Manufacturing device and method for bimetal composite hot bend

A bimetallic composite pipe and hot simmering elbow technology, which is applied in the field of pipeline connection, can solve the problems that it is difficult to meet the technical requirements of bimetal hot simmering elbows, the corrosion resistance of carbon steel elbows is difficult to meet the requirements, and the mechanical properties are difficult to guarantee. , to achieve reasonable design, prevent high temperature oxidation, and achieve the effect of convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

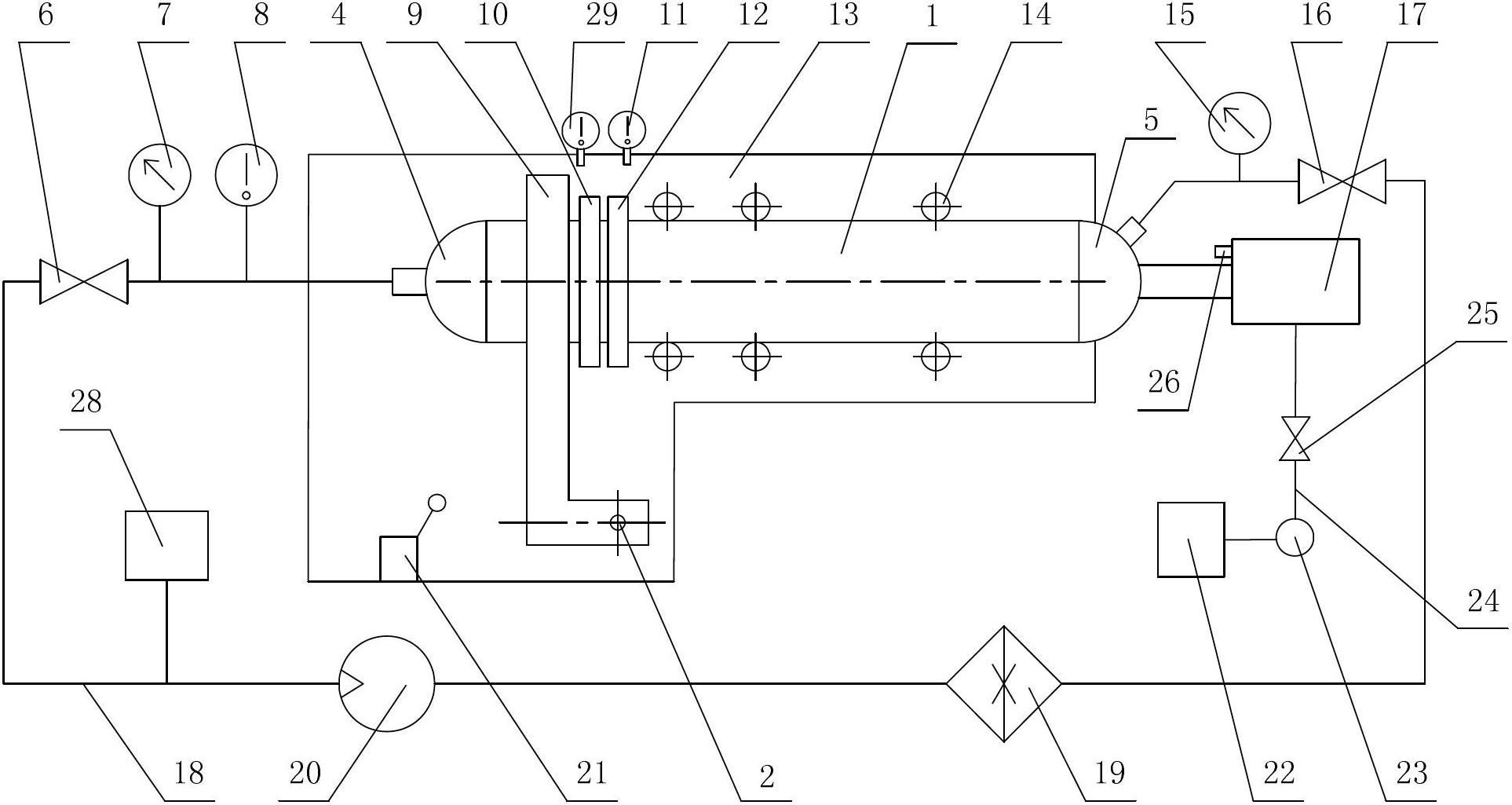

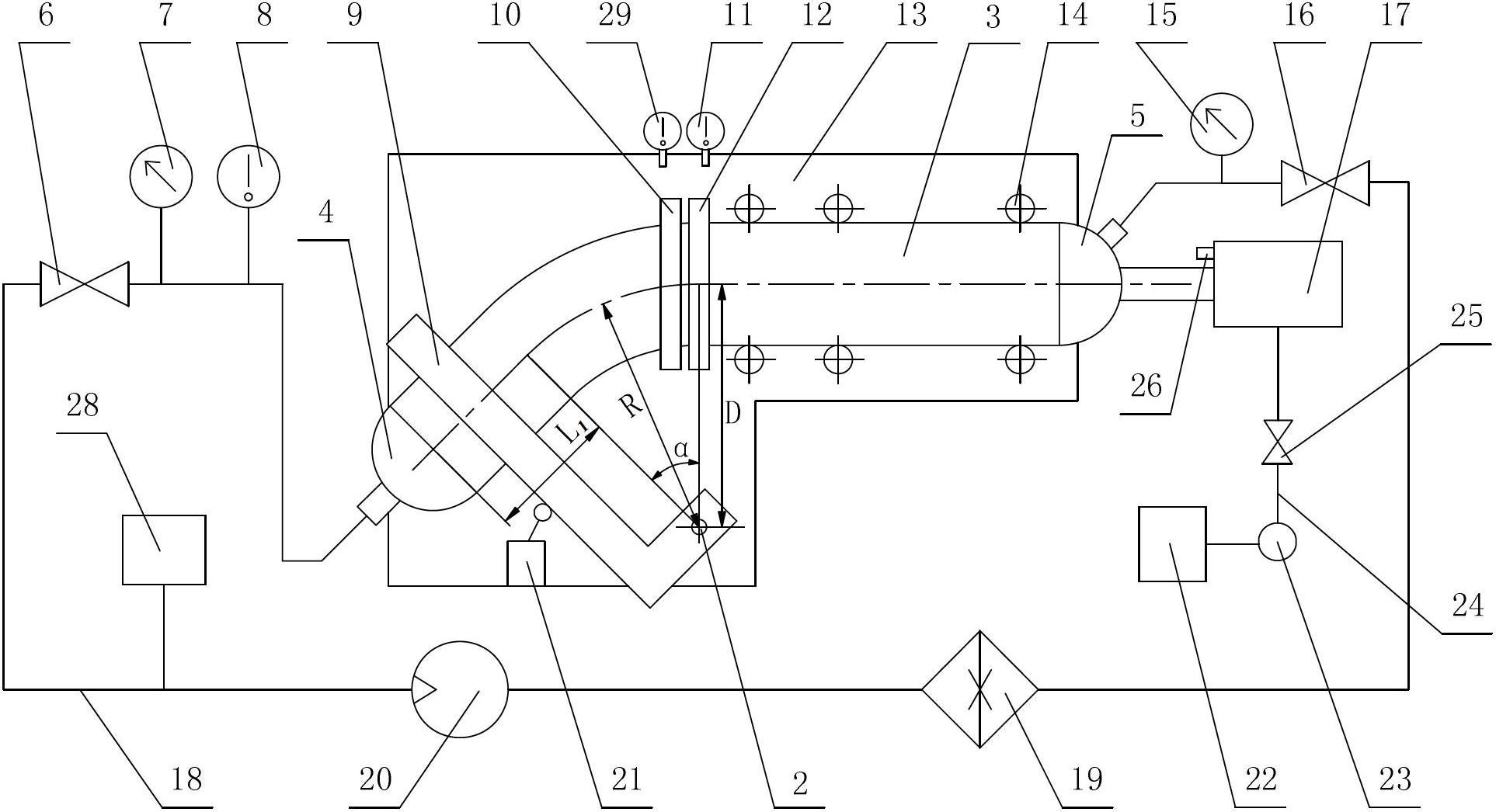

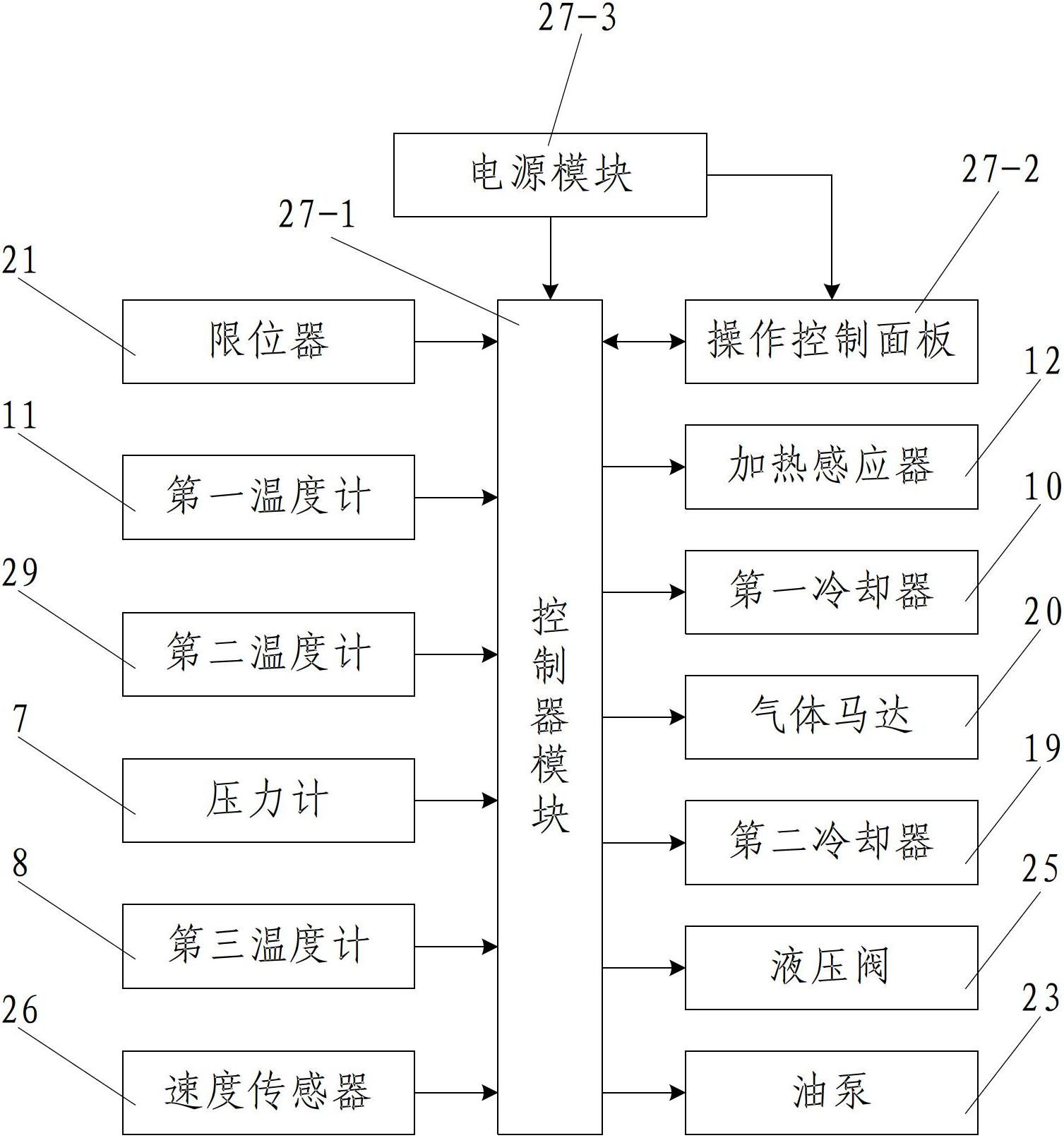

[0037] Such as figure 1 with figure 2 As shown, the manufacturing equipment of the bimetallic composite hot-simmer bending pipe according to the present invention includes a heat-induction pipe bending mechanism for hot-simmering the bimetallic composite pipe 1 and a bimetallic composite pipe 1 inner cavity The inert gas protection system that feeds the inert cooling gas, and the automatic control system used to automatically control the thermal induction bending mechanism and the inert gas protection system; the thermal induction bending mechanism includes a frame 13, which is used to push the The hydraulic cylinder 17 that the metal composite pipe moves and is connected with the hydraulic cylinder 17 and is used to control the hydraulic control system that the hydraulic cylinder 17 moves, and is installed on the frame 13 and is used for placing the roller 14 of bimetallic composite pipe, is used for heating bimetallic The heating sensor 12 of the composite pipe 1 and the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com