Washing machine

a washing machine and washing machine technology, applied in the field of washing machines, can solve the problems of waste of energy in the washing machine and high energy consumption in the heating air, and achieve the effect of preventing waste of cooling water and drying laundry faster

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

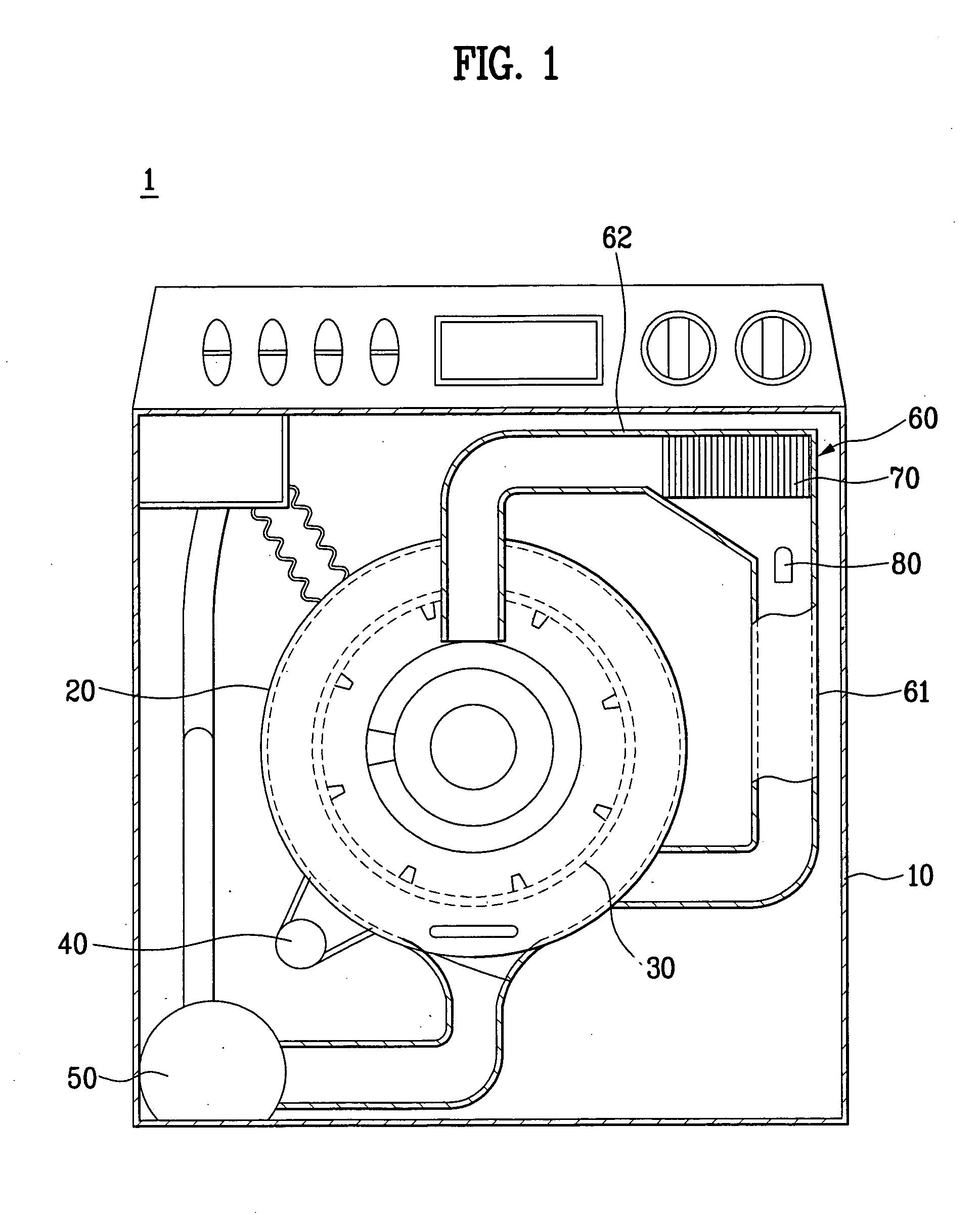

[0050] the present invention will be described with reference to FIG. 1.

[0051] Referring to FIG. 1, the washing machine 1 includes a cabinet 10 forming an exterior of the washing machine 1 having a door mounted on a front thereof, a tub 20 mounted in the cabinet 10, a drum 30 rotatably mounted in the tub 20, a motor 30 for rotating the drum 30, and a drain pump 50 for draining the washing water from the tub 20.

[0052] In addition to this, for drying laundry in the tub 20, in the washing machine, there is a duct 60 having opposite ends connected to the tub 20. The duct 60 includes a drying duct 62 connected to an upper portion of a front of the tub, and a condensing duct 62 connected to a lower portion of a side of the tub.

[0053] In the duct 60, there is a fan 70 for circulating air in the tub 20, and in the condensing duct 61, there is a water supply device 80 for supplying cooling water for condensing moisture in the air in the tub 20.

[0054] The cooling water supplied to the cond...

second embodiment

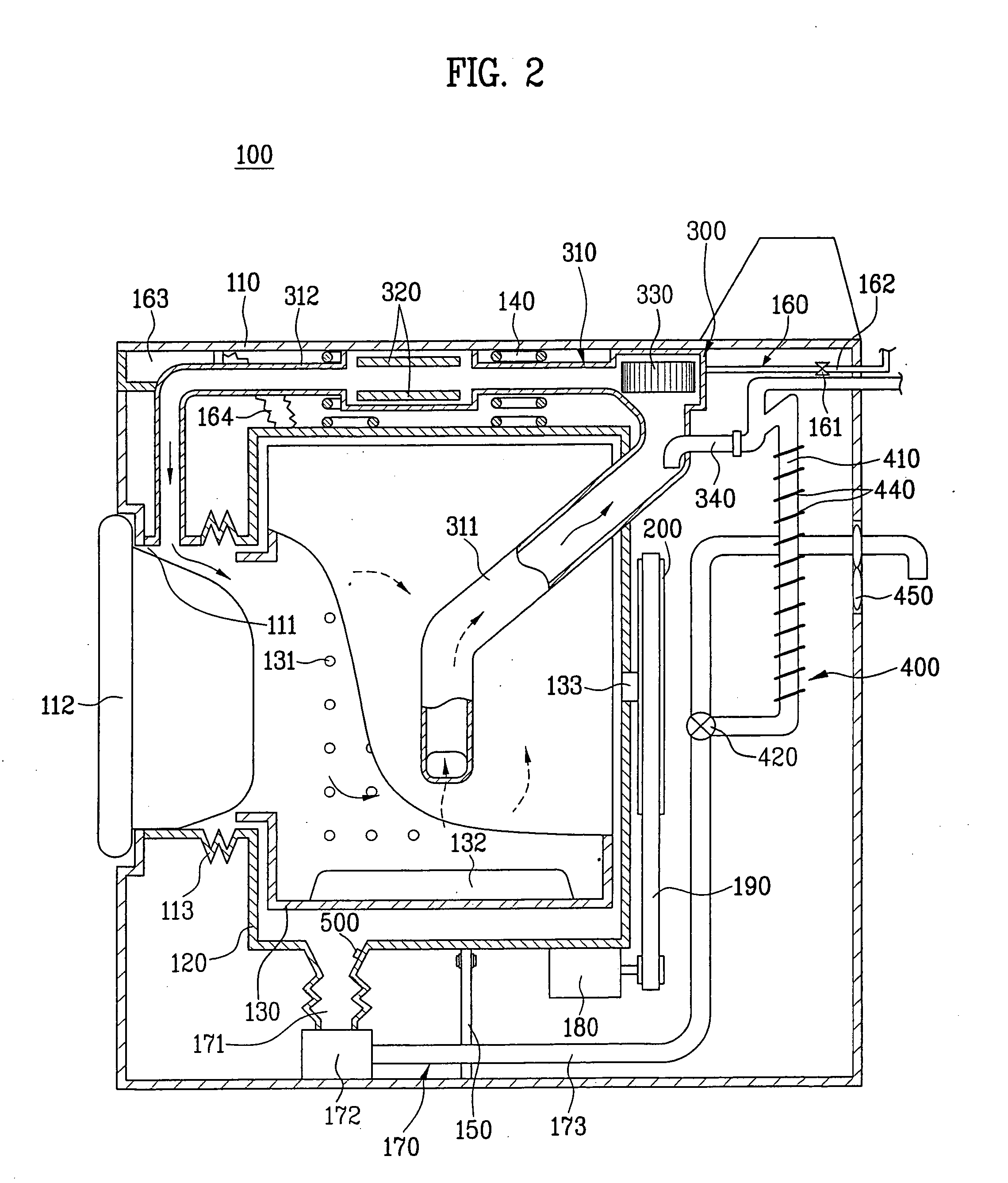

[0057] the present invention will be described with reference to FIG. 2. The washing machine 100 of the present invention includes a cabinet 110 which forms an exterior of the washing machine 100. There is a tub 120 suspended in the cabinet 110. For this, a top of the tub 120 is connected to a spring 140 secured to the cabinet 110, an underside of the tub 120 is connected to a damper 150 hinge coupled to a bottom of the cabinet 110. The spring 140 and the damper 150 not only suspend the tub 120 from the cabinet 110, but also attenuate vibration applied to the tub 120 during operation of the washing machine 100.

[0058] There is a drum 130 rotatably mounted in the tub 120. The drum 130 will be described in more detail.

[0059] The drum 130 has a plurality of pass through holes 131 in an outside circumferential surface, and a plurality of tumbling ribs 132 on an inside circumferential surface. Therefore, water supplied to the tub 120 can move between the drum 130 and the tub 120 through ...

third embodiment

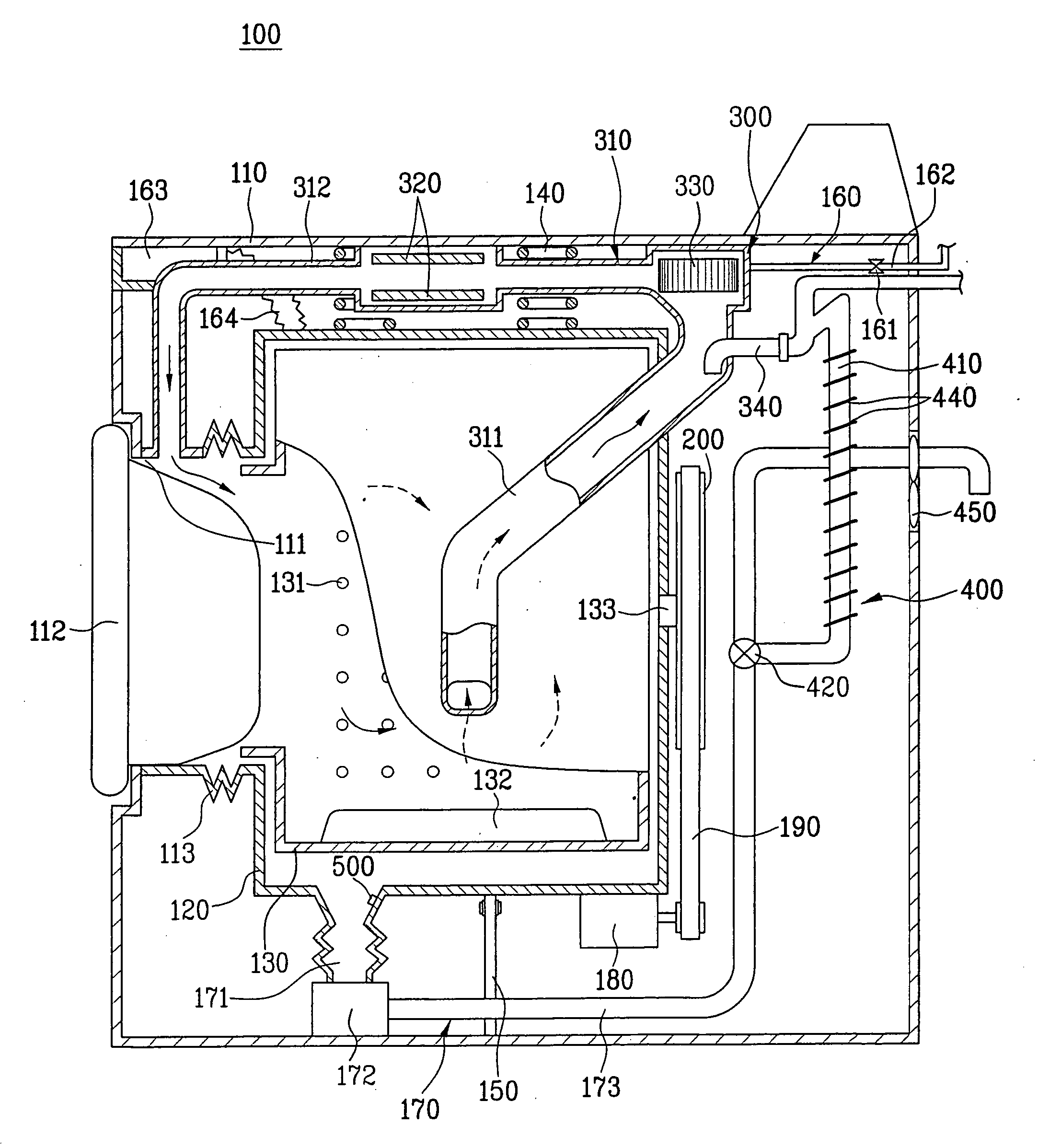

[0079] the present invention will be described with reference to FIG. 3. The washing machine 100 in accordance with a third preferred embodiment of the present invention includes a cabinet 110, a tub 120, a drum 130, and a drying device 300. The drying device 300 includes a duct 310, a fan 330, a water supply device 340, a heater 320, and a cooling water circulating device 400. The cooling water circulating device 400 includes a pump, a circulating hose 410, and a valve 420.

[0080] In description of the third embodiment of the present invention, repetitive description of parts identical to the second embodiment of the present invention will be omitted.

[0081] That is, in the third embodiment of the present invention, the circulating hose 410 has one end connected to the drain hose 173, and the other side connected to the duct 310. In more detail, the circulating hose 410 is connected to an upper portion of the condensing duct 311, for guiding the cooling water from the drain pump 172...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com