Method for controlling oxide iron scale on surface of low-carbon steel hot rolled wire rod

A hot-rolled wire rod and surface oxidation technology, applied in the field of metallurgy, can solve the problems of difficult mechanical descaling, etc., and achieve the effects of facilitating mechanical descaling, excellent mechanical descaling effect, and eliminating red rust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A method for controlling the oxide scale on the surface of a low-carbon steel hot-rolled wire rod, the method controls the composition ratio and thickness of the oxide scale on the surface of the low-carbon steel hot-rolled wire rod by controlling the spinning temperature and the Stelmore cooling process, wherein, The weight composition of low-carbon steel is C%: 0.03-0.08%, Si%: 0.05-0.10%, Mn%: 0.20-0.40%, and includes micro-alloy steel without Cr and Cu corrosion-resistant elements.

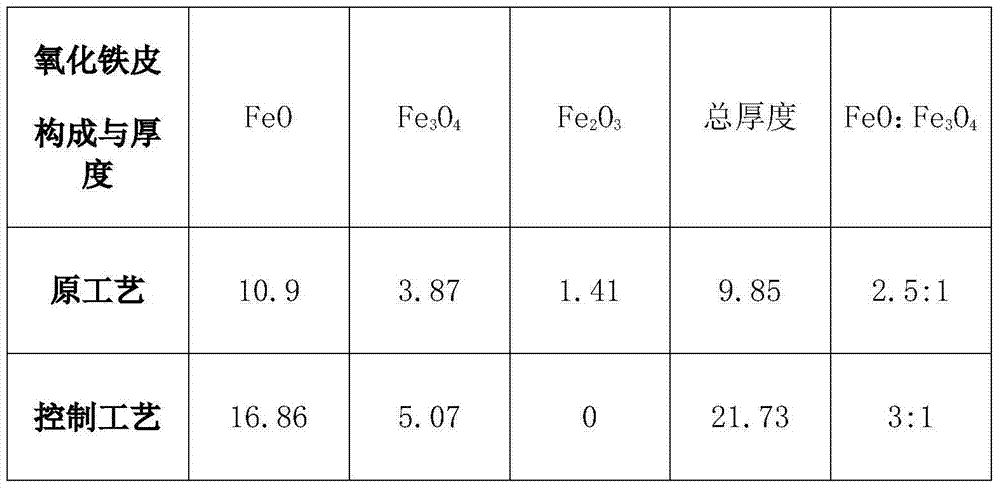

[0024] As shown in Table 1, it is the technological scheme of the method for controlling the scale on the surface of the low-carbon steel hot-rolled wire rod in Example 1. The spinning temperature was increased from 810°C to 830°C, which increased the oxidation temperature of the oxide scale on the surface of the wire rod; the speed of the roller table was increased from 0.4m / s to 0.6m / s, and the number of covers was increased from 4 to 8. Prolong the oxidation time of the iron scale on...

Embodiment 2

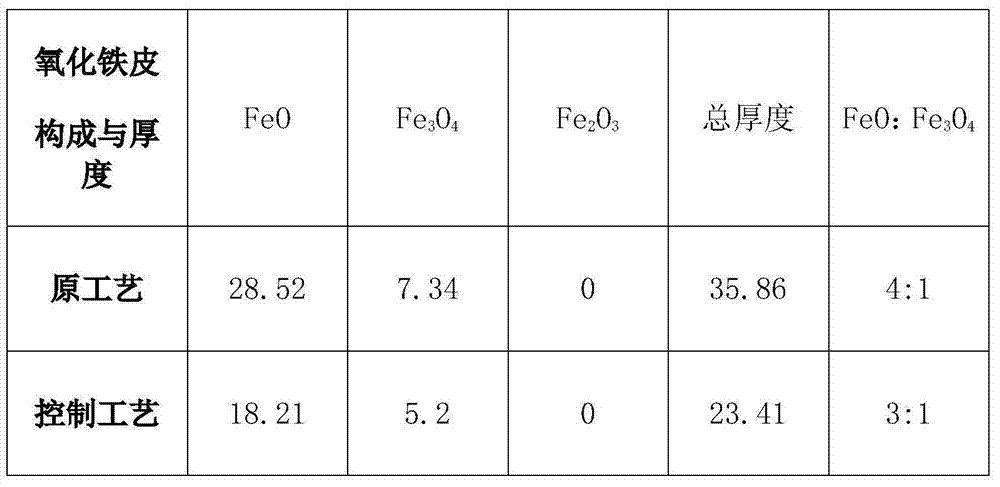

[0031] As shown in Table 3, it is the technological scheme of the method for controlling the scale on the surface of the low-carbon steel hot-rolled wire rod in Example 2. The spinning temperature has been reduced from 880°C to 850°C, which reduces the oxidation temperature of the oxide scale on the surface of the wire rod; the speed of the roller table has been reduced from 1m / s to 0.8m / s, and the number of covers has been increased from 4 to 10. The oxidation time of the oxide scale on the surface of the wire rod is determined. By controlling the high-temperature oxidation temperature and oxidation time of the wire rod, the composition and thickness of the oxide scale on the surface of the low-carbon steel hot-rolled wire rod are controlled.

[0032] As shown in Table 4, it is the proportion and thickness of the oxide scale on the surface of the low-carbon steel hot-rolled wire rod in Example 2. There is no red rust Fe in the scale structure of the control process. 2 o 3 p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com