Single-tub pulsator washing machine and assorted removable spin-dry basket

A pulsator washing machine and washing machine technology, applied in the field of washing machines, can solve the problems of unusable washing water, large volume of washing machine, complex structure, etc., and achieve the effects of small footprint, good effect and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following will be further described in conjunction with the accompanying drawings, not to limit the scope of the present invention.

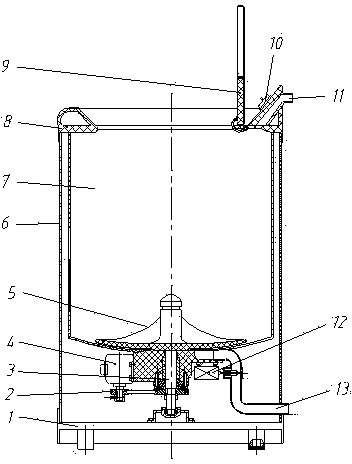

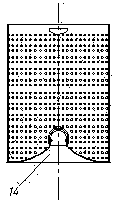

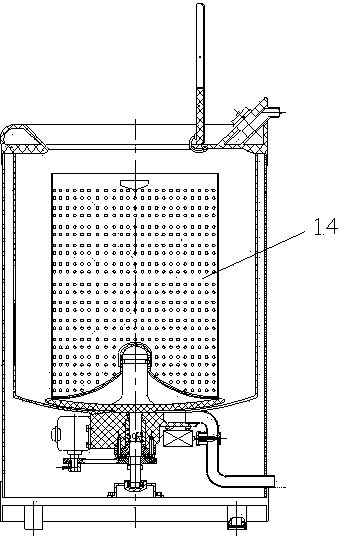

[0024] see Figure 1 to Figure 7 As shown, the composition of the whole machine structure of the present invention includes: a washing machine base plate 1, a transmission belt 2, a main shaft 3, a motor 4, a pulsator 5, a washing machine shell 6, a washing bucket 7, an upper machine cover 8, a washing bucket cover 9, and a control panel 10 , water inlet pipe 11, drain valve 12, drain pipe 13, drying basket 14, clamping cap 15, clamping ball 16; The washing machine is a whole, the lower end of the main shaft 3 is elastically connected to the bottom plate 1 of the washing machine, the driving motor 4 is driven by the transmission belt 2 to drive the main shaft 3, the upper end of the shaft is connected to the pulsator 5, the pulsator 5 is at the bottom of the washing bucket 7, and there is a washing machine outside the washing bucket 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com