Method for controlling washing during spinning in tilt-type washing machine for attenuation of vibration

a technology of tilt-type washing machine and control method, which is applied in the direction of other washing machines, washing machines with receptacles, textiles and paper, etc., to achieve the effect of attenuating vibration and minimizing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

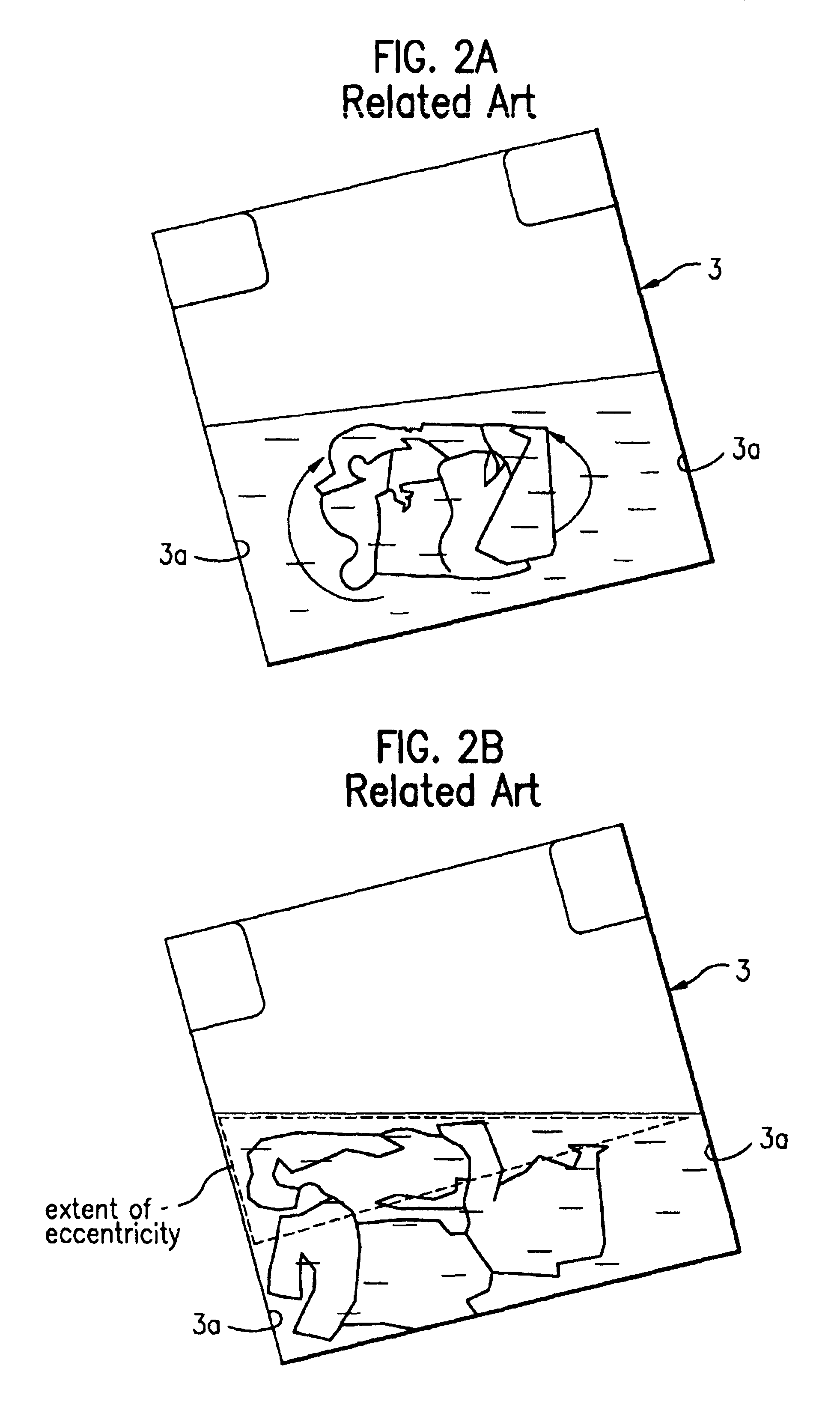

[0034]Along with this, referring to FIG. 4C, in order to keep the laundry evenly distributed in the tilted inner tub 3 during the water discharging step, it is preferable that the first embodiment method of the present invention further includes a supplementary rotating step for rotating the inner tub at a preset RPM. The supplementary rotating step utilizes a principle that a radial acceleration becomes the greater as it goes the farther from a center of rotation of the inner tub when the inner tub 3 rotates at a fixed angular speed, which may be explained in detail, as follows.

[0035]When it is assumed that a radius of the inner tub 3 is ‘R’, and a tilted angle of the inner tub with respect to the ground is ‘θ’, a maximum radial acceleration exerting to the laundry on an inside wall 3a of the inner tub is Rω2, an average radial acceleration exerting to the laundry at a half way to the inside wall 3a is ½(Rω2), and a gravitational acceleration exerting to the laundry in the inner tu...

second embodiment

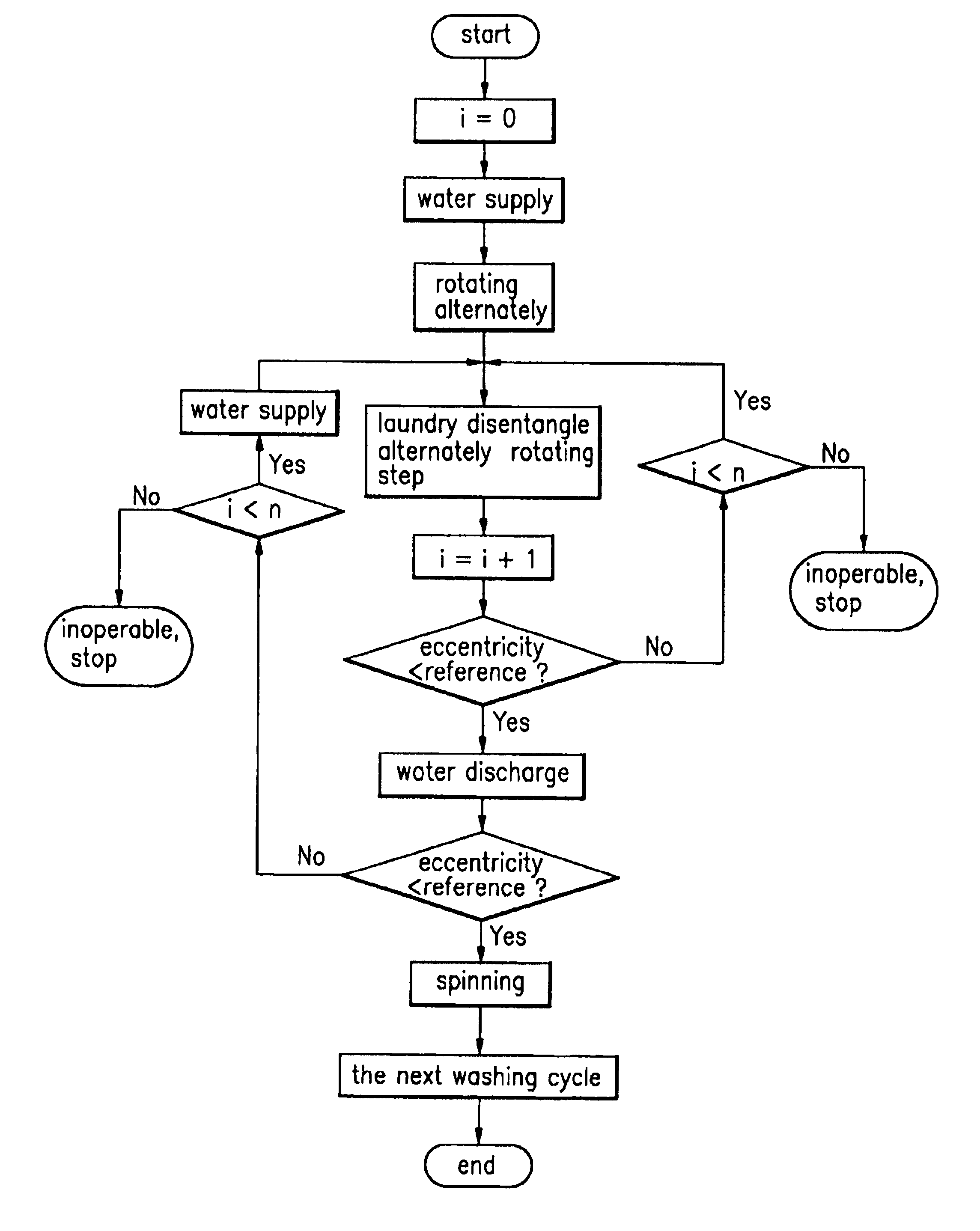

[0047]Referring to FIG. 7, in the second embodiment control pattern, for eliminating the eccentricity of the laundry, after determining the extent and position of eccentricity of the laundry, the optimal laundry disentangle alternate rotating is carried out, to spread the laundry in the inner tub evenly, and the extent of eccentricity of the laundry is detected and determined again. In this instance, though the operation proceeds to the water discharging step if the eccentricity of the laundry detected in the determining step is smaller than the preset value, the operation proceeds to the step for determining the eccentric position of the laundry, the optimal laundry disentangle alternately rotating step, and the determining step again, if the eccentricity of the laundry detected in the determining step is greater than the preset value. However, because there may be such occasion that an operation time period of the washing machine is prolonged, or the washing machine is overloaded,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com