Method for processing large single-weight titanium and titanium alloy wire rods

A processing method and titanium alloy technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low yield, small unit weight, low efficiency, etc., and achieve good stress state, good metallographic structure, Improved stability and consistency effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to further illustrate the technical means and effects adopted by the present invention to achieve the intended purpose, the specific implementation, structural features and effects of the present invention will be described in detail below in conjunction with the accompanying drawings and examples.

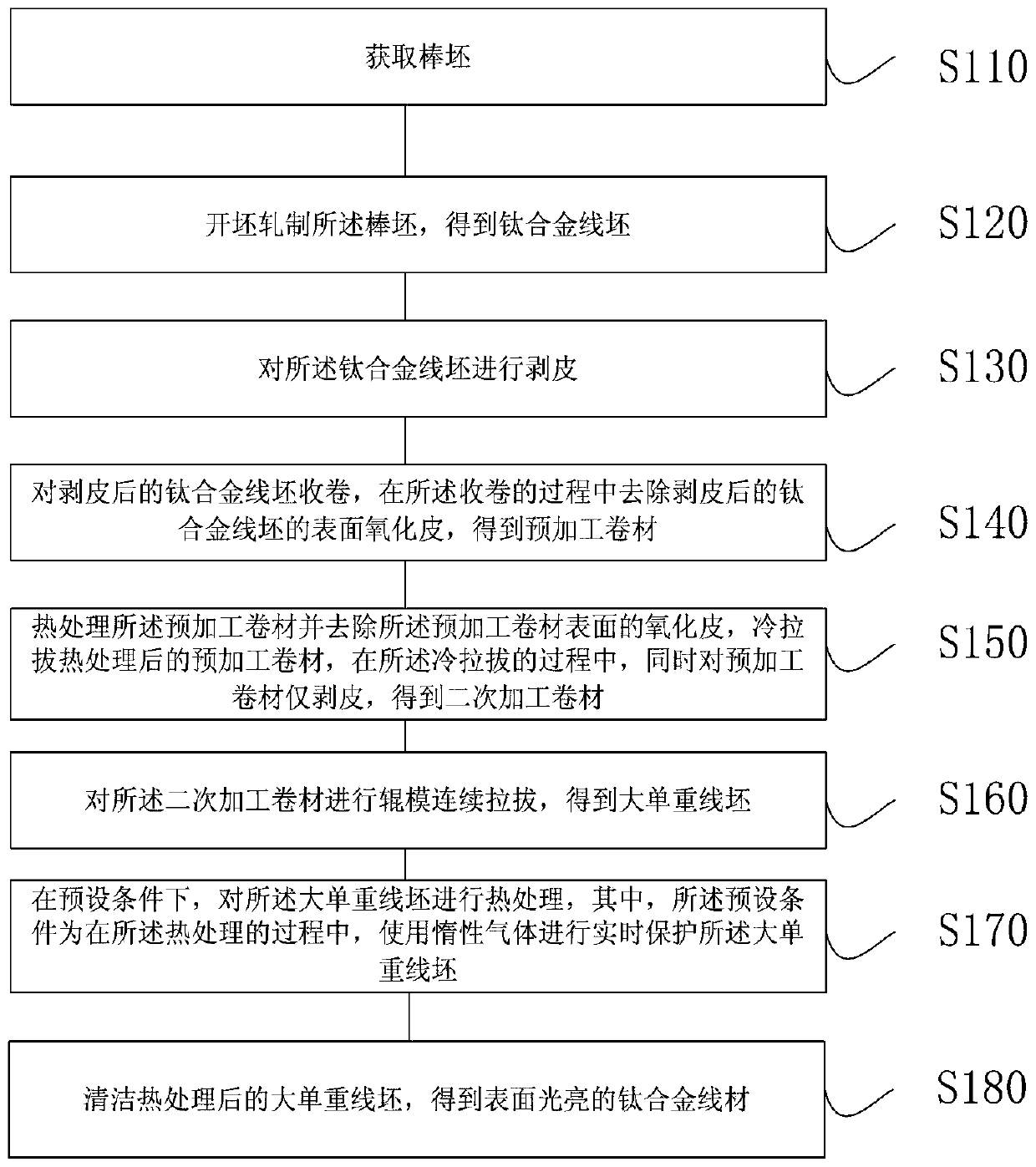

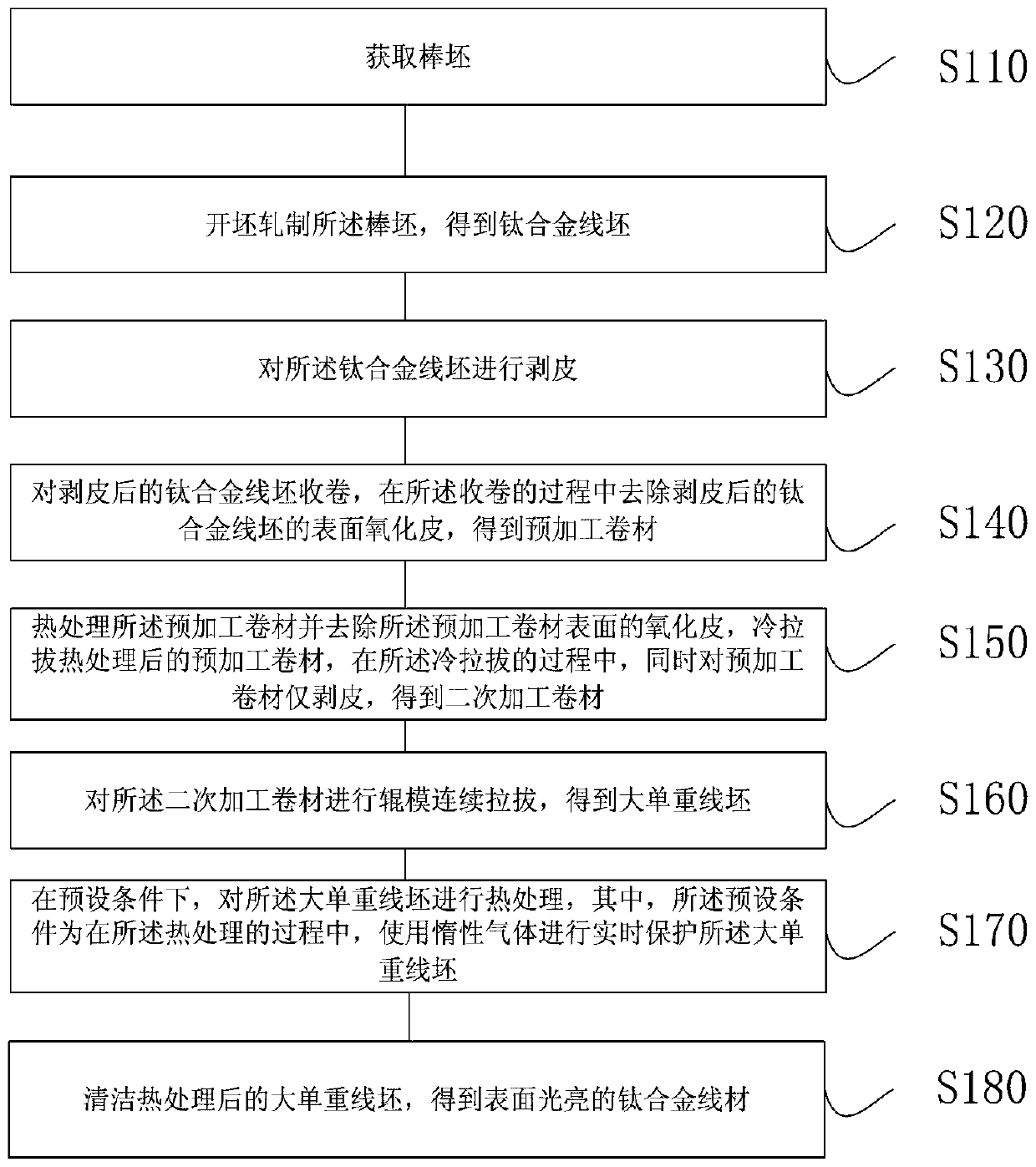

[0033] See figure 1 . The embodiment of the present invention provides a processing method for large single-weight titanium and titanium alloy wires, including:

[0034] S110. Obtain a billet, wherein the diameter range of the billet is 122mm-124mm;

[0035] S120. Billet rolling the billet to obtain a titanium alloy wire billet; wherein, the diameter range of the titanium alloy wire billet is 8mm-15mm;

[0036] S130. Peeling the titanium alloy wire blank;

[0037] S140. Winding the peeled titanium alloy wire billet, removing the surface oxide skin of the peeled titanium alloy wire billet during the winding process to obtain a pre-processed coil;

[0038] S150. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com