Patents

Literature

54results about How to "Good homogenization effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for regulating lighteness of filmed display screen based on image inductor

InactiveCN101350933AGood homogenization effectImprove display qualityCathode-ray tube indicatorsTelevision systemsInductorImage sensor

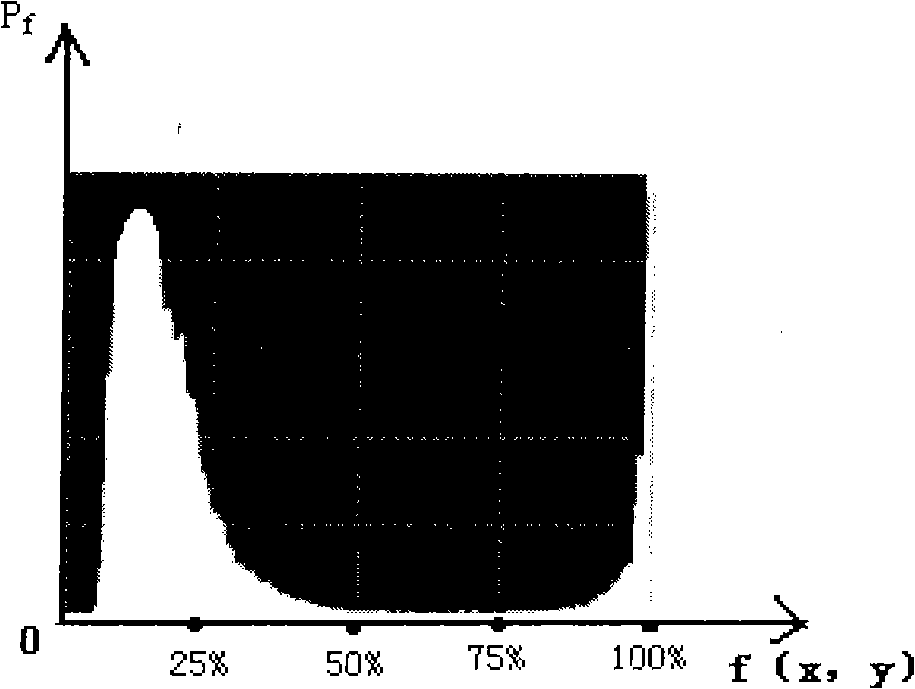

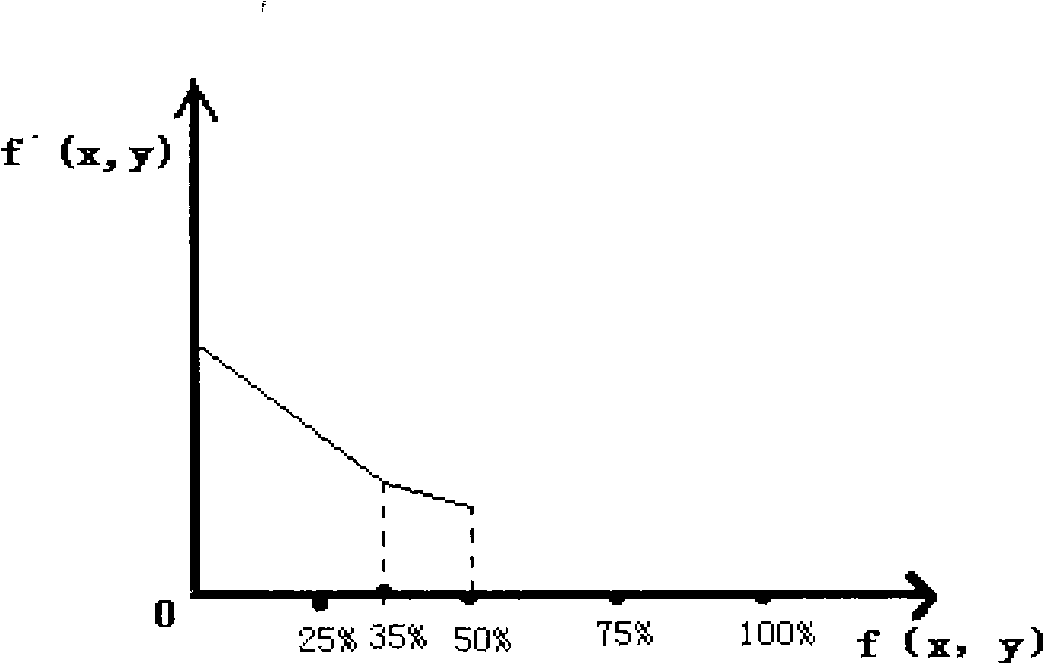

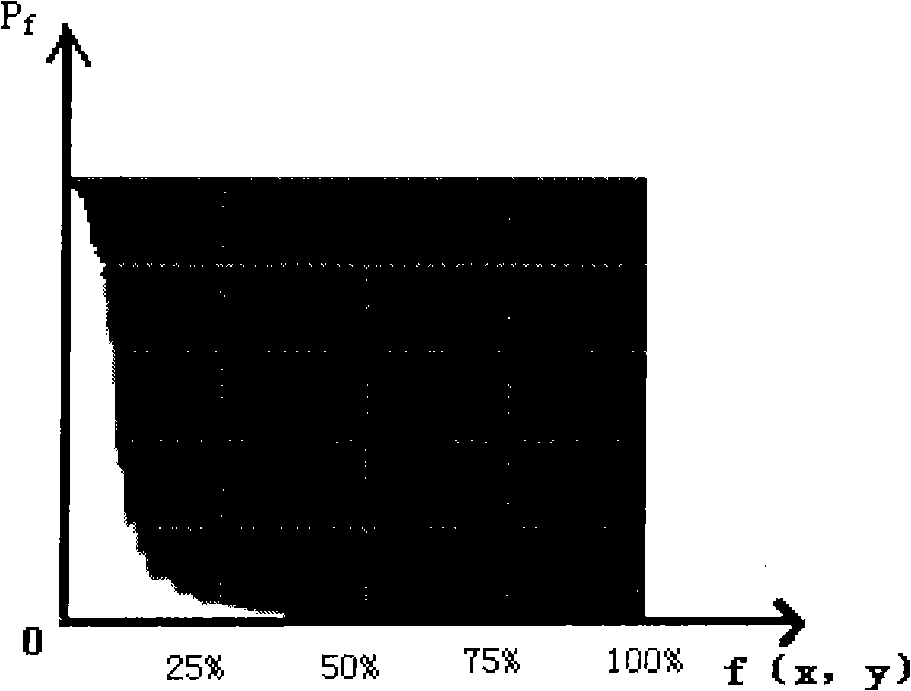

The invention provides a brightness adjusting method which is based on photographing the display screen by an image sensor; the method comprising the following steps that (1) the screen of a display equipment displays all-black image under normal lighting situation and an image sensor is used for photographing the all-black image for adjusting bright spot deflection; (2) the brightness value of pixels in the all-black image which is more than 0% is adjusted lower and the position coordinates of all the bright spots and the plus adjusting value of every pixel bright spot are recorded; (3) according to the position coordinates of the bright spots and the plus adjusting values acquired from the step (2), the brightness of the display screen images which are photographed by every image sensor is automatically homogenized. The method of the invention has comparatively homogenization effect on the display screen image brightness; in particular, with the invention, the image display quality could be improved and the positioning precision of the screen positioning system with the brightness detection technique could be promoted.

Owner:GUANGDONG VTRON TECH CO LTD

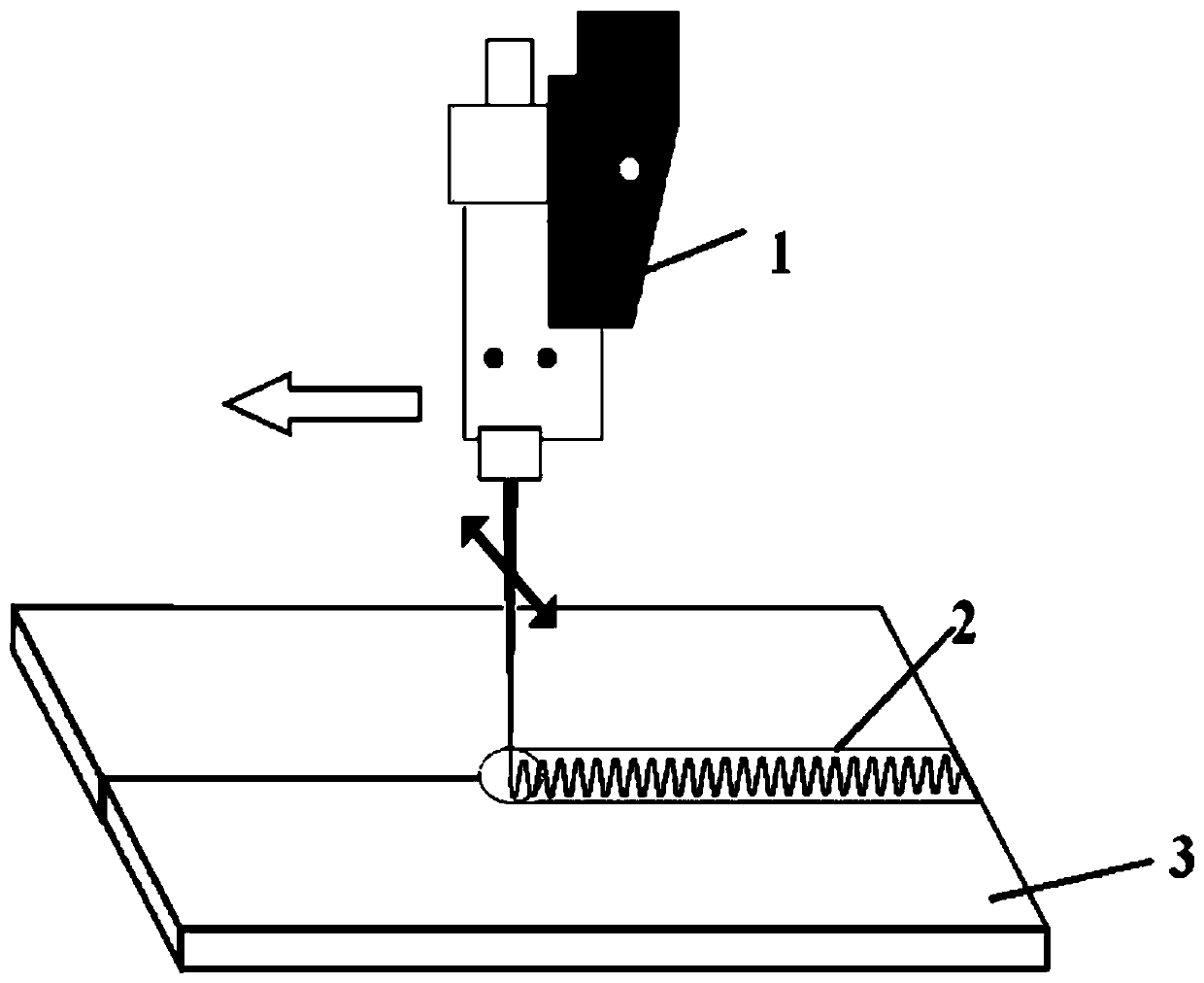

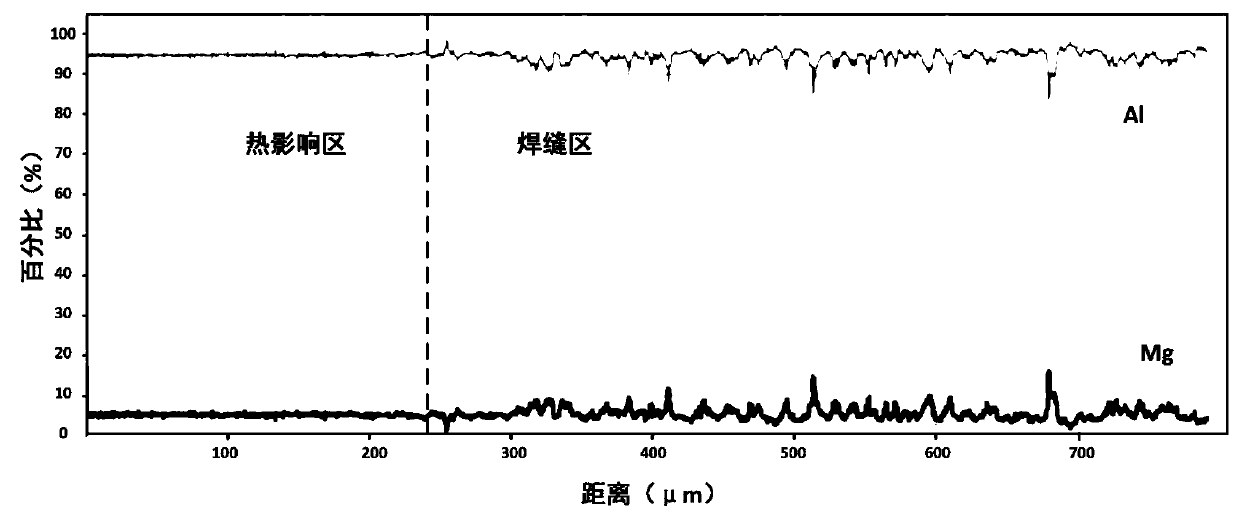

Homogenized Al-Mg series aluminum alloy weld microstructure laser welding method

InactiveCN110153557AAchieve homogenizationImprove efficiencyLaser beam welding apparatusBeta phaseShielding gas

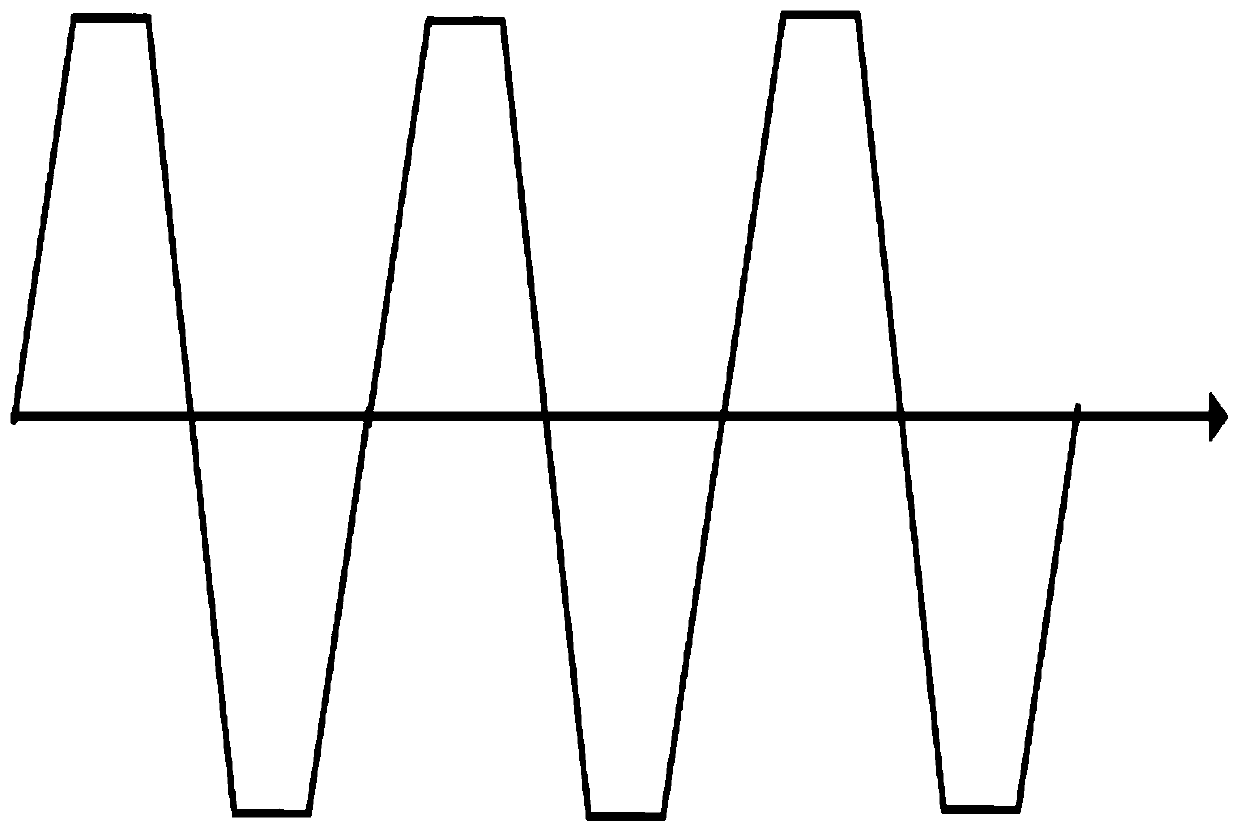

The invention provides a homogenized Al-Mg series aluminum alloy weld microstructure laser welding method. The homogenized Al-Mg series aluminum alloy weld microstructure laser welding method comprises the following steps that (1), pre-welding polishing is carried out, wherein a weld center area is firstly mechanically ground, oxide skin on the weld surface is taken out, and acetone is used for wiping oil stains or other impurities; (2), pre-welding parameter adjustment is carried out, wherein a laser head of a laser device is aligned to the place, needing to be welded, of a workpiece, and theheight is adjusted; and (3), waveform welding is carried out, wherein the position needing to be welded is welded, protective gas is used for protection, laser beams advance in the weld direction inparallel, in the advancing process, a galvanometer is used for making the oscillating laser beams symmetrically move back and forth on the two sides in the welding direction, and the light spot motiontrajectory is a square wave path. In the welding process, oscillating of the laser beams can agitate a molten pool and delay solidification in the molten pool, Mg elements in the weld are uniformly distributed, the beta phase (Mg2Al3) is uniformly precipitated, the weld microstructure homogenization is achieved, and the weld mechanical properties are improved.

Owner:HUST WUXI RES INST

Preparation method of hybrid collector for oxide ore flotation

InactiveCN101181700AGood homogenization effectGood dispersion effectFlotationRevolutions per minuteSolvent

The invention relates to a preparation method of oxide ore flotation mixed collectors. The preparation method is characterized in that the preparation process comprises the steps that: (1) saponifier which is weighted in proportion is fully dissolved in hot water; (2) the weighted collecting flotation agent is stirred and mixed homogeneously at the speed of more than 600 revolutions per minute; (3) the prepared original mixture of the collecting flotation agent is added in the hot solvent which is dissolved with the saponifier, and the mixed solvent is stirred for 30 to 120 minutes until the solvent is homogeneous at the temperature of 50 DEG C to 90 DEG C and the speed of 10 to 200 revolutions per minute. The invention has the advantages that: agents are modified by controlling feeding order, preparation temperature, stirring speed and stirring time of agents, thus homogenization effect is good; agents do not agglomerate at comparatively low temperature, and dispersant effect is good; aging of the agents is long.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

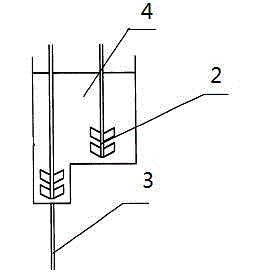

Method for controlling drum

InactiveCN1760430AEasy to controlGood homogenization effectControl devices for washing apparatusTextiles and paperGood controlDewatering

The present invention provides a uniformization method, eccentricity detection method and dewatering control method which can make the material in the drum washing machine and similar centrifugal dewatering equipment be uniformly distributed so as to reduce vibration and noise due to eccentricity. Said invention adopts a short-periodic power-on and power-off method of motor and collects rotating speed change due to eccentricity of drum which is rotated for a turn at 72-85 RPM to make detection of eccentricity, so that it can obtain good control effect.

Owner:朱筱杰

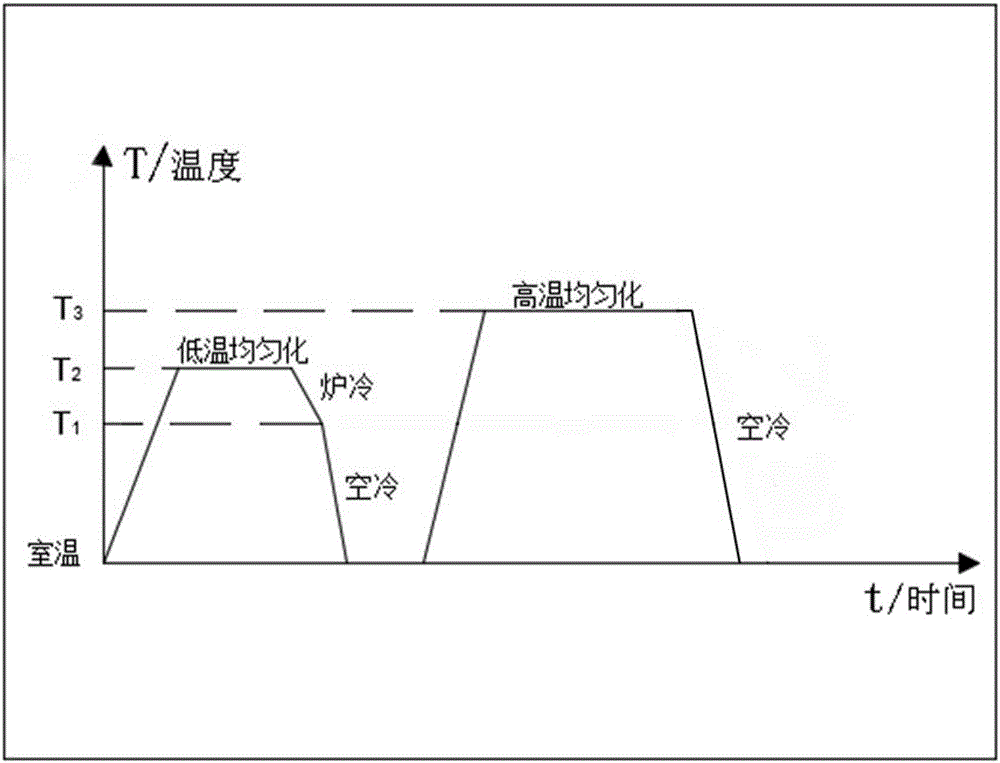

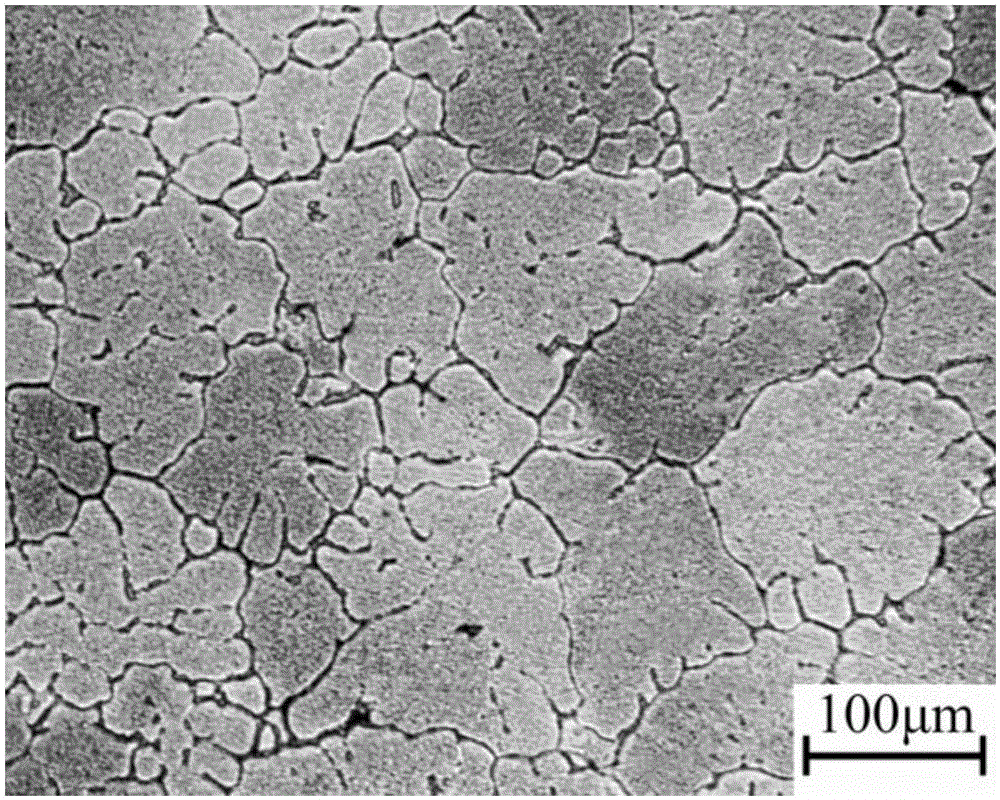

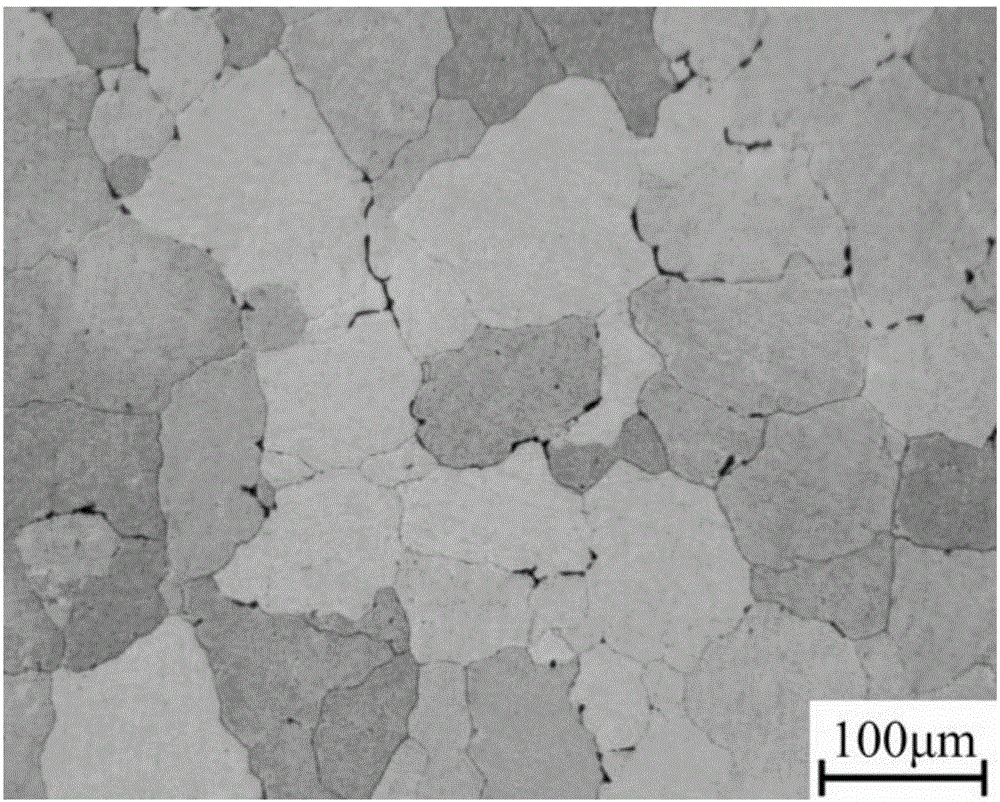

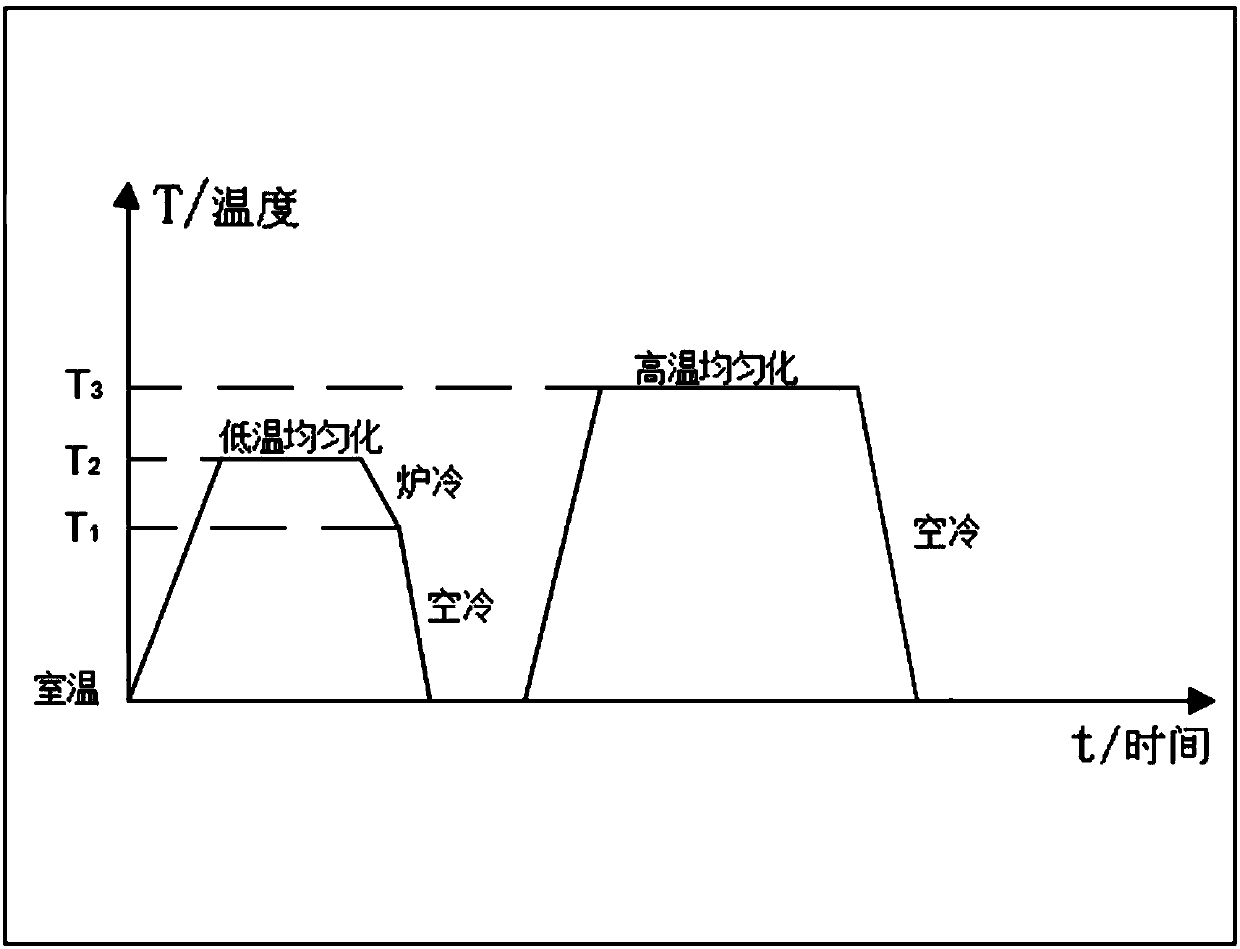

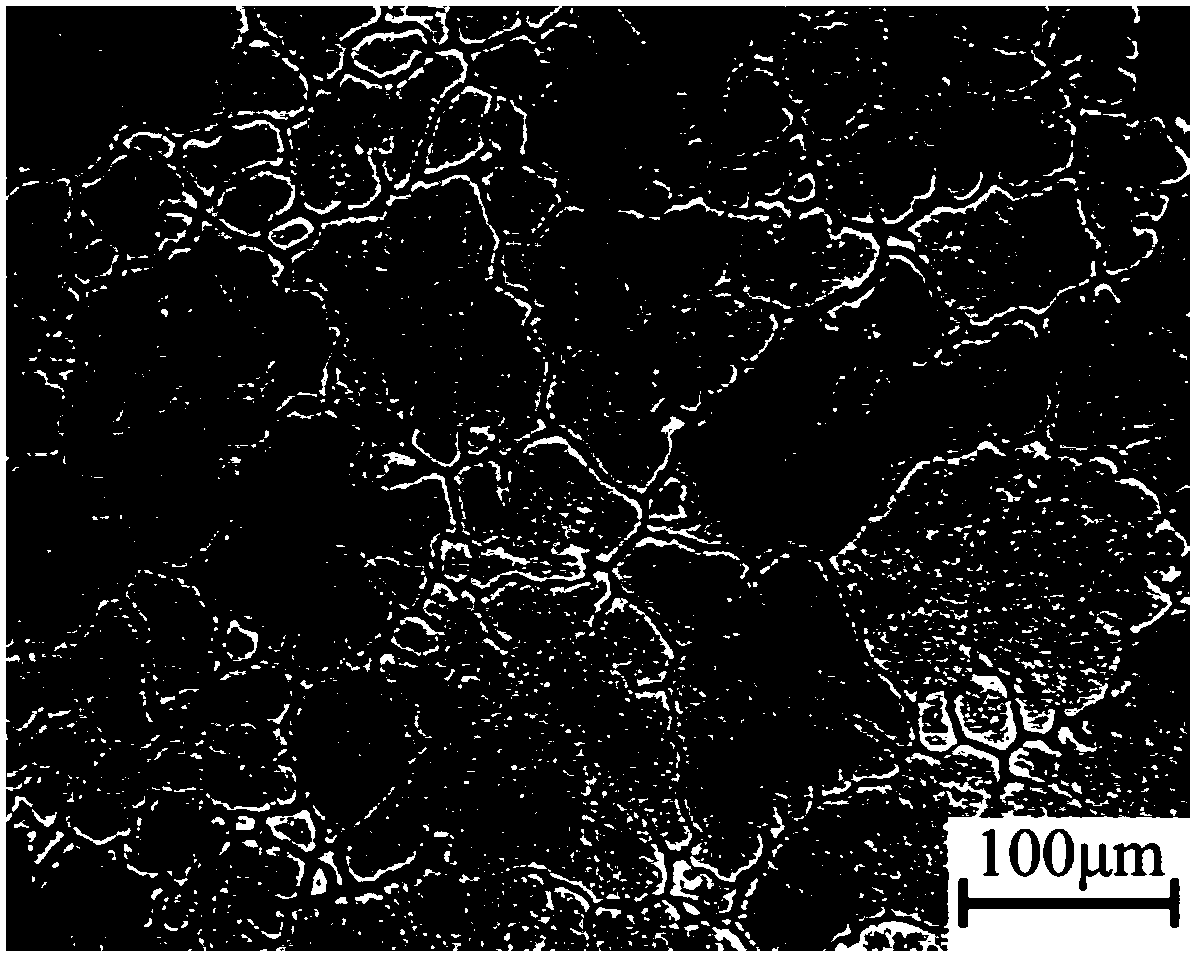

Homogenizing heat treatment technology for eliminating Al-Cu-Mg-Si-Mn alloy casting crystal phase

The invention provides a homogenizing heat treatment technology for eliminating the Al-Cu-Mg-Si-Mn alloy casting crystal phase. The homogenization technology comprises the steps that an Al-Cu-Mg-Si-Mn alloy ingot is placed into a furnace, is heated to 470-480 DEG C at the speed of 15-20 DEG C / min, is subjected to heat preservation for 8-12h, then is subjected to furnace cooling to 250-300 DEG C, and is subjected to air cooling to the room temperature; then the ingot is placed into a heat preservation furnace with the temperature being 510-520 DEG C and subjected to heat preservation for 18-24h; and finally, the ingot is subjected to air cooling to the room temperature. According to the homogenizing heat treatment technology, the homogenization problem that Al-Cu-Mg series alloy ingots containing a high amount of Si, Fe and Mn are high in melting point, so that a complex second phase is difficult to eliminate is solved, the technology is simple and convenient to operate, the feasible homogenizing heat treatment scheme is provided for the various Al-Cu-Mg series alloy ingots containing a high amount of Si, Fe and Mn, and industrial production is facilitated.

Owner:CENT SOUTH UNIV

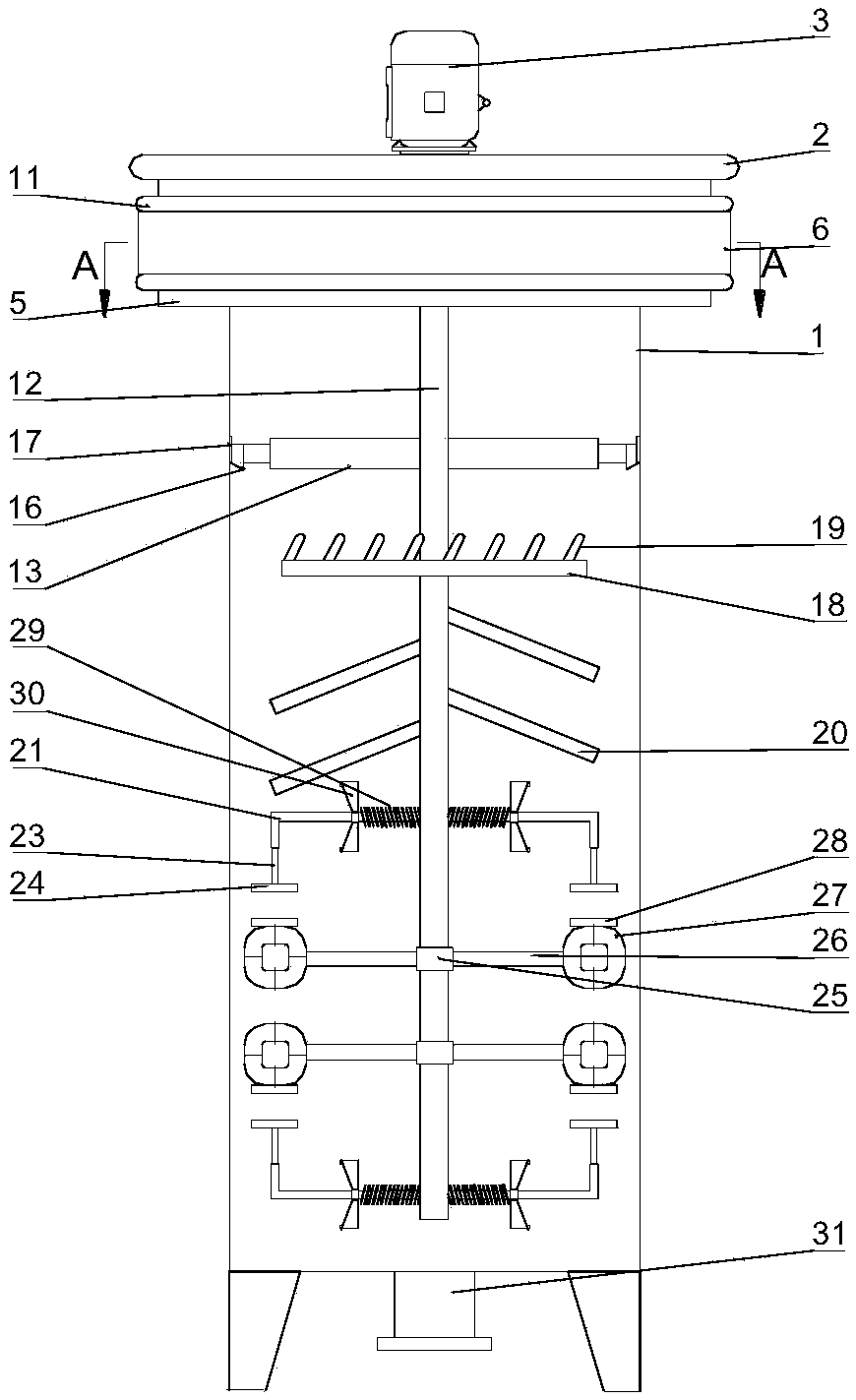

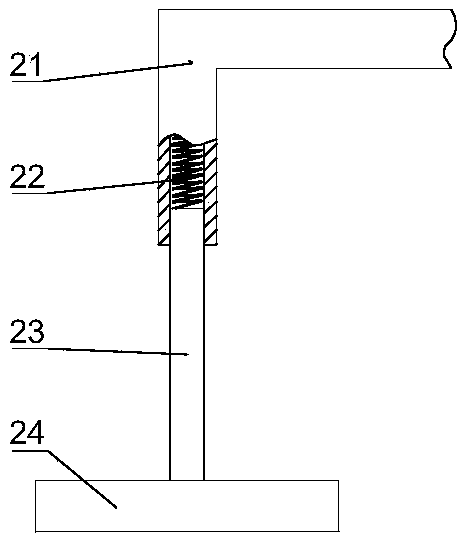

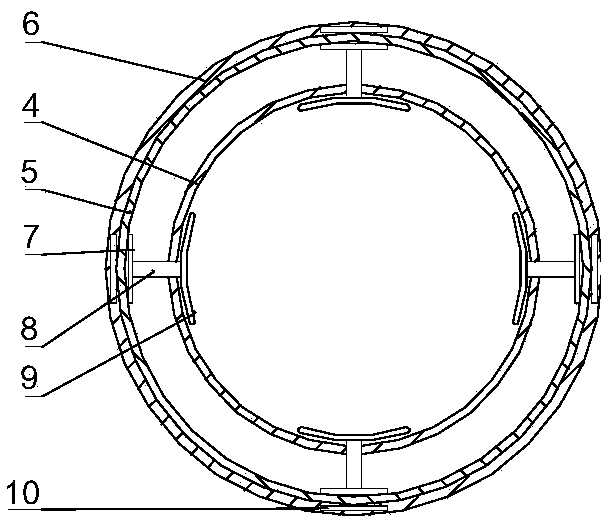

Paint tank homogenizing device for highway pavement mark scraper

InactiveCN108927024AGood homogenization effectEasy to install and removeRotary stirring mixersTransportation and packagingMagnetEngineering

The invention discloses a paint tank homogenizing device for a highway pavement mark scraper, and relates to the technical field of highway equipment, wherein the paint tank homogenizing device includes a paint tank; a fixed plate is arranged on the upper part of the paint tank, a motor is fixed in the middle of the upper part of the fixed plate, a rotating shaft is arranged inside the paint tank,and the output end of the motor is fixedly connected with the rotating shaft; sheets scrape adhesive paint blocks of an inner wall, a paint is stirred by stirring rods, and with cooperation of the action of inclined baffle plates on a disc body, the homogenizing effect of the paint is better; a rotating ring is twisted, when the directions of magnetic south poles and magnetic north poles of corresponding magnets c and magnets d are opposite, and the magnets c and the magnets d are repelled with each other, so a moving rod moves to make a friction pad extrude the outer wall of the paint tank,the fixed plate is firmly placed on the upper part of the paint tank and is easy to mount and dismount, and the time is saved; the moving rod moves up and down reciprocatingly, a rotating area is increased, and with cooperation of the rotation of right angle parts, the paint can be dispersed and the homogenization effect of the paint can be improved.

Owner:陈婷

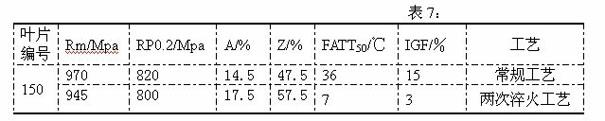

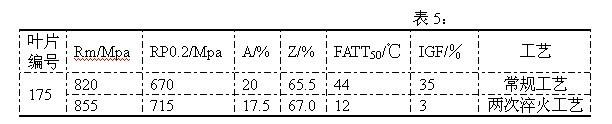

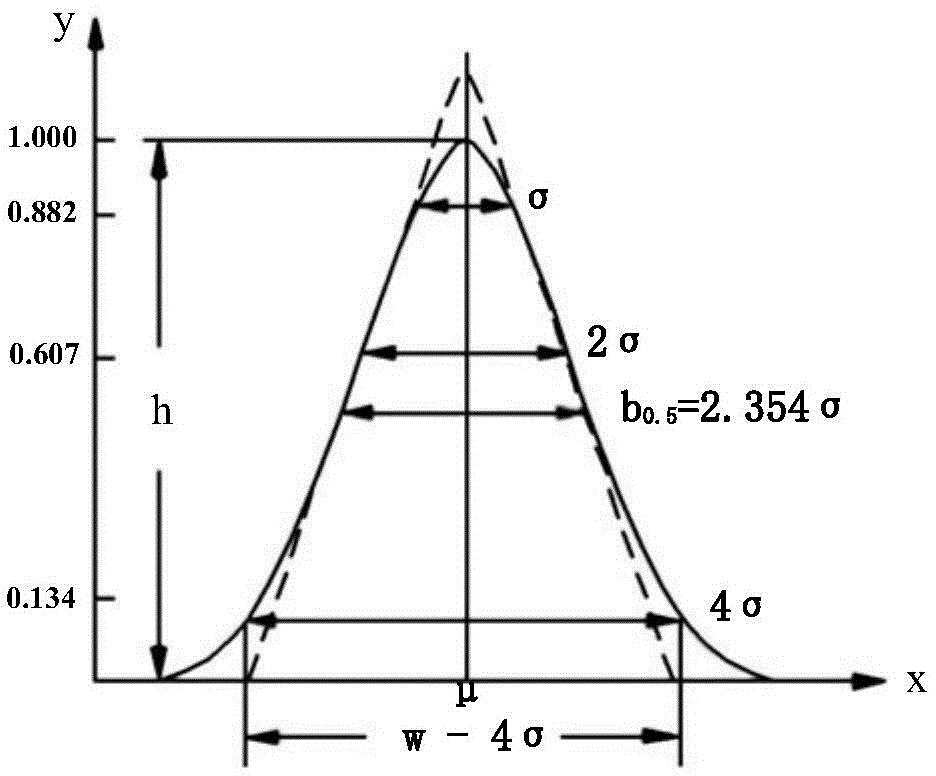

Heat process capable of lowering ductile-brittle transition temperature and intergranular fracture ratio of turbine blades

ActiveCN102220459AShort residence time at high temperatureFully solid solutionFurnace typesHeat treatment process controlChemical compositionTurbine blade

The invention provides a heat treatment process capable of lowering ductile-brittle transition temperature and intergranular fracture ratio of turbine blades. When the heat treatment process is used, the problem that the process effect is susceptible to influences of chemical components of the raw material of the blades when the conventional sub-temperature annealing process is used to treat the turbine blades and the problem of high ductile-brittle transition temperature and intergranular fracture ratio of the turbine blades due to overlong high-temperature retention during heat treatment ofthe blades in the sub-temperature annealing process are solved. In the invention, the blades are uniformly placed in a common quenching material basket according to a technical scheme and then the quenching material basket is placed in a heat treatment quenching furnace. The heat treatment process is characterized in that: the blades are quenched twice in a quenching furnace; the temperature of primary quenching is 980 to 1070 DEG C; the temperature is kept constant for 1 to 3 hours; the cooling speed is 20 to 50 DEG C per minute; the temperature of secondary quenching is 900 to 1,000 DEG C; the temperature is kept constant for 15 to 120 minutes; the cooling speed is 30 to 50 DEG C minutes; and the temperature of the primary quenching is 20 to 100 DEG C higher than the temperature of the secondary quenching.

Owner:WUXI TURBINE BLADE

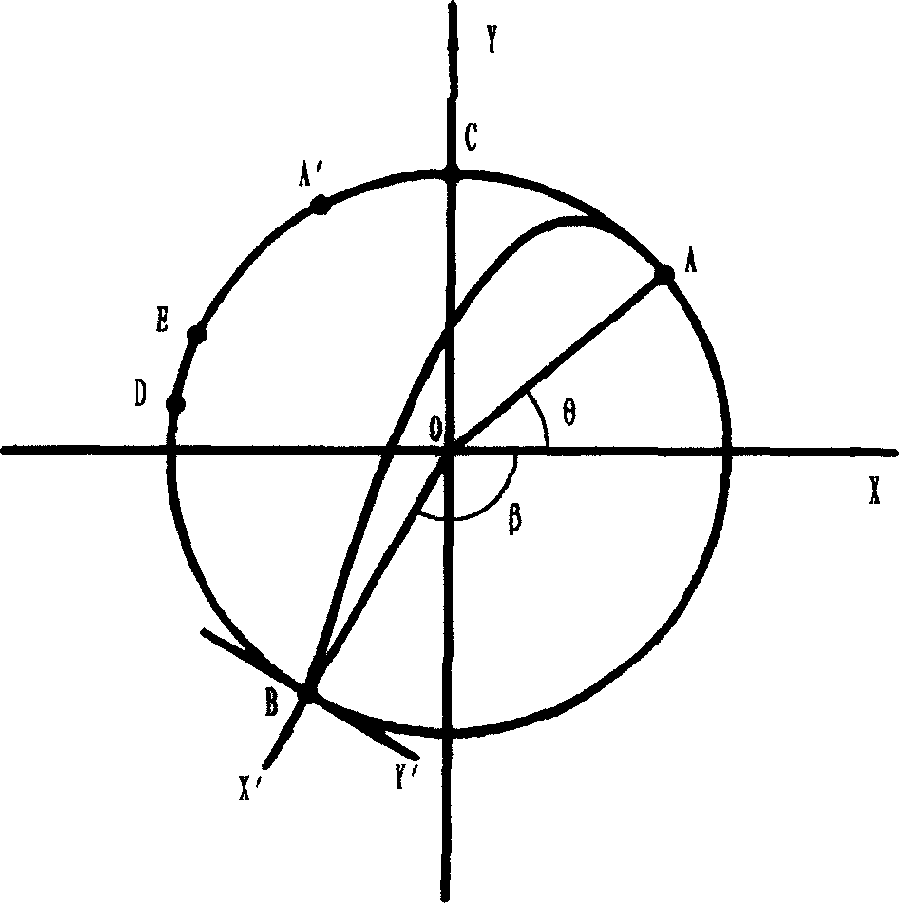

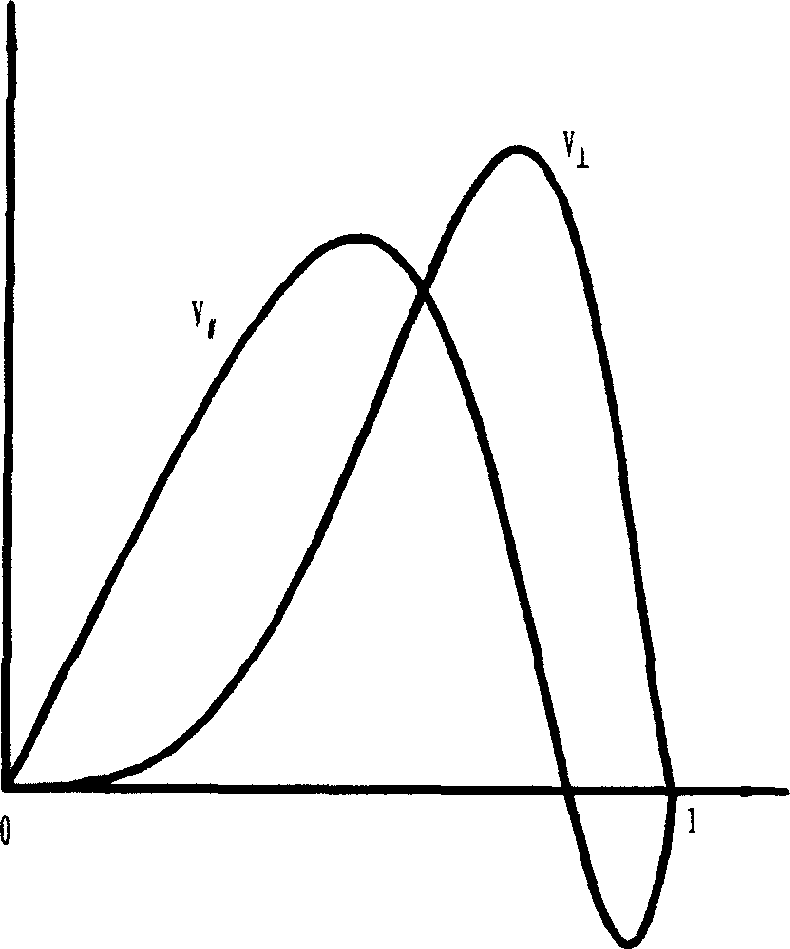

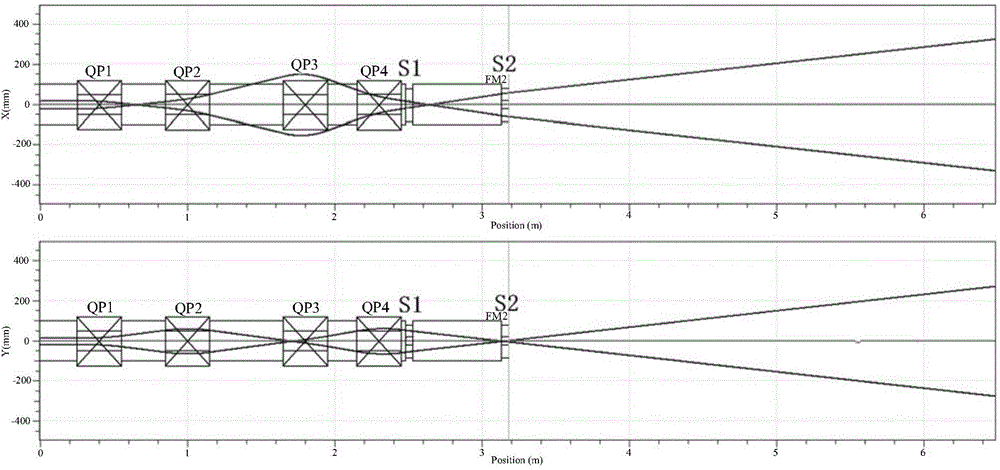

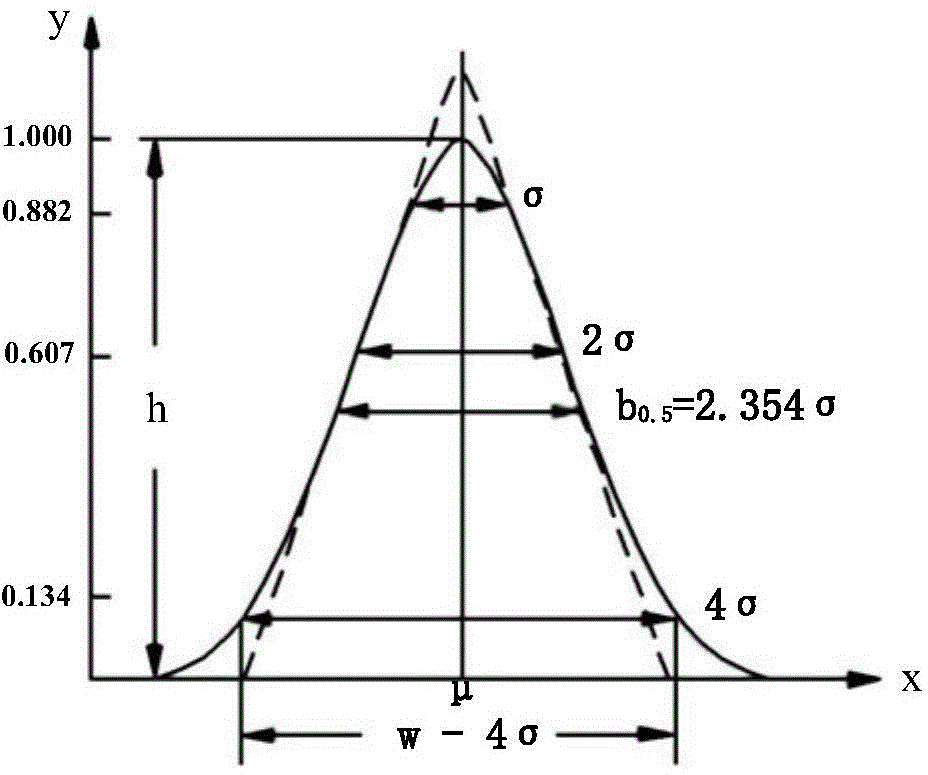

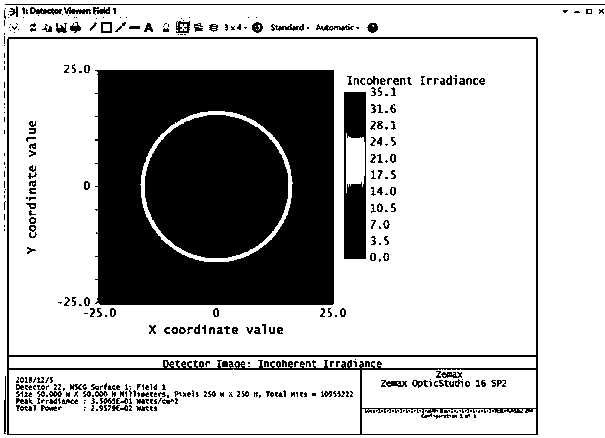

Beam homogenizing sextupole magnet for accelerator

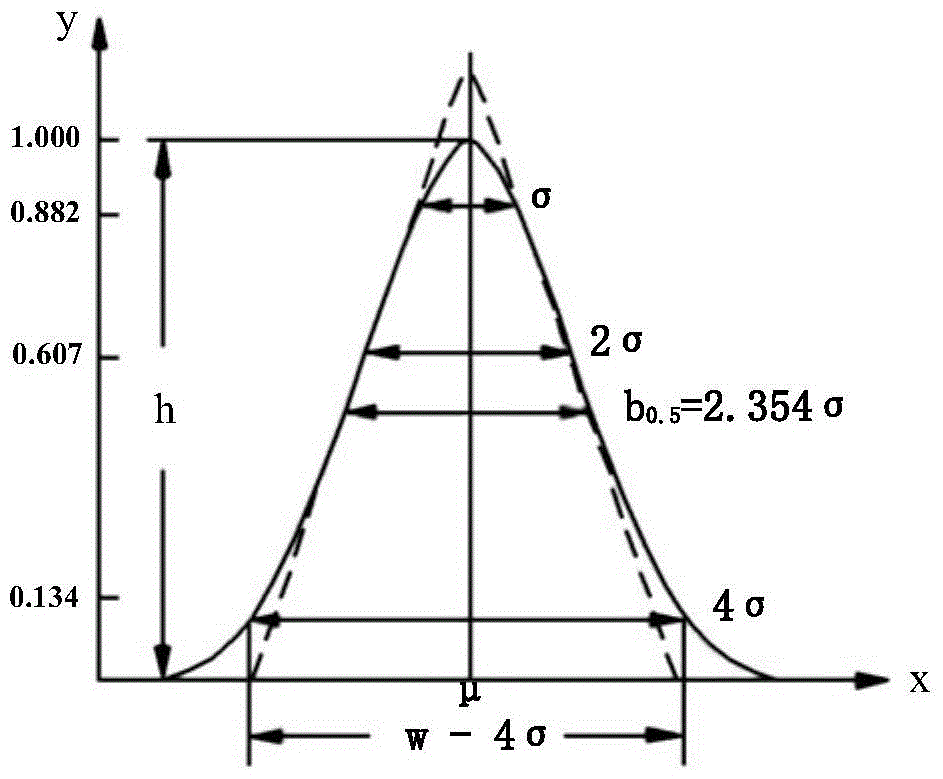

ActiveCN104681230AReduce distanceChange the direction of the currentPermanent magnetsPower flowDensity distribution

The invention belongs to the design technique of accelerators and particularly relates to a beam homogenizing sextupole magnet for an accelerator. On the basis of a traditional design, excitation coils of an opposite pair of magnetic poles are eliminated, distance between the magnetic poles is shortened, and a current direction of coils of a pair of adjacent magnetic poles is changed. The beam homogenizing sextupole magnet has the advantages that a magnetic field generated on an X axis can be symmetric about an origin of a coordinate, the size of the magnetic field is proportional to a square of the position of the magnetic field, and beam spots in similar triangular density distribution can be homogenized effectively.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

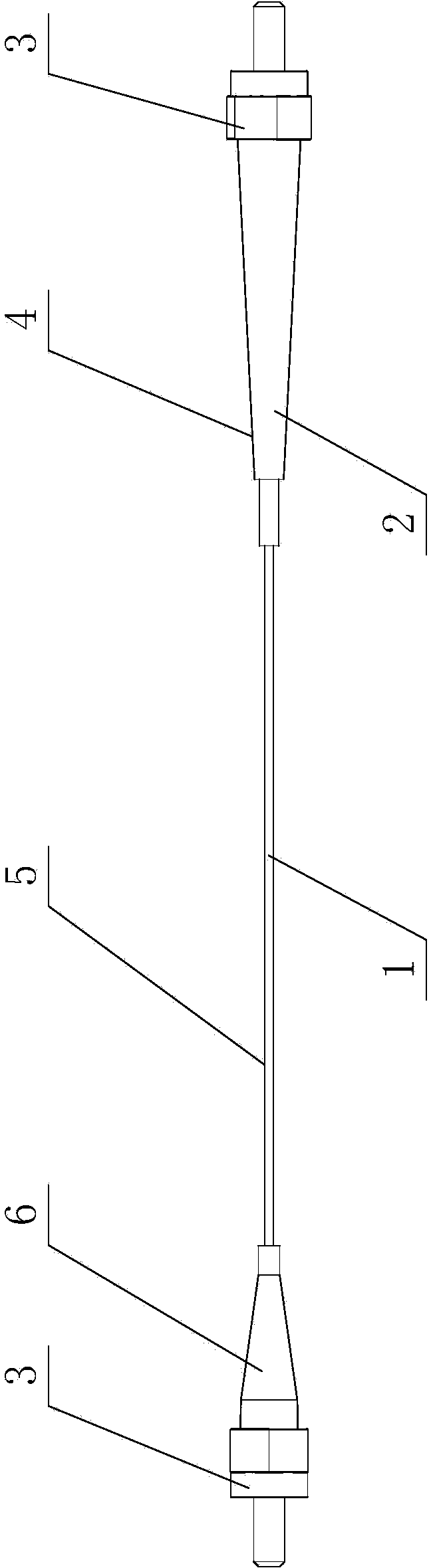

Light spot homogenizing device and manufacturing method thereof

ActiveCN103439772AGood homogenization effectEasy to makeLaser detailsCoupling light guidesSemiconductorCoating

The invention discloses a light spot homogenizing device. The light spot homogenizing device comprises an optical fiber, wherein the optical fiber comprises an input end socket, an output end socket and a homogenized optical fiber formed by heat treatment; an optical fiber protecting sleeve is sleeved outside the optical fiber; the output end socket of the optical fiber is provided with an optical fiber tail sleeve; an optical fiber heat shrinkable tube is arranged on the homogenized optical fiber of the optical fiber. The invention further discloses a manufacturing method of the light spot homogenizing device. The manufacturing method comprises the steps of stripping a coating layer on the optical fiber; carrying out heat treatment on the optical fiber part without the coating layer, wherein the temperature is 1300-1500 DEG C; after enabling the optical fiber without the coating layer to reach a fused state, cooling the optical fiber; covering the optical fiber protecting sleeve on the whole optical fiber and covering the optical fiber tail sleeve on the output end socket of the optical fiber; fixing the optical fiber of the heat treatment part by using the optical fiber heat shrinkable tube. The light spot homogenizing device is good in homogenizing effect and the manufacturing method is simple and convenient; the problem that output light spots of a semiconductor laser device are not uniform is solved effectively.

Owner:WUXI LUMISOURCE TECH

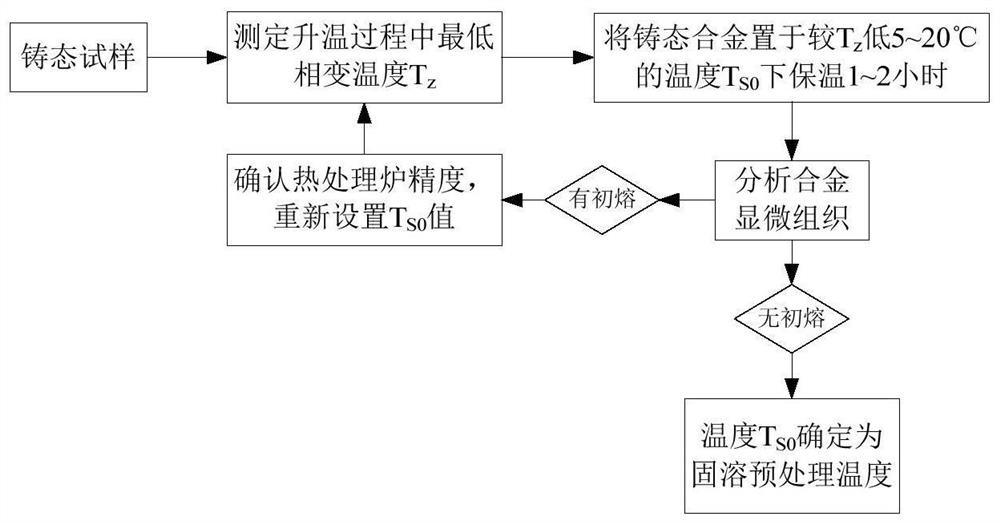

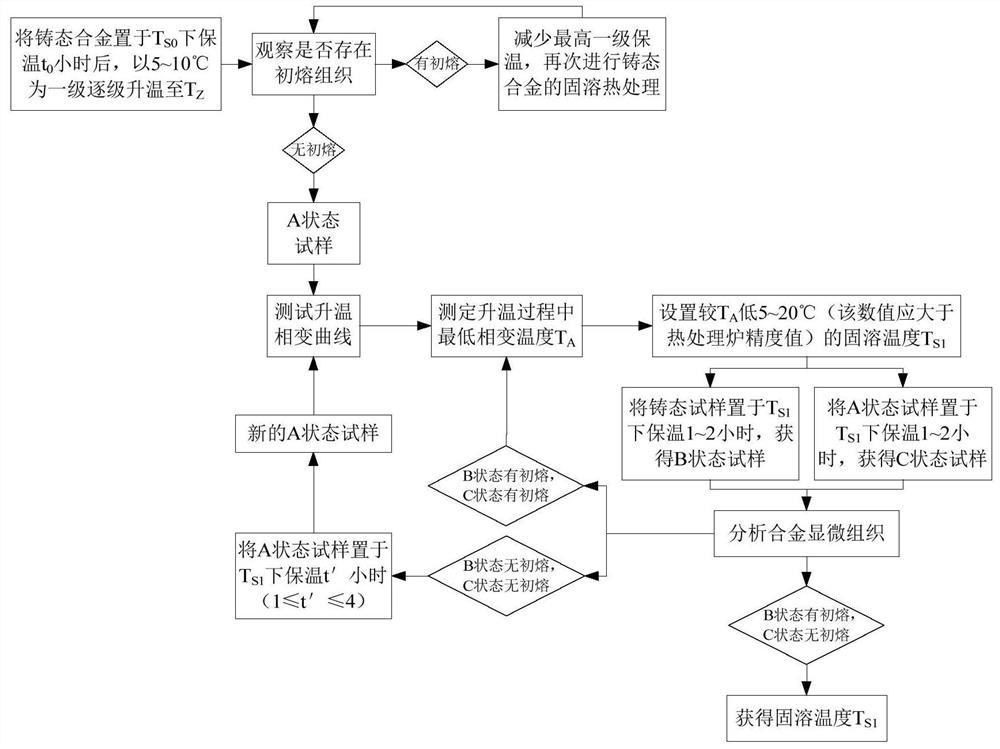

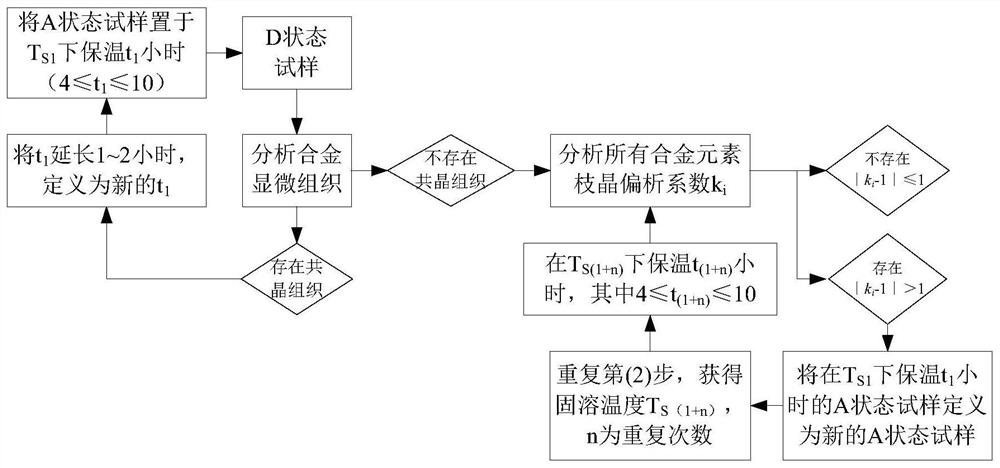

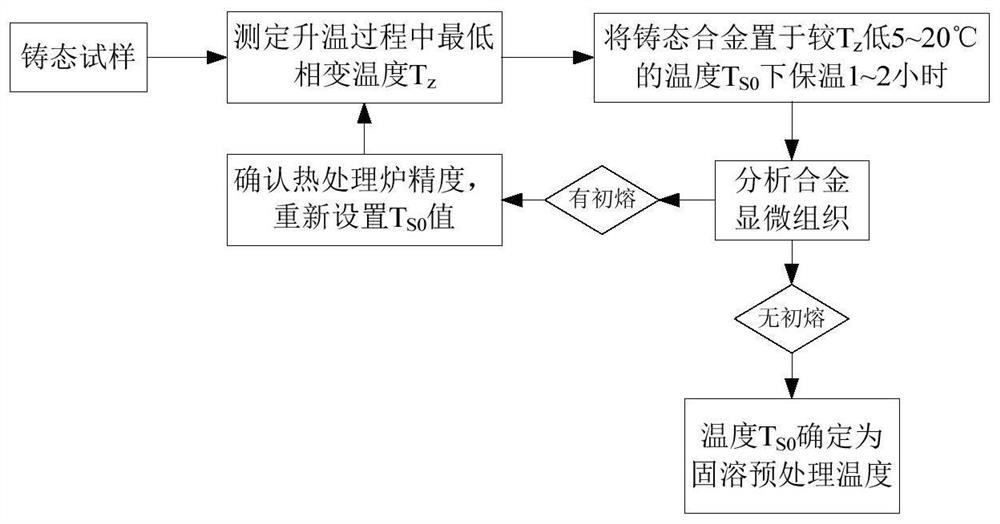

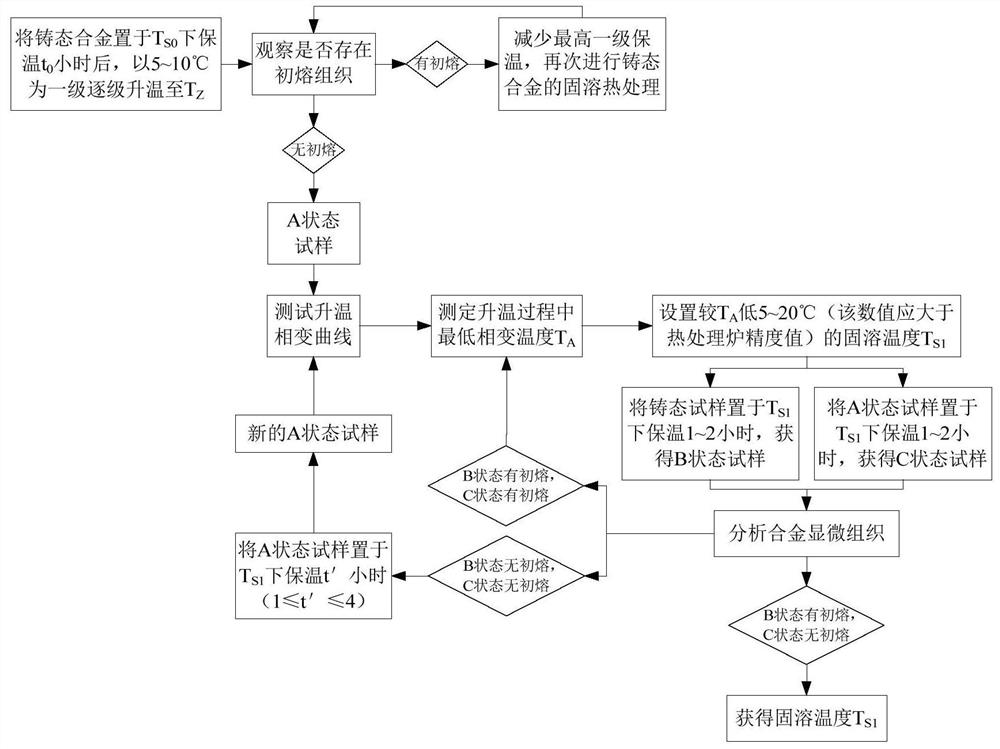

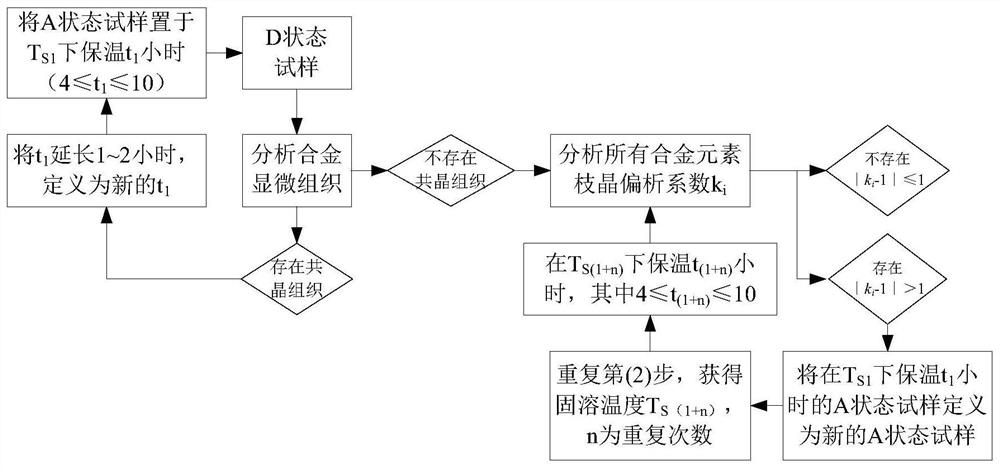

Method of determining homogenization/solid solution heat treatment institution of nickel-base monocrystal high temperature alloy

ActiveCN111763897AImprove efficiencyImprove diffusion efficiencyPolycrystalline material growthAfter-treatment detailsPhysicsNickel

The invention belongs to the technical field of nickel-base monocrystal high temperature alloy preparation, and relates to a method of determining a homogenization / solid solution heat treatment institution of nickel-base monocrystal high temperature alloy. The method comprises the steps that the first-stage homogenization / solid solution heat treatment temperature is determined; the highest-stage homogenization / solid solution heat treatment temperature is determined; the intermediate-stage homogenization / solid solution heat treatment temperature is determined; and the homogenization / solid solution heat treatment institution is determined. When the method is used, the alloy can be subjected to homogenization / solid solution heat treatment at the temperature higher than the cast-state initialmelting temperature, and no initial melting defect is generated. Meanwhile, due to the fact that the higher homogenization / solid solution heat treatment temperature is adopted, the better homogenization effect can be obtained in the short homogenization / solid solution heat treatment period, no initial melting defect is generated, and then the problems that due to the fact that the contents of high-melting-point elements are high, dendritic segregation of the elements is serious, a homogenization / solid solution heat treatment window is small, and the homogenization difficulty is high are effectively solved.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

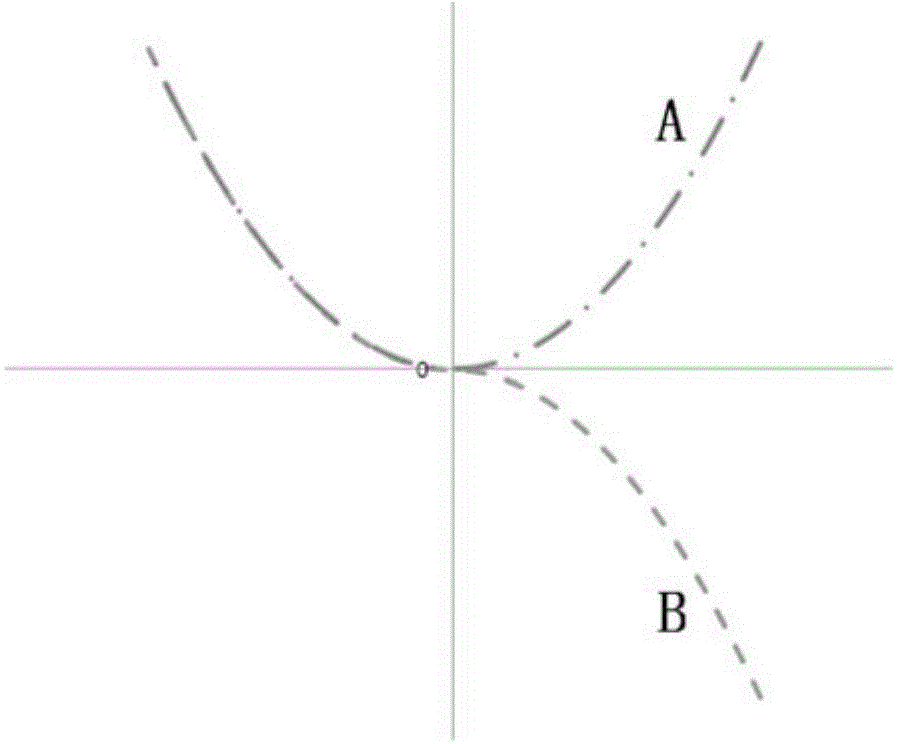

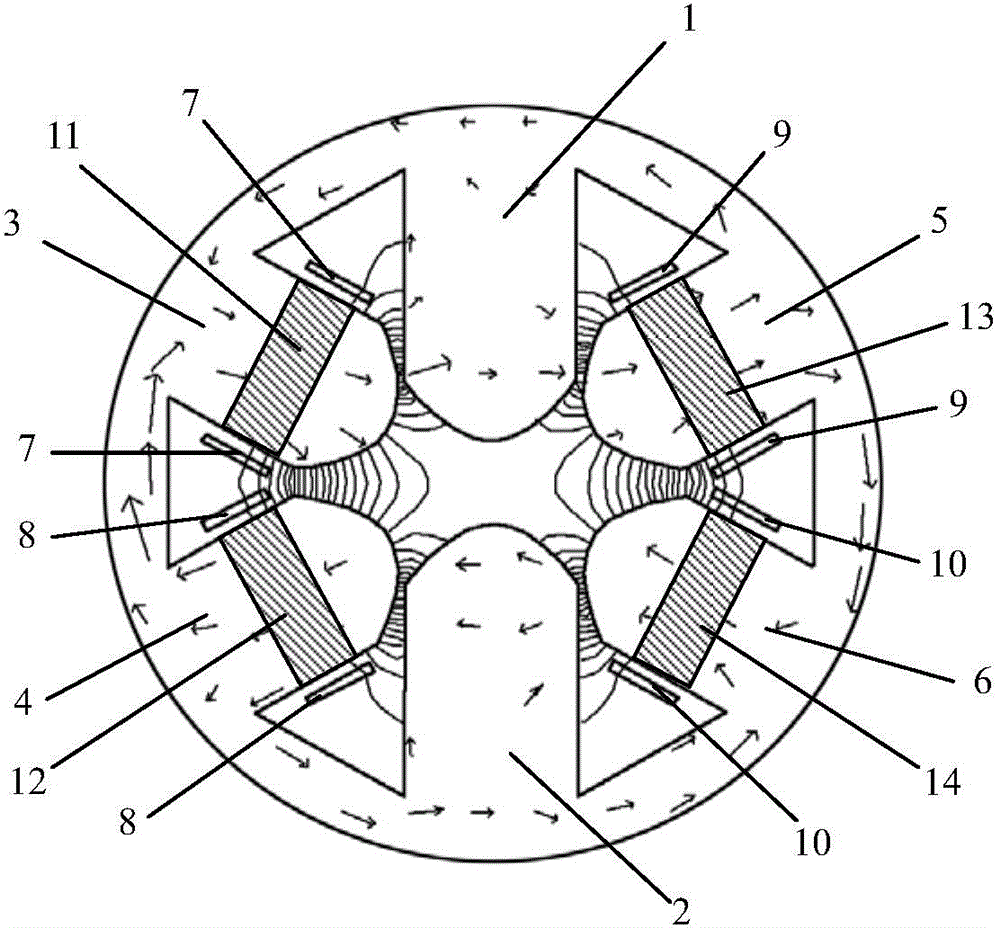

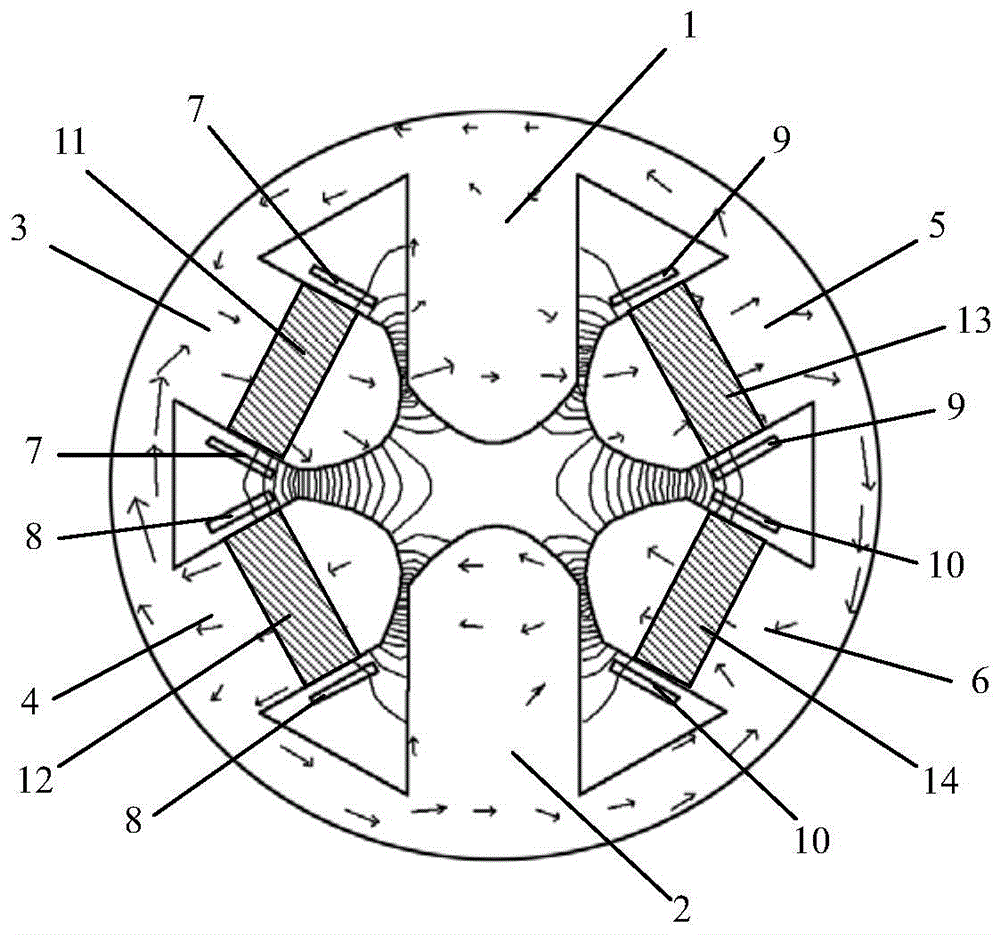

Homogenized sextupole magnet of permanent magnet beam

ActiveCN104703378AReduce distanceGood homogenization effectAcceleratorsElectromagnetsDensity distributionSextupole magnet

The invention belongs to the design technology of an accelerator, and particularly relates to a homogenized sextupole magnet of a permanent magnet beam. According to the sextupole magnet, the field exciters of a pair of relative magnetic poles are cancelled based on a traditional design, the distance between the pair of magnetic poles is shortened, and field excitation directions in a pair of adjacent magnetic poles is changed at the same time. A field excitation component comprises a permanent magnet as a main field exciter and an excitation wire wrap as an auxiliary field exciter. According to the homogenized sextupole magnet provided by the invention, the symmetric about the origin of a coordinate of a magnetic field generated on an X axis can be realized, and the square of the size is proportional to the square of the position of the magnetic field, therefore a good homogenization effect can be provided to beam spots which are in a trigonometrical density distribution way.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

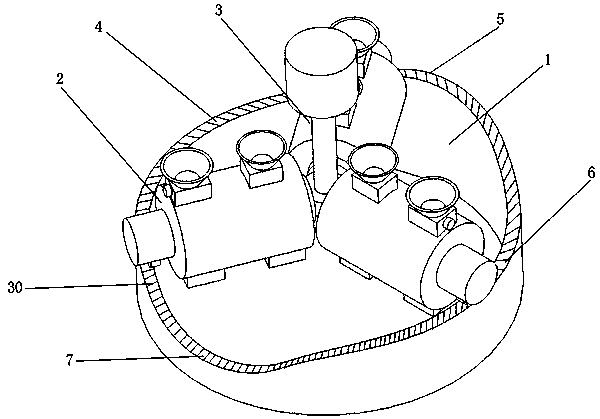

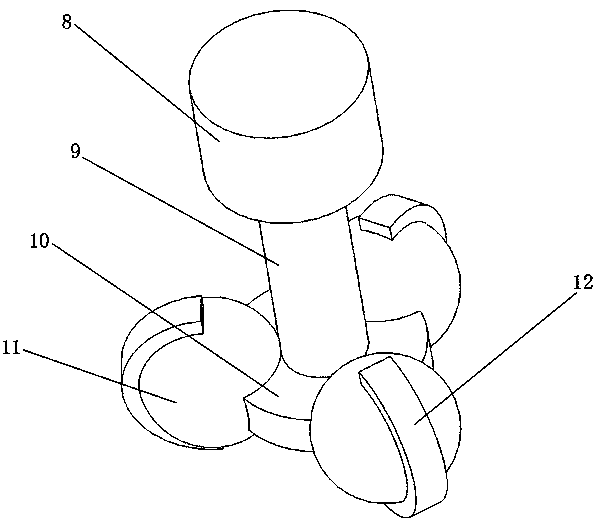

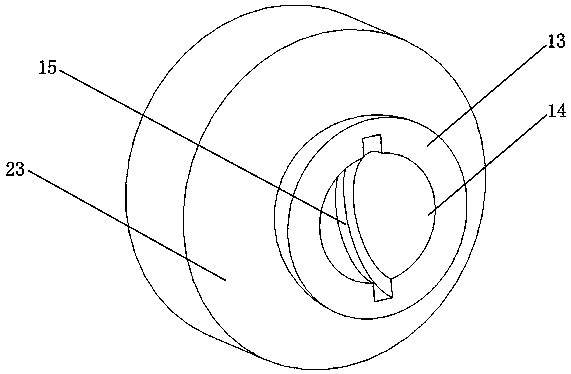

Cement homogenization equipment capable of automatically feeding

ActiveCN108908732AWell mixedTo ensure the homogenization effectCement mixing apparatusControl apparatusControl systemEngineering

The invention provides cement homogenization equipment capable of automatically feeding, comprising a support ring seat, a triple homogenizer, a power connecting device, a feeding device and a controlsystem; the support ring seat is an annular base, and the upper surface thereof is provided with a ring rail, a raised high seat, two horizontal flat seats and a recessed low seat; the triple homogenizer is formed by three sets of connected powder homogenizing devices, the tail part of the triple homogenizer is semi-circular teeth, and the end part of the triple homogenizer is provided with a rolling gear; the rolling gear of the triple homogenizer is meshed with the ring rail; the power connecting device is provided with a servo motor, and the triple homogenizer is driven by the servo motorto rotate on the ring rail; a pneumatic homogenization device, a roller and dispersing and stirring blades are arranged inside the triple homogenizer; the roller has an opposite rotation direction anda slower speed than the dispersing and stirring blades; a feeding device is arranged at the top of the triple homogenizer. The cement homogenization equipment has the advantages of ingenious and practical mechanism design, high degree of automation, space saving and good effect, and is suitable for use in cement production and processing.

Owner:韦波

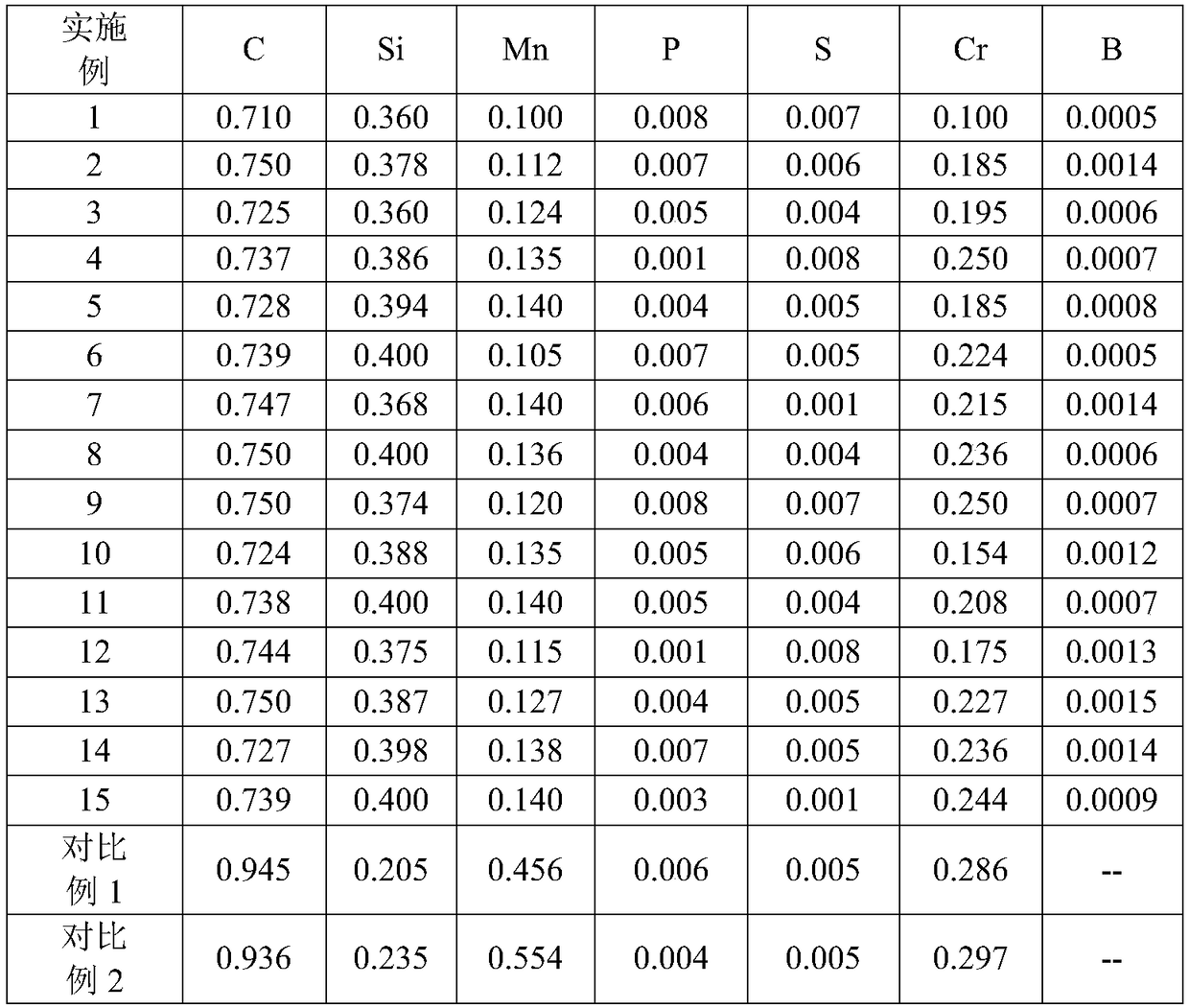

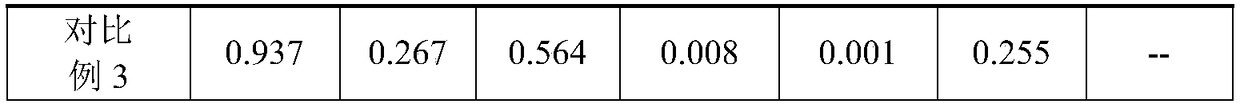

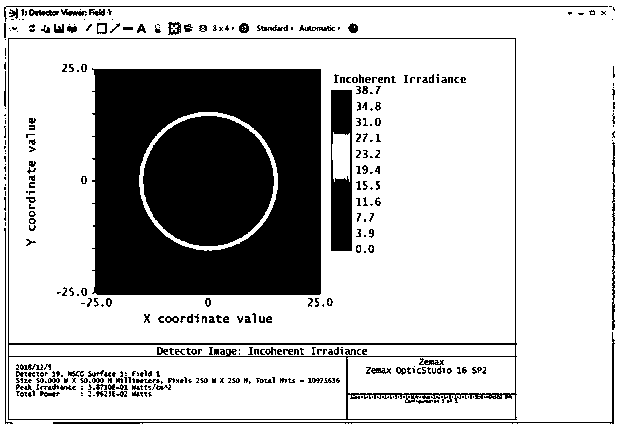

Hot-rolled wire rod for cord thread with tensile strength being 4000MPa and production method

The invention relates to a hot-rolled wire rod for a cord thread with tensile strength being the 4000MPa grade. The hot-rolled wire rod is prepared from the components in percentage by weight: 0.71 to0.75 percent of C, 0.36 to 0.40 percent of Si, 0.10 to 0.14 percent of Mn, less than or equal to 0.01 percent of P, less than or equal to 0.01 percent of S, 0.10 to 0.25 percent of Cr, and 0.0005 to0.0015 percent of B. A production method comprises the steps of smelting through a converter; carrying out RH vacuum treatment; continuously casting into small square ingots; slow cooling the ingot blanks; heating the ingot blanks; rolling at high speed; spinning; and air cooling for standby use. According to the hot-rolled wire rod for cord thread with tensile strength being the 4000MPa grade andthe production method provided by the invention, through reducing the content of carbon, improving the content of silicon, and adopting the matched process, on the premise of ensuring the tensile strength to be larger than 4000MPa, the diameter of a wire material reaches to 3.0 to 3.5mm, so that the fracture surface of the wire material is homogenized in structure and better in performance, gammacrystal particles are micronized, the aging during wire drawing processing is inhibited, and the fracturing of a cementite is inhibited; and the strength and the wire drawing limit of the wire material are improved, the times of stranding filament break does not exceed 2 times / ton steel, and secondary processing by a user can be omitted and simplified, so that the production cost is reduced, andthe production efficiency is improved.

Owner:武汉钢铁有限公司

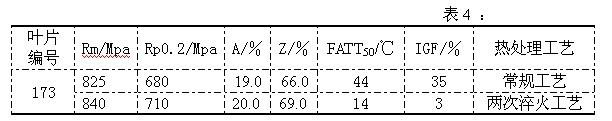

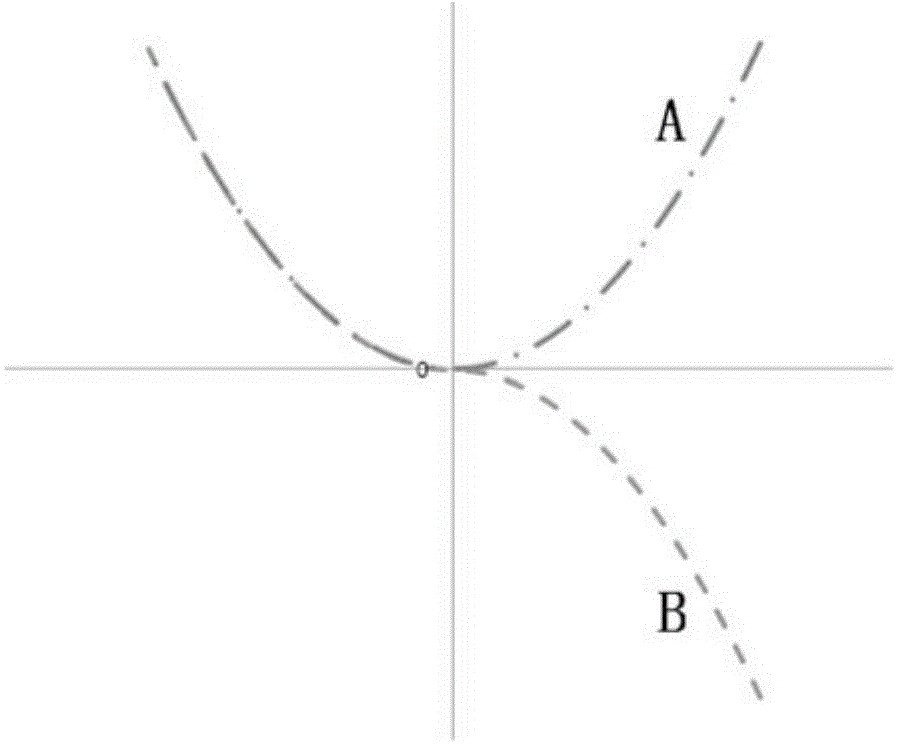

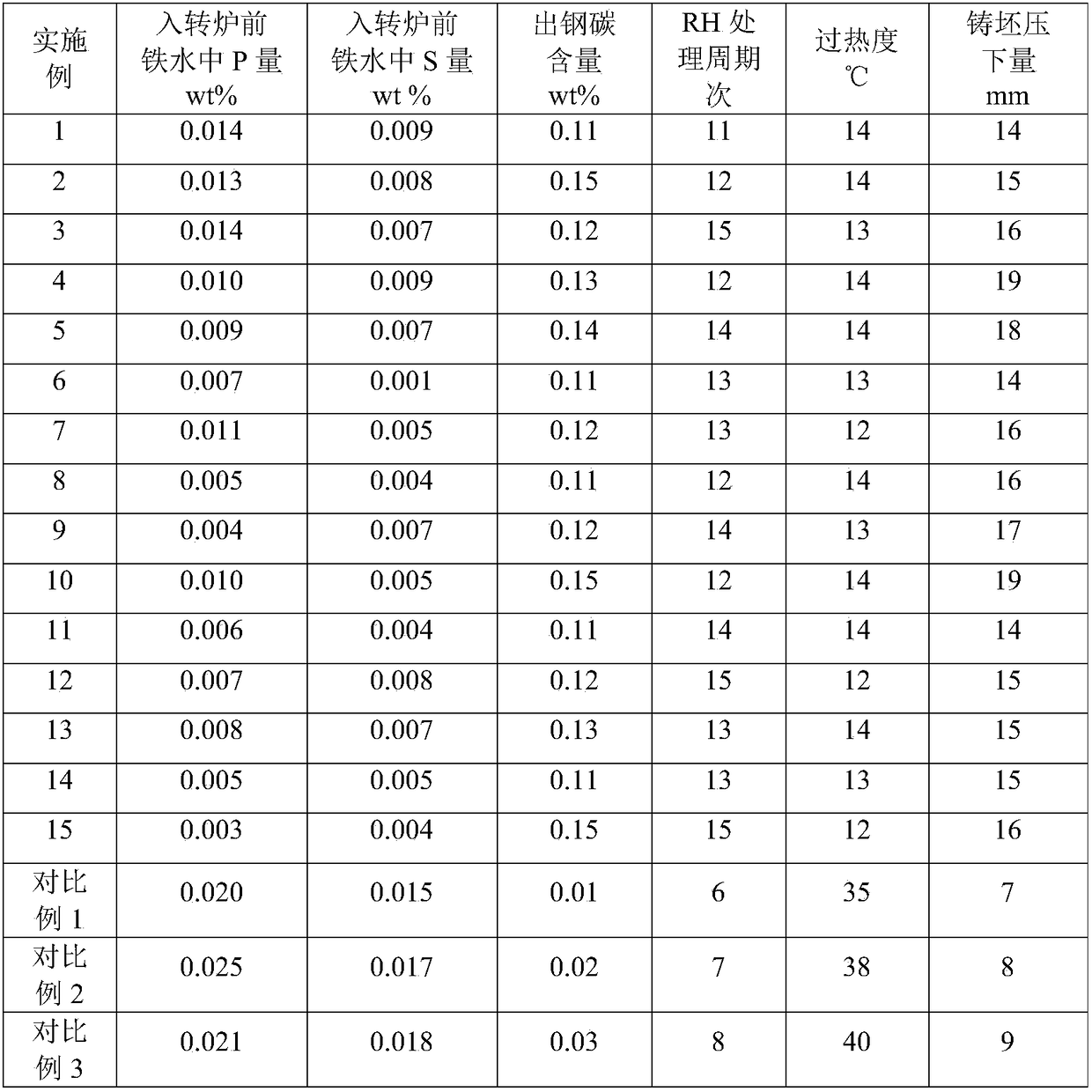

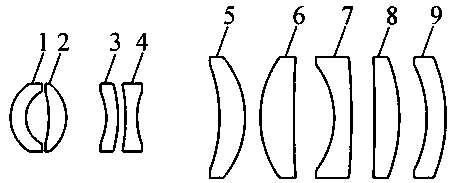

Long focal depth laser beam homogenizing optical system based on aspheric mirror difference effect

ActiveCN109557675AEven energy distributionImprove signal-to-noise ratio and measurement accuracyOptical elementsAspheric lensPositive power

The invention discloses a long focal depth laser beam homogenizing optical system based on aspheric mirror difference effect. The optical system comprises a beam homogenizing aspheric mirror group anda long focal depth spherical collimating mirror group, wherein the beam homogenizing aspheric mirror group comprises a negative power meniscus convex lens, a first positive power meniscus convex lens, an aspheric negative power meniscus concave lens, negative power double concave lens, and a second positive power meniscus convex lens; the long focal depth spherical collimating mirror group comprises a third positive power meniscus convex lens, a negative power concave lens, a positive power convex lens, and a negative power meniscus concave lens; and respective lenses are sequentially coaxially arranged in the light propagation direction. The optical system can convert Gaussian beams into uniformly distributed flat-topped Gaussian beams, which provides high-quality and efficient laser beams for intense laser damage measurement, laser cleaning, laser polishing, and laser combustion diagnostics, and facilitates further development in these areas.

Owner:HARBIN INST OF TECH

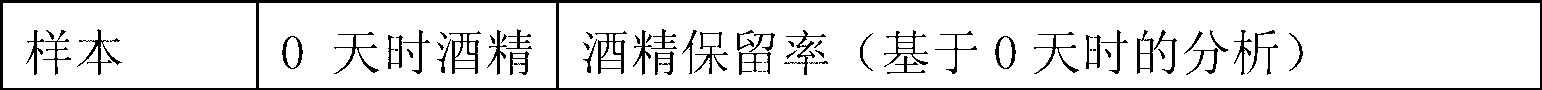

Easily carried powder white wine and preparation method thereof

ActiveCN103013796AHigh gel strengthGood homogenization effectAlcoholic beverage preparationSodium carboxymethylcelluloseCarboxymethyl cellulose

The invention provides an easily carried powder white wine and a preparation method thereof. The easily carried powder white wine is prepared by using the method comprising the following steps of: preparing colloid obtained by compounding xanthan gum, carrageenan and konjac glucomannan with white wine of which the alcohol content is not less than 25% into gel with white wine; subsequently homogenizing the gel with the white wine; further homogenizing the gel with the white wine with a mixed solution and lauryl sodium sulfate for 1.5 hours by using a high-pressure homogenizer in 100MPa, wherein the mass ratio of carboxymethyl cellulose to ethanol of the mixed solution is 1:10; and removing the moisture through microwave vacuum drying so as to obtain the powder white wine. According to the powder white wine provided by the invention, the volatilization, oxidation and deterioration of alcohol and aromatic substances in original white wine are avoided to the maximum extent; when the white wine is used, only hot water is added into the powder white wine, and then the alcohol and the aromatic substances in the original white wine are released, so that the original character of the wine is recovered with good taste; and as a result, the powder white wine has the advantages of simple process, high finished product quality, preservation easiness and the like.

Owner:天津华易科技发展有限公司

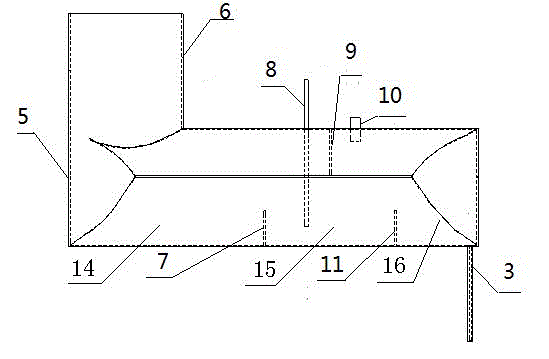

Platinum device for optical glass feed preparation

ActiveCN103145317AIncrease or decrease diameterImprove melting efficiencyGlass furnace apparatusGlass productionPlatinumOptical property

The invention relates to a platinum device for optical glass feed preparation and belongs to the technical field of a feed preparation furnace for continuous smelting in a tank furnace. The platinum device mainly solves the problems that a conventional single crucible generates optical property fluctuation, influences uniformity and has limited smelting capacity. The platinum device is mainly characterized in that the crucible is a boot-shaped crucible; a left division plate and a right division plate are arranged at the inner bottom of the crucible at intervals and are used for dividing the inner bottom of the crucible into a material melting chamber, a homogenization chamber and a discharging chamber which are communicated; a discharging pipe is arranged at the bottom of the discharging chamber; a feeding pipe is arranged on the upper port of the material melting chamber of the crucible, and the port of the feeding pipe is higher than the upper flat surface of the crucible; and a breather pipe, a middle division plate and an air-bleed hole are arranged on the crucible above the homogenization chamber. The platinum device has the characteristics that the continuous smelting process can be realized, the glass smelting capacity and efficiency under the same volume can be effectively improved, the product is uniform, and the yield is high; and the platinum device is used for a continuous platinum smelting device for optical glass feed preparation.

Owner:HUBEI NEW HUAGUANG NEW INFORMATION MATERIALS CO LTD

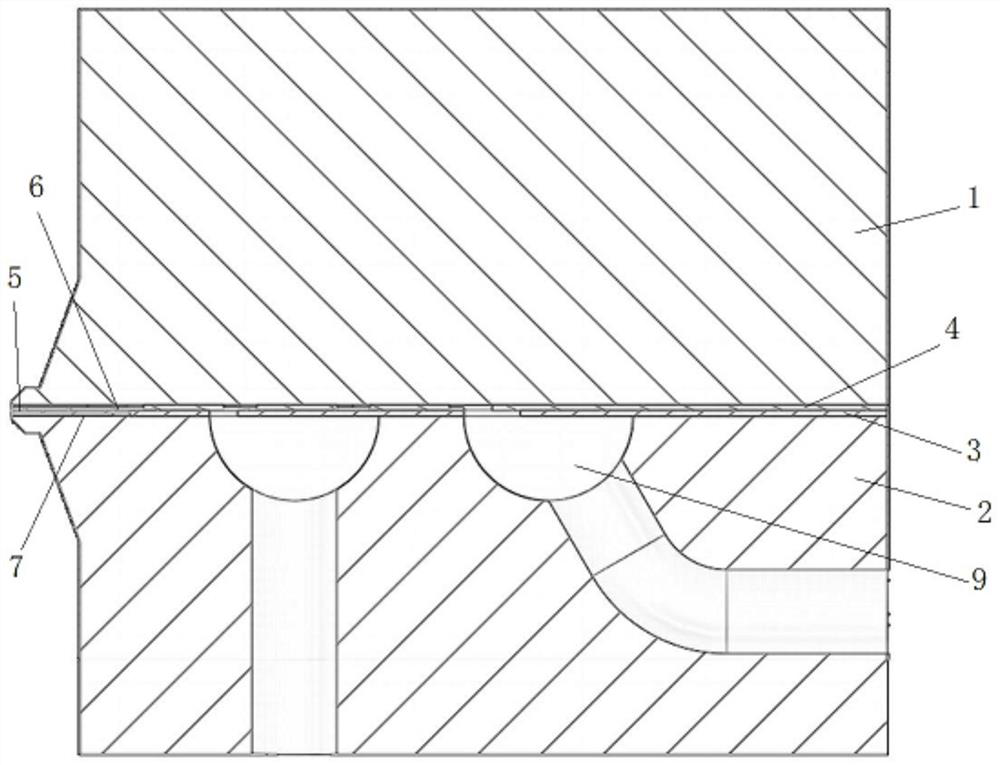

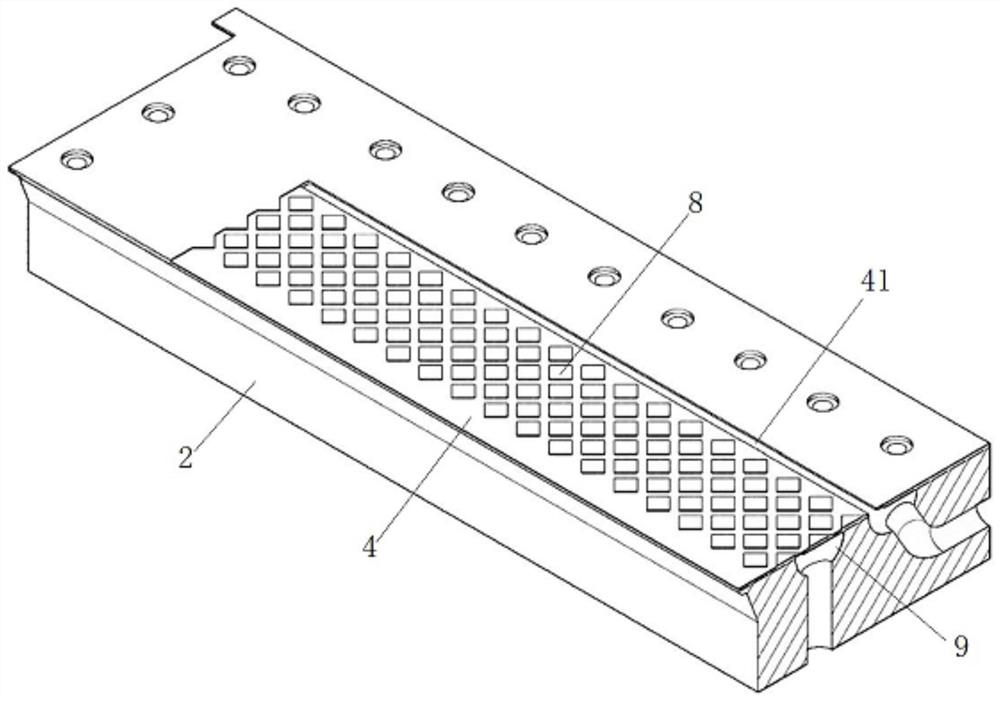

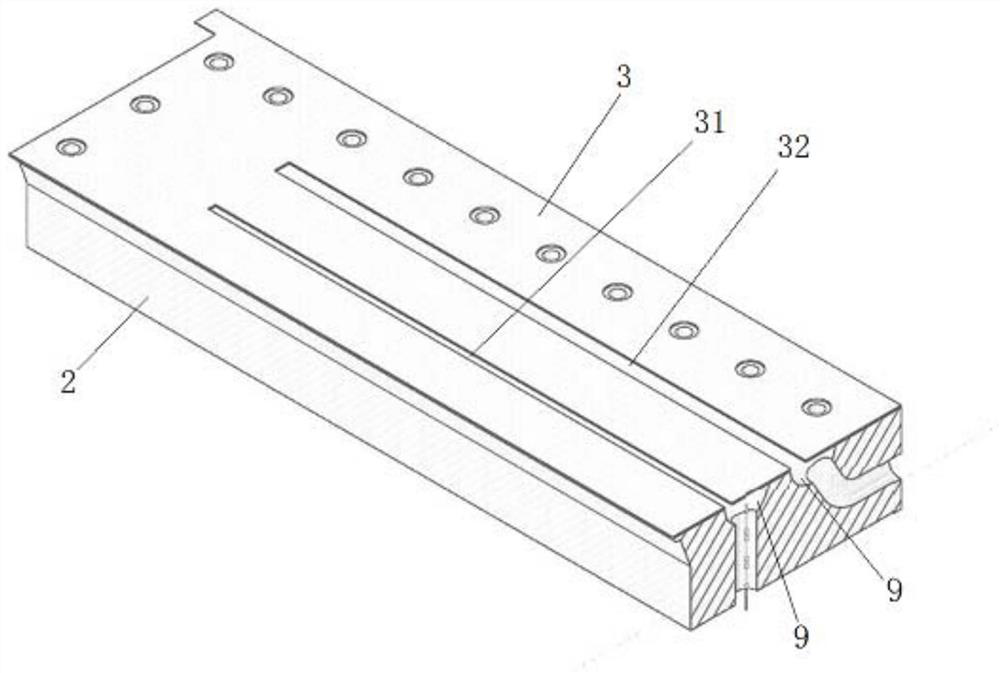

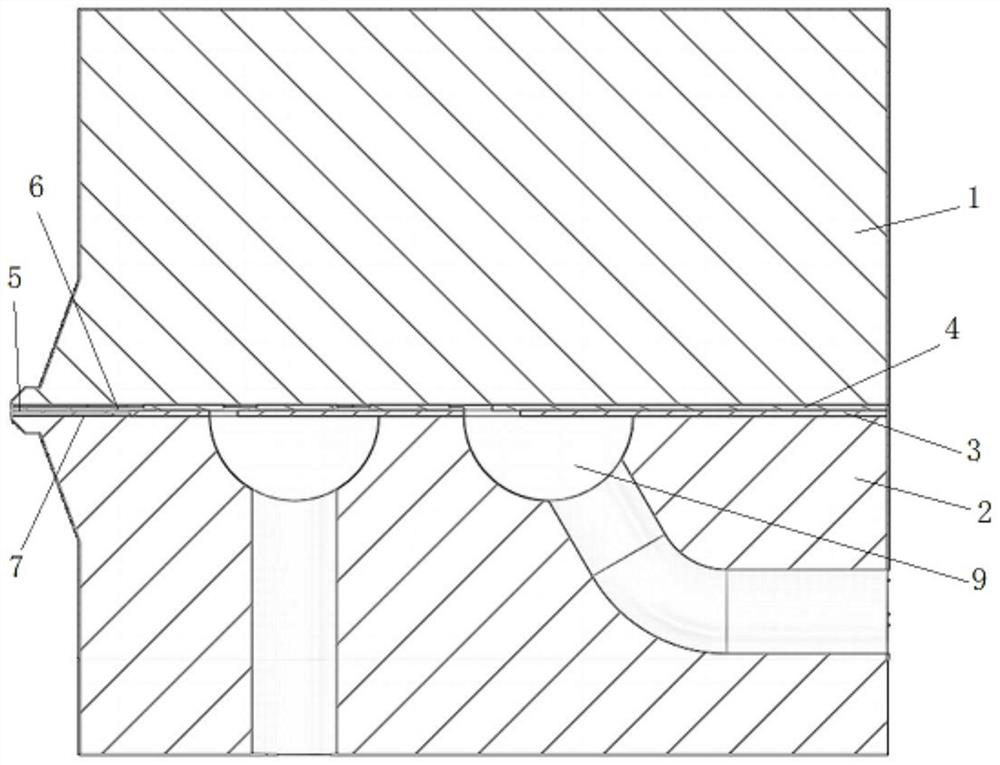

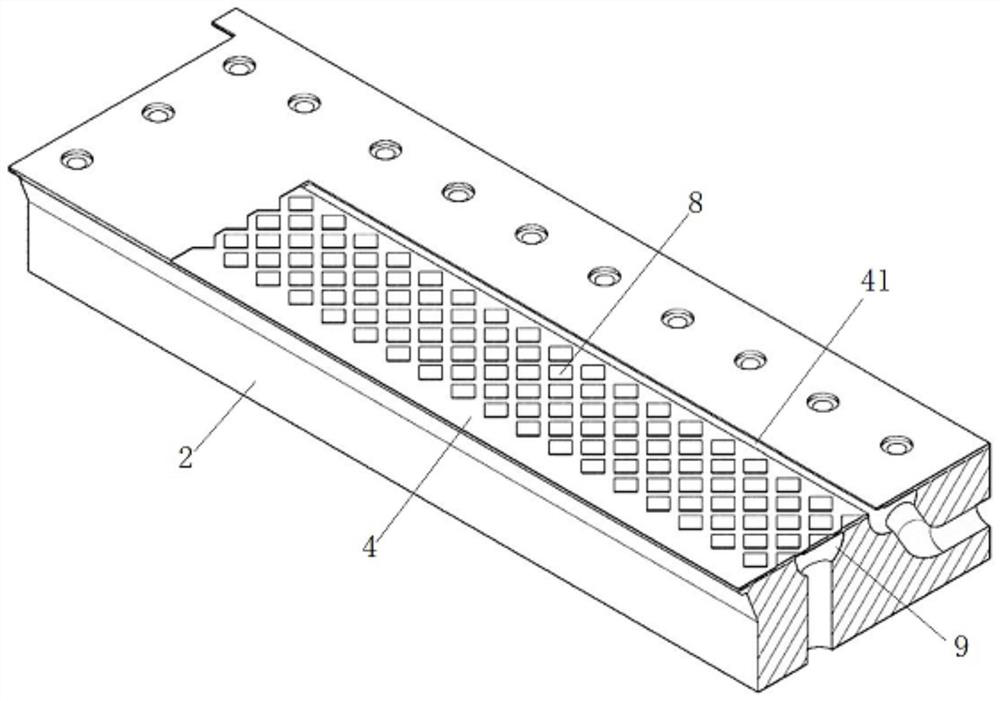

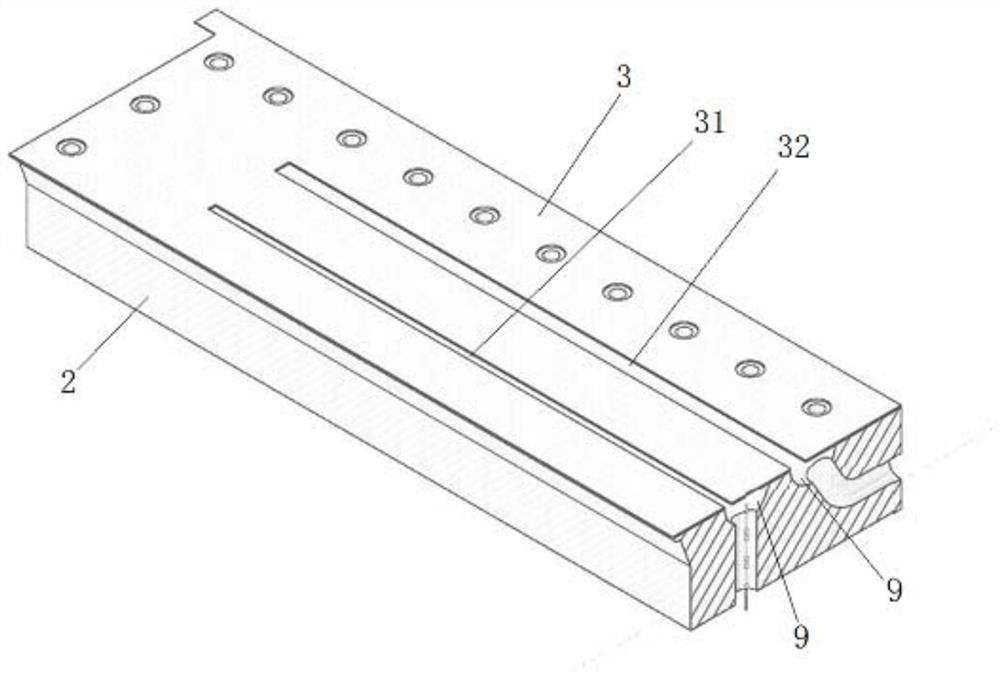

Coating gasket, coating die head and coating machine

ActiveCN113083617AUniform density distribution across the transverse areaImprove coating qualityLiquid surface applicatorsCoatingsSlurry flowCoating

The invention discloses a coating gasket, a coating die head and a coating machine. The coating die head comprises an upper die head body and a lower die head body which are matched with each other, an extrusion gap is formed between the upper die head body and the lower die head body, a discharging opening is formed in one end of the extrusion gap, the coating gasket is arranged in the extrusion gap, at least one coating opening used for discharging is formed in the coating gasket, and a plurality of protrusions which are arranged at intervals are arranged on the part, between the coating opening and the discharging opening, of the coating gasket; and a plurality of layers of coating gaskets are arranged in the extrusion gap, and a plurality of protrusions which are arranged in a staggered mode are arranged on the coating gaskets. On one hand, the multiple protrusions can play a supporting role between different layers of coating gaskets, and the problem that the coating quality is affected due to the fact that all the positions of the coating gaskets in extrusion gaps are deformed due to the large pressure difference is solved; and on the other hand, the multiple protrusions can achieve the homogenization effect on the slurry flowing in a coating channel, so that the density distribution of all transverse surfaces is more uniform when the slurry is extruded out, and then the coating quality is improved.

Owner:SHENZHEN MANST TECH CO LTD

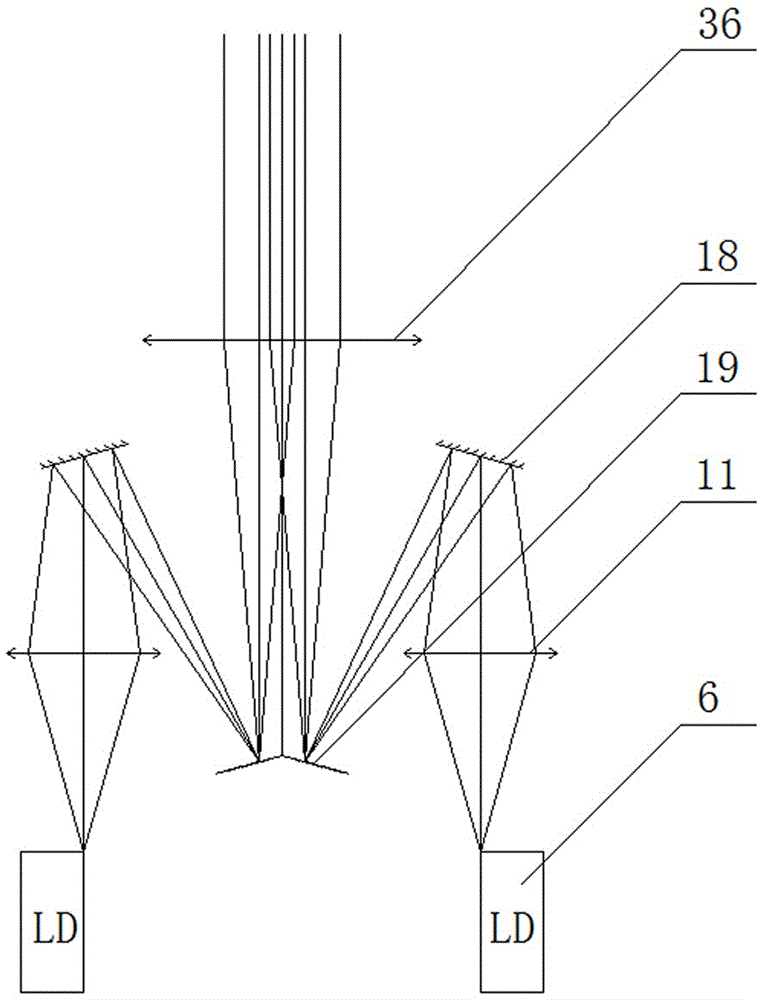

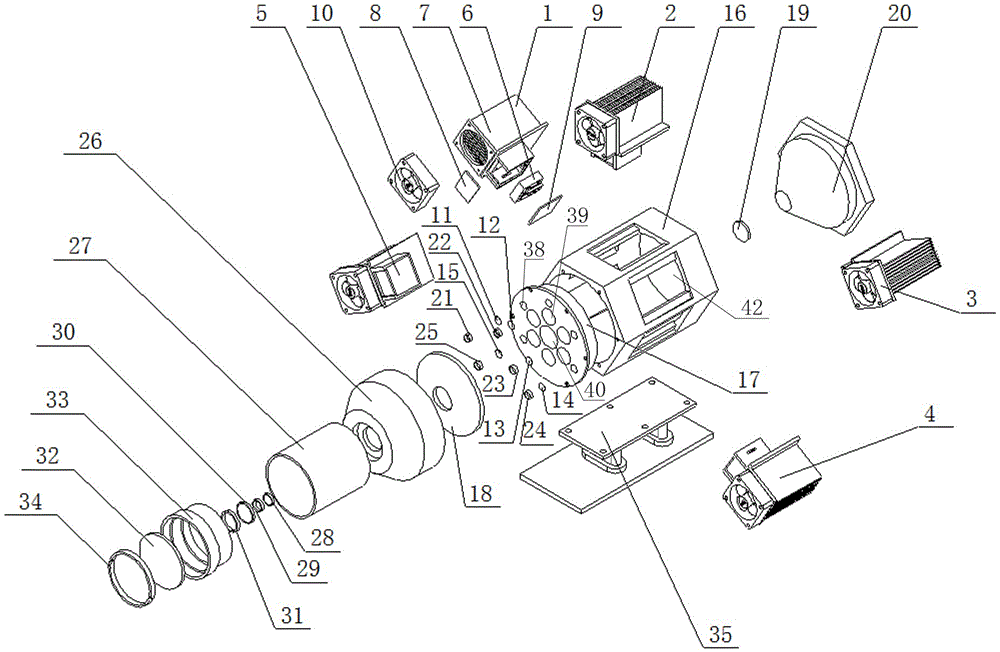

Ultrahigh-power near-infrared semiconductor laser illuminator

ActiveCN105627253AGood homogenization effectGood effectSemiconductor devices for light sourcesRefractorsPhysicsSemiconductor laser theory

The invention discloses an ultrahigh-power near-infrared semiconductor laser illuminator which comprises a main shell and a plurality of laser modules. Each laser module is composed of a single-bar semiconductor laser and a fixed laser cooling assembly, wherein the single-bar semiconductor laser is used for generating a laser beam. A convergent lens is arranged at the front end of each single-bar semiconductor laser, and a primary reflector and a secondary reflector are arranged at the front end and the rear end of each convergent lens correspondingly. A plurality of laser beams are reflected by the primary reflectors and then are converged on the surfaces of the secondary reflectors, and the laser beams are reflected by the secondary reflectors and then are combined to form a laser beam with a good homogenized effect. A shaping prism set is used for adjusting the light emitting angle of the laser beam to meet illumination requirements. According to the ultrahigh-power near-infrared semiconductor laser illuminator, the laser beams emitted by the lasers are overlapped to form an overlapped laser with the good homogenized effect, so that the problems that multiple illuminators are large in size, high in cost and difficult to align and overlap when a kilowatt semiconductor laser emits lasers in a pulse way are solved; the beneficial effects are remarkable, and the illuminator is suitable for application and popularization.

Owner:山东神戎电子股份有限公司

A Homogenization Heat Treatment Process for Eliminating Al-cu-mg-si-mn Alloy Casting Crystalline Phase

The invention provides a homogenizing heat treatment technology for eliminating the Al-Cu-Mg-Si-Mn alloy casting crystal phase. The homogenization technology comprises the steps that an Al-Cu-Mg-Si-Mn alloy ingot is placed into a furnace, is heated to 470-480 DEG C at the speed of 15-20 DEG C / min, is subjected to heat preservation for 8-12h, then is subjected to furnace cooling to 250-300 DEG C, and is subjected to air cooling to the room temperature; then the ingot is placed into a heat preservation furnace with the temperature being 510-520 DEG C and subjected to heat preservation for 18-24h; and finally, the ingot is subjected to air cooling to the room temperature. According to the homogenizing heat treatment technology, the homogenization problem that Al-Cu-Mg series alloy ingots containing a high amount of Si, Fe and Mn are high in melting point, so that a complex second phase is difficult to eliminate is solved, the technology is simple and convenient to operate, the feasible homogenizing heat treatment scheme is provided for the various Al-Cu-Mg series alloy ingots containing a high amount of Si, Fe and Mn, and industrial production is facilitated.

Owner:CENT SOUTH UNIV

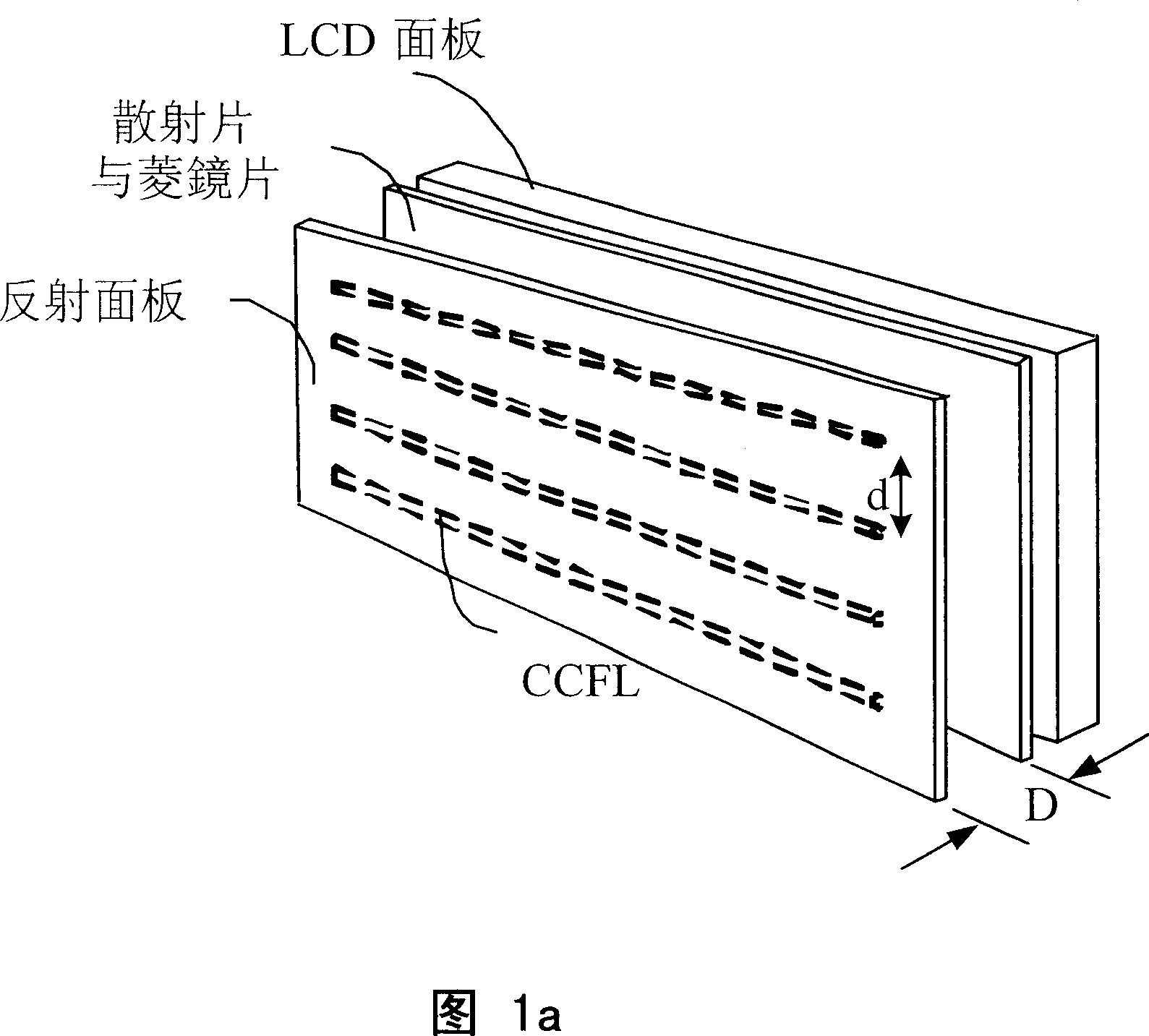

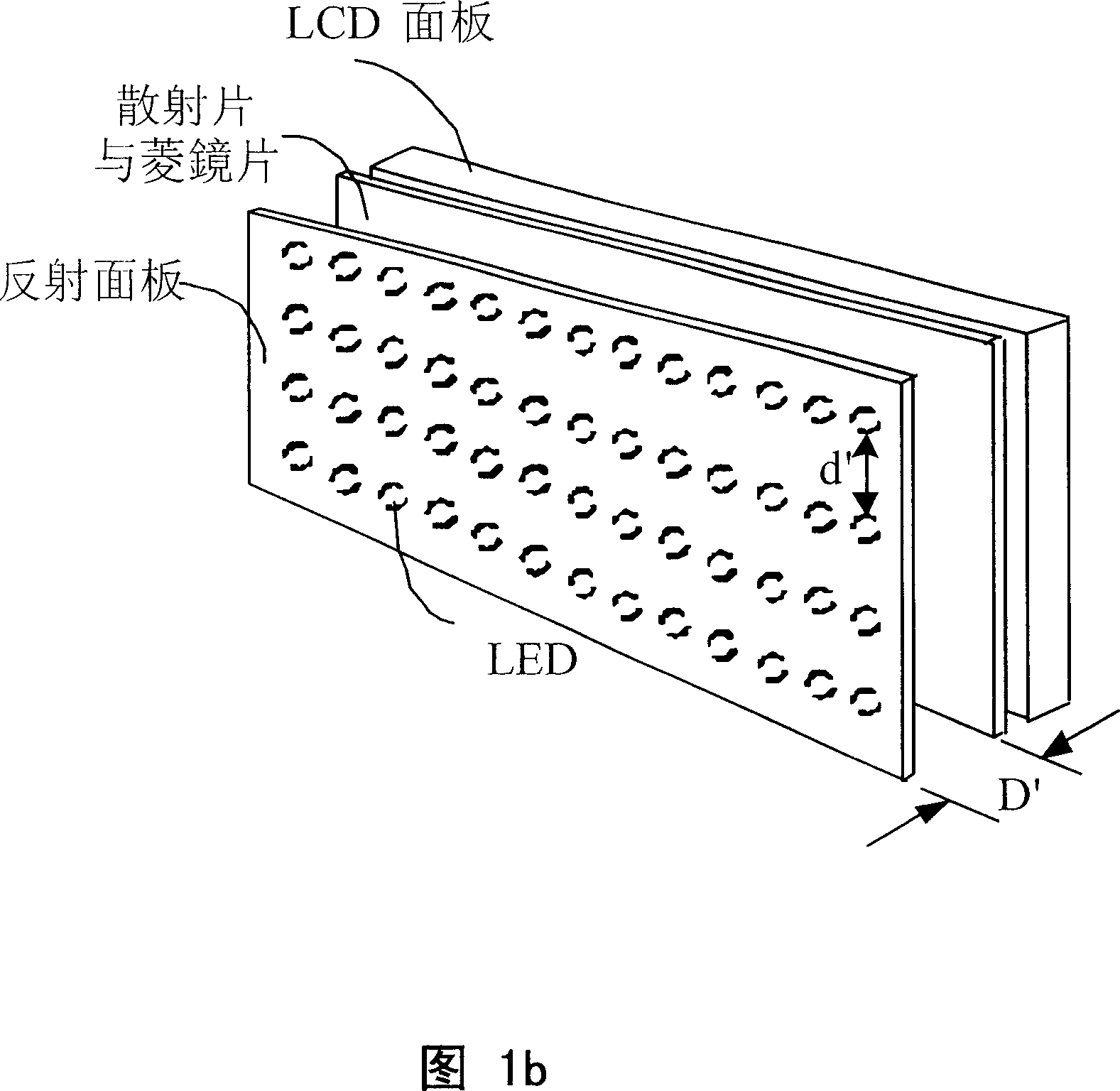

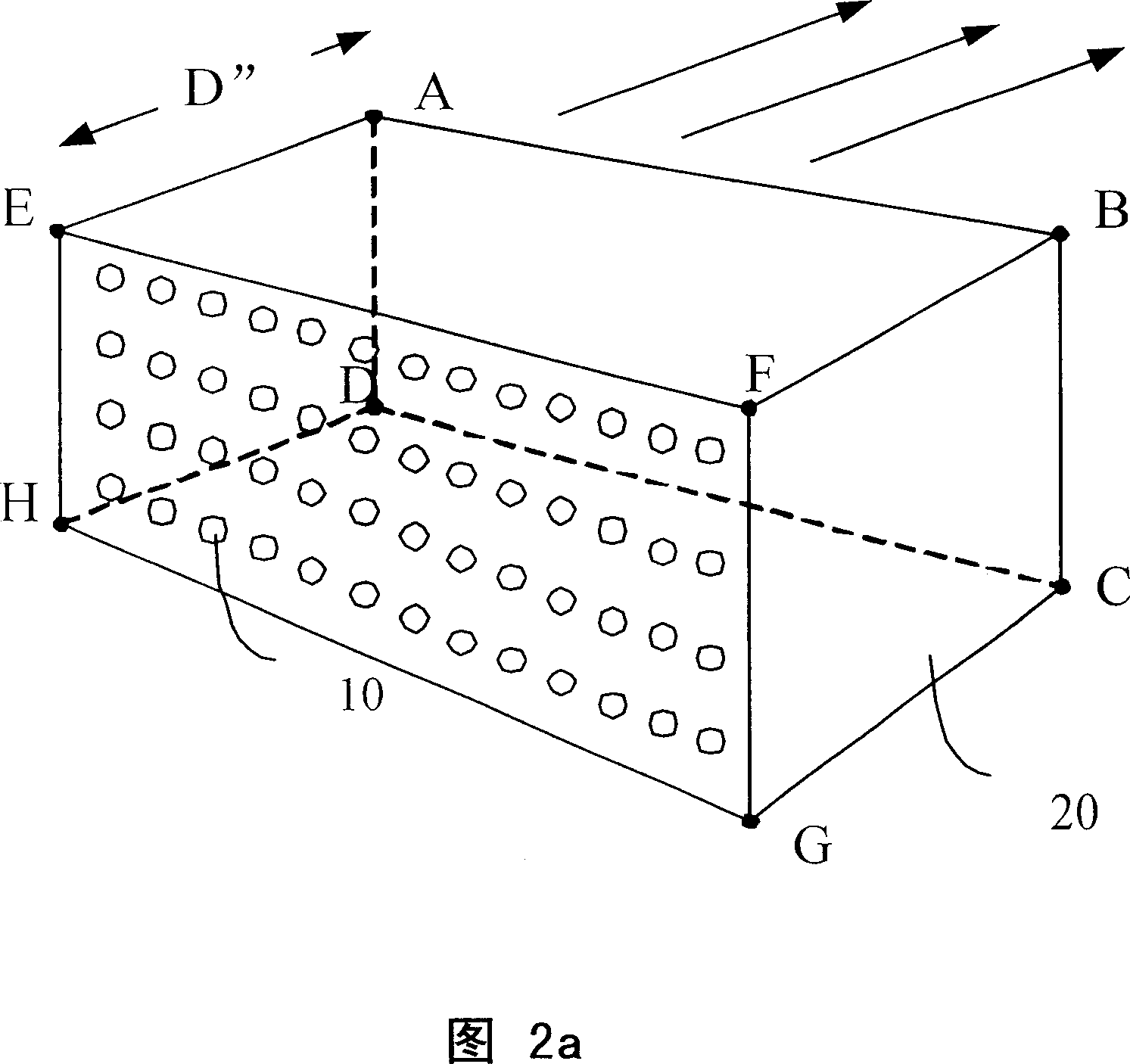

High-homogenized ultra-thin LCD backlight device

InactiveCN1991510AReduce thicknessLow costNon-linear opticsSemiconductor devicesLiquid-crystal displayEffect light

The invention provides a LCD backlight device that includes several LED as the light source, and a uniform cavity mounted between the LED and the back of LED. The ray emitted from the LED are mixed and homogenized via several reflections to form a homogenizing front lighting, and it can omit the diffusing lens and the prismatic lens to reduce the cost and avoid the loss of luminous flux. The backlight device can reduce the thickness at the lowest and not need sacrifice the cost, heat dispersion and power, the service time, the whole homogenization of surface light is not affected by the difference of brightness,the chroma of special LED, and the fault.

Owner:DYNASCAN TECH

Method for Determining Homogenization/Solution Heat Treatment System of Nickel-based Single Crystal Superalloy

ActiveCN111763897BImprove diffusion efficiencyGood homogenization effectPolycrystalline material growthAfter-treatment detailsSingle crystal superalloySingle crystal

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Refining method for purifying and homogenizing molten steel through high-frequency vibration

PendingCN109576439AAchieve purificationThe crystallization densification process is favorableVibration amplitudeMolten steel

The invention discloses a refining method for purifying and homogenizing molten steel through high-frequency vibration. After the molten steel is injected into a steel ladle, the steel ladle is placedon a high-frequency vibration table, the vibration amplitude is adjusted to be 0.5-1.0 mm, the frequency ranges from 100 Hz to 200 Hz, vibration is conducted for 60-150 seconds, gas is enabled to escape, impurities float, and parts are cast after purifying and homogenizing. The refining method has the advantages that the molten steel purifying and homogenizing method is easy to operate, safe, reliable and rapid; refining equipment is low in cost, investment is low, the operation cost is low, power required by 5 tons of molten steel of a vibration motor of the high-frequency vibration table is5 kilowatts, the vibration table is started for 120 seconds, and power consumption is 0.17 kilowatt, so that the refining cost is 0.1 yuan equivalently; and the molten steel purifying and homogenizing effect are excellent, and castings with high quality can be cast.

Owner:刘玉满

Raw material bag applied to food processing machine

The invention relates to a raw material bag applied to a food processing machine. The food processing machine is used for mixing the raw material bag and water and crushing into slurry at the crushingrotating speed of 5000 to 30000 r / min, wherein the raw material bag comprises 40 to 60 percent of oat, 10 to 25 percent of soybeans, 5 to 15 percent of dried apples and 17 to 35 percent of mixed nuts; the soybeans are baked whole beans; the dried apples are subjected to low-temperature drying; the mixed nuts are subjected to microwave treatment. The food processing machine is used for crushing the raw material bag; a manufactured beverage cannot generate delamination; instant eating and instant use are realized; various nutrition elements benefiting intelligence and tonifying the brain can beprovided; meanwhile, the loss and nutrition risk caused by the raw material crushing in advance can be reduced.

Owner:JOYOUNG CO LTD

A coating die and coating machine

ActiveCN113083617BImprove structural strengthAvoid deformationLiquid surface applicatorsCoatingsCoatingSlurry flow

The invention discloses a coating die head and a coating machine. The coating die head comprises an upper die head and a lower die head that cooperate with each other, an extrusion gap is provided between the upper die head and the lower die head, and one end of the extrusion gap is provided. There is a discharge port, the coating gasket is arranged in the extrusion gap, at least one coating opening for discharging is formed on the coating gasket, and the coating gasket is located in the part between the coating opening and the discharging port There are a plurality of protrusions arranged at intervals. A multi-layer coating gasket is arranged in the extrusion gap, and a plurality of staggered protrusions are arranged on the coating gasket; on the one hand, the plurality of protrusions can play a supporting role between different layers of the coating gasket, Avoid the problem that the coating gasket is deformed due to the large pressure difference in the extrusion gap, thereby affecting the coating quality; on the other hand, multiple protrusions can homogenize the slurry flowing in the coating channel , so that when the slurry is extruded, the lateral surface density distribution is more uniform, and the coating quality is improved.

Owner:SHENZHEN MANST TECH CO LTD

Method for preparing copper-based self-lubricating material through in-situ stirring method

The invention belongs to the technical field of high-performance materials, and relates to a method for preparing a copper-based self-lubricating material through an in-situ stirring method. The method specifically comprises the steps that copper-based melt is made to form vortex flow in a heating furnace in a stirring manner; a raw material forming a wild phase or a lubricating phase is added into the copper-based melt in a blowing manner; the raw material forming the wild phase or the lubricating phase and the copper-based melt generate the wild phase and the lubricating phase in situ under the action of the vortex flow, and the wild phase and the lubricating phase are rolled into the copper-based melt; and the wild phase and the lubricating phase are distributed in the copper-based melt highly evenly and dispersedly in an eccentric stirring manner and a quick cooling solidification manner. According to the method, the preparation process of the copper-based self-lubricating material is simplified in an in-situ generation manner, the interface bonding force of a second phase and a matrix is improved, and the self-lubricating copper-based alloy material with the wild phase and the lubricating phase distributed highly dispersedly is achieved through the means of eccentric stirring, solidification control and the like.

Owner:NORTHEASTERN UNIV

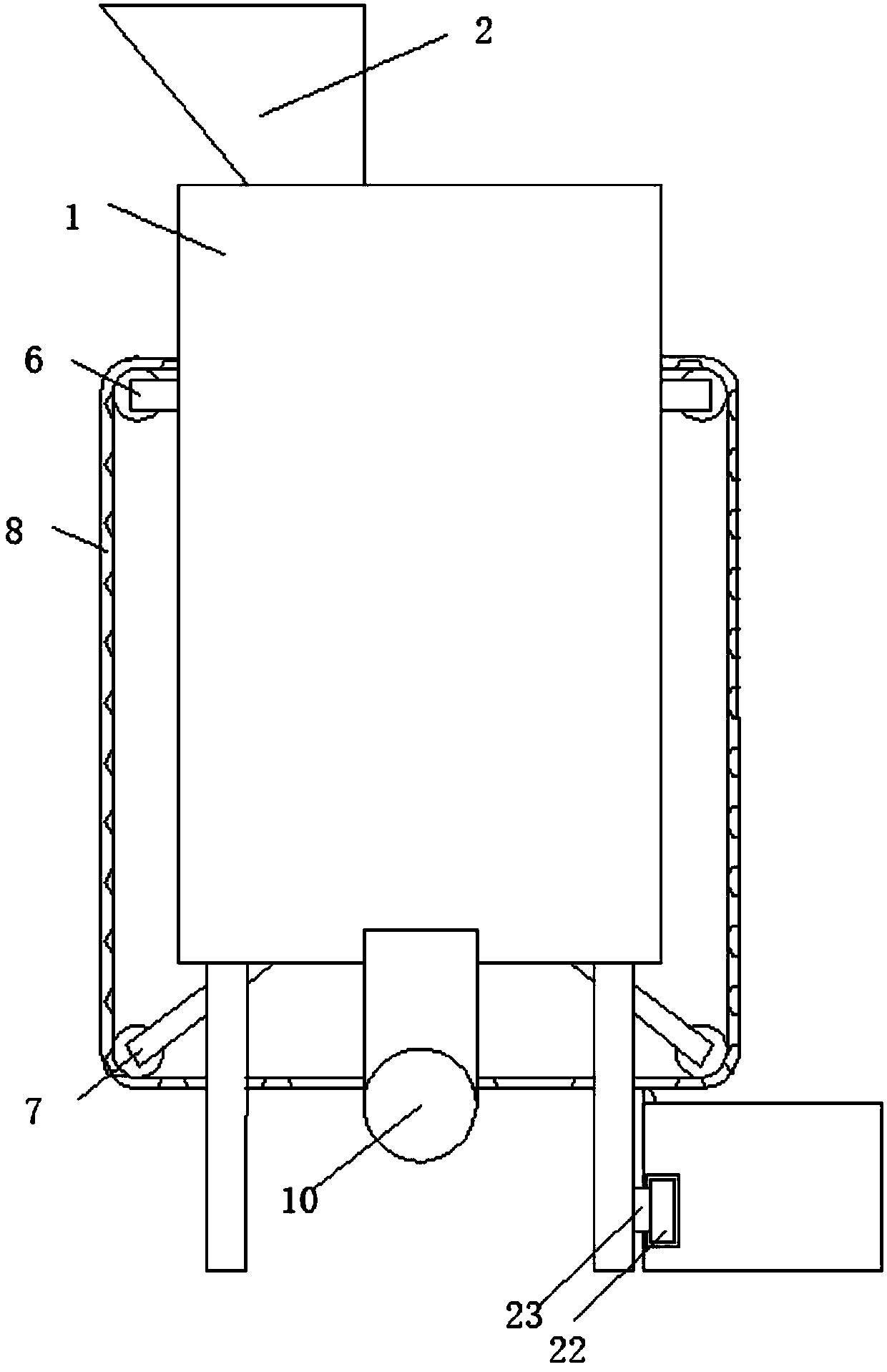

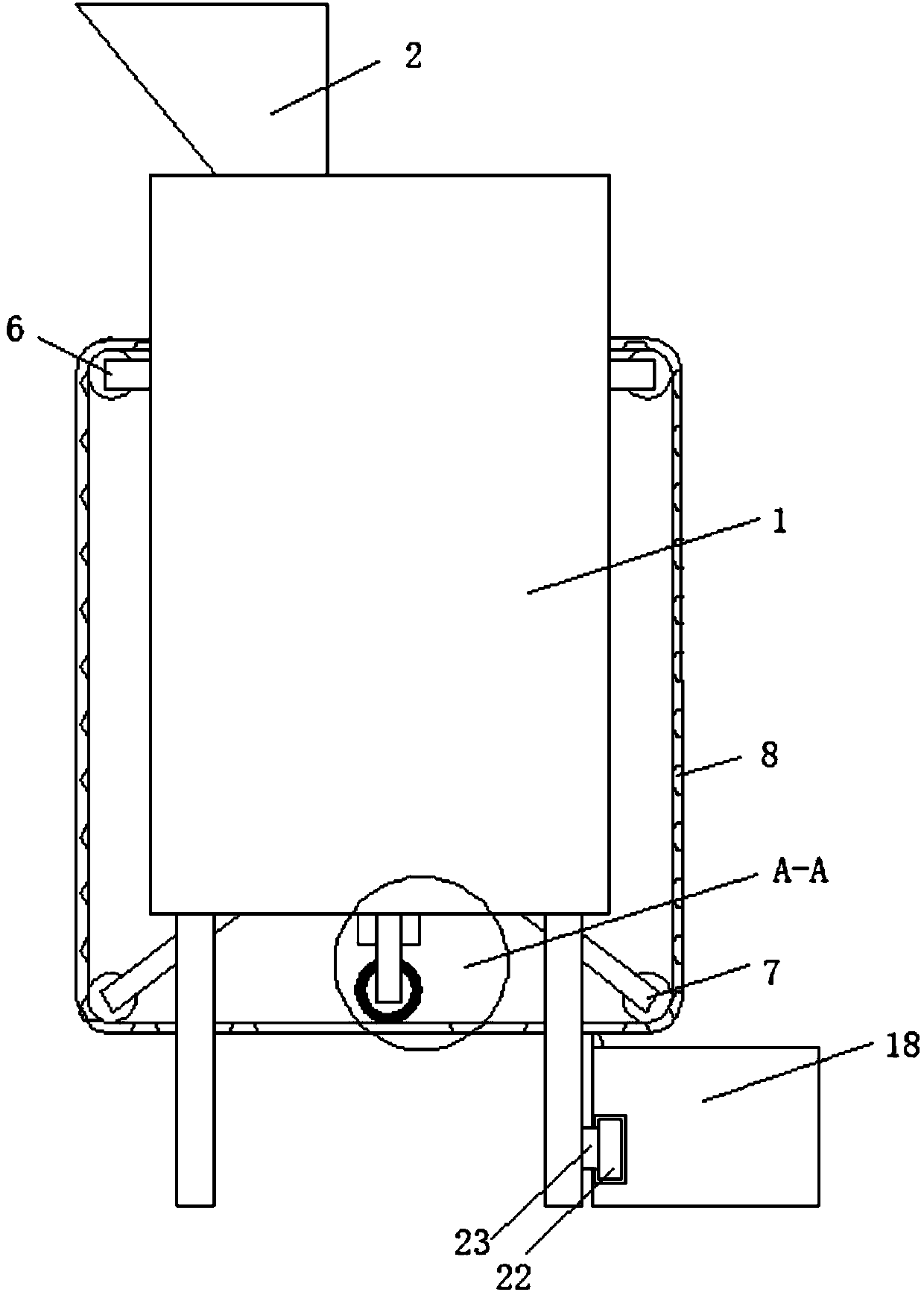

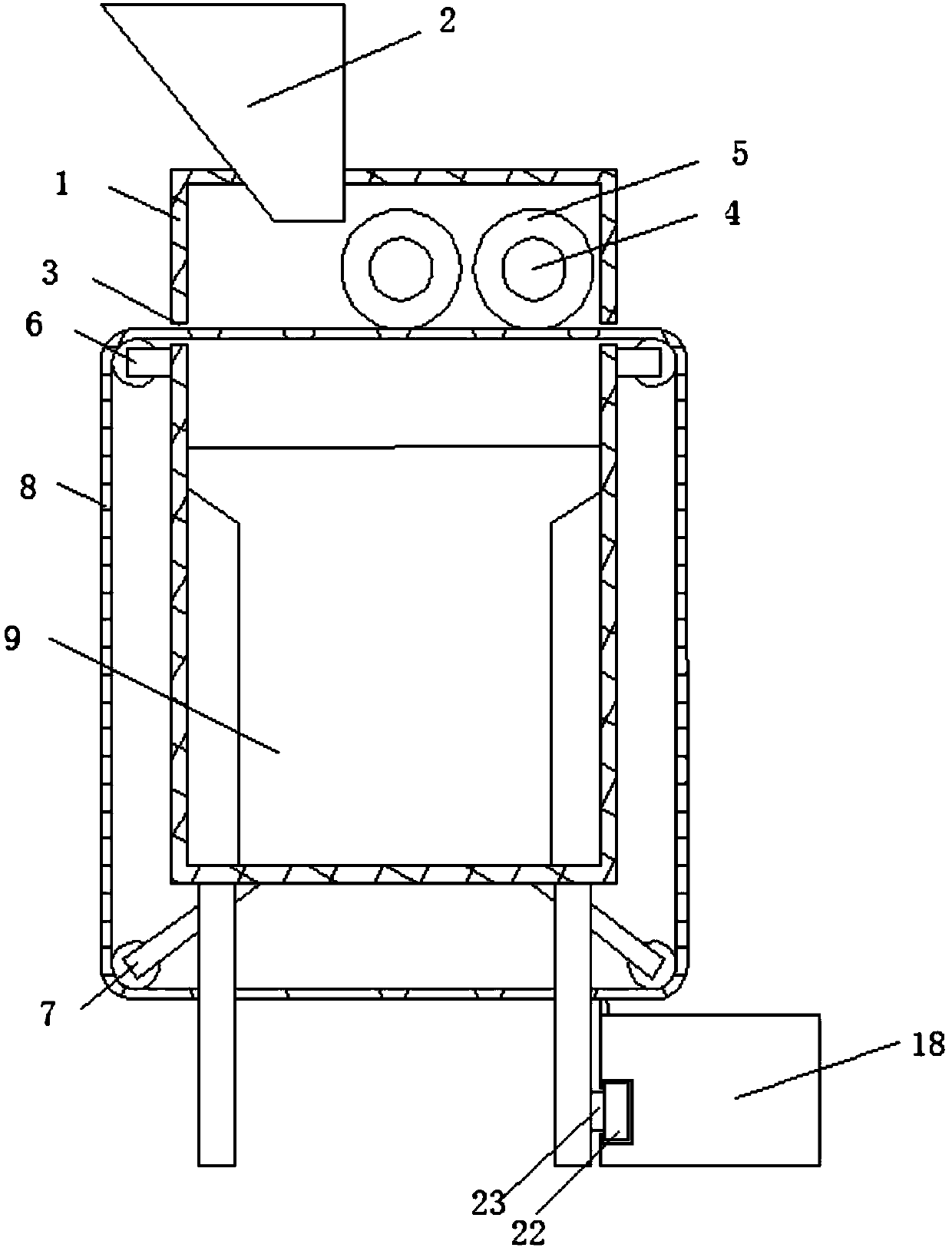

Ore soil raw material storage used for bentonite production

InactiveCN107715718AGood homogenization effectImprove work efficiencySievingScreeningEngineeringDriving mode

The invention discloses an ore soil raw material storage used for bentonite production. The ore soil raw material storage comprises a raw material bin, a feed hopper communicated with the raw materialbin is installed on one side on the top of the raw material bin, through holes are symmetrically formed in the two sides of the raw material bin, a plurality of electric rotary shafts above the through holes are rotationally installed in the raw material bin along the horizontal straight line, and the electric rotary shafts are located on the same side of the feed hopper. The outer side of each electric rotary shaft is sleeved with a rubber sleeve, first rotary rollers below the through holes are rotationally installed on the two sides of the raw material bin respectively, two symmetrical second rotary rollers are rotationally installed on the bottom of the raw material bin, and the two second rotary rollers and the two first rotary rollers are connected with a same filtering screen in afriction drive mode. The ore soil raw material storage is economical and practicable, large-grained ore soil can be placed in a material receiving box without the need of stopping, the work efficiencyof the ore soil raw material storage is improved, and moreover, the homogenizing effect of the ore soil raw material storage is improved.

Owner:湖州壤之沃生物技术有限公司

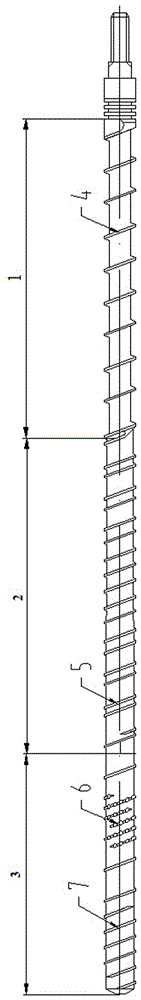

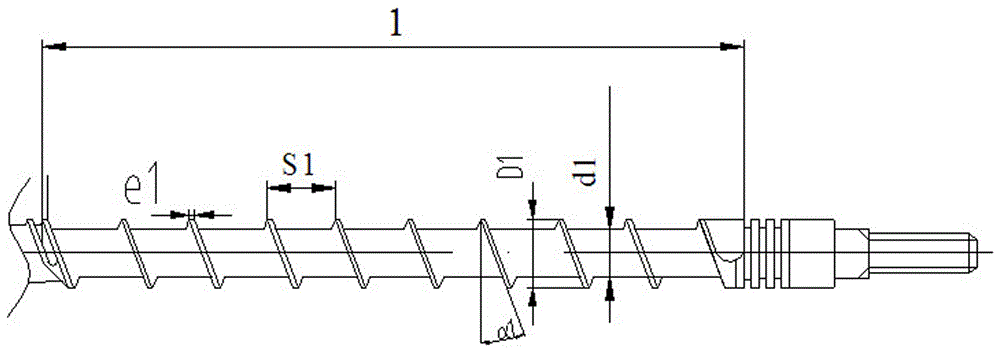

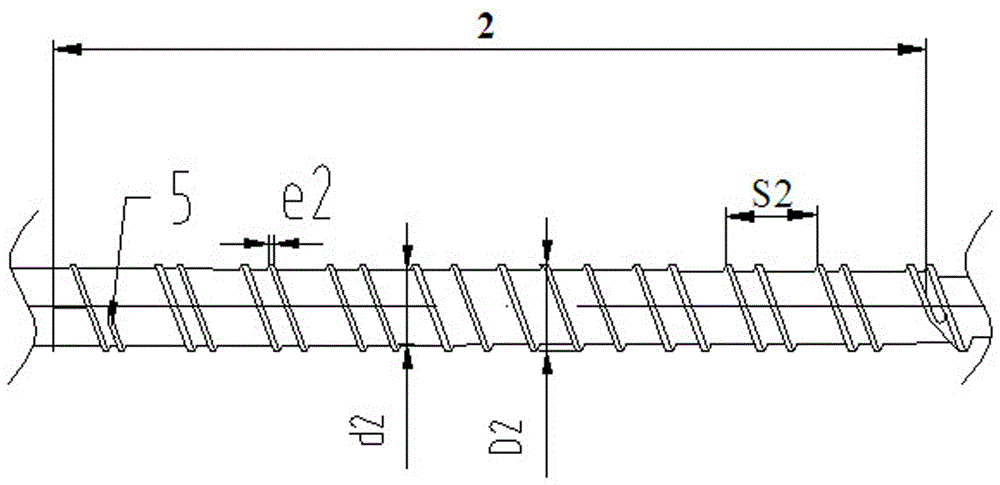

Special screw for single-screw plastic extruding machine

PendingCN106827452AStrong conveying capacityImprove extrusion efficiencyScrew threadPlastics extrusion

The invention provides a special screw for a single-screw plastic extruding machine. The screw has a satisfactory homogenizing effect, is low in power consumption and is strong in material conveying ability. The screw sequentially comprises a charging section, a melting section and a metering section, wherein main threads are arranged on the whole screw; the charging section is equal in distance and constant in depth, and the root diameter of the screw is suddenly increased on a beginning part of the melting section; first auxiliary threads are arranged on the whole melting section, the top diameters of the first auxiliary threads are gradually increased in the top 2 / 3 course of the melting section and are constant in the last 1 / 3 course of the melting section; on the tail part of the melting section, the top diameters of the main threads are identical to the top diameters of the first auxiliary threads; three-start screws are arranged in the middle of the metering section, and double-start threads are arranged on the tail part of the metering section.

Owner:安徽汇东机械有限责任公司

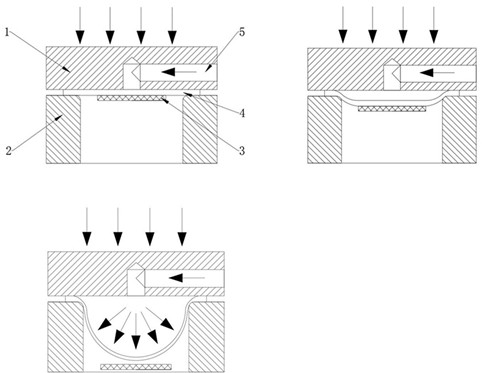

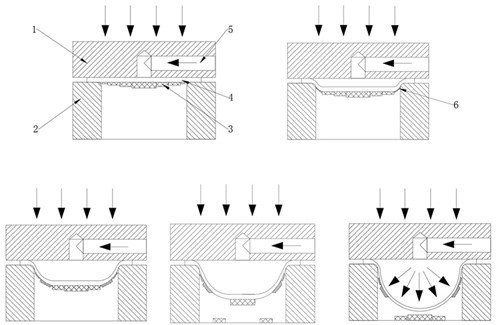

A Method of Using Inorganic Glue to Improve the Uniformity of Wall Thickness of Magnesium Alloy Superplastic Inflatable Forming

InactiveCN109675997BPlay a fixed roleEasy to processMetal-working feeding devicesPositioning devicesAdhesive cementAluminium oxides

The invention relates to a method of improving the uniformity of the wall thickness of a magnesium alloy superplastic gas bulging formed piece by utilizing an inorganic adhesive. The method concretelycomprises the following step of utilizing multiple inorganic adhesives with different viscosities, or coating different deformation areas of a magnesium alloy bulged piece with the inorganic adhesivewith different thicknesses and same viscosity, wherein the deformation rates of different deformation regions are homogenized through the "adhesion" effect of the inorganic adhesive, so that the improvement effect to different wall thicknesses of magnesium alloy is achieved; a selected type of the inorganic adhesive is a double-component adhesive, a component A is water glass, and a component B is formed by mixing and sintering silica, alumina and the like; and by changing the content of the water glass, the adhesives with different viscosities can be obtained. By adopting the method of the invention, the problem of unevenness in wall thickness of a magnesium alloy plate caused by factors including plate instability, unevenness in stress, different thinning rate and poor die adhering effect in the magnesium alloy high temperature gas bulging forming process can be solved, the formation effect of the process is further improved, operation is simple, realization is easy, the cost is lowered, and the production efficiency is improved.

Owner:HARBIN UNIV OF SCI & TECH

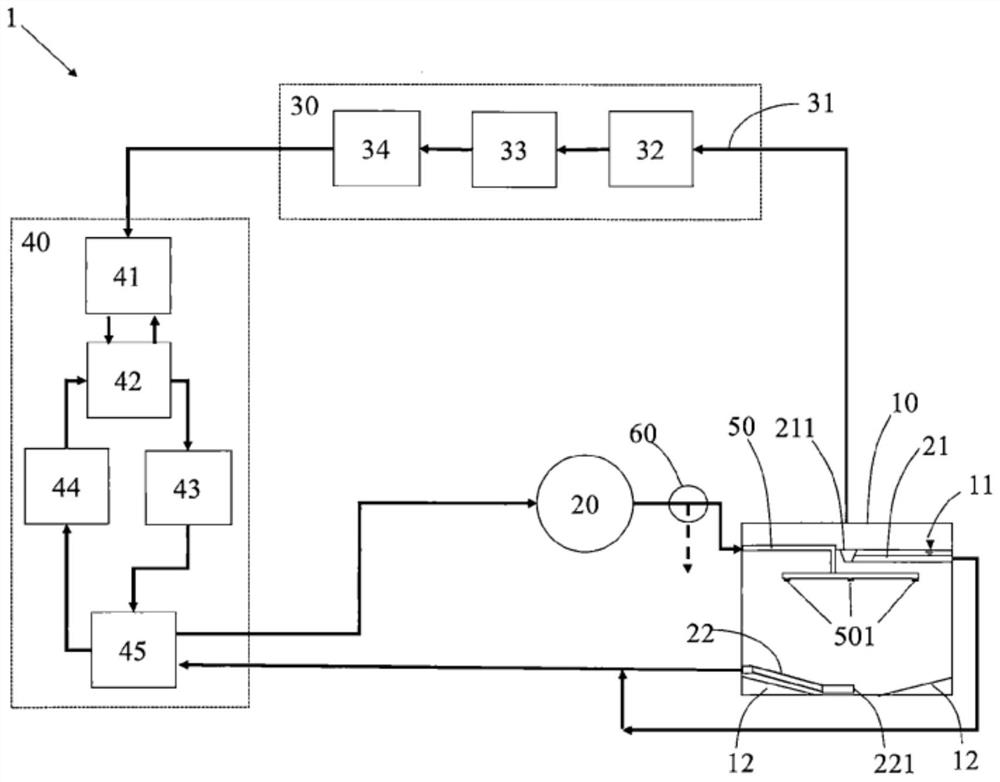

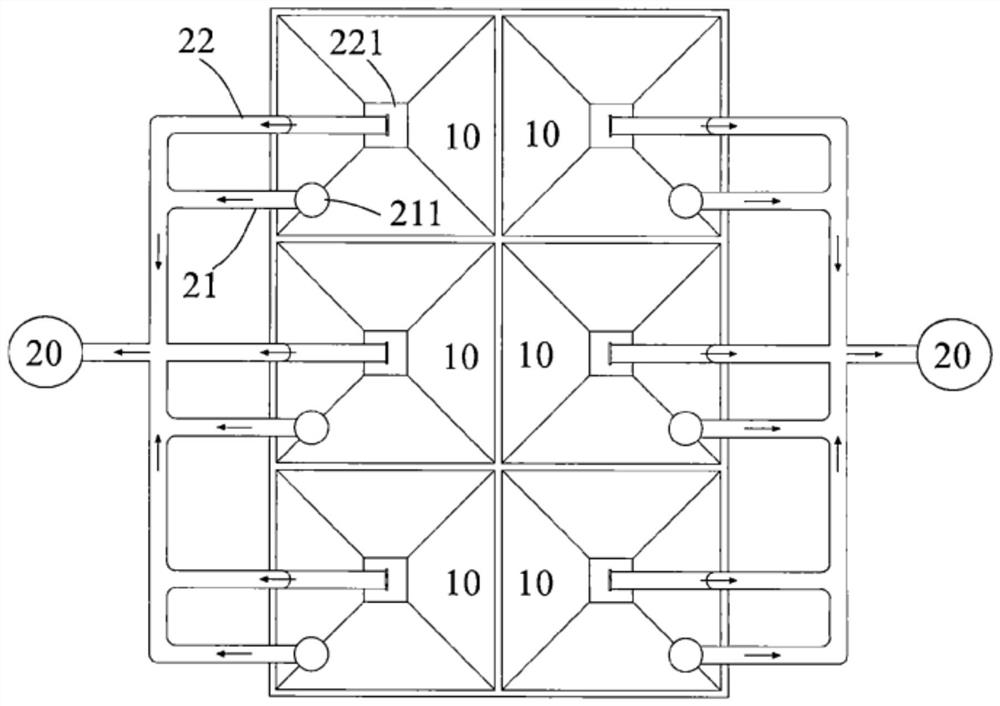

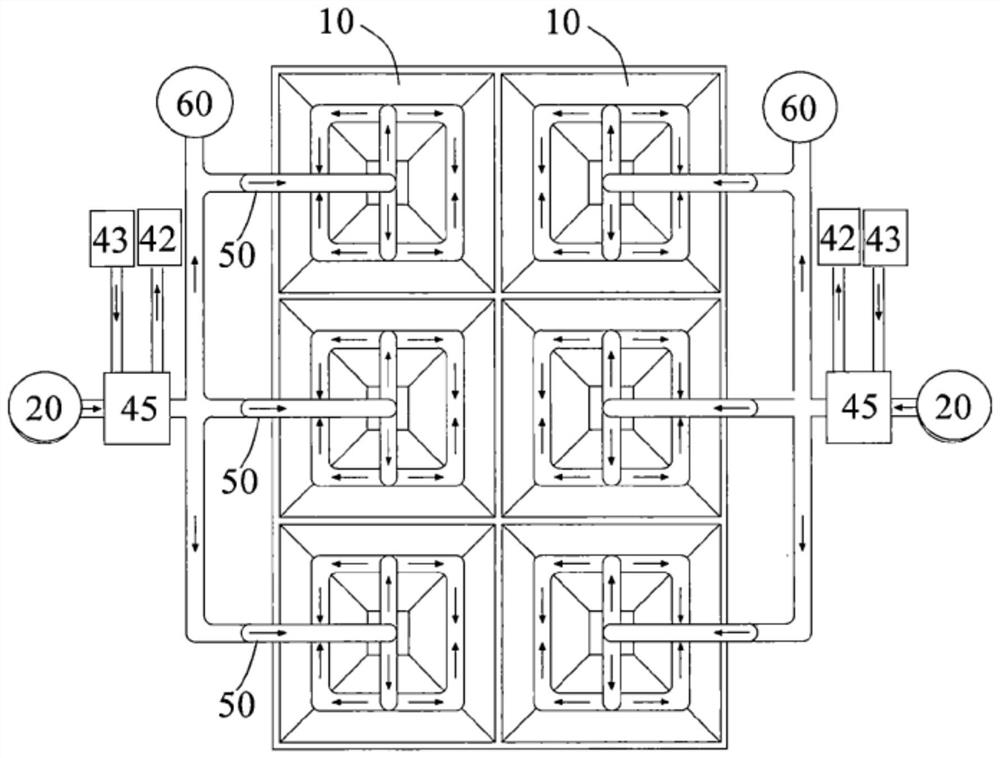

Anaerobic fermentation system

PendingCN111646664AReduce generationNo need to destroyBiological sludge treatmentSludgeCirculator pump

The present invention provides an anaerobic fermentation system comprising: an anaerobic fermentation tank configured to store and break down a waste to produce the marsh gas; an external circulationpump connected to the anaerobic fermentation tank for sludge break down and circulation, utilizing a scum-extraction pipe and a sludge-extraction pipe to extract a scum and a sludge from the anaerobicfermentation tank respectively; a gas treatment device configured to collect and remove H2S in the marsh gas for corrosion prevention of the following electricity production devices and pipes; a heatexchanger for recycled sludge, which uses the redundant heat from the electricity generator to heat up a cold water. The heated water was used to increase the temperature of recycled scum and sludgethrough the heat exchanger; and an injection pipe connected to the circulation pump for injecting the heated scum and the heated sludge into the anaerobic fermentation tank under the water level surface of the anaerobic fermentation tank. The materials in the anaerobic fermentation tank can be completely mixed through this design.

Owner:昆山瑞淞环境科技有限公司

A six-pole magnet for homogenizing permanent magnetic beam current

ActiveCN104703378BReduce distanceGood homogenization effectAcceleratorsElectromagnetsDensity distributionSextupole magnet

The invention belongs to the design technology of an accelerator, and particularly relates to a homogenized sextupole magnet of a permanent magnet beam. According to the sextupole magnet, the field exciters of a pair of relative magnetic poles are cancelled based on a traditional design, the distance between the pair of magnetic poles is shortened, and field excitation directions in a pair of adjacent magnetic poles is changed at the same time. A field excitation component comprises a permanent magnet as a main field exciter and an excitation wire wrap as an auxiliary field exciter. According to the homogenized sextupole magnet provided by the invention, the symmetric about the origin of a coordinate of a magnetic field generated on an X axis can be realized, and the square of the size is proportional to the square of the position of the magnetic field, therefore a good homogenization effect can be provided to beam spots which are in a trigonometrical density distribution way.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com