Hot-rolled wire rod for cord thread with tensile strength being 4000MPa and production method

A technology of tensile strength and hot-rolled wire rod, which is applied in the field of wire rod and production, can solve problems such as user quality complaints and product quality fluctuations, and achieve the goal of improving strength and wire drawing limit, improving production efficiency, and refining γ grains Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention is described in detail below:

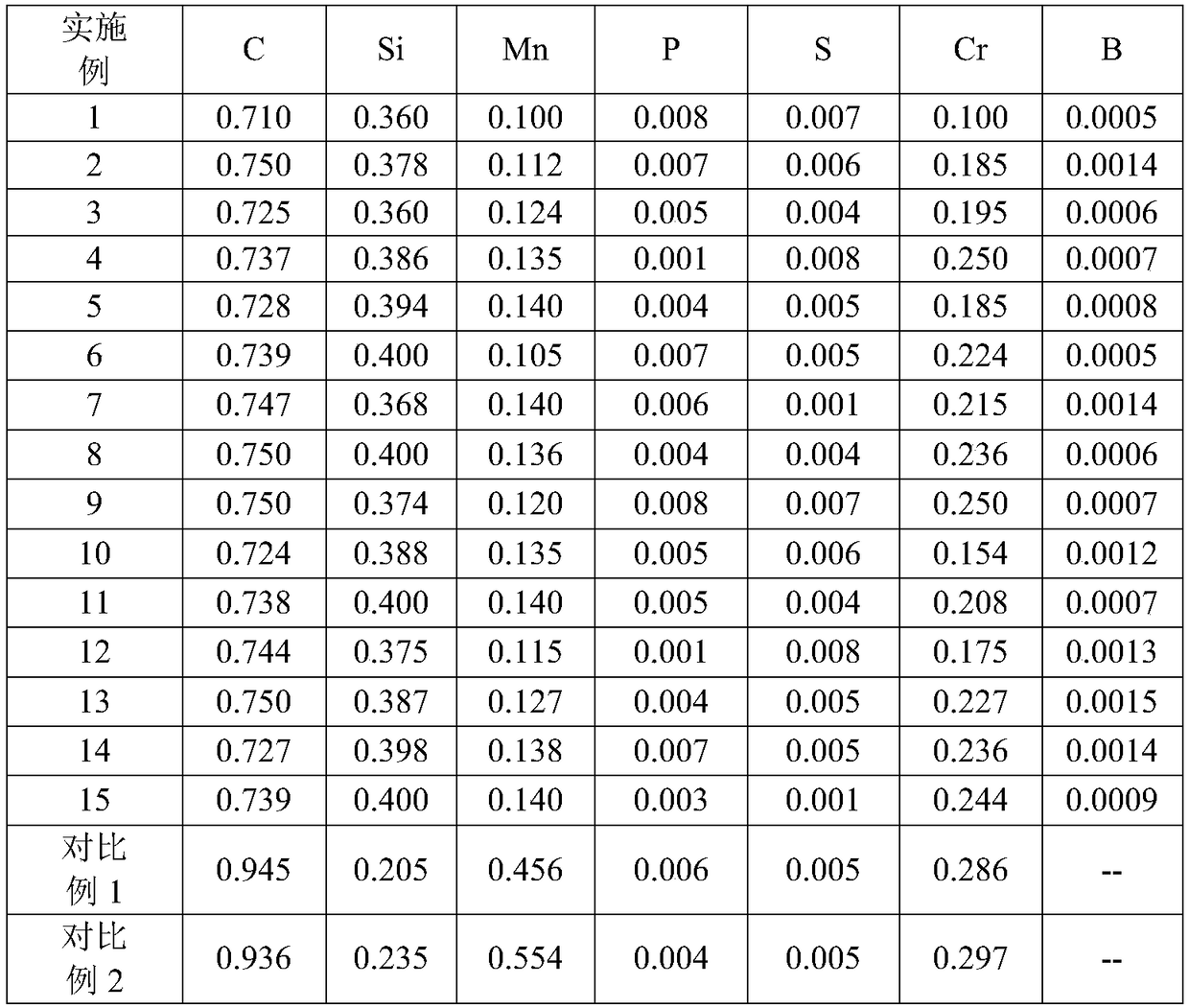

[0041] Table 1 is the chemical composition list of each embodiment of the present invention and comparative example;

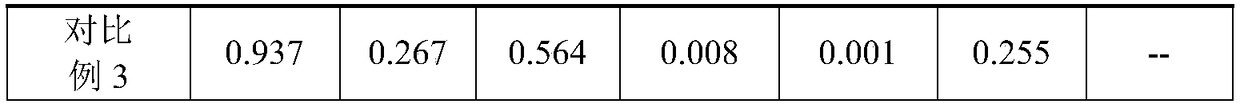

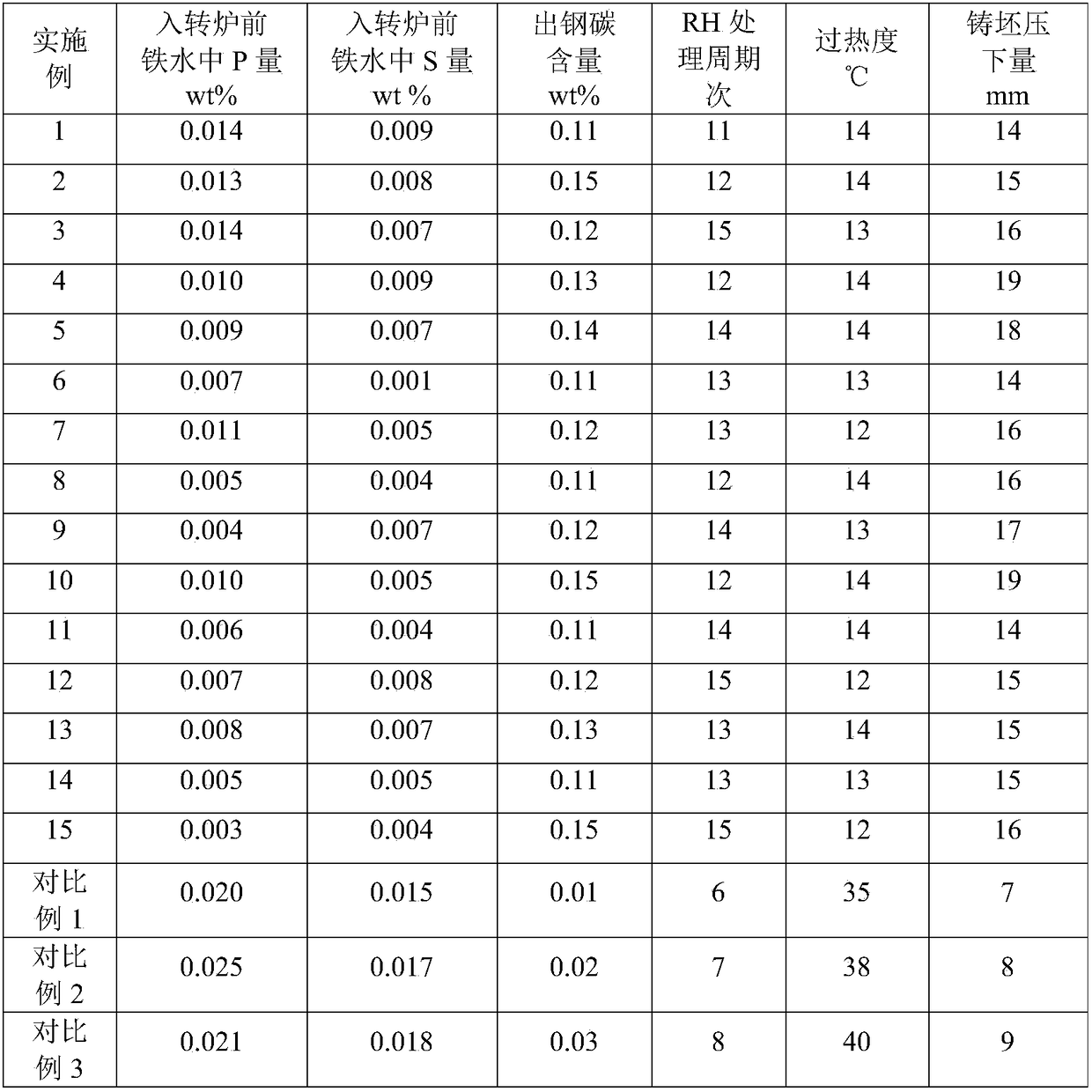

[0042] Table 2 is the smelting process technological parameter list of each embodiment of the present invention and comparative example;

[0043] Table 3 is the rolling process technological parameter list of each embodiment of the present invention and comparative example;

[0044] Table 4 is the comparison list of the deep processing flow process of each embodiment of the present invention and comparative example;

[0045] Table 5 is the list of test results of each embodiment of the present invention and comparative examples.

[0046] Each embodiment of the present invention all produces according to the following steps:

[0047] 1) Carry out converter smelting, control the P<0.015% and S<0.01% in the molten iron before entering the converter; and control the C in the molten steel not less than...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com