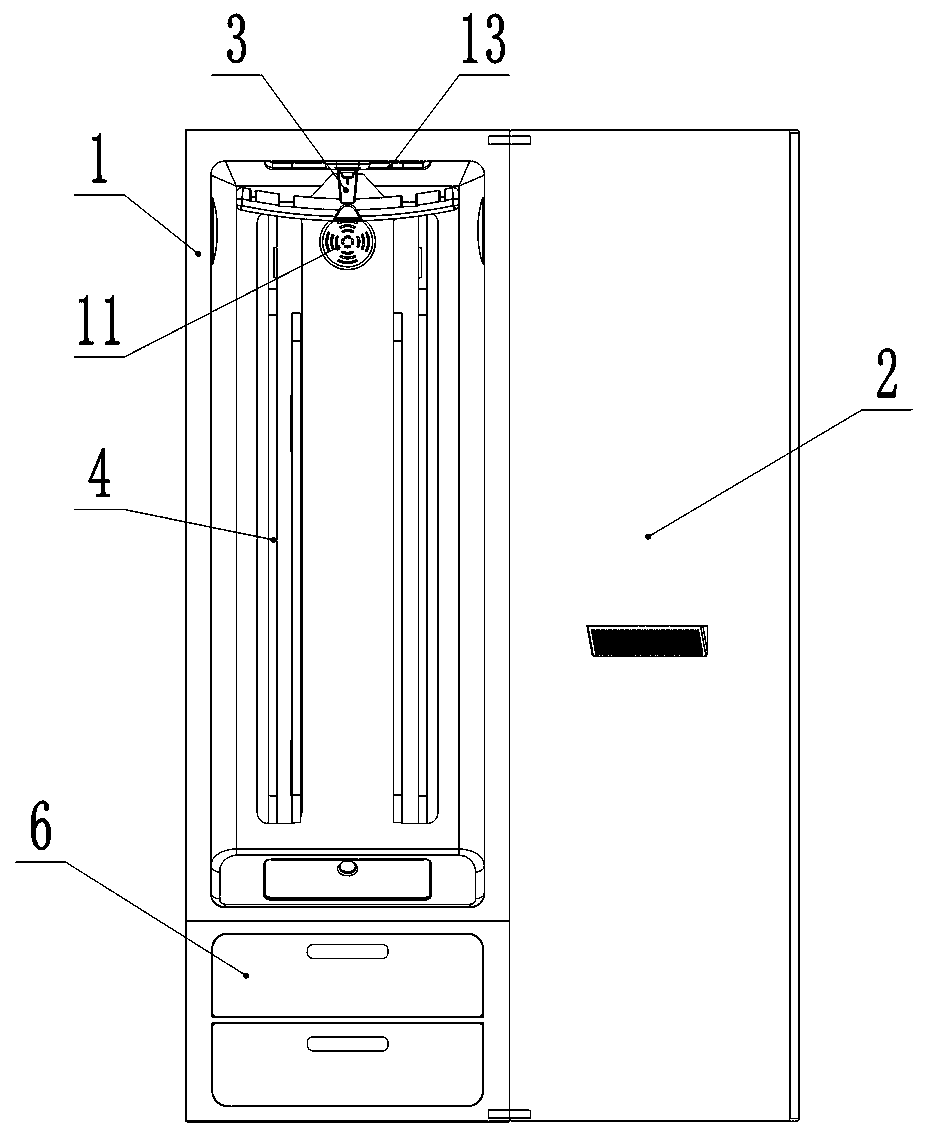

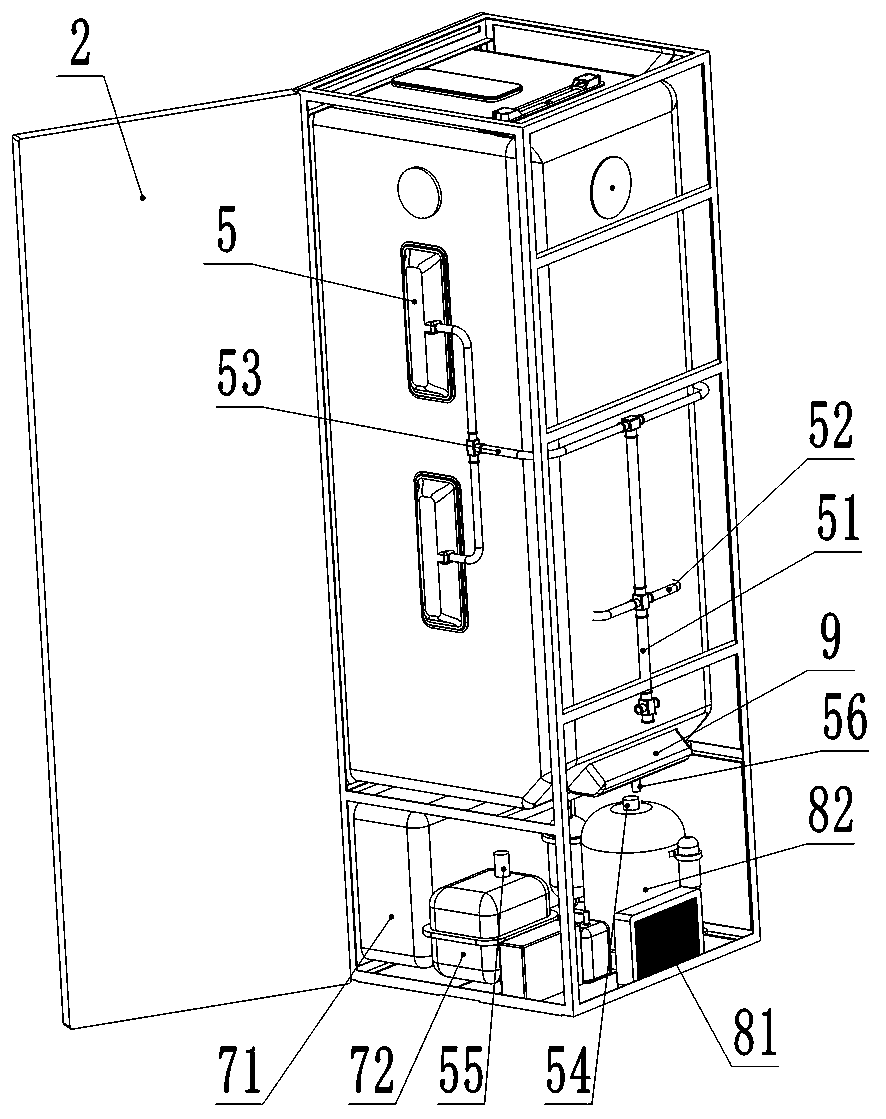

Clothing care machine

PendingCN109695146AImprove nursing effectConserve waterIroning apparatusTextiles and paperAir filterAgricultural engineering

The invention discloses a clothing care machine which comprises a shell, a sealing door, a drying device, an ironing device, a fan, a dry cleaning device, an air duct and a wind hood, wherein an ironing and drying chamber is formed in the shell; the drying device comprises an air filter and a heat exchange chamber; the heat exchange chamber is communicated with the air duct; a drainage bunker is arranged at the bottom of the ironing and drying chamber; the wind hood is fixed on the side wall of the wind hood; the ironing device comprises a water inlet tank and a steam generator; the steam generator is communicated with the air duct; the dry cleaning device comprises a dry cleaning agent storage box and an atomizer; the atomizer is communicated with the air duct; dry cleaning agents in thedry cleaning agent storage box enter the air duct via the atomizer and then are sprayed onto clothing in the ironing and drying chamber by virtue of the wind hood. According to the clothing care machine disclosed by the invention, the clothing can be subjected to dry cleaning and anti-wrinkle ironing, the comprehensive care ability of the product clothing is improved, and water usage and airing time can be saved.

Owner:郑州市恋日智能家居有限公司

Drum type washing machine

InactiveCN1531611AAvoid entanglementImprove washing effectOther washing machinesWashing machine with receptaclesLaundryMechanical engineering

Drum type washing machine including a tub fitted in a cabinet, and a pair of drums fitted in the tub to be rotatable in opposite directions, thereby permitting to obtain an excellent washing effect as an entire surface of laundry is made to make uniform friction with the inner drum and the outer drum, and to prevent entangling of the laundry as the laundry is washing during the laundry back and forth the inner drum and the outer drum, alternately.

Owner:LG ELECTRONICS INC

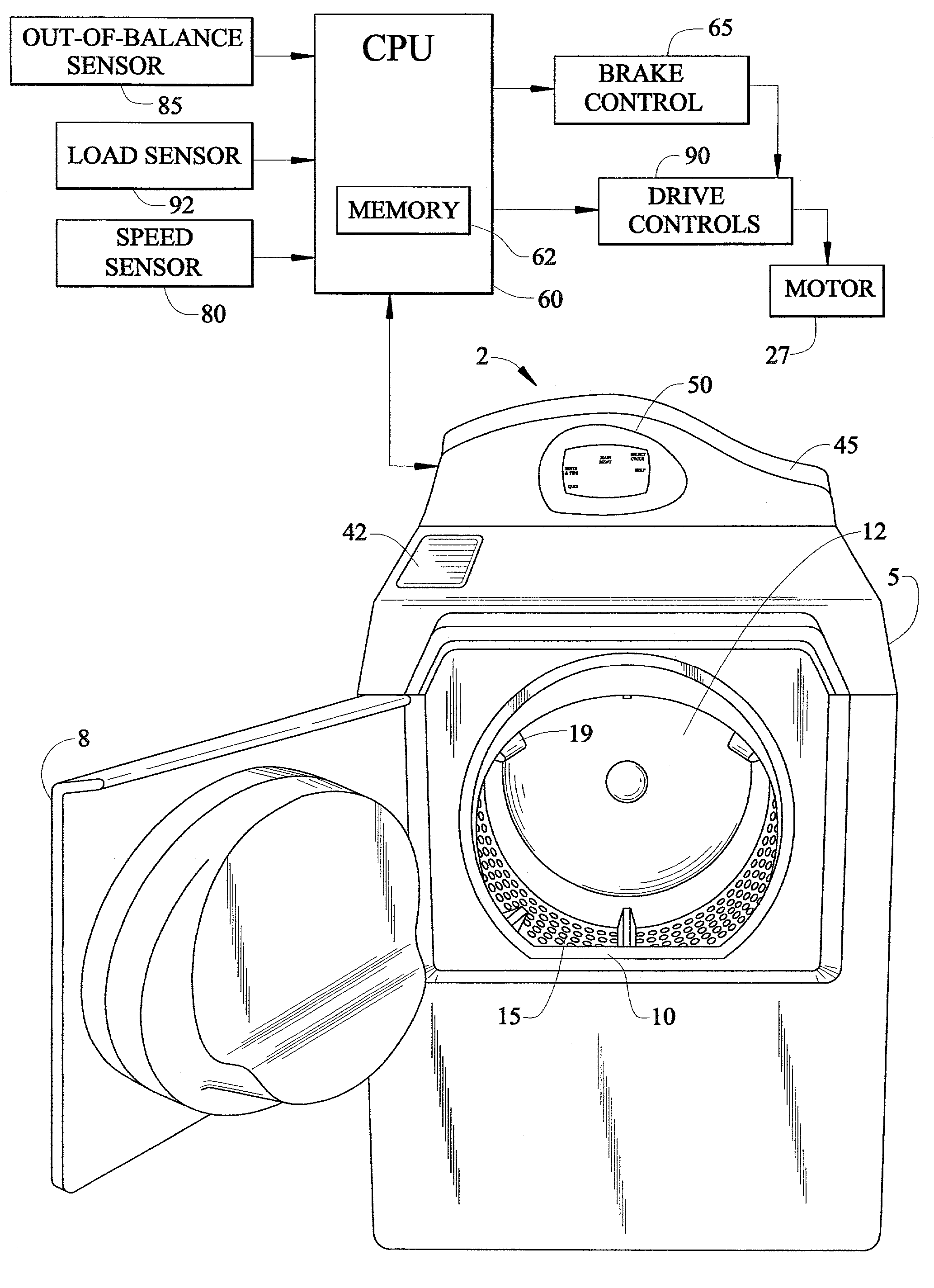

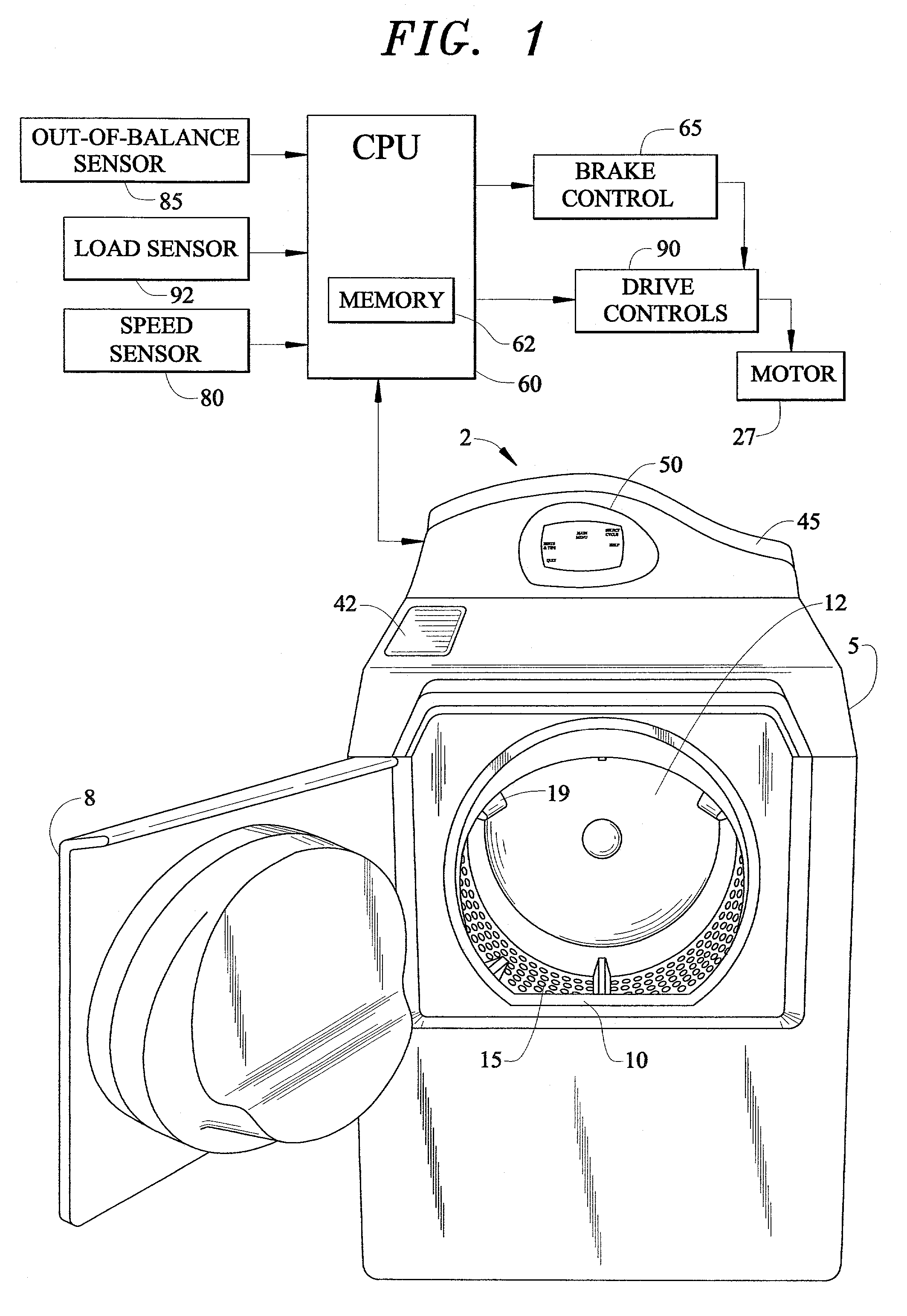

Braking control system for a washing machine

InactiveUS7039976B2Shorten the timeEffective brakingOther washing machinesControl devices for washing apparatusControl systemSpins

An inner tub of a washing machine is rapidly braked during a portion of a deceleration phase following an extraction phase of an overall spin cycle. A controller establishes the braking operation over a critical speed band or resonant frequency zone during which excessive vibrations would be developed. The critical speed band is preferably determined based on one or more signals received from speed, load, and / or out-of-balance sensors.

Owner:MAYTAG

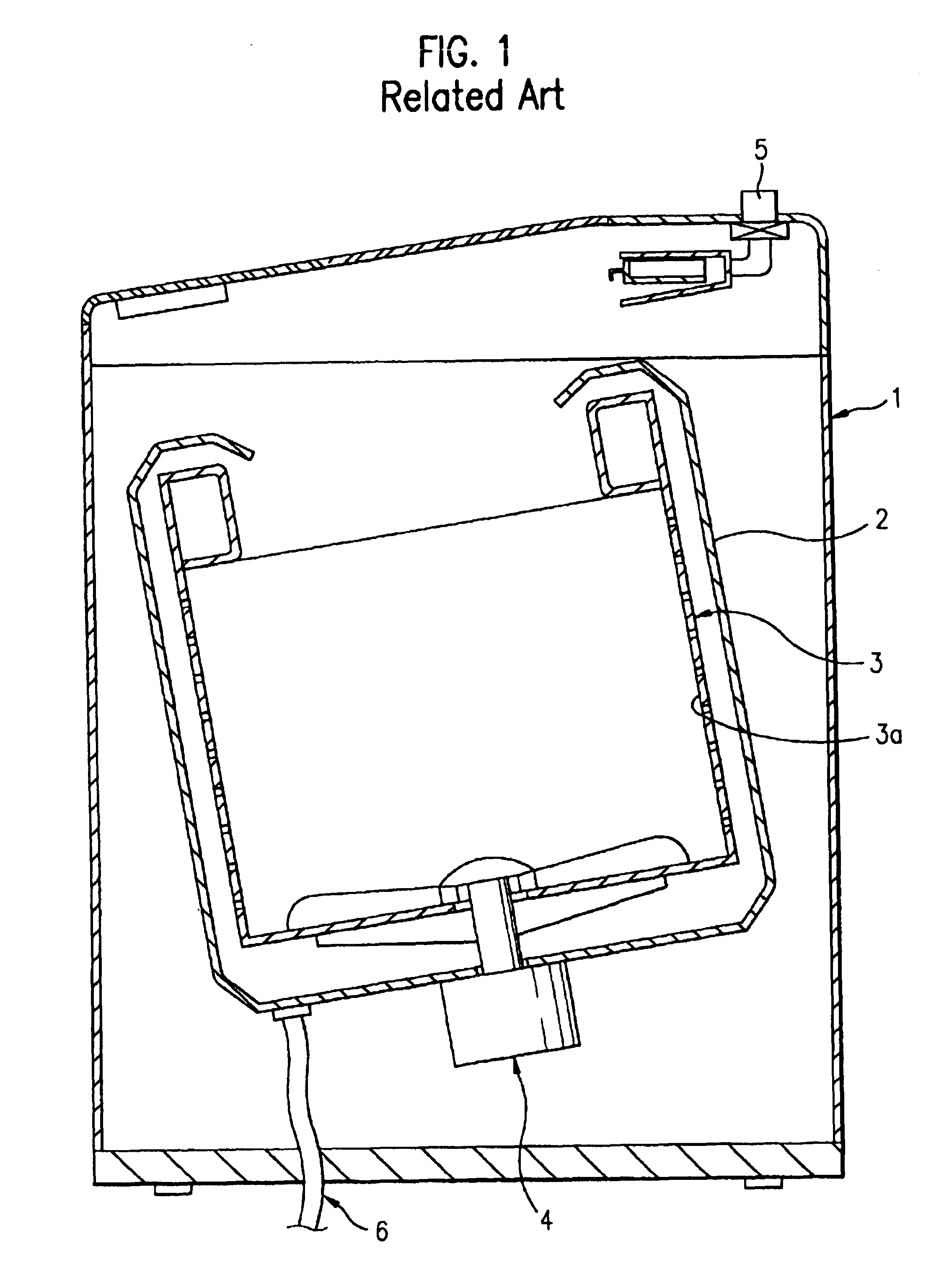

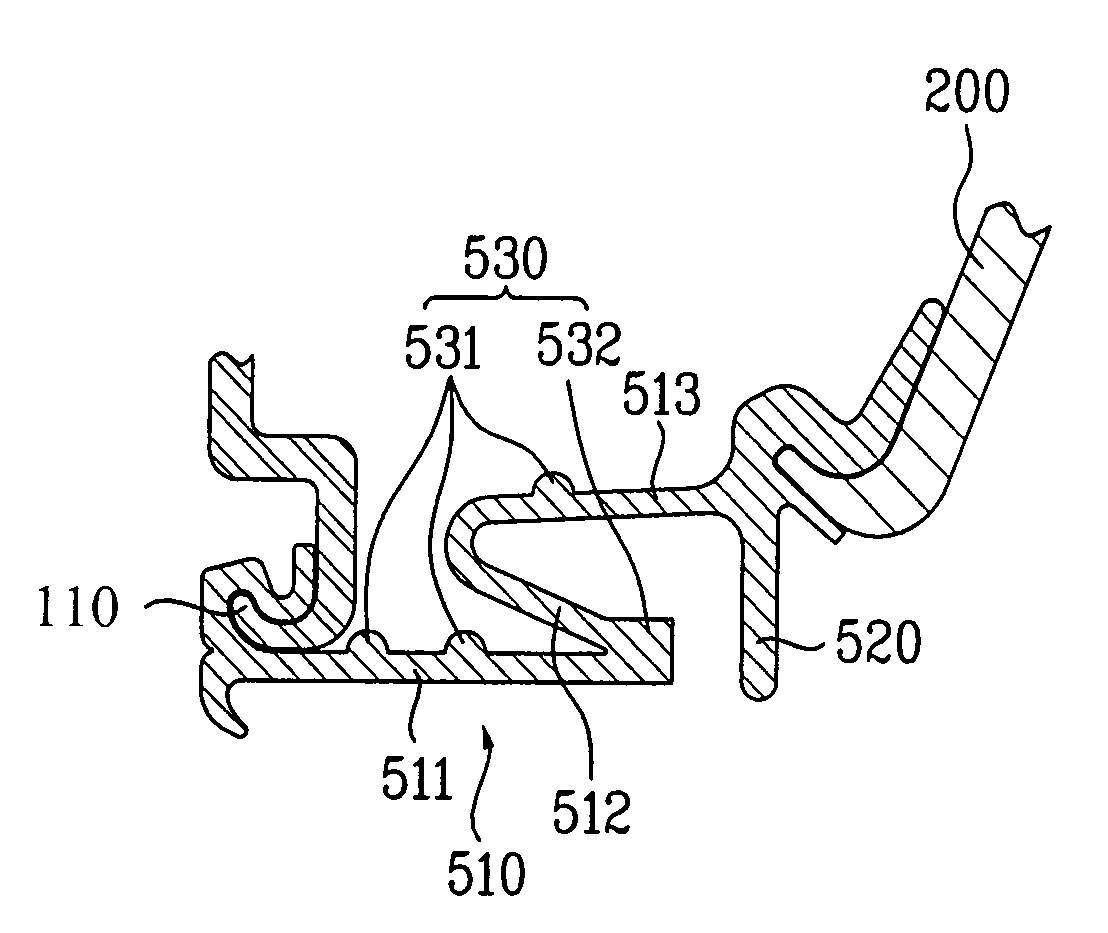

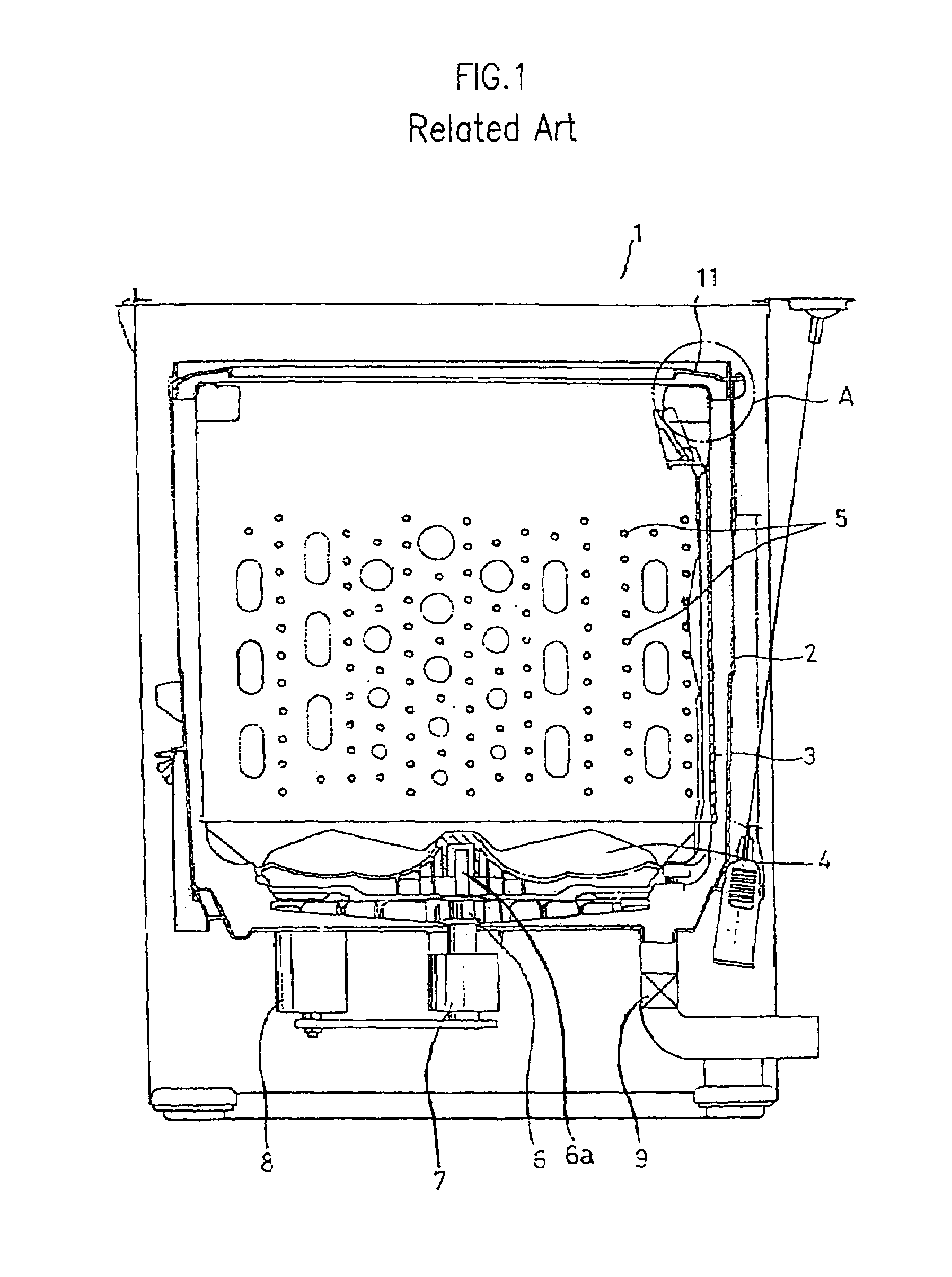

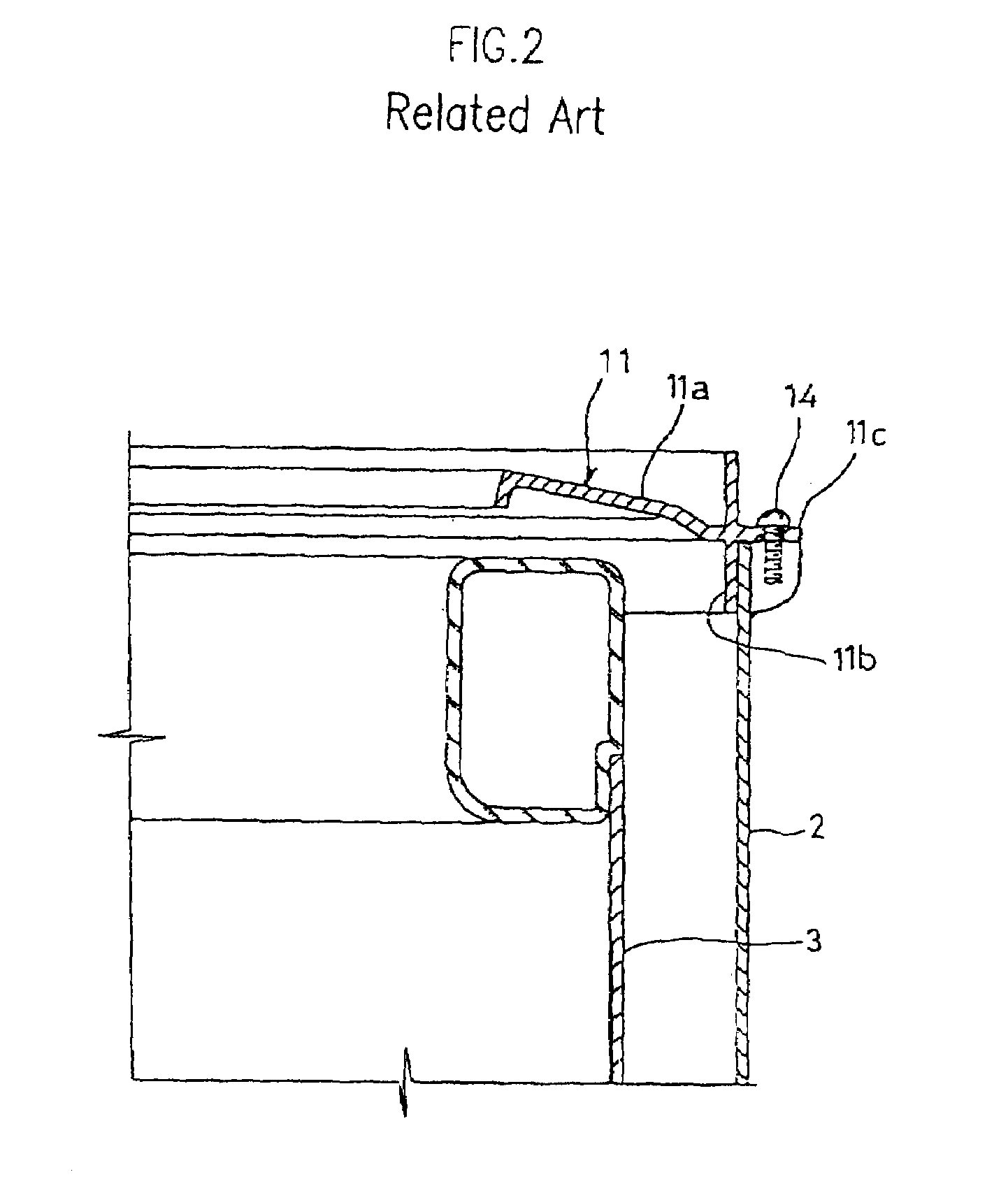

Gasket and washing machine using the same

InactiveUS7398662B2Prevent water leakageAvoid vibrationTextile treatment machine partsOther washing machinesWater leakageEngineering

A gasket and drum washing machine using the same. The washing machine includes a cabinet having a first opening through which a laundry is put in the cabinet, a tub installed in the cabinet to have a second opening corresponding to the first opening, a drum installed in the tub to have a third opening corresponding to the second opening, and a gasket for preventing leakage of water. The gasket includes a leakage preventing part having one end connected to a rim of the first opening and the other end connected to a rim of the second opening to prevent water leakage, a deformation preventing part connected to the leakage preventing part, and a laundry-stuck preventing part provided on an inner circumference of the leakage preventing part to prevent the laundry from being stuck between the second and third openings.

Owner:LG ELECTRONICS INC

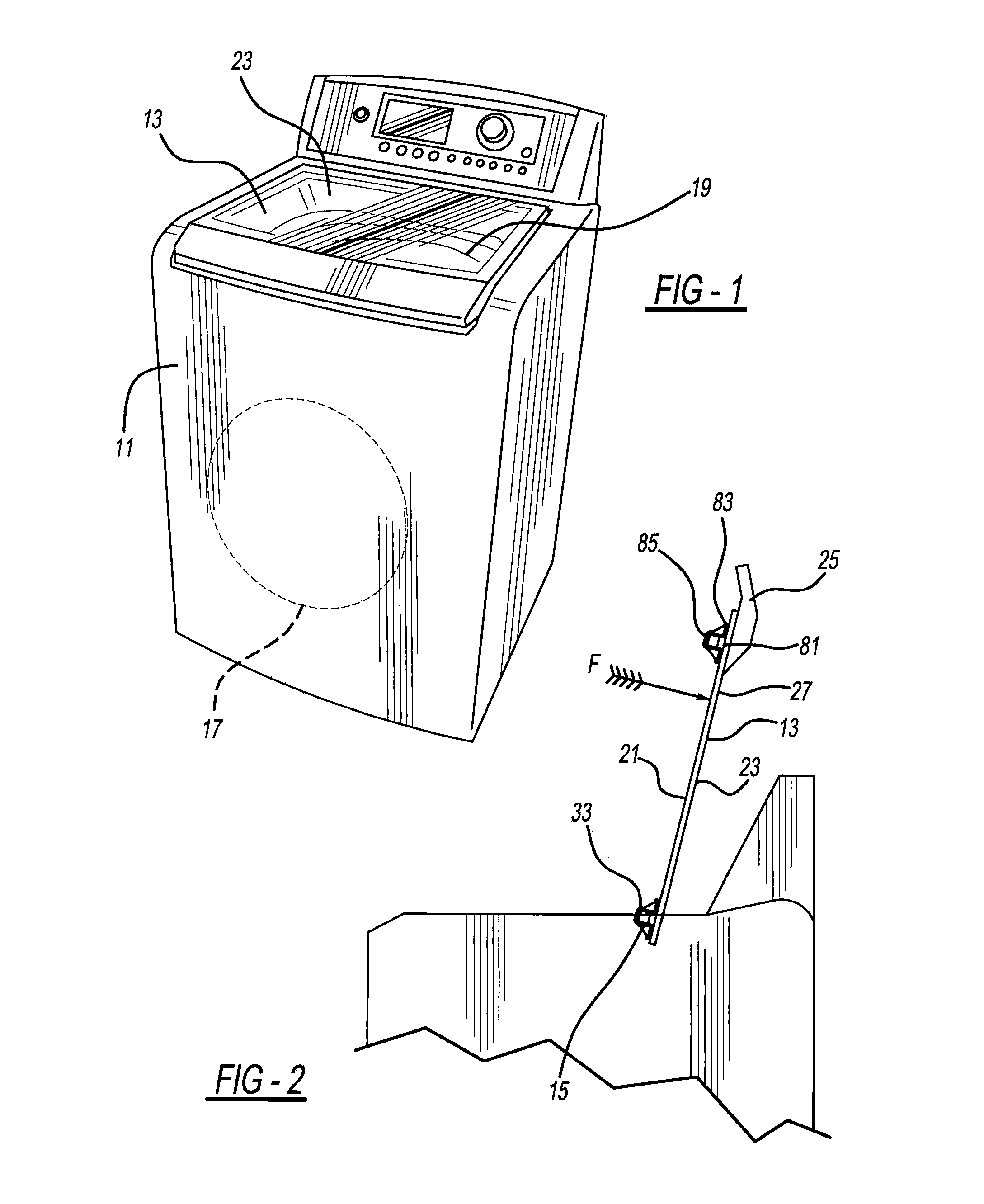

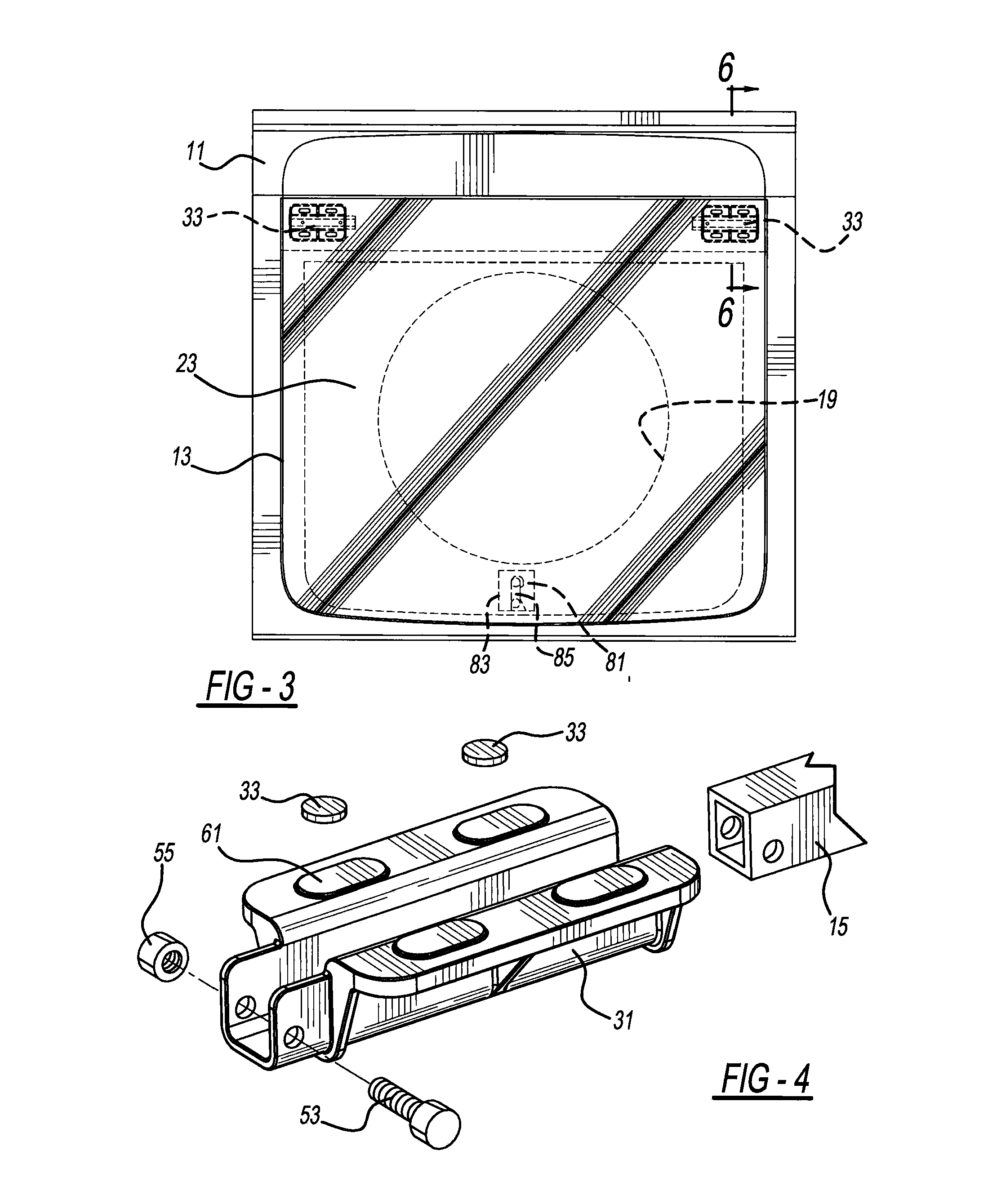

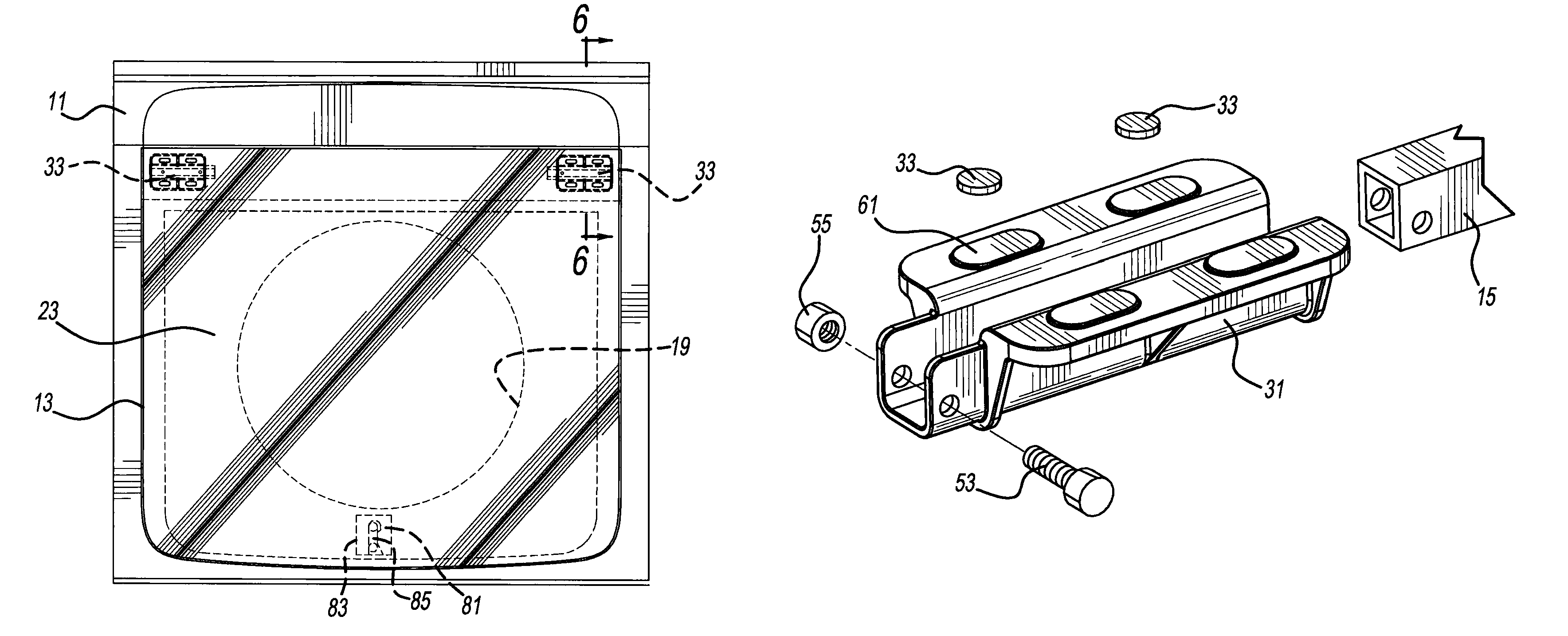

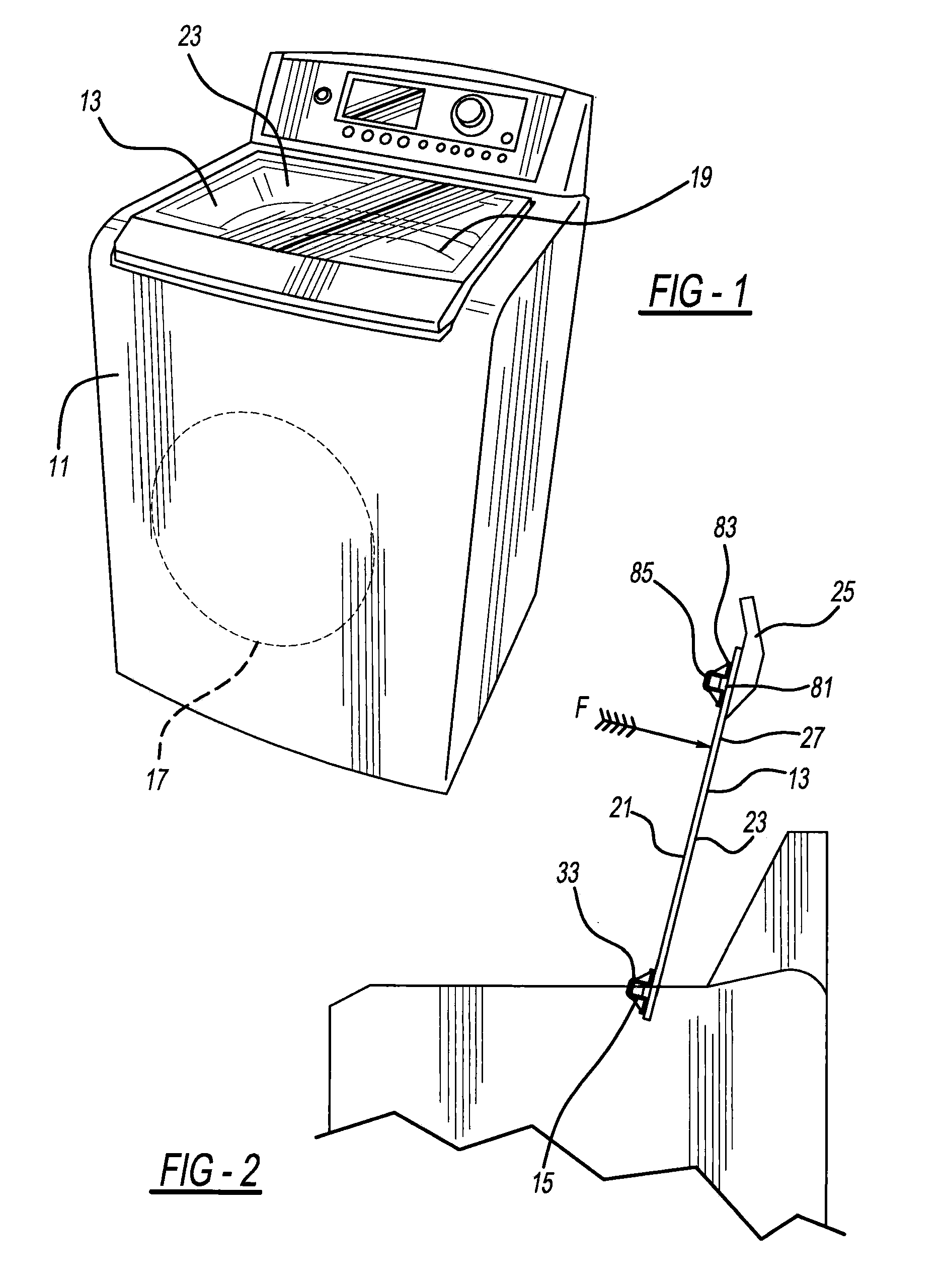

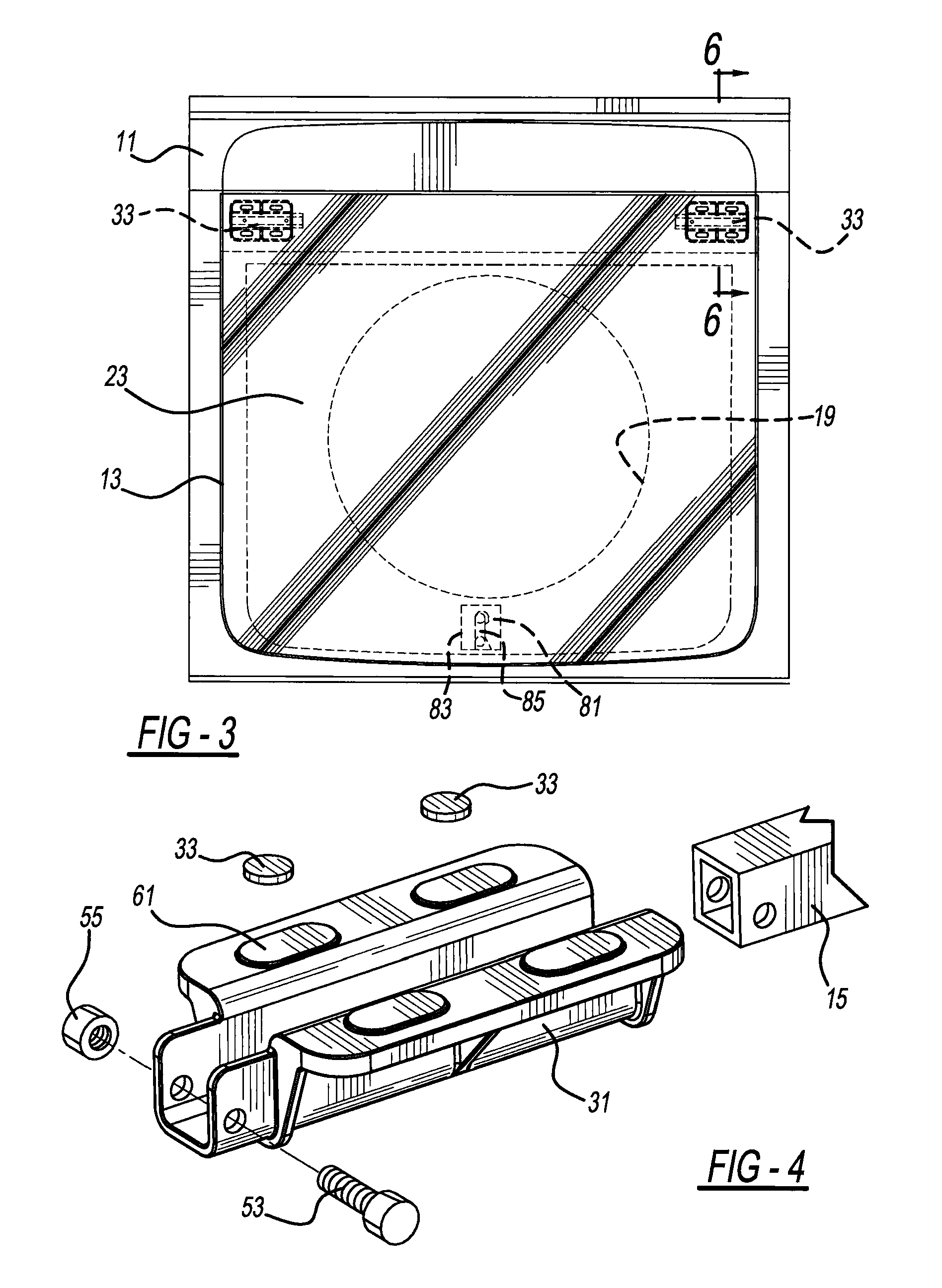

Appliance apparatus including a bonded bracket

InactiveUS20140210324A1Show cabinetsSynthetic resin layered productsPolyurethane adhesiveEngineering

An appliance apparatus includes an adhesively bonded bracket or support. In another aspect, a clothing apparatus includes a moveable transparent panel, such as a glass door or lid, which has a polymeric support or bracket adhesively bonded thereto. A further aspect provides polyurethane adhesive pellets bonding a polymeric hinge bracket to only a backside of a glass appliance panel.

Owner:A RAYMOND & CO

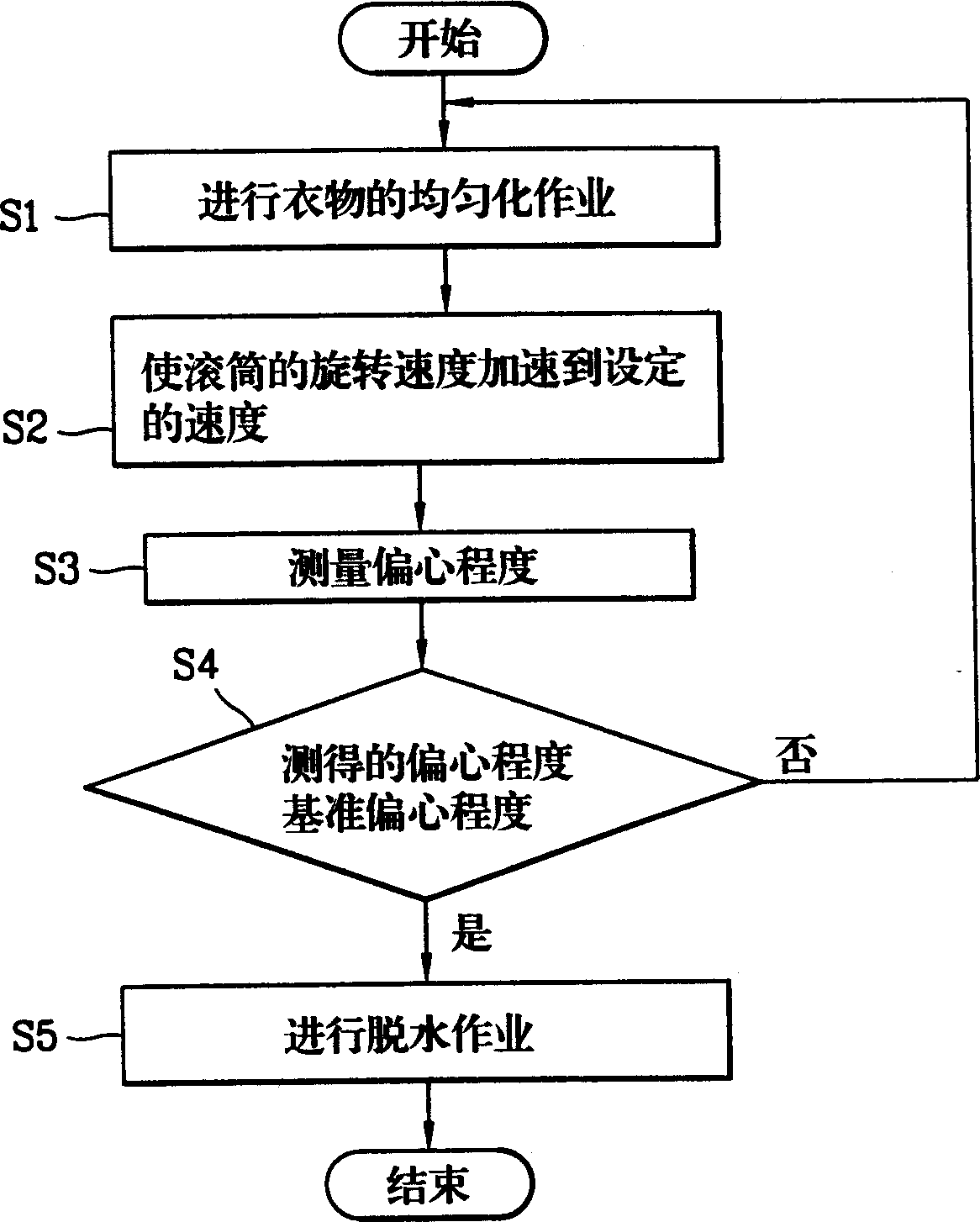

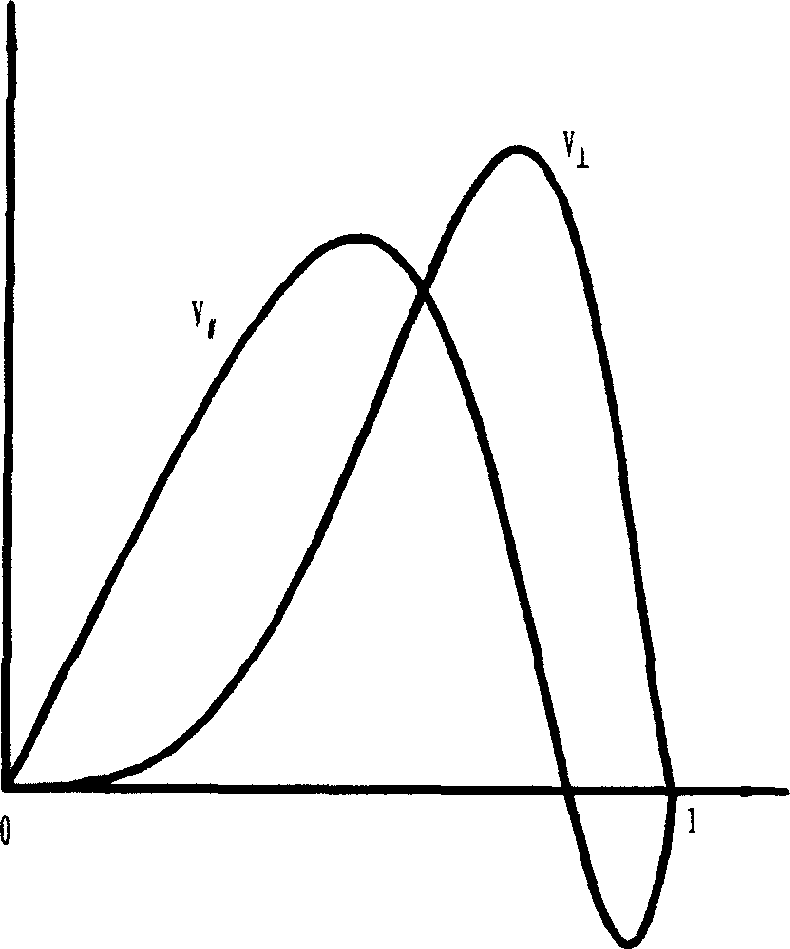

Spin-drying controlling method for drum washer

InactiveCN1459529AImprove reliabilityImprove drying effectOther washing machinesControl devices for washing apparatusLow speedRotation velocity

In a dehydration control method of a drum washing machine capable of improving reliability of eccentricity sensing by sensing not only forward eccentricity but also diagonal eccentricity by performing eccentricity sensing at a low speed and a high speed respectively, the method includes a first step for accelerating a drum to a first rotational speed when a uniforming process is finished; a second step for measuring first eccentricity when the rotational speed of the drum reaches the first rotational speed; a third step for comparing the measured first eccentricity with a preset first reference eccentricity; a fourth step for storing the measured first eccentricity when the measured first eccentricity is less than the preset first reference eccentricity in the third step; a fifth step for accelerating the rotational speed of the drum to a second rotational speed and measuring a second eccentricity when it reaches the second rotational speed; a sixth process for comparing the measured second eccentricity with the stored first eccentricity; and a seventh step for performing a dehydrating process when the measured second eccentricity is less than the stored first eccentricity.

Owner:LG ELECTRONICS INC

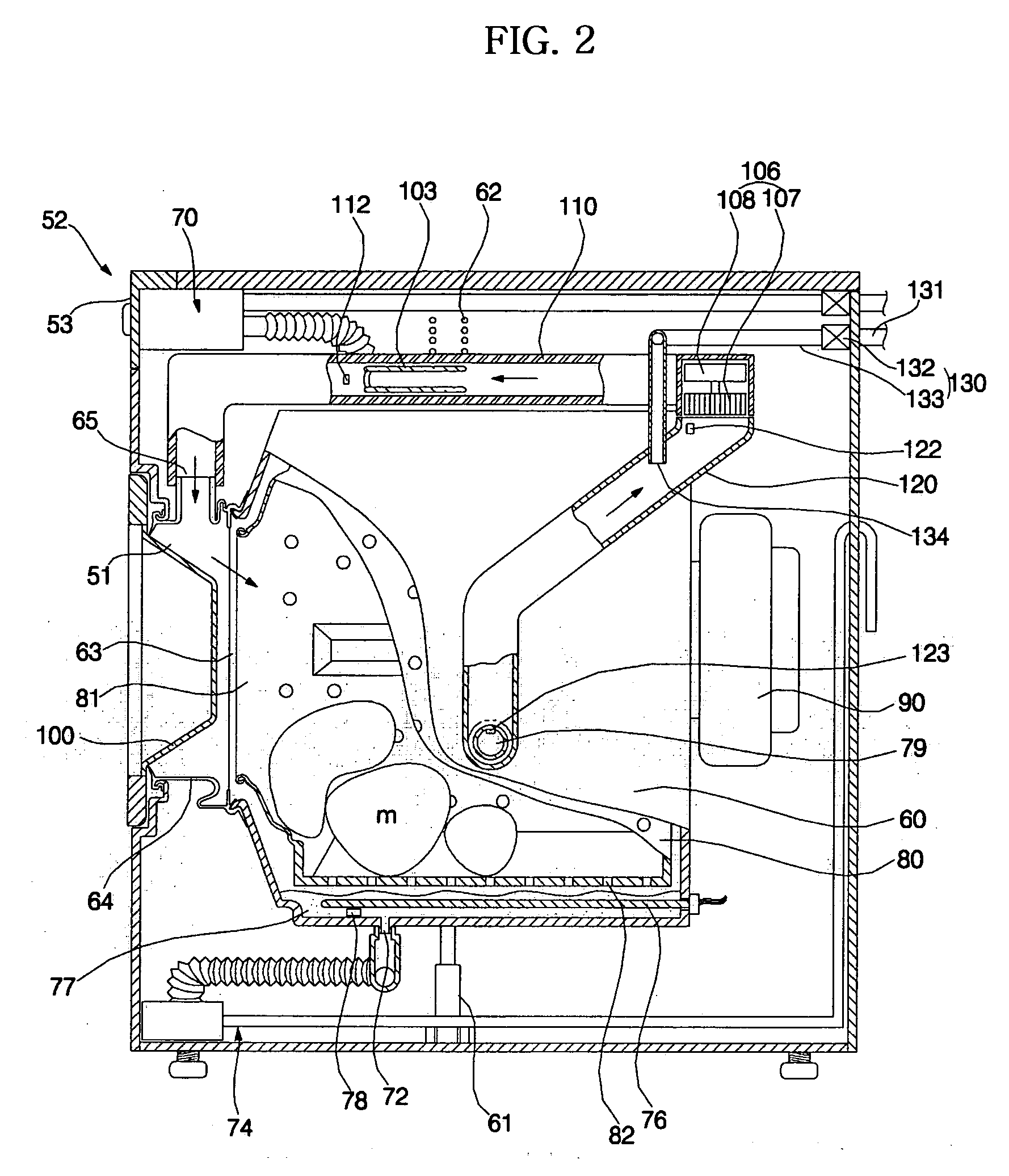

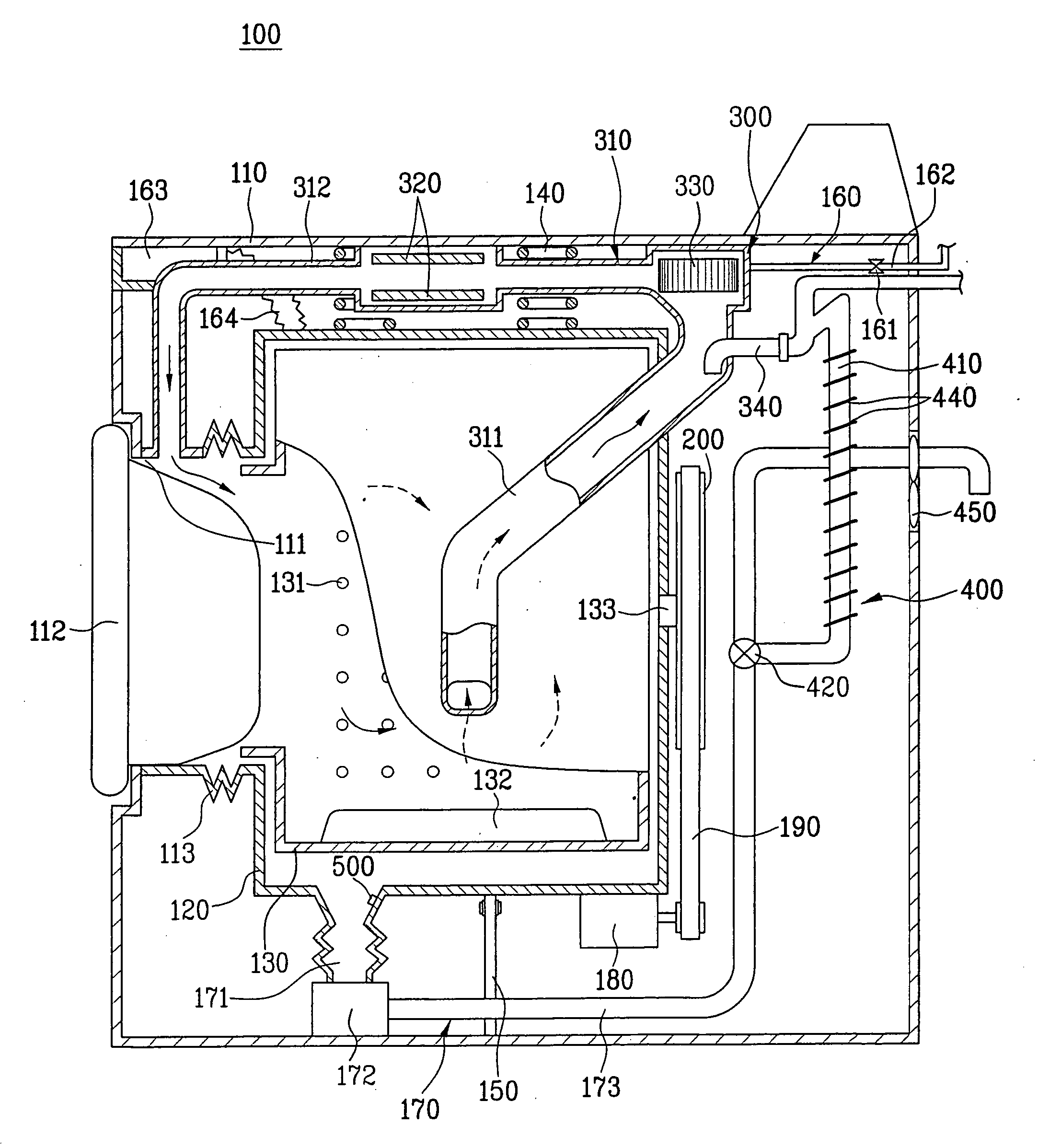

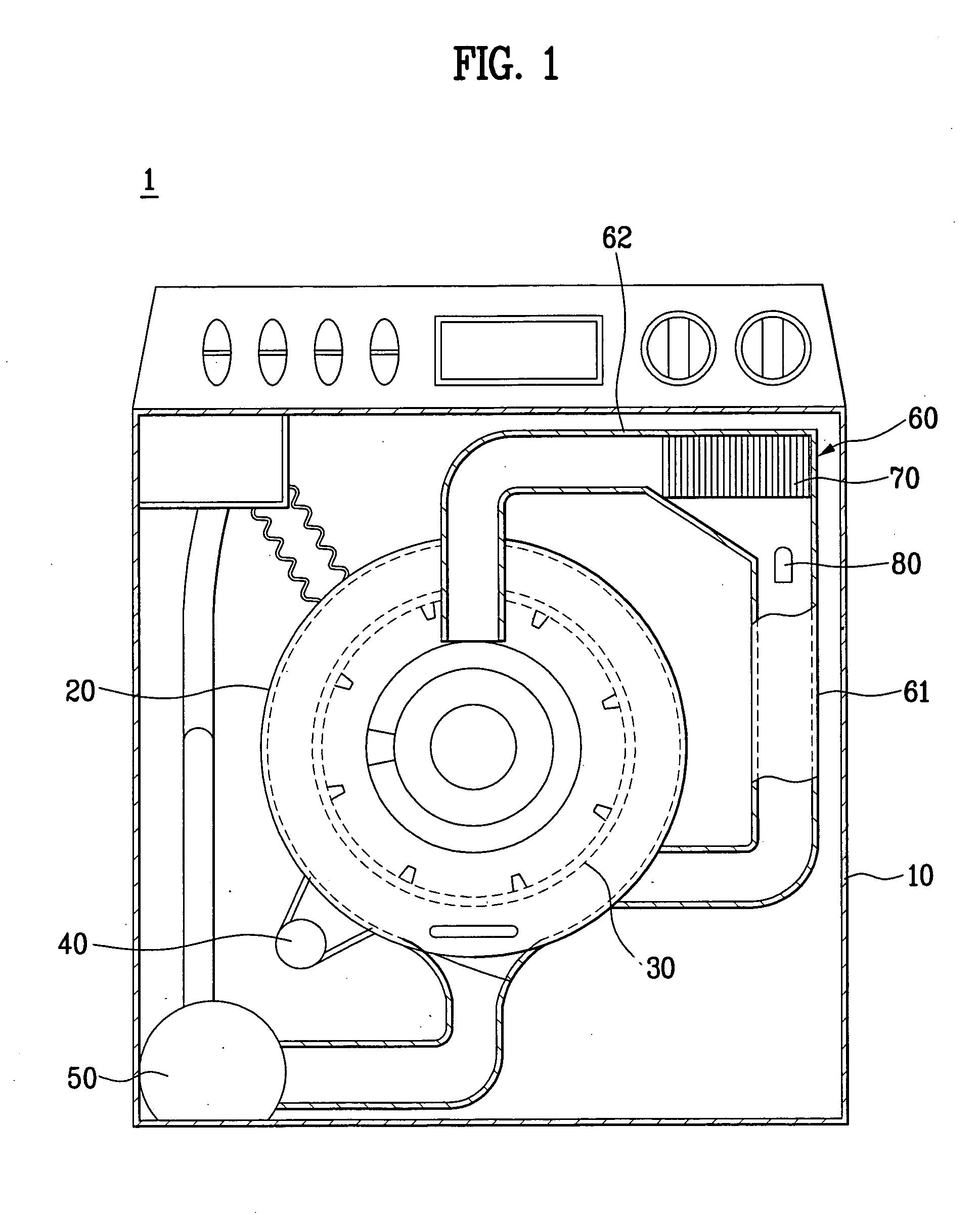

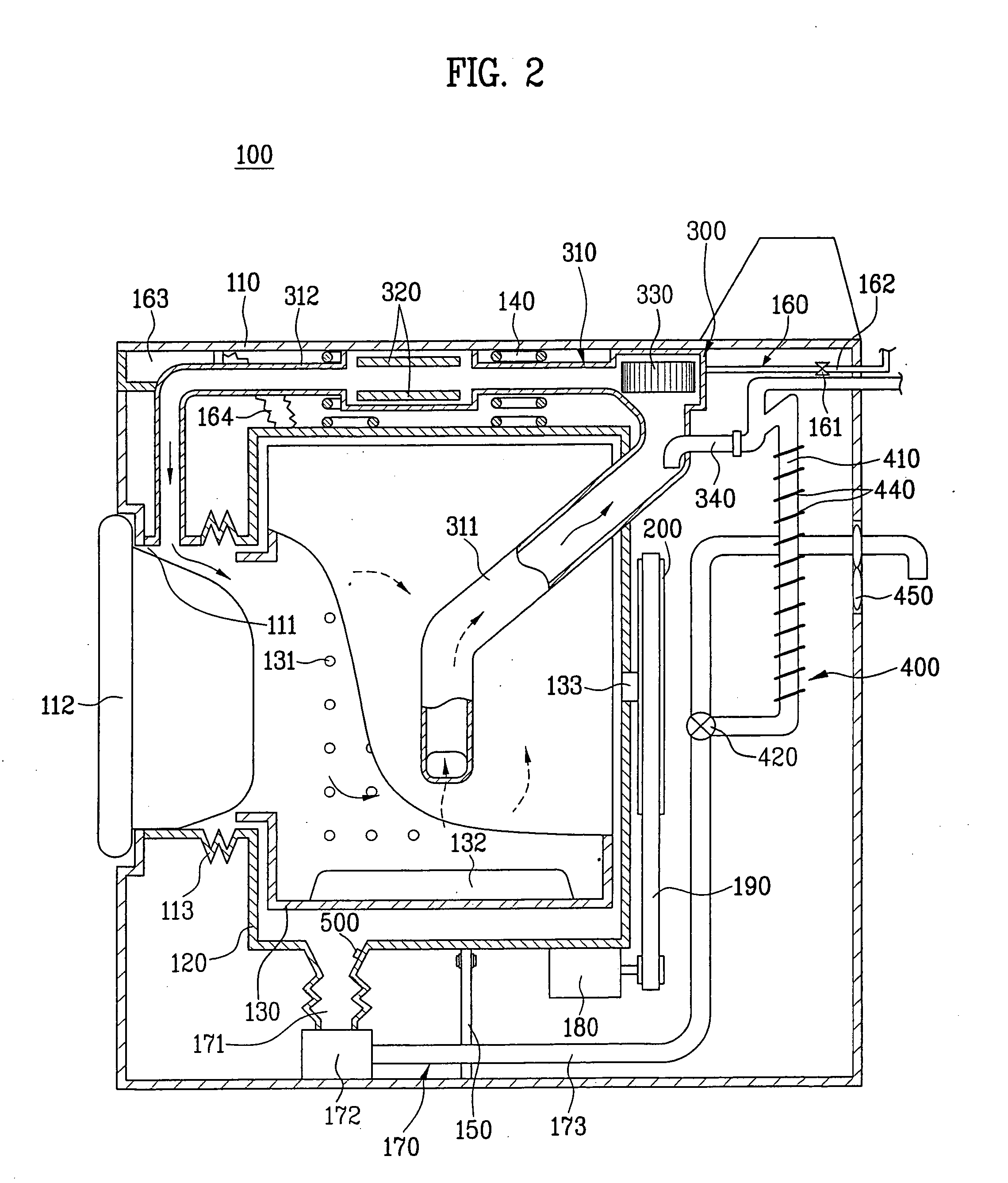

Washing machine

InactiveUS20050223755A1Fast dryingAvoid wastingDrying gas arrangementsOther washing machinesPulp and paper industryWater circulation

Washing machine including a duct having opposite ends connected to a tub of the washing machine such that air in the tub passes through the duct, and is supplied to the tub again, a fan in the duct for drawing air from an inside of the tub, and discharging to the inside of the tub, a water supply device connected to the duct, for supplying cooling water to the inside of the duct to condense moisture in the air passing through the inside of the duct, a heater in the duct, for heating the air passing through the duct, and a cooling water circulating device for supplying cooling water held at a bottom of the tub after passed through the duct to an inside of the duct, again.

Owner:LG ELECTRONICS INC

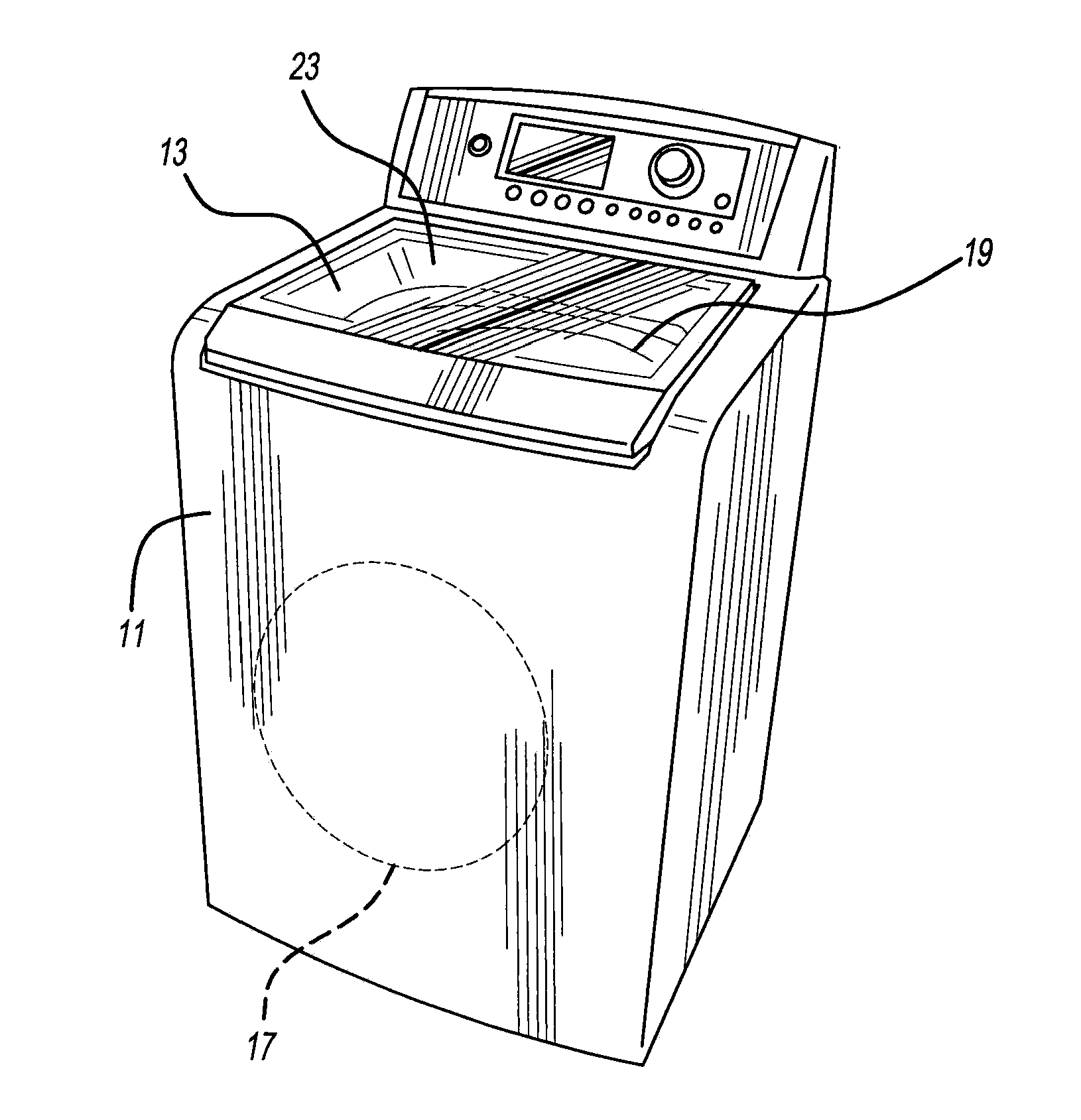

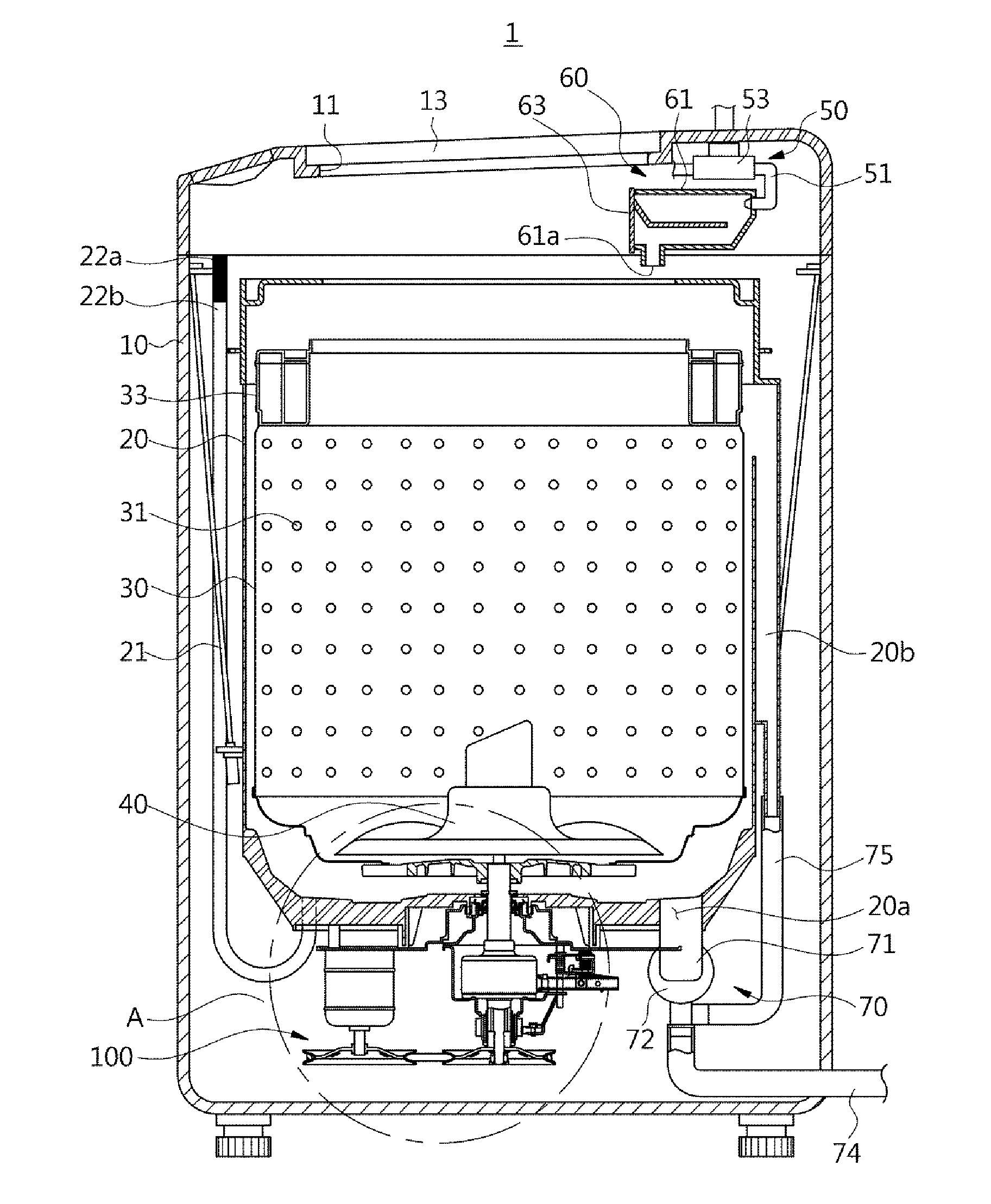

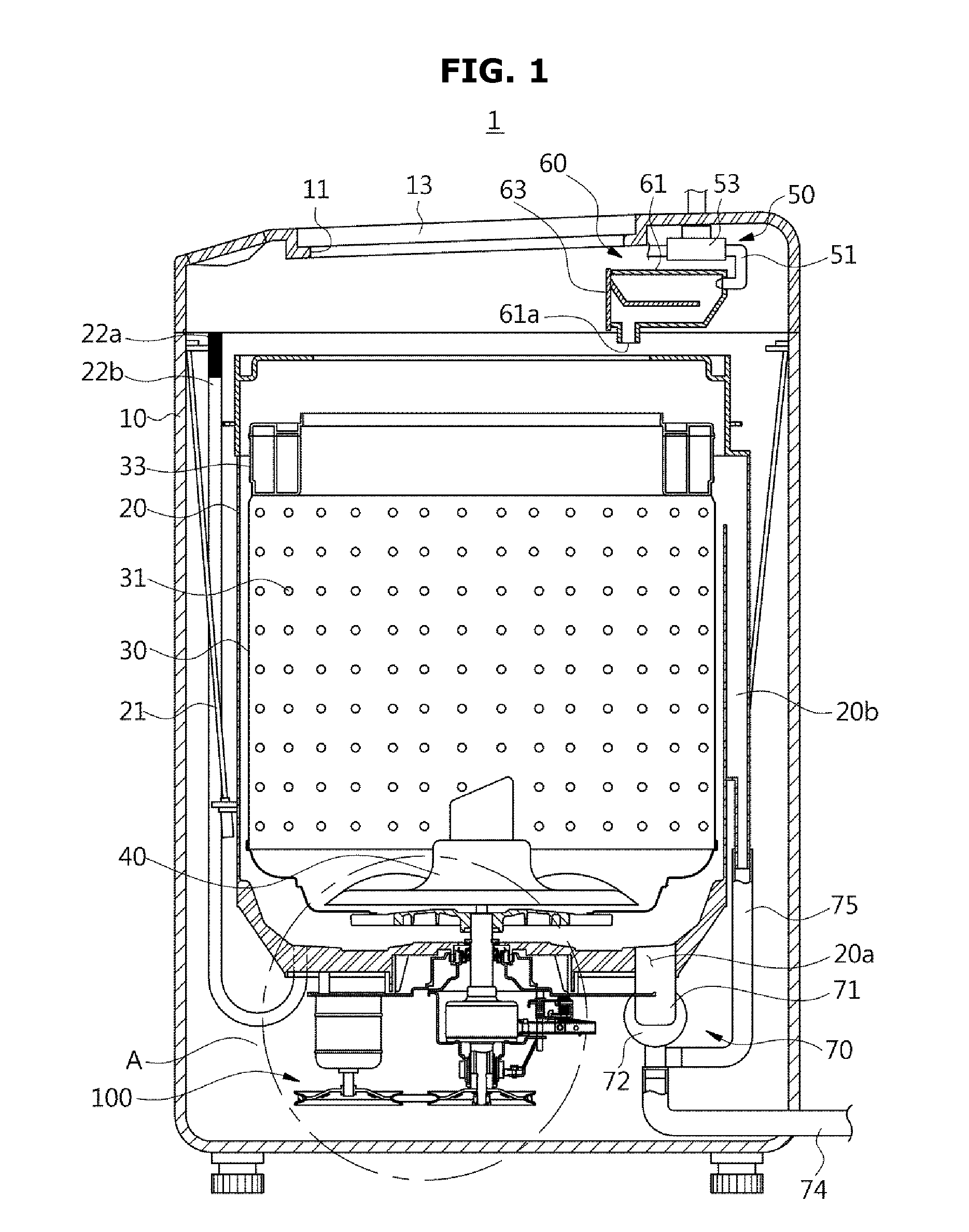

Washing machine

A washing machine comprises an outer tub disposed in a case and receiving water therein, an inner tub installed in the outer tub, receiving laundry therein and rotated for washing and dewatering the laundry and a lower balancer installed at a lower part of the inner tub for reducing vibration generated during rotation of the inner tub. Accordingly, a lopsidedness and vibration of the inner tub generated during washing and dewatering operations can be prevented.

Owner:LG ELECTRONICS INC

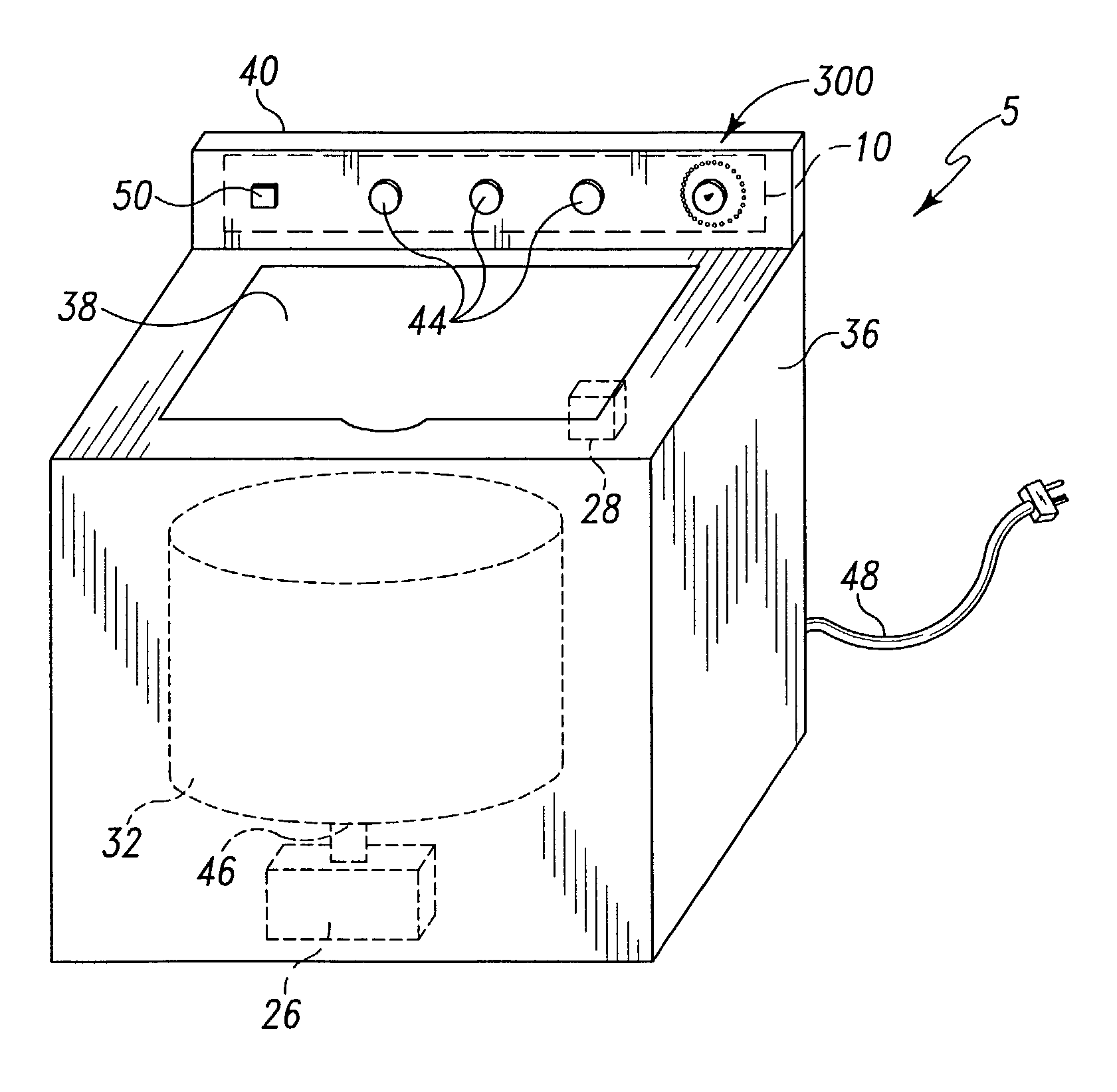

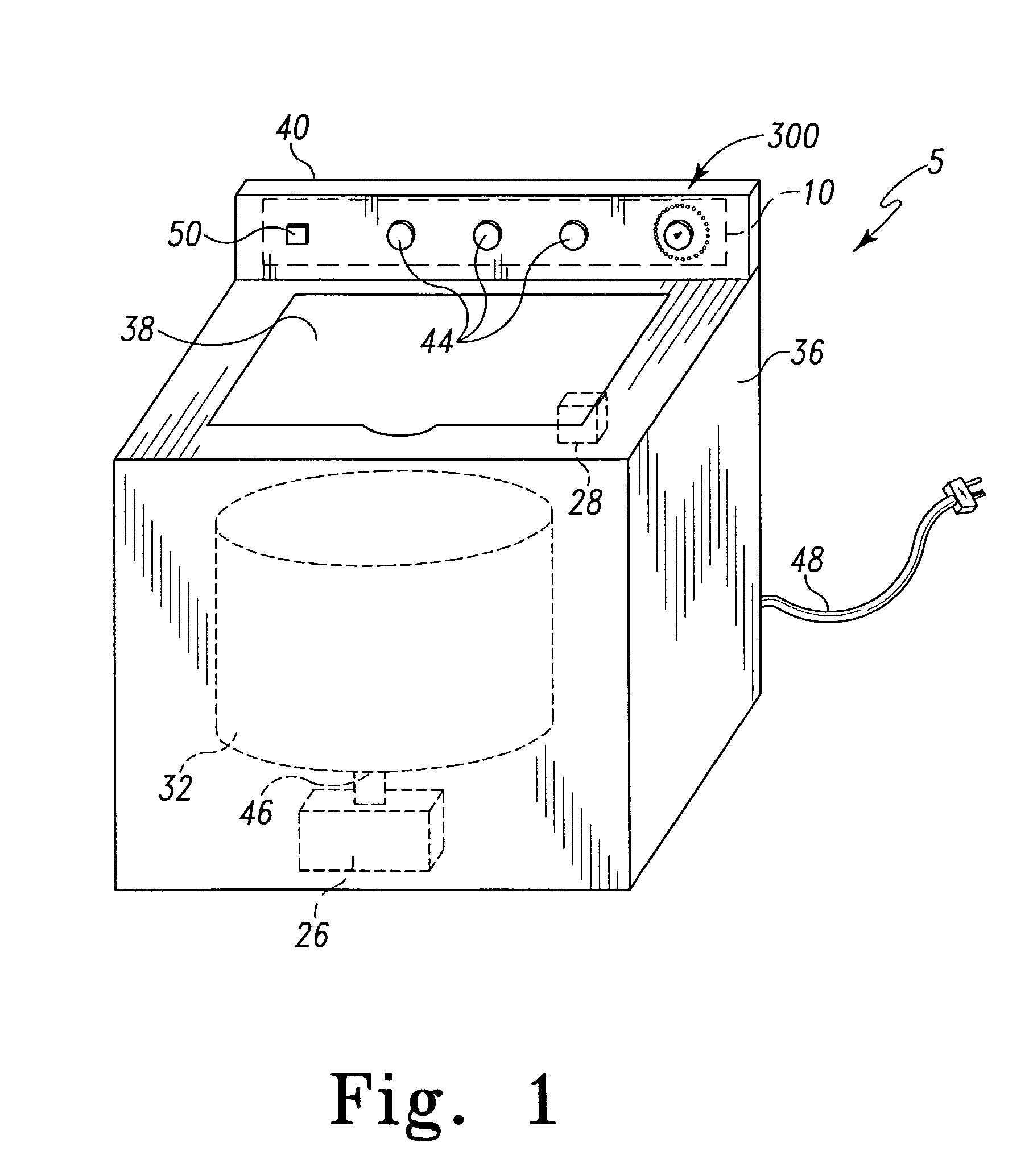

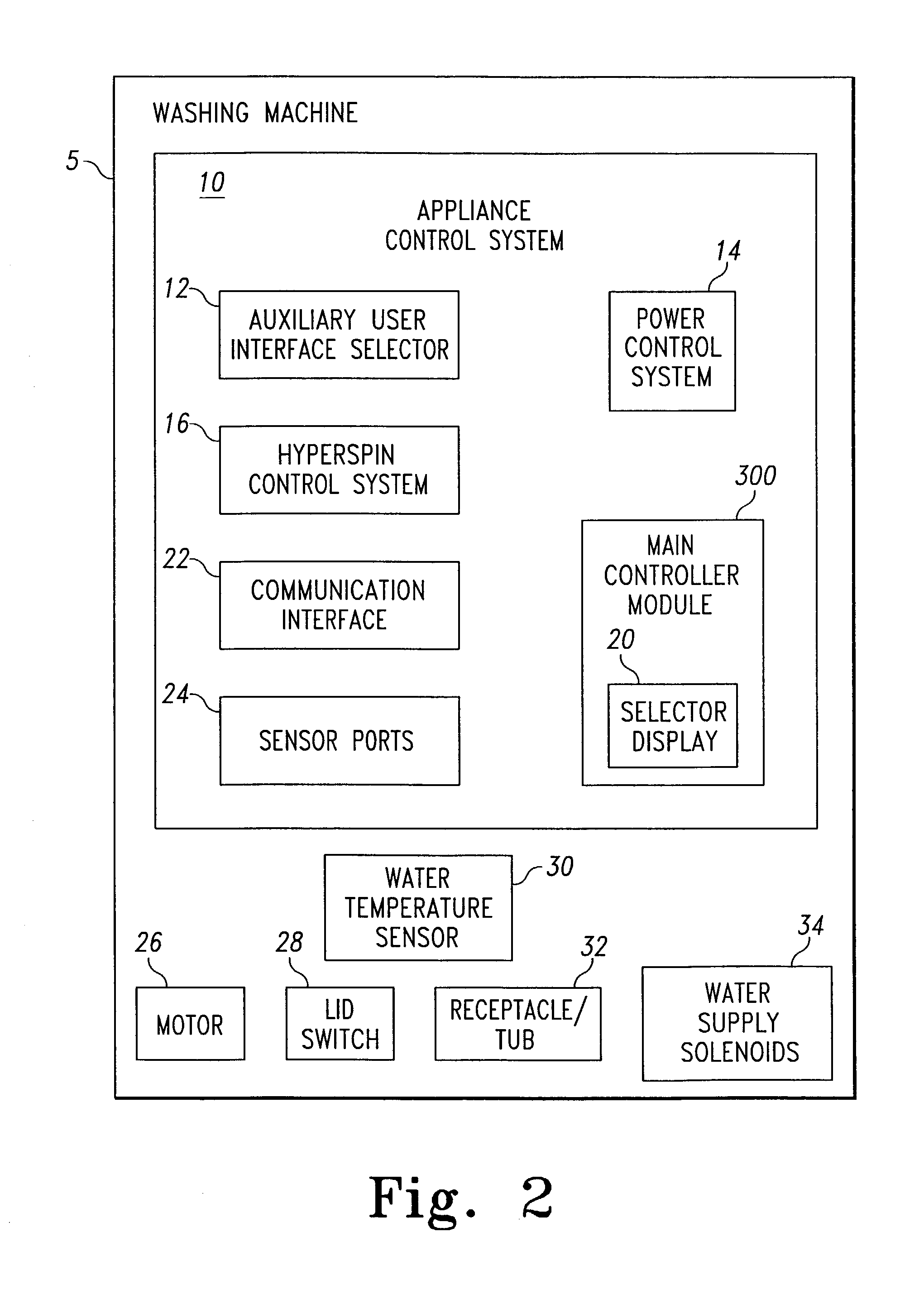

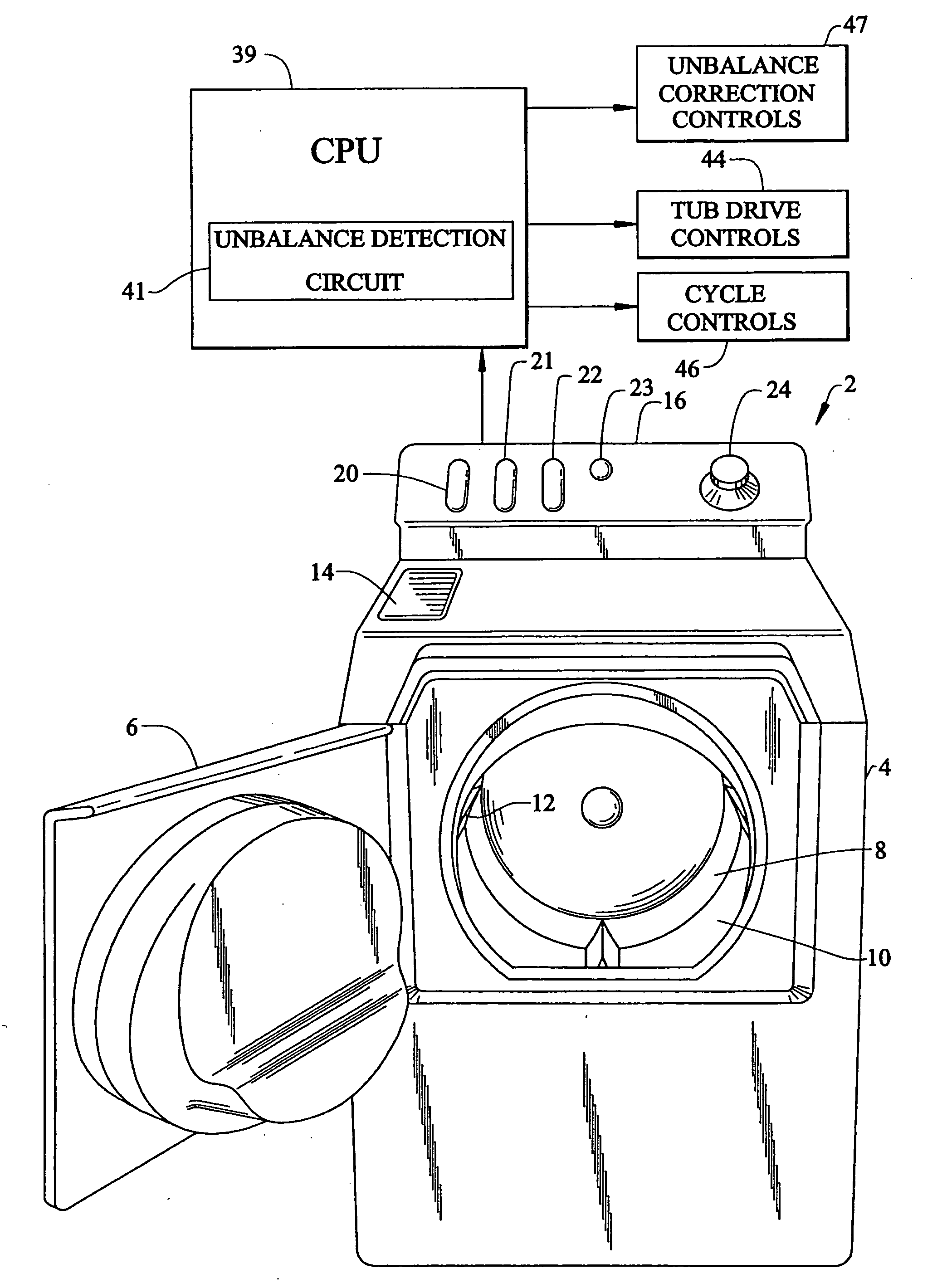

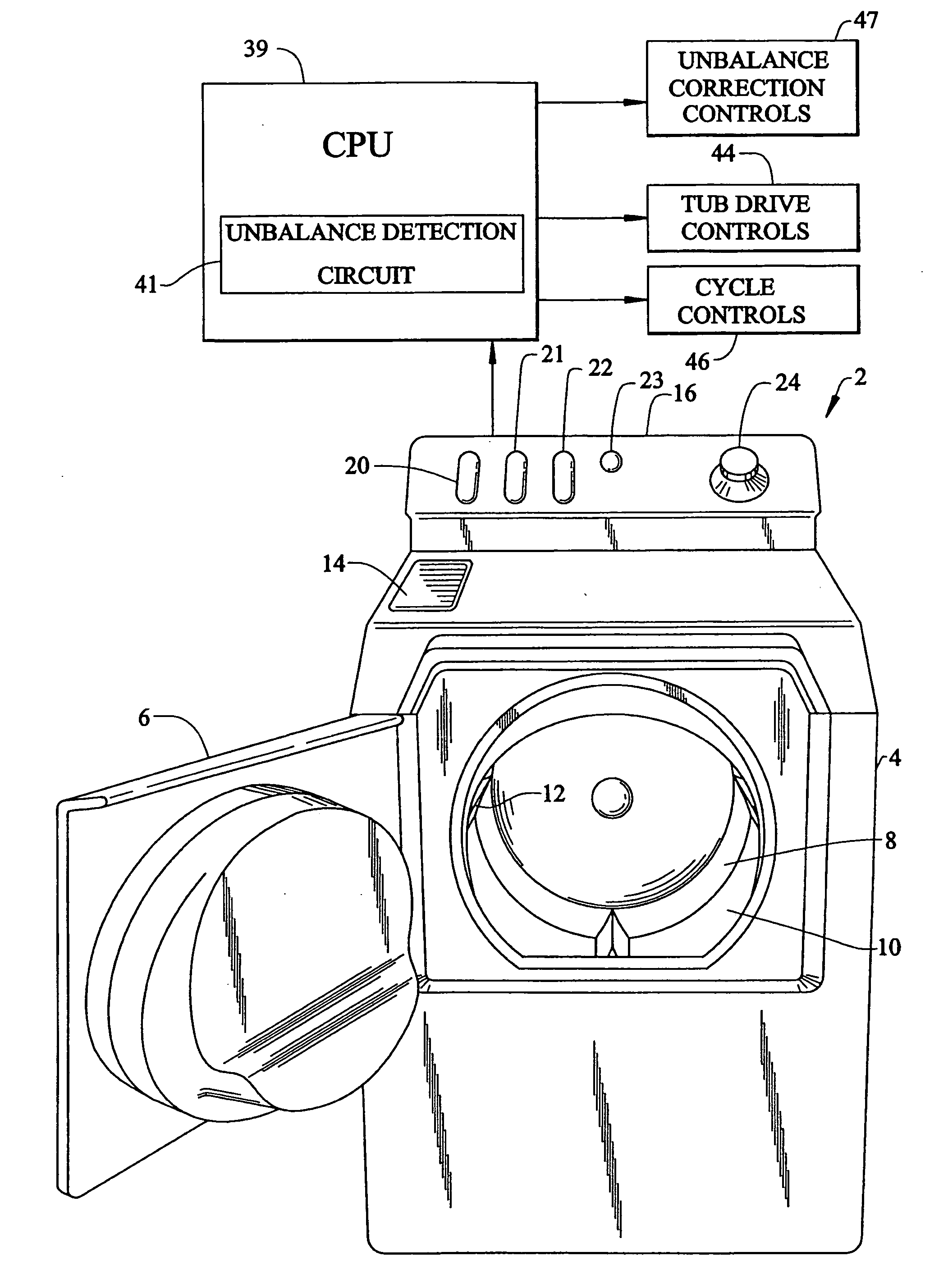

Appliance control system with hyperspin mode

A power controller for an appliance, especially a washing machine, is operative to place the appliance into a hyperspin mode. When in the hyperspin mode, the washing machine rotates its washing basket at a higher speed in relation to a traditional spin mode for the washing machine. In order to prevent damage to the washing machine that could result from spinning heavier, unbalanced loads at higher speeds (i.e. hyperspin speeds), a controller detects vibration of the washing machine basket while the items are being spun at a lower speed (i.e. at the speed of the traditional spin mode). If the washing basket vibration is less than a predetermined threshold vibration value, the washing machine controller operates to cause the washing machine to rotate its washing basket at a higher speed. This results in removal of more water from the clothes being spun dried.

Owner:NIDEC MOTOR CORP

Washing apparatus and controlling method thereof

ActiveUS20150240404A1Minimizes a resonance phenomenonMotor/generator/converter stoppersAC motor controlElectric machineControl theory

A washing apparatus including an AC motor configured to generate a rotating force, a clutch unit configured to selectively transmit the rotating force to a rotating tub and a pulsator, a speed detector configured to detect a rotating speed of at least one of the AC motor and the clutch unit, and a controller configured to repeat power supply and power cut-off to the AC motor according to the rotating speed. The washing apparatus can control the power supply and power cut-off to the AC motor based on the rotating speed.

Owner:SAMSUNG ELECTRONICS CO LTD

Appliance apparatus including a bonded bracket

An appliance apparatus includes an adhesively bonded bracket or support. In another aspect, a clothing apparatus includes a moveable transparent panel, such as a glass door or lid, which has a polymeric support or bracket adhesively bonded thereto. A further aspect provides polyurethane adhesive pellets bonding a polymeric hinge bracket to only a backside of a glass appliance panel.

Owner:A RAYMOND & CO

Single-tub pulsator washing machine and assorted removable spin-dry basket

InactiveCN104233696ASimple structureReduce volumeOther washing machinesWashing machine with receptaclesImpellerDrive shaft

The invention relates to a single-tub pulsator washing machine and an assorted removable spin-dry basket. The single-tub pulsator washing machine comprises a washing machine shell, an inner tub, a washing impeller and the spin-dry basket convenient to assemble and disassemble. A clamp ball is arranged in the center of the basket, the spin-dry basket can be nested in a clamp groove structure of a center shaft of a pulsator when clothes are about to be subjected to spin-dry, the clothes can be placed in the spin-dry basket, and clothes spin-dry procedures can be completed by the aid of a transmission shaft, the impeller and the spin-dry basket; the spin-dry basket is taken out when the clothes are about to be washed, so that water feeding, draining and timed clothes washing and rinsing procedures can be implemented by the washing machine. The single-tub pulsator washing machine and the assorted removable spin-dry basket have the advantages that the size of the single-tub pulsator washing machine can be reduced by 2 / 5 as compared with an existing double-tub washing machine on the premise that basic functions keep unchanged, and the cost of the single-tub pulsator washing machine can be reduced.

Owner:QINGDAO KANGWEILONG COMMODITY COMPANY

Method for controlling drum

InactiveCN1760430AEasy to controlGood homogenization effectControl devices for washing apparatusTextiles and paperGood controlDewatering

The present invention provides a uniformization method, eccentricity detection method and dewatering control method which can make the material in the drum washing machine and similar centrifugal dewatering equipment be uniformly distributed so as to reduce vibration and noise due to eccentricity. Said invention adopts a short-periodic power-on and power-off method of motor and collects rotating speed change due to eccentricity of drum which is rotated for a turn at 72-85 RPM to make detection of eccentricity, so that it can obtain good control effect.

Owner:朱筱杰

Penetration type washing machine, method for controlling the same, and tub cover for the same

InactiveUS7263864B2Simple structureImprove washing efficiencyRinsing apparatusCapsPulp and paper industryCentrifugal force

Method for controlling a full automatic washing machine, the method comprising a washing cycle, a rinsing cycle, and a dewatering cycle, wherein the washing or the rinsing cycle includes the step of rotating an inner tub at a high speed higher than a preset speed in one direction, thereby making a centrifugal force caused by high speed rotation of the inner tub, to push laundry against a wall of the inner tub, to enforce washing water in the inner tub to penetrate through the laundry at a speed higher than required to make the washing done, and to pump the washing water penetrated through the laundry and discharged into an outer tub upward, to recirculate to the inner tub.

Owner:LG ELECTRONICS INC

Stepping-free electric dehydration barrel

InactiveUS20110197463A1Easily and rapidly dehydratingAvoid contactCarpet cleanersFloor cleanersElectricityRechargeable cell

A stepping-free electric dehydration barrel includes a barrel unit, a dehydration unit, a motor, a control unit, a rechargeable battery and a recharging connection port. The dehydration unit includes a dehydration basket and a spindle which supports the dehydration basket. The spindle is installed on an elastic lifting unit below which is a starting switch being electrically connected to the control unit. After a user has put a mop into the dehydration basket, he or she only needs to exert a little force to descend the dehydration basket to turn on the starting switch, and then the control unit can drive the motor spinning in a predefined time, thereby achieving an object of easily and rapidly dehydrating.

Owner:SHIH SHU CHEN

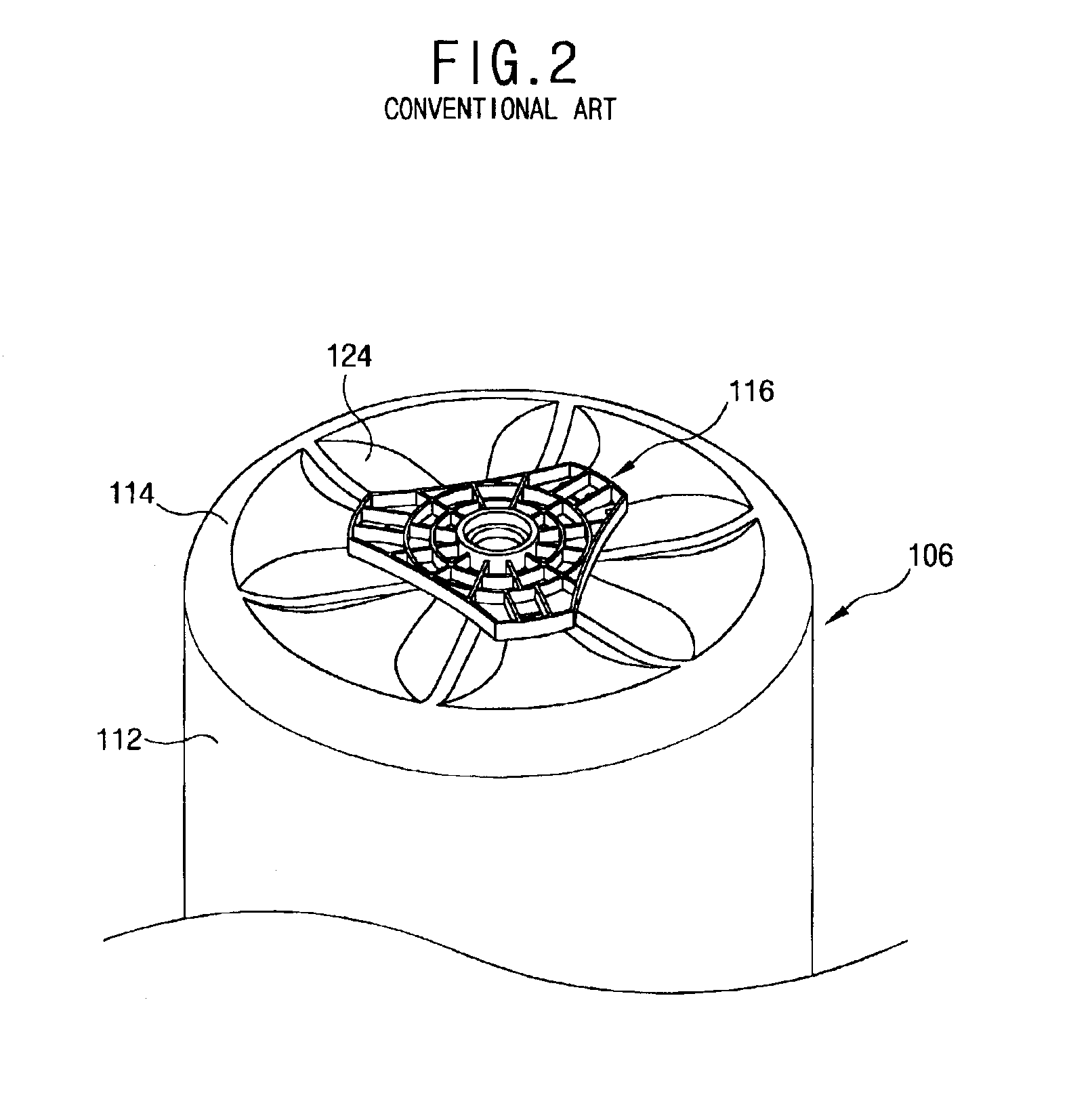

Inner tub for washing machine

InactiveUS6918271B2Simple structureDegree of improvementOther washing machinesWashing machine with receptaclesCouplingElectric machinery

An inner tub for a washing machine, which is able to increase a dried degree of laundries and to increase a reliability of the washing machine by improving a structure of an inner tub hub and reinforcing the inner tub to make a spin-drying of high speed possible, comprises an inner tub body; an inner tub base formed on a lower part of the inner tub body; and an inner tub hub coupled on a lower surface of the inner tub base, including a rotating shaft coupling portion to which a rotating shaft for transmitting a rotating force of a driving motor is coupled, a radial supporting portion extended in an outer boundary direction of the rotating shaft coupling portion with a predetermined gap therebetween, and a ring type supporting portion having a predetermined width in an outer circumferential direction of the radial supporting portion formed integrally.

Owner:LG ELECTRONICS INC

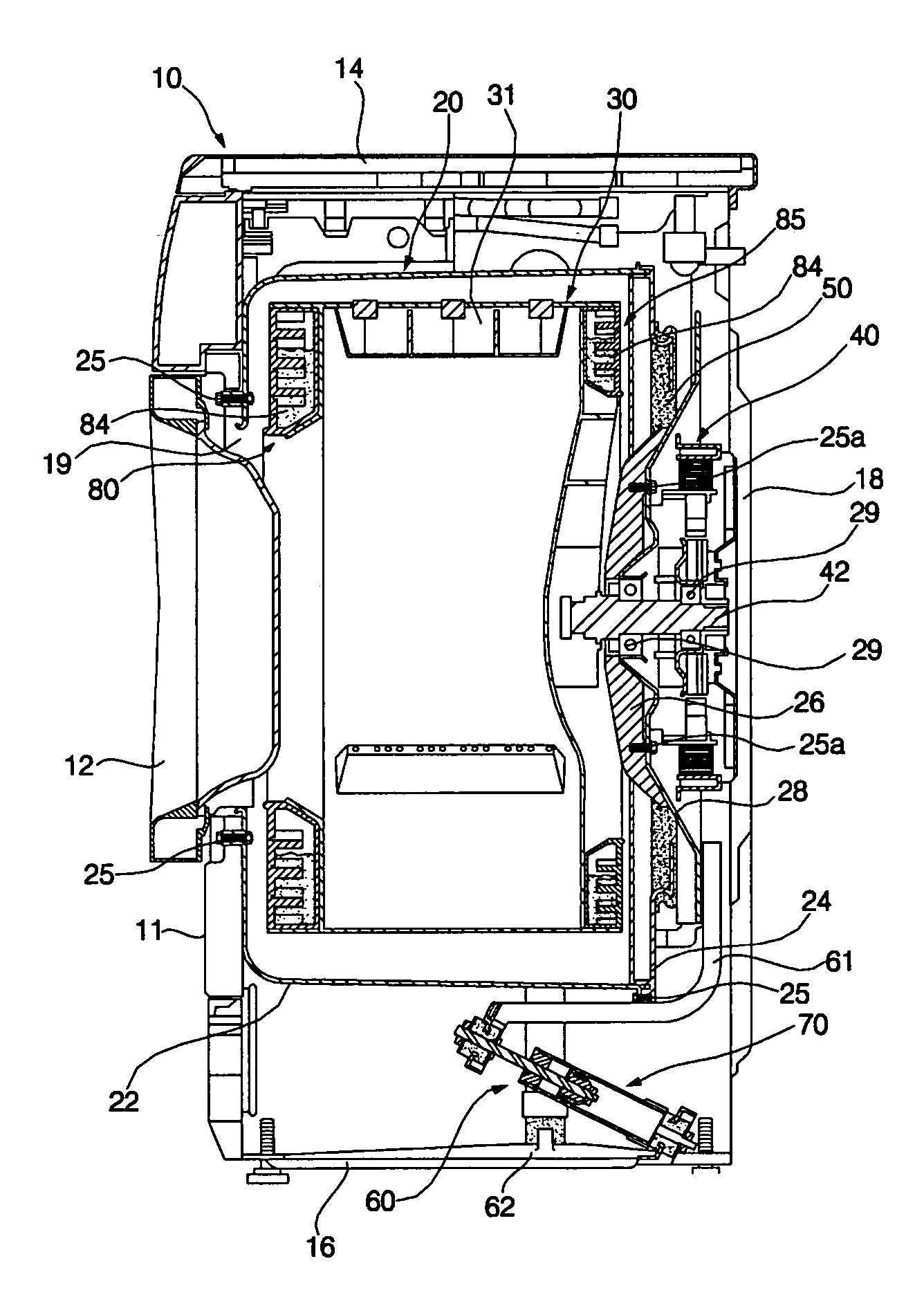

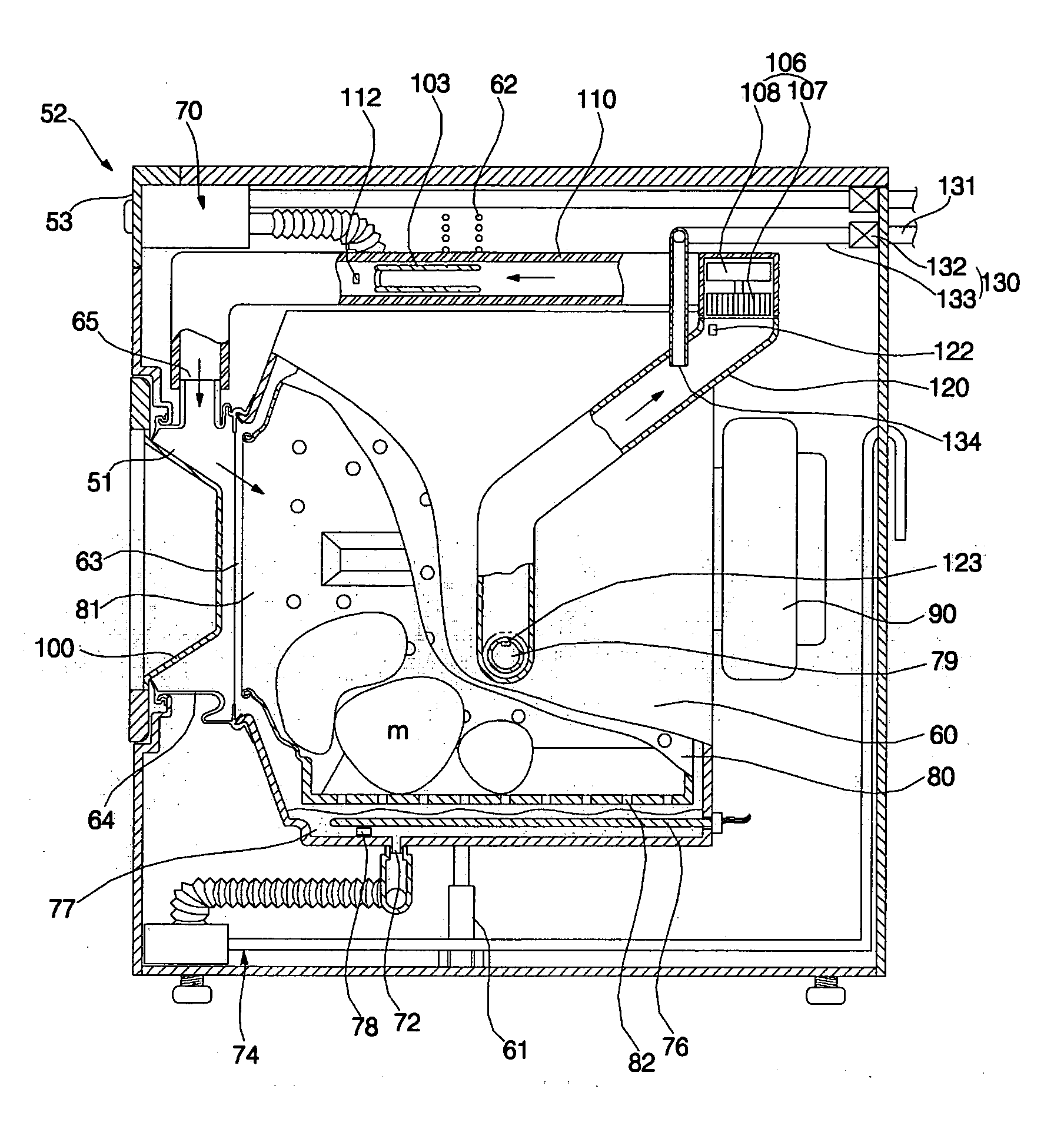

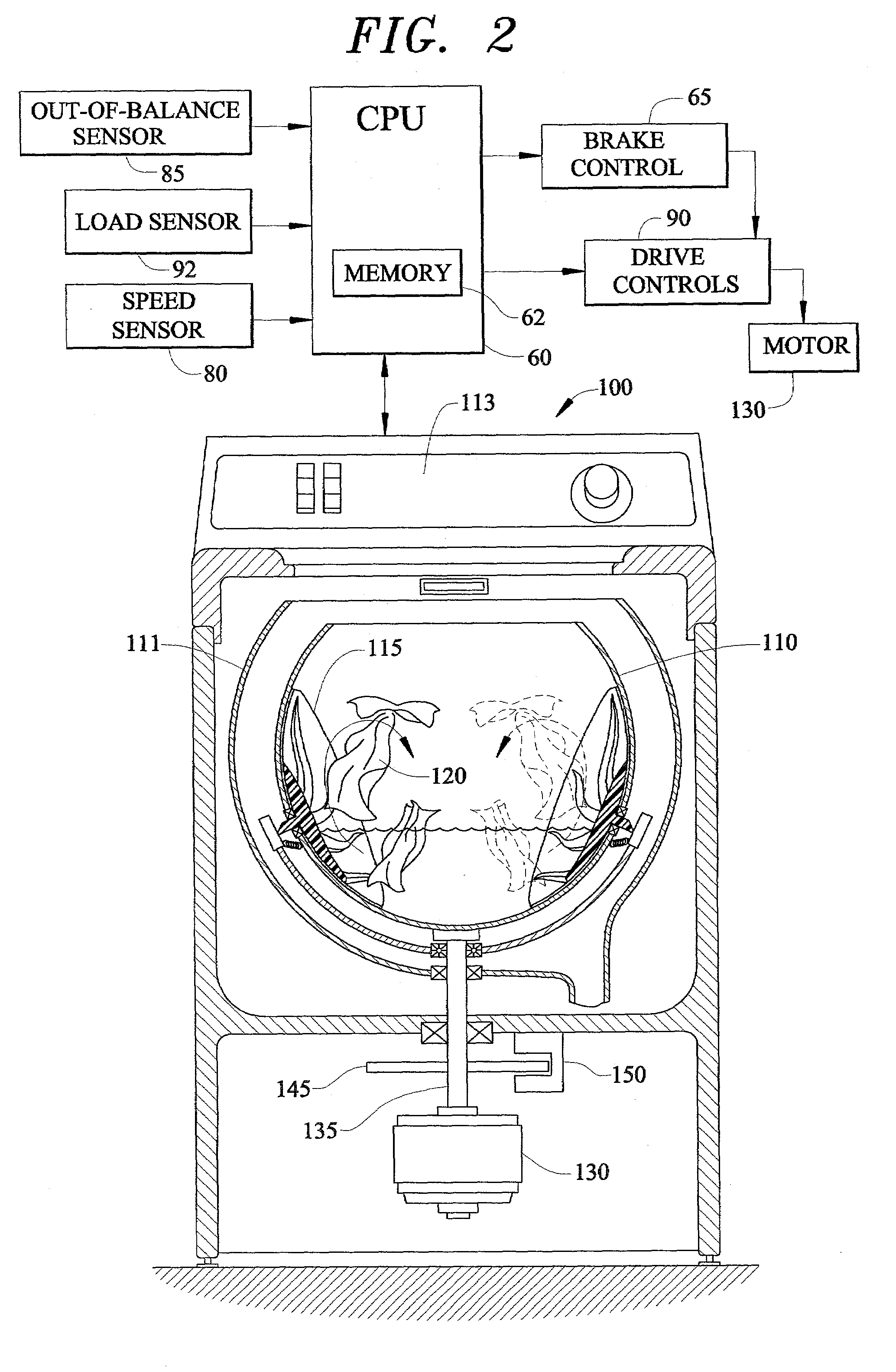

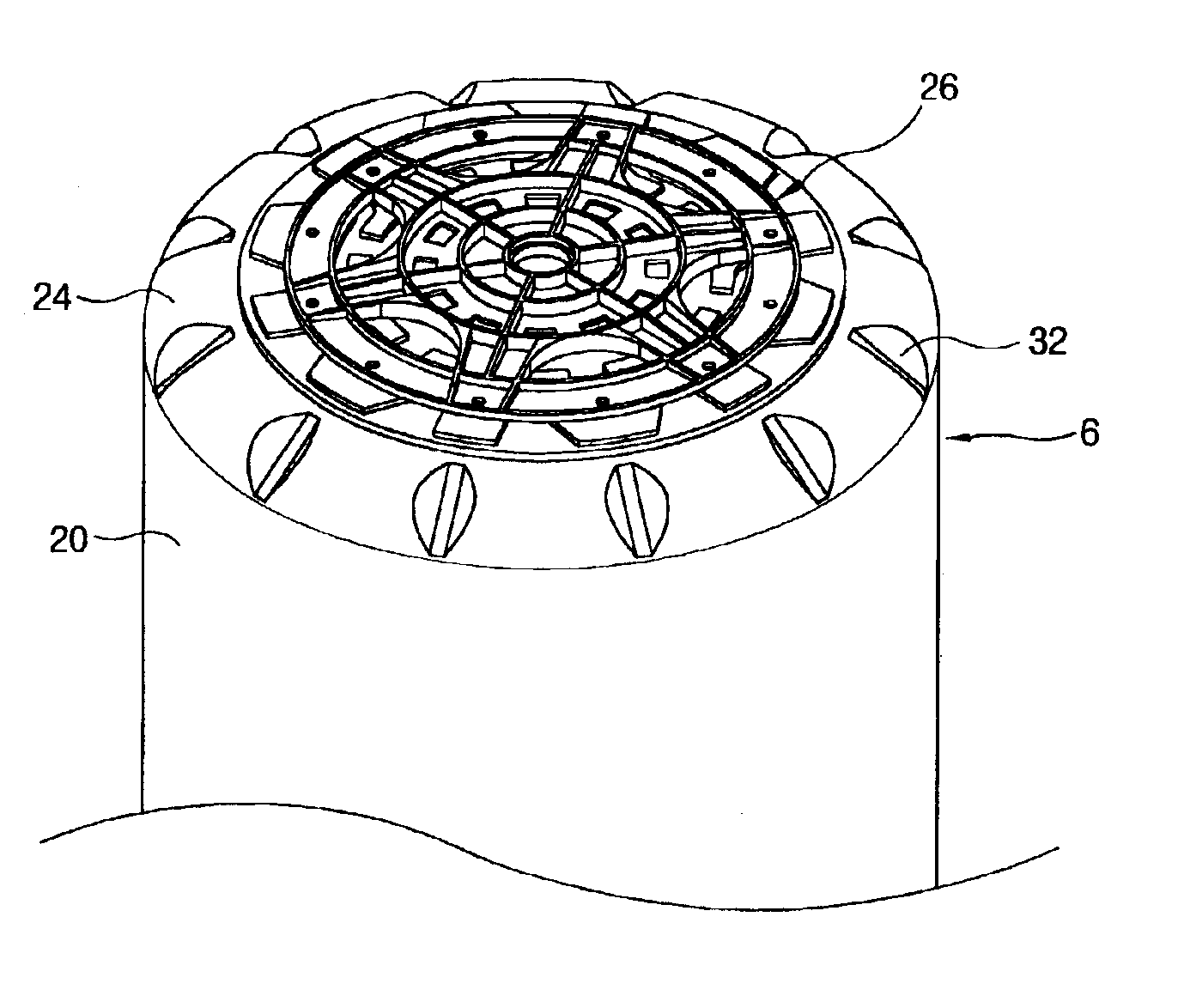

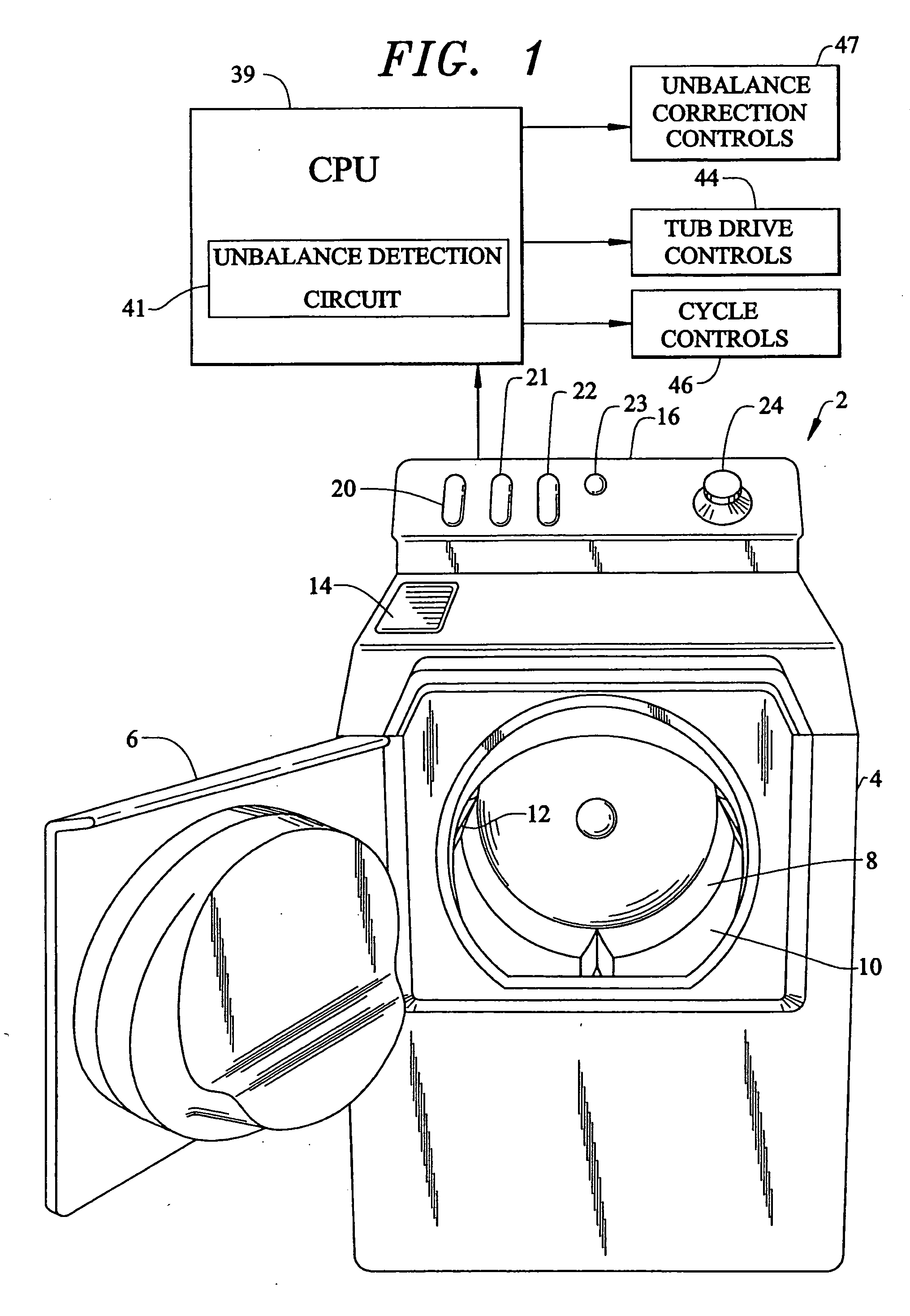

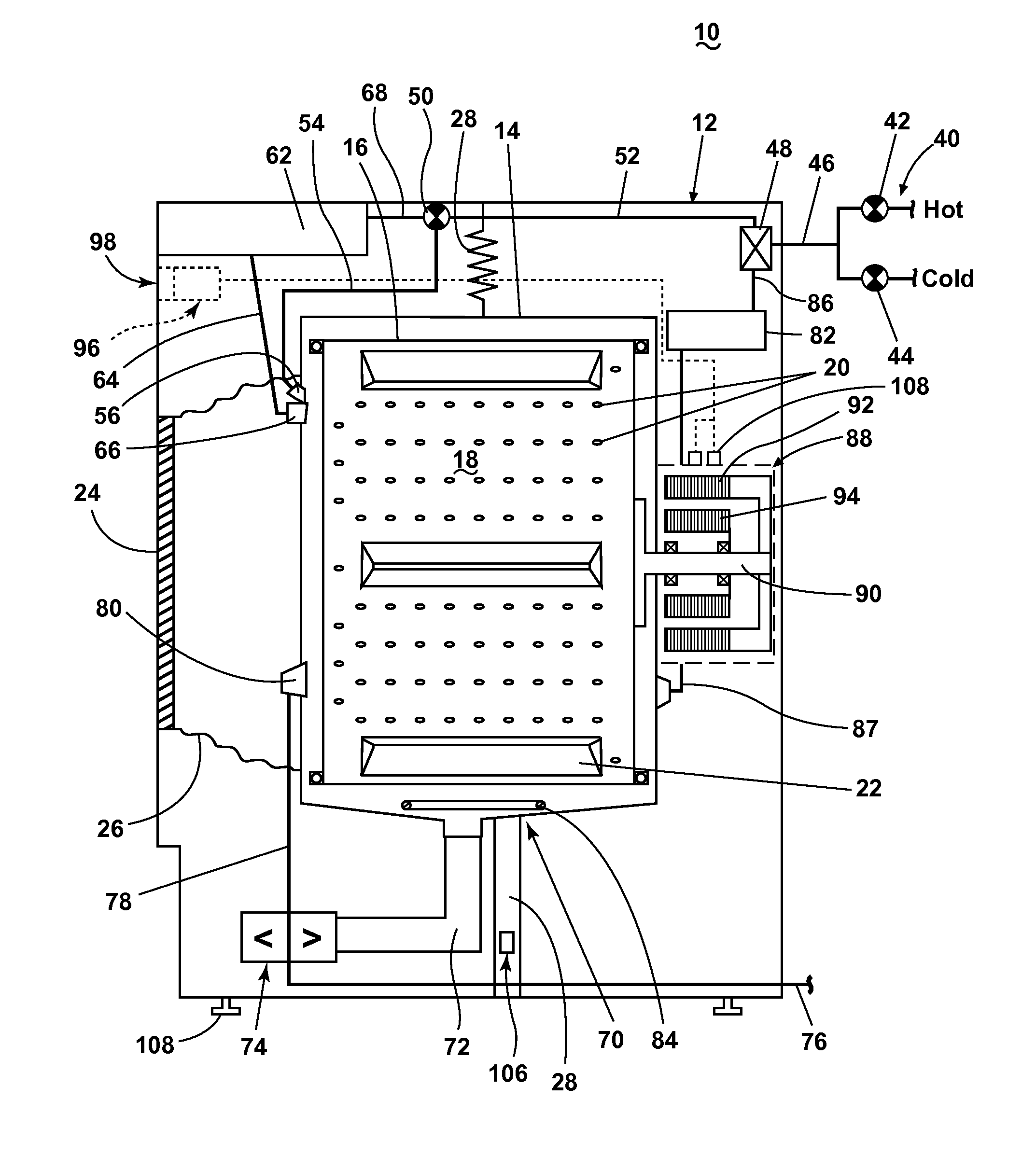

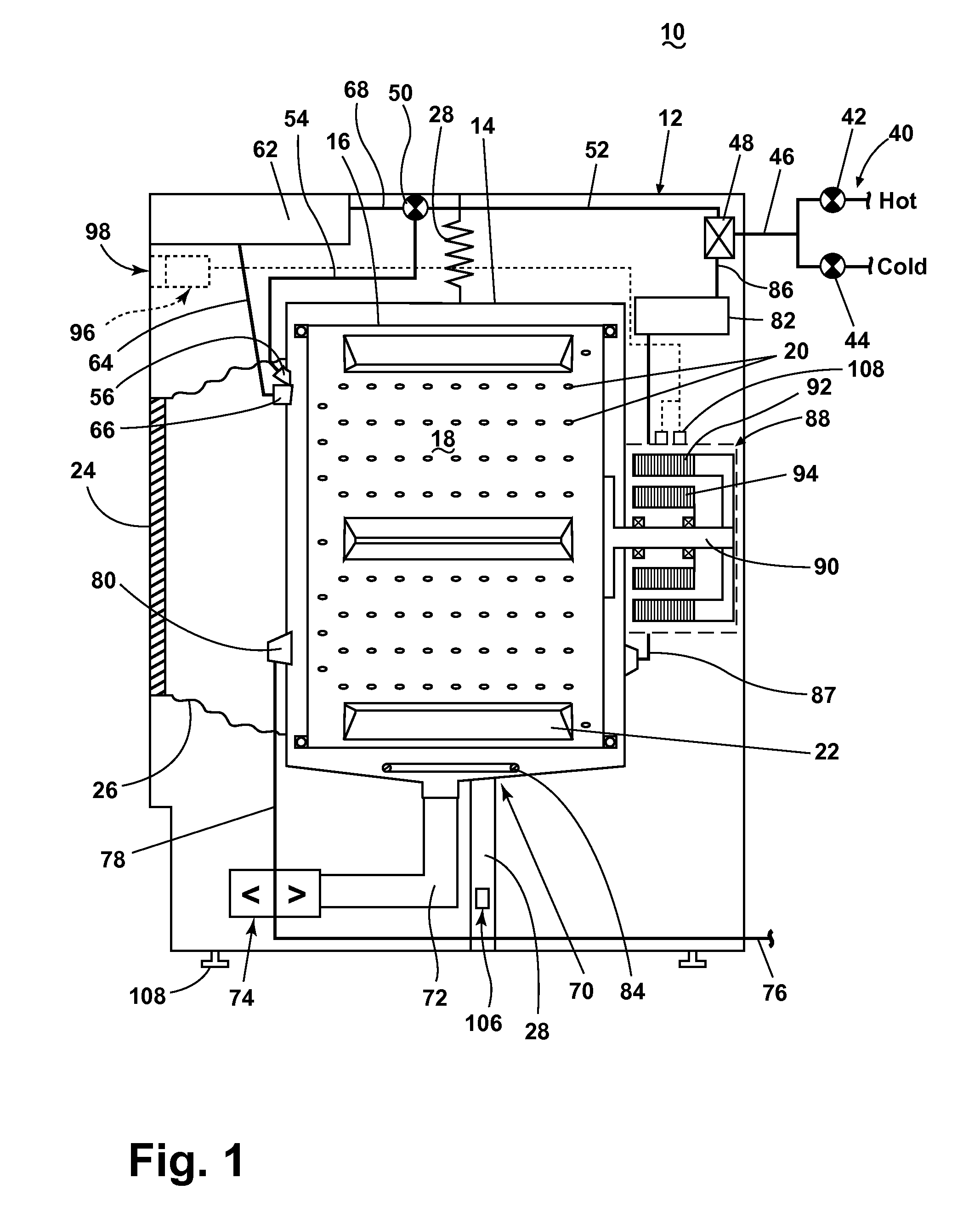

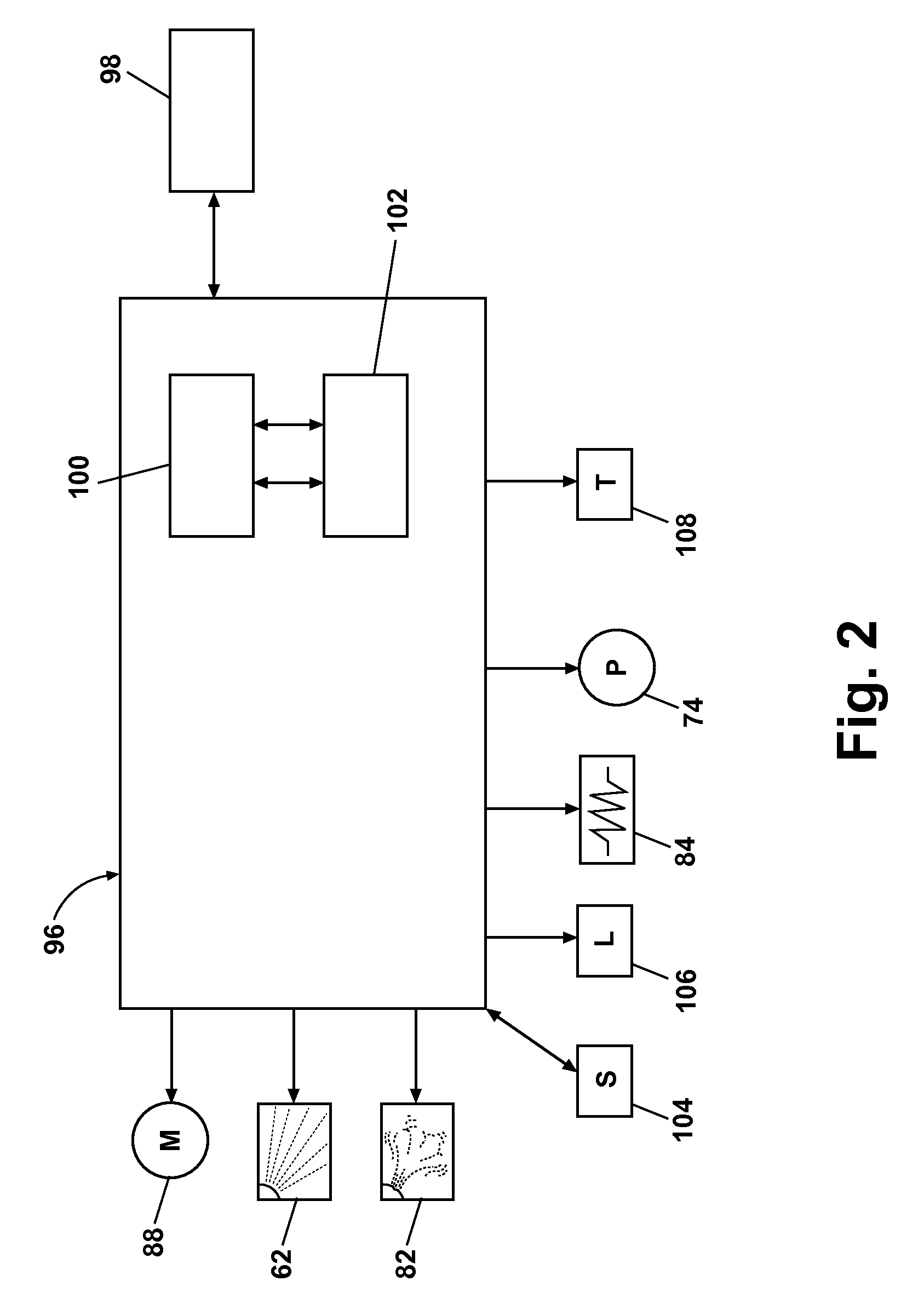

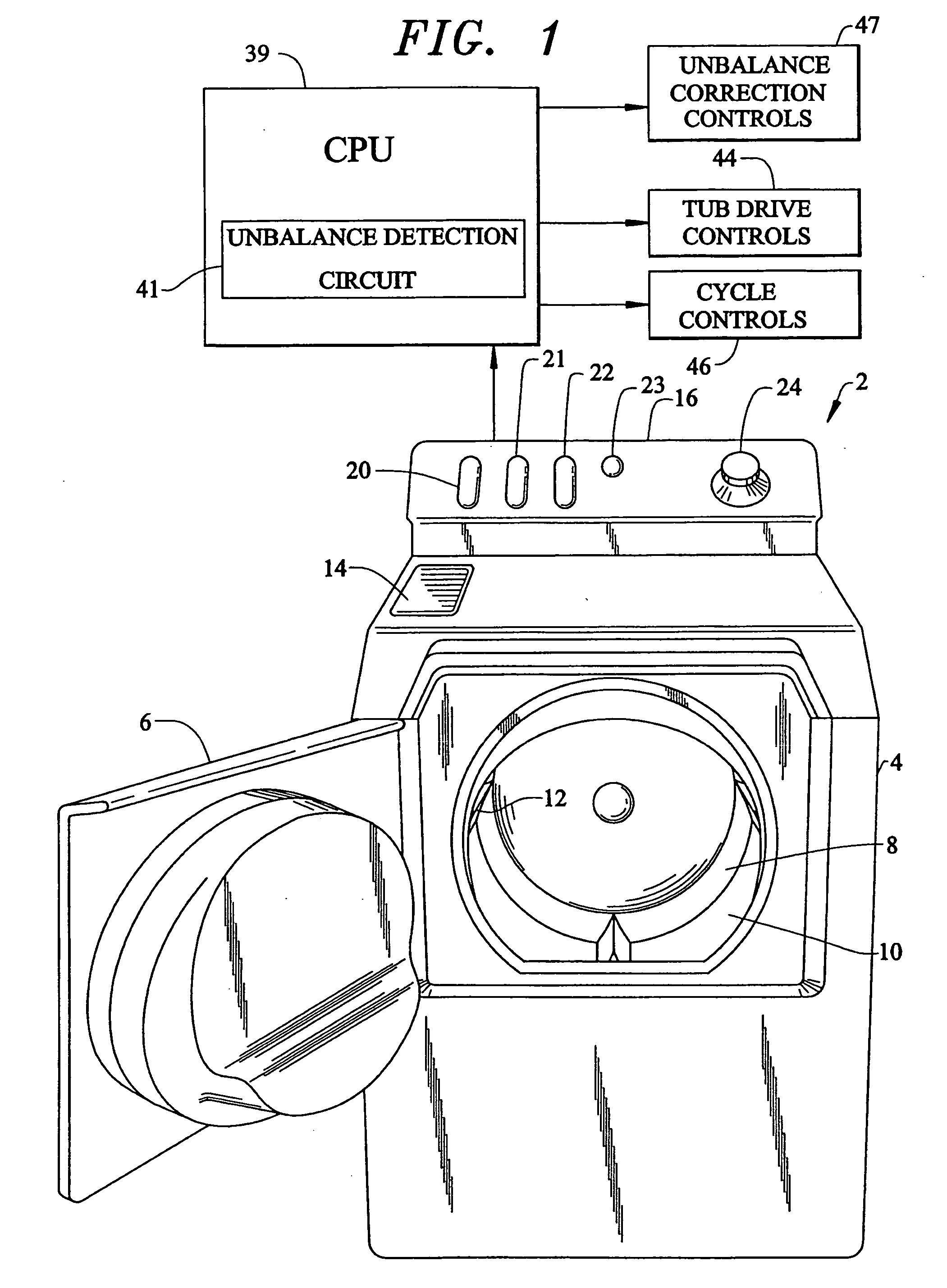

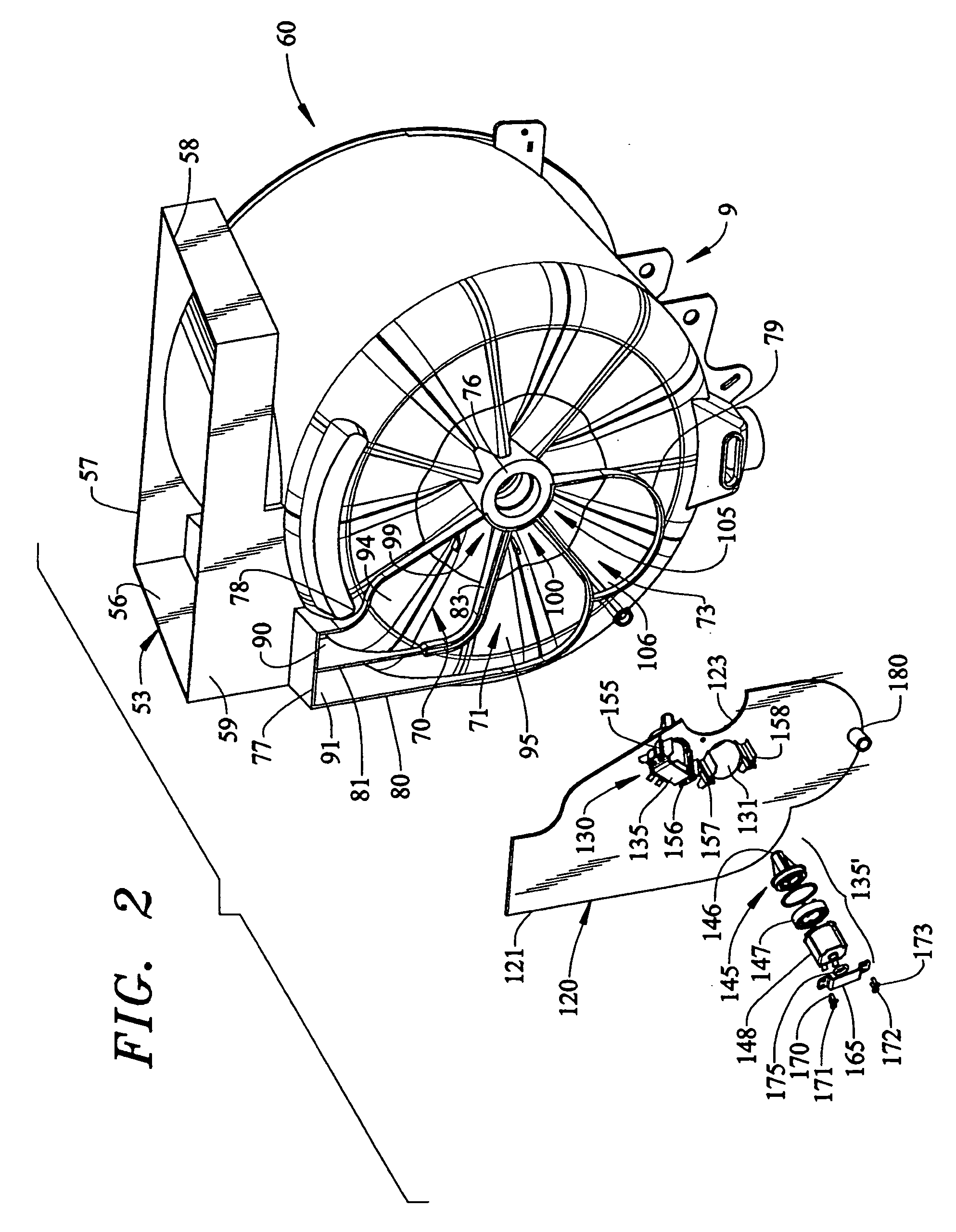

Balancing fluid flow arrangement in an inner tub of a washing machine having an out-of-balance correction system

InactiveUS20050210929A1Reliable and accurate and cost-effectiveOther washing machinesControl devices for washing apparatusInjectorCorrection system

A washing machine is provided with an out-of-balance correction system which can sense an out-of-balance condition of an inner tub during a washing cycle. More specifically, the correction system supplies an amount of balancing fluid to one or more receiving pockets formed in the inner tub about front and rear injection zones of the inner tub. Stationary injectors are provided to selectively dispense the balancing fluid through molded passages extending between an outer tub and the receiving pockets.

Owner:MAYTAG

Semi-dry method of washing machine and the ventilating structure, control apparatus for the same

InactiveUS20070107473A1High degree of dehydrationAvoid damageDrying solid materials without heatOther washing machinesProcess engineeringDehydration

A semi-drying method of a washing machine, and a ventilating structure and a control apparatus for the same. In the semi-drying method, the dehydration and disentanglement of cloth are repeated plural times, and a washing tub is rotated at a designated dehydration speed for a time longer than that of the conventional dehydrating operation so as to minimize the jamming of the cloth into water pores of the washing tub, thereby increasing the dehydration degree of the cloth compared to the conventional dehydrating operation, removing offensive odors from the cloth, preventing damage to the cloth, allowing a user to select the duration of a semi-drying operation and to see the state of the semi-drying operation, and ventilating the washing tub during the semi-drying operation to improve the dehydration degree of the cloth.

Owner:LG ELECTRONICS INC

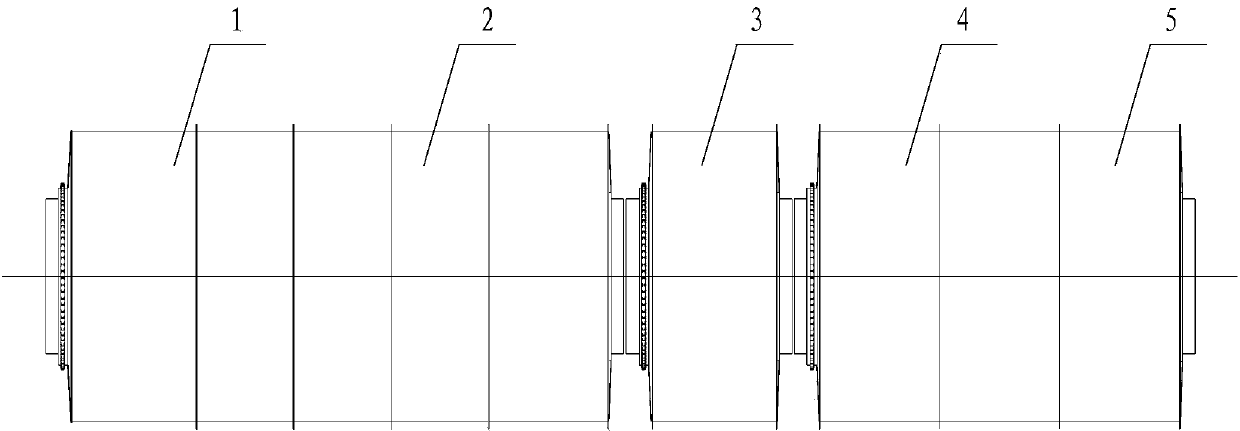

Tunnel type continuous washing machine

InactiveCN103726256AReduce the amount of sewageImprove washing effectOther washing machinesTextiles and paperAfter treatmentEngineering

The invention relates to a tunnel type continuous washing machine, and belongs to the field of washing equipment. The tunnel type continuous washing machine comprises a pre-washing area, a main washing area, a rinsing area and an after-treatment area, wherein a dewatering area is inserted between the main washing area and the rinsing area and comprises an inner barrel and an outer barrel; two panels are respectively fixed at an inlet and an outlet of the inner barrel; an inlet supporting steel ring and an outlet supporting steel ring are respectively fixed on surfaces, which are not fixed on the inner barrel, of the inlet panel and the outlet panel; the inlet supporting steel ring, the outlet supporting steel ring and the inner barrel are integrated; an optional one of the inlet supporting steel ring and the outlet supporting steel ring is connected with an external driving device; a conveying screw plate is fixed in the inner barrel; a through hole is formed in the inner wall of the inner barrel; and the inner barrel of the dewatering area is driven by an independent motor to rotate. By using the tunnel type continuous washing machine, the rinsing efficiency can be effectively improved; water consumed during rinsing is reduced; resources are saved; dewatered cloth grasses are easily rinsed cleanly; and a washing effect is obviously improved.

Owner:SHANGHAI WEISHI MACHINERY

Efficient energy usage for a laundry appliance

A laundry treating appliance has a rotatable drum at least partially defining a treating chamber for receiving a laundry load for treatment according to at least one cycle of operation and operated such that the extraction of liquid from the laundry load is controlled based on the inertia of the laundry load so that the total energy usage by the laundry treating appliance and a laundry drying appliance with which it is operably coupled may be minimized.

Owner:WHIRLPOOL CORP

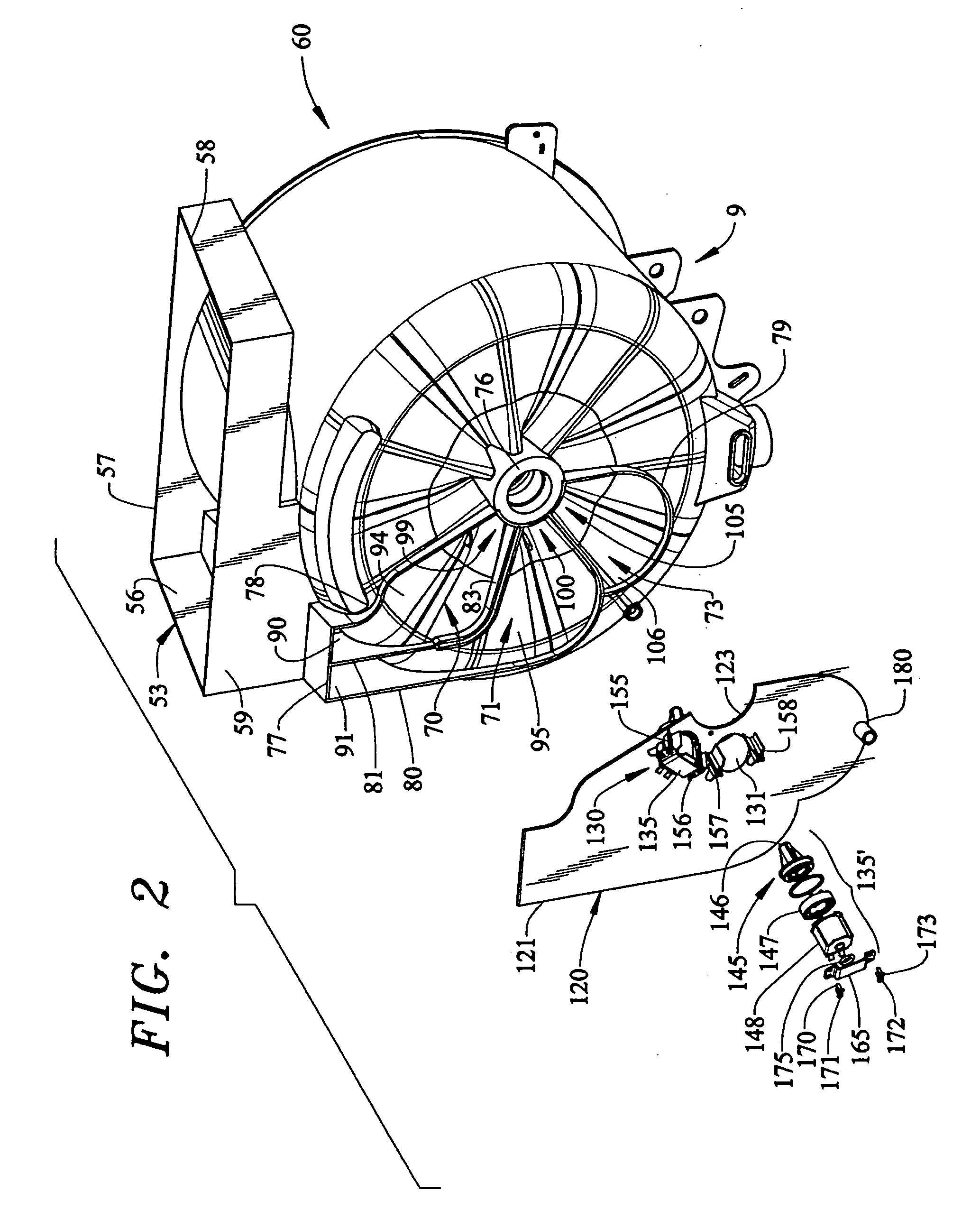

Solenoid plunger cushioning system for a washing machine balancing fluid valve

InactiveUS20050210930A1Reduce the impactAccurate timingOther washing machinesControl devices for washing apparatusEngineeringPole piece

A washing machine includes an out-of-balance correction system having a plurality of injector valves each having an associated solenoid element. Each of the injector valves is adapted to selectively inject a balancing fluid into a pocket carried by an inner tub to offset the out-of-balance condition. The valves are rapidly and repeatedly cycled to achieve a timed dispensing of the balancing fluid. To reduce the effects of the repeated cycling on the solenoid, a cushion element is mounted to a rear portion of a plunger carried within a solenoid coil. Additionally, a texturing process is applied to a pole piece arranged within the solenoid coil to establish a controlled leakage of air from a central portion of the cushion element once the plunger contacts the pole piece. With this arrangement, the service life of the injector valve is increased and proper control and timing of the injector valve is assured.

Owner:MAYTAG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com