Drum type washing machine

A drum-type washing machine and drum technology, which can be applied to other washing machines, washing machines with containers, spin dryers, etc., can solve problems such as uneven washing, clothing damage, and clothing that are easily entangled with each other, to prevent clothing from entanglement and excellent washing effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

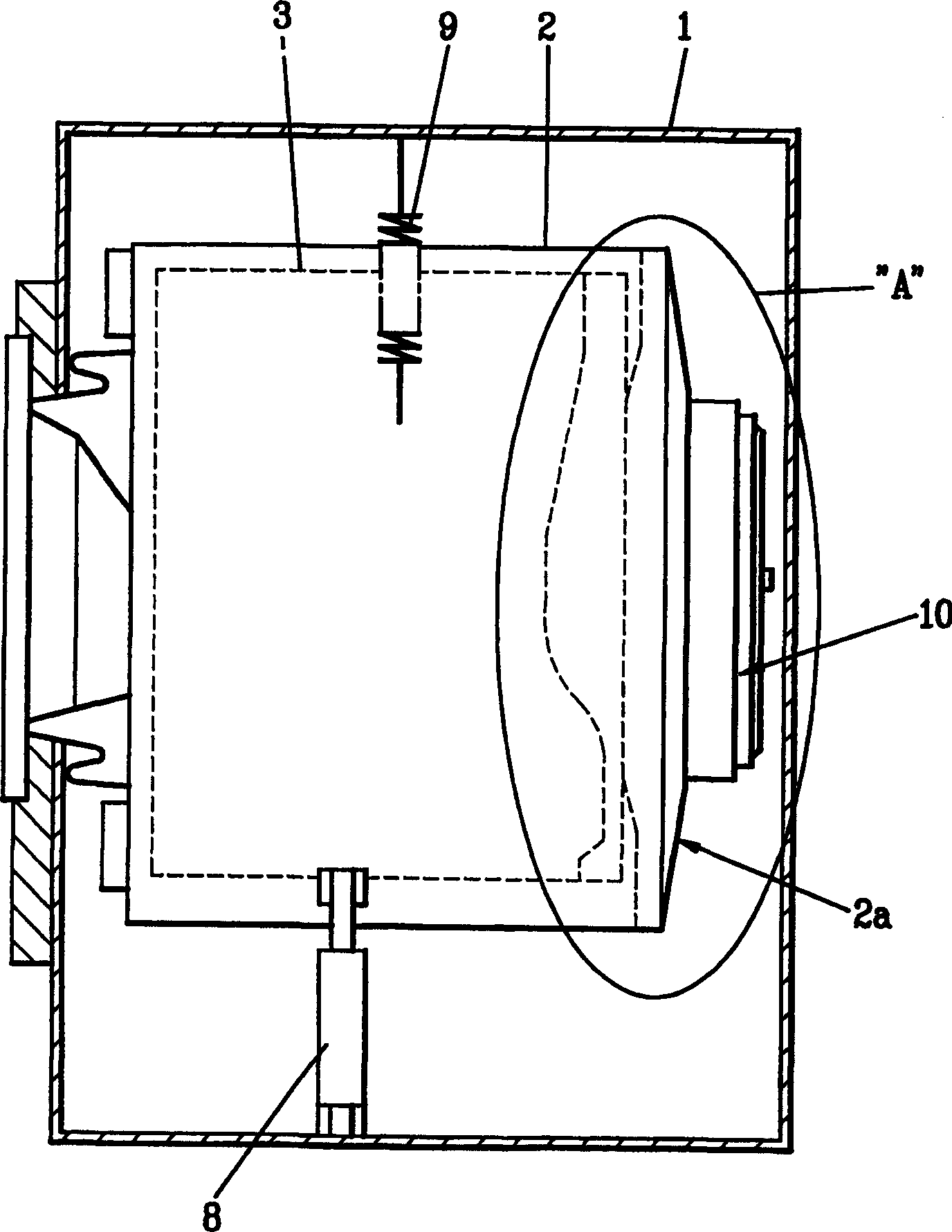

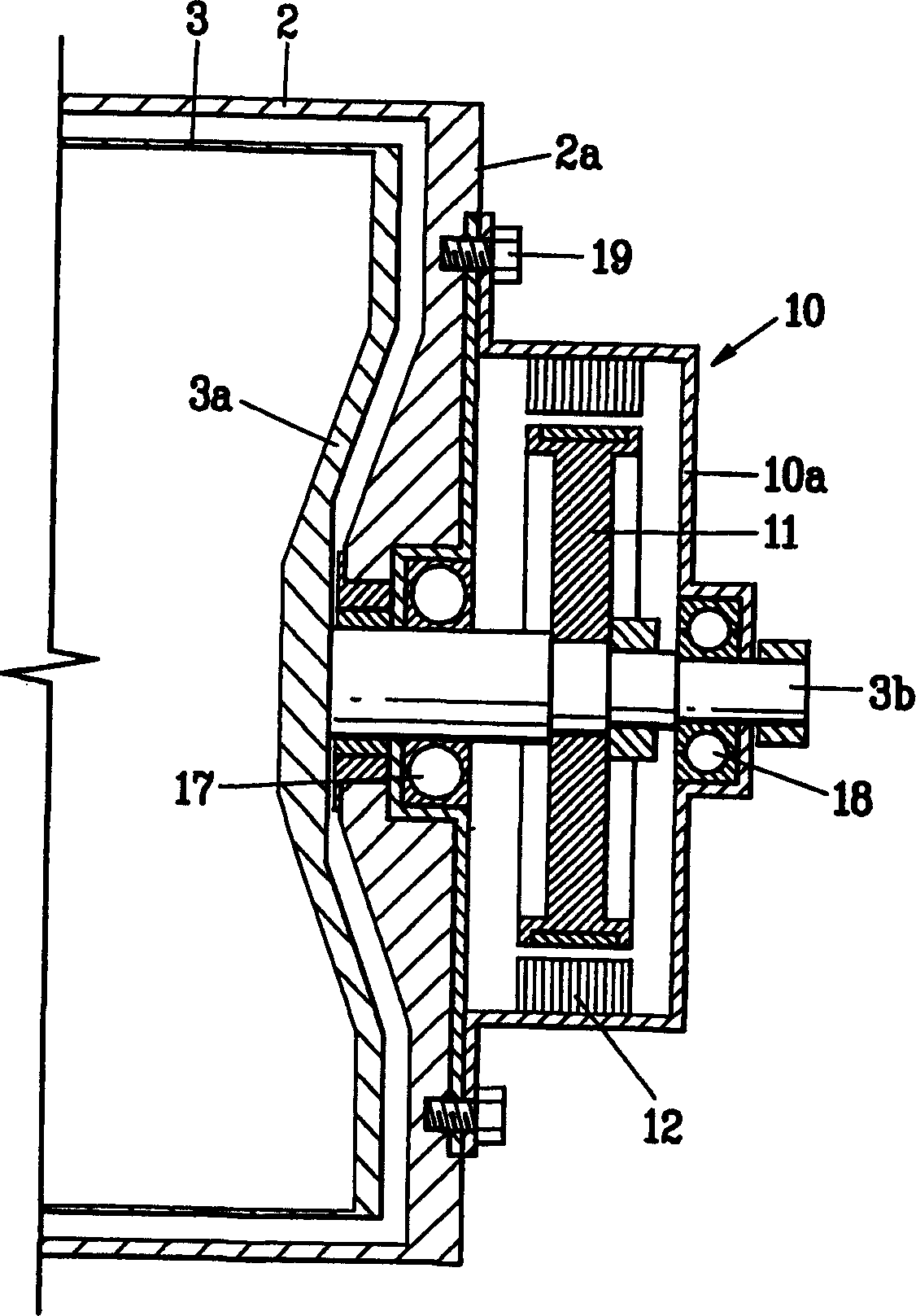

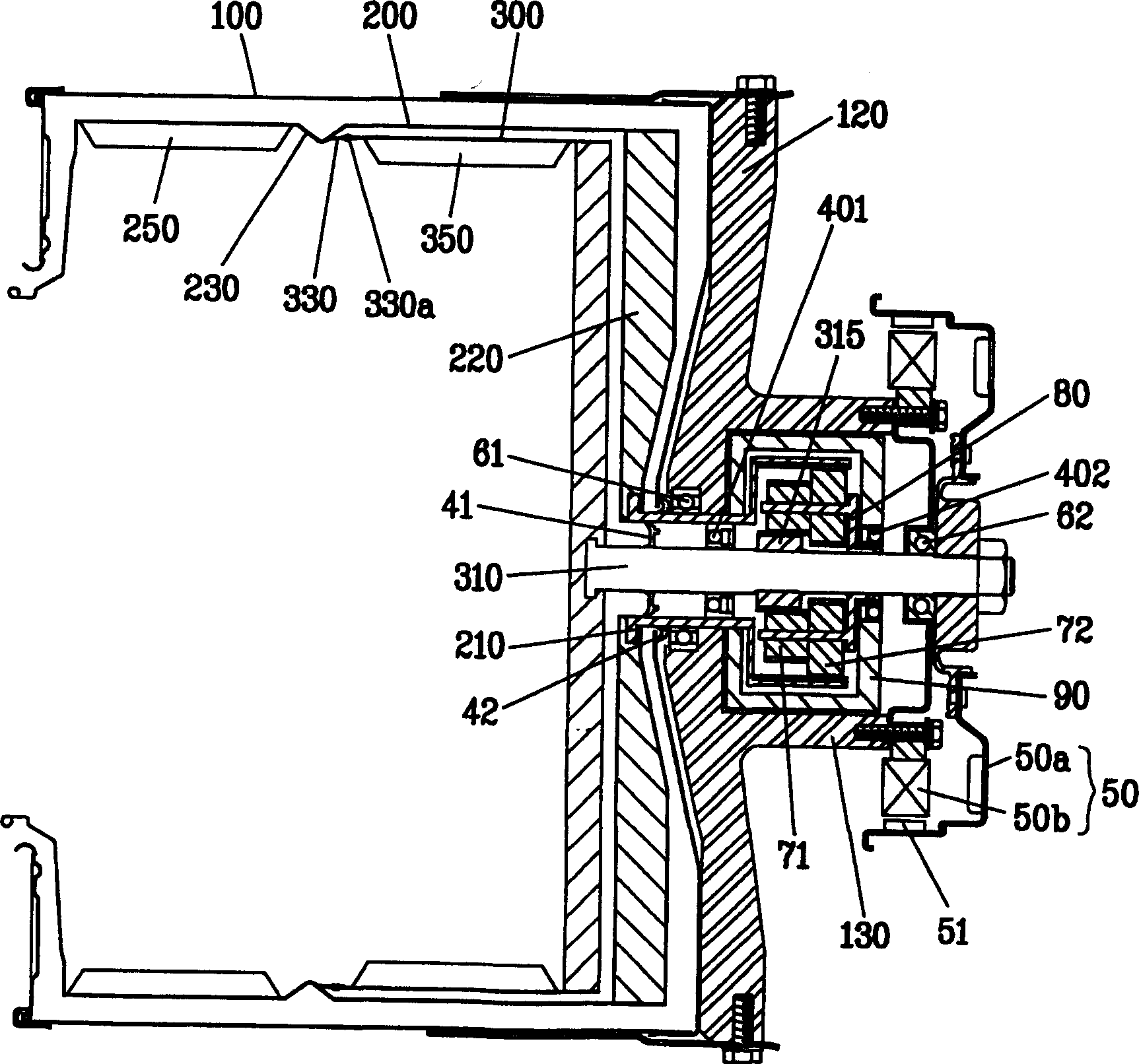

[0051] image 3 Shown is a sectional view of a drum-type washing machine according to a first preferred embodiment of the present invention; Figure 4 shown as image 3 The enlarged view of the key parts, the system and working process of the drum type washing machine of the present invention will be described below with reference to them.

[0052] see image 3 , The drum type washing machine according to the first preferred embodiment of the present invention includes a tub body 100 inside the box and an outer tub 200 with an opening at the front, and the opening is rotatably installed in the tub body 100 . Inside the outer cylinder 200 is an inner cylinder 300 with an opening at the front, which is smaller in diameter and axial length than the outer cylinder 200 and coaxial with the outer cylinder 200 . The outer cylinder 200 has an inner ridge 230 at a position opposite to the front end of the inner cylinder 300 , which may or may not be integrally formed with the outer cyl...

no. 2 example

[0066] Figure 5 Shown is a sectional view of a drum type washing machine according to a second preferred embodiment of the present invention.

[0067] see Figure 5 , The drum type washing machine according to the second preferred embodiment of the present invention includes a driving motor 30 installed on one side of the tub body 100 , and a motor pulley 34 installed on the shaft of the driving motor 30 . The inner cylinder shaft 310 is assembled in the central part of the rear end of the inner cylinder 300, and its rear end is connected with a drum pulley 214, which is connected with the motor pulley 34 through a belt device 35, and is used to transmit the rotational force of the drive motor to the Inner cylinder 300.

[0068] At the other end, there is an outer cylinder 200, the rear end of which is fitted to one end of an outer cylinder shaft 210 which receives a rotational force from an inner cylinder shaft 310 through a rotation transmission device, and the first and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com